Crystallization purification method for paclitaxel

A purification method, paclitaxel technology, applied in the field of compound crystallization, can solve the problems of high equipment requirements, no purification effect, poor purification effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

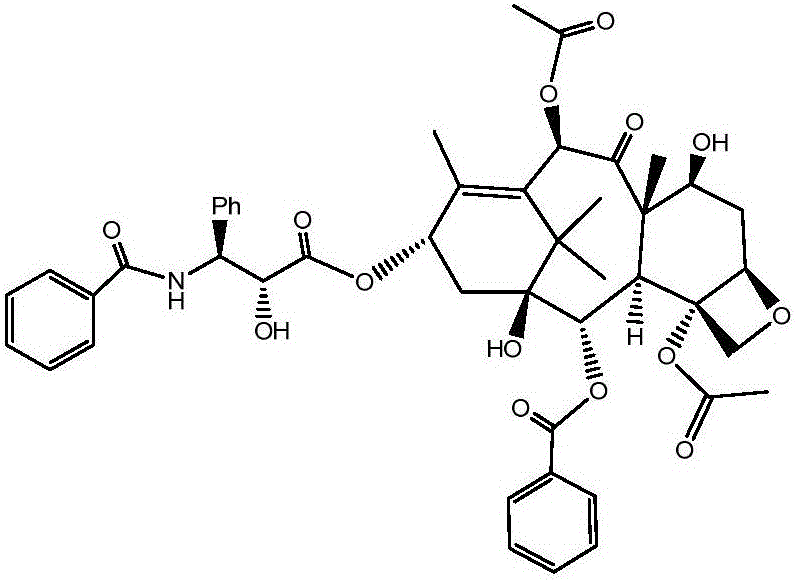

Image

Examples

Embodiment 1

[0060] Weigh 10g of paclitaxel (HPLC purity 93%, 7-epitaxol is 0.12%), add 44ml of dichloromethane, 88ml of acetone, heat to 40°C to dissolve, cool to 25°C, add dropwise 264ml of n-hexane to make it crystallize, After the dropwise addition was completed, the temperature was lowered to 5° C., filtered, and vacuum-dried at 50° C. to obtain 9.20 g of a white solid with an HPLC purity of 97.5% and 0.091% of 7-epitaxel. The molar yield is 92%.

Embodiment 2

[0062] Weigh 5g of paclitaxel (sample in Example 1), add 22ml of dichloromethane and 44ml of acetone, heat to 40°C to dissolve, cool to 25°C, add dropwise 110ml of n-heptane to crystallize, dropwise complete, cool to 5 °C, filtered, and vacuum-dried at 50 °C to obtain 4.66 g of a white solid with an HPLC purity of 99.5% and 0.088% of 7-epitaxel. The molar yield is 93.2%.

Embodiment 3

[0064] Weigh 10g of paclitaxel (HPLC purity 93%, 7-epitaxol is 0.12%), add 44ml of chloroform, 88ml of acetone, heat to 40°C to dissolve, cool to 25°C, add dropwise 264ml of n-hexane to crystallize, add dropwise After completion, the temperature was lowered to 5° C., filtered, and vacuum-dried at 50° C. to obtain 9.20 g of a white solid with an HPLC purity of 97.1% and 0.105% of 7-epitaxel. The molar yield is 92.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com