Purification method of gradient elution solvent acetonitrile

A technology of elution solvent and purification method, applied in the direction of carboxylic acid nitrile purification/separation, organic chemistry, etc., can solve the problems of high degree of containment and high cost, and achieve the effects of simple production process, stable operation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

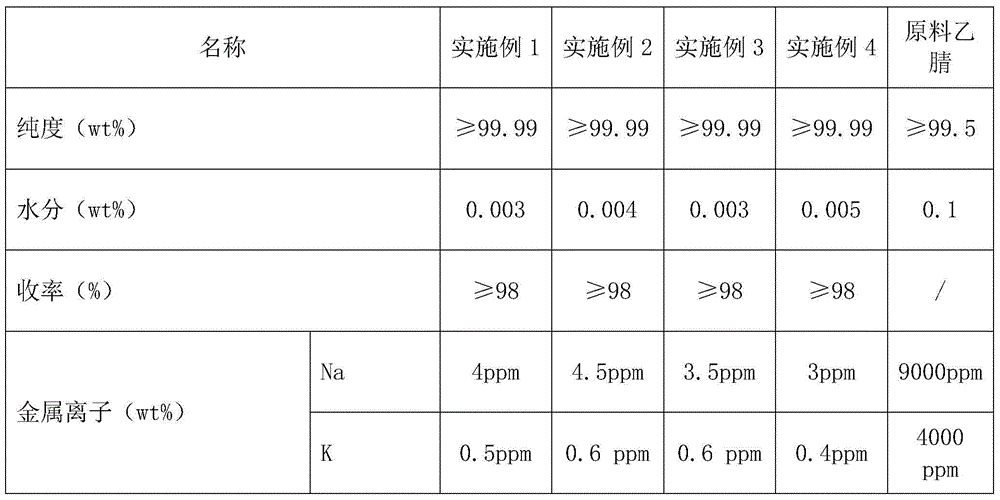

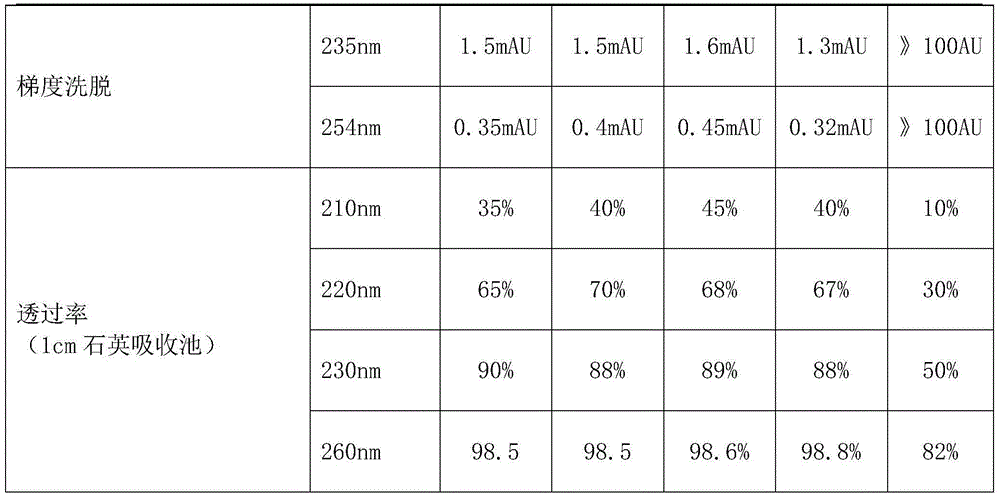

Examples

Embodiment 1

[0022] The purification method of gradient elution solvent acetonitrile is characterized in that, comprises the steps:

[0023] a. get the raw material acetonitrile with a purity of 99.5% (wt), add sodium carbonate and adjust the pH of the solution to 7, and shake to make the organic acid impurities in the sodium carbonate and the raw material acetonitrile fully react to generate salt precipitates; Separate the layers, discard the aqueous layer, filter the organic layer, and keep the filtrate.

[0024] Pass the above-mentioned filtrate into the adsorbent column equipped with 3A molecular sieve with aluminum hydroxide attached on the surface at a rate of 20 column volumes / hour, further remove the moisture in the organic layer, and remove aromatic hydrocarbons and polar compounds in acetonitrile at the same time Impurities. The mass concentration of aluminum hydroxide is 0.5%, and the particle size of 3A molecular sieve is 100 mesh. After adsorption, the water content of the a...

Embodiment 2

[0029] The purification method of gradient elution solvent acetonitrile is characterized in that, comprises the steps:

[0030] a. get the raw material acetonitrile with purity of 99.5% (wt), add sodium carbonate and adjust the pH of the solution to 8, and shake to make sodium carbonate fully react with the organic acid impurities in the raw material acetonitrile to generate salt precipitate; Separate layers, discard the aqueous layer and precipitate, filter the organic layer, and keep the filtrate.

[0031] Pass the above-mentioned filtrate into the adsorbent column equipped with 3A molecular sieve with aluminum hydroxide attached on the surface at a rate of 30 column volumes / hour, to further remove the moisture in the organic layer, and at the same time remove the aromatic hydrocarbons and polar compounds in acetonitrile Impurities. The concentration of aluminum hydroxide is 1.5%, and the particle size of 3A molecular sieve is 20 mesh. After adsorption, the water content o...

Embodiment 3

[0036] The purification method of gradient elution solvent acetonitrile is characterized in that, comprises the steps:

[0037] a. get the raw material acetonitrile with purity of 99.5% (wt), add sodium carbonate and adjust the pH of solution to 7.5, and shake to make sodium carbonate fully react with the organic acid impurities in the raw material acetonitrile to generate salt precipitate; Separate layers, discard the aqueous layer and precipitate, filter the organic layer, and keep the filtrate.

[0038]Pass the above filtrate into the adsorbent column equipped with 4A molecular sieve with aluminum hydroxide attached on the surface at a rate of 0.5 column volume / hour, further remove the moisture in the organic layer, and remove aromatic hydrocarbons and polar compounds in acetonitrile at the same time Impurities. The concentration of aluminum hydroxide is 0.9%, and the particle size of 4A molecular sieve is 60 mesh. After adsorption, the water content of acetonitrile is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com