Hydrothermal synthesis method of nano Sn-Beta molecular sieve aggregate

A hydrothermal synthesis and molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long crystallization time, large grain size, low tin content, etc., and achieve improved catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

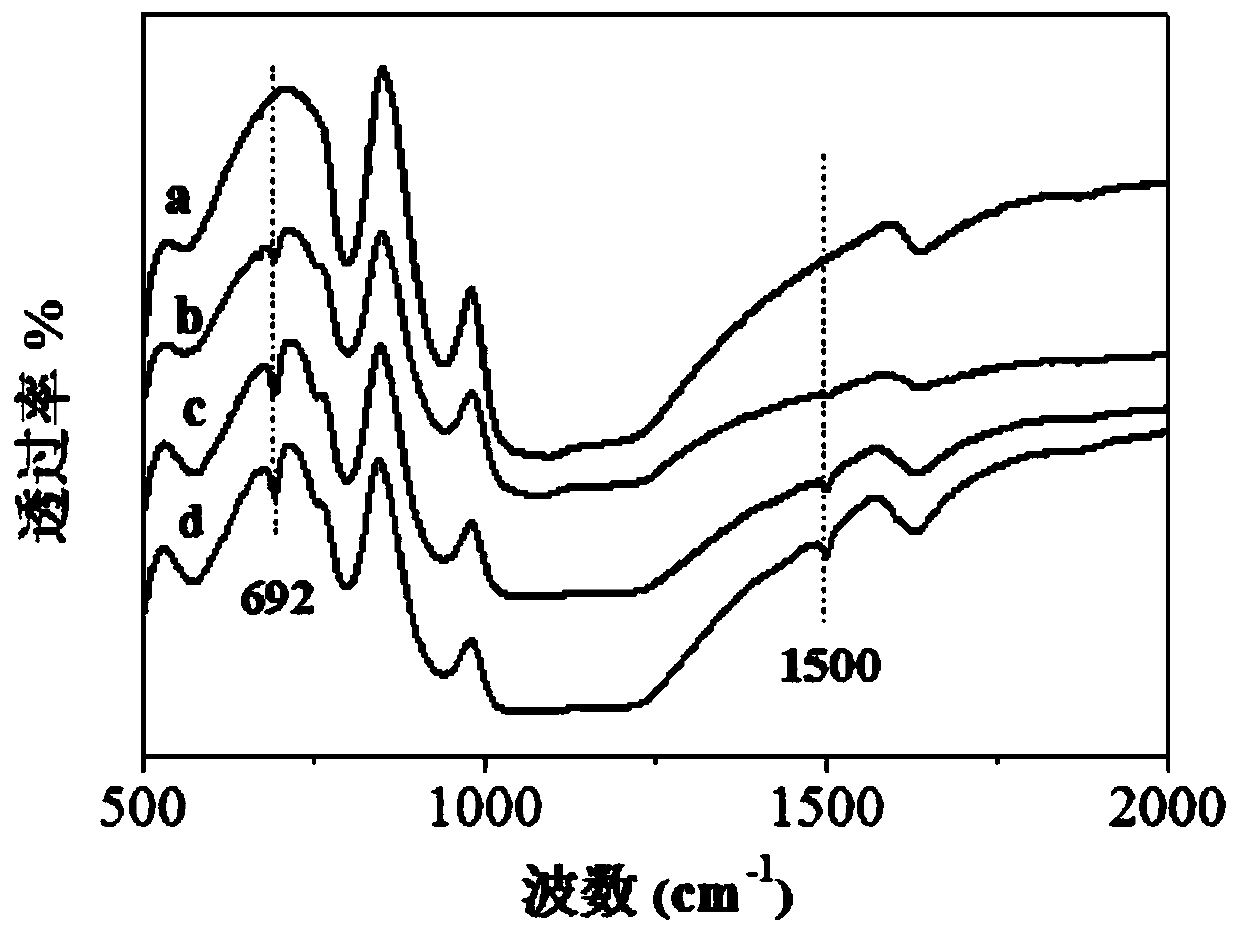

[0047] Synthesis of tin silicon oxide precursors. Hydrochloric acid, deionized water, trimethoxy[3-(phenylamino)propyl]silane (PHAPTMS), crystalline tin tetrachloride (SnCl 4 ·5H 2 O) mixed with tetraethyl orthosilicate (TEOS), stirred at room temperature until a homogeneous solution was formed. The final molar composition is 1.0SiO 2 :x SnO 2 (x=0.008, 0.01 and 0.0125): 20H 2 O:0.15HCl:0.08PHAPTMS. The solution was passed through an aerosol spray drying device (BILON-6000Y, drying temperature is 483K) to obtain a white powder. The powder was dried at 383K for 3h to obtain a tin silicon oxide sample.

Embodiment 2

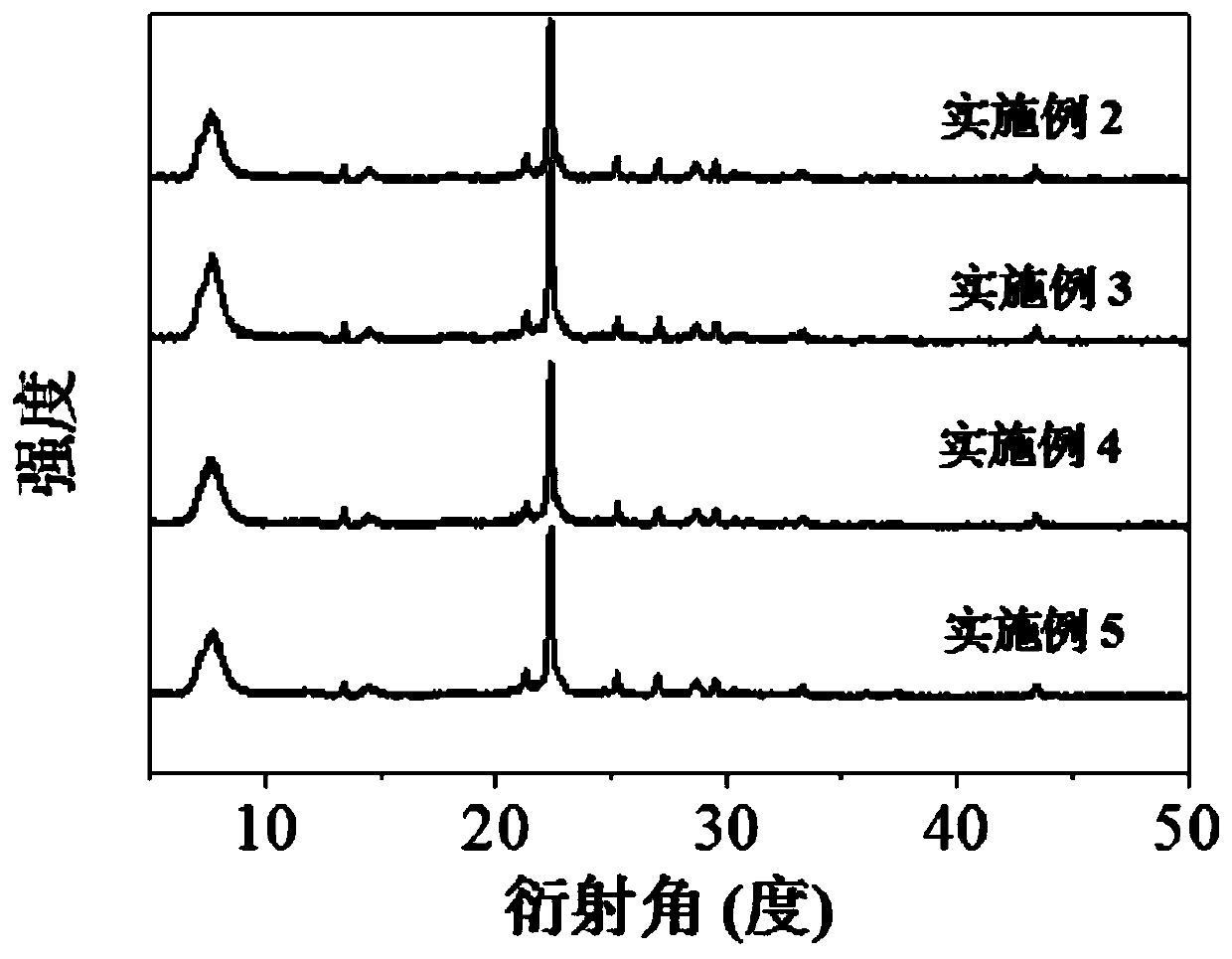

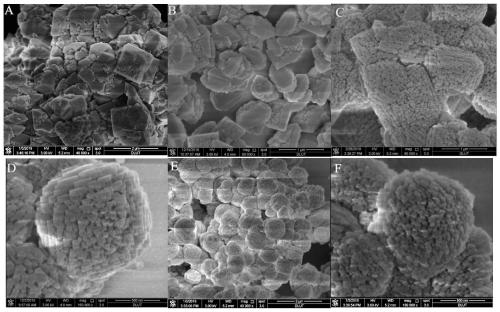

[0052] Synthesis of Sn-Beta molecular sieves. Weigh 1g of the tin-silicon precursor that is not doped with organosilane and add it to a certain amount of template agent tetraethylammonium hydroxide (TEAOH, 40wt%) and hydrofluoric acid solution (HF, 40wt%), and add a certain amount of Beta Seed. After mixing well, put the gel in an oven at 353K for a period of time to remove part of the water. The composition of the final gel is 1.0SiO 2 :0.008SnO 2 :0.4TEA + :0.4F - :2H 2 O: 3 wt% seed crystals. The above gel was transferred to a hydrothermal synthesis kettle with a 10 mL polytetrafluoroethylene liner, and statically crystallized at 443K for 4 days. The crystallized sample was filtered and washed until neutral, dried overnight at 383K, and finally calcined at 813K for 10h in air atmosphere to obtain the product.

Embodiment 3

[0054] Synthesis of Sn-Beta molecular sieves. Weigh 1g of organosilane-doped tin-silicon precursor and add it to a certain amount of template agent tetraethylammonium hydroxide (TEAOH, 40wt%) and hydrofluoric acid solution (HF, 40wt%), and add a certain amount of Beta crystal kind. After mixing well, put the gel in an oven at 353K for a period of time to remove part of the water. The composition of the final gel is 1.0SiO 2 :0.008SnO 2 :0.02PHAPTMS:0.4TEA + :0.4F - :2H 2 O: 3 wt% seed crystals. The above gel was transferred to a hydrothermal synthesis kettle with a 10 mL polytetrafluoroethylene liner, and statically crystallized at 443K for 4 days. The crystallized sample was filtered and washed until neutral, dried overnight at 383K, and finally calcined at 813K for 10h in air atmosphere to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com