A ceramic thin plate inkjet underglaze decorative glaze and its preparation method and ceramic thin plate

A technology of ceramic thin plate and underglaze color, applied in the field of ceramic tiles, can solve the problems of warping, shrinking glaze, avoiding glaze, etc., and achieves the effect of reducing the proportion, low production cost, energy saving and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

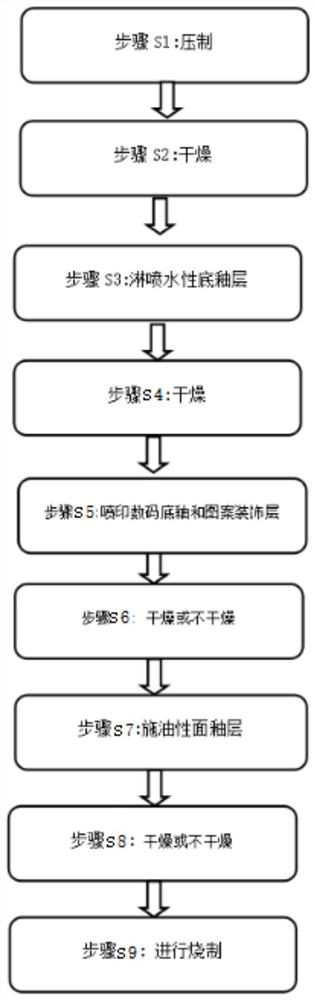

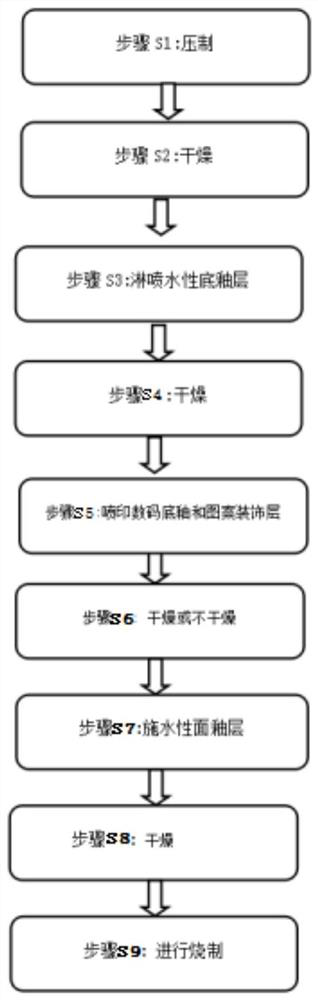

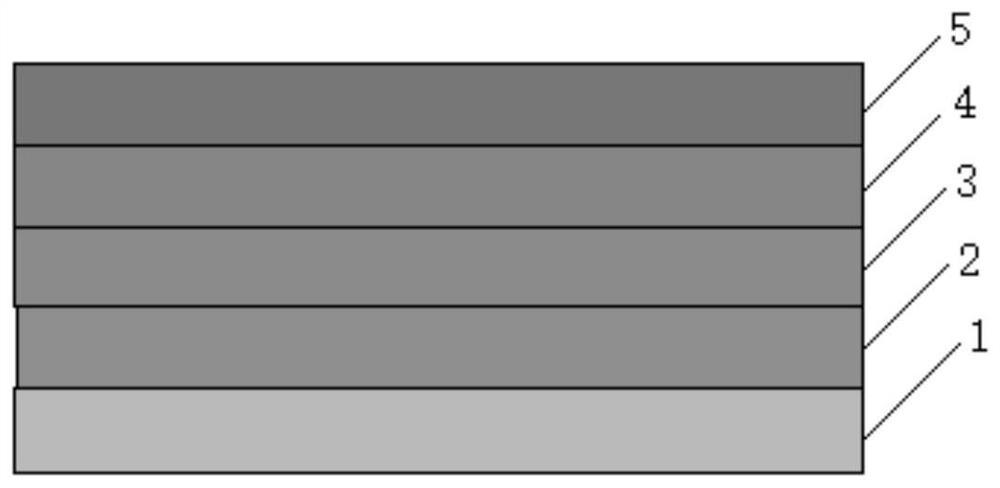

Method used

Image

Examples

Embodiment 1

[0051] Manufacture 1600mm*3200mm*6mm ceramic thin plate

[0052] A ceramic sheet ink-jet underglaze decorative glaze, comprising the following raw materials in parts by weight:

[0053] 30 parts of solvent

[0054] Basic glaze 70 parts

[0055] 5 parts of additives;

[0056] Each part of the base glaze includes the following raw materials in parts by weight:

[0057]

[0058] Each part of the solvent is a mixture of isooctyl cocoate, soybean oil, olive oil and 3# industrial white oil in a weight ratio of 0.8:0.1:0.4:0.6.

[0059] Each part of the additive is a mixture of anti-sedimentation viscosity-reducing agent, wetting dispersant and suspending agent in a weight ratio of 0.8:0.4:0.6.

[0060] Each part of the anti-settling viscosity-reducing agent is a modified polyamide wax, preferably MT PLUS polyamide wax produced by Shanxi Taiyuan Meitexiang Technology Co., Ltd.

[0061] The wetting and dispersing agent per part is wetting and dispersing agent F410.

[0062] E...

Embodiment 2

[0079] Manufacture 1600mm*3200mm*6mm ceramic thin plate

[0080] A ceramic sheet ink-jet underglaze decorative glaze, comprising the following raw materials in parts by weight:

[0081] Solvent 100 parts

[0082] Basic glaze 50 parts

[0083] Additive 0.03 parts;

[0084] Each part of the base glaze includes the following raw materials in parts by weight:

[0085]

[0086] Each part of the solvent is a mixture of isooctyl cocoate, soybean oil, olive oil and 5# industrial white oil in a weight ratio of 0.9:0.2:0.5:0.7.

[0087] Each part of the additive is a mixture of anti-sedimentation viscosity-reducing agent, wetting dispersant and suspending agent in a weight ratio of 0.9:0.5:0.7.

[0088] Each part of the anti-settling viscosity-reducing agent is a modified polyamide wax, preferably MT PLUS polyamide wax produced by Shanxi Taiyuan Meitexiang Technology Co., Ltd.

[0089] The wetting and dispersing agent per part is polyether-modified dimethylsiloxane.

[0090] Ea...

Embodiment 3

[0107] Manufacture 1500mm*3000mm*6mm ceramic sheet

[0108] A ceramic sheet ink-jet underglaze decorative glaze, comprising the following raw materials in parts by weight:

[0109] 30 parts of solvent

[0110] Basic glaze 67 parts

[0111] 3 parts of additives;

[0112] Each part of the base glaze includes the following raw materials in parts by weight:

[0113]

[0114] Each part of the solvent is a mixture of isooctyl cocoate, soybean oil, olive oil and 7# industrial white oil in a weight ratio of 1.0:0.3:0.6:0.8.

[0115] Each part of the additive is a mixture composed of an anti-sedimentation viscosity-reducing agent, a wetting dispersant and a suspending agent in a weight ratio of 1.0:0.6:0.8.

[0116] Each part of the anti-settling viscosity-reducing agent is a modified polyamide wax, preferably MT PLUS polyamide wax produced by Shanxi Taiyuan Meitexiang Technology Co., Ltd.

[0117] The wetting and dispersing agent per part is wetting and dispersing agent F410. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com