On-line dynamic real-time monitoring method and apparatus for magnetic suspension concentration

A real-time monitoring, magnetic suspension technology, applied in the direction of material magnetic variables, etc., can solve the problems of not being found in time, taking a long time, affecting the quality of detection, etc., to avoid missed detection, improve work efficiency, and ensure the effect of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

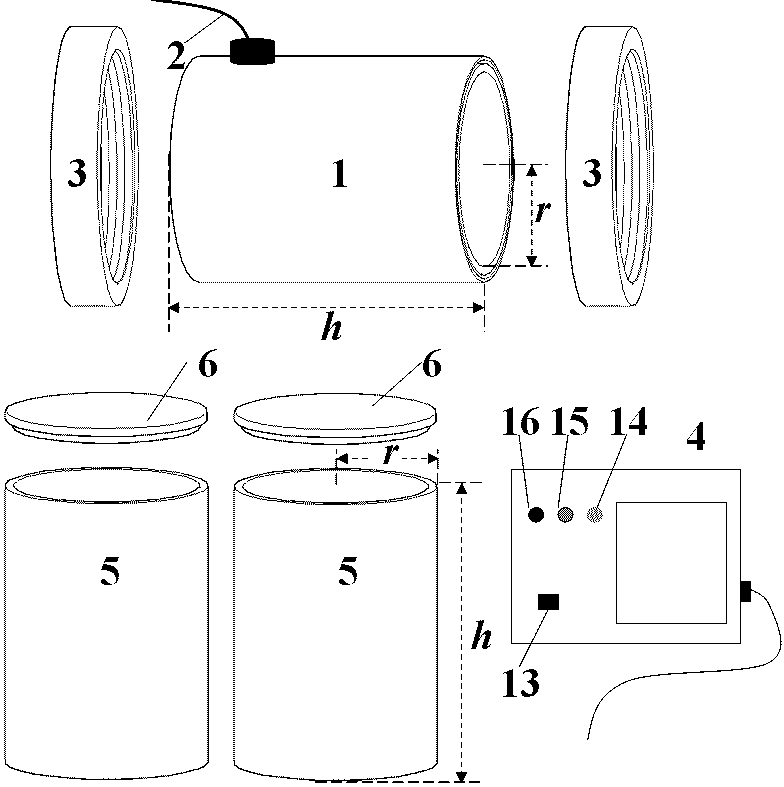

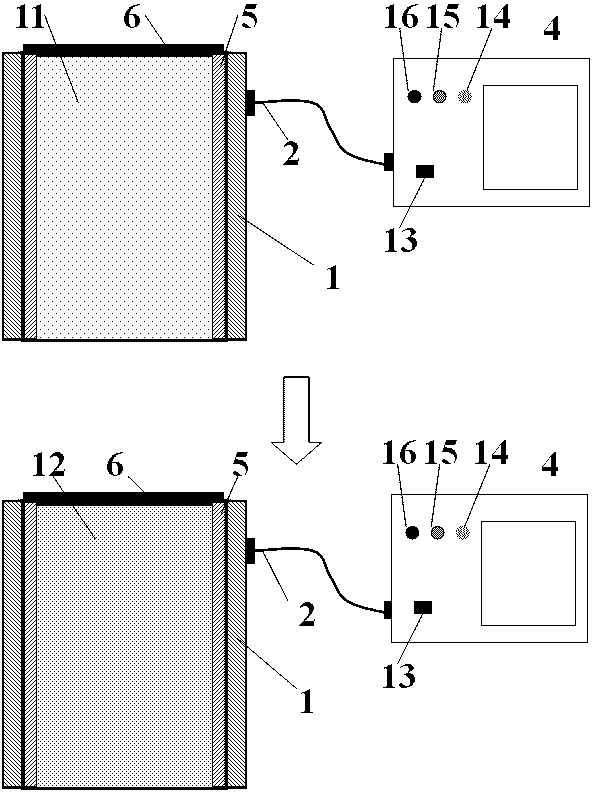

[0026] exist figure 1 In the shown embodiment, an online dynamic real-time monitoring method and device for the concentration of a magnetic suspension, the device includes a round tube electromagnetic sensor (1), a sensor cable (2), two adapter rings (3), an electromagnetic detection Instrument (4), two standard magnetic suspension concentration calibration test tubes (5).

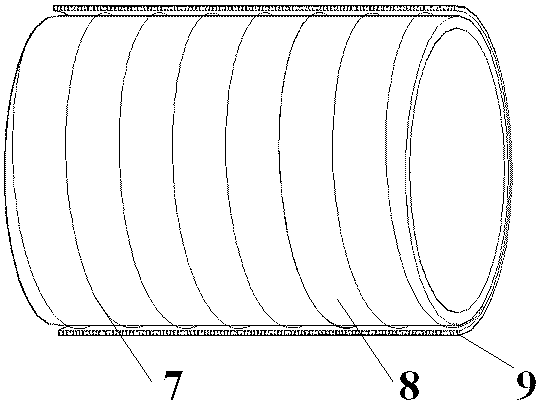

[0027] exist figure 2 In the shown embodiment, the round tube type electromagnetic sensor (1) includes a jacket type electromagnetic detection coil (7), a non-metallic round tube (8), and a metal shielding tube (9). The jacket type electromagnetic detection coil (7) is evenly wound and fixed outside the non-metallic round pipe (8), the outer jacket type electromagnetic detection coil (7) is evenly wound and fixed outside the non-metal round pipe (8), and the metal shielding tube ( 9) The fixed sleeve is outside the jacket-type electromagnetic detection coil (7), shielding and protecting the jacket-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com