Patents

Literature

88results about How to "Avoid incompatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

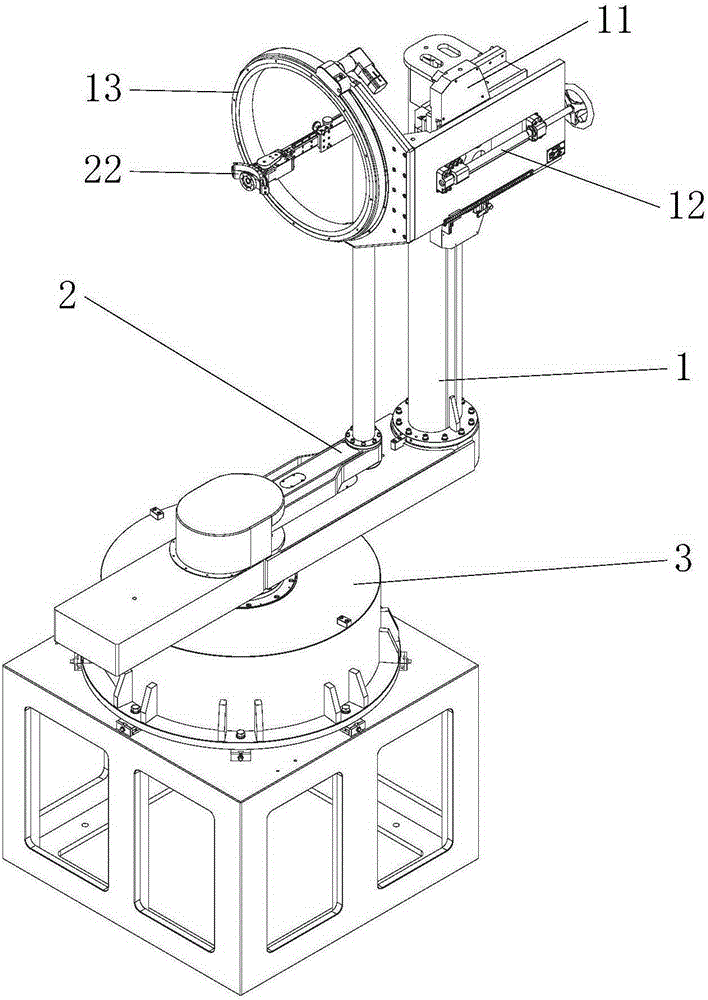

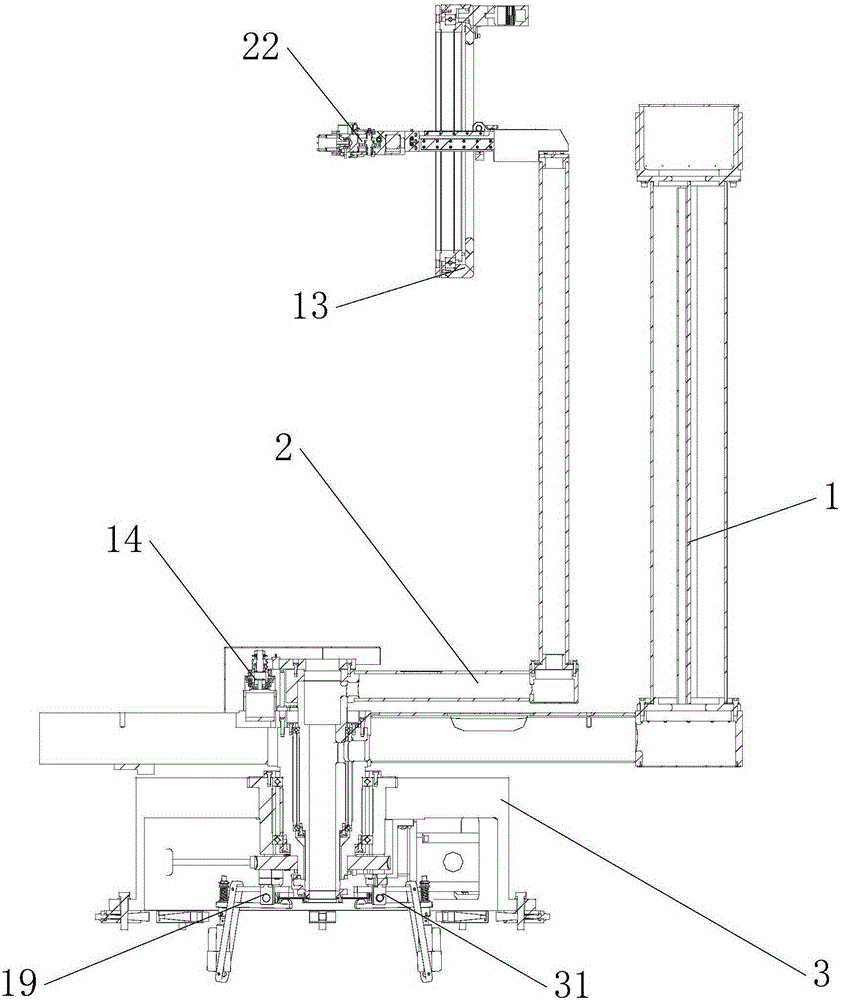

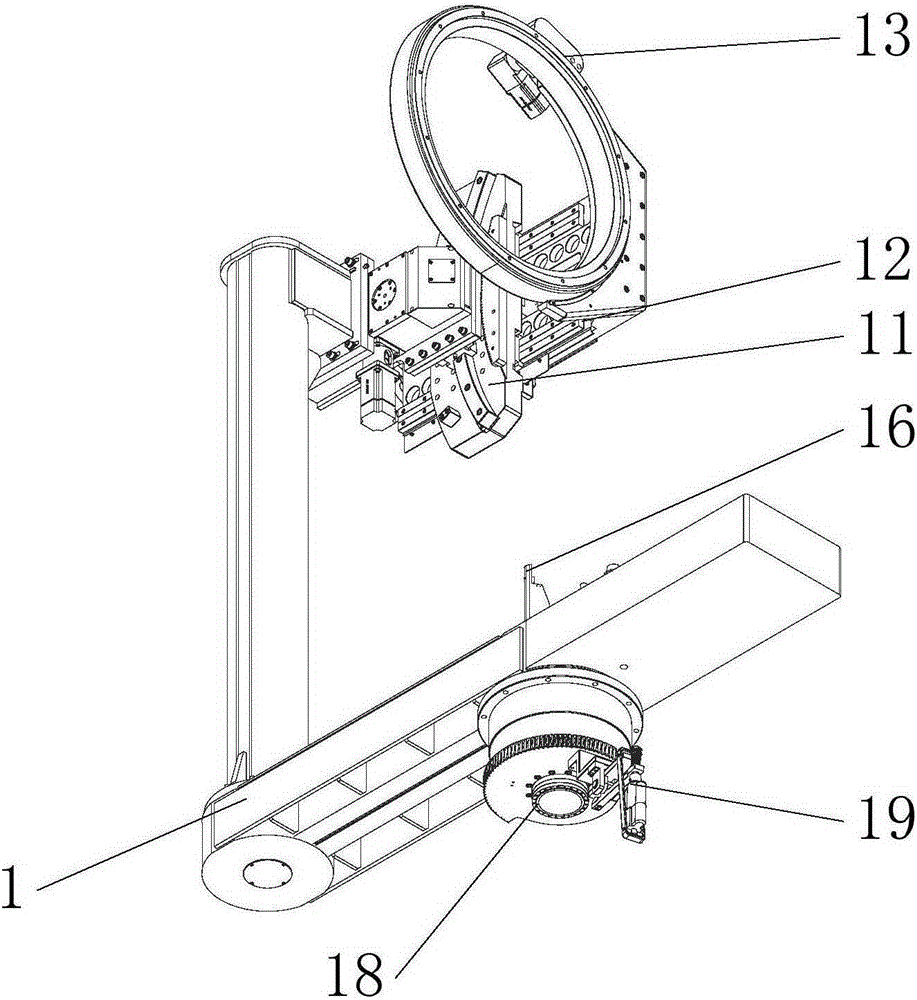

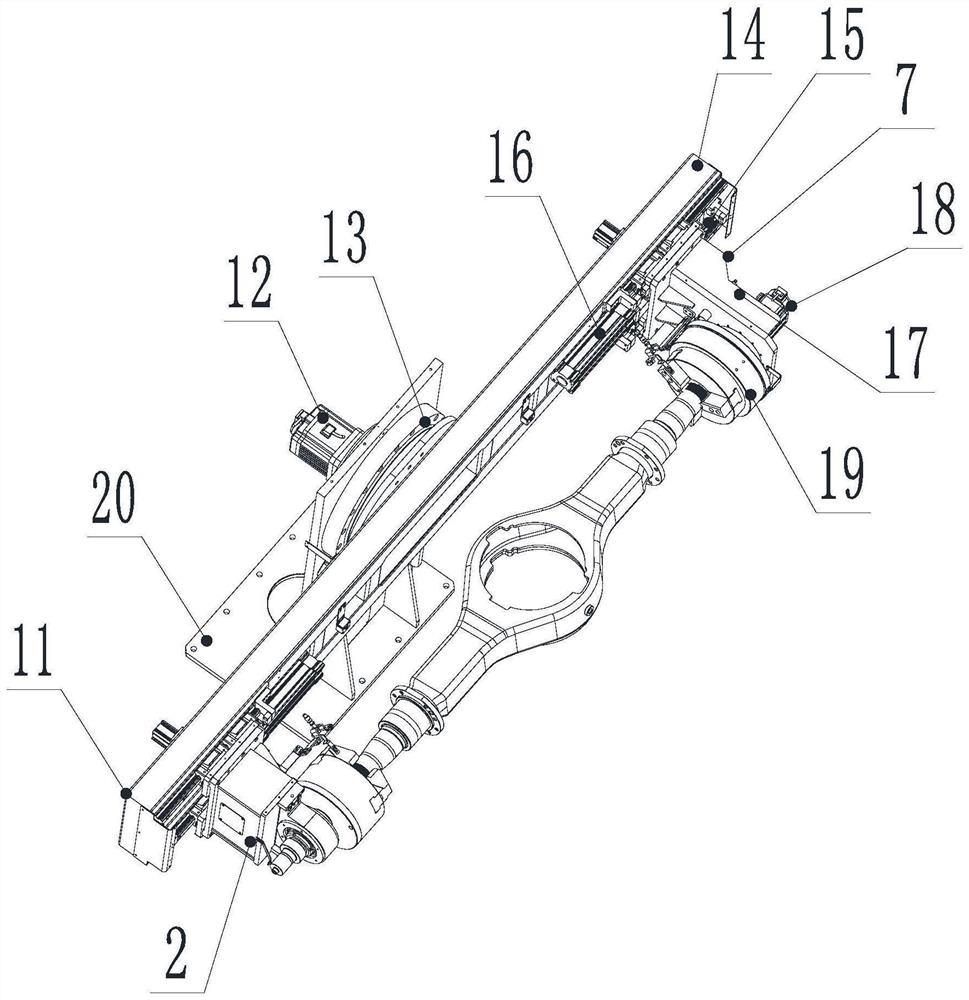

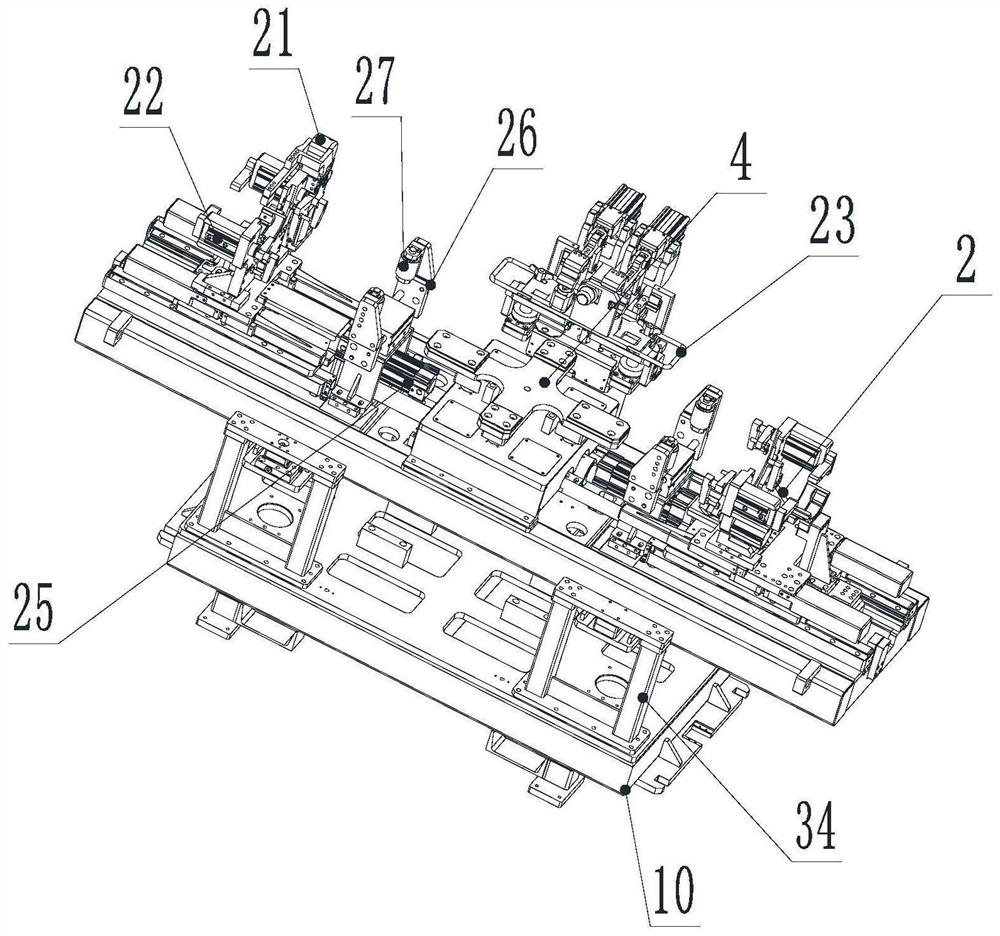

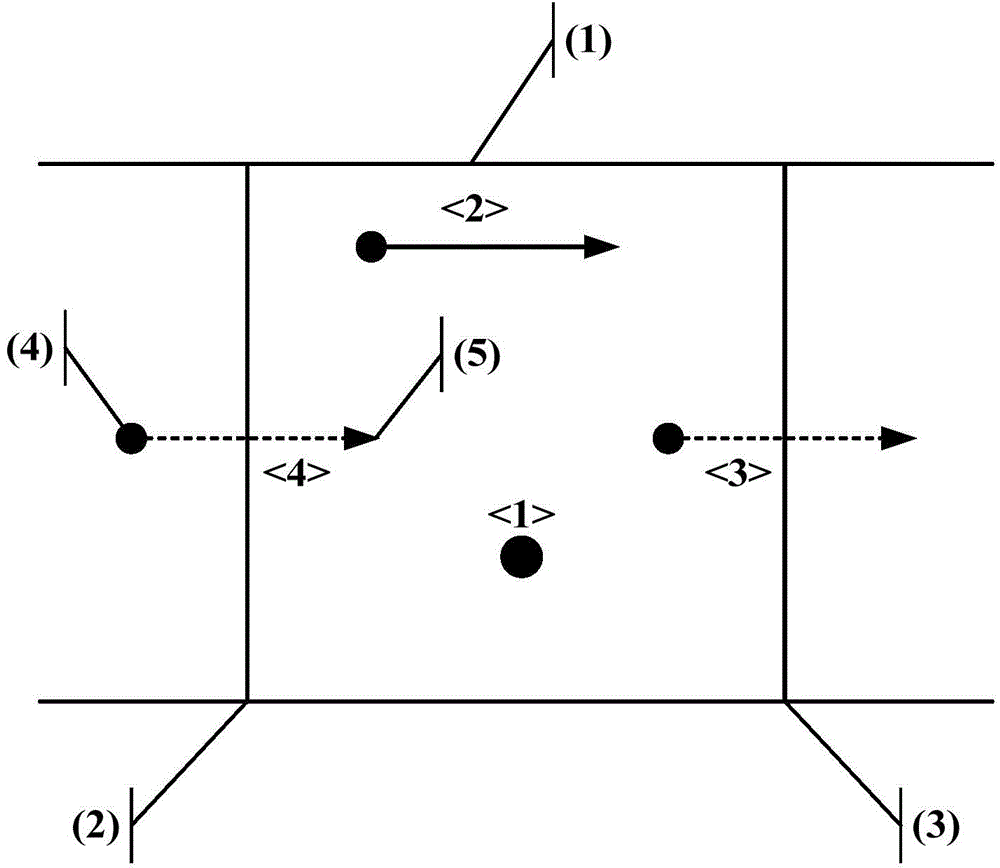

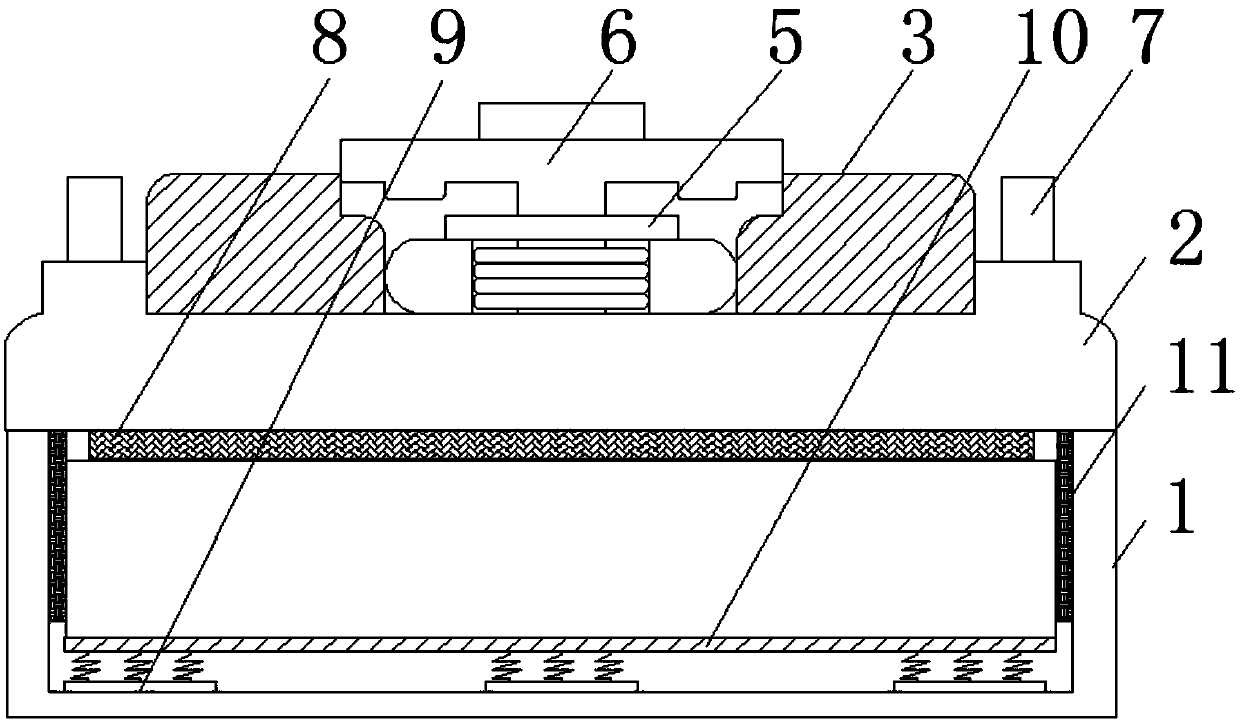

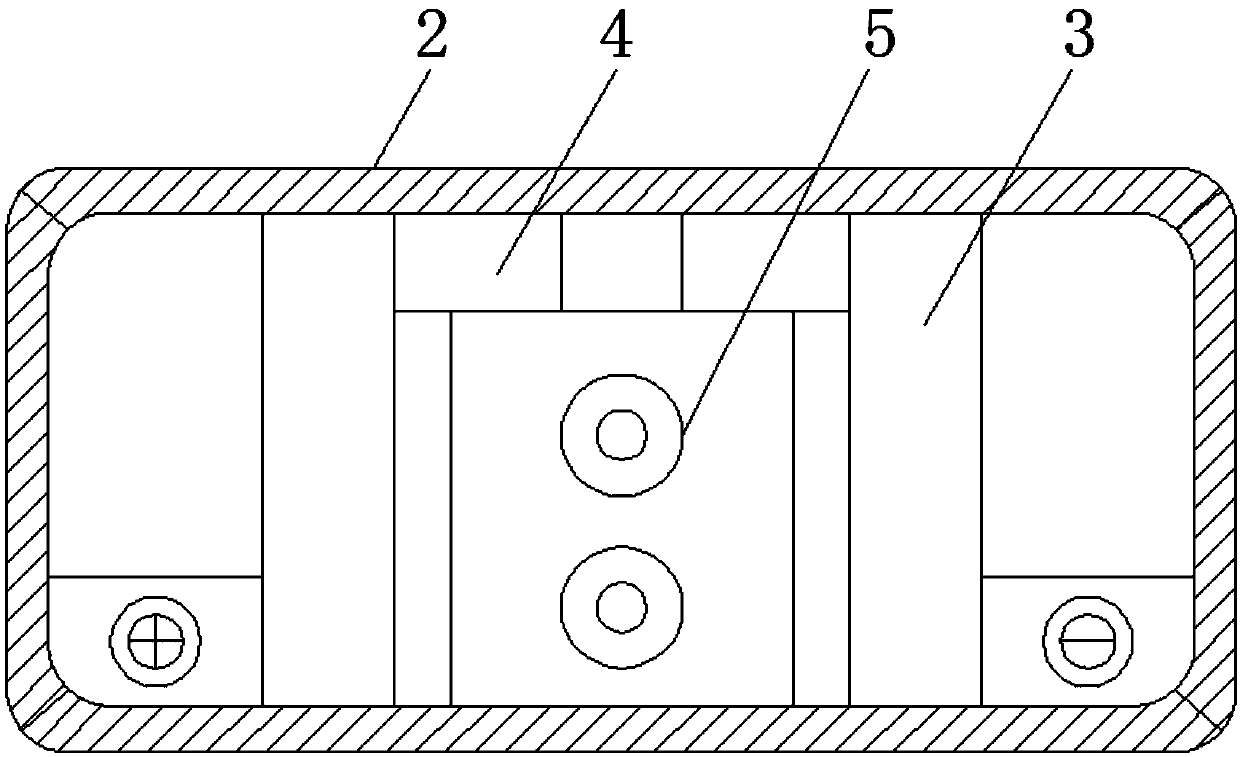

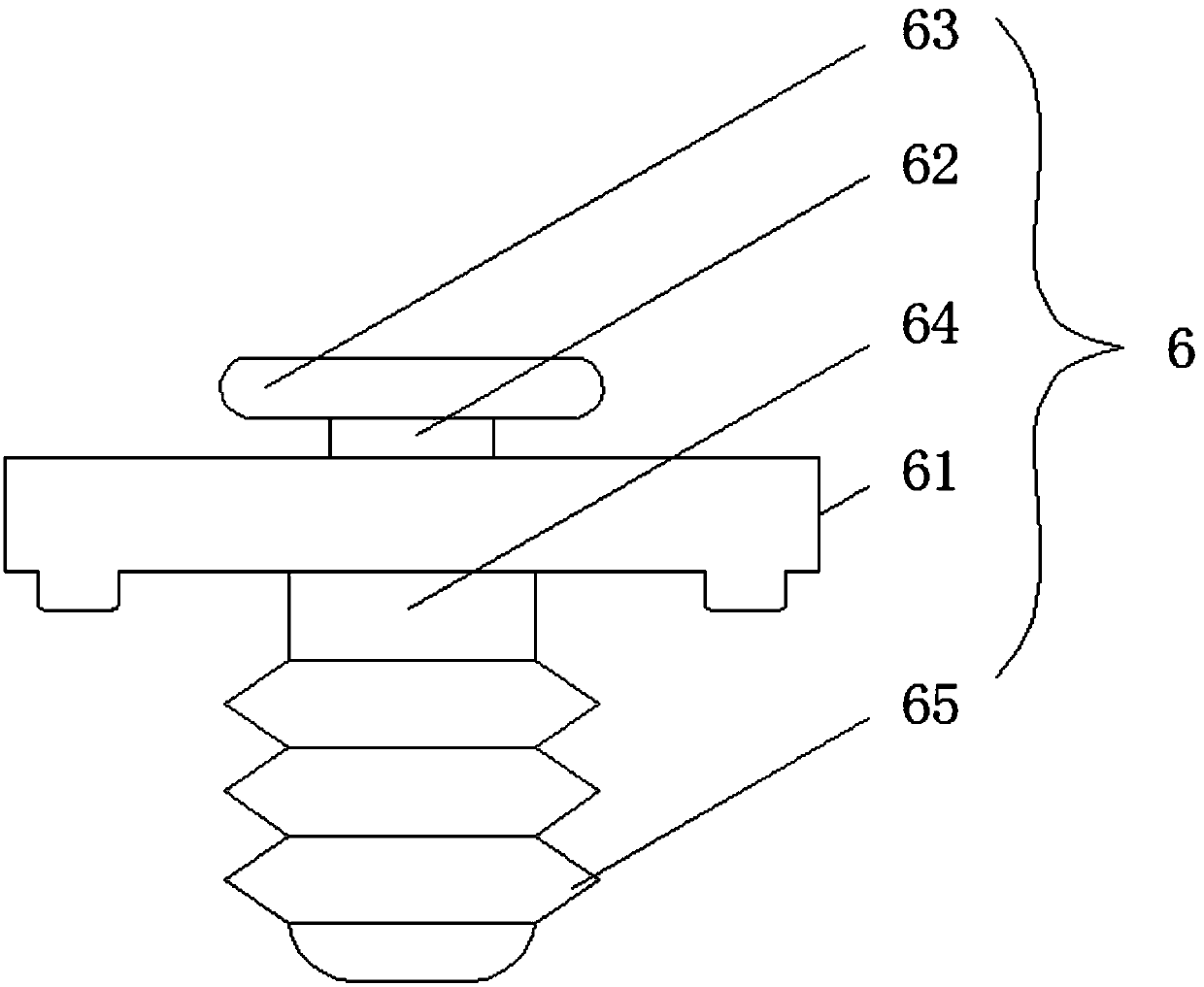

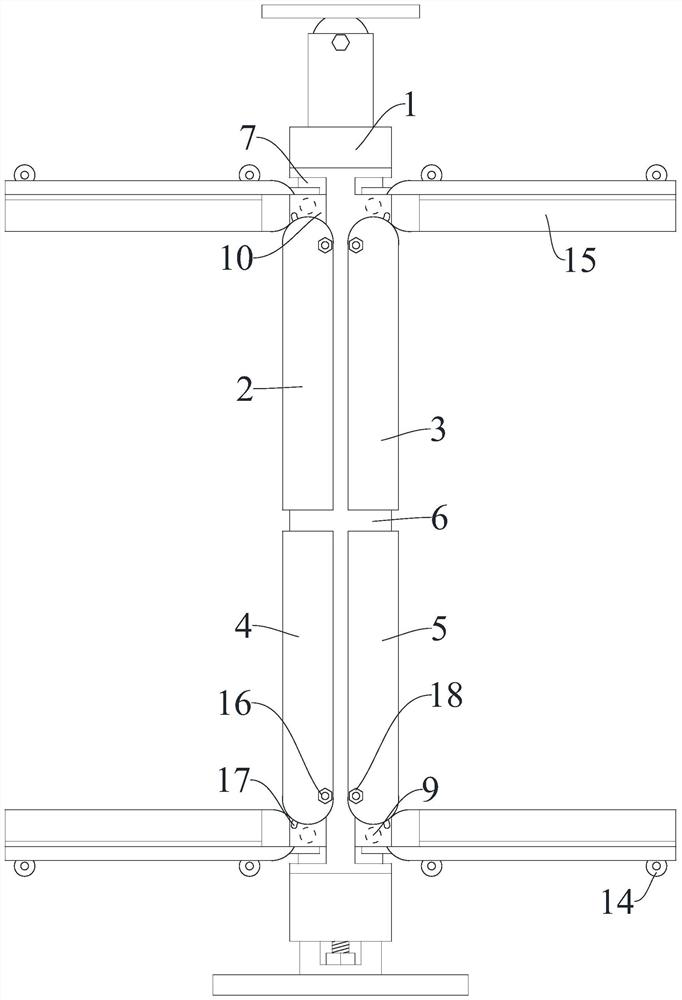

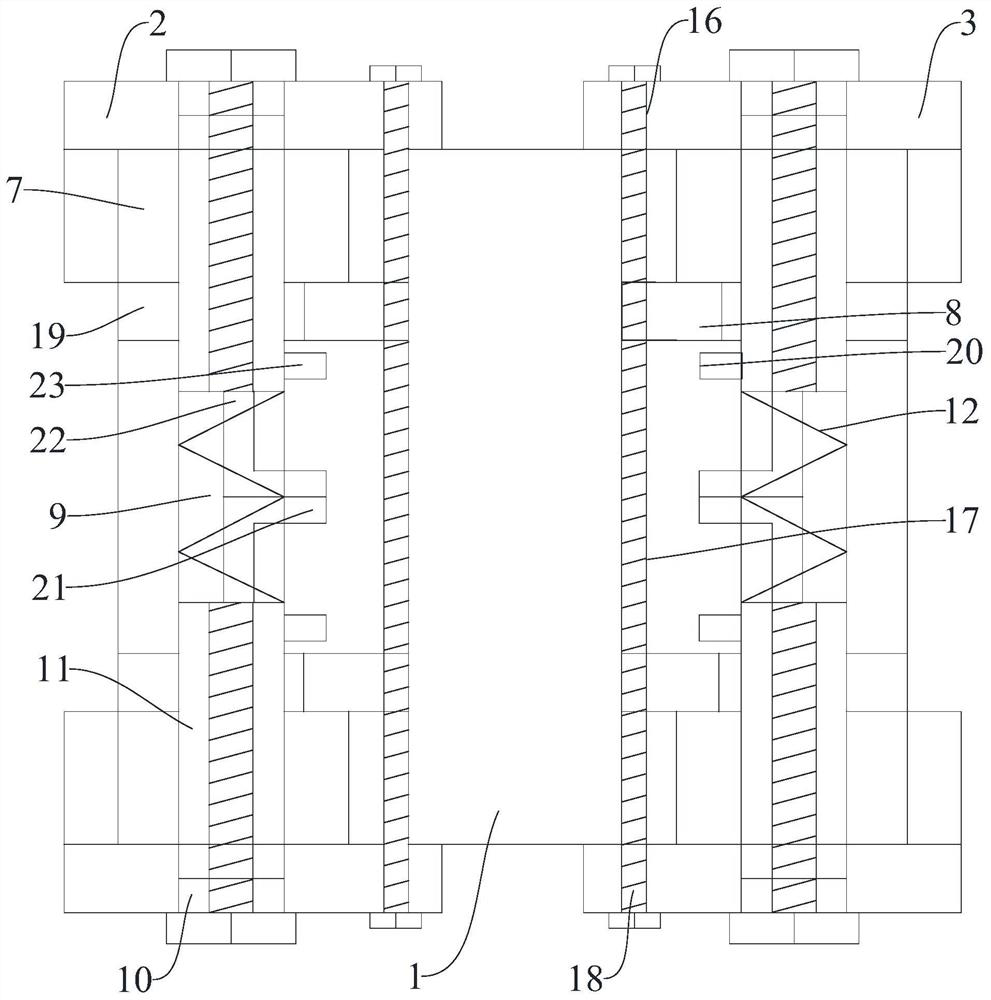

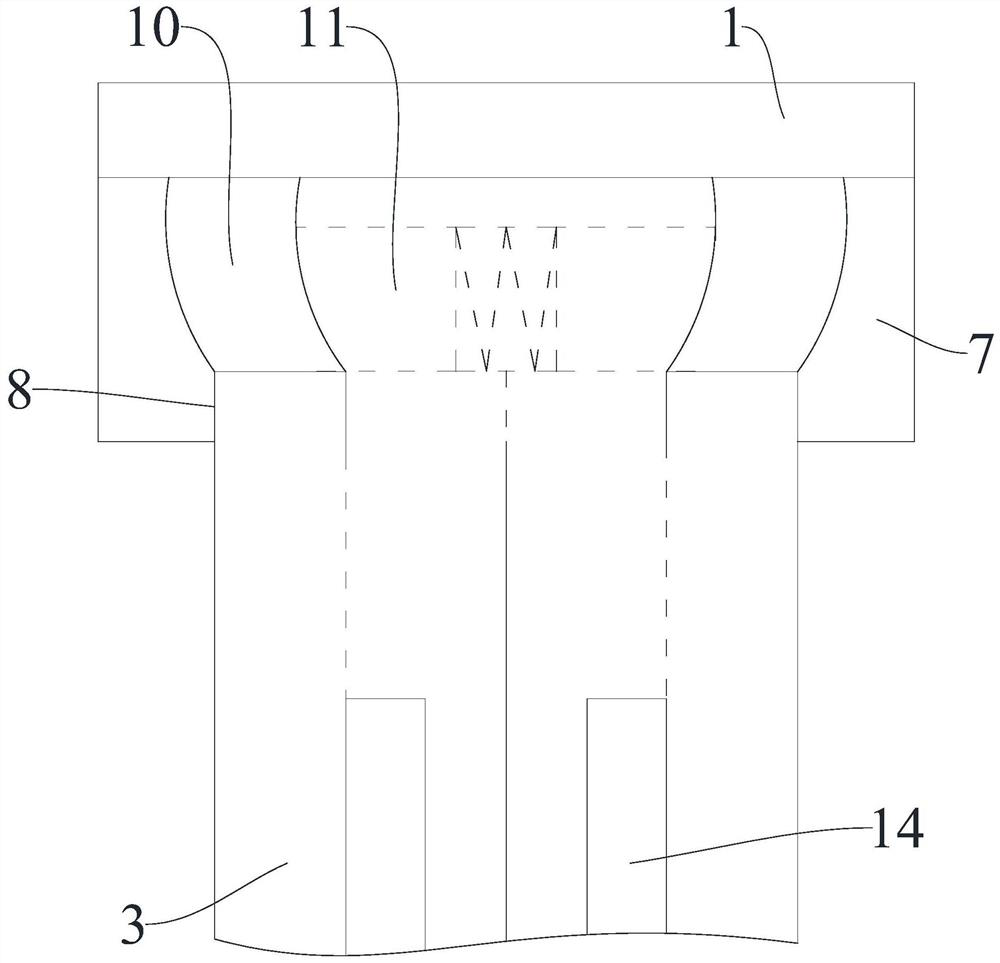

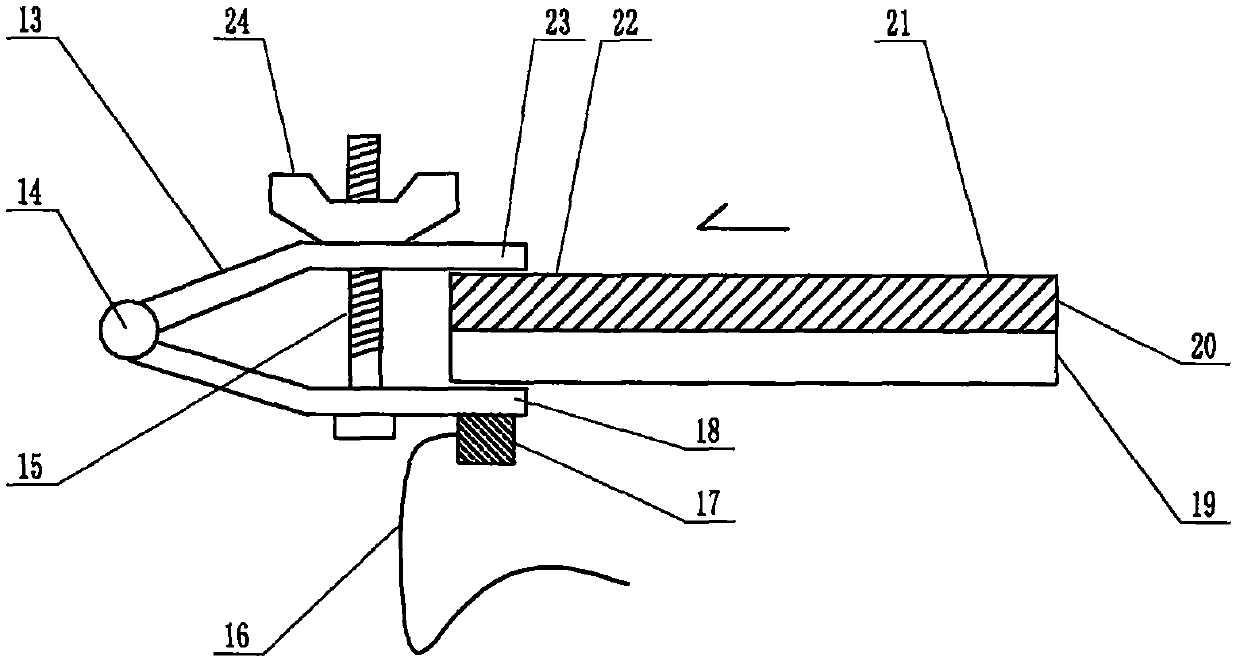

High-precision radome electrical performance wide-angle automatic measurement turret

ActiveCN105277745AReduce consumptionSolve the site problem of measurementElectrical measurement instrument detailsElectrical testingElectricityGrating

The invention discloses a high-precision radome electrical performance wide-angle automatic measurement turret. The high-precision radome electrical performance wide-angle automatic measurement turret comprises an antenna azimuth shaft which is substantially L-shaped, a radome azimuth shaft, a chassis and an industrial personal computer. The antenna azimuth shaft and the radome azimuth shaft are rotationally arranged on the base, and the rotation axes of the antenna azimuth shaft and the radome azimuth shaft coincide. According to the invention, the radome azimuth shaft, the antenna azimuth shaft and SMAP are under closed-loop control; the radome azimuth shaft and the antenna azimuth shaft share a circular raster; and the problem of angle error, which is caused by mechanical deformation and the like, can be eliminated to the maximum extent.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

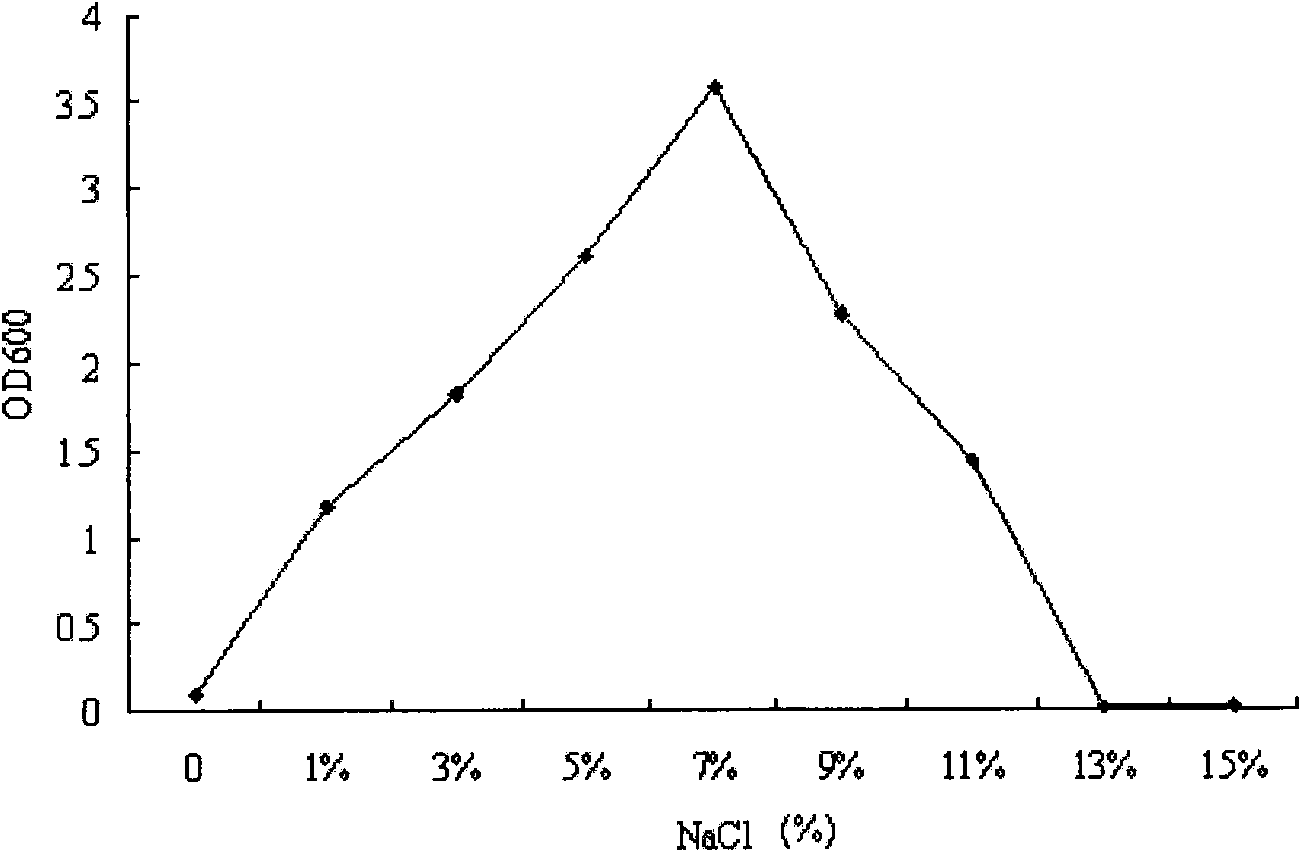

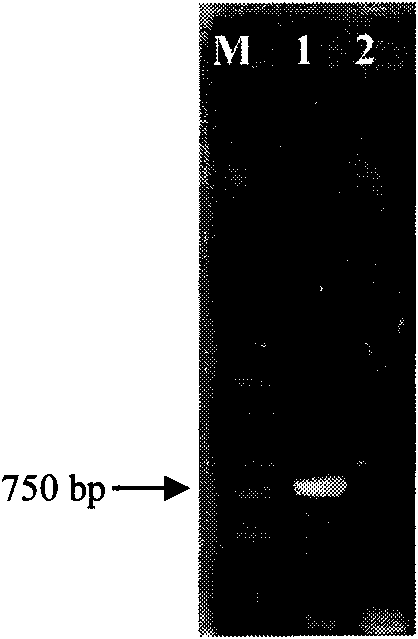

Bacillus alcalophilus as well as culture method and application

InactiveCN101597581AImprove salt toleranceStrong salt toleranceBacteriaMicroorganism based processesMicroorganismBacillus alcalophilus

The invention discloses a Bacillus alcalophilus SD 7903 with the preservation number of CGMCC No. 3158, belonging to the field of microbial technology; the invention also discloses a culture method thereof and an application in producing Ectoine. The Bacillus alcalophilus has higher Ectoine synthesis capability and is a strain of Gram positive bacteria, thus expanding biological resource utilization space and having good industrial application prospect in respect to production of Ectoine mainly by applying Gram negative bacteria in the current industry.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

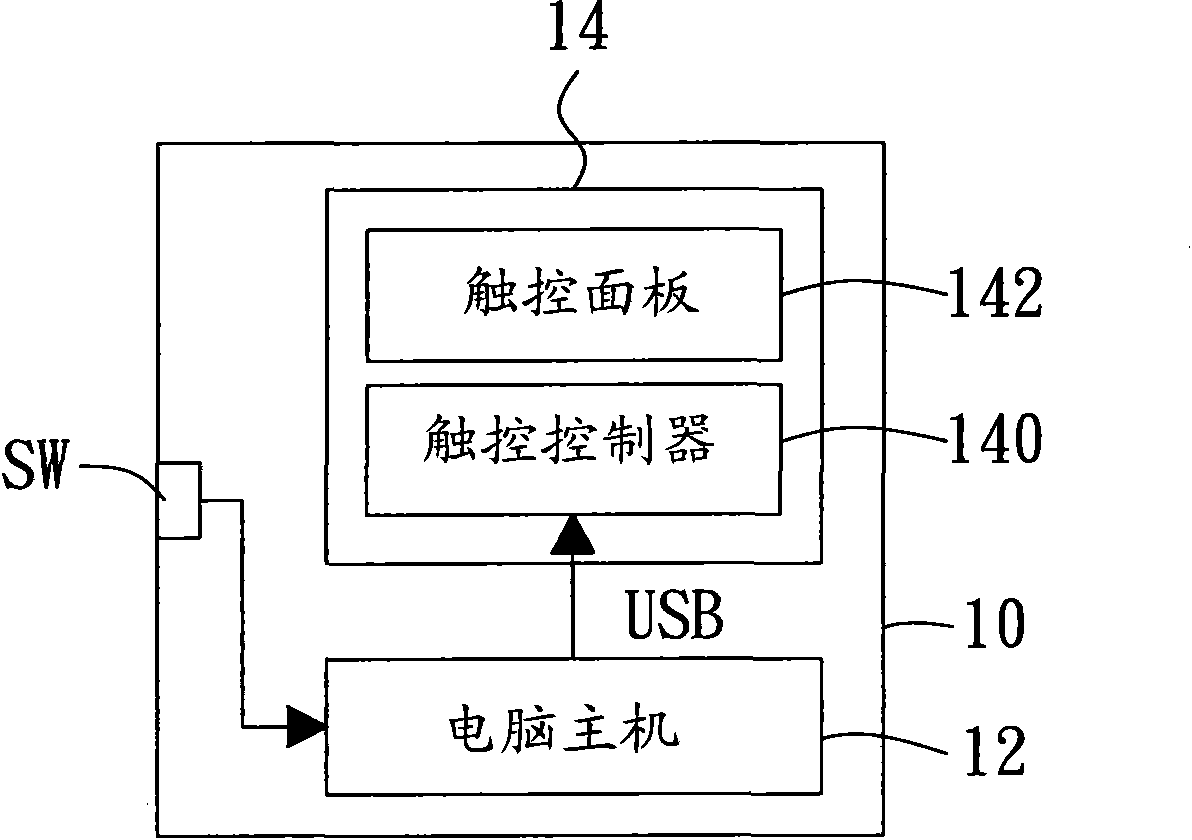

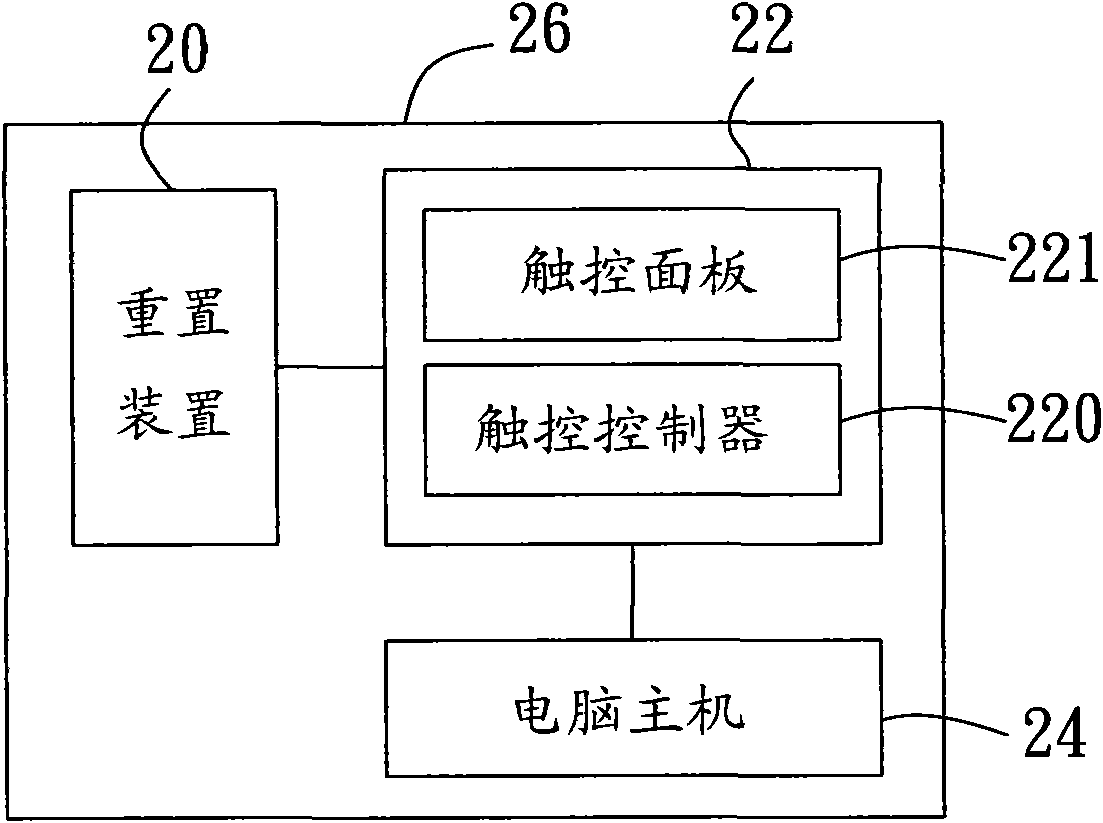

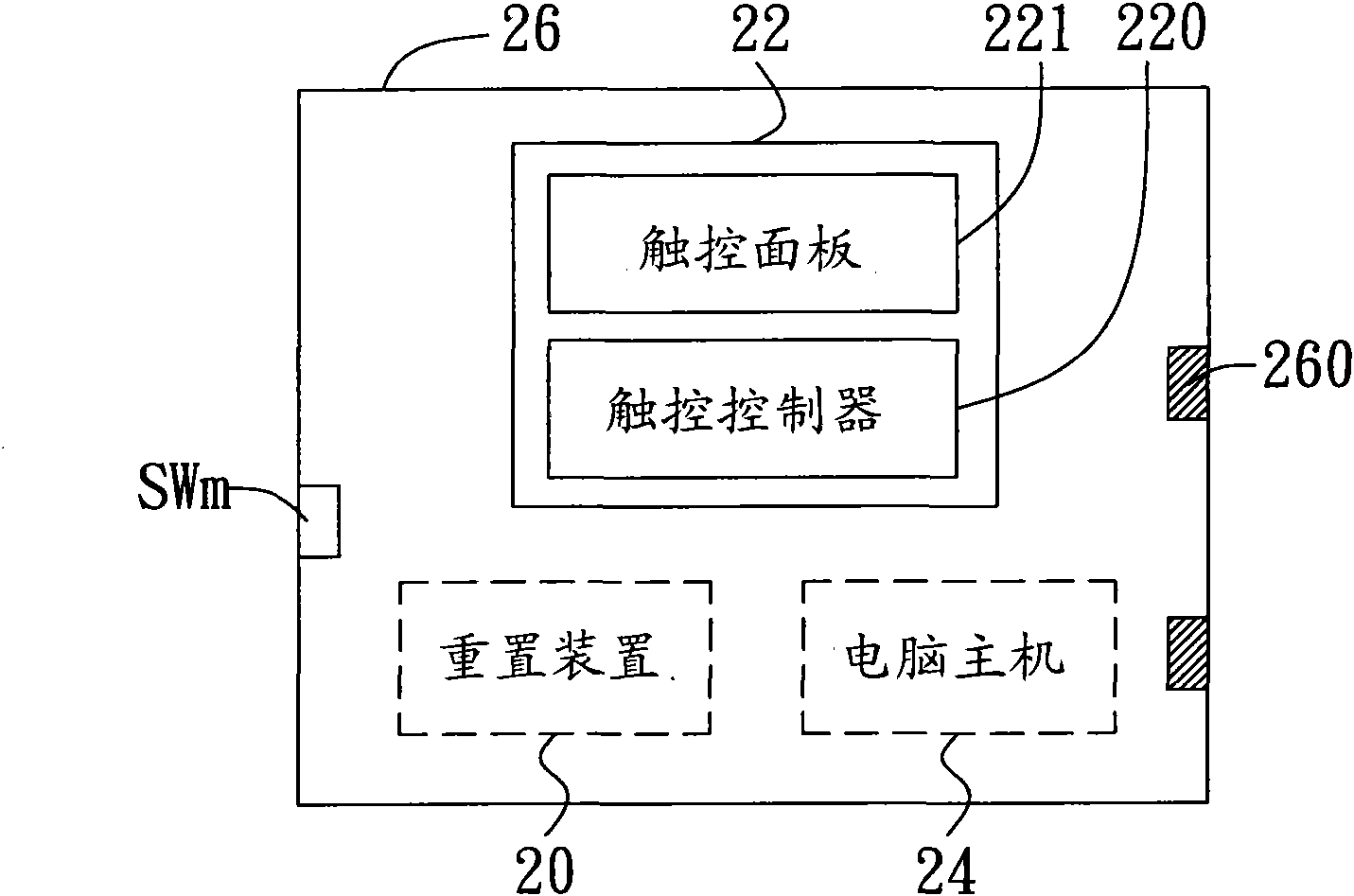

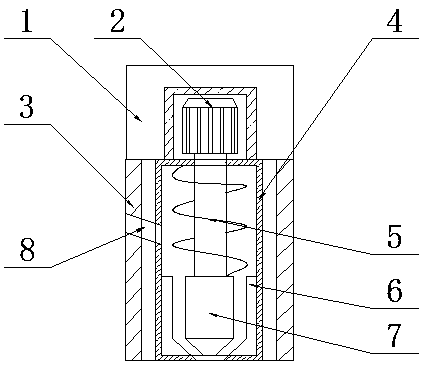

Automatic detection and reply touch system and resetting device thereof

InactiveCN102141850AAvoid incompatibilitySolve the problem of inaccurate touchData resettingPulse shapingControl signalControl circuit

The invention relates to an automatic detection and reply touch system and a resetting device thereof. The resetting device of the automatic detection and reply touch system mainly comprises a state detector, a control signal generating circuit and a resetting control circuit. The state detector detects the opening or closing state of a frame body for accommodating a touch device to generate corresponding state signals. The control signal generating circuit generates corresponding control signals according to the state signals. The resetting control circuit resets the touch device according to the control signals. Therefore, the touch device is reset after the opening or closing state of the frame body is changed, a touch electric field environment around the device is searched again aiming at the changed touch environment, and then the touch accuracy can be replied. The invention also provides the automatic detection and reply touch system.

Owner:TVM CORP

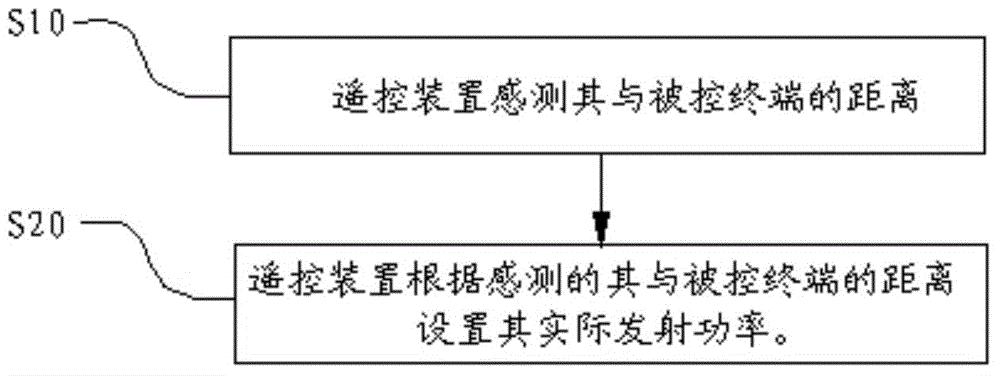

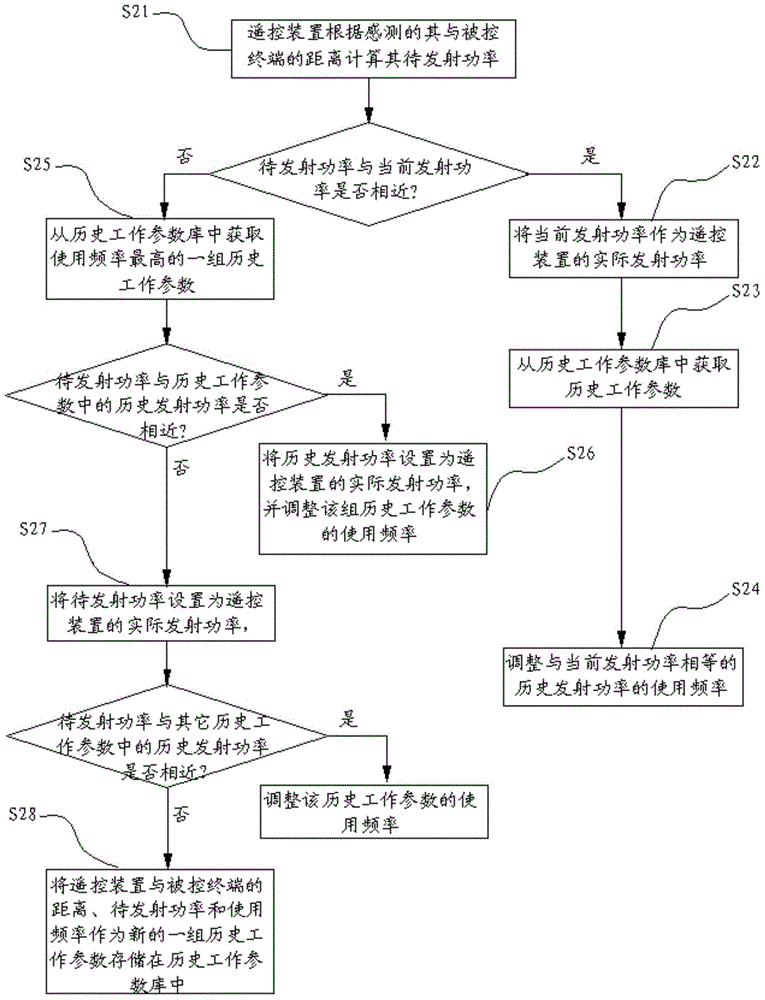

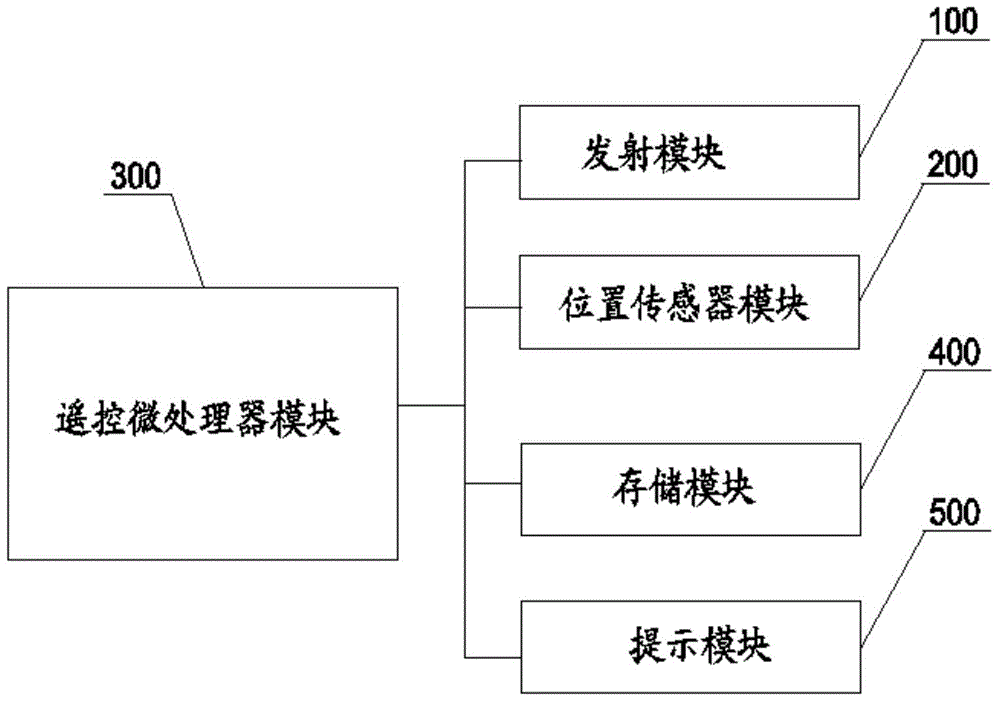

Remote control device and method for improving sensitivity thereof

ActiveCN104978839AHigh sensitivityAvoid transmitting powerTransmission systemsTransmission control/equalisingTransmitted powerRemote control

The invention discloses a method for improving the sensitivity of a remote control device. The method comprises the following steps: S10, sensing the distance between the remote control device and a controlled terminal; and S20, setting actual transmitting power of the remote control device according to the sensed distance between the remote control device and the controlled terminal. According to the method, the actual transmitting power of the remote control device is set based on the distance between the remote control device and the controlled terminal, so that the actual transmitting power of the remote control device is increased when the remote control device is far away from the controlled terminal, and is lowered when the remote control device is close to the controlled terminal, so that the actual transmitting power of the remote control device can be adjusted to be in an optimal state, the problem of not taking both the actual transmitting power of the remote control device and the effective control distance into account can be avoided, and furthermore, the sensitivity of the remote control device is improved while the power consumption of the remote control device is lowered.

Owner:SHENZHEN TCL NEW-TECH CO LTD

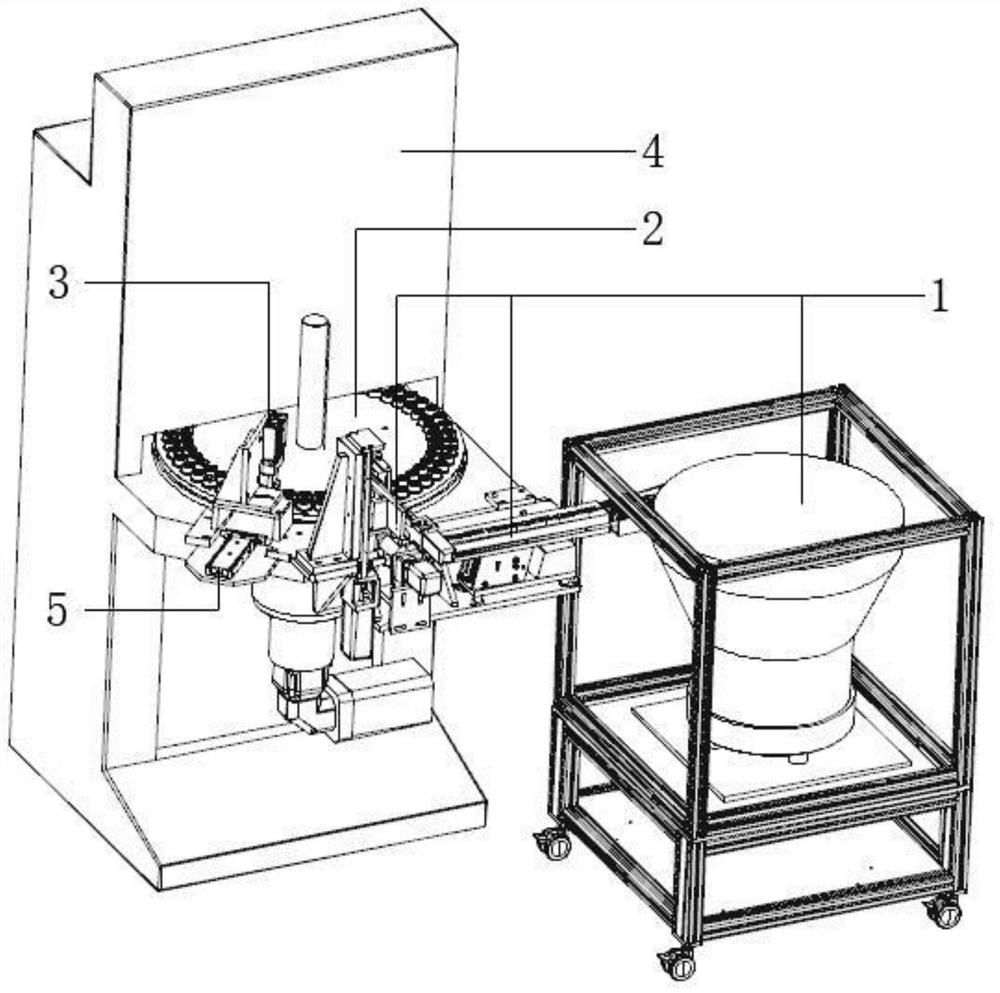

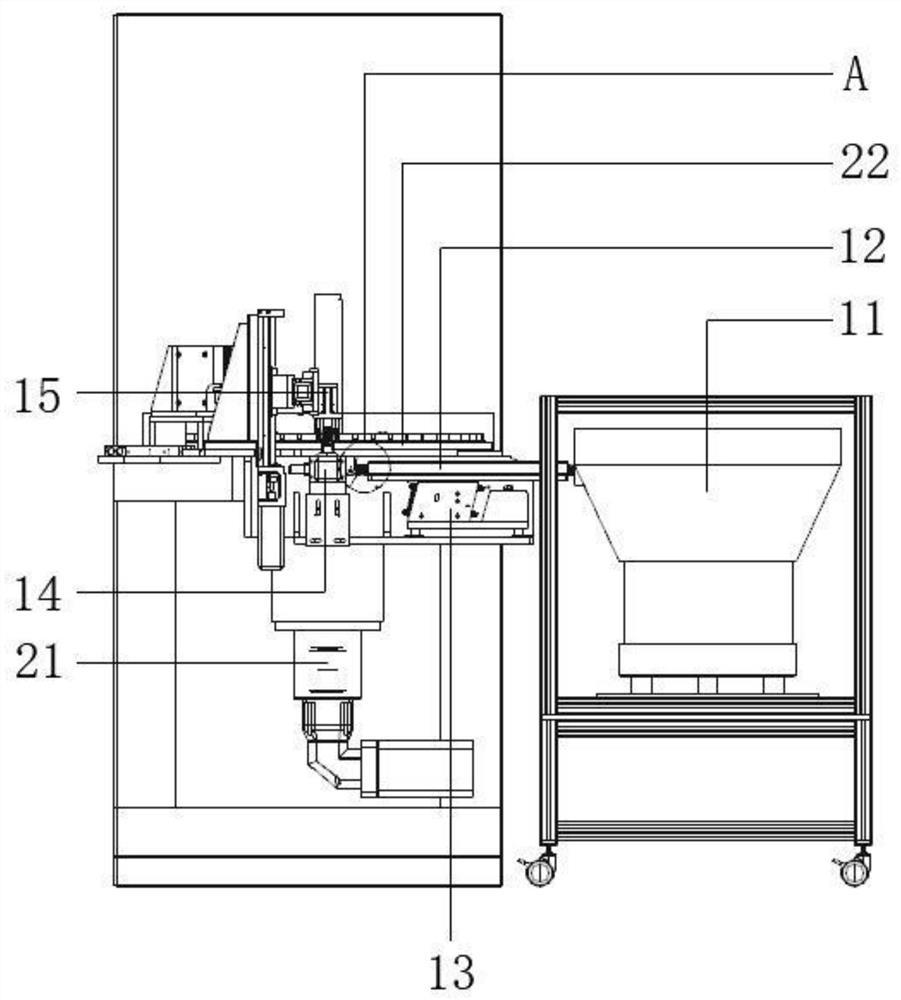

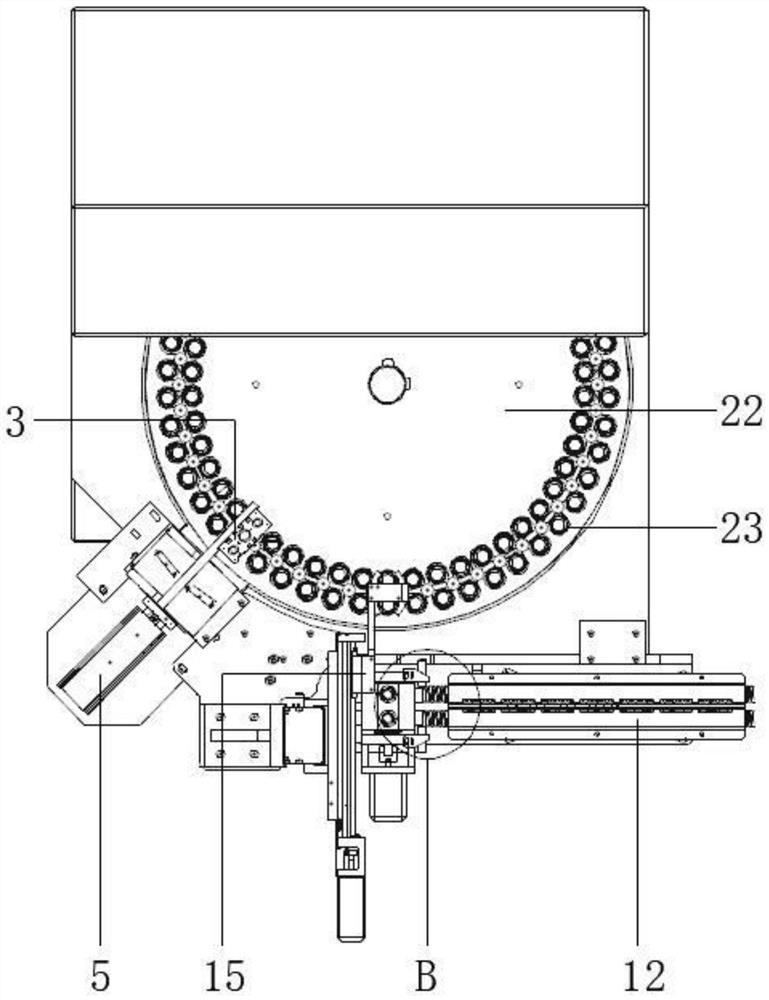

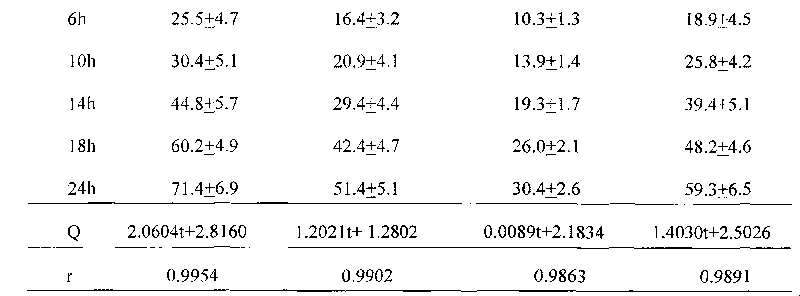

Spring grinder with automatic feeding function

ActiveCN111805324ASolve the technical problem of easy blockage in the delivery hoseSmooth feedingGrinding feedersPlane surface grinding machinesRotating discPhysics

The embodiment of the invention provides a spring grinder with an automatic feeding function, and belongs to the technical field of spring grinders. The spring grinder with the automatic feeding function comprises a spring grinder main body, a conveying mechanism, a spring base, a feeding mechanism, an overturn assembly and a manipulator assembly, wherein the conveying mechanism comprises a rotating disc, and the rotating disc is movably arranged on the spring grinder main body; the spring base is arranged on the rotating disc; the feeding mechanism comprises a vibration plate assembly; the overturn assembly comprises an overturn base, an turnover shaft movably arranged on the turnover base, and a core rod arranged on the turnover shaft; the core rod can penetrate through a spring; and themanipulator assembly is movable and is arranged between the core rod and the spring base. The technical effect of smooth spring feeding is achieved.

Owner:诸暨迈思特自动化科技有限公司

Solid gel capable of eliminating formaldehyde and odor in rooms and vehicles

ActiveCN108744849ASimple ingredientsSimple preparation processGas treatmentDispersed particle separationDeodorantChemistry

The invention provides solid gel capable of eliminating formaldehyde and odor in rooms and vehicles. The solid gel at least comprises gel powder, essential oil, a deodorant, a nonionic surfactant, parachlorometaxylenol, ethanol and water. The solid gel has the advantages that the solid gel is simple cheap in raw materials and simple in preparation process; the incompatibility among compounding rawmaterials can be avoided effectively, and the odor eliminating, sterilizing and formaldehyde eliminating performance can be brought into play in a most efficient manner.

Owner:浙江施维康生物医学材料有限公司

Medical ultrasonic probe sterilizing gel and preparation method thereof

InactiveCN101987201AAvoid incompatibilityImprove stabilityAntibacterial agentsBiocideCelluloseUltrasonography

The invention provides a medical ultrasonic probe stelrizing gel and a preparation method thereof. The gel comprises the following components of 0.5-5 percent (w / v) of non-ionic cellulose material or 5-20 percent (w / v) of poloxamer, 0.1-0.5 percent (w / v) of chlorhexidine acetate, 0.1-0.5 percent (w / v) of double-chain quaternary ammonium salt sterilizing agent, 0.5-2 percent (v / v) of wetting agent and the balance of water. The sterilizing agent has the function of sterilizing and disinfecting a medical ultrasonic probe and the skin; and a soluble medical ultrasonic probe sterilizing gel with better acoustical property, safety and stability can be used as a coupling agent, can realize high-efficiency sterilization within short time and concurrent disinfection on the ultrasonic probe, and achieves the purpose of reducing cross infection risk caused possibly in the clinical ultrasonic detection process.

Owner:北京财之源科技有限公司

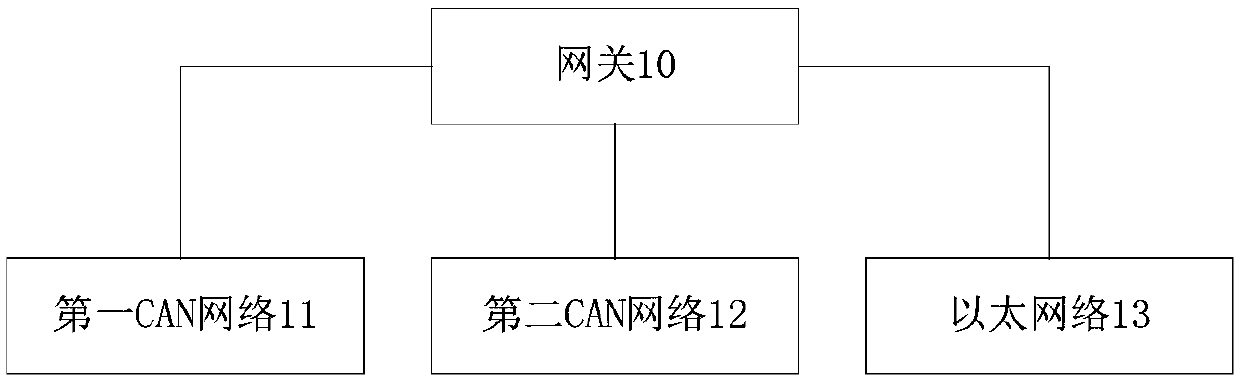

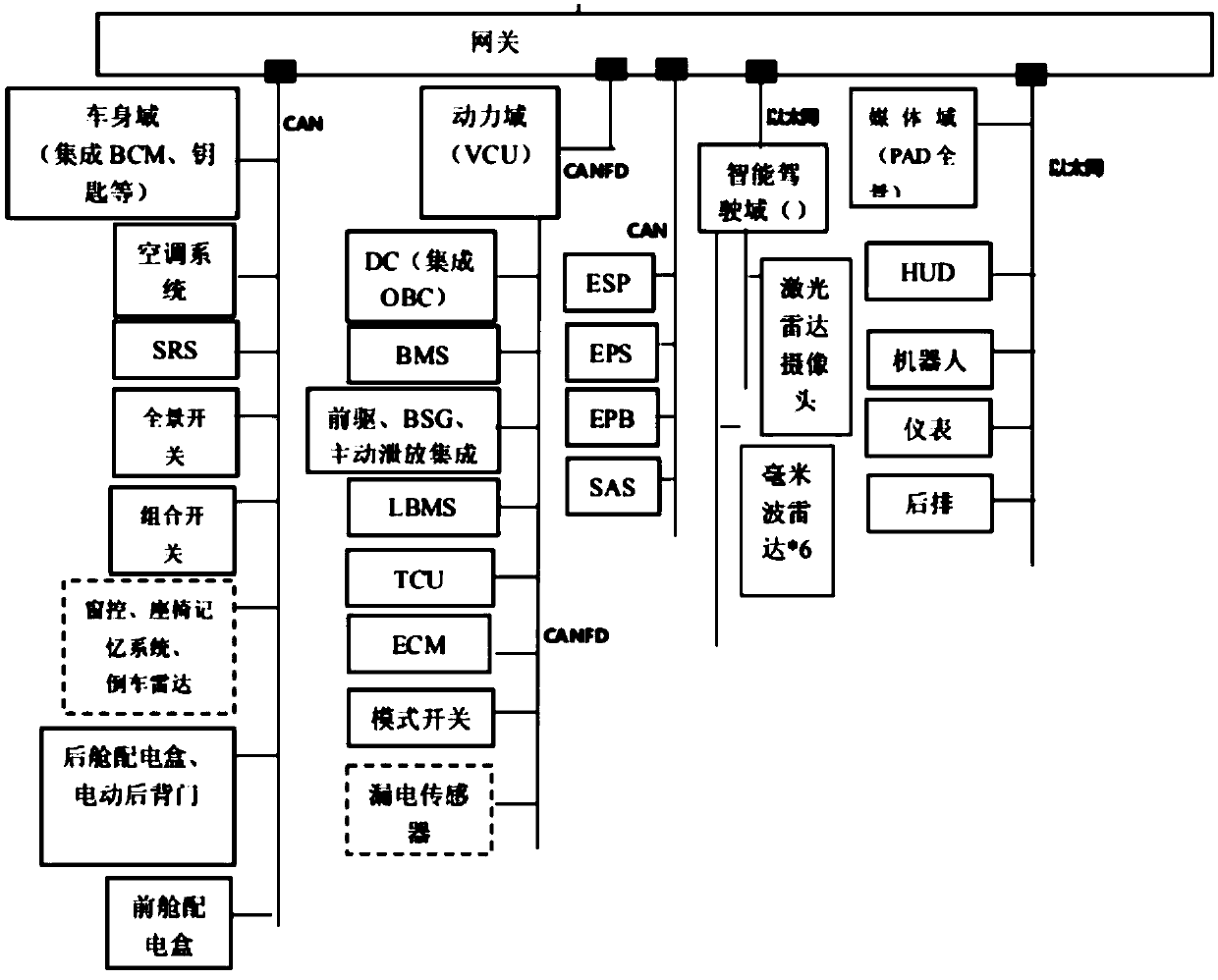

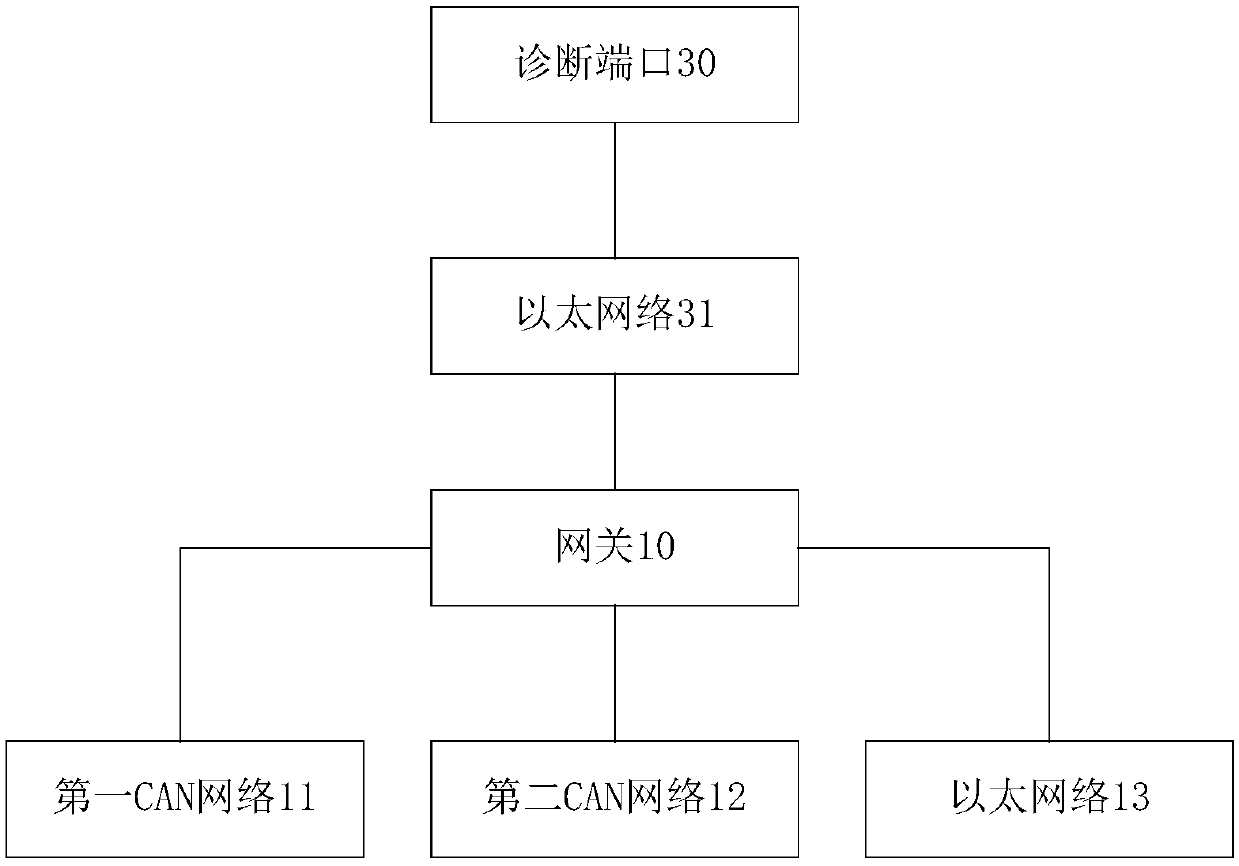

Vehicle and communication system and method thereof

InactiveCN111385176ASolve technical problemsAvoid frame dropsNetwork connectionsBus networksCommunications systemEngineering

The invention discloses a vehicle and a communication system and method thereof. The communication system of the vehicle comprises a first CAN network, a second CAN network, an Ethernet and a gateway.The first CAN network, the second CAN network and the Ethernet are all connected with the gateway; the first CAN network, the second CAN network and the Ethernet are respectively used for transmitting data of a target domain according to network requirements of the first CAN network, the second CAN network and the Ethernet; the gateway is used for receiving the data transmitted in the source network and converting the data in the source network so as to meet the transmission requirement of the target network; and the source network and the target network are any one of the first CAN network,the second CAN network and the Ethernet, and the source network and the target network are different networks at the same moment. According to the system, normal interaction of data among all networksin the whole vehicle is achieved, and the phenomena of data frame loss or wrong frames and data interaction incapability are effectively avoided.

Owner:BYD CO LTD

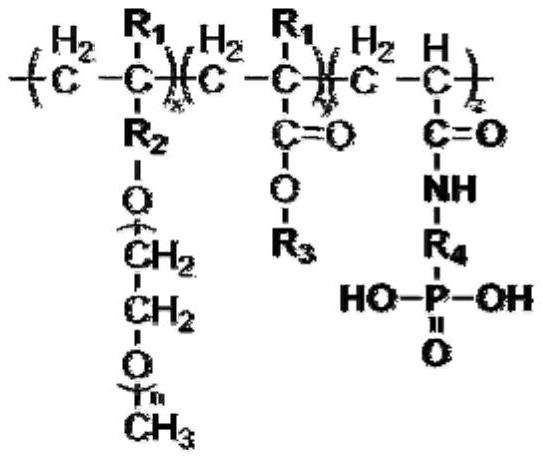

Phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and preparation method and application thereof

InactiveCN112745464AImprove stabilitySimple preparation techniquePhosphoric Acid EstersPolymer science

The invention provides a phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and a preparation method and application thereof, and relates to the technical field of concrete admixtures. The phosphate-containing high-adaptability early-strength polycarboxylic acid water reducer is prepared by copolymerizing 90 to 110 parts of unsaturated polyether macromonomer, 10 to 20 parts of unsaturated carboxylic acid and 1 to 6 parts of phosphate-containing acrylamide free radical. A polyacrylic acid derivative and a polyether side chain on the molecular chain of the water reducing agent provide dispersing performance, the phosphate ester-containing polyacrylamide improves the adaptability of the water reducing agent due to the existence of a phosphate group on one hand, and amido balances the retarding effect of the phosphate group on the other hand, and also improves the early strength effect of the product. Therefore, the cement early strength agent has better adaptability and early strength effect when being used for mixing different types of cement and high-mud-content aggregate concrete.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Amphoteric mud-resistant polycarboxylate superplasticizer

The invention discloses an amphoteric mud-resistant polycarboxylate superplasticizer. Unsaturated quaternary ammonium salt monomers are introduced to obtain the amphoteric mud-resistant polycarboxylate superplasticizer. The specific preparation process is as follows: under an oxidation-reduction initiation system, unsaturated carboxylic acid monomers, unsaturated polyether monomers and the unsaturated quaternary ammonium salt monomers are subjected to free radical polymerization reaction in a water phase to obtain the mud-resistant polycarboxylate superplasticizer. The preparation method is simple and easy to implement and stable in process, the cationic quaternary ammonium salt in the synthesized amphoteric mud-resistant polycarboxylate superplasticizer can effectively inhibit expansion of a clay layered structure, water absorbed by clay expansion can be reduced, and the intercalation effect of polyether side chains of the polycarboxylate superplasticizer in the clay layered structure can be reduced; and anionic carboxylic acid in the amphoteric mud-resistant polycarboxylate superplasticizer can form an electrostatic adsorption effect on the surfaces of cement particles, so that the effect of effectively dispersing concrete is achieved. Moreover, the dispersion retentivity and adaptability of the amphoteric mud-resistant polycarboxylate superplasticizer are improved, and the workability of concrete can be effectively improved.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

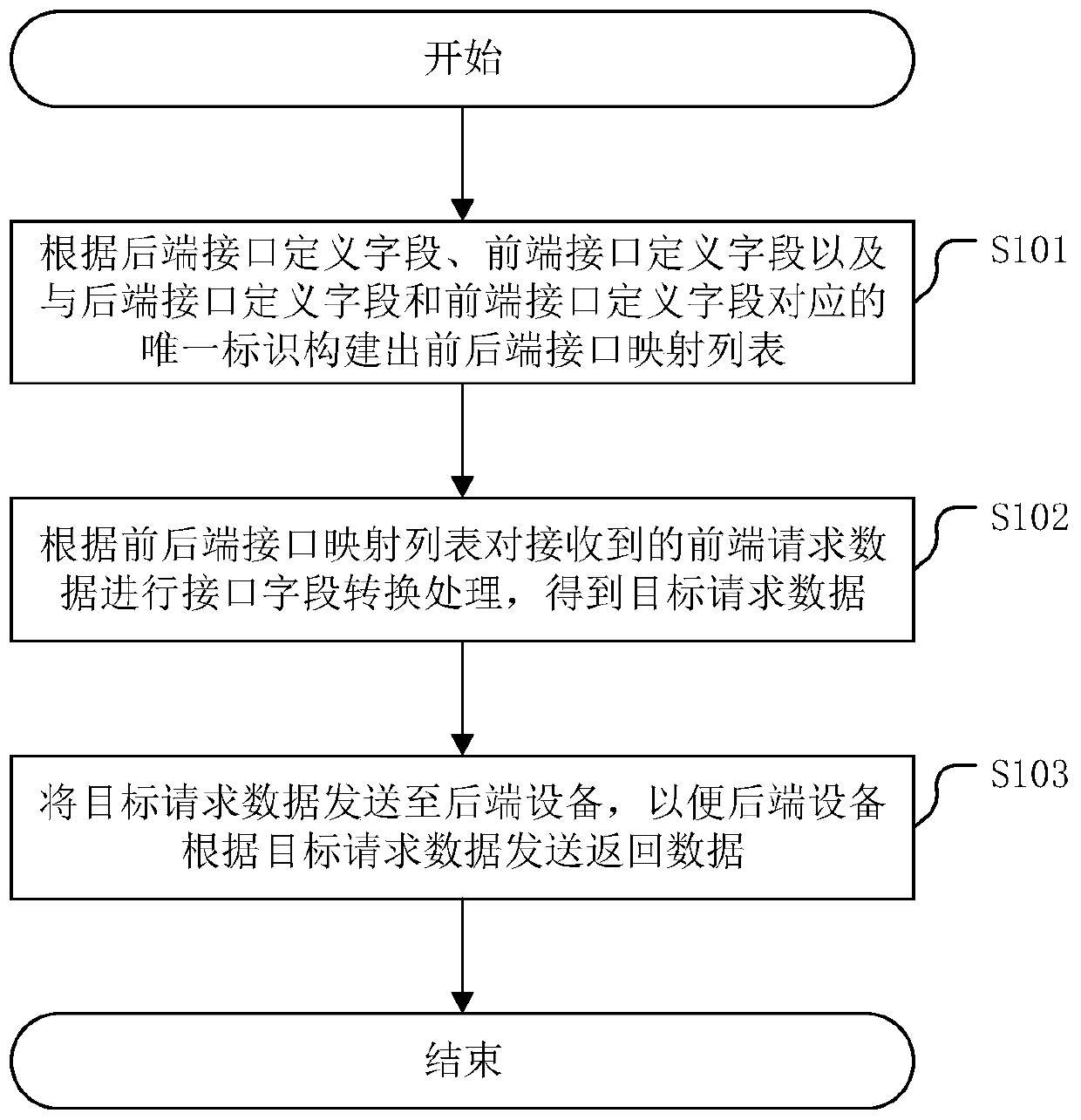

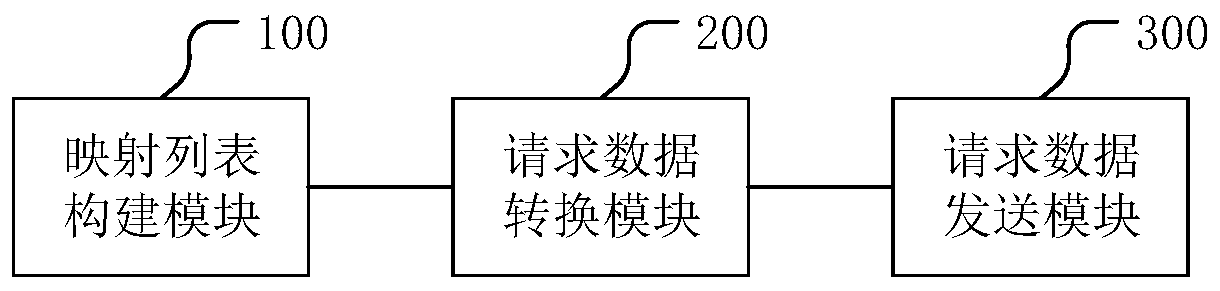

Front-end request data processing method and related device

PendingCN110826004ALow costAvoid incompatibilityWebsite content managementSpecial data processing applicationsComputer hardwareUnique identifier

The invention discloses a front-end request data processing method. The method comprises the following steps: constructing a front-end interface mapping list and a rear-end interface mapping list according to a rear-end interface definition field, a front-end interface definition field and unique identifiers corresponding to the rear-end interface definition field and the front-end interface definition field; performing interface field conversion processing on the received front-end request data according to the front-end and rear-end interface mapping list to obtain target request data; and sending the target request data to back-end equipment, so as to enable the back-end equipment to send return data according to the target request data. The rear-end interface definition field and the front-end interface definition field are matched through the constructed front-end and rear-end interface mapping list, so that the front-end and rear-end matching cost is reduced, and the matching cost is avoided. The invention further discloses a front-end request data processing device, computer equipment and a computer readable storage medium, which have the above beneficial effects.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

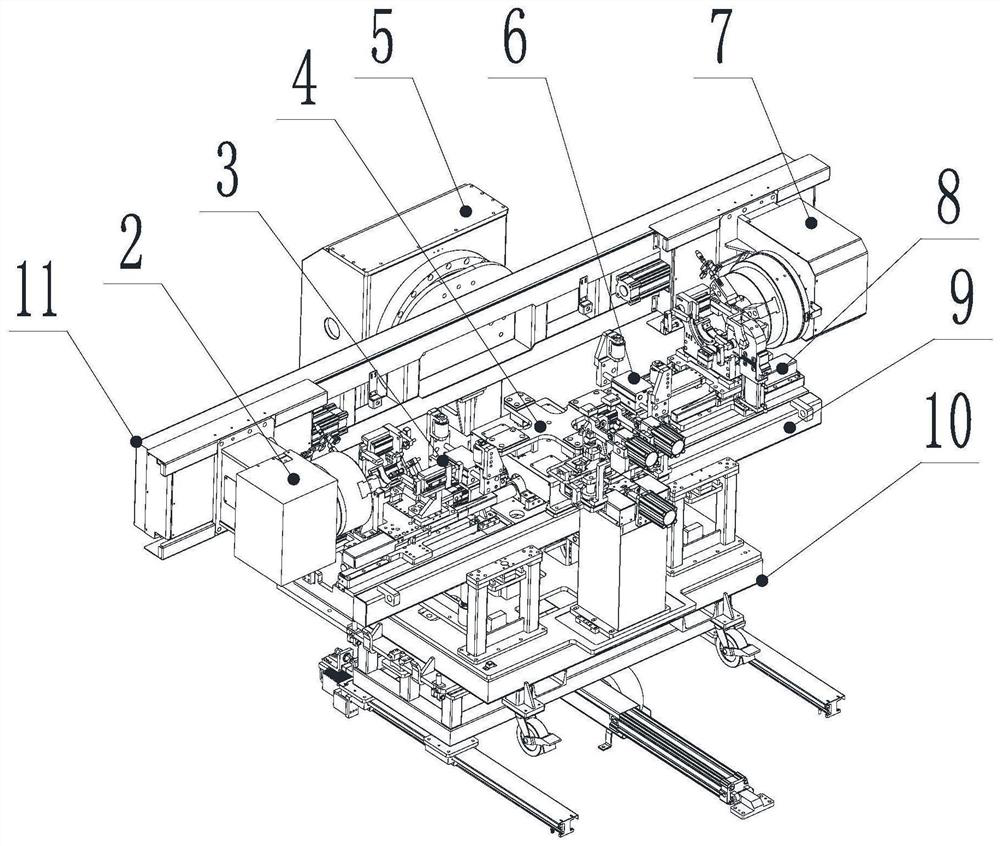

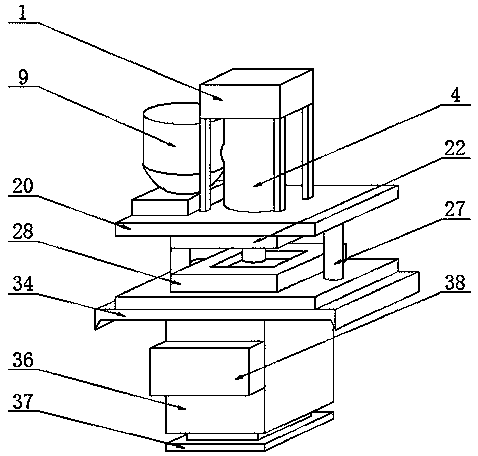

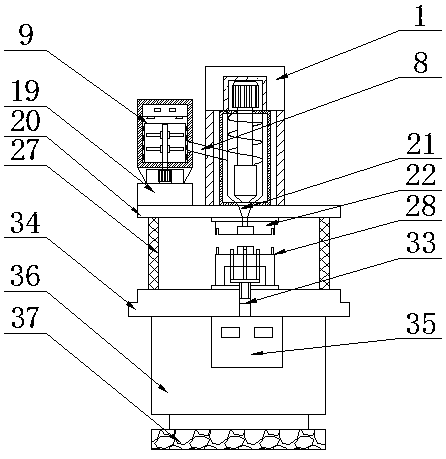

Automatic assembly welding clamp for axle housing flanges

ActiveCN112743283AAvoid repeated switchingAvoid the defect of manually flipping the workpiece repeatedlyWelding/cutting auxillary devicesAuxillary welding devicesFlangeWelding

The invention discloses an automatic assembly welding clamp for axle housing flanges, belongs to the technical field of axle clamp equipment, and aims to solve the problems that in the prior art, a clamp is single in structure and cannot adapt to fixation of a plurality of parts on the same equipment, and an axle housing assembly cannot be overturned. The automatic assembly welding clamp for the axle housing flanges comprises an overturning device and a clamping device, wherein the overturning device comprises a large overturning structure, as well as a driving end chuck device and a driven end chuck device which are connected to the two ends of the large overturning structure respectively; the clamping device comprises a first flange plate positioning device and a second flange plate positioning device which clamp the two ends of an axle housing respectively; an axle housing smoothening device is arranged between the first flange plate positioning device and the second flange plate positioning device; and a lifting positioning assembly matched with the axle housing smoothening device for clamping is further arranged on the side face of a mounting plate, so that workpieces of different sizes are fixed, and the problem that the workpieces of different sizes are not matched is avoided.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

A dimethyl ether synthetic catalyst as well as its preparing method

InactiveCN101157040AGood stabilitySolve catalyst deactivationMetal/metal-oxides/metal-hydroxide catalystsEther preparation by compound dehydrationChemistryDimethyl ether

The invention relates to dimethyl ether synthetic catalyst and the preparation method thereof, and belongs to the catalyst preparation technical field. The invention has the purpose to provide the catalyst suitable for the use of a slurry bed and the preparation method thereof. The invention is characterized in that inert reaction medium is taken as the oil phase, catalyst raw materials are respectively prepared into sol and solution as the water phase, and catalyst precursor milk gel is obtained through the process of sol-emulsion-gel. The milk gel performs the heating treatment under the ambience of N2 and the strong stirring after being aged, and thus the slurried catalyst is obtained to be directly used for the dimethyl ether synthetic reaction of the slurry bed. The invention takes water phase liquid beads in the emulsion as the micro-reaction environment to prepare a catalyst precursor, and has the predominant advantage that the granularity and the appearance can be controlled, the preparation environment and the operation environment of the catalyst are the very same, and the problem of the easy inactivation of the catalyst and the abrasion of the catalyst in the dimethyl ether synthesis of the slurry bed can be solved.

Owner:TAIYUAN UNIV OF TECH

Vertical injection molding machine for production of electronic accessories

InactiveCN108995120APrevent precipitation and solidificationAvoid harmAir purifiersInjection molding machine

The invention discloses a vertical injection molding machine for production of electronic accessories. The vertical injection molding machine comprises a driving box, an injection motor, a support, aninjection barrel, a screw rod, a discharging groove, a conical post, a conveying pipe, a hopper, an air purifier, a smoke removal hole, a heating barrel, a heating coil, a stirring shaft, a stirringrack, a connecting block, a conveying port, a stirring motor, a bottom plate, a top plate, an injection molding pipe, an upper mold seat, a first fixing plate, a dropping hole, an injection molding cavity, a mounting positioning hole, an electric telescopic rod, a lower mold seat, a second fixing plate, a discharging frame, a positioning pin, an accessory mold, a hydraulic rod, an operation table,a hydraulic station, a case, a support plate and an electric control box, wherein the electronic control box is mounted on one side of the case through bolts, the hydraulic station is mounted in thecase through bolts, and the operation table is mounted at the top of the case through bolts. The vertical injection molding machine can perform injection molding conveniently through upper and lower molds and has material ejection and air purification functions, and the convenience in use is greatly improved.

Owner:连云港久鑫电子有限公司

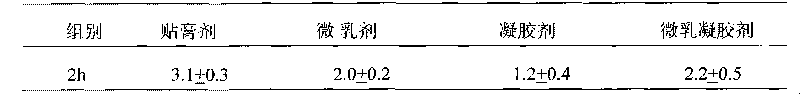

Tamoxifen citrate emplastrum and preparation method thereof

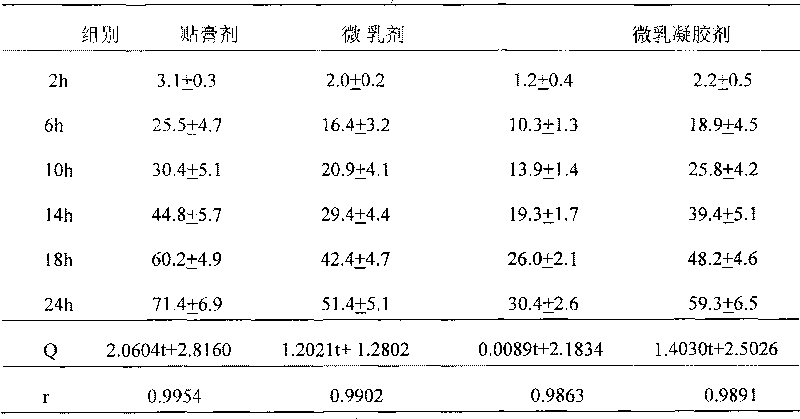

InactiveCN101711754AConvenient treatmentStabilize local blood drug concentrationOrganic active ingredientsSexual disorderTransdermal patchAdditive ingredient

The invention relates to a tamoxifen citrate emplastrum and a preparation method thereof. A tamoxifen citrate micro emulsion is prepared into a transdermal emplastrum, and the transdermal emplastrum is divided into four layers: an anti-adhesion layer, a viscose layer, a back lining layer and a medicine storage layer. The tamoxifen citrate micro emulsion is used as a drug effect ingredient and comprises tamoxifen citrate used as an active ingredient, polysorbate 80 used as a surfactant, propylene glycol used as a cosurfactant, pure water or distilled water, and the like. Besides the drug effect ingredient, some non-polar polymers, a plasticizer, a tackifier, transdermal enhancer and an antioxidant are also added to the emplastrum. Compared with the traditional dosage forms such as tablets, solutions, oral cavity disintegrants, dispersants and external micro emulsion preparations, the tamoxifen citrate emplastrum has the prominent advantages of safety, low toxicity, convenient and simple use and accurate drug dosage.

Owner:河南省生物工程技术研究中心

Automatic labeling method for photovoltaic components

InactiveCN108516170AReduce mismatchReduce quality problemsLabelling machinesProduction lineTest flow

The invention discloses an automatic labeling method for photovoltaic components. The automatic labeling method comprises the following steps: (A) nameplate mold plates and frame barcodes of all pre-designed gears are stored in an exclusive labeling program root directory; (B) the components finishing IV test flow into a labeling station automatically by a production line and are fixed and stopped; (C) an automatic barcode scanning gun is automatically triggered, scans barcodes of the glass surfaces of the components, and transmits the scanned barcodes into an exclusive labeling program in a computer by a data line; (D) the exclusive labeling program automatically calls power and current data of the corresponding barcodes from a shared IV database, analyzes and judges the shifts of power and current automatically according to the data and transmits information to printers by the data line; (E) the two printers are respectively and automatically started after receiving printing commands, and print corresponding frame barcodes and nameplates. The automatic labeling method disclosed by the invention realizes full-automatic labeling operation, has higher automation degree and operationefficiency, and meanwhile has the beneficial effects that the labor can be reduced and the labor cost can be reduced.

Owner:格润智能光伏南通有限公司

Polyphenylene-oxide-filled (PPO-filled) aligned carbon nanotube bundle (ACNTB)/thermosetting resin and preparation method thereof

ActiveCN106221212AImprove mechanical propertiesModifiable mechanical propertiesHeat resistanceCarbon nanotube

The invention relates to a polyphenylene-oxide-filled (PPO-filled) aligned carbon nanotube bundle (ACNTB) / thermosetting resin and a preparation method thereof. The preparation method comprises the following steps: adding PPO-filled ACNTB particles into a cyanate ester (CE) resin system, and curing to obtain the high-performance CE composite material system. The PPO is filled into the gaps between carbon tubes in the ACNTB, so that the mechanical properties of the ACNTB are enhanced; the PPO-filled ACNTB particles are added into the CE resin; and curing treatment is carried out to obtain the high-performance CE resin system composite material. The PPO-filled (ACNTB) / thermosetting resin has the advantages of excellent mechanical properties, excellent heat resistance, excellent flame retardancy and the like. The preparation method has the characteristics of wide applicability and simple operating technique. The resin system can be used for preparing high-performance composite materials, electronic devices and the like for aerospace.

Owner:重庆辰鸿实业发展有限公司

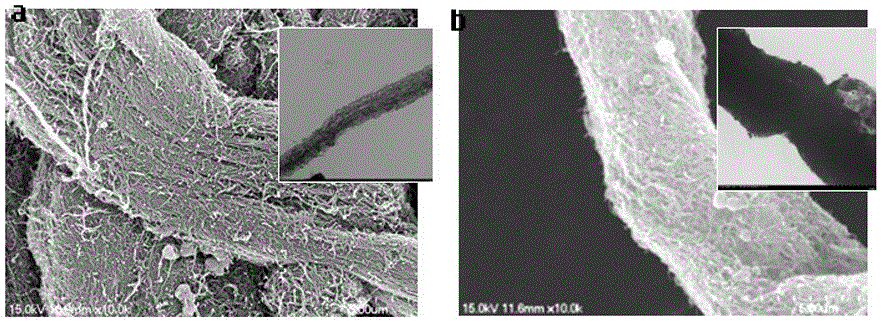

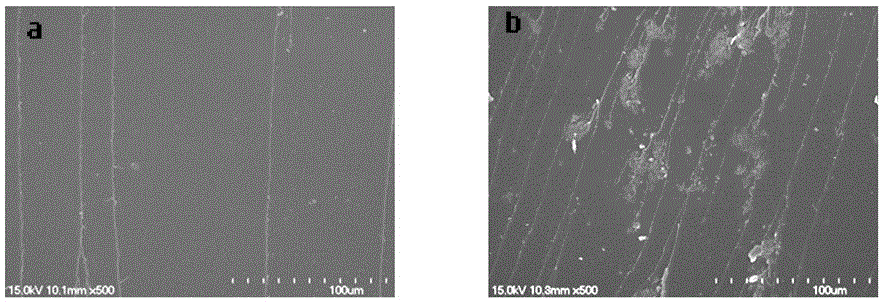

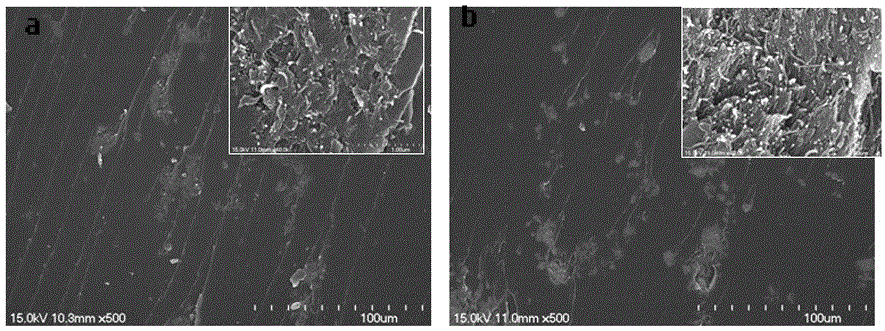

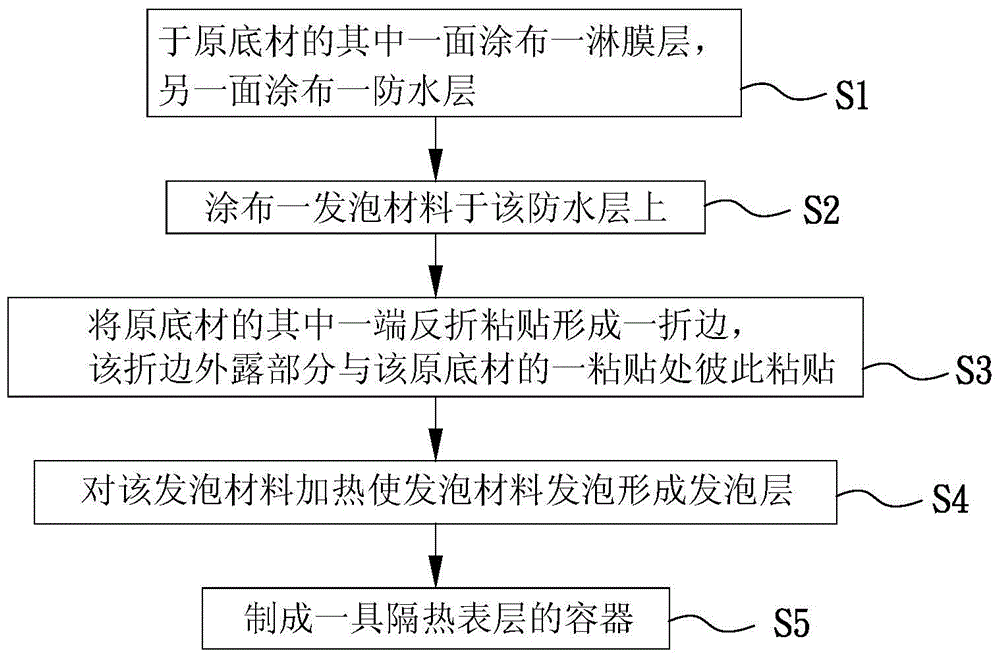

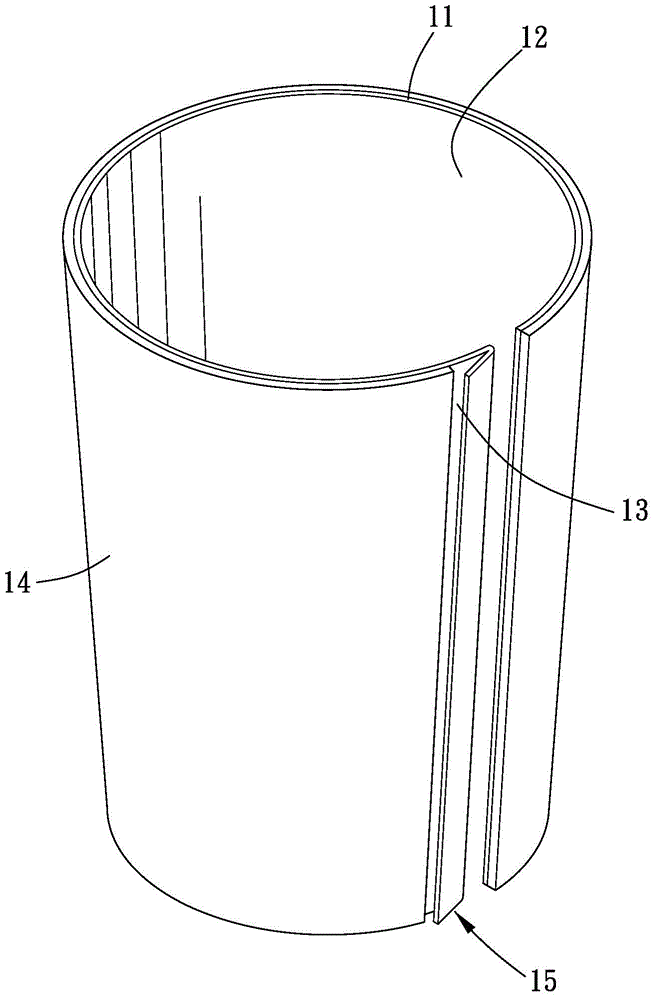

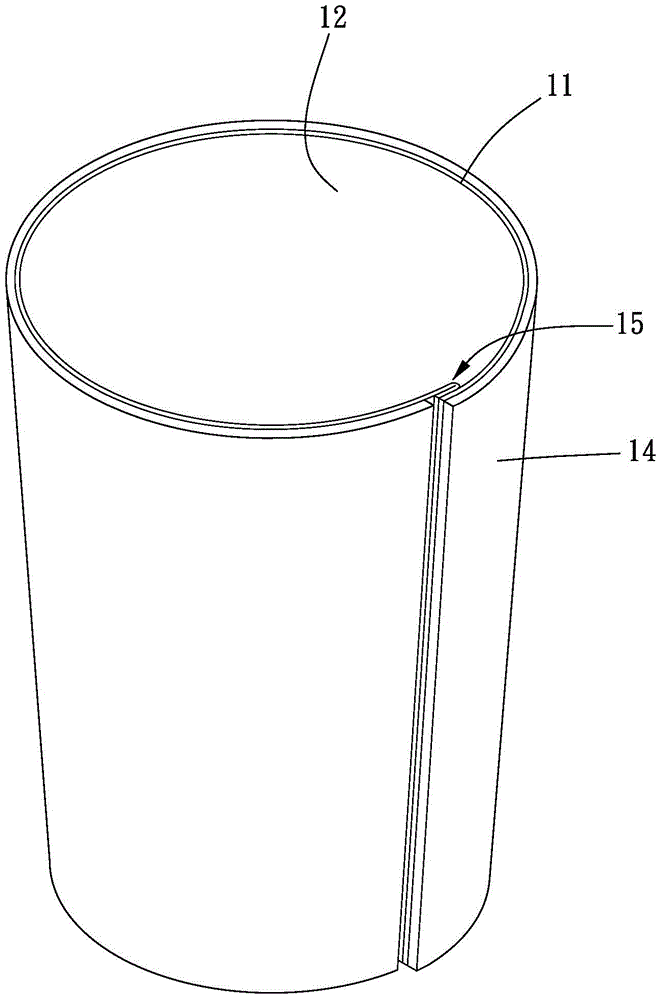

Manufacturing method for container with thermal insulation surface layer

InactiveCN104417926AAvoid incompatibilityAvoid softeningDomestic cooling apparatusLighting and heating apparatusSurface layerThermal insulation

The invention provides a manufacturing method for a container with a thermal insulation surface layer. The manufacturing method for the container with the thermal insulation surface layer comprises the following steps of preparing an original substrate and respectively coating a lamination layer and a polyethene waterproof layer on two oppositely sides of the original substrate; coating foam materials on the waterproof layer; enabling one end of the original substrate to be pasted in a reverse folding mode to form into a folding edge and enabling a pasting position of the original substrate and the folding edge to be mutually pasted, wherein an exposition portion of the folding edge and the pasting position are both one of the lamination layer or the waterproof layer; an internally concave pasting portion of the folding edge is the other one of the lamination layer or the waterproof layer; the foam materials are heated and foamed to form into a foaming layer; manufacturing the container with the thermal insulation surface layer, wherein the lamination layer faces the interior of the container and the waterproof layer and the foam layer are towards the exterior of the container. Accordingly, the manufacturing method for the container with the thermal insulation surface layer can improve the pasting effect and avoid the external layer of the container from being softened when the external layer is in wet.

Owner:张静文

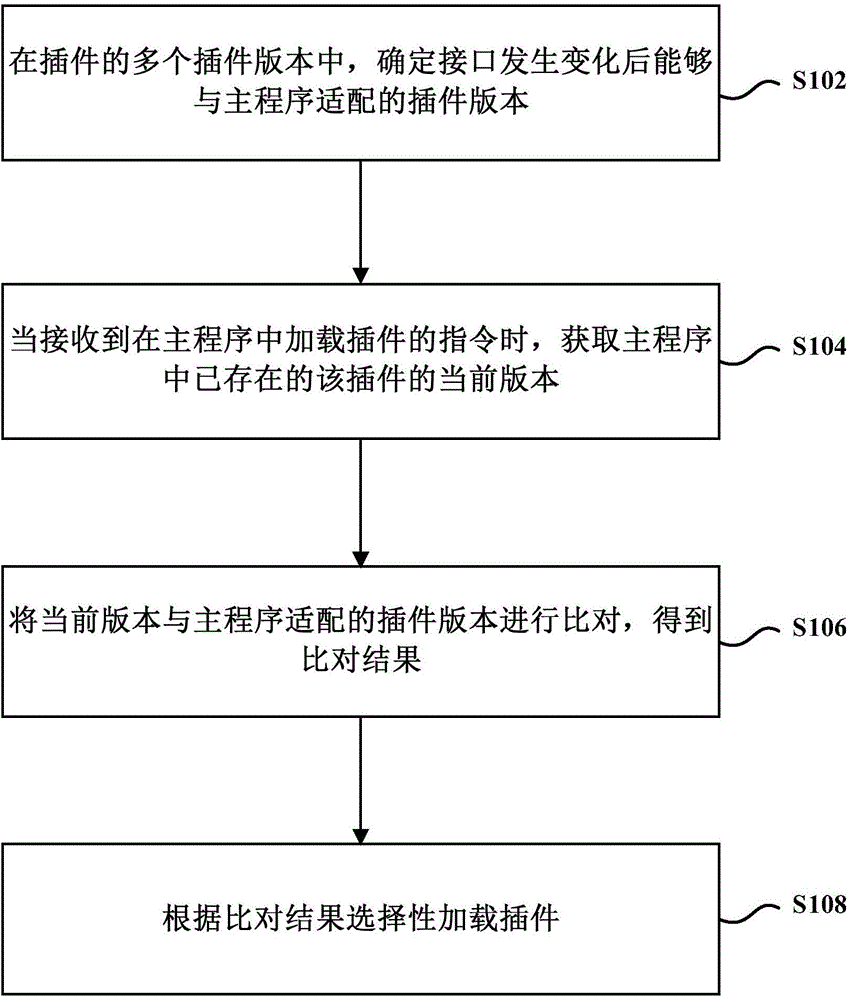

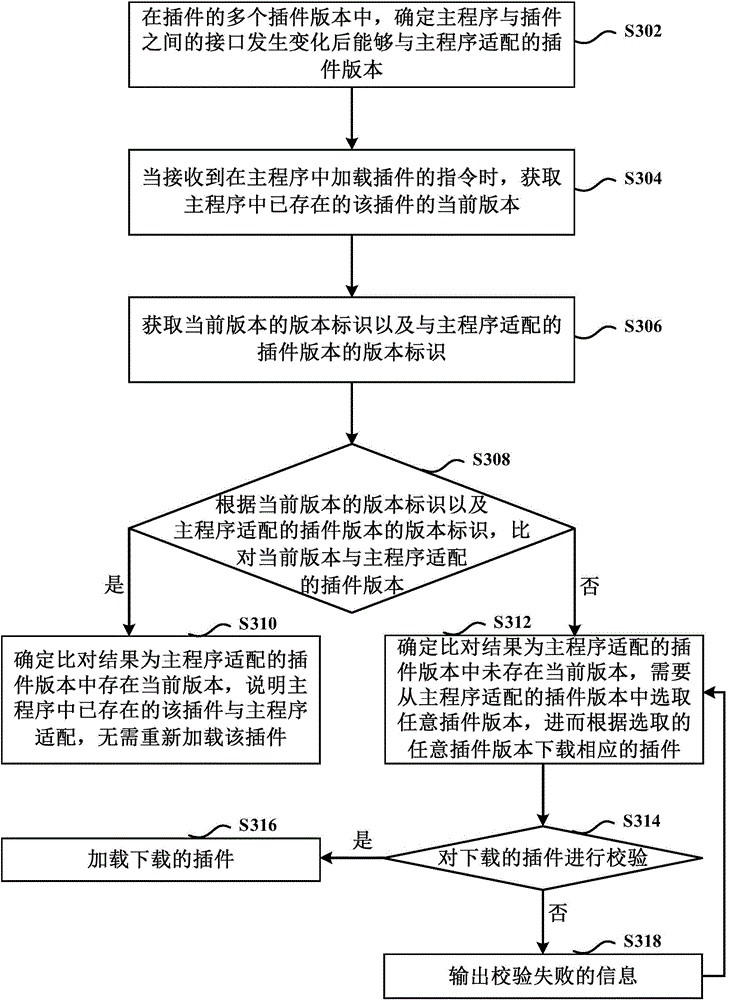

Plug-in loading method, device and equipment

ActiveCN106155709AImprove the comparison rateAvoid incompatibilityProgram loading/initiatingComputer engineering

Owner:北京世界星辉科技有限责任公司

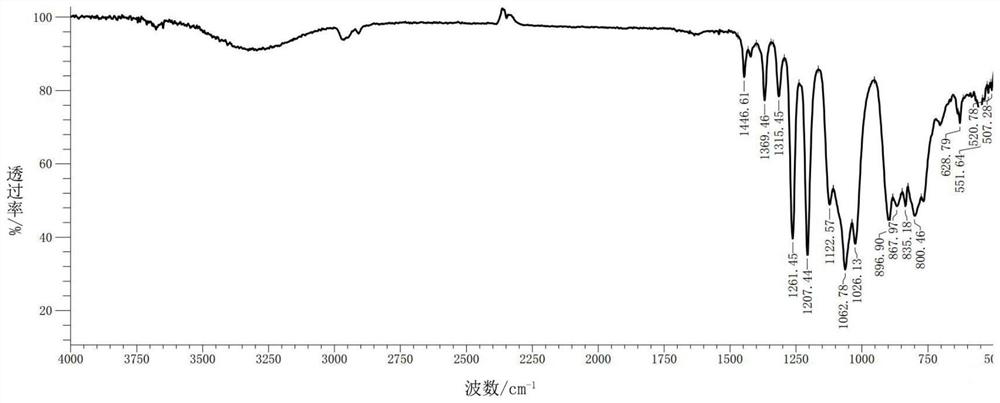

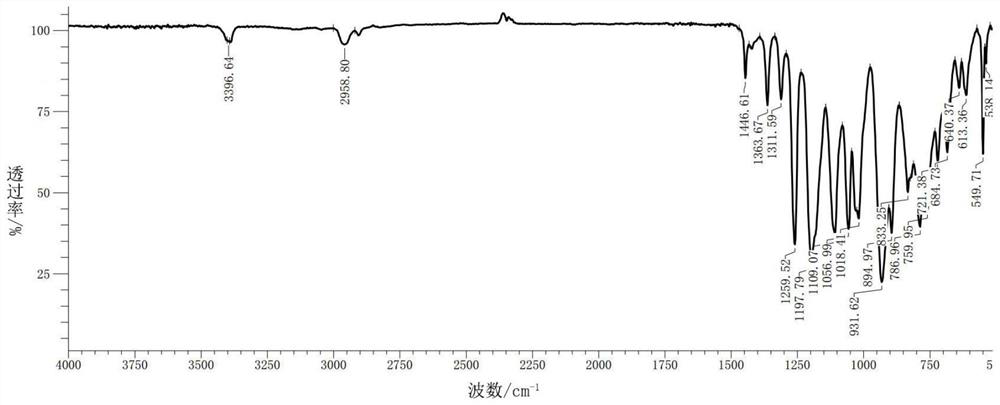

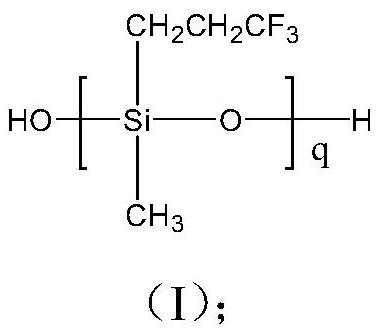

Engine oil-resistant low-pressure-change addition type liquid fluorinated silicone rubber and preparation method thereof

The invention relates to engine oil-resistant low-pressure-change addition type liquid fluorosilicone rubber and a preparation method thereof. The engine oil-resistant low-pressure-change addition type liquid fluorosilicone rubber comprises the following components in parts by weight: 100 parts of fluorosilicone base rubber; 10 to 20 parts of fumed silica; 10-20 parts of precipitated white carbon black; 1-3 parts of hydroxyl fluorosilicone oil; 2 to 5 parts of trifluoropropyl methyl cyclosilazane; 0.1 to 0.3 part of divinyl tetramethyl disilazane; 1-3 parts of distilled water; 0.1 to 0.3 part of a heat-resistant additive; 1.3 to 2.9 parts of a cross-linking agent; 0.3 to 0.6 part of a platinum catalyst; and 0.05 to 0.2 part of an inhibitor. According to the preparation method, fluorosilicone treating agents such as low-molecular-weight hydroxyl fluorosilicone oil and trifluoropropyl methyl cyclosilazane are used, the fumed silica and the precipitated silica are compounded to achieve a synergistic effect, and the specific cross-linking agent and the preparation method are matched, so that the compression set of the addition type liquid fluorosilicone rubber is greatly reduced, and the service life of the addition type liquid fluorosilicone rubber is prolonged. Even if the lubricating oil is soaked in high-temperature engine oil for a long time, the system cannot be damaged, the lower deformation rate can still be kept, and the oil pressure change resistance is very excellent.

Owner:新元化学(山东)股份有限公司 +1

Multi-function ship bottom sealant and production method thereof

InactiveCN104017530AImprove sound insulationAvoid incompatibilityNon-macromolecular adhesive additivesOther chemical processesRosinButadiene-styrene rubber

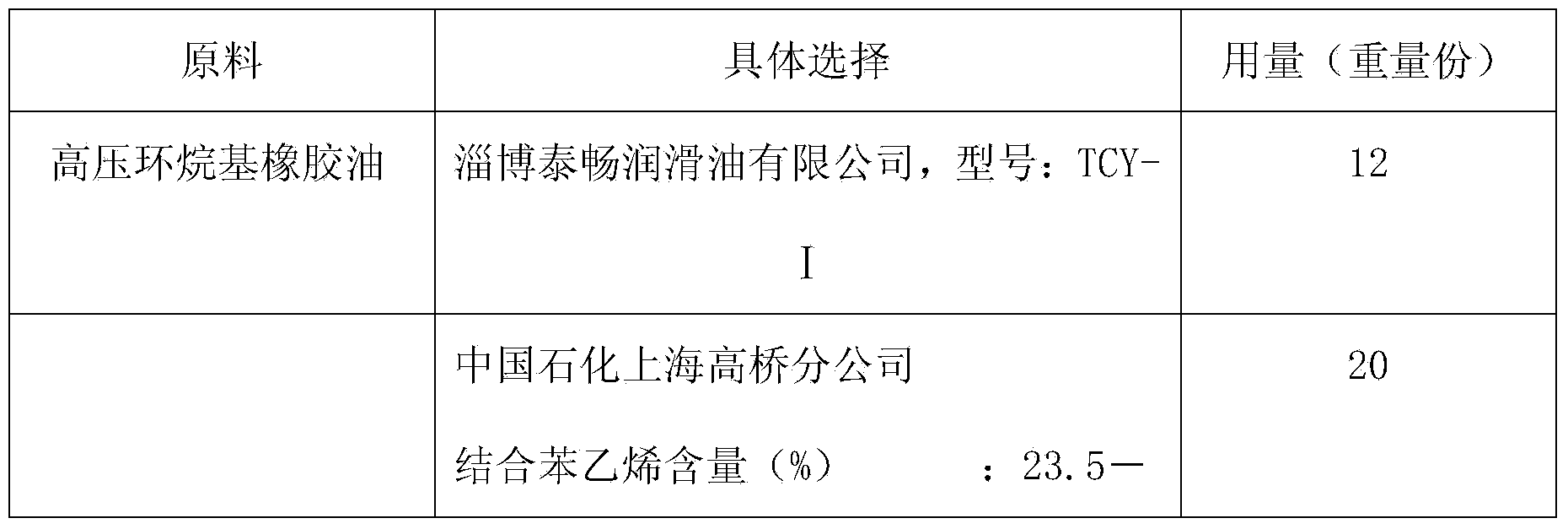

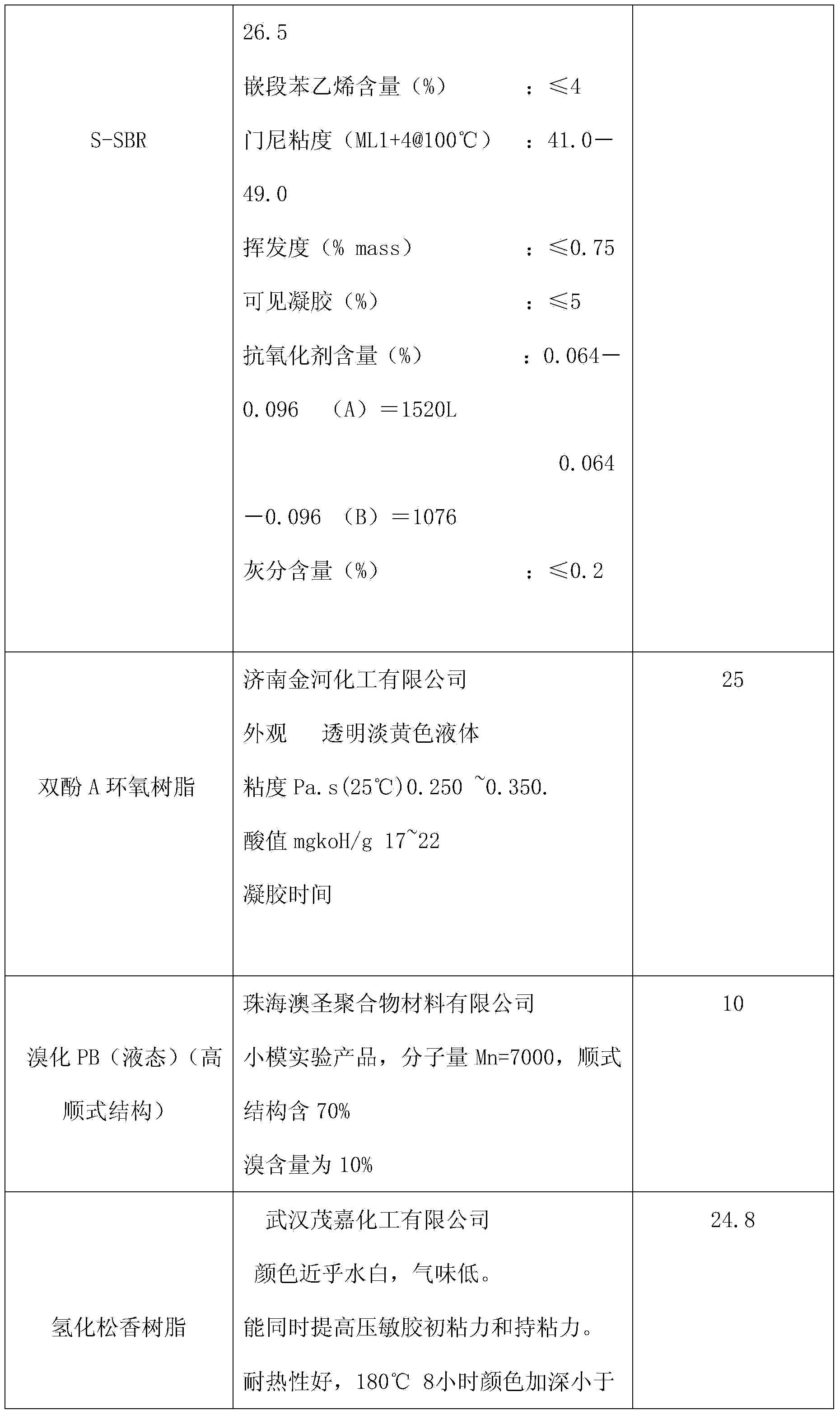

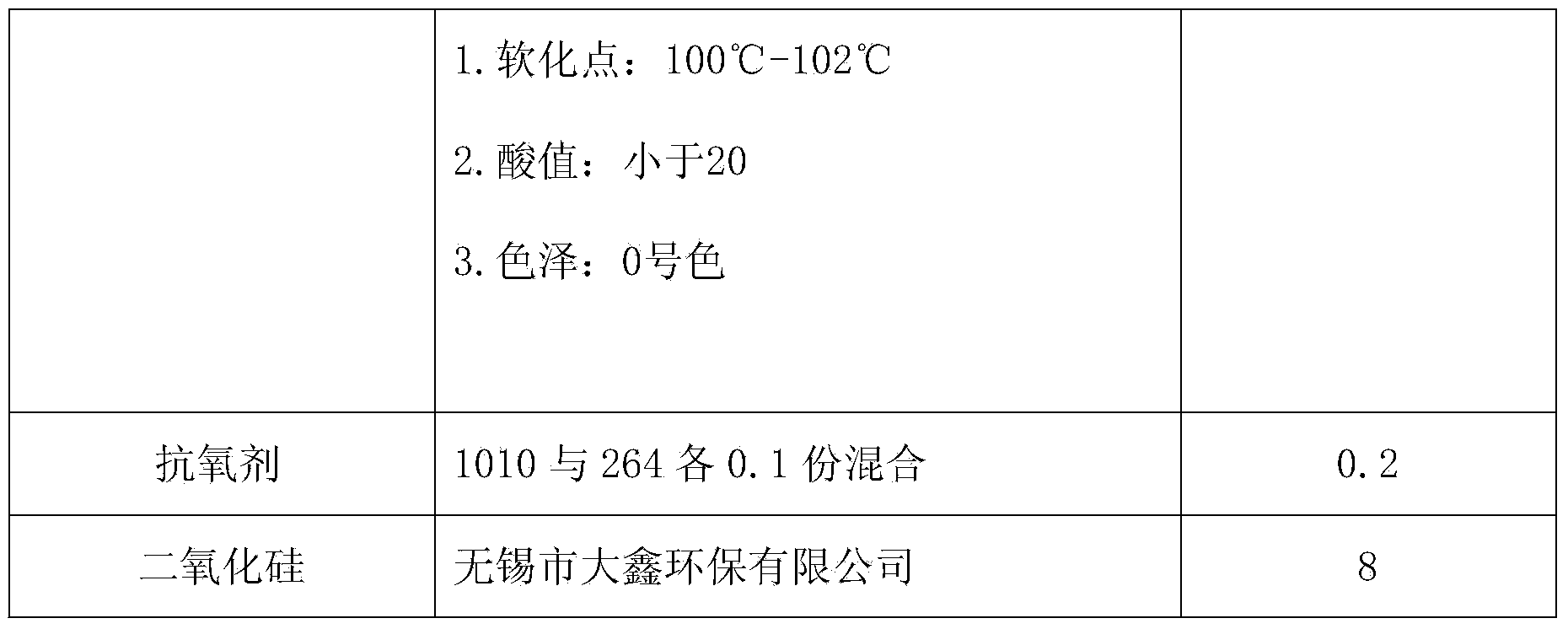

The invention discloses a multi-function ship bottom sealant with good adhesive force and a production method thereof, and aims to provide the multi-function ship bottom sealant with good toughness and a stable structure and the production method thereof; the multi-function ship bottom sealant includes 12-25 parts of high pressure naphthenic rubber oil, 15-30 parts of solution polymerized butadiene styrene rubber (S-SBR), 20-35 parts of bisphenol A epoxy resin, 5-15 parts of brominated polybutadiene (PB) glue solution, 18-35 parts of hydrogenated rosin resin, 5-8 parts of silica and 0.2 part of an antioxidant; the multi-function ship bottom sealant has the advantages of good toughness, sterilization, more stable structure, strong adhesive force, alkali resistance and the like.

Owner:浙江固特新材料科技股份有限公司

Raloxifene emplastrum preparation and preparation method thereof

InactiveCN101700241AConvenient treatmentStabilize local blood drug concentrationOrganic active ingredientsSkeletal disorderTransdermal patchAdditive ingredient

The invention relates to a raloxifene emplastrum and a preparation method thereof. Raloxifene microemulsion is made into a transdermal emplastrum which is divided into an anti-adhesion layer, a viscose layer, a backlining layer and a medicine storage layer. The raloxifene microemulsion taken as a medical ingredient of the raloxifene emplastrum comprises the following ingredients: raloxifene taken as an active ingredient, polysorbate taken as surfactant, propanediol taken as cosurfactant, pure water or distilled water, and the like. Except for the medical ingredient, a plurality of nonpolar polymers, plasticizing agent, caking agent, transdermal enhancing agent and antioxidant are also added in the emplastrum. Compared with the prior dosage forms, such as tablets, the invention has the remarkable advantages of durable medical effect, safety, low toxicity, simple, convenient and sanitary, and accurate medical dosage.

Owner:河南省生物工程技术研究中心

Anti-fatigue composite nutrient and preparation method thereof

The invention relates to an anti-fatigue composite nutrient and a preparation method thereof, belonging to the field of functional nourishment. The invention comprises the following components in parts by weight: 4000-8000 parts of pawpaw powder, 500-3000 parts of taurine, 2500-5000 parts of tyrosine, 500-3000 parts of carnosine and 5-20 parts of vitamin B6. The preparation method comprises the following steps: preparing the taurine, tyrosine, carnosine and vitamin B6 into micro-capsules respectively or jointly, then mixing with pawpaw powder uniformly, and preparing the mixture into various dosage forms. The composite nutrient can dissipate fatigue quickly and continuously with sound effect.

Owner:ARMY MEDICAL UNIV

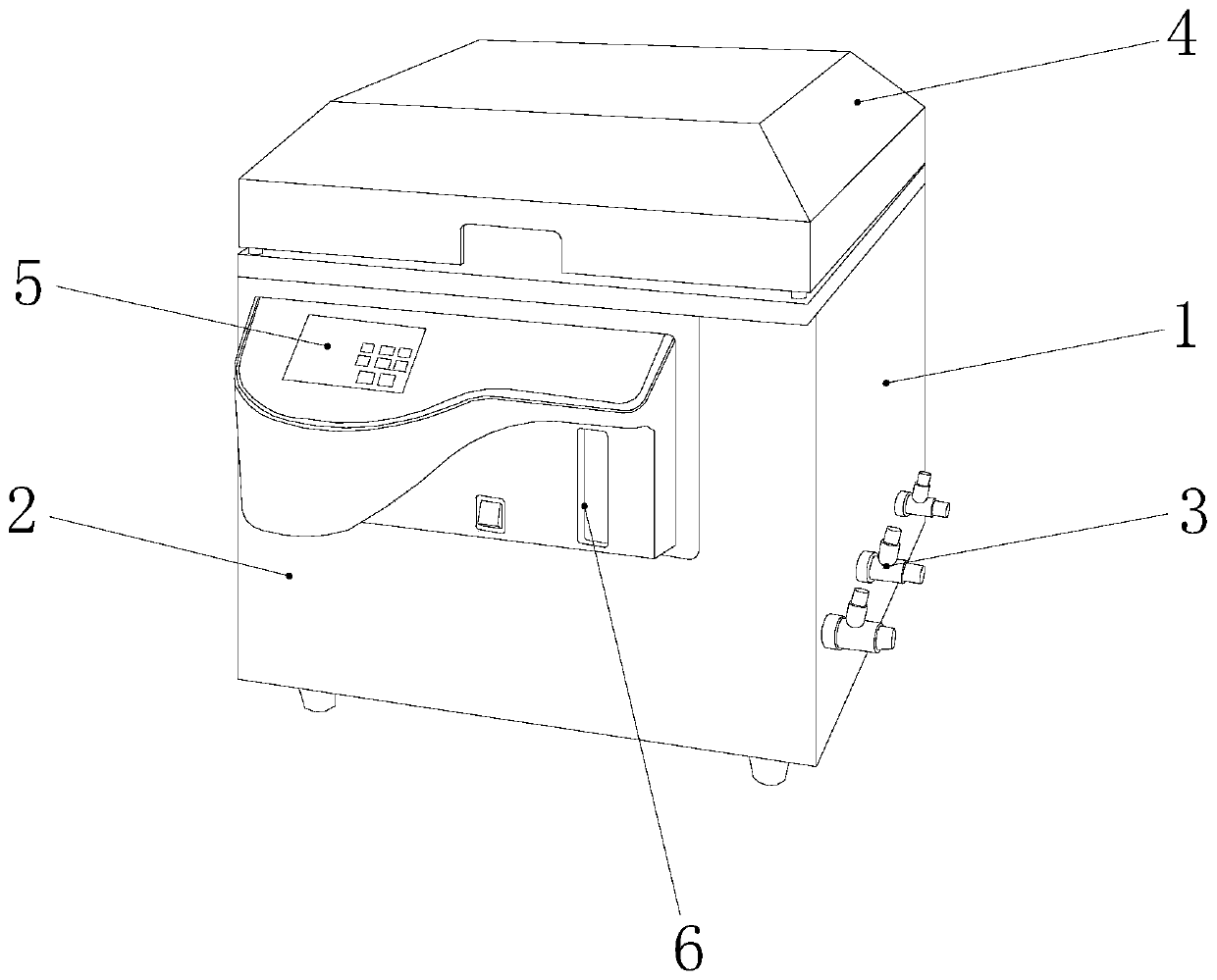

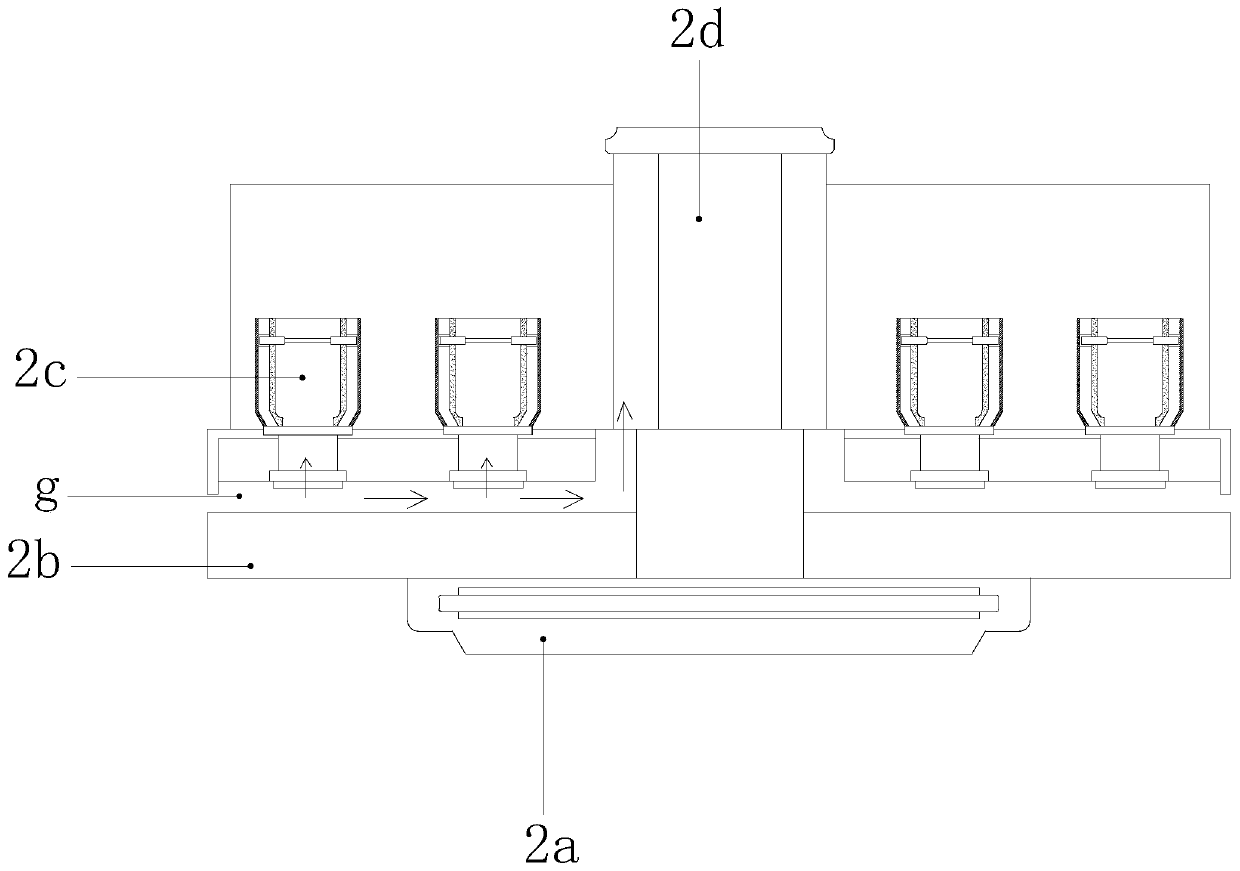

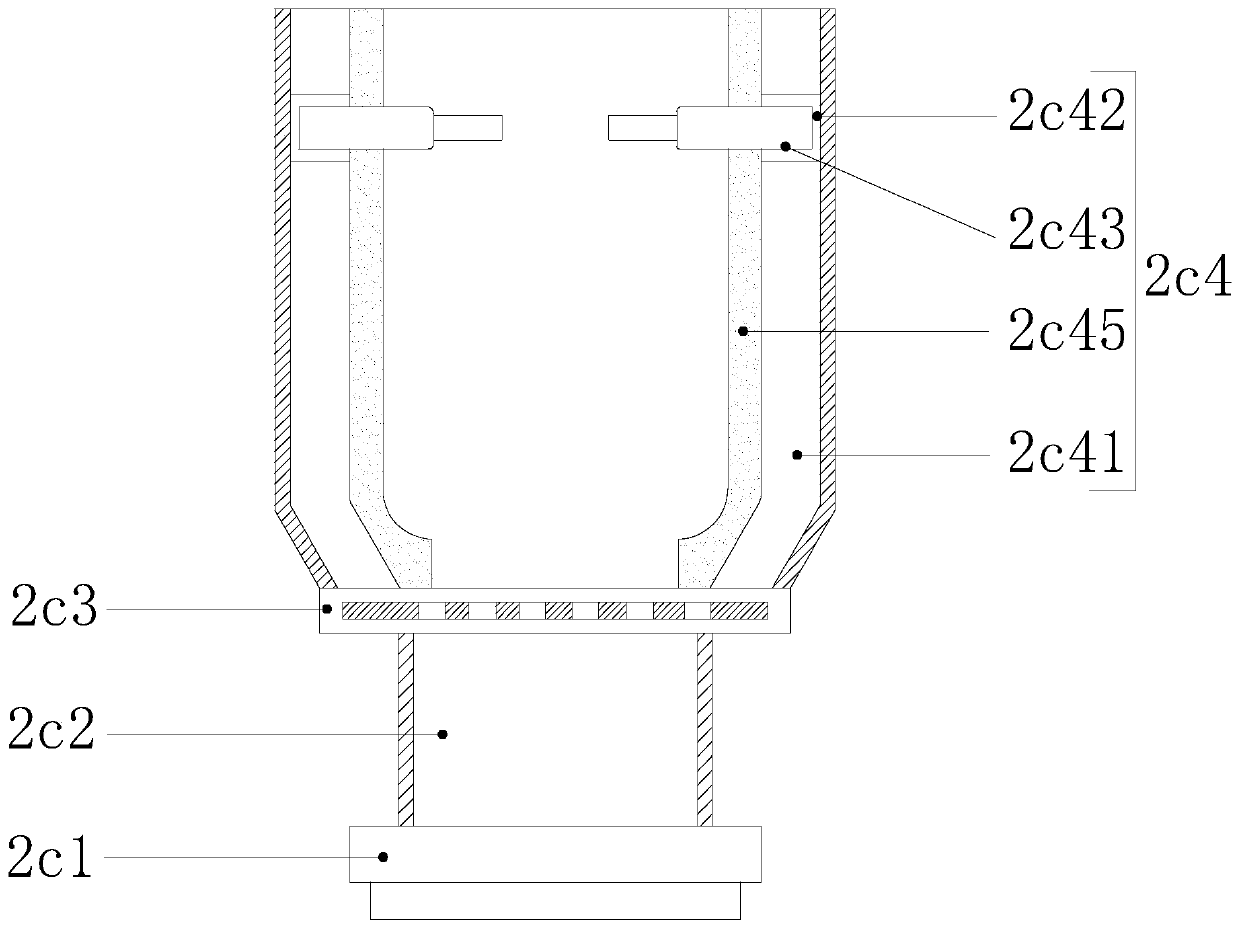

Culture medium preparation machine using pushed circling-motion oscillation and heat homogenization

InactiveCN110628575AAvoid incompatibilityAchieve air flowBioreactor/fermenter combinationsBiological substance pretreatmentsTest tubeNormal conditions

The invention discloses a culture medium preparation machine using pushed circling-motion oscillation and heat homogenization. The culture medium preparation machine comprises a machine body, a homogeneous oscillation heat-expansion device, outer end connection holes, a sealing cover, a control panel and an observation port. The culture medium preparation machine of the present invention has beneficial effects as follows: the culture medium preparation machine utilizes an improved test tube holder that is fixed by a movable chain rod and an arc-shaped plate, so that an upper part and a lower part of a test tube do a movable motion to realize mixing and stirring for lower liquid under the action of back-and-forth impact, thereby avoiding incompatibility of stock solution in the lower liquid, the height difference between an isolation plate and the test tube as well as round holes in the surface of the isolation plate can be used to achieve the airflow at the bottom of the test tube, thereby avoiding that the accumulated bottom heat is difficult to dissipate after heat treatment, resulting in a local temperature difference in the culture medium, and a heat homogenization structure isused to uniformly heat a culture medium solution in the test tube in order to prevent microorganisms from being destroyed in the culture medium solution, resulting in unavailability of the culture medium solution in normal conditions.

Owner:泉州台商投资区大千机械科技有限公司

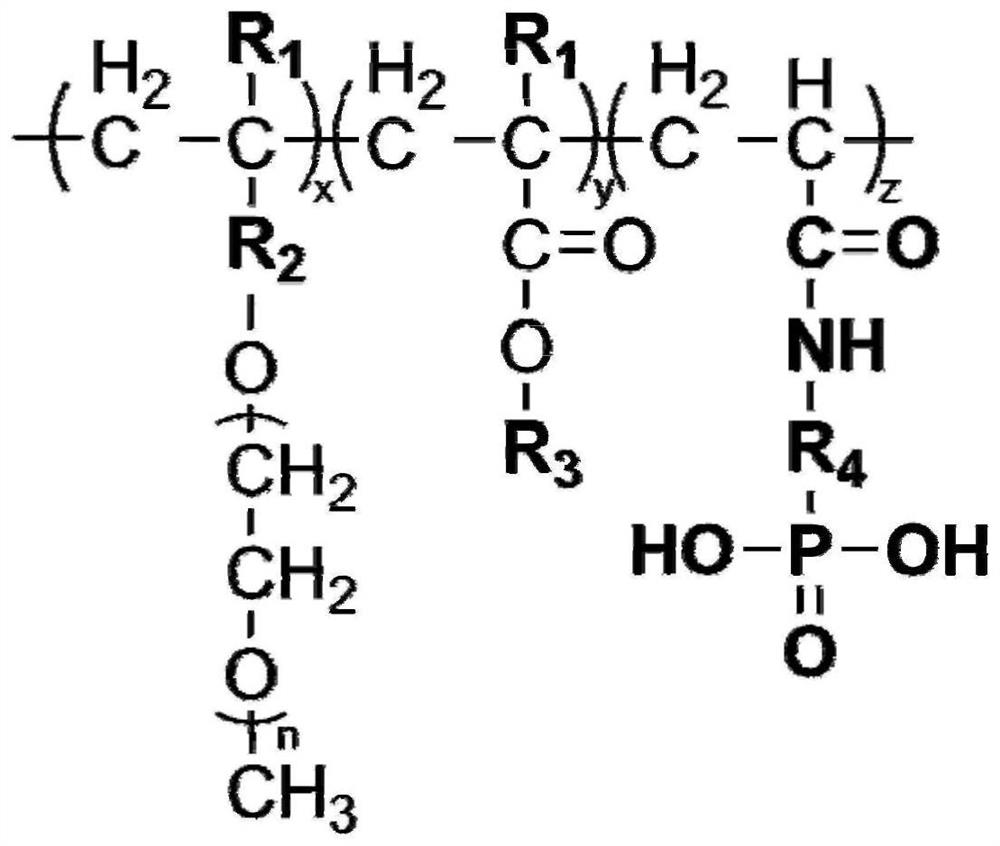

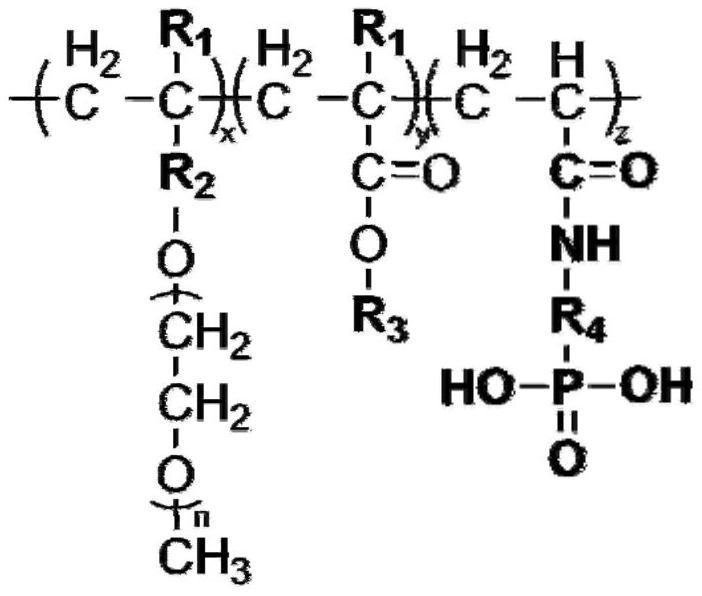

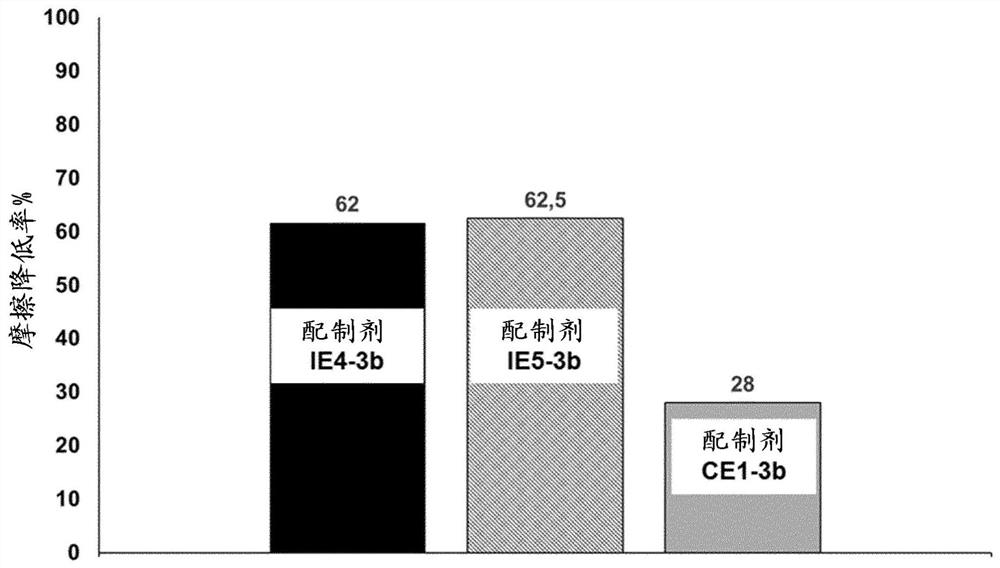

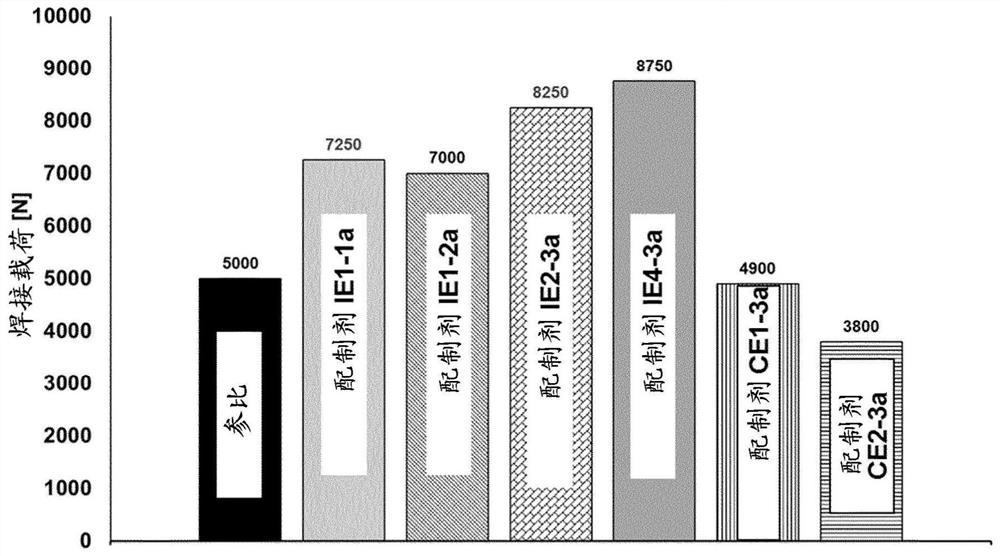

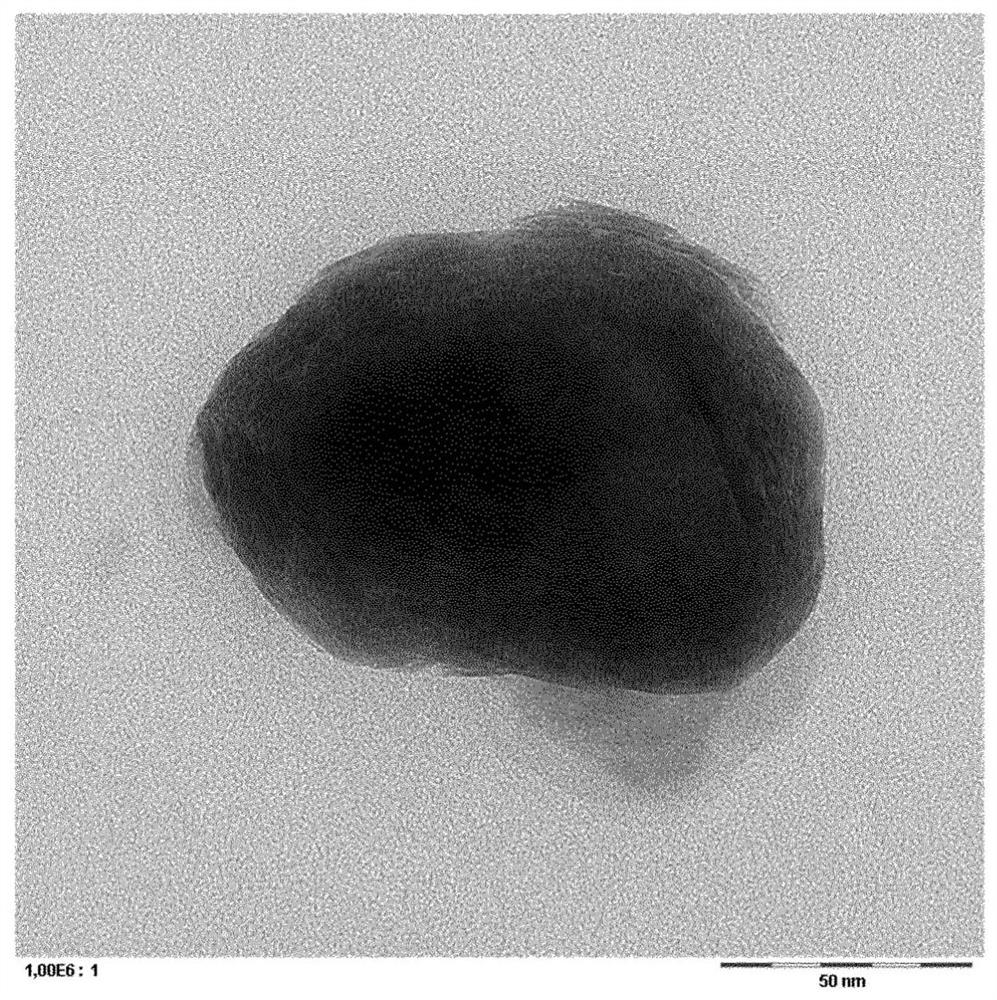

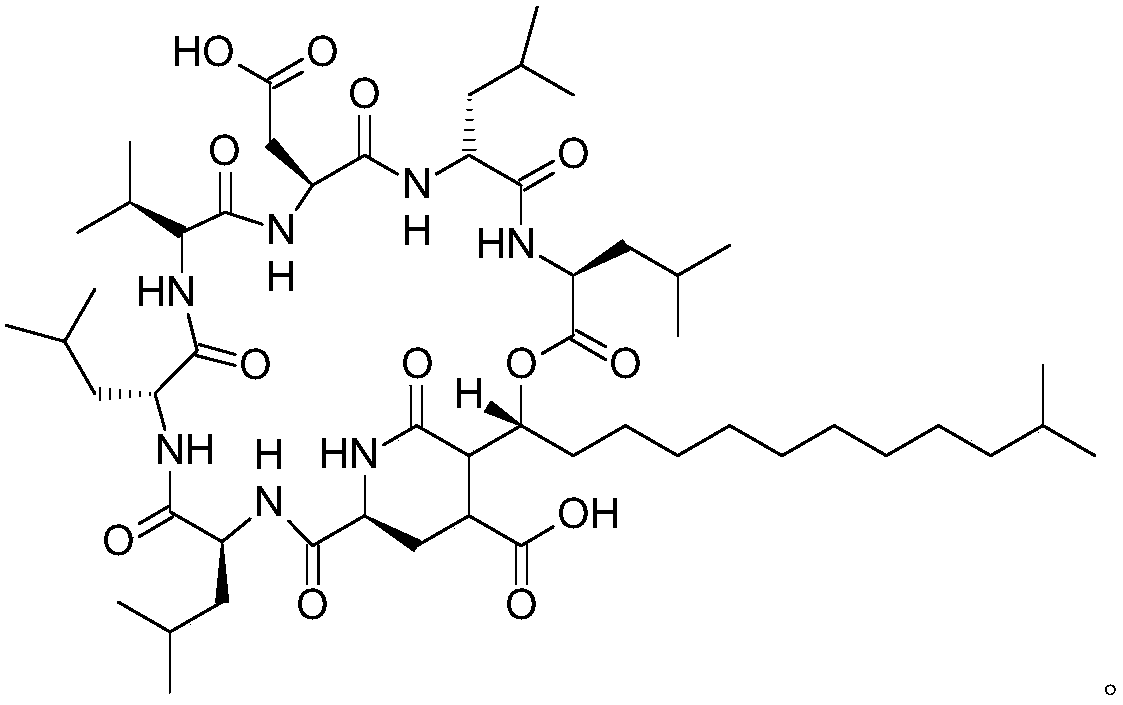

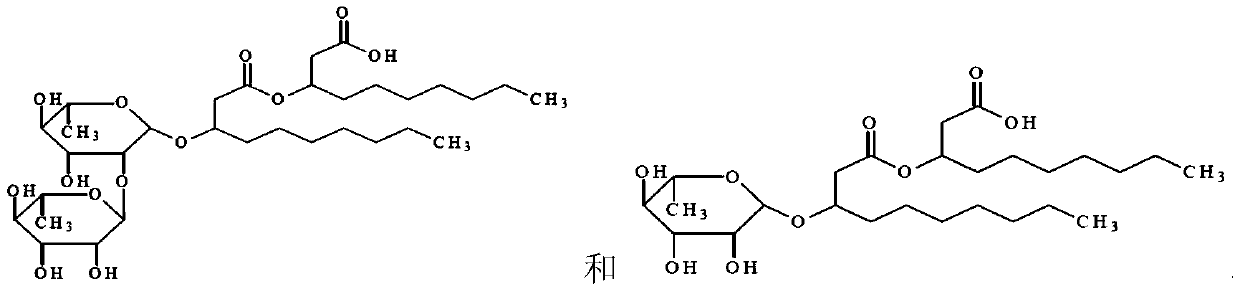

Polymeric-inorganic nanoparticle compositions, manufacturing process thereof and their use as lubricant additives

ActiveCN111655827AExcellent extreme pressureGood anti-frictionMaterial nanotechnologyAdditivesNanoparti clesMaterials science

The invention relates to polymeric-inorganic nanoparticle compositions and preparation processes thereof. The invention also relates to an additive and lubricant compositions comprising these polymeric-inorganic nanoparticle compositions, as well as to the use of these polymeric-inorganic nanoparticle compositions in an oil lubricant formulation to improve tribological performance, in particular to improve extreme pressure performance and friction reduction on metal parts.

Owner:EVONIK OPERATIONS GMBH

Enhanced liquid-rich battery with seal battery cover

InactiveCN110739439AImprove sealingAffect the service lifeCell lids/coversCell sealing materialsElectrical batteryEngineering

The invention discloses an enhanced liquid-rich battery with a seal battery cover, which belongs to the technical field of batteries. The battery comprises a casing body. A casing cover is arranged onthe top of the casing body. A matched acid injection cap is arranged on the inner wall of an acid injection hole. The acid injection cap includes a fixed plate connected with a boss. A plug is connected with the bottom of the fixed plate. The bottoms of positive and negative poles are connected with positive and negative terminals of a battery pole plate which is arranged in the inner cavity of the casing body respectively. According to the device, the matched acid injection cap is arranged on the inner wall of the acid injection hole, which effectively improves the sealing of the acid injection hole; the acid injection cap is provided with the fixed plate connected with the boss, which effectively improves the fixedness of the acid injection cap and prevent the leakage of the internal electrolyte of the battery caused by the fall of the acid injection cap; the outer walls of the poles are sleeved by gaskets and pressure rings; the gaps between the poles and the pressure rings are filled with sealants, which effectively improves the fixing effect of the poles; and furthermore, the sealing effect of the poles and pole holes is improved through the filling of the sealants.

Owner:风帆(扬州)有限责任公司

Punching-free stainless steel glass handrail support

ActiveCN112252616ALower assembly costsAvoid incompatibilityBalustersBalustradesProtective glassesBaluster

The invention relates to the technical field of stainless steel handrails, in particular to a punching-free stainless steel glass handrail support. The punching-free stainless steel glass handrail support comprises a longitudinal support body fixed to the ground through bolts. According to the punching-free stainless steel glass handrail support, a lateral storage groove, a lateral adjusting groove and a lateral installation clamping groove which are communicated are formed in the side wall of the longitudinal support body. A first lateral assembly plate, a second lateral assembly plate, a third lateral assembly plate and a fourth lateral assembly plate are movably installed in the lateral storage groove through assembly cylinders and internal springs. The assembly plates are turned over and contracted to be fixedly installed at the upper end and the lower end of protective glass on the two sides respectively, the glass is assembled and fixed, holes do not need to be punched in the surface of the glass, the assembly cost is greatly saved, meanwhile, the problem of discomfort caused by punching precision is avoided, and the application range is widened.

Owner:江苏柏芸金属科技有限公司

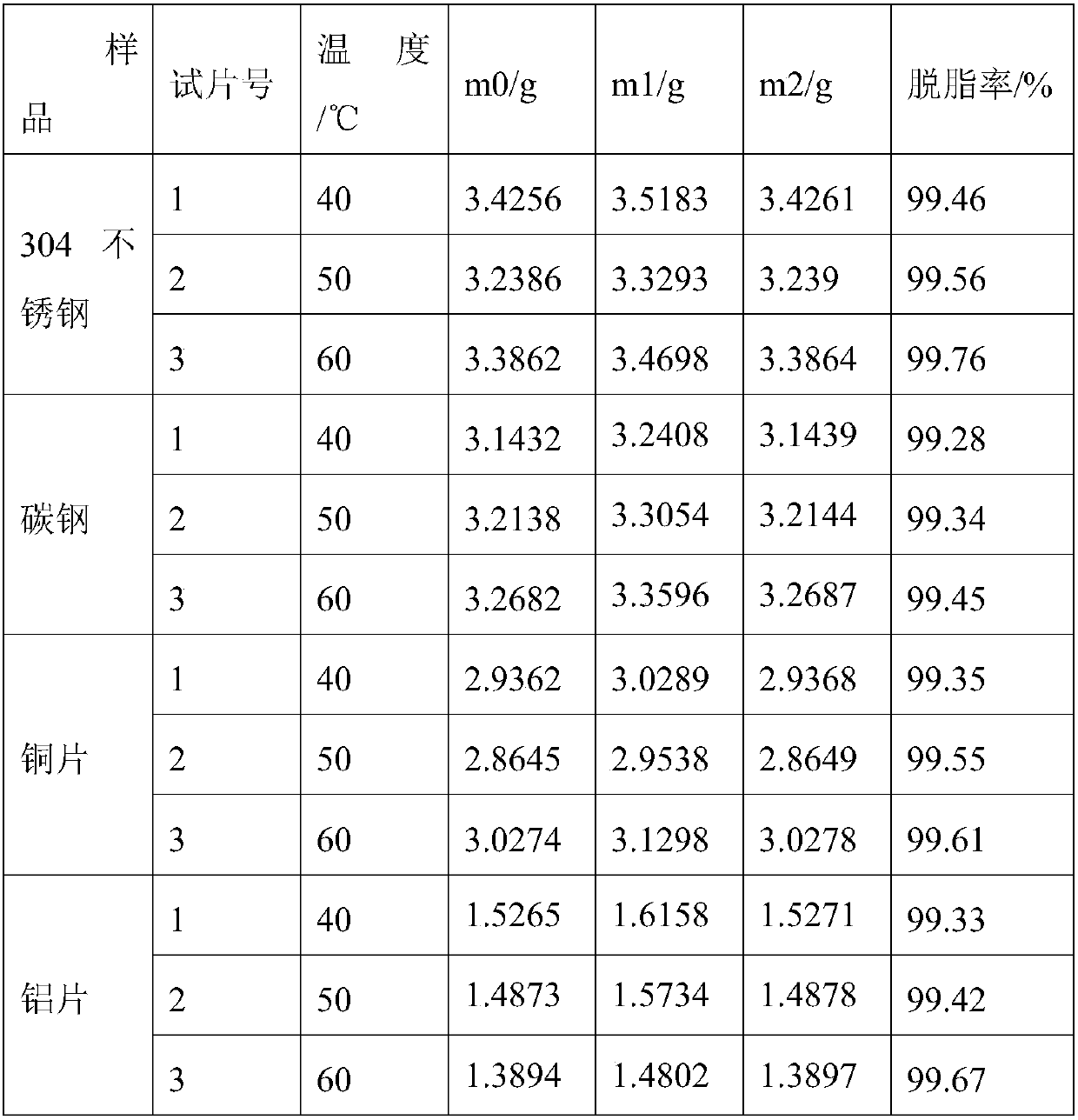

Cleaning agent composition for metal processing product surface as well as preparation method and using method thereof

ActiveCN109536972APromote degradationExcellent low temperature washing performanceCleansing AgentsMonosodium Aspartate

The invention discloses a cleaning agent composition of a metal processing product surface as well as a preparation method and a using method thereof. The cleaning agent composition comprises 1%-5% ofsurface active peptide, 2%-5% of rhamnolipid biological surfactant, 1%-3% of sodium polyaspartate, 1%-5% of lysine, 3%-6% of sodium oxalate, 0.1%-1% of a defoaming agent and the balance water. The metal product cleaning agent is mainly composed of the biodegradable biological surfactant, does not contain carcinogenic substances such as phosphorus and nitrite, and does not contain APED surfactant,the cleaning effect is excellent, the cleaning time is short, and automatic cleaning is facilitated; the cleaning agent is alkaline, the corrosion of the surface of the stainless steel product is negligible, and the cleaning agent can be safely used; and the product is a water-soluble liquid, the cleaned waste liquid is convenient to treat and discharge, the surfactant component is biodegradableand does not pollute the environment.

Owner:新沂肽科生物科技有限公司

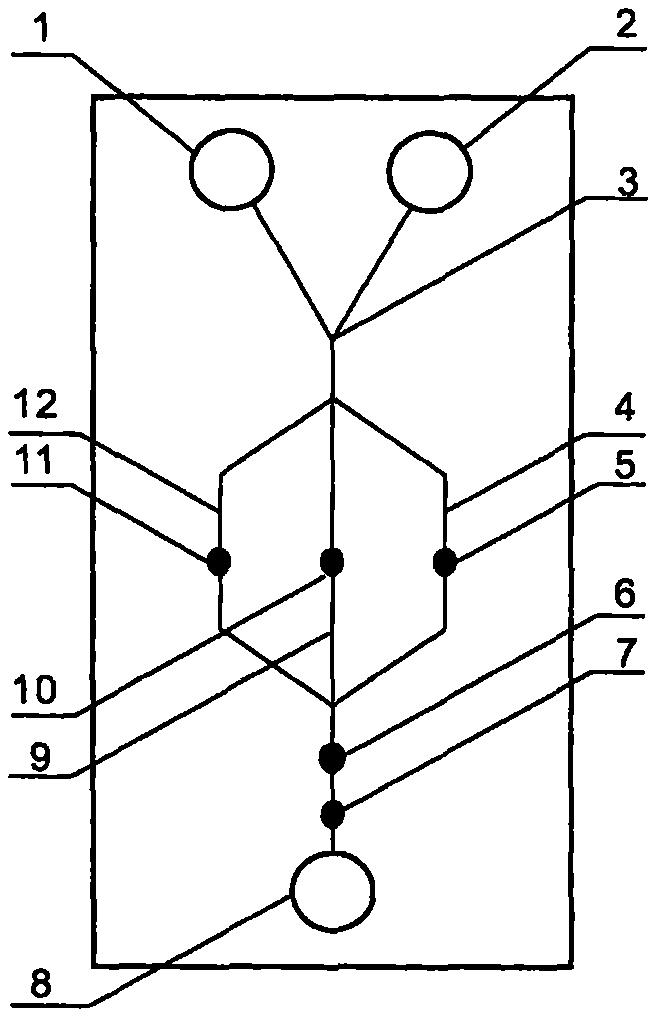

Subtype swine influenza detection chip apparatus with strongly-hydrophobic PDMS substrate

InactiveCN107754906ACounteract flow resistanceOvercome flow resistanceLaboratory glasswaresBiological testingSilica particleTransducer

The present invention relates to a subtype swine influenza detection chip apparatus with a strongly-hydrophobic PDMS substrate, and belongs to the field of analysis and testing. According to the present invention, the use of inexpensive and easily-processed polydimethylsiloxane (PDMS) to produce the substrate of a microfluidic chip for diagnosing subtype swine influenza has a plurality of barriers; and the subtype swine influenza detection chip apparatus is characterized in that the substrate selects the PDMS having an original ecological surface, a hinge type fixture provided with a miniatureultrasonic wave transducer is manually fastened and positioned at the position close to the sample liquid flow terminal of the microfluidic chip, ultrasonic waves induce the sample liquid flow to flow from the sample injection end of the chip to the terminal direction along the pipeline of the chip, the pipeline of the chip is filled with a micro-scale silica particle filler, and the micro-scalesilica particle filler is used for supporting the inner wall of the pipeline, compensating the original hydrophobic pipeline with the set of hydrophilic micro-flow channels, and extruding and coveringthe inner wall surface of the pipeline so as to reduce the opportunity of the contact between biological macromolecules and the inner wall surface.

Owner:葛光奇

Traditional Chinese medicine composition for curing purpura

ActiveCN106389598ANo side effectsSignificant effectUnknown materialsBlood disorderRhinocerosImmunocompetence

The invention discloses a traditional Chinese medicine composition for curing purpura. The composition comprises the following raw materials: 5-30 g of rhinoceros horn or cornu bubali, 5-25 g of lithospermum, 6-20 g of root bark of tree peony, 8-20 g of root of common peony, 6-25 g of sanguisorba officinalis, 5-18 g of radix salviae miltiorrhizae, 6-25 g of madder, 8-20 g of fructus forsythia, 6-20 g of honeysuckle flower, 8-20 g of rhizoma atractylodis macrocephalae, 6-30 g of astragalus membranaceus, 8-20 g of codonopsis pilosula, 5-12 g of liquorice, 5-20 g of buckwheat or sophora flower bud, and 3-20 Chinese date. The medicine components supplement one another on the actions, produce a synergistic effect, have a drug effect better than that of a single medicine, and can effectively clear heat, cool blood, invigorate the circulation of blood, disperse blood stasis, remove freckles, detoxify, and tonify qi to check bleeding. The capillary permeability is reduced, the immunocompetence of a body is strengthened, and the purpose of treating both symptoms and root causes is achieved.

Owner:蒋南海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com