Automatic assembly welding clamp for axle housing flanges

A technology for welding fixtures and axle housing flanges, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as inability to adapt to the fixing of multiple parts, inability to flip axle housing components, and single fixture structure , to achieve the effect of avoiding manual repeated flipping of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

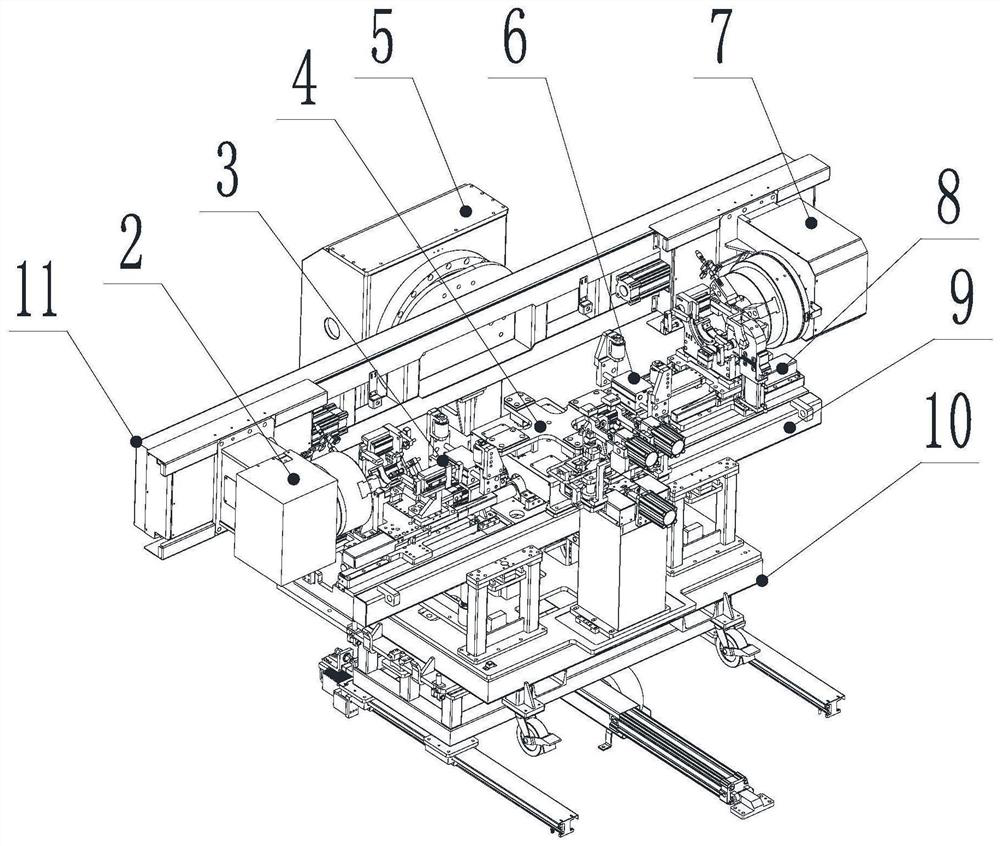

[0033] Such as figure 1 As shown, an axle housing flange automatic butt welding fixture includes a turning device 11, a clamping device 8, and a mounting plate 9 for installing the clamping device 8. The clamping device 8 includes a second clamping device for clamping the two ends of the axle housing respectively. A flange plate positioning device 3, a second flange plate positioning device 6, an axle housing smoothing device 4 is arranged between the first flange plate positioning device 3 and the second flange plate positioning device 6, and the axle housing is smoothed The device 4, the first flange positioning device 3 and the second flange positioning device 6 are all connected to the mounting plate 9; on the side of the mounting plate 9, there is also a lifting and positioning assembly for clamping with the axle housing smoothing device 4 10. The lifting and positioning assembly 10 is vertically arranged on the ground along the horizontal direction of the axle housing sm...

Embodiment 2

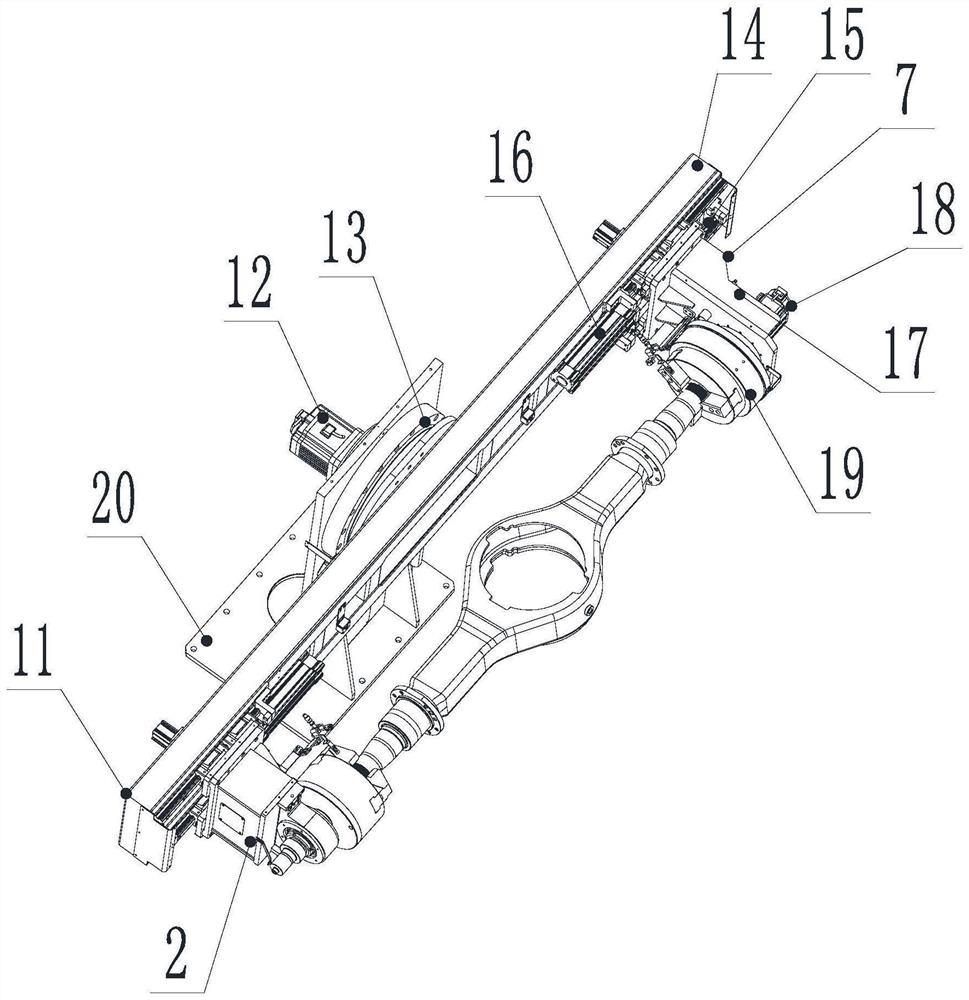

[0036] This embodiment is carried out on the basis of embodiment 1, as figure 2 As shown, the large overturn structure 5 includes a cabinet 20, a first motor 12 is arranged in the cabinet 20, a frame beam 14 is arranged on the side of the cabinet 20, the frame beam 14 is connected with the cabinet 20 through a slewing bearing 13, and the active end chuck device 7 Connected to one end of the frame beam 14, the driven end chuck device 2 is connected to the other end of the frame beam 14; the chassis 20 can be fixedly installed on the ground, driven by the first motor 12 in the chassis 20 and connected to the slewing bearing 13 The frame crossbeam 14 rotates, and then the clamping workpiece between the active end chuck device 7 and the driven end chuck device 2 will be tilted, and then the active end chuck device 7 and the driven end chuck device 2 are aligned on the same horizontal plane. The height difference is formed, and the follow-up manual welding or mechanical welding ob...

Embodiment 3

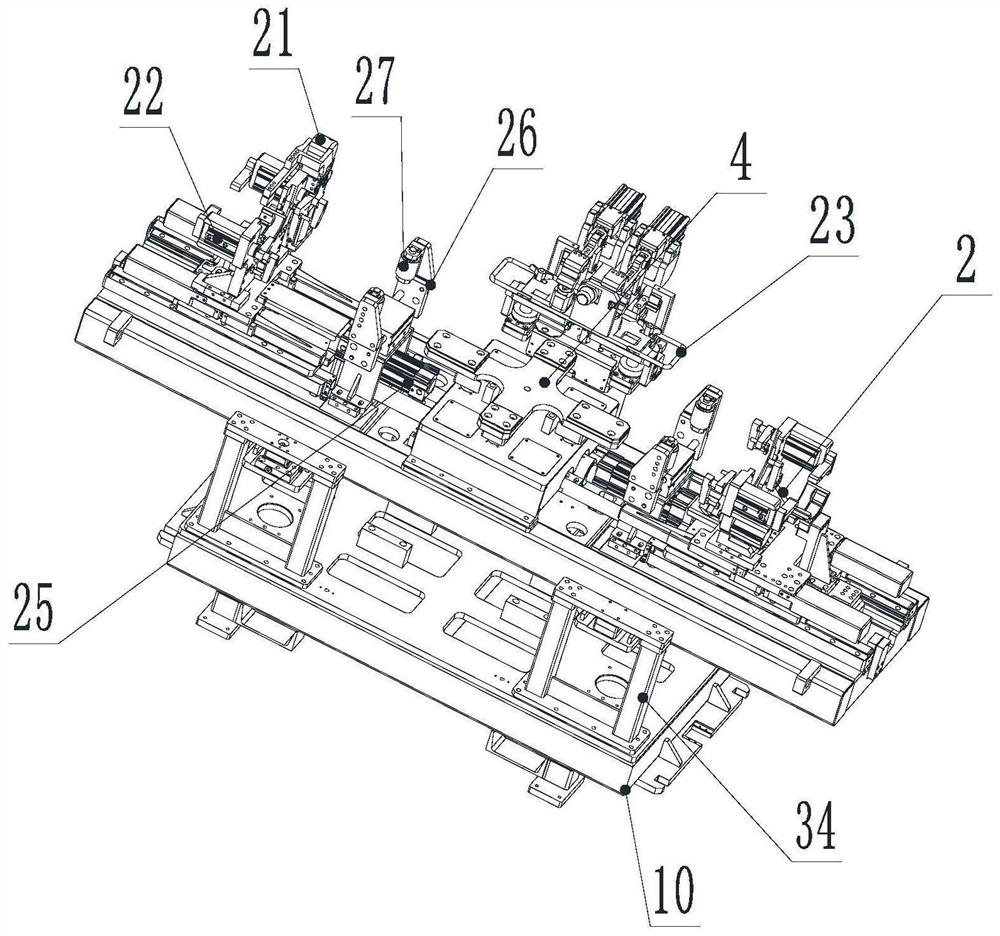

[0040] This embodiment is carried out on the basis of embodiment 2, such as Figure 3-5 As shown, first, the first flange positioning device 3 and the second flange positioning device 6 both include a clamping assembly 21, and the bottoms of the two clamping assemblies 21 are horizontally provided with a second slide rail along the long axis of the mounting plate 9 24. The two second slide rails 24 are connected to the mounting plate 9, and the sides of the two clamping components 21 are provided with a centering clamping device for pushing the first flange positioning device 3 and the second flange positioning device 6 respectively. The second air cylinder 25 is used, and the two second air cylinders 25 are all connected to the mounting plate 9; wherein the clamping assembly 21 can adopt a clamping device 8 with a symmetrical structure, in order to ensure that the clamping assembly 21 is adjusted to the corresponding position, the second slide rail 24 is designed below the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com