Patents

Literature

339results about How to "Realize continuous adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

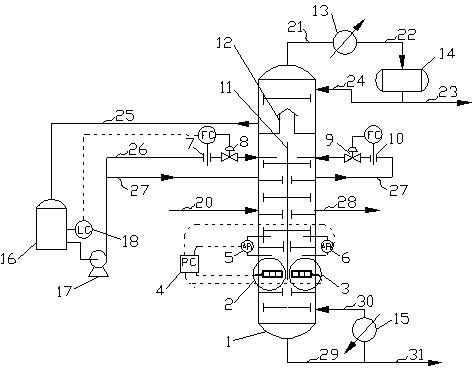

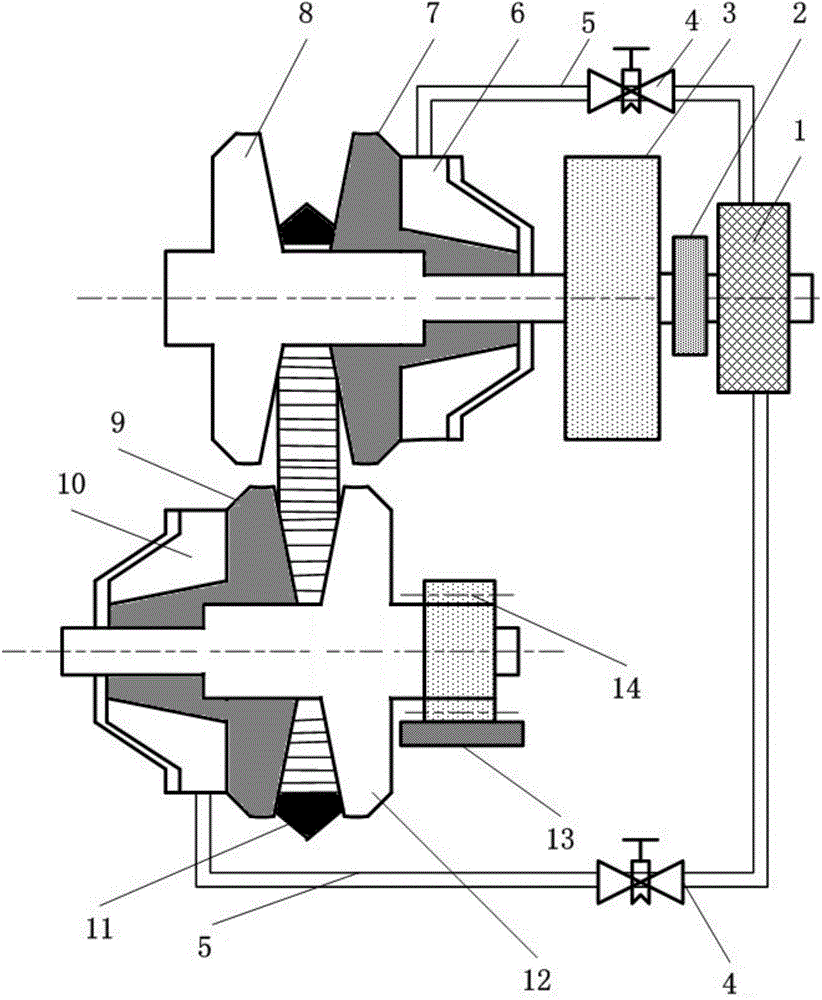

Dividing wall rectifying tower

ActiveCN102872609AEasy to controlRealize continuous adjustmentDistillation regulation/controlFractional distillationDistribution controlControl system

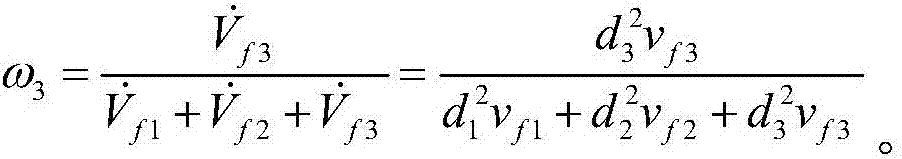

The invention discloses a dividing wall rectifying tower. In the rectifying tower, a spliter plate is arranged along the vertical direction of the tower, and the inner space of the rectifying tower is divided into a tower top combination zone, a dividing wall zone charging side, a dividing wall zone delivery side and a tower bottom combination zone. The rectifying tower also comprises a liquid intermediate section reflux distribution system and a tower bottom rising gas distribution control system. The dividing wall rectifying tower can be used to flexibly adjust liquid reflux distribution ratio and gas distribution ratio at the two sides of the spliter plate of the dividing wall tower, thus achieving an ideal product separation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

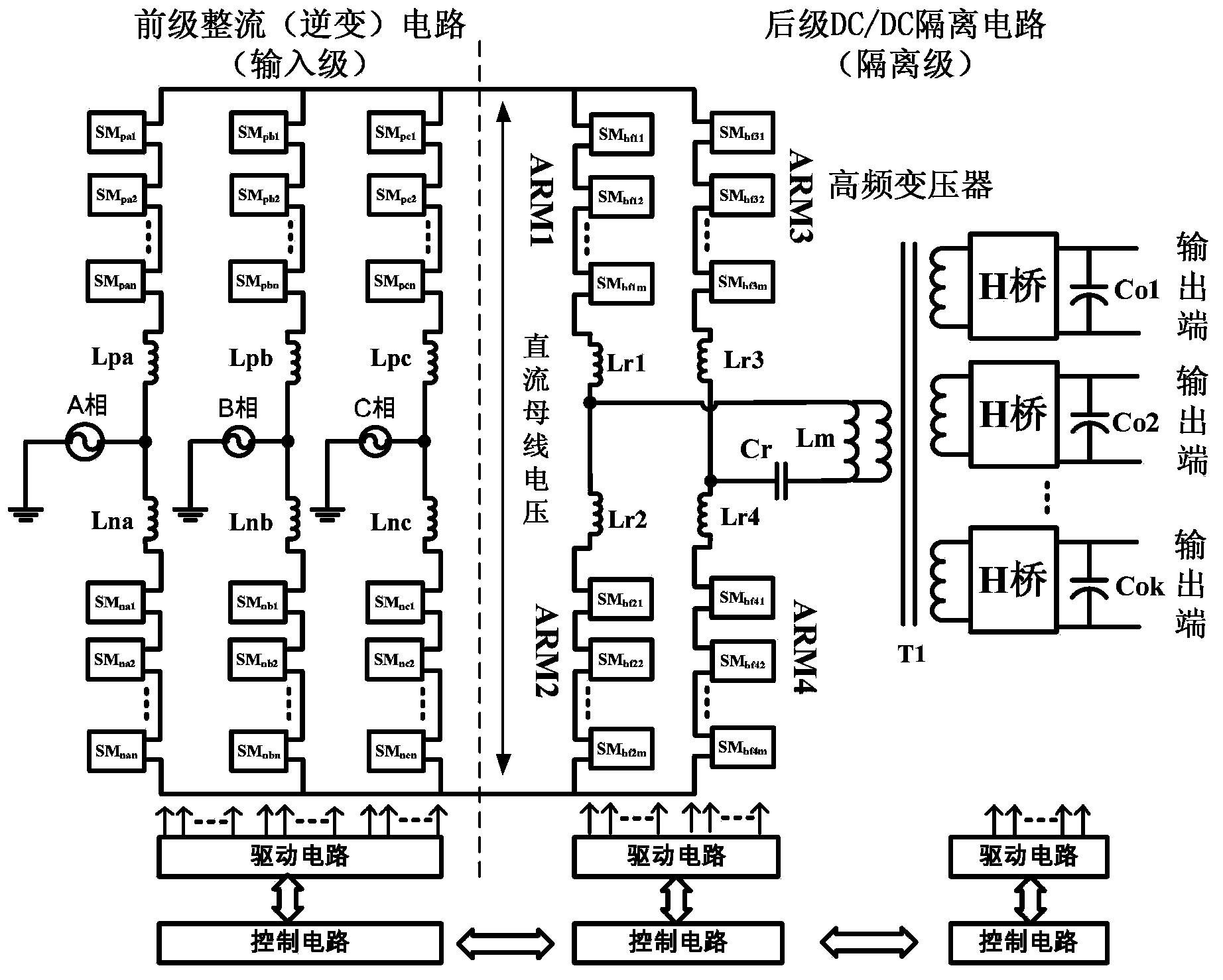

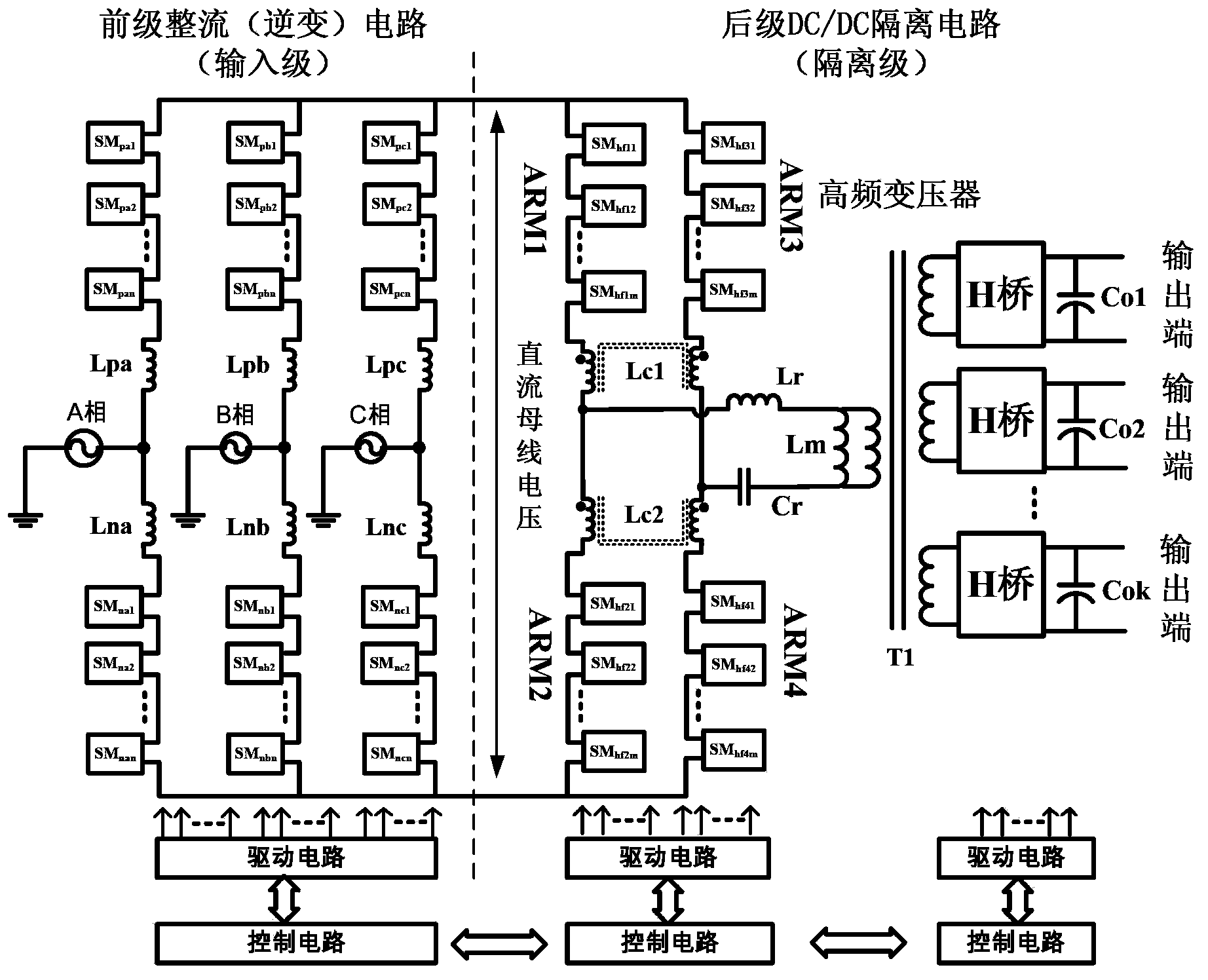

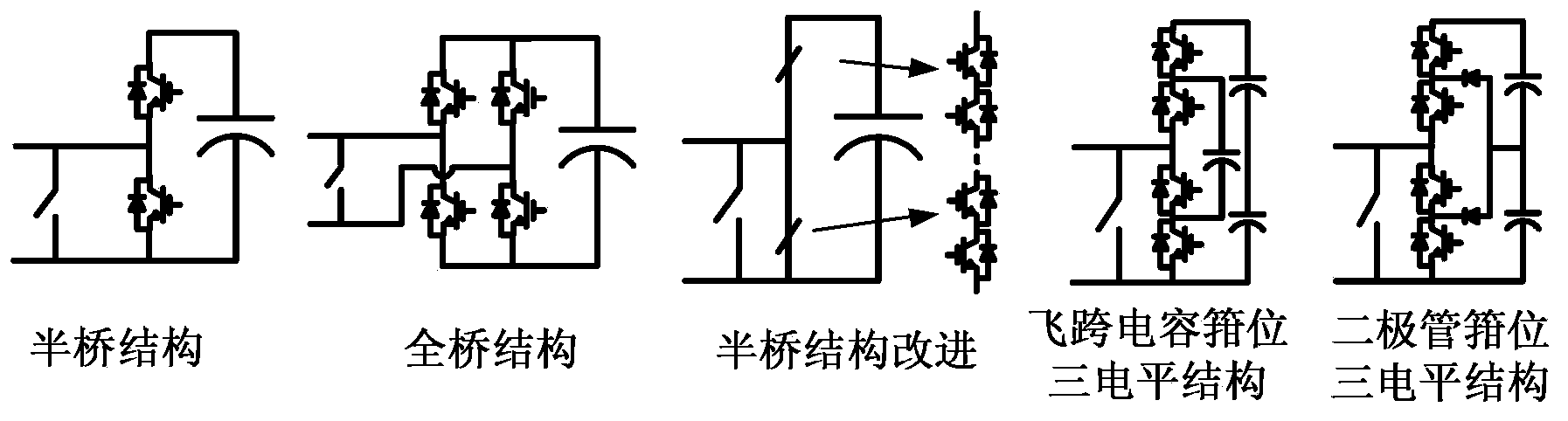

Resonance-type power electronic current transformer and current transformer device

ActiveCN103441691AHigh-efficiency energy transfer and intelligent controlLow costEfficient power electronics conversionAc-dc conversionPower gridThree-phase

The invention relates to the technical field of power electronic current transformers, and provides a resonance-type power electronic current transformer and a current transformer device. The current transformer comprises an input-stage rectifying circuit and a rear-stage DC / DC circuit. The input-stage rectifying circuit comprises three bridge arms. Each bridge arm is composed of an upper half bridge arm body and a lower half bridge arm body. The midpoints of the bridge arms are connected with three phases of a high-voltage alternating-current power grid respectively. Each half bridge arm body comprises n module units. Ports of the module units are connected in a head-to-tail mode to form a bridge arm structure. Due to the high-frequency isolation of the input side and the output side, a heavy lower-frequency transformer is removed, and meanwhile efficient energy transmission and intelligent control are achieved. Harmonic wave transmission between different power grids and mutual influences caused by failures of the different power grids can be intercepted, meanwhile, the range of the output voltage is wide, continuous adjustment of the current and the voltage can be achieved, system operation information of the current transformer is easy and convenient to collect, mutual communication can be achieved among a plurality of current transformer systems, and the intelligent power grid is obtained.

Owner:ZHEJIANG UNIV

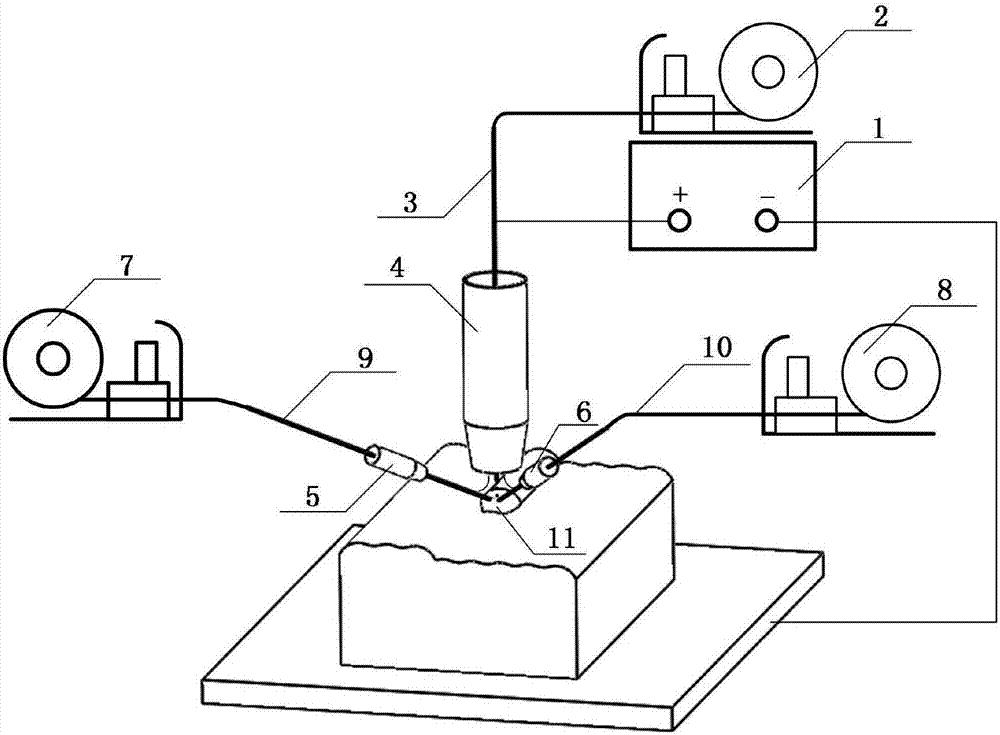

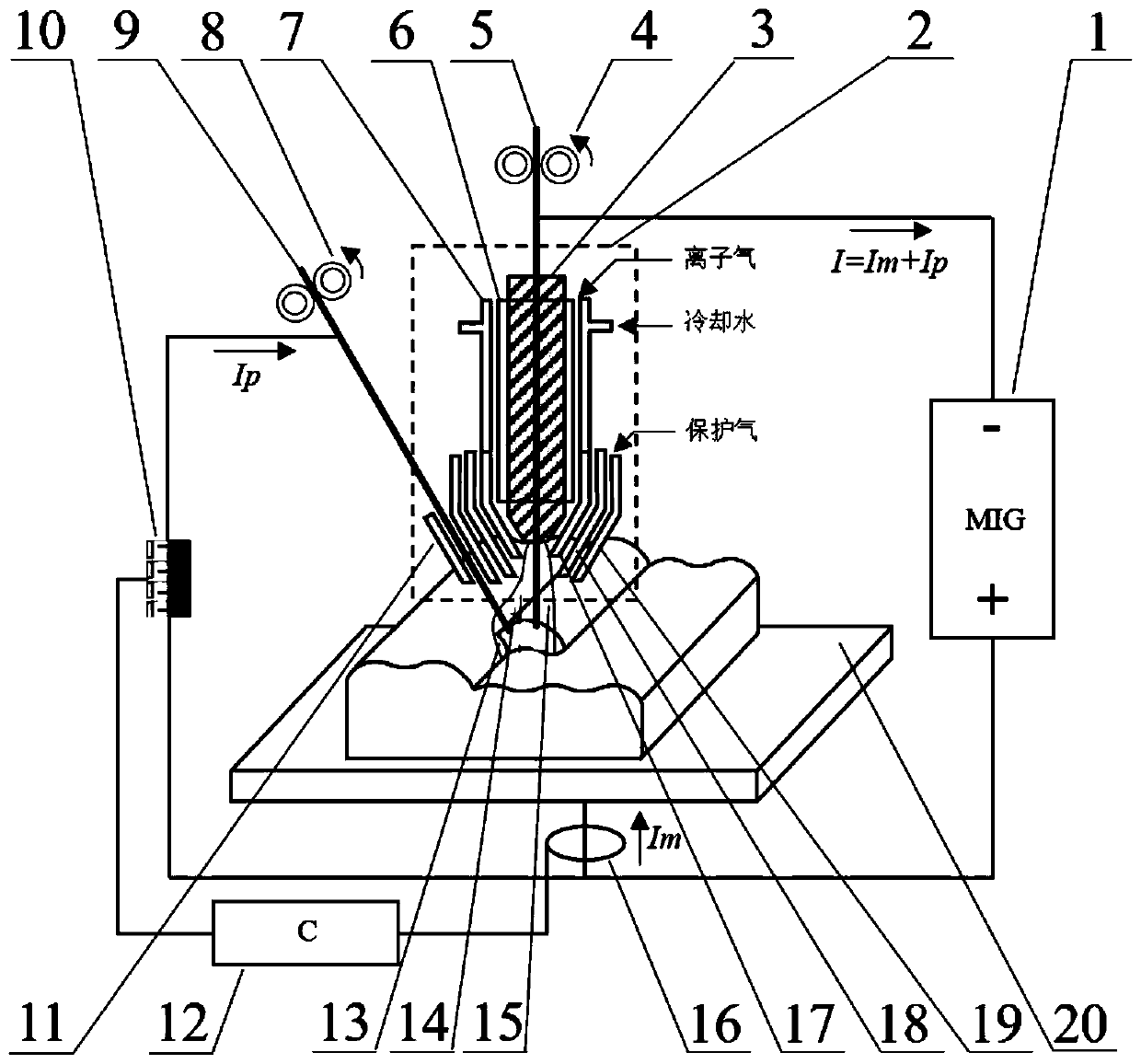

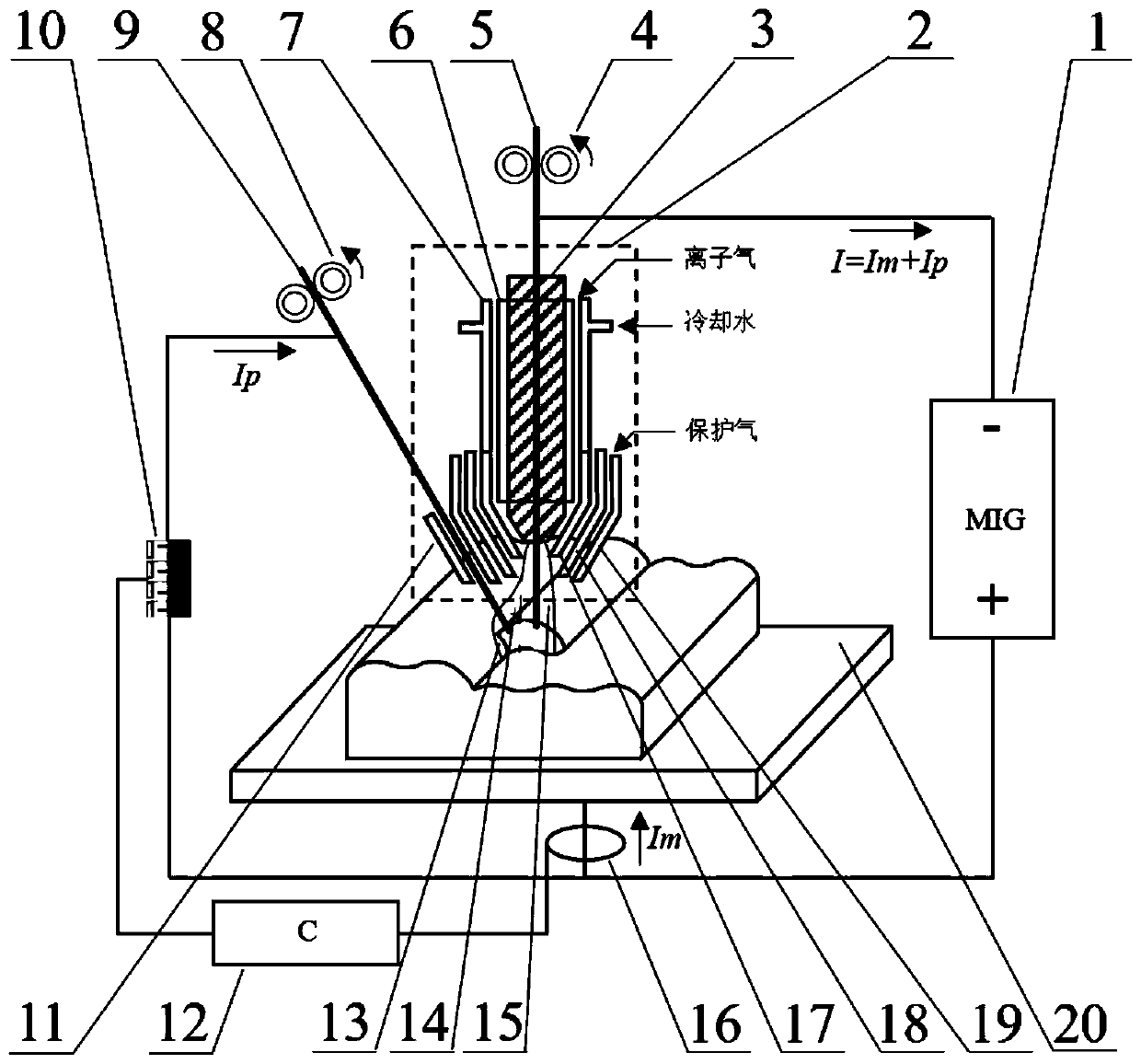

Auxiliary wire filling GMA additive manufacturing device and method for gradient material manufacturing

ActiveCN107414259AImprove energy utilizationSimple structureWelding accessoriesMelting tankGradient material

The invention discloses an auxiliary wire filling GMA additive manufacturing device and method for gradient material manufacturing. The device comprises a GMAW arc welding power source, a wire feeder, a GMAW welding gun, two wire guiding nozzles and two auxiliary wire filling wire feeders. The wire feeder is used for conveying a consumable electrode welding wire, and a feeding hose of the wire feeder is connected with the GMAW welding gun. The GMAW welding gun is vertically arranged over a molten bath and used for guiding the consumable electrode welding wire into the molten bath, and the generated arc is located between the consumable electrode welding wire and the molten bath. The two auxiliary wire filling wire feeders are used for conveying homogenous filling welding wires and heterogeneous filling welding wires, and feeding hoses of the two auxiliary filling wire feeders are connected with the two wire guiding nozzles correspondingly. The two wire guiding nozzles are fixed to the front end of the GMAW welding gun and used for guiding the homogenous filling welding wires and the heterogeneous filling welding wires to be fed into the molten bath. The auxiliary wire filling GMA additive manufacturing device and method solve the problem that in the traditional GMA additive manufacturing process, heat accumulation of a formed part is serious, and continuous component adjustment cannot be achieved.

Owner:HARBIN INST OF TECH

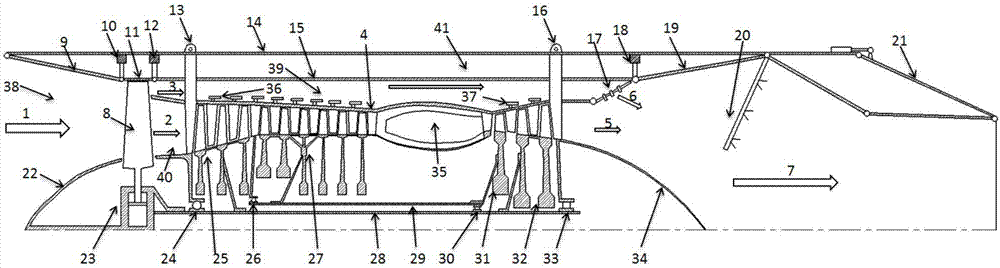

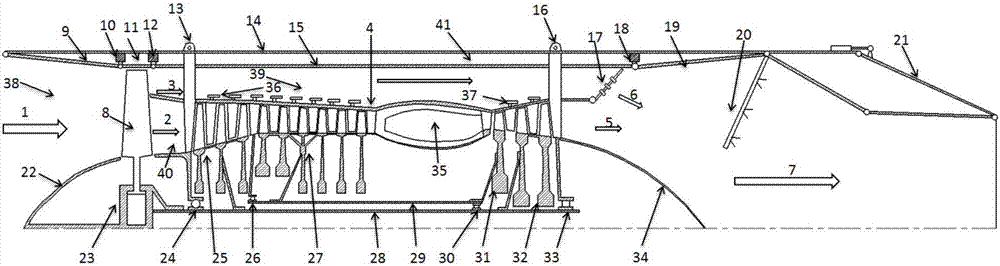

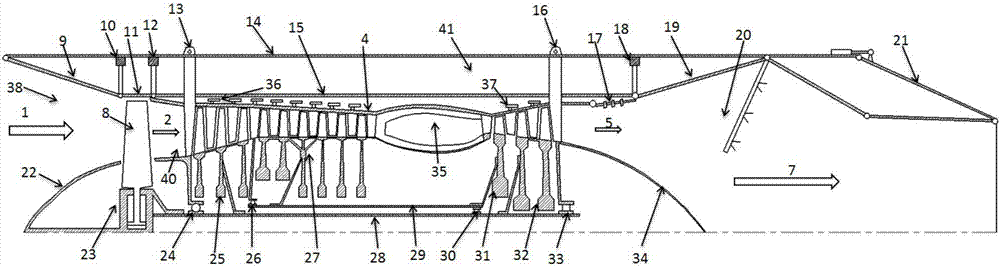

Intelligent engine adopting self-adaptive machine case and self-adaptive fan

ActiveCN108005812ALarge external duct flowAxial dimension shortJet propulsion plantsEngineeringFan blade

The invention provides an engine adopting a self-adaptive machine case and a self-adaptive fan. The engine comprises the self-adaptive machine case, the self-adaptive fan and a fuel gas generator; theself-adaptive machine case comprises a self-adaptive machine case driving execution part, an inlet section self-adaptive machine case, a fan section self-adaptive machine case, an engine middle section self-adaptive machine case and an outlet section self-adaptive machine case, wherein the inlet section self-adaptive machine case, the fan section self-adaptive machine case, the engine middle section self-adaptive machine case and the outlet section self-adaptive machine case are sequentially connected; the self-adaptive fan comprises self-adaptive fan blades and a fan driving execution part;a self-adaptive external duct is formed between the engine middle section self-adaptive machine case and an internal duct machine case of the fuel gas generator; an internal duct is formed in the internal duct machine case; the self-adaptive machine case driving execution part drives the self-adaptive machine case to move to control the cross section area of the external duct; and the fan drivingexecution part drives the self-adaptive fan blades to move in the axial direction to enable the self-adaptive fan blades to be matched with the fan section self-adaptive machine case.

Owner:AERO ENGINE ACAD OF CHINA

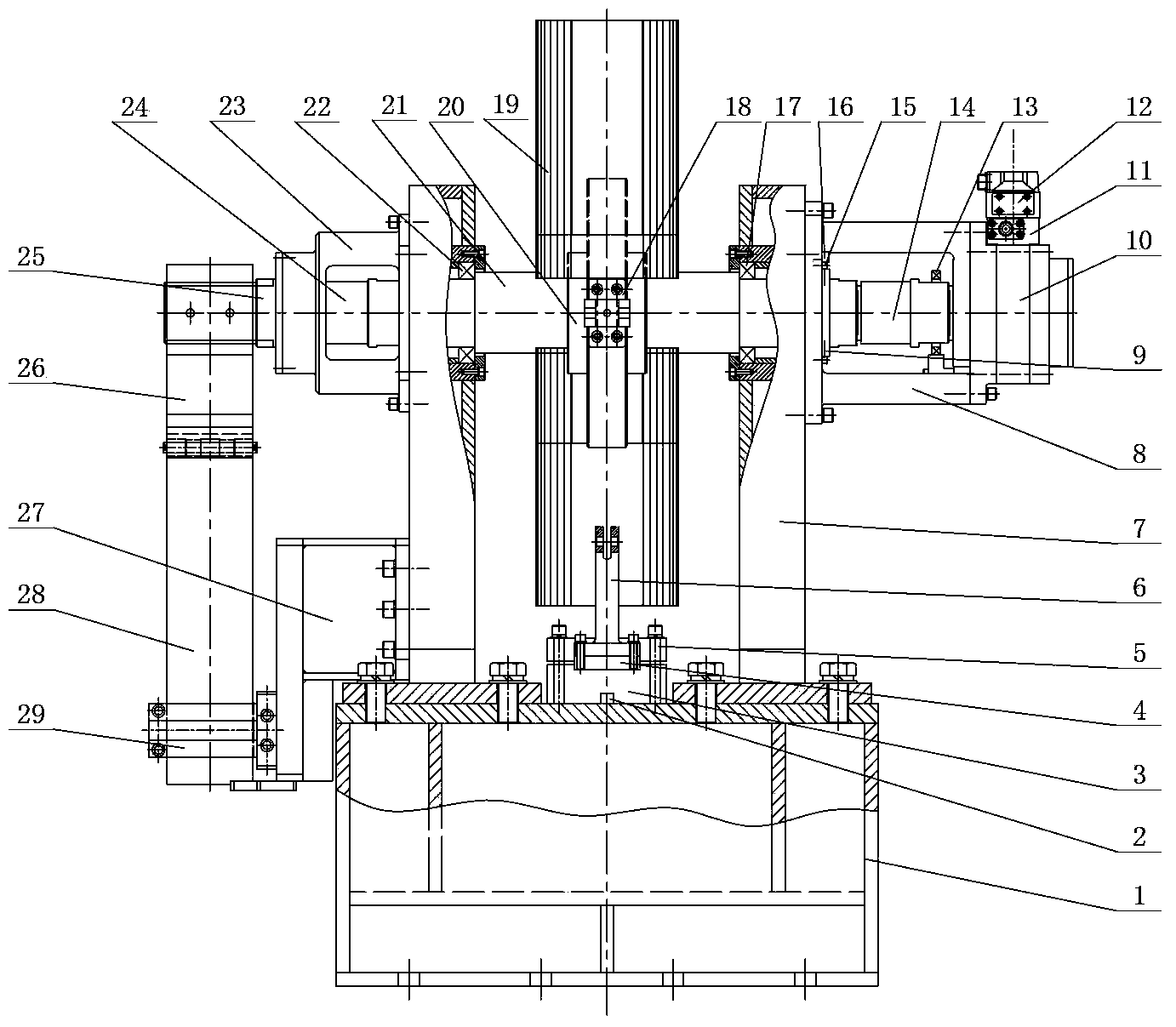

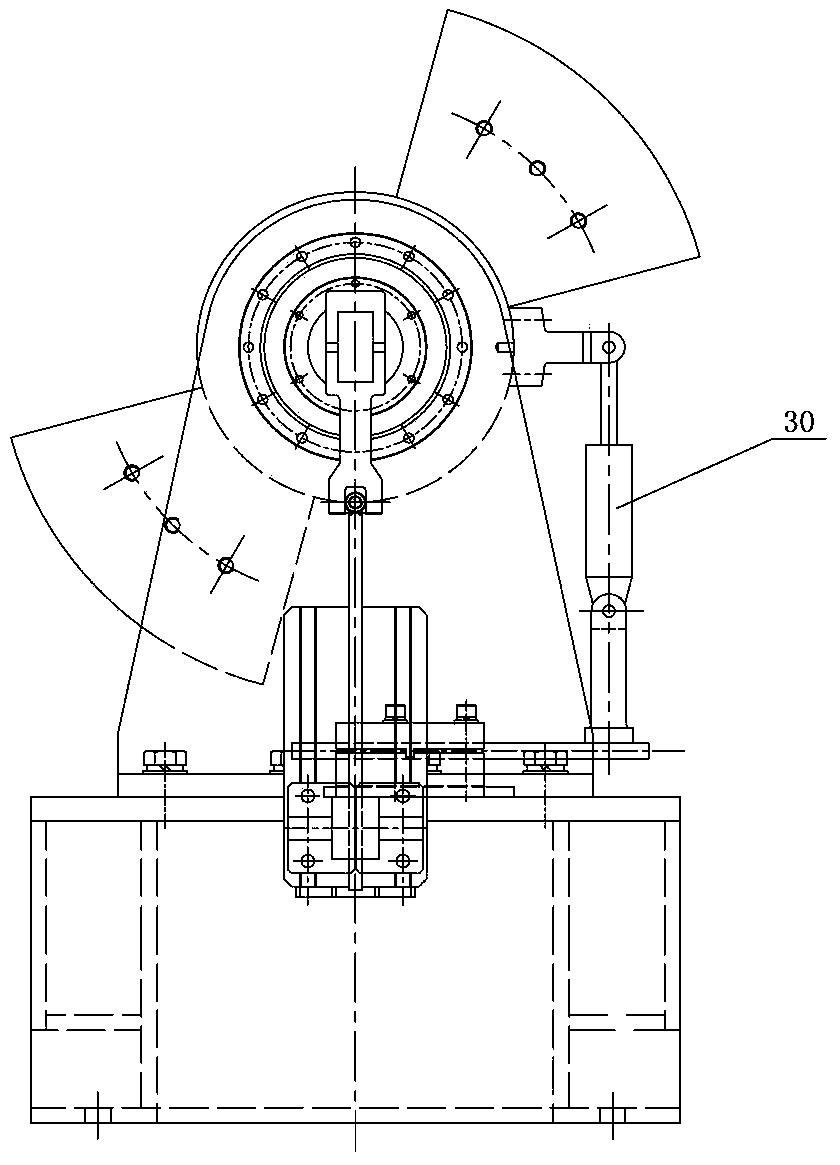

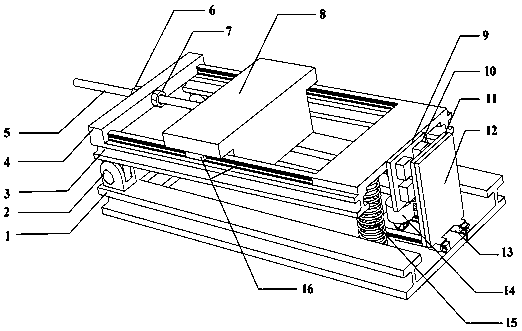

Torque servo control loading load simulator

InactiveCN103413489AReal-time monitoring sizeContinuous regulationEducational modelsTorque sensorRocket

A torque servo control loading load simulator comprises a base, a guide strip, a supporting spring plate base, a supporting spring plate, a supporting spring plate cover plate, a lower supporting lug, a side vertical plate, a motor mounting seat, a photoelectric encoder mounting seat, a swing hydraulic motor, a valve block, a servo valve, a rolling bearing, a loading torque sensor, a photoelectric encoder, a probe, a ball bearing, an upper supporting lug, an inertia counterweight disk, an inertia base disk, a spindle, an elastic torque mounting support, an elastic torque sensor, an elastic torque rotating shaft, a swing shifting fork, an elastic torque loading support, an elastic torque spring plate and a spring torque spring plate clamping plate. The torque servo control loading load simulator can simulate the structural characteristics of a rocket exhaust nozzle, wherein the structural characteristics comprise inertia loads, elastic torque loads, set torque loads and supporting stiffness. The torque servo control loading load simulator has the advantages of being simple and compact in structure, flexible in servo loading torque, high in precision, and capable of better reproducing the structural characteristics of the actual rocket exhaust nozzle.

Owner:BEIHANG UNIV

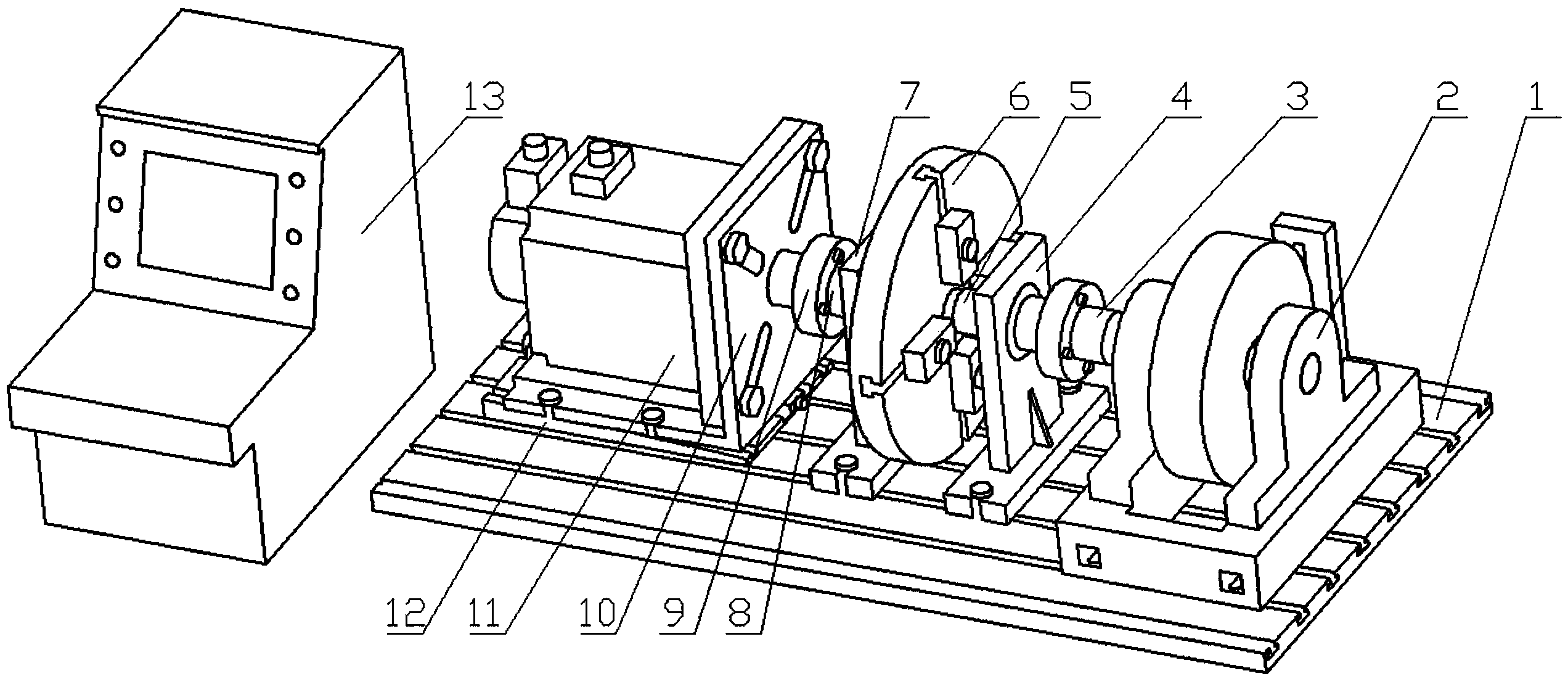

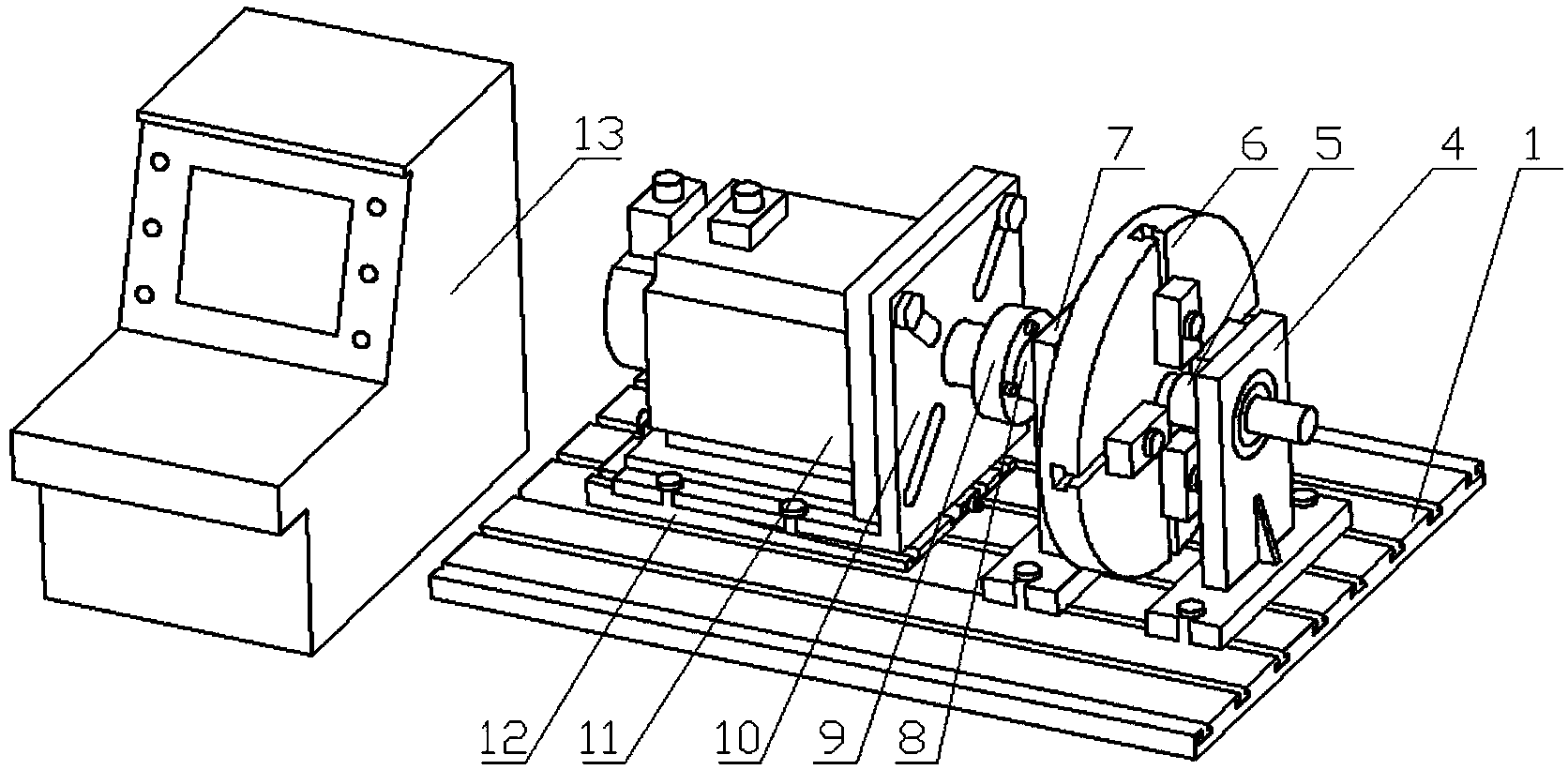

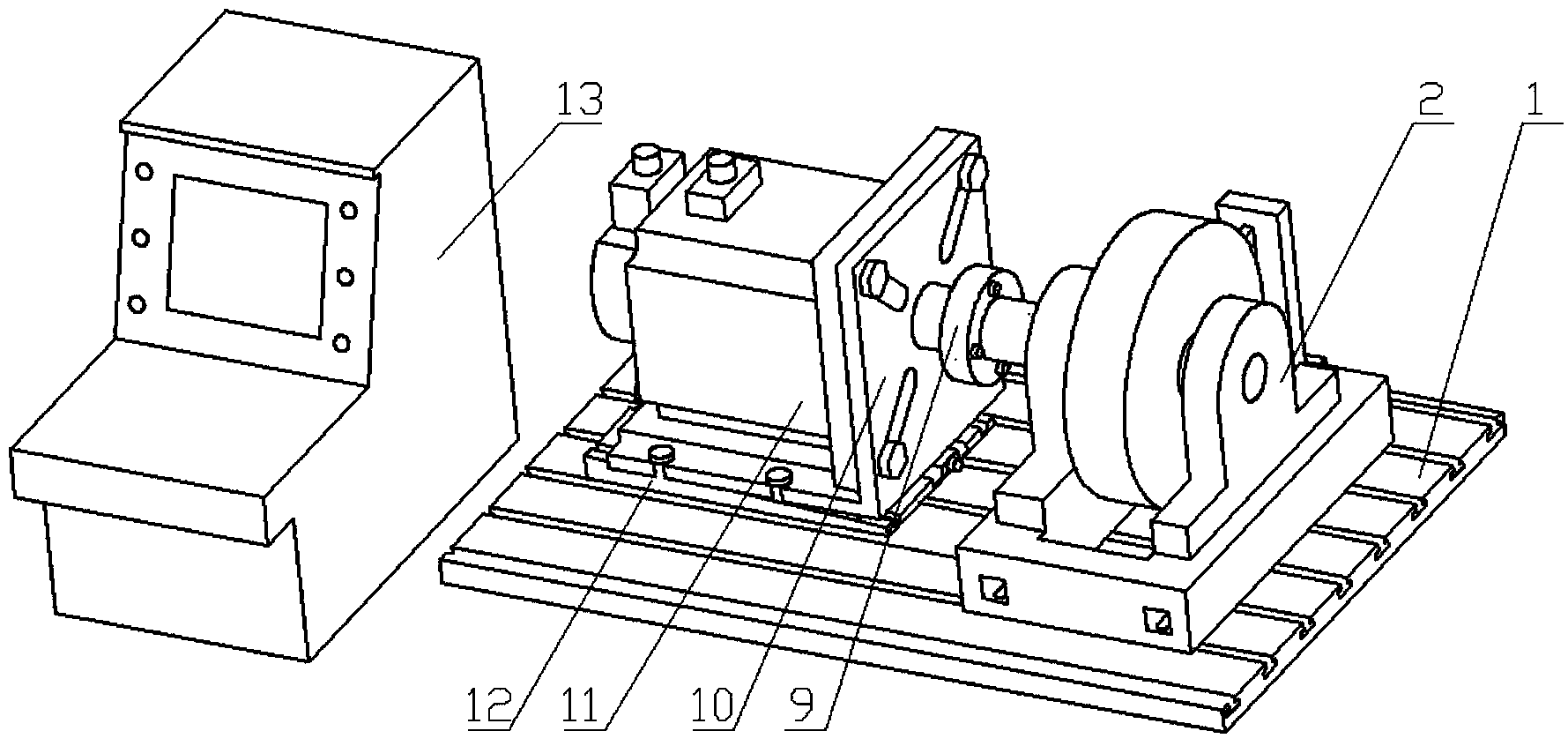

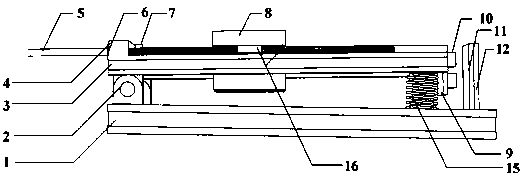

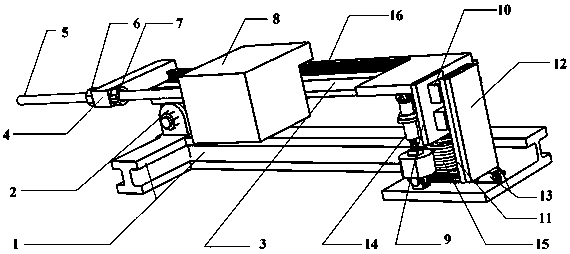

Testbed of mixed loading servo drive system reliability

ActiveCN104048844ADemonstrate flexibilityRealize continuous adjustmentStructural/machines measurementAutomatic controlCoupling

The invention discloses a testbed of mixed loading servo drive system reliability. The testbed solves the problems that a loading mode in the prior art is simple and cannot reflect the actual working conditions of a servo drive system. The testbed comprises a servo motor supporting part, an inertia loading part, a torque loading part, a vibration temperature-humidity loading part and an automatic control part. The servo motor supporting part is arranged on the left side of a horizontal iron (1), the inertia loading part is arranged on the position, on the right side of the servo motor supporting part, of the horizontal iron (1), and the torque loading part is arranged on the position, on the right side of the inertia loading part, of the horizontal iron (1). A servo motor (11) to be tested is connected with a left-end coupling of a stepped shaft (8) of the inertia loading part, the right end of the stepped shaft (8) of the inertia loading part is connected with an output shaft coupling of a dynamometer machine (2) of the torque loading part, and the RS-232C port of the vibration temperature-humidity loading part is connected with the RS-232C port of an industrial personal computer (13) of the automatic control part through wires.

Owner:JILIN UNIV

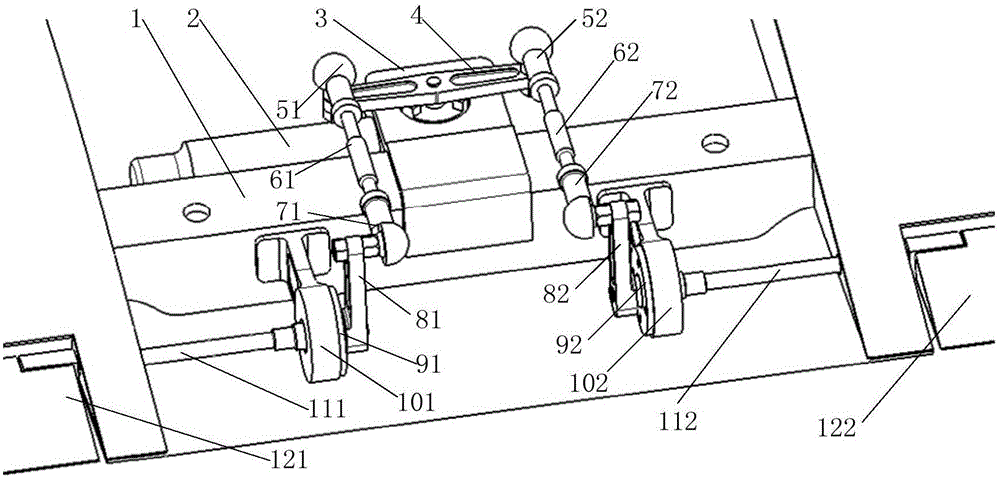

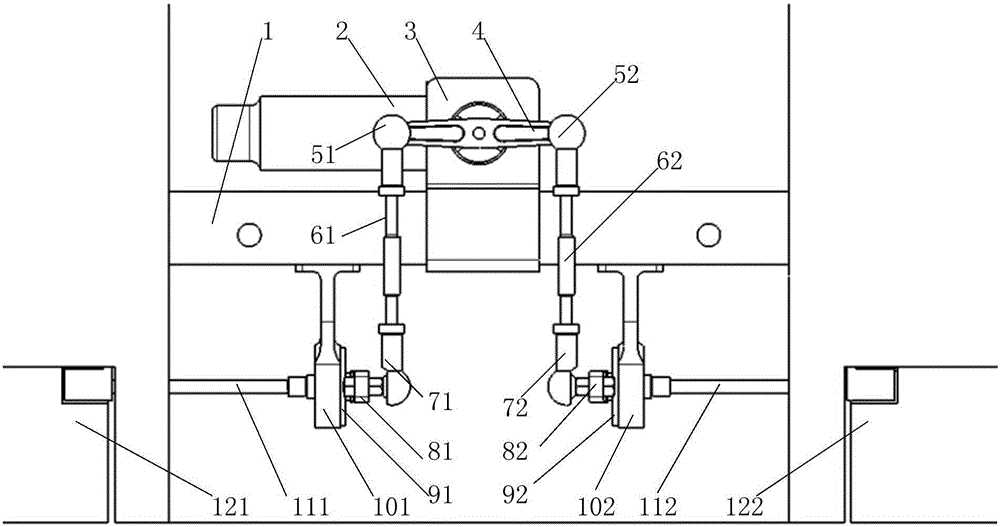

Control surface differential drive mechanism suitable for unmanned aerial vehicle

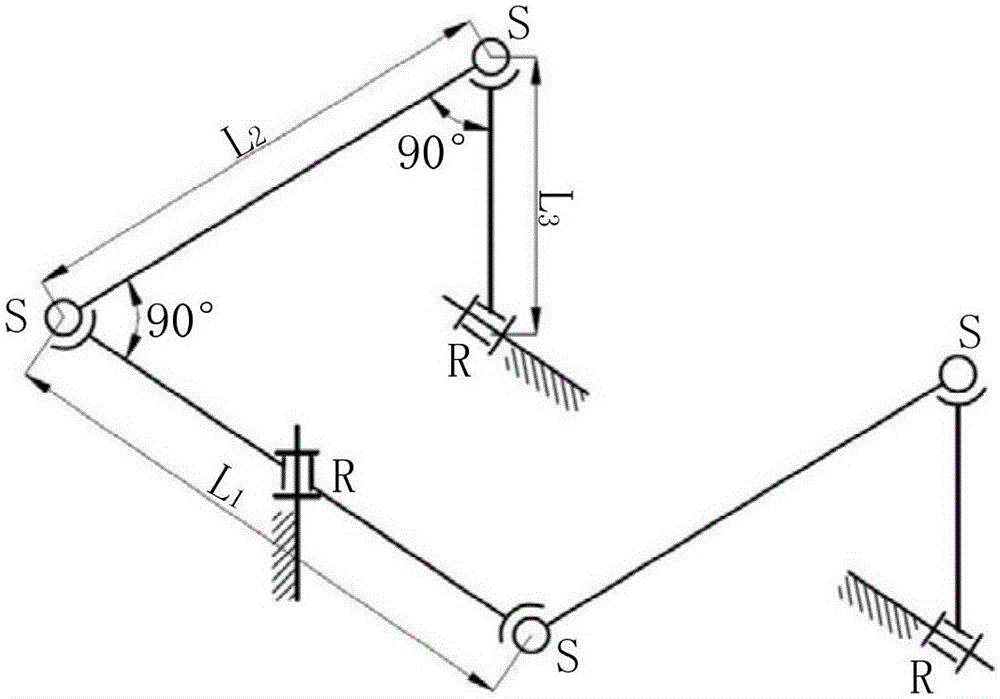

ActiveCN105151278ARealize differential rotationReduce control difficultyWithout power ampliicationWith power amplificationEngineeringUnmanned air vehicle

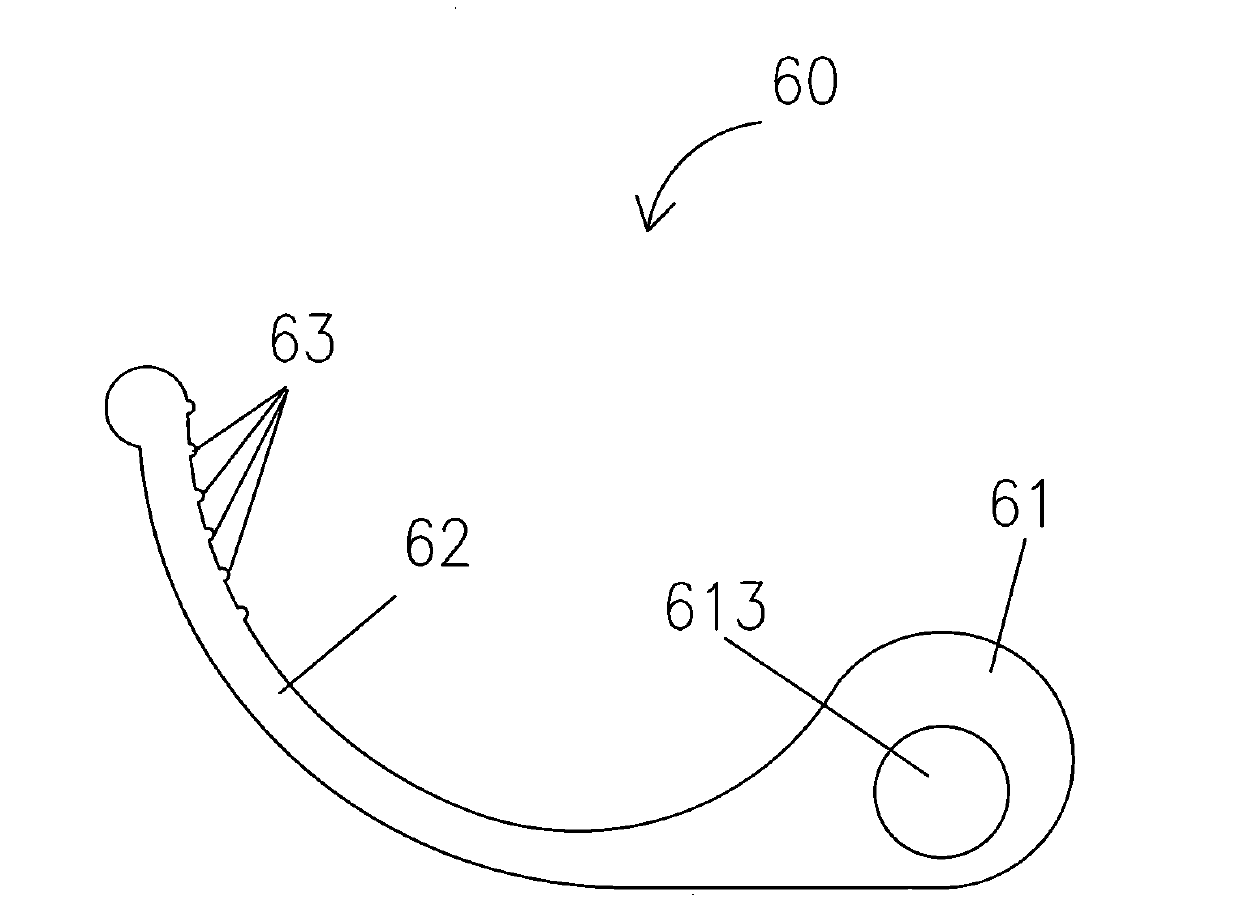

The invention relates to a control surface differential drive mechanism suitable for an unmanned aerial vehicle. The control surface differential drive mechanism comprises a common module, a left aileron drive mechanism module and a right aileron drive mechanism module. A dual-output steering engine connecting rod (2) is driven by an electric steering engine (2) to rotate, and a left aileron rudder shaft (111) and a right aileron rudder shaft (112) are driven to rotate oppositely through movement of a left connecting rod (61), a right connecting rod (62), a left rudder shaft connecting rod (81) and a right rudder shaft connecting rod (82), so that a left aileron (121) and a right aileron (122) deflect oppositely. Differential drive of the left aileron and the right aileron is achieved through a dual RSSR space four-connecting-rod combined mechanism, movement synchronization of the left aileron and the right aileron is achieved, constant-speed transmission of the left aileron and the right aileron is achieved, meanwhile, the requirements for machining precision and tools are lowered, and manufacturing cost is reduced.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

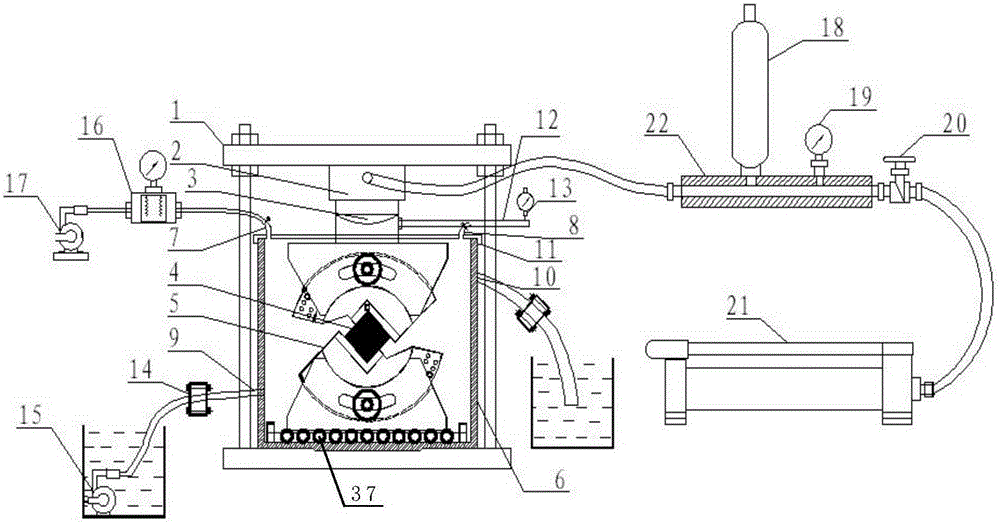

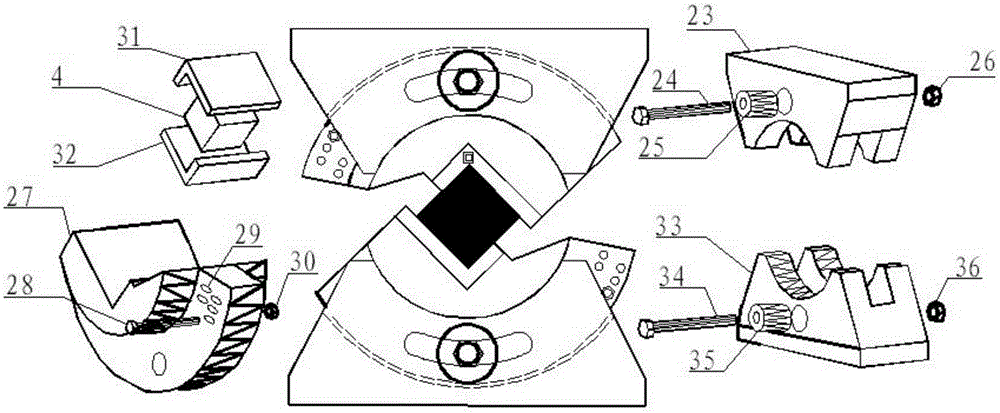

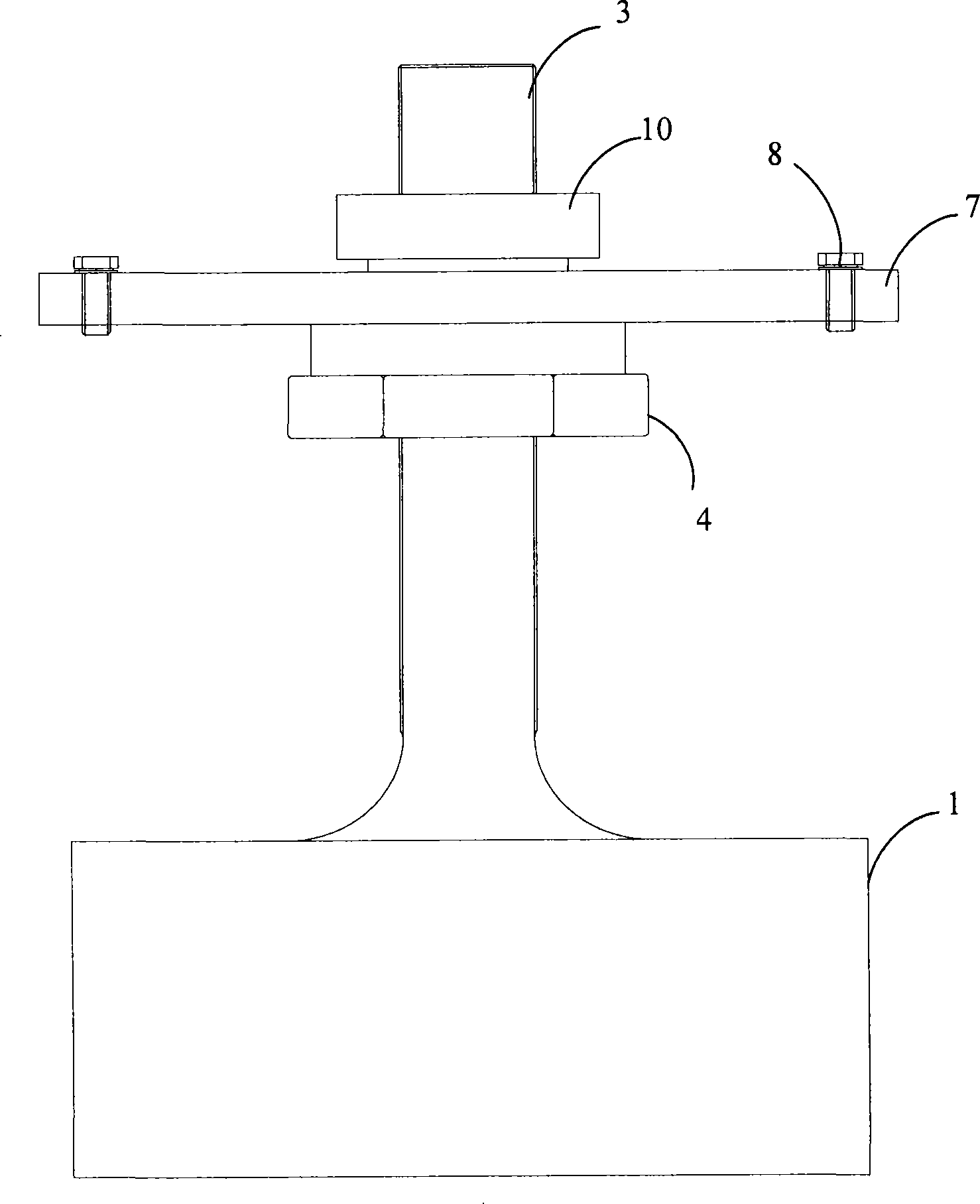

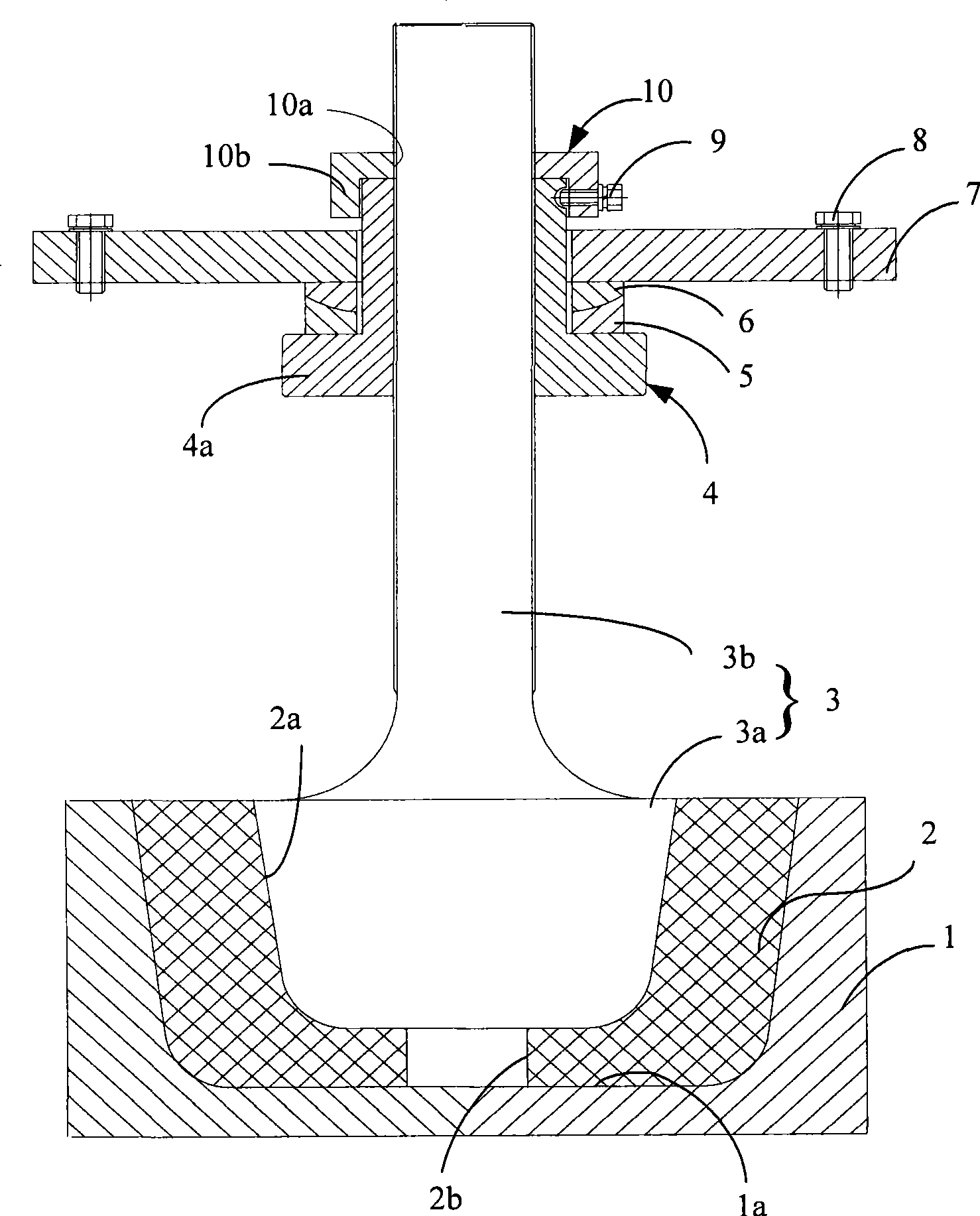

Compression-shear testing apparatus for rock in dry-wet cyclic process

ActiveCN105181483ASimple structureEasy to operateMaterial strength using steady shearing forcesCyclic processEngineering

The invention belongs to the field of geotechnical engineering, and in particular relates to a compression-shear testing apparatus for a rock in a dry-wet cyclic process. The apparatus comprises an angle-variable compression-shear unit, and a compression machine for vertically applying load onto the angle-variable compression-shear unit; the apparatus also comprises a reservoir, water injection equipment for carrying out moisture saturation treatment on a rock sample in the angle-variable compression-shear unit, and heating equipment for carrying out hot-gas drying treatment on the rock sample in the angle-variable compression-shear unit. The angle-variable compression-shear unit is located in the reservoir, and the reservoir is communicated with the water injection equipment and the heating equipment. By adopting the compression-shear testing apparatus, the integration of rock sample dry-wet cyclic treatment and a shear test is realized, and the apparatus has the advantages of simple structure, convenient operation, low cost, wide application range and long service life; the rock samples in different states after different dry-wet cyclic times can be accurately simulated, shear test research is carried out on the rock samples, and moreover, failure load and displacement of the rock samples in the vertical direction in the shear test process can be recorded in real time.

Owner:ANHUI INST OF BUILDING RES & DESIGN

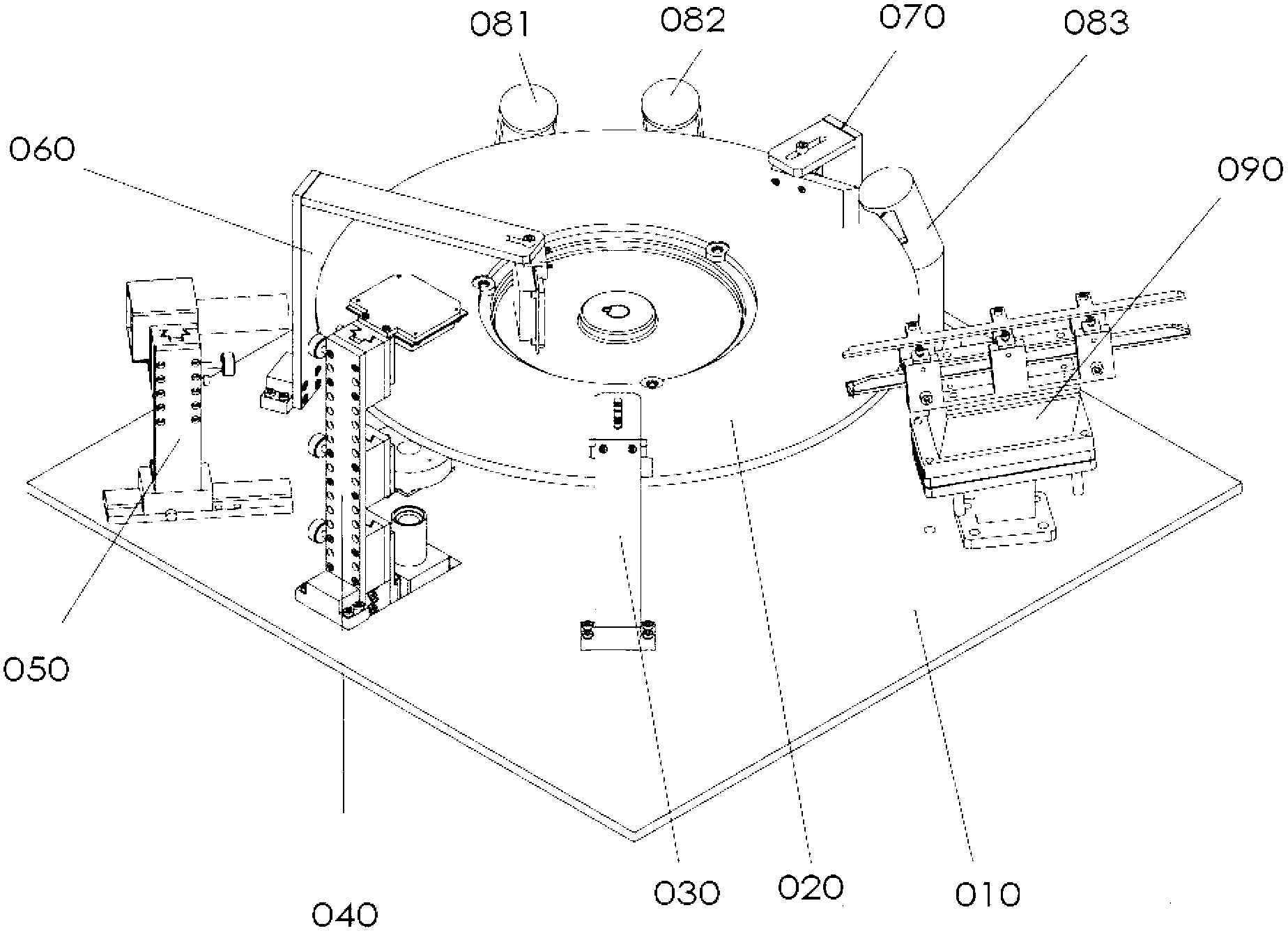

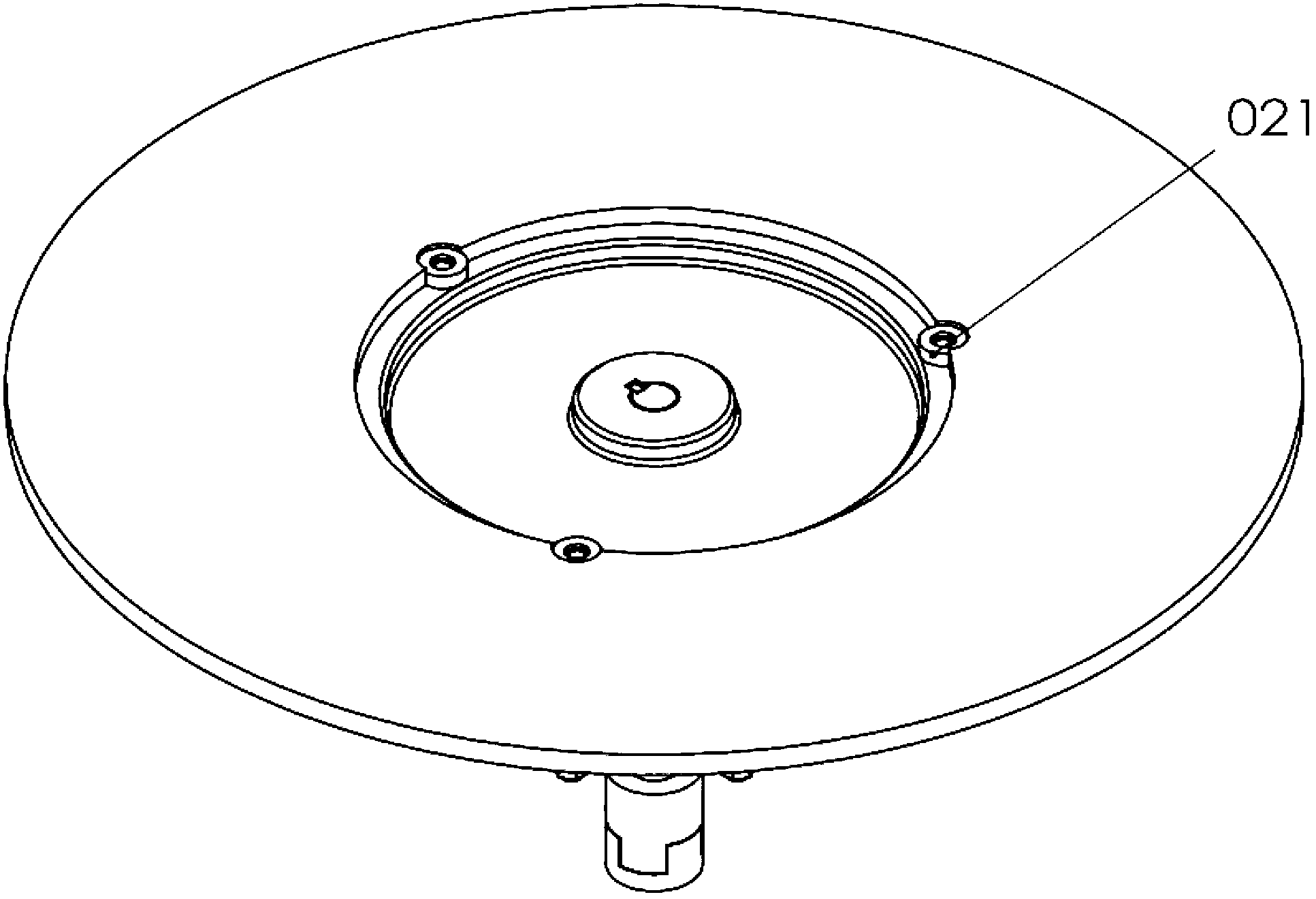

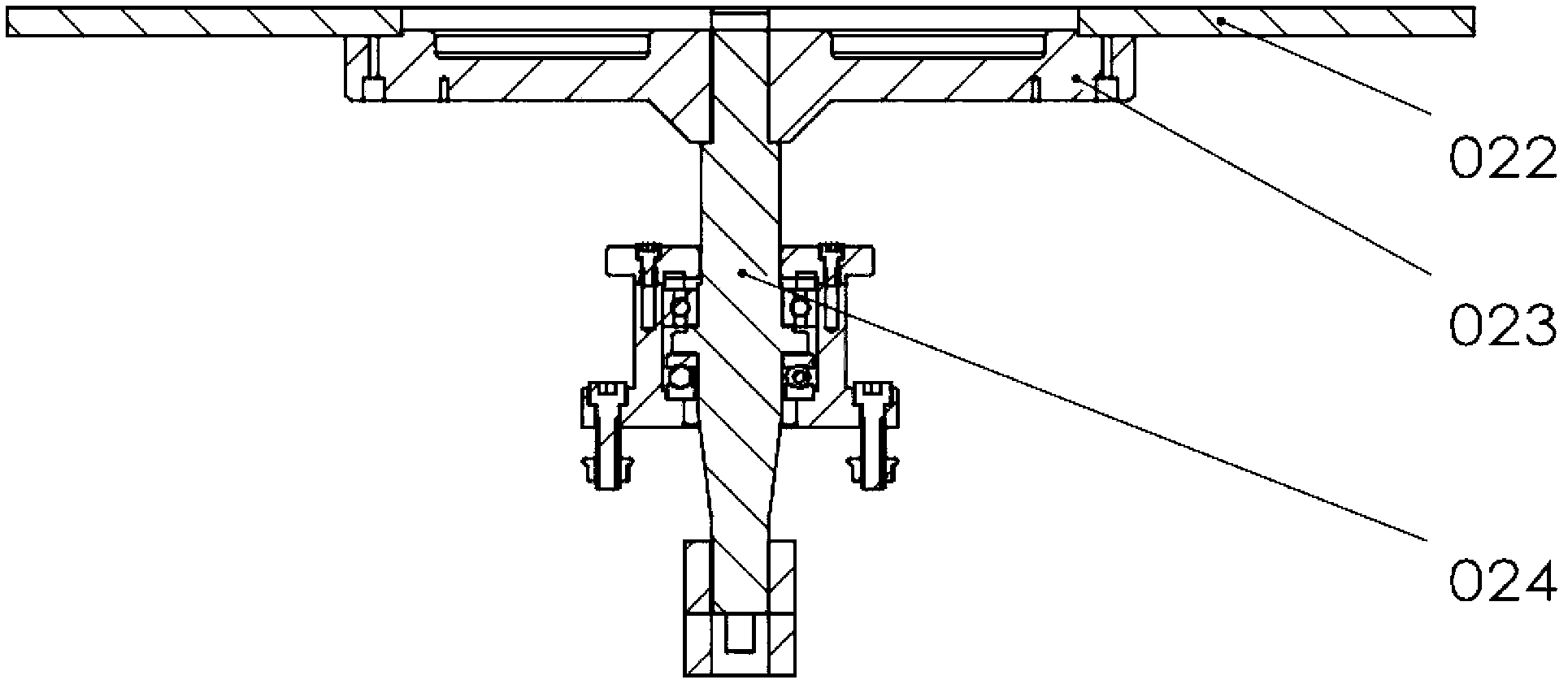

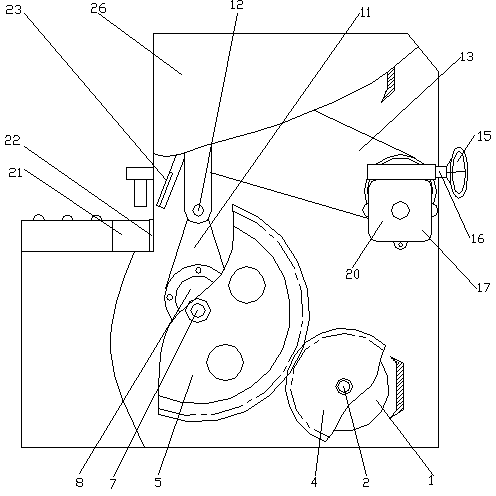

Accurate screw high-speed detection device capable of feeding materials through glass rotary plate

InactiveCN102840826AIncrease line speedThe detection process is fastUsing optical meansStops deviceEngineering

The invention discloses an accurate screw high-speed detection device capable of feeding materials through a glass rotary plate. The accurate screw high-speed detection device capable of feeding the materials through the glass rotary plate comprises a controller, a rotary plate which is arranged on a flat operation platform, a stop device, a material switching device, a vertical light resource, an camera adjusting seat, a horizontal camera adjusting seat, a horizontal light resource adjusting seat, a material feeding mechanism, a discharging opening of unqualified products, a discharging opening of mixed materials and a discharging opening of qualified products. The material feeding mechanism, the stop device, the vertical light resource, the camera adjusting seat, the horizontal camera adjusting seat, the horizontal light resource adjusting seat and the material switching device are clockwise arranged around the rotary plate. Without changing a device, the horizontal camera adjusting seat, the vertical light resource and the camera adjusting seat are adjusted, so that detection on screws with different size is achieved.

Owner:SOUTH CHINA UNIV OF TECH

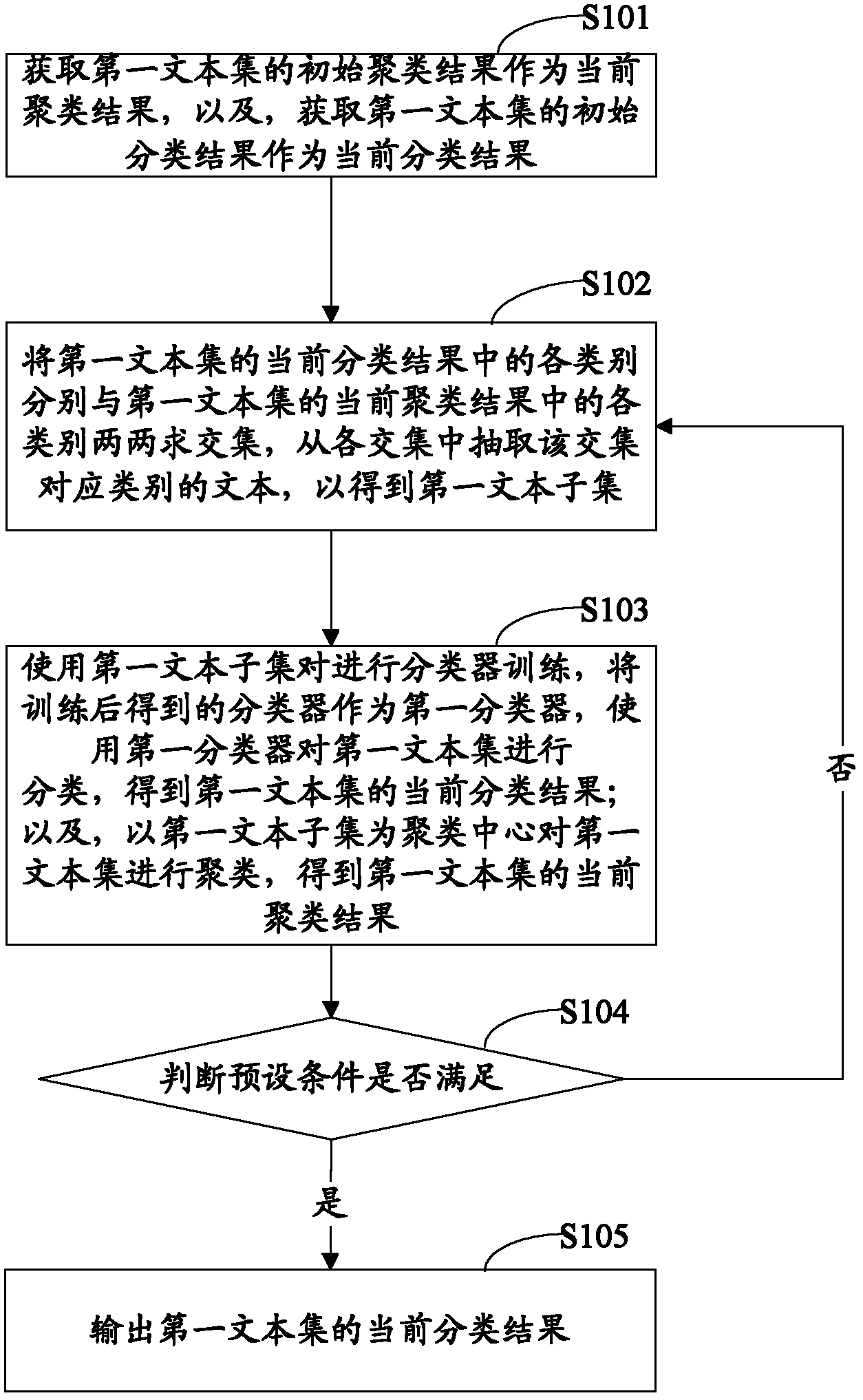

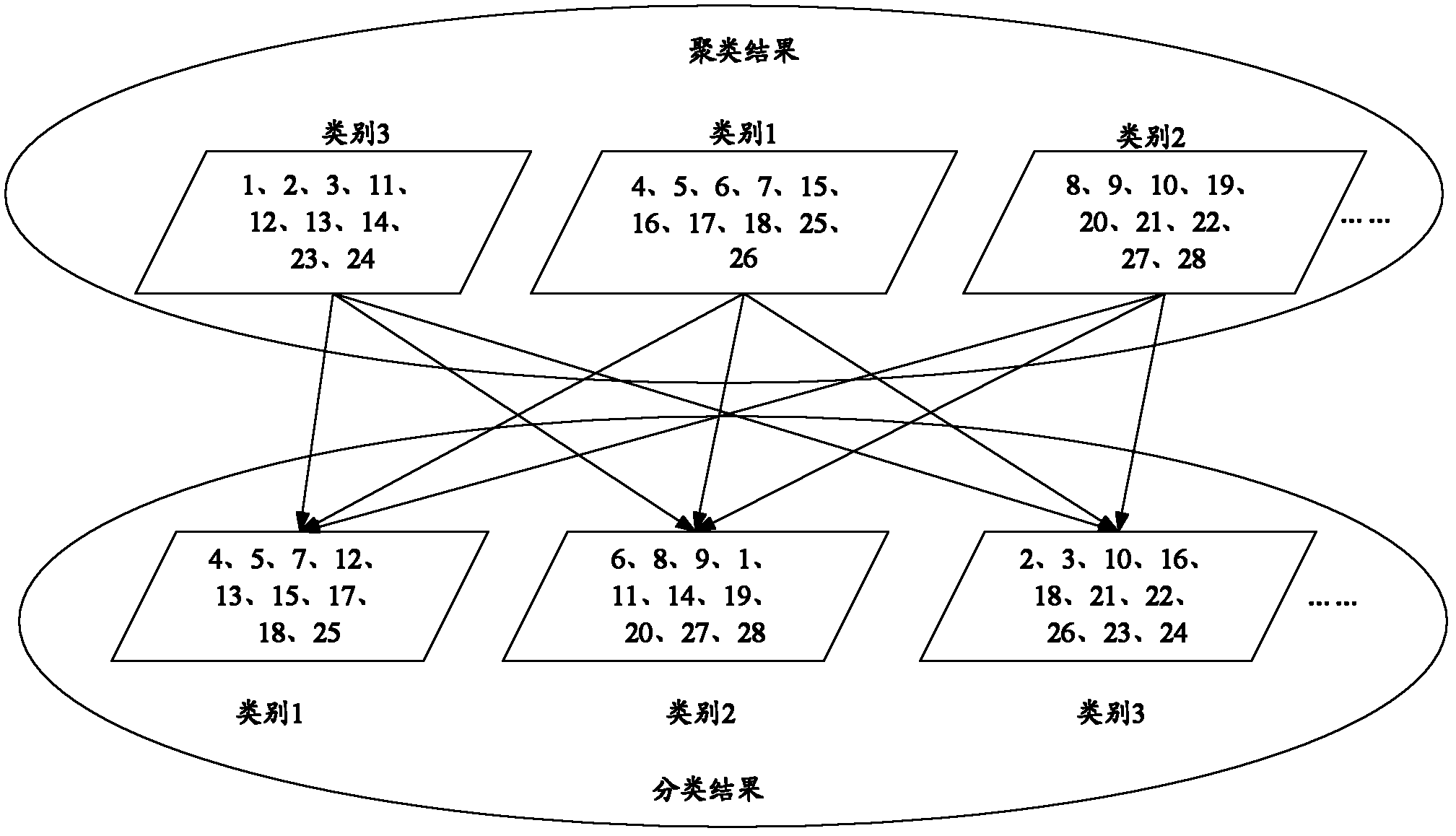

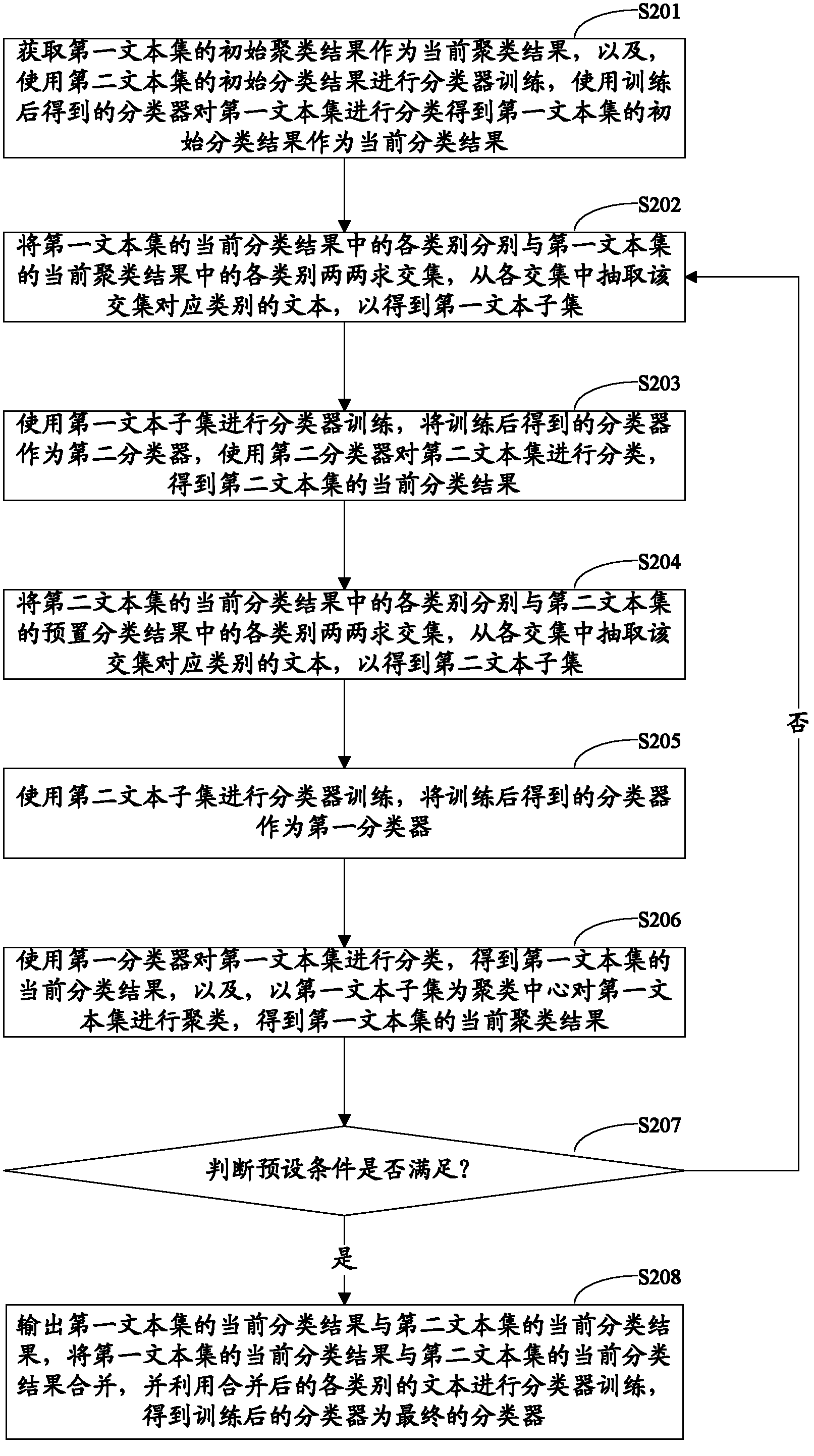

Method and device for classifying text

ActiveCN102999516AHigh precisionRealize continuous adjustmentSpecial data processing applicationsText categorizationMachine learning

The invention provides a method and device for classifying a text. The method comprises the following steps of A, acquiring the primary clustering result of a first text set as the current clustering result, and acquiring the primary classifying result of the first text set as the current classifying result; B, acquiring a first text sub set by using the current clustering result and the current classifying result; and C, acquiring a first classifier by using the first text sub set to classify the first text set to acquire the current classifying result, clustering the first text set by using the first text sub set as a clustering center to acquire the current clustering result, judging whether a preset condition is satisfied or not, if so, outputting the current classifying result of the first text set, and otherwise, returning to the step B. The text classifying precision is improved by the way.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

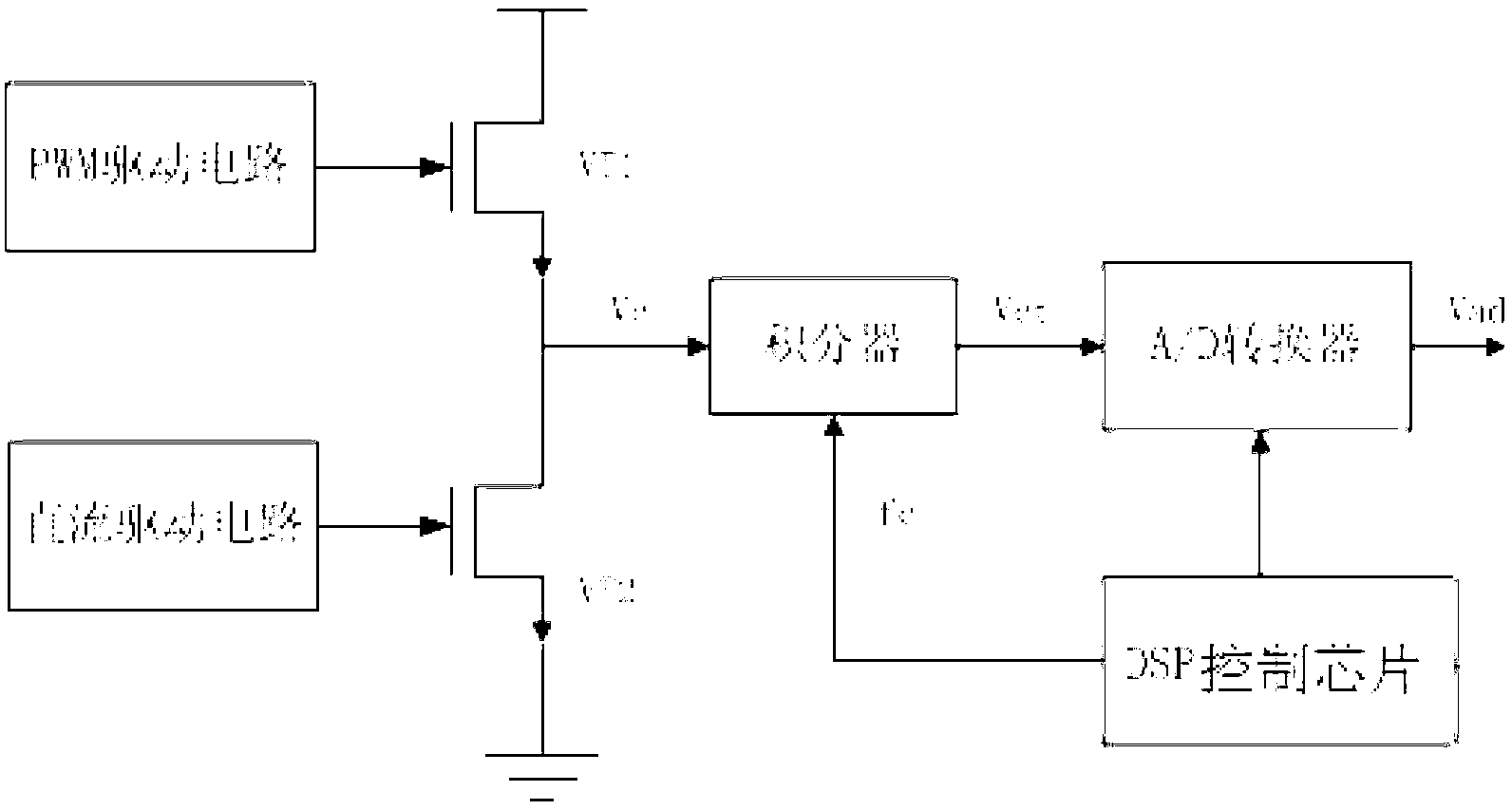

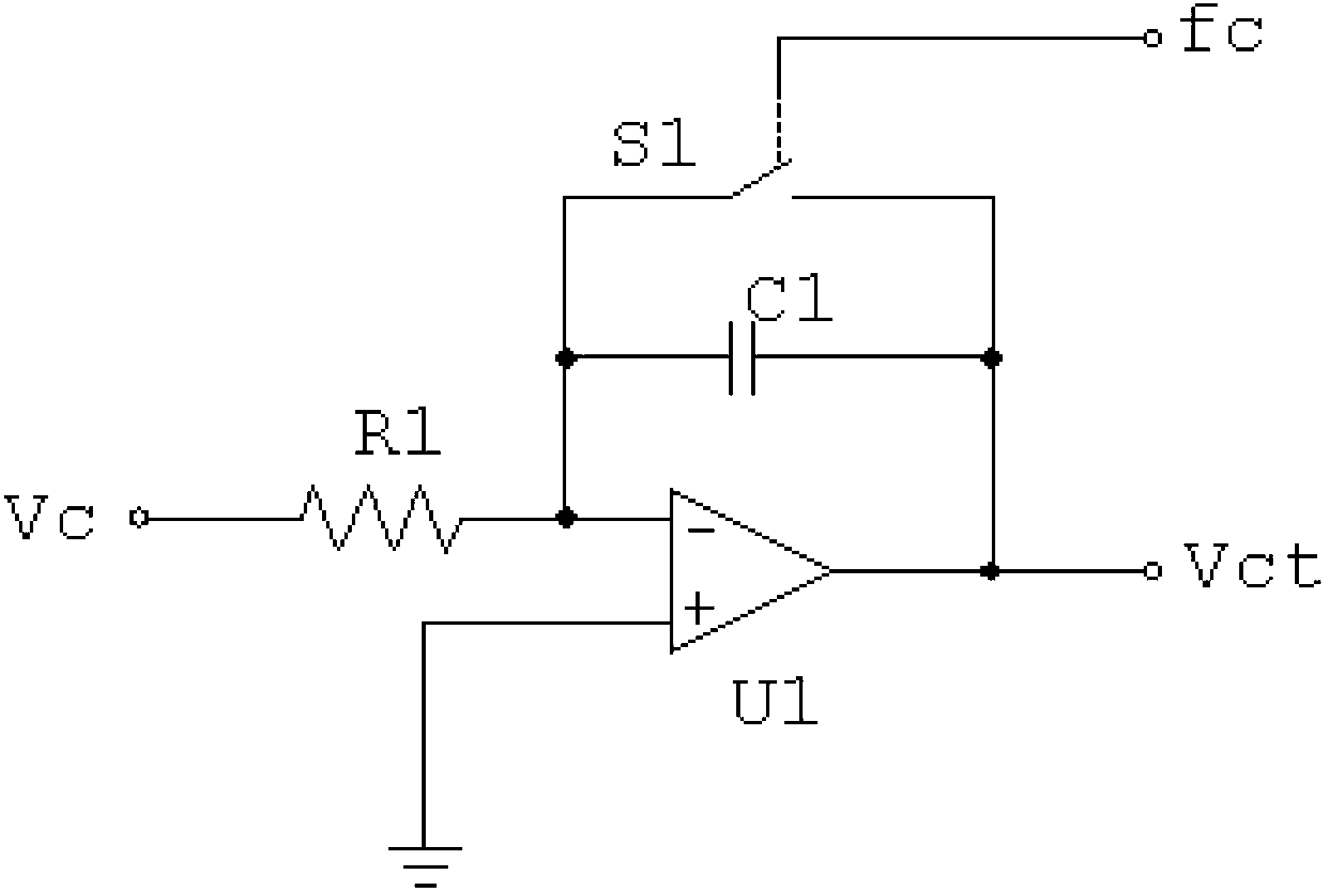

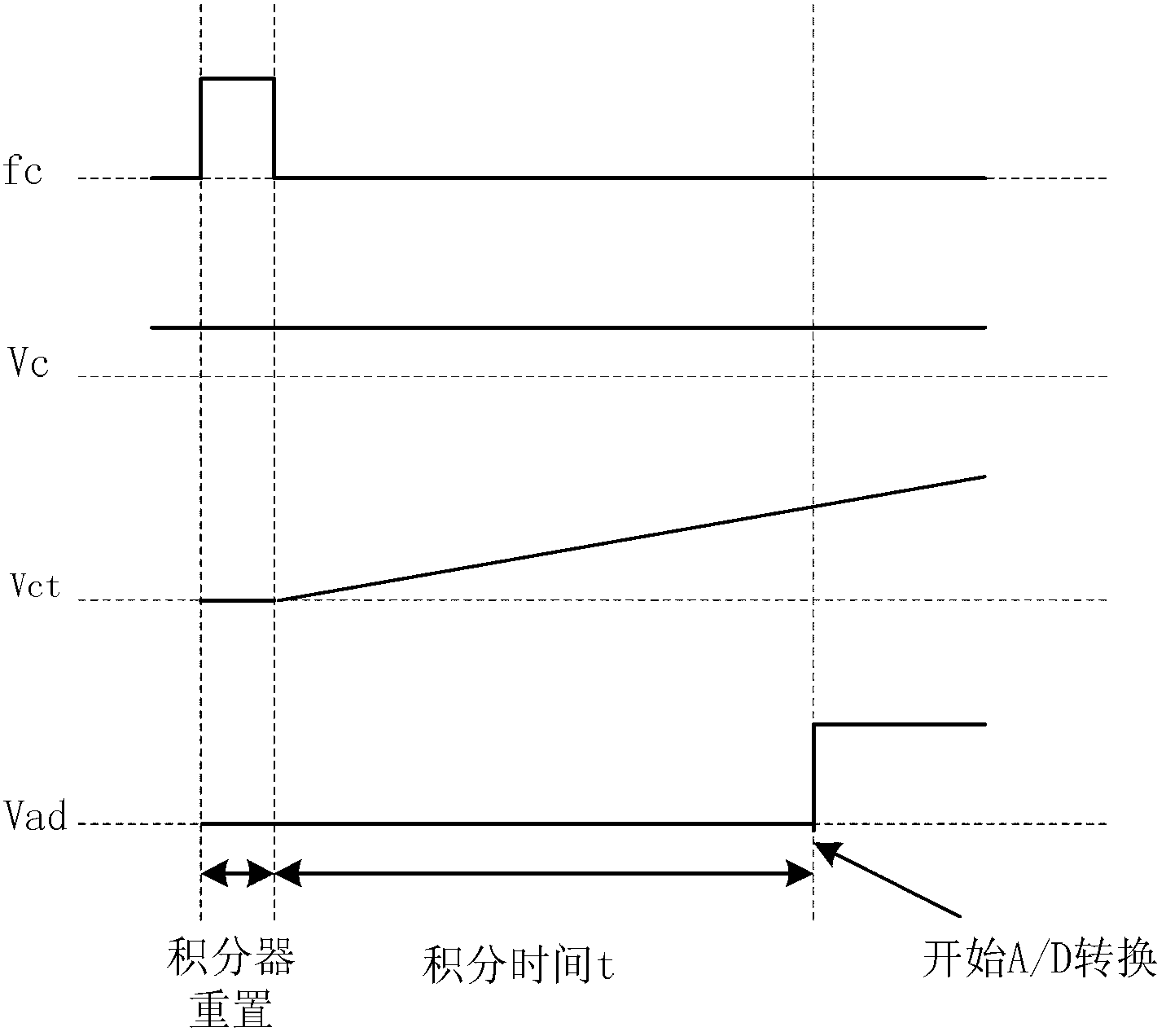

Lossless current detecting circuit based on digital correction

InactiveCN103267891ARealize continuous adjustmentThe detection output voltage does not changeMeasurement using digital techniquesPower conversion systemsEngineeringDigital control

The invention discloses a lossless current detecting circuit based on digital correction. The lossless current detecting circuit comprises a main power tube VT1, a detecting tube VT2 used for detecting a working current, a PWA driving circuit, a direct current driving circuit and a digital correction circuit. The main power tube VT1 is connected with a drain electrode of the detecting tube VT2, a source electrode of the detecting tube VT2 is connected with the ground, the PWA driving circuit is connected with a grid electrode of the main power tube VT1, and the direct current driving circuit is connected with a grid electrode of the detecting tube VT2. The lossless current detecting circuit based on digital correction introduces variable gain adjustment of digital control on the basis of connecting an impedance RDS detecting current and carries out real-time on-line correction on deflection of a detected voltage value under different temperatures so as to complete high precision lossless detection of the current. The lossless current detecting circuit based on digital correction has the advantages that the digital correction circuit of gain continuous adjustment is provided, real-time correction of deflection of a connected impedance RDS detecting voltage value under different temperatures is carried out, and high precision lossless detection of the current is ensured.

Owner:CHONGQING UNIV

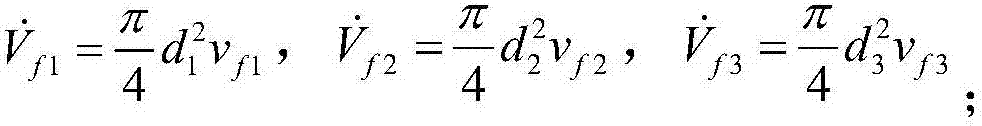

Additive manufacturing device and method for plasma arc gradient material of bypass hot wire consumable electrode

ActiveCN111168263AImprove Additive Deposition EfficiencyReduce welding heat inputAdditive manufacturing apparatusWelding apparatusElectric arcWelding power supply

The invention provides an additive manufacturing device and method for a plasma arc gradient material of a bypass hot wire consumable electrode. The device consists of an MIG welding power supply, a bypass hot wire consumable electrode plasma arc welding gun, an IGBT shunt controller, a workpiece, a current sensor and a current controller, wherein the MIG welding power supply, the bypass hot wireconsumable electrode plasma arc welding gun, the workpiece and the current sensor define a closed circuit; the MIG welding power supply, the bypass hot wire consumable electrode plasma arc welding gun, the workpiece, the IGBT shunt controller and the current controller define a closed circuit. The additive manufacturing device efficiently improves conventional electric arc welding basically, is controllable in heat input, is high in welding electric arc restraint intensity, and has the characteristics of low cost, high efficiency, high stability and the like of electric arc additive manufacturing.

Owner:HARBIN ENG UNIV

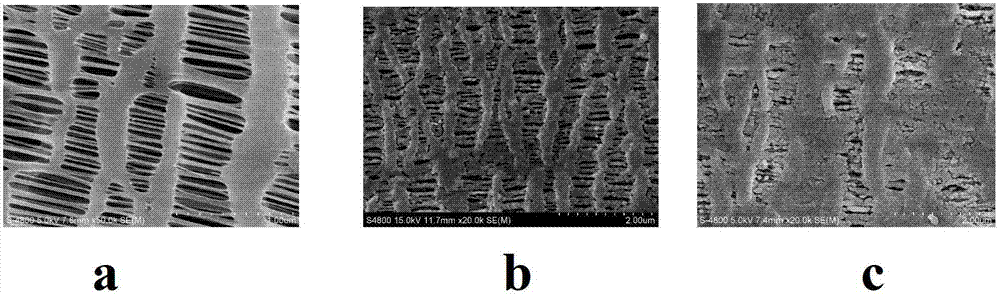

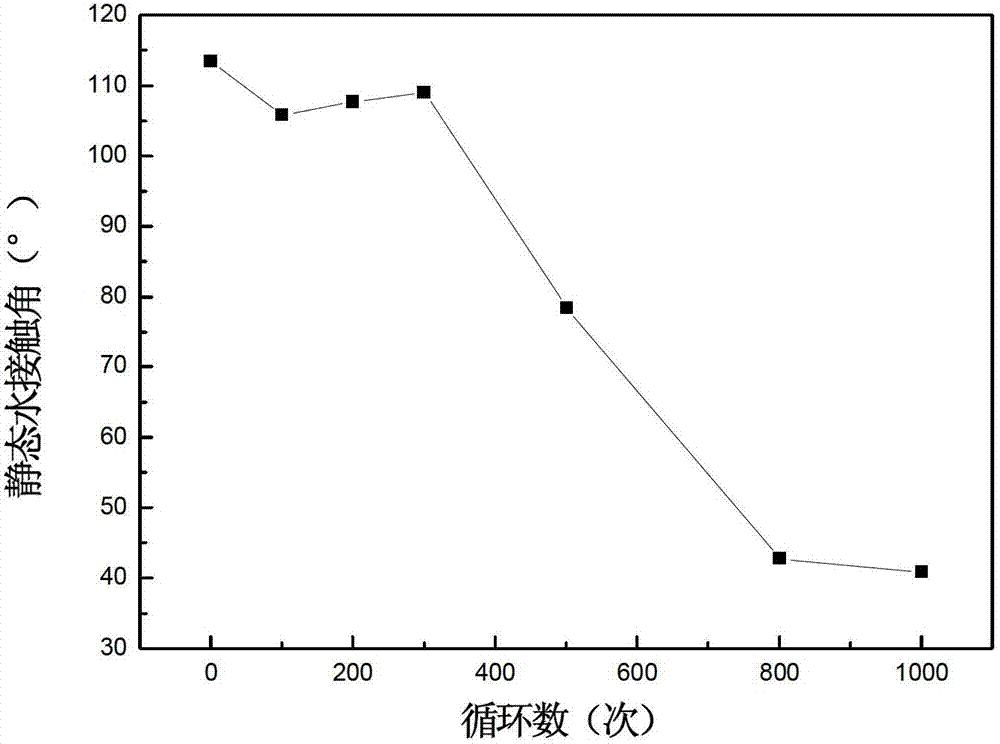

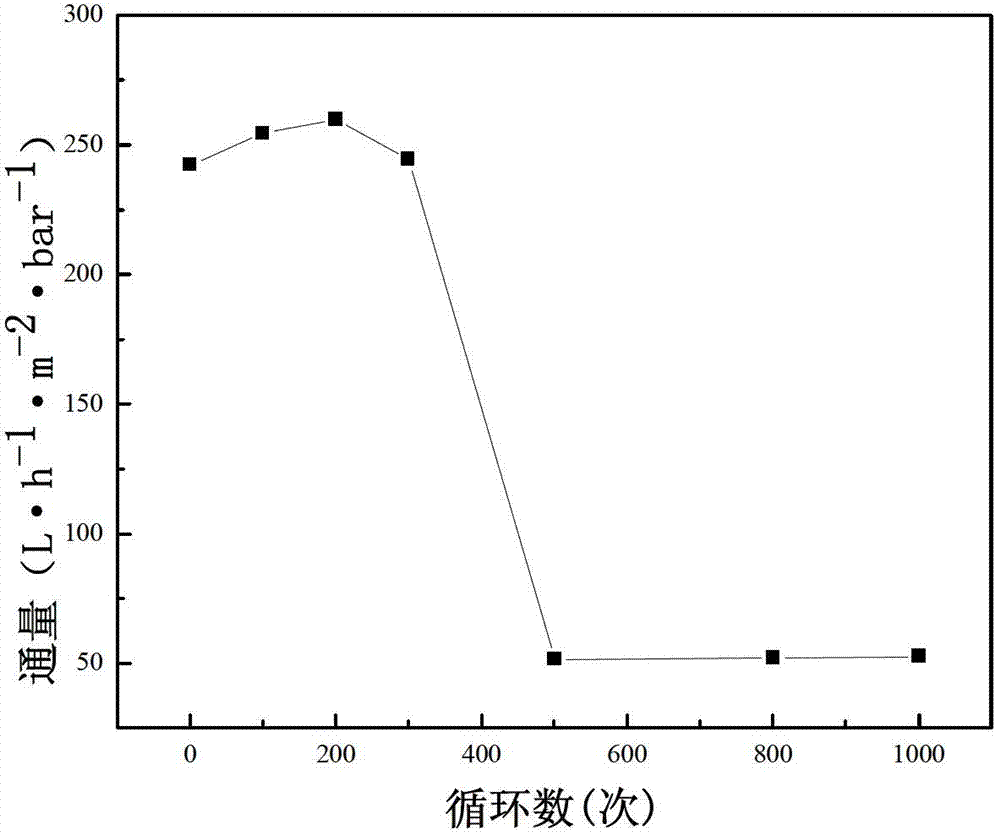

Method for modifying surface of polypropylene separation membrane

ActiveCN102728238AImprove surface propertiesImprove hydrophilicitySemi-permeable membranesPolypropyleneAtomic layer deposition

The invention relates to a method for modifying the surface of a polypropylene separation membrane, belonging to the field of membrane material. According to the method, the problems that the polypropylene separation membrane is poor in hydrophily, small in flux and easy to pollute can be solved; when the modified separation membrane is used as a lithium battery membrane, the performance and the safety of the lithium battery can be improved. According to the method, an oxide thin layer is continuously deposited on the channel surface of the PP separation membrane by using the atomic layer deposition, and the accuracy regulation of the aperture and the surface performance of the separation membrane are realized. The specific steps are as follows: (1) using acid, alkali, organic solvent and water to wash the PP (Propene Polymer) membrane, drying the PP membrane; (2) putting the PP membrane to a reaction chamber of an ALD (atomic layer deposition) instrument; vacuumizing and heating up to the deposition temperature; and maintaining temperature of the membrane for a certain time at set temperature; (3) pulsing metal source titanium tetrachloride or isopropyl titanate, cleaning air, water and cleaning air to the reaction chamber in sequence; and (4) preparing the modified membrane with needed performance by changing cycle indexes. According to the method, not only can the hydrophily, pure water flux and pollution resistance of the PP separation membrane be improved, but also the process is simple; and therefore, the batch production is realized easily.

Owner:NANJING UNIV OF TECH

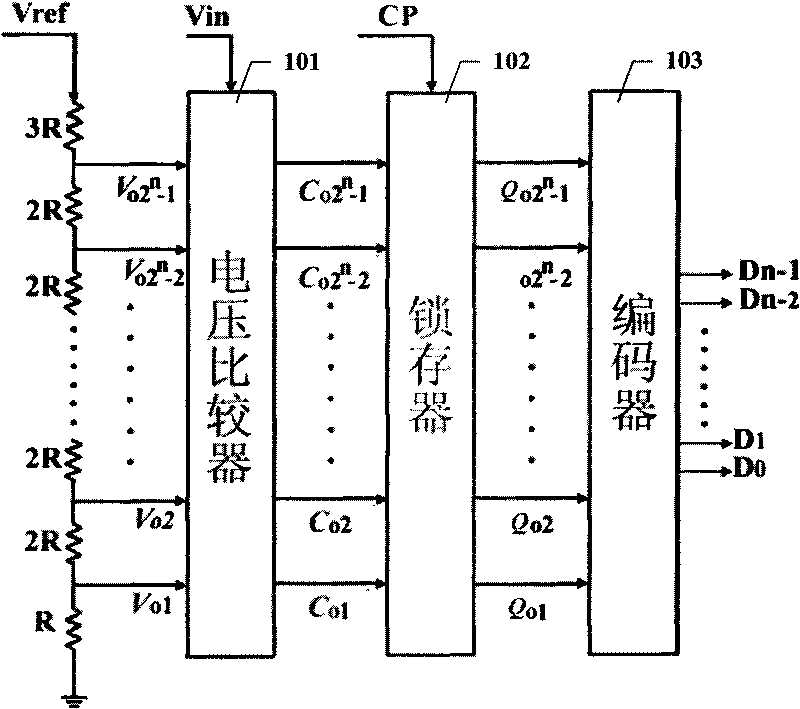

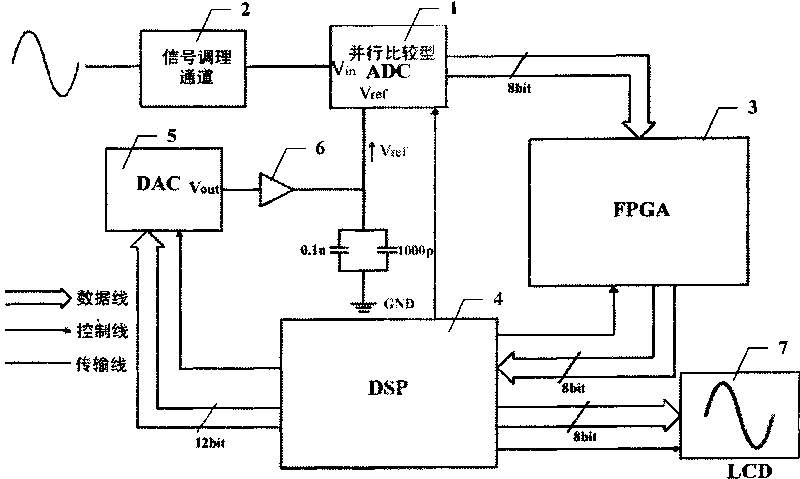

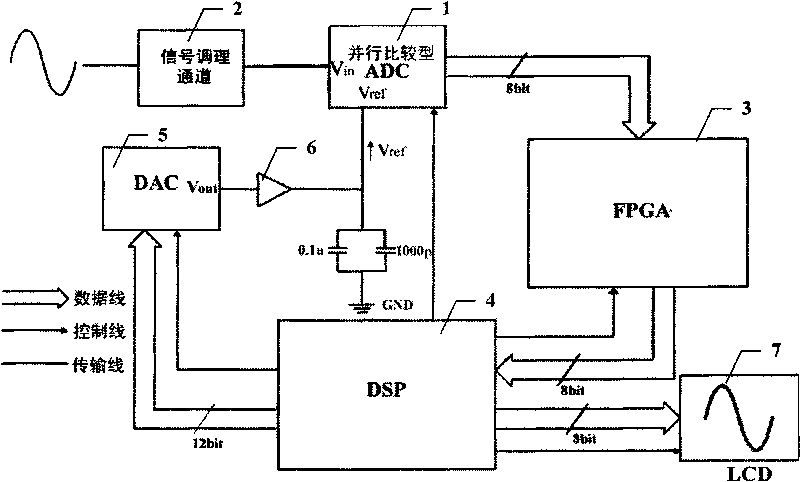

Digital storage oscilloscope with function of gain calibration

InactiveCN101706520AContinuous regulationAchieve correctionDigital variable displayVoltage referenceData memory

The invention discloses a digital storage oscilloscope with a function of gain calibration, which is characterized by comprising a DAC, wherein the DAC receives gain control words output by a processor, converts the gain control words into voltage, and outputs the voltage to a parallel comparison type ADC serving as the reference voltage of analog-digital conversion. During calibration, the gain control words are changed, so that the reference voltage of the analog-digital conversion of the parallel comparison type ADC is changed, and the quantized value of sampled data is adjusted, and the gain control words are updated until the difference between an actual amplitude quantized value and a theoretical amplitude quantized value is not more than a stated range; and in normal use, the gain control words are sent to the DAC and are converted into the voltage which serves as the reference voltage of the analog-digital conversion, acquisition data output by the analog-digital conversion is sent into a data storage device for storage, and then the acquisition data is read out by the processor for processing and displaying. The invention provides a scheme for adjusting the reference voltage of the analog-digital conversion to perform gain control, which can perform continuous adjustment on gains so as to improve the accuracy of the gain control and effectively achieve the calibration of the digital storage oscilloscope.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

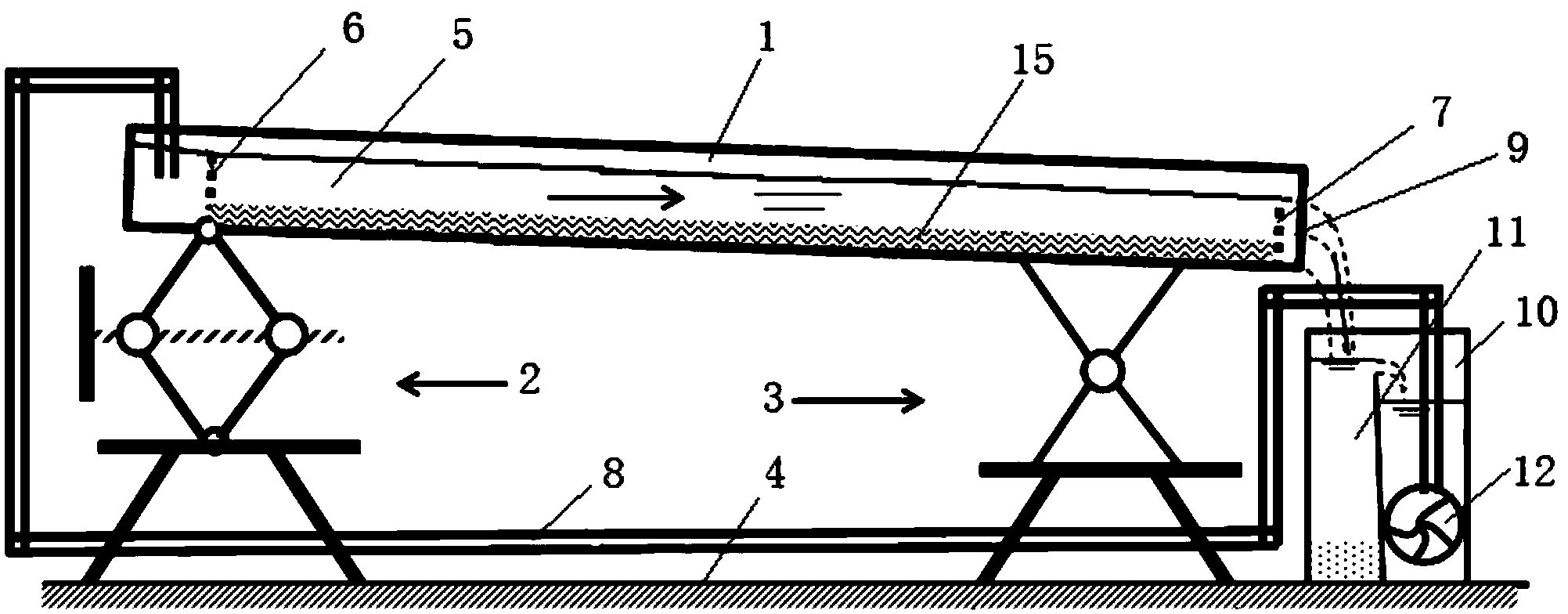

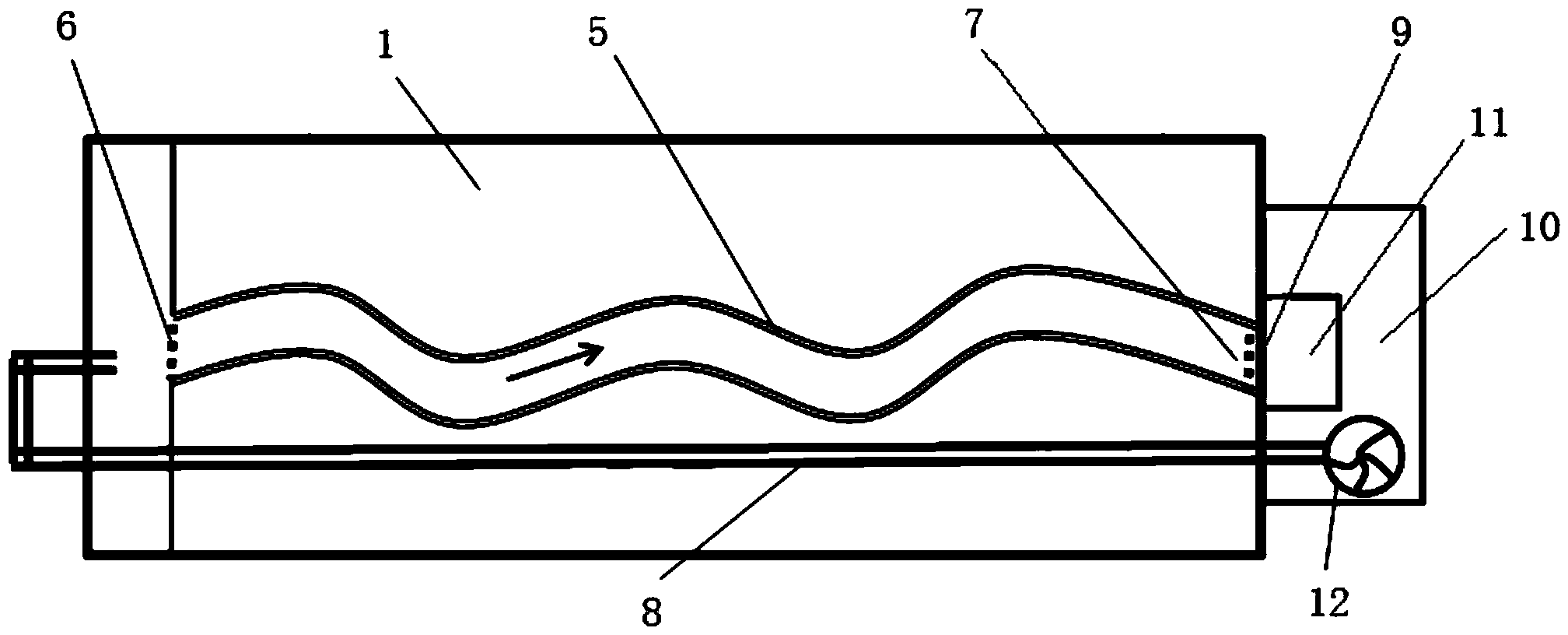

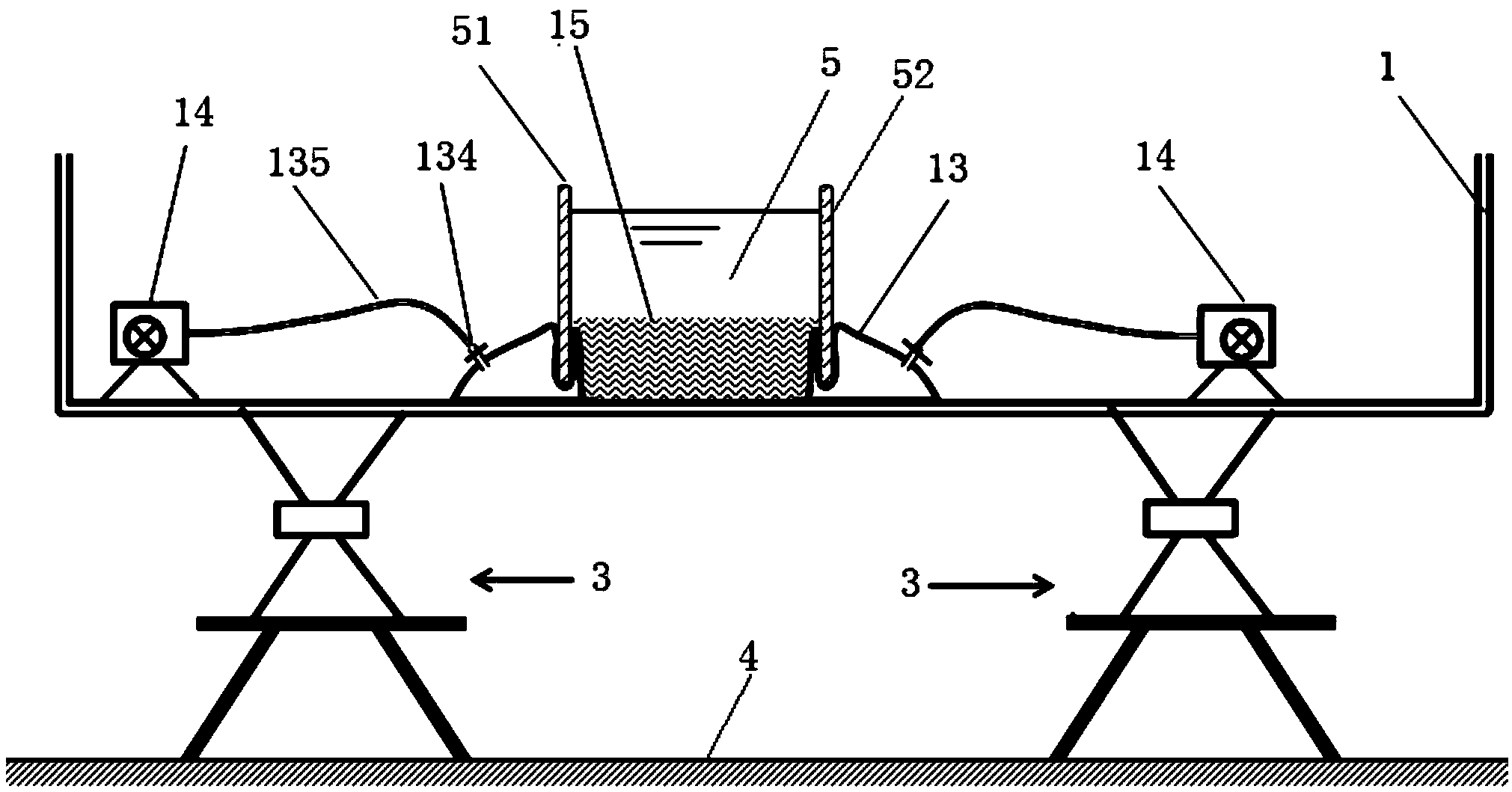

Deformable open channel curve water channel device for water flow silt experiment

InactiveCN103711101ARealize continuous adjustmentOptimize the adjustment methodHydrodynamic testingHydraulic modelsWater storagePipeflow

The invention discloses a deformable open channel curve water channel device for a water flow silt experiment. A curve water channel is arranged in an experimental pool in the length direction, a water channel inlet is formed in one end of the curve water channel, a water channel outlet is formed in the other end of the curve water channel, silt is arranged in the curve water channel, the portion, on one side of the water channel inlet, of the experimental pool is connected with one end of a water conveying pipeline, a water outlet is formed in the portion, on one side of the water channel outlet, of the experimental pool, a water storage tank is arranged below the water outlet, a desilting basin and a water pump are arranged in the water storage box, an upper end opening of the desilting basin is lower than an upper end opening of the water storage tank, the drainage end of the water pump is connected with the other end of the water conveying pipeline, two rotation adjusting mechanisms which are identical in structure are arranged on the portion, on one side of the experimental pool, of the bottom of the experimental pool, and two height adjusting mechanisms which are identical in structure are arranged on the portion, on the other side of the experimental pool, of the bottom of the experimental pool. According to the deformable open channel curve water channel device for the water flow silt experiment, the form of a curve can be easily and conveniently changed, the purpose that parameters such as the width and the curvature of the water channel can be adjusted at will is achieved, and the experiment conditions of curve water and silt are greatly improved.

Owner:TIANJIN UNIV

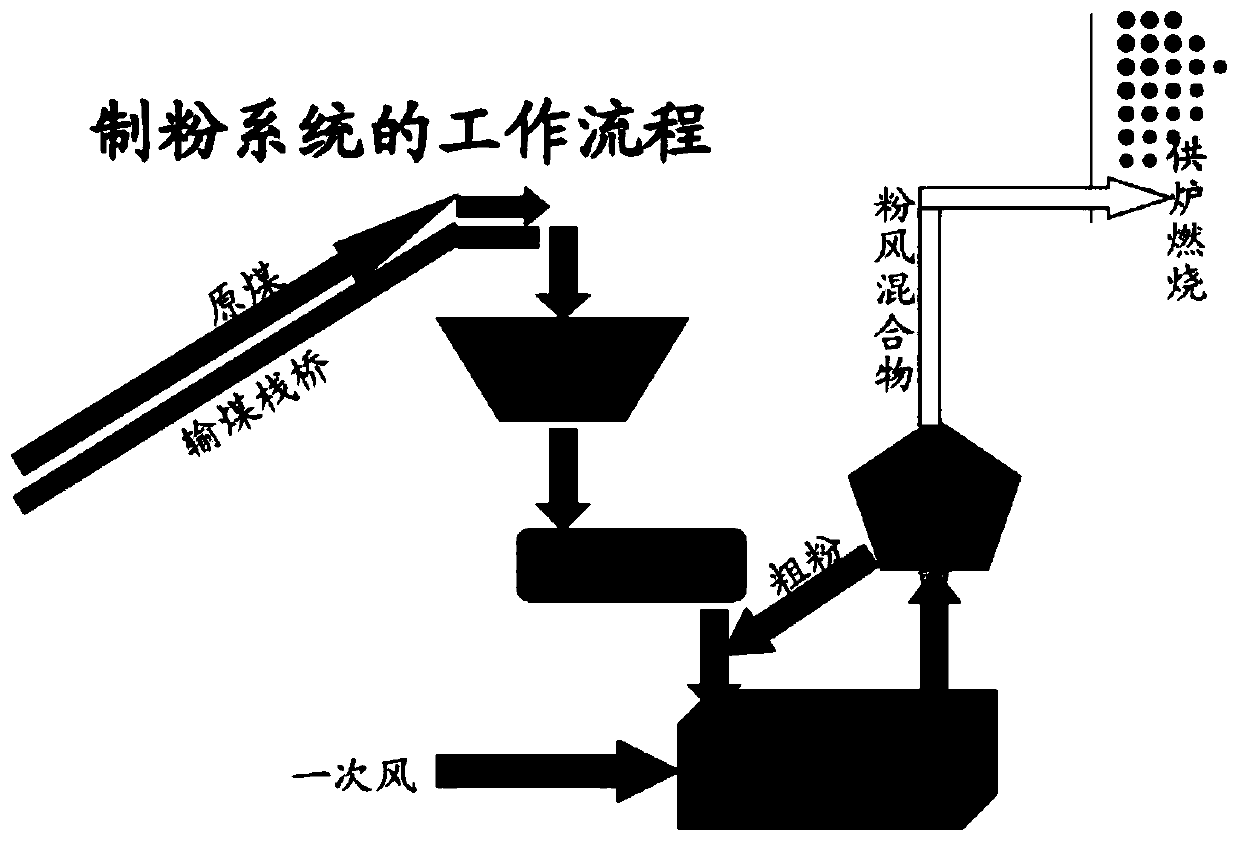

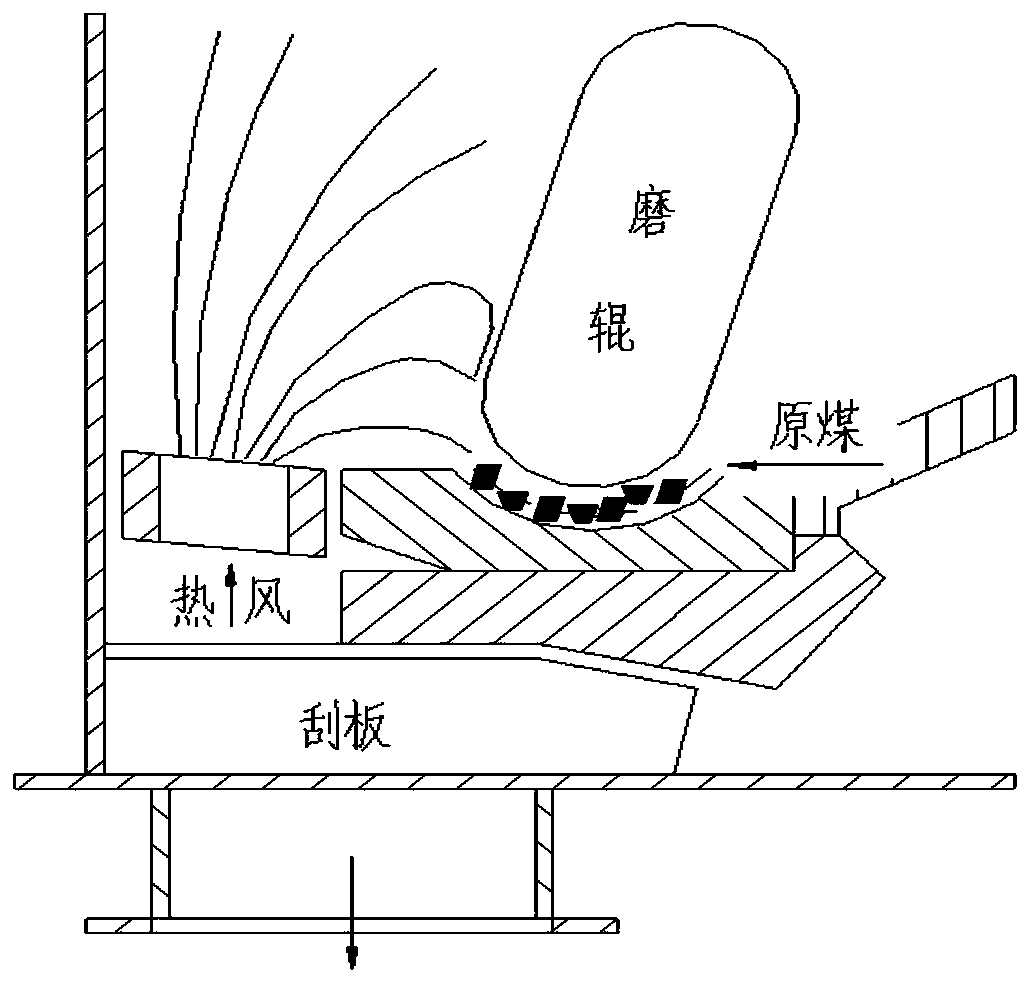

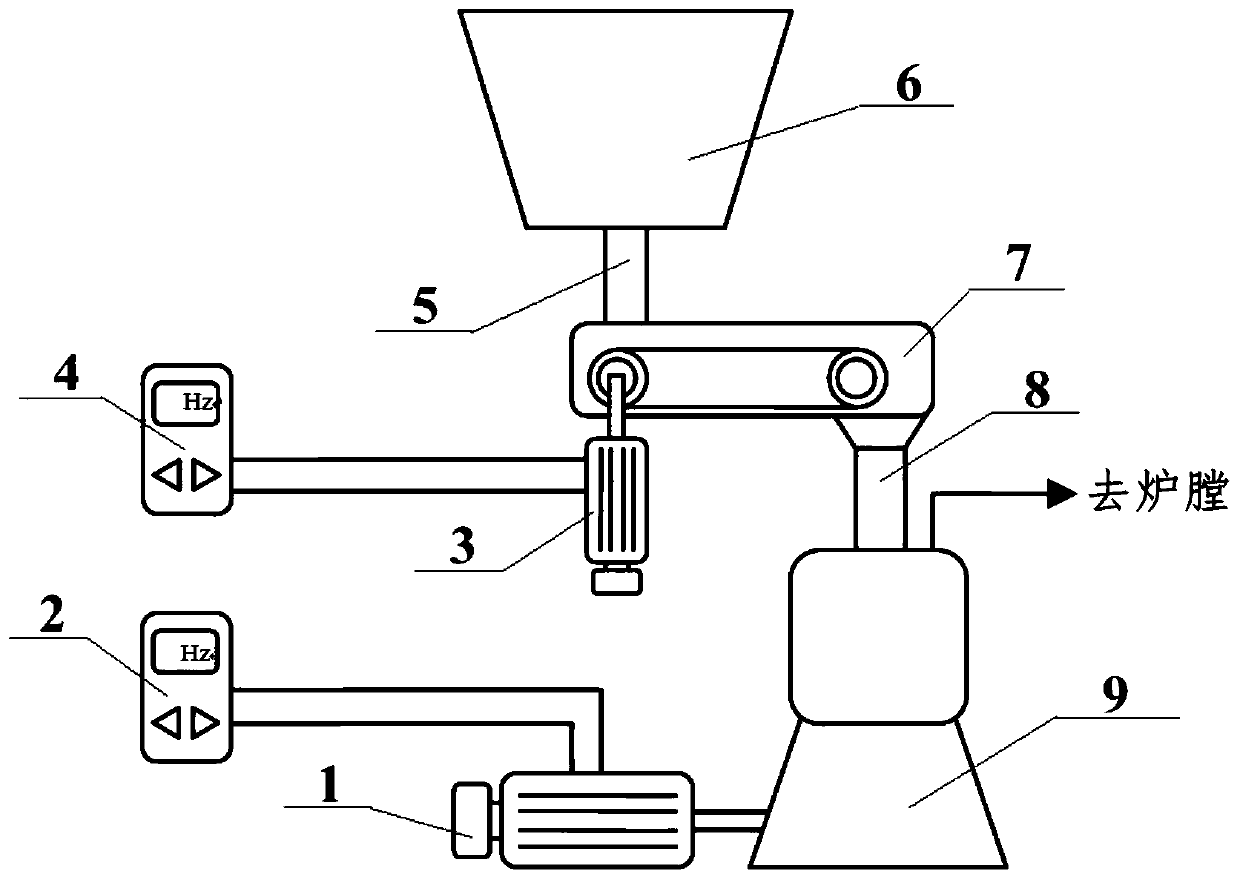

Full-variable-frequency pulverizing system without minimum coal quantity limitation and debugging method

PendingCN111515009ASafe and stable operationRealize continuous adjustmentGrain treatmentsFrequency changerElectric machine

The invention discloses a full-variable-frequency pulverizing system without minimum coal quantity limitation and a debugging method. A raw coal bunker communicates with a belt coal feeder through a coal discharging pipe, and the belt coal feeder communicates with a grinding disc of a roller type coal mill through a coal falling pipe; the grinding disc of the roller type coal mill is driven to rotate by a coal mill motor through a speed reducer, and the rotating speed of the coal mill motor is adjusted through a coal mill frequency converter; the rotating speed of the grinding disc is furtheradjusted, and the grinding force is adjusted; and the belt coal feeder is driven by a coal feeder motor, and the coal feeder motor is controlled by a coal feeder frequency converter 4 to realize speedregulation. The rotating speeds of the grinding disc of the coal mill and a belt of the coal feeder are cooperatively adjusted, so that deep matching of the coal feeding quantity and the grinding force is realized, then the minimum coal quantity limitation set by an existing belt coal feeder is completely cancelled, the force of the pulverizing system can be adjusted from zero, therefore, in thevariable load process of a boiler, the total coal quantity can not have jump-changes when the coal mill is increased or decreased, and thus the stable combustion and stable steam temperature and steampressure in the boiler are ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD

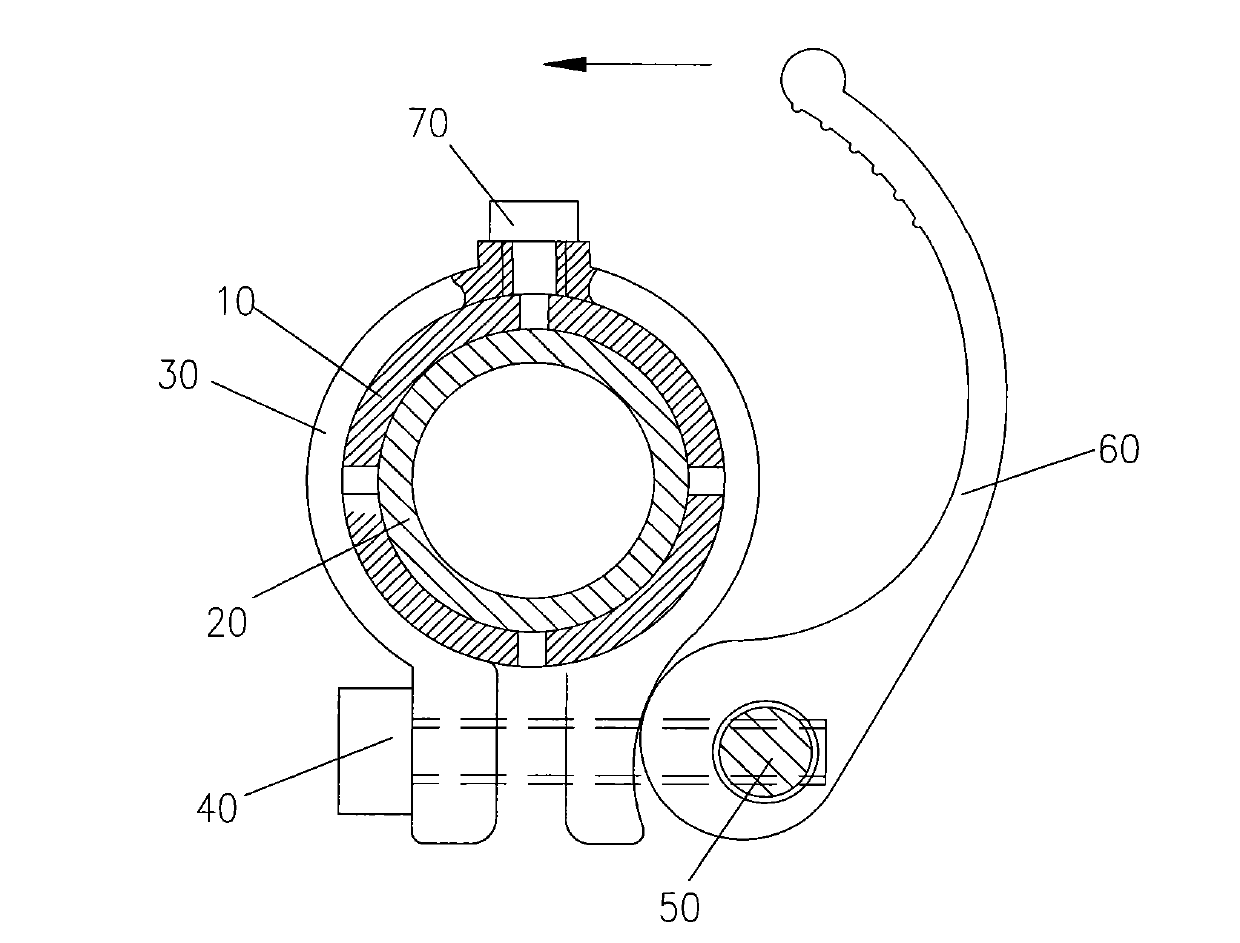

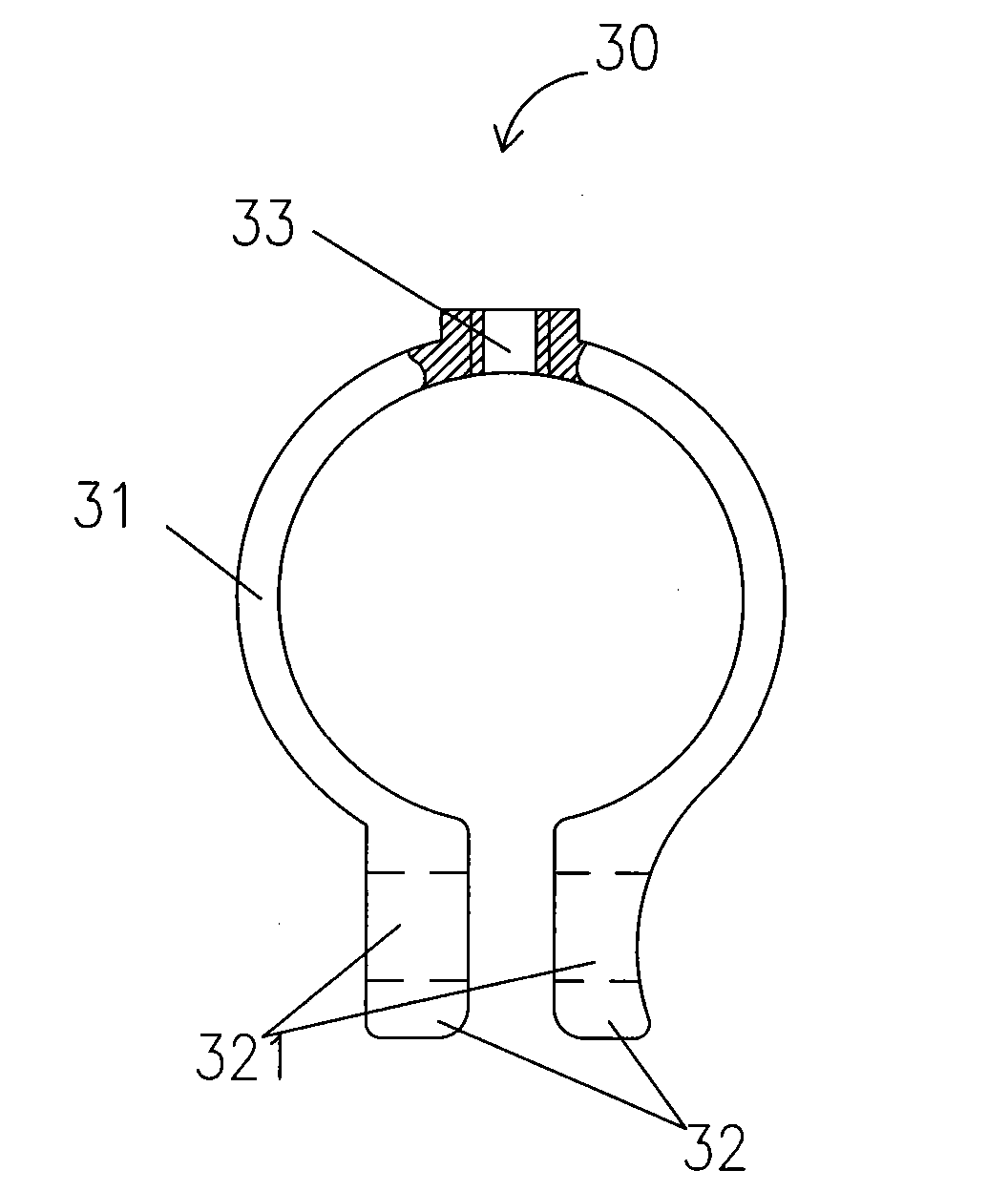

Lifting rod connecting structure and lifting rod

InactiveCN102562743AAdjust pressureImplement a locked connectionRod connectionsFriction grip releasable fasteningsEngineeringFastener

The invention relates to a lifting rod connecting structure and a lifting rod, wherein the lifting rod connecting structure comprises a lock hoop which is used for applying pressure an outer pipe so as to hold an inner pipe tightly, and the lock hoop is of a ring-shaped structure with openings; two opening ends of the lock hoop are correspondingly provided with fixed holes; locking screws are arranged in the fixed holes in a penetrating manner; the tail ends of the locking screws are connected in screw holes of a rotating shaft so as to lock the opening ends of the lock hoop tightly; a hand fastener is relatively rotatably connected to the rotating shaft, and the outer edge of one end, which is connected with the rotating shaft, of the hand fastener is set as a continuous curved surface tangential to the outer surfaces of the opening ends of the lock hoop; the distances from points on the continuous curved surface to the center of the rotating shaft are unequal so as to apply pressure with different sizes on the opening ends of the lock hoop and adjust the size of the pressure applied by the lock hoop on an outer pipe. The lifting rod connecting structure has the advantages that the design is simple, the processing and manufacturing cost is low, the installation and the use are convenient, and the continuous adjustment of the height can be realized.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

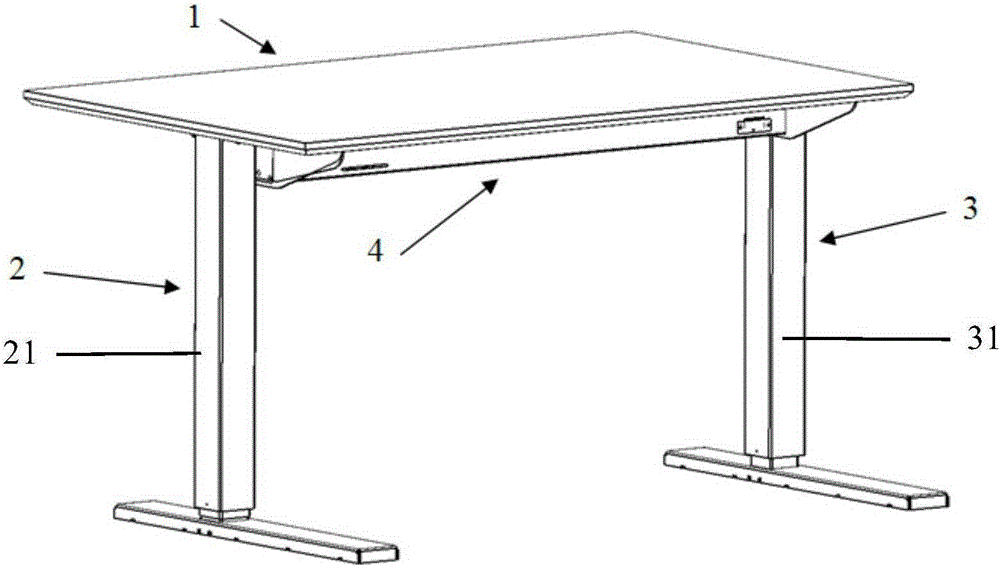

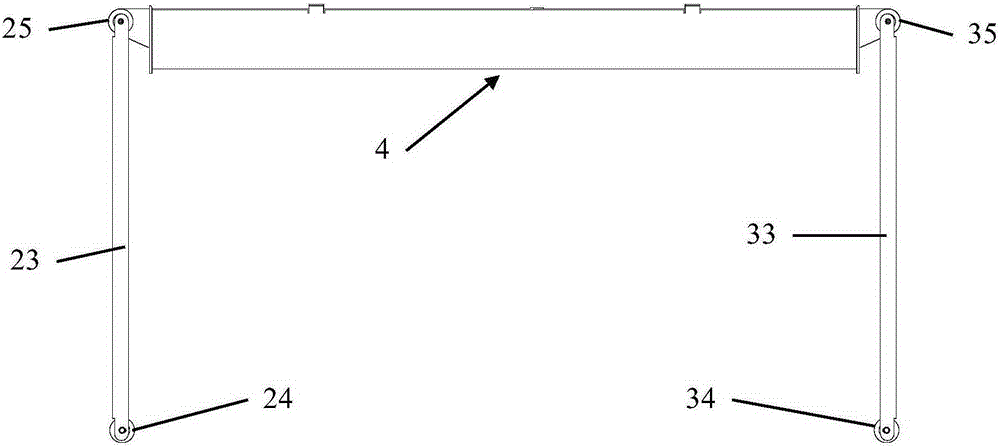

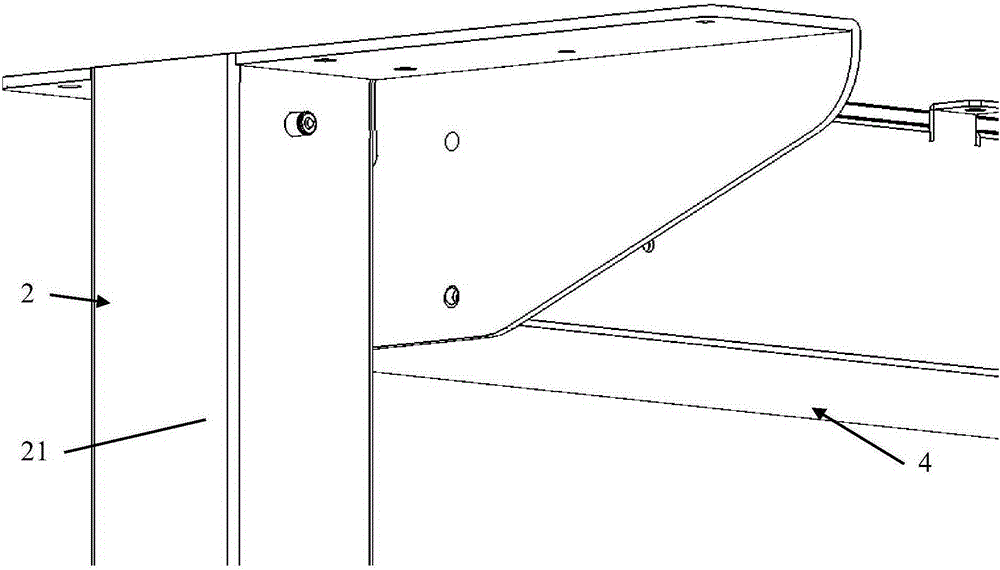

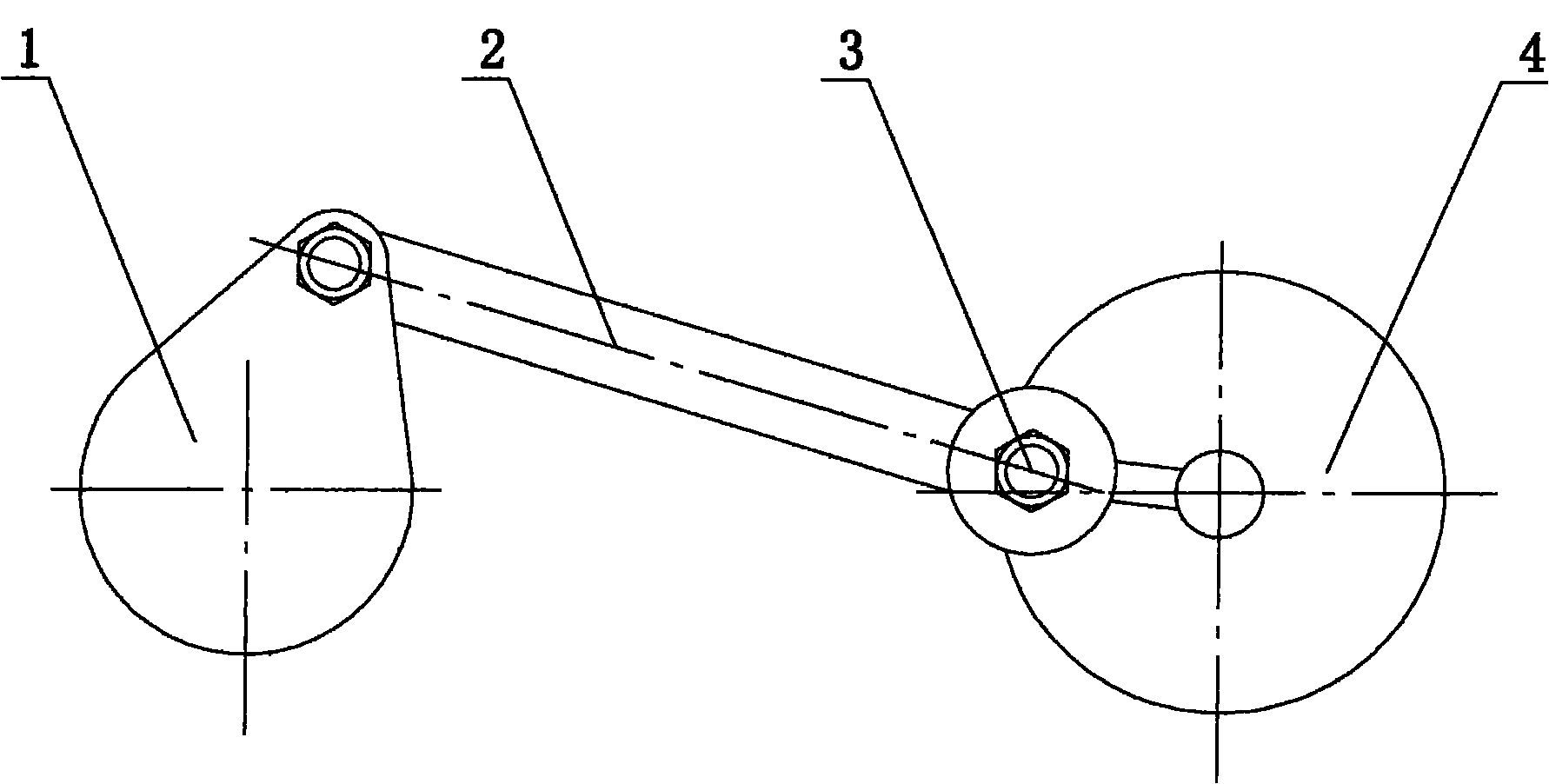

Manual lifting table

ActiveCN105231661ARealize continuous adjustmentOperation saves time and effortVariable height tablesEngineeringPulley

The invention relates to a manual lifting table which comprises a first supporting component, a second supporting component and a table top, wherein the first supporting component and the second supporting component are fixedly connected with the table top; the manual lifting table further comprises a first power wire rope and a driving cabin fixedly connected with the table top; the first supporting component comprises a first inner tube, a first external tube and a first lifting rod; a first lifting pulley is arranged at a free end of the first lifting rod; a first power deflecting pulley is arranged at a fixed end of the first lifting rod; the first power wire rope is provided with a first input end and a first output end fixedly connected with the first inner tube; the first output end is fixedly connected with the first inner tube; the first power wire rope is connected with the first power deflecting pulley by striding across the first lifting pulley. The manual lifting table has the advantages that the height of the table top can be continuously regulated, the operation process is time-saving and labor-saving and the table top can be randomly adjusted to the required height and stopped at the required height.

Owner:SHANGHAI TENGFEI COMM EQUIP IND CO LTD

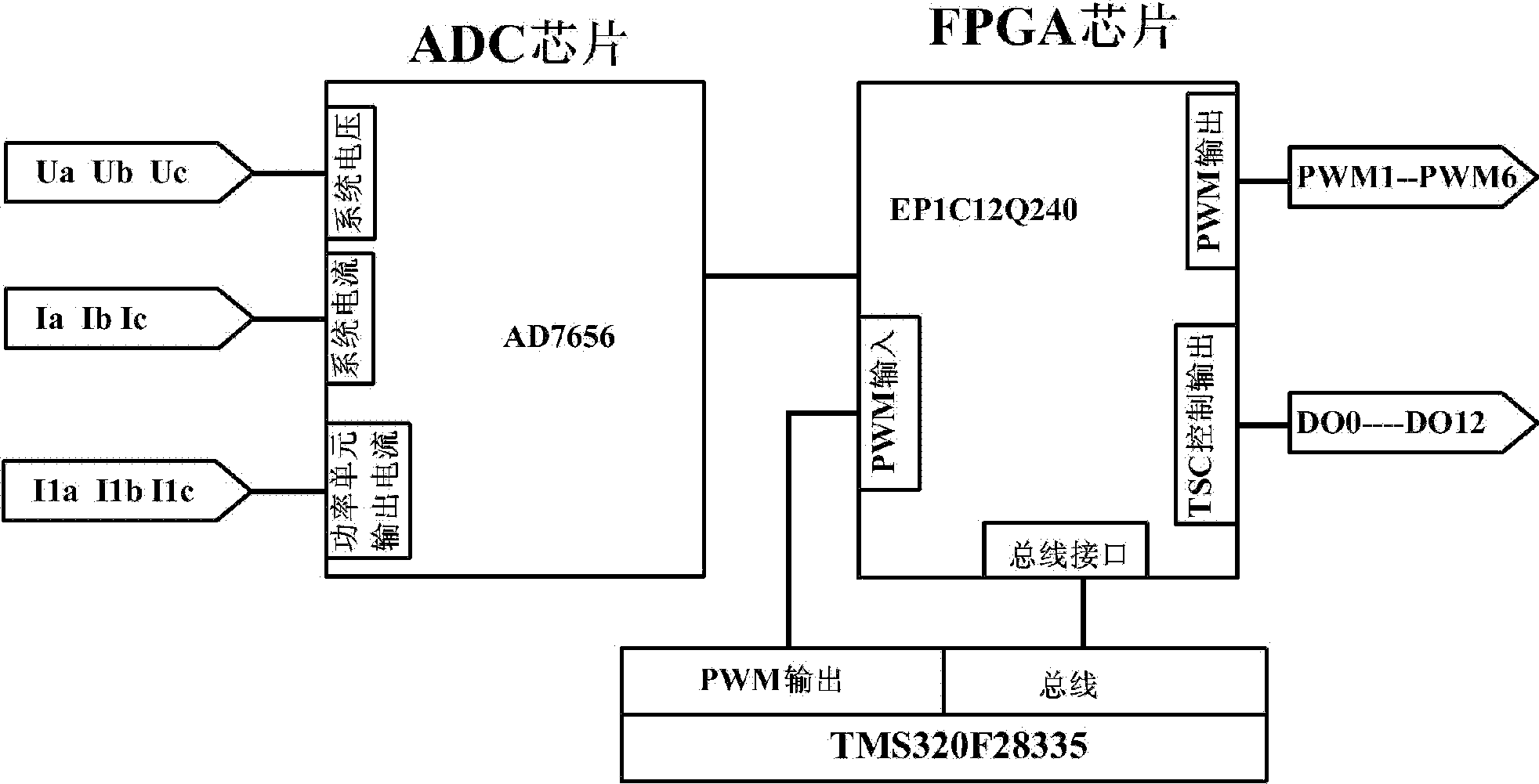

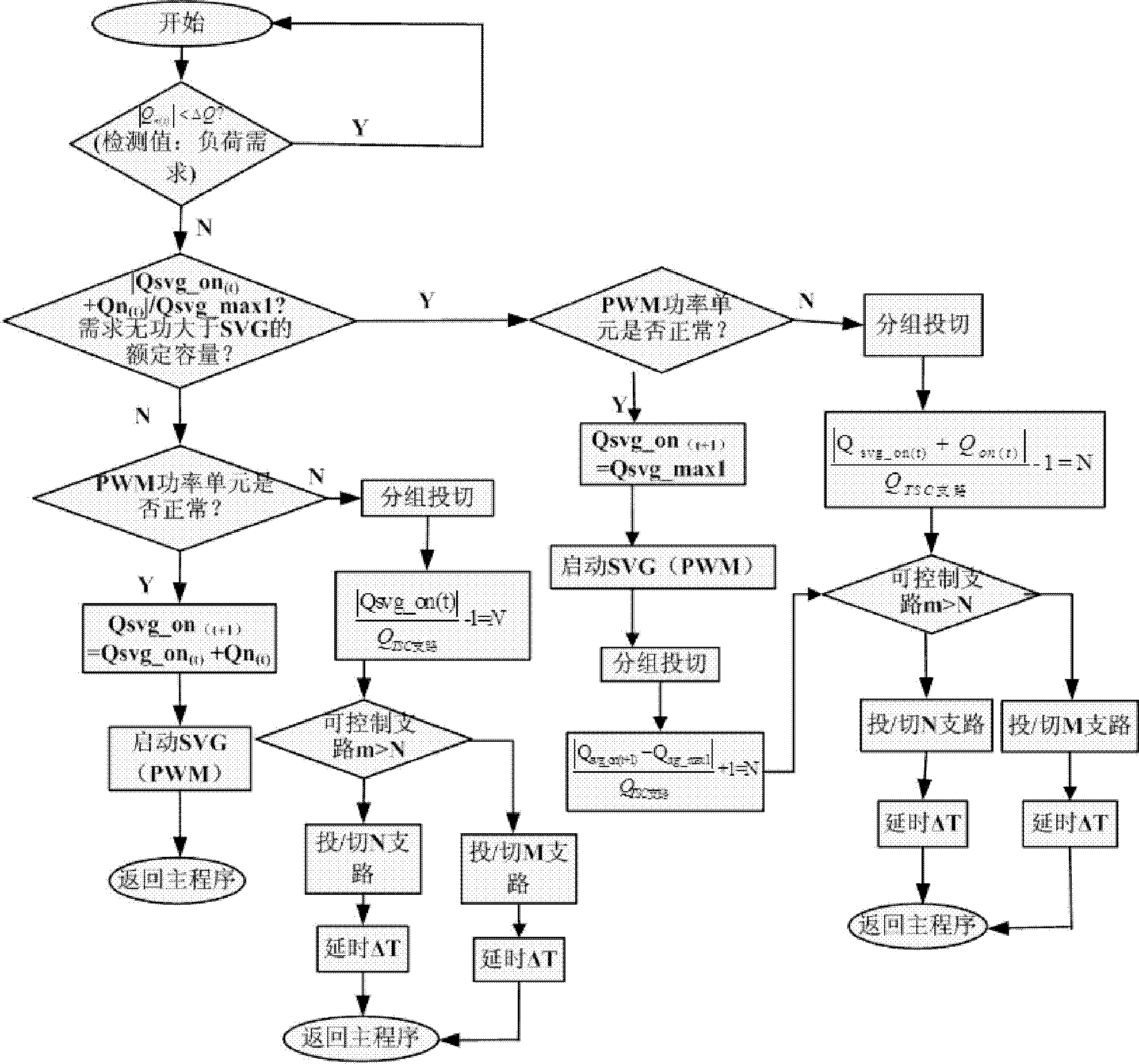

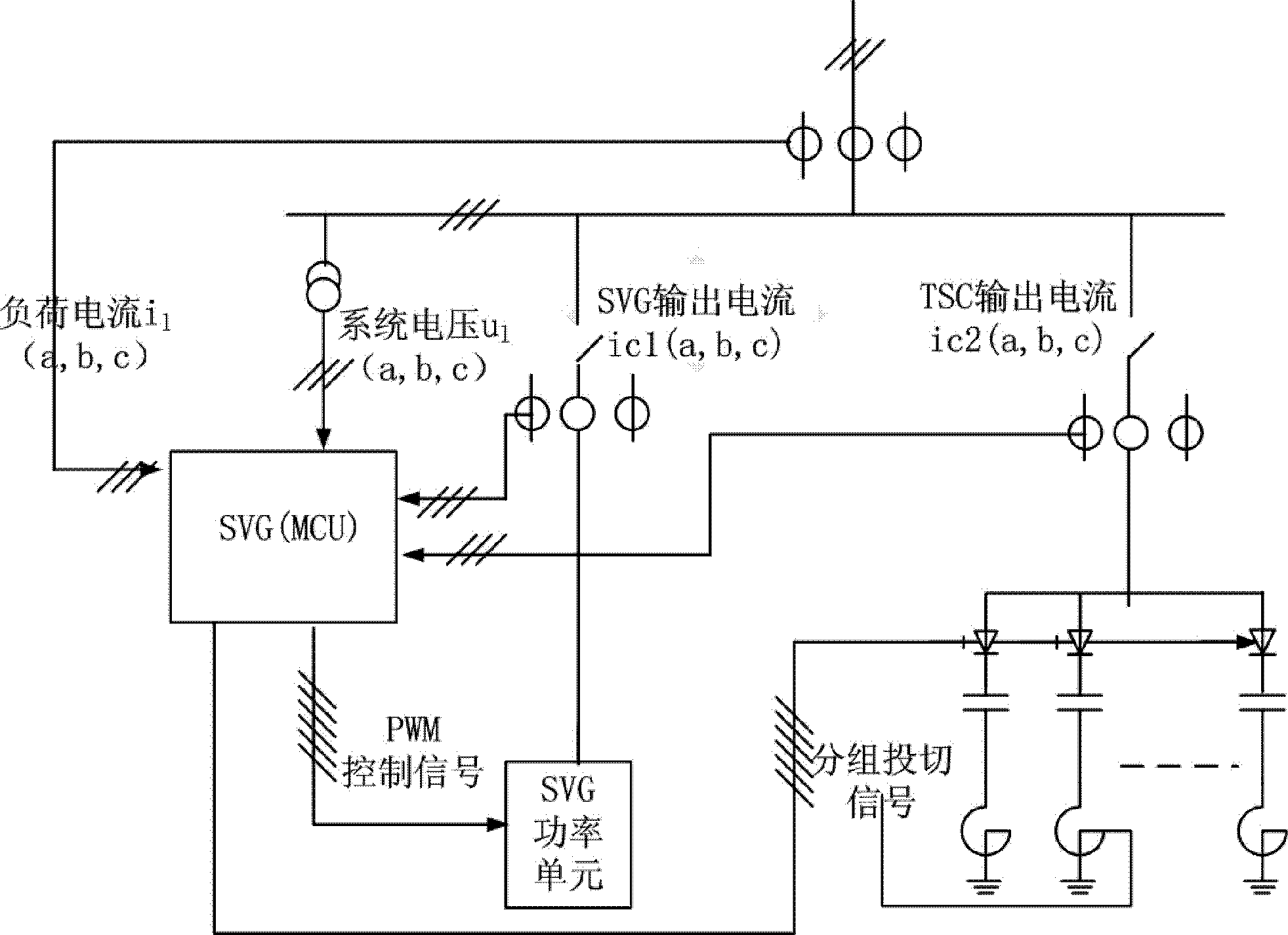

Method for carrying out intelligent control on dynamic reactive power compensation of SVG (TSC) (static var generator (thyristor switched capacitor))

InactiveCN102684203ASolve the problem of reversing reactive powerSolve voltage fluctuationsFlexible AC transmissionReactive power adjustment/elimination/compensationPower compensationElectric power system

The invention discloses a method for carrying out intelligent control on the dynamic reactive power compensation of a SVG (TSC) (static var generator (thyristor switched capacitor)), which comprises the following steps of: controlling the SVG and the TSC by using a master control unit; carrying out centralized sampling, calculation and control by using the master control unit, and automatically adjusting to adopt a reactive power compensation mode of the SVG and adopt a reactive power compensation mode of the TSC; and preferably starting the reactive power compensation mode of the SVG, and when the SVG has a fault, adopting the reactive power compensation mode of the TSC. When the reactive power demand of a system is instantly changed dynamically, the SVG starts a PWM (pulse-width modulation) control program at a predetermined response speed firstly, and then outputs compensation currents so as to rapidly and dynamically adjust the variable quantity of reactive power; and when the load of the electric power system is changed within a large range and exceeds the capacity of the SVG, a grouping switch function of the TSC is started so as to compensate the reactive power demand of the system. The method for carrying out intelligent control on the dynamic reactive power compensation of the SVG (TSC), disclosed by the invention, has the advantages that: the response speed of reactive power compensation can be improved, an effect of carrying out dynamic and continuous adjustment on reactive power can be achieved, and the like.

Owner:安徽华祝电气技术有限公司

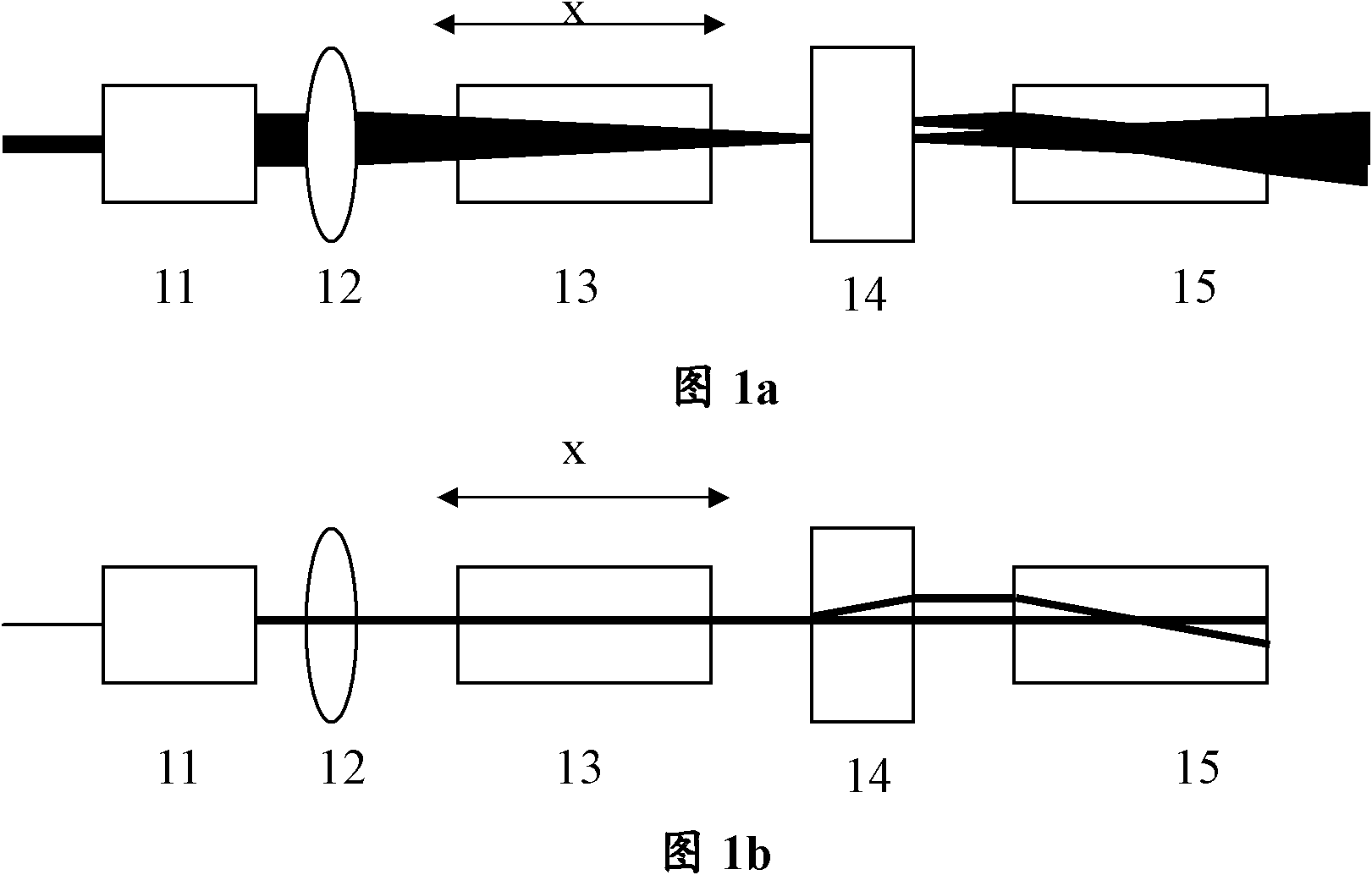

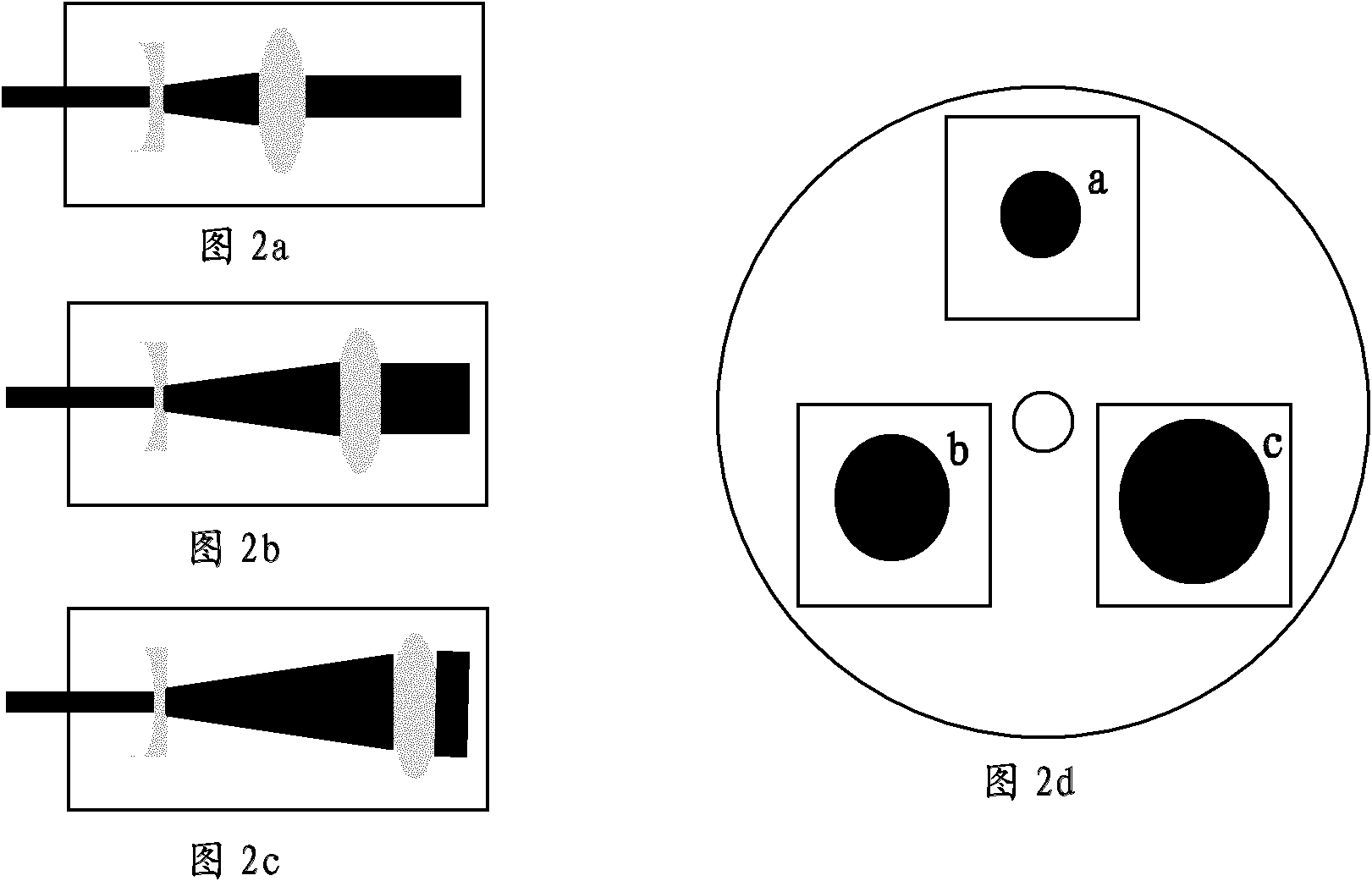

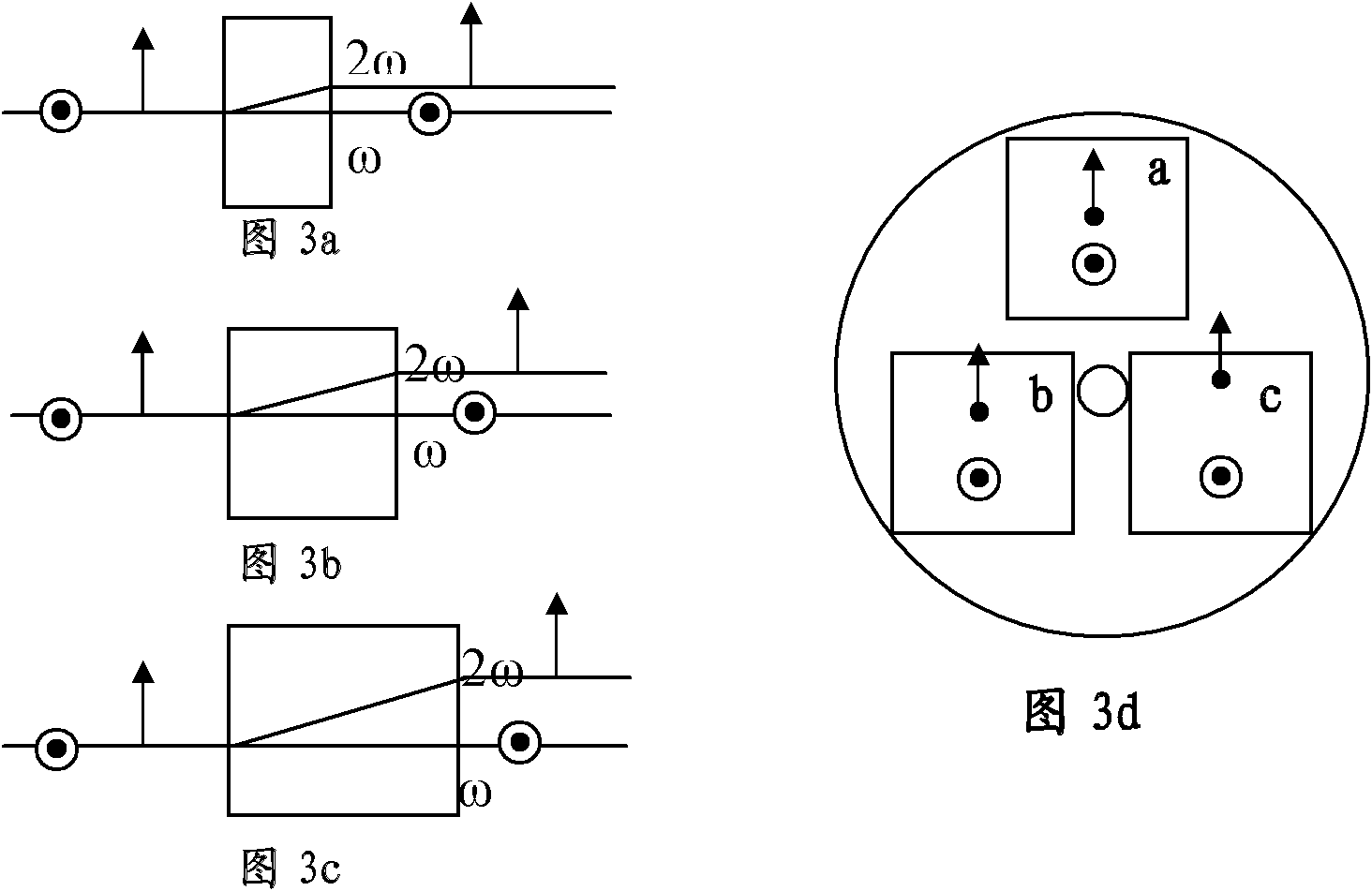

Laser triple frequency system

InactiveCN101986484AEasy to findImprove laser conversion efficiencyLaser detailsNonlinear opticsBirefringent crystal

The invention discloses a laser triple frequency system, which belongs to the field of nonlinear optics. The system mainly comprises a focusing system, a frequency doubling system, a frequency summing system, a base frequency light power density adjusting device and a deviation compensating device, wherein base frequency laser enters the frequency doubling system after being focused by the focusing system so as to generate double frequency light in the frequency doubling system; the double frequency light and the remaining base frequency light enter the frequency summing system together so as to generate triple frequency light; the base frequency light power density adjusting device is arranged in front of the focusing system and can continuously adjust the power density of the base frequency light; and the deviation compensating device is arranged between the frequency doubling system and the frequency summing system and can continuously adjust a deviation compensating value. The laser power density and deviation compensation dosage are optimized, so that a higher triple frequency conversion efficiency is obtained; simultaneously, a doubly refracting crystal or dispersion glass is taken as the deviation compensating device, so that the cost of the triple frequency system can be lowered greatly.

Owner:DAHENG NEW EPOCH TECH

Adjustable ultralow-frequency vertical eddy current tuned mass damper (TMD)

ActiveCN110984418AMagnification mass ratioImprove vibration damping effectProtective buildings/sheltersShock proofingElectrical conductorClassical mechanics

The invention discloses an adjustable ultralow-frequency vertical eddy current tuned mass damper (TMD) and belongs to the technical field of structural vibration control. The ultralow-frequency vertical eddy current TMD comprises a base, a rigid framework, a rigid framework cross beam, a mass block position adjusting rod, a first nut, a second nut, a mass block, a permanent magnet fixed plate, a permanent magnet set, a conductor copper plate, a magnetic conductive steel plate, a first linear guide rail, an inerter-damping system, a coil spring and a second linear guide rail. The actual physical mass of the TMD is reduced by the inerter-damping system, and the problem of net elongation of a spring of an ultralow-frequency vertical eddy current is too large is solved; the device frequency isadjusted continuously by adjusting the distance between the mass block and a fixed reamer; and an eddy current damping technology is adopted, and the device damping is adjusted continuously by adjusting the distance between the permanent magnet set and the conductor copper plate. In addition, the device has the advantages of simple assembly, easy-to-adjust frequency and damping, good durability and the like.

Owner:SOUTHEAST UNIV

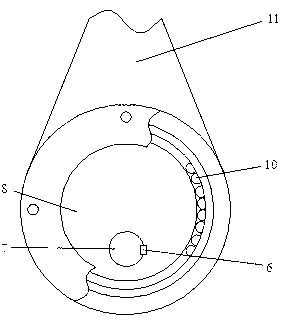

Inertial container device with continuously-adjustable inertia coefficient

The invention provides an inertial container device with a continuously-adjustable inertia coefficient. The inertial container device comprises a driving wheel, a driven wheel, a gear, a rack / flywheel / hydraulic pump, a driving wheel hydraulic control cylinder and a driven wheel hydraulic control cylinder, wherein a V-shaped groove is formed between the movable part and the fixed part of the driving wheel; the gear is arranged on a driving shaft, and is meshed with the rack; a V-shaped groove is formed between the movable part and the fixed part of the driven wheel; the flywheel is arranged on a driven shaft; the driven wheel is driven by an elastic metal belt arranged in the two V-shaped grooves; the movable parts of the driving wheel and the driven wheel are driven by the driving wheel hydraulic control cylinder and the driven wheel hydraulic control cylinder which are connected with a hydraulic pump respectively. The engagement radius of the metal belt is adjusted through axial movement of the movable part of the driving wheel and the movable part of the driven wheel, so that the transmission ratio between the driving wheel and the driven wheel is adjusted, and continuous adjustment of the inertia coefficient is realized.

Owner:JIANGSU UNIV

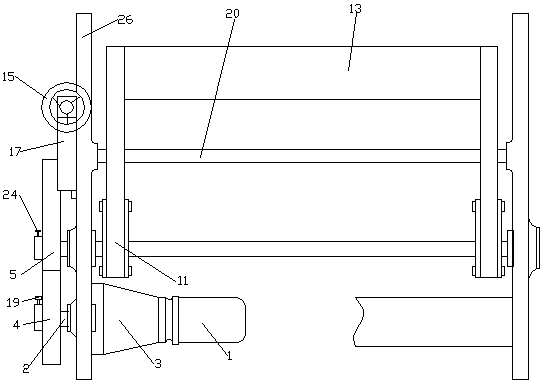

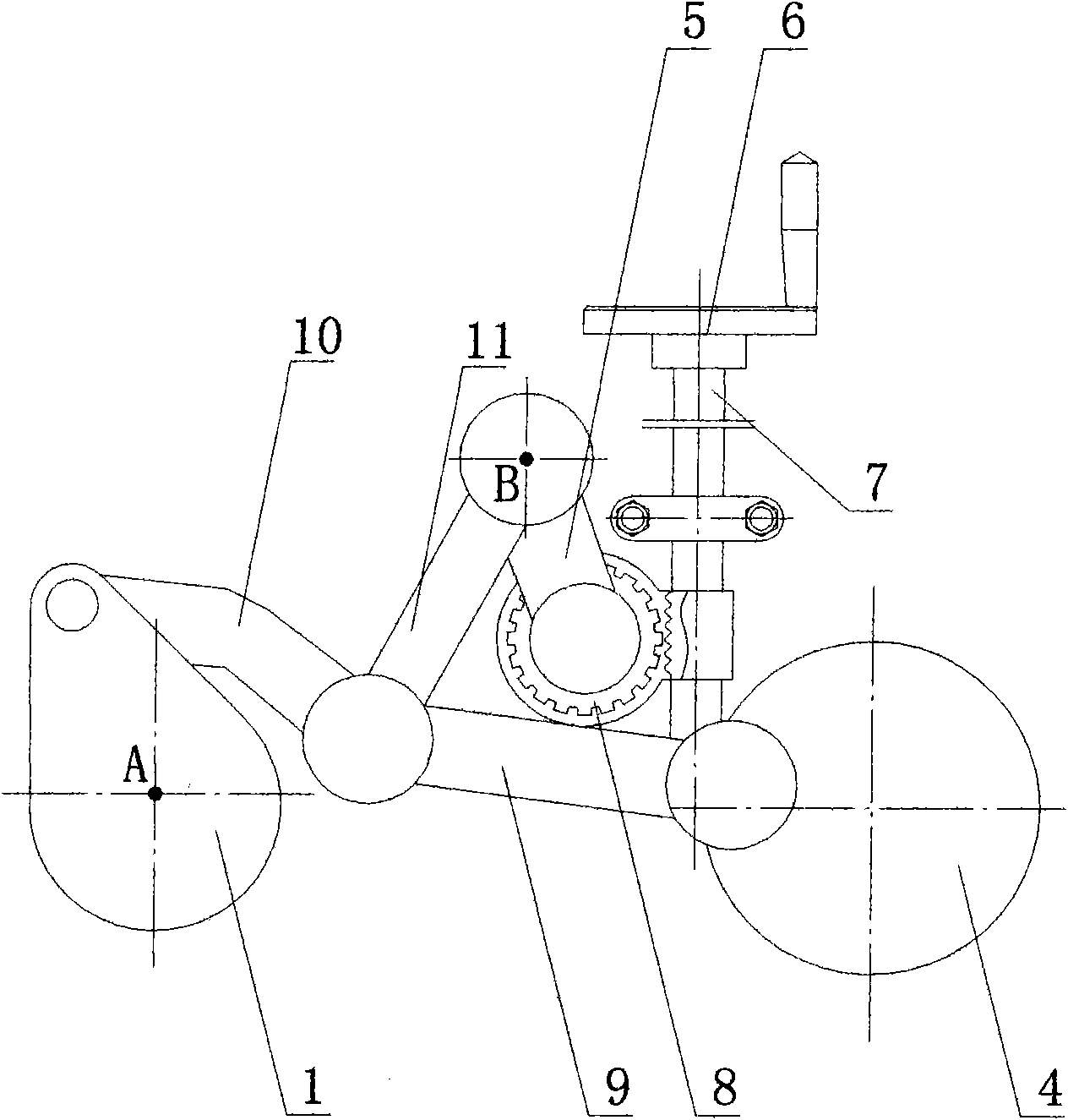

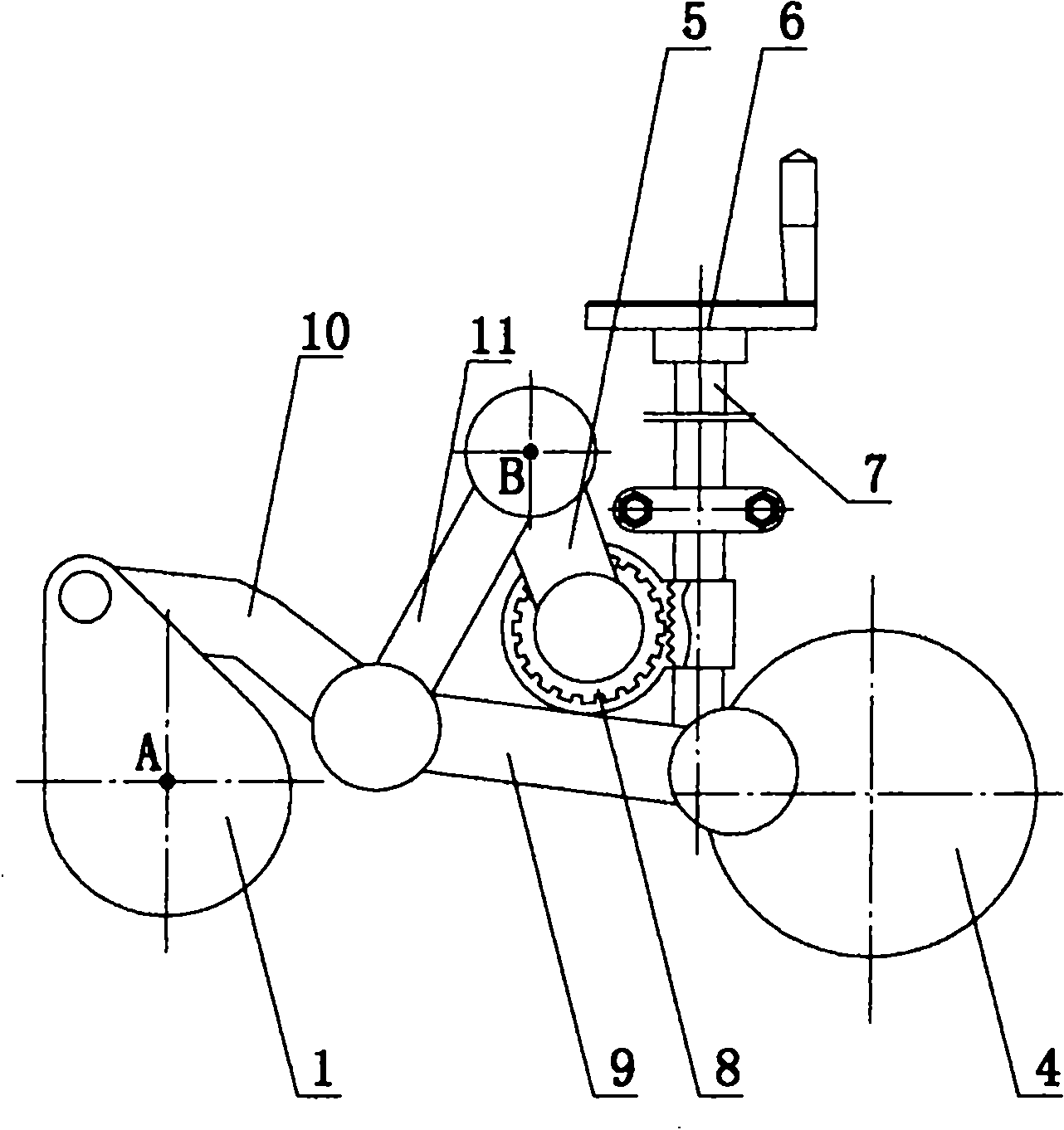

Novel plate shearer based on optimized crank-rocker mechanism

ActiveCN103240456ARealize continuous adjustmentExtended service lifeShearing machinesDrive shaftAgricultural engineering

The invention discloses a novel plate shearer based on an optimized crank-rocker mechanism. The novel plate shearer based on the optimized crank-rocker mechanism comprises a main shaft of the plate shearer, an upper knife rest and a plate shearer wall plate; the novel plate shearer based on the optimized crank-rocker mechanism further comprises an actuating device, a transmission device, and a blade gap adjusting mechanism; and the actuating device comprises a switched reluctance speed regulation motor and a transmission shaft, the switched reluctance speed regulation motor is connected with the transmission shaft, the transmission device is connected with the actuating device, and the blade gap adjusting mechanism is connected with the upper knife rest. The novel plate shearer based on the optimized crank-rocker mechanism can accurately adjust the blade gap, namely, can continuously adjust the shear angle so as to guarantee the accuracy of processing; and meanwhile enables the actuating device of the plate shearer to achieve stepping speed regulation so that the shearing efficiency is improved. Besides, the transmission mode of the novel plate shearer based on the optimized crank-rocker mechanism is stable, the transmission ratio is accurate, the working is reliable, the working efficiency is high, the service life is long, and the applicable ranges of power, speed and size are wide.

Owner:安徽金大进重工机床有限公司

Vibration isolator used for orbit traffic floating board

ActiveCN101240519AMeet the three-way stiffness requirementsGood vibration dampingRailway tracksCouplingEngineering

The invention relates to a vibration isolator for a rail traffic floating slab, comprising a lower support, a rubber vibration reduction ring, a height adjusting screw, a height adjusting nut and a coupling flange. The lower support is disposed on a base, a concave groove is disposed on the lower support, and the rubber vibration reduction ring is disposed in the concave groove. The head of the height adjusting screw is disposed in the vibration reduction ring, the screw extends upwards and has male thread. The height adjusting nut is connected with the height adjusting screw by female thread thereof. The coupling flange is mounted on the height adjusting nut and is connected with the floating slab to make the vibration isolator to support the floating slab. The vibration reduction effect of the invented vibration isolator is better than that of the traditional metal spring vibration isolator, and can satisfied road bed height adjustment request better.

Owner:SHANGHAI QIYAO HEAVY IND CO LTD

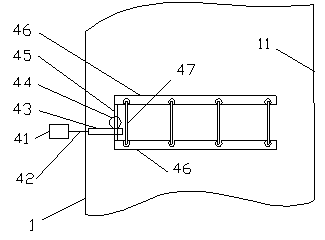

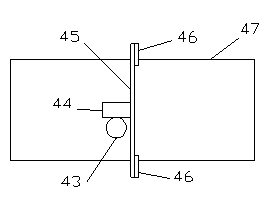

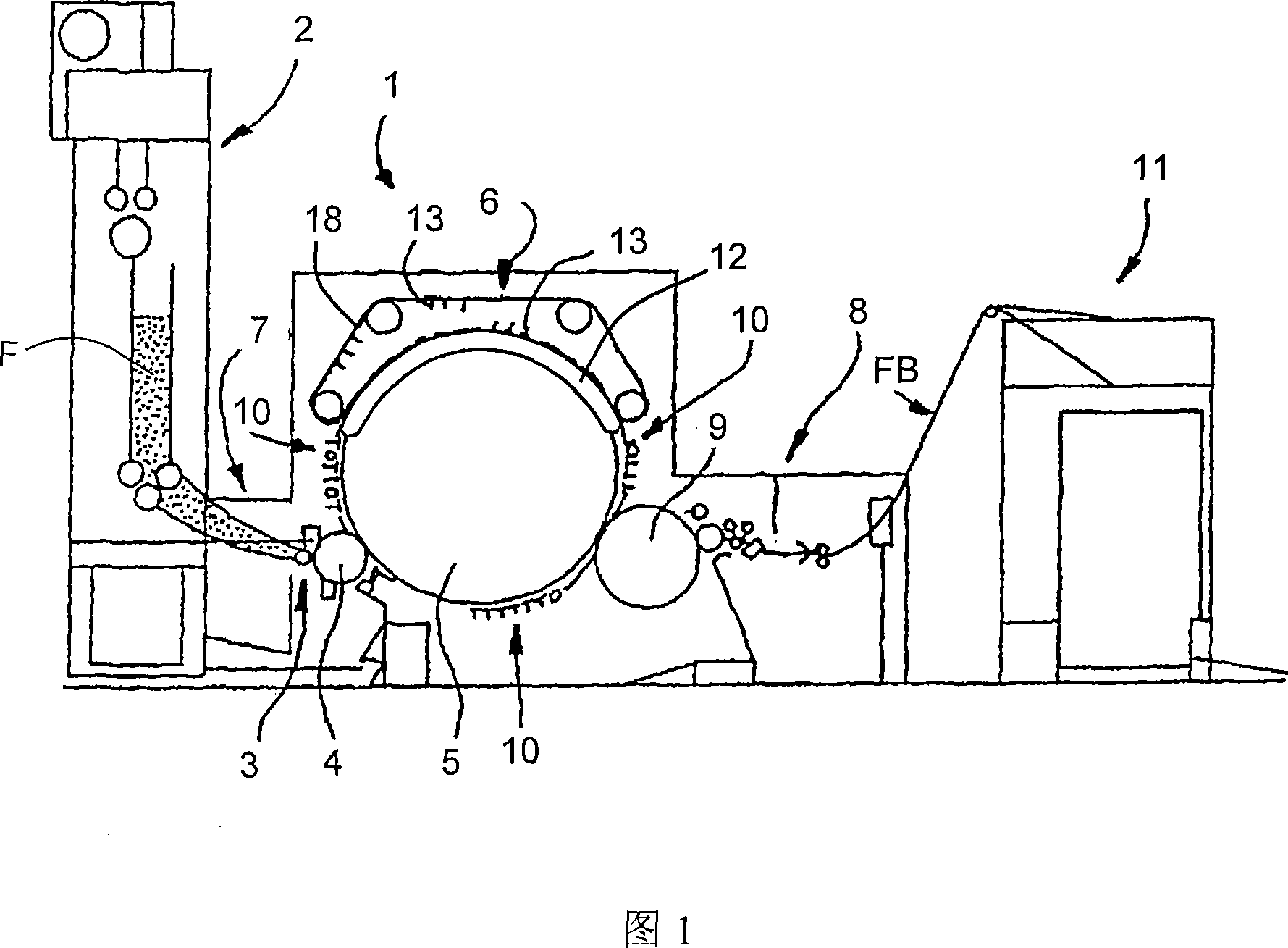

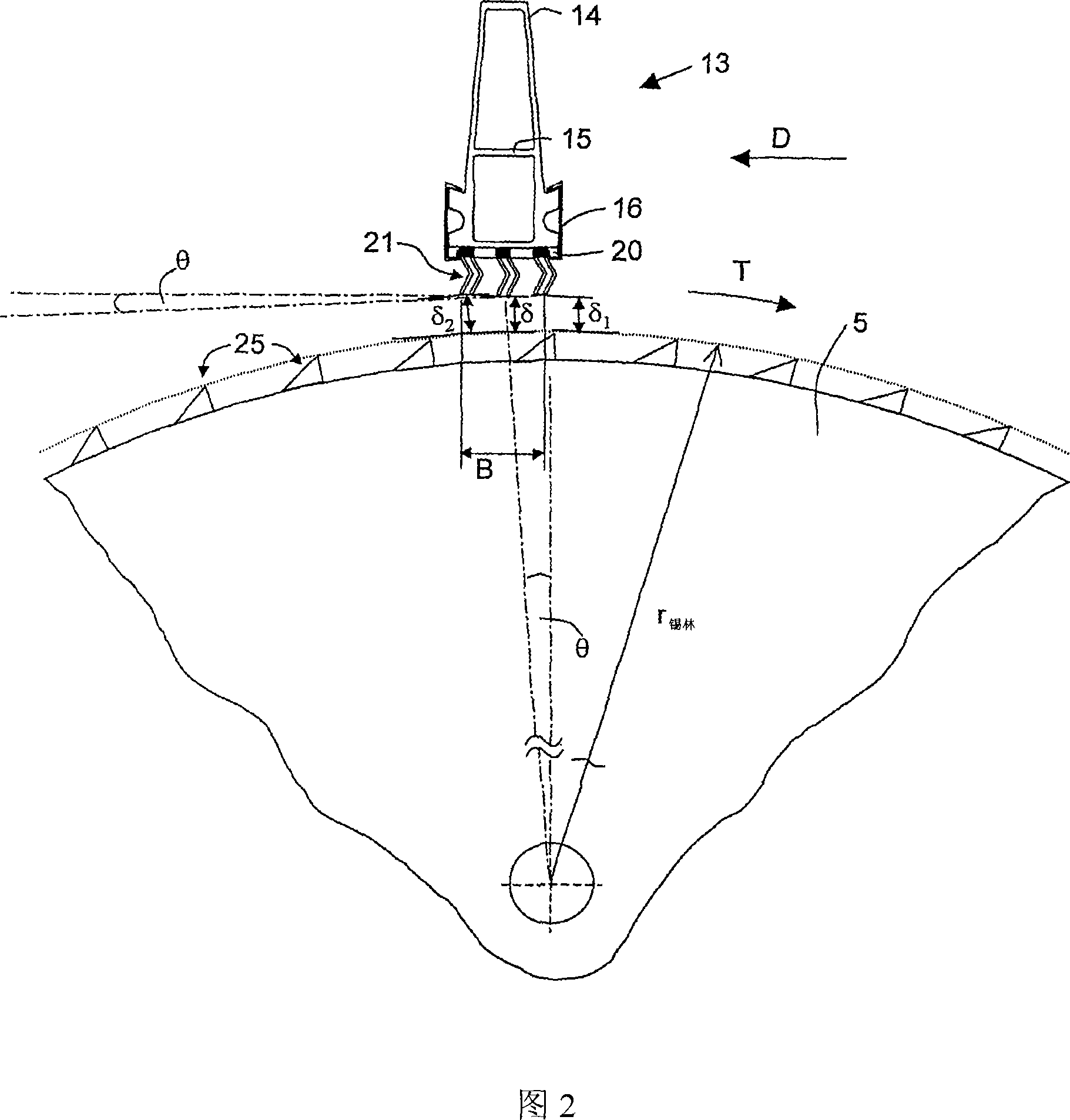

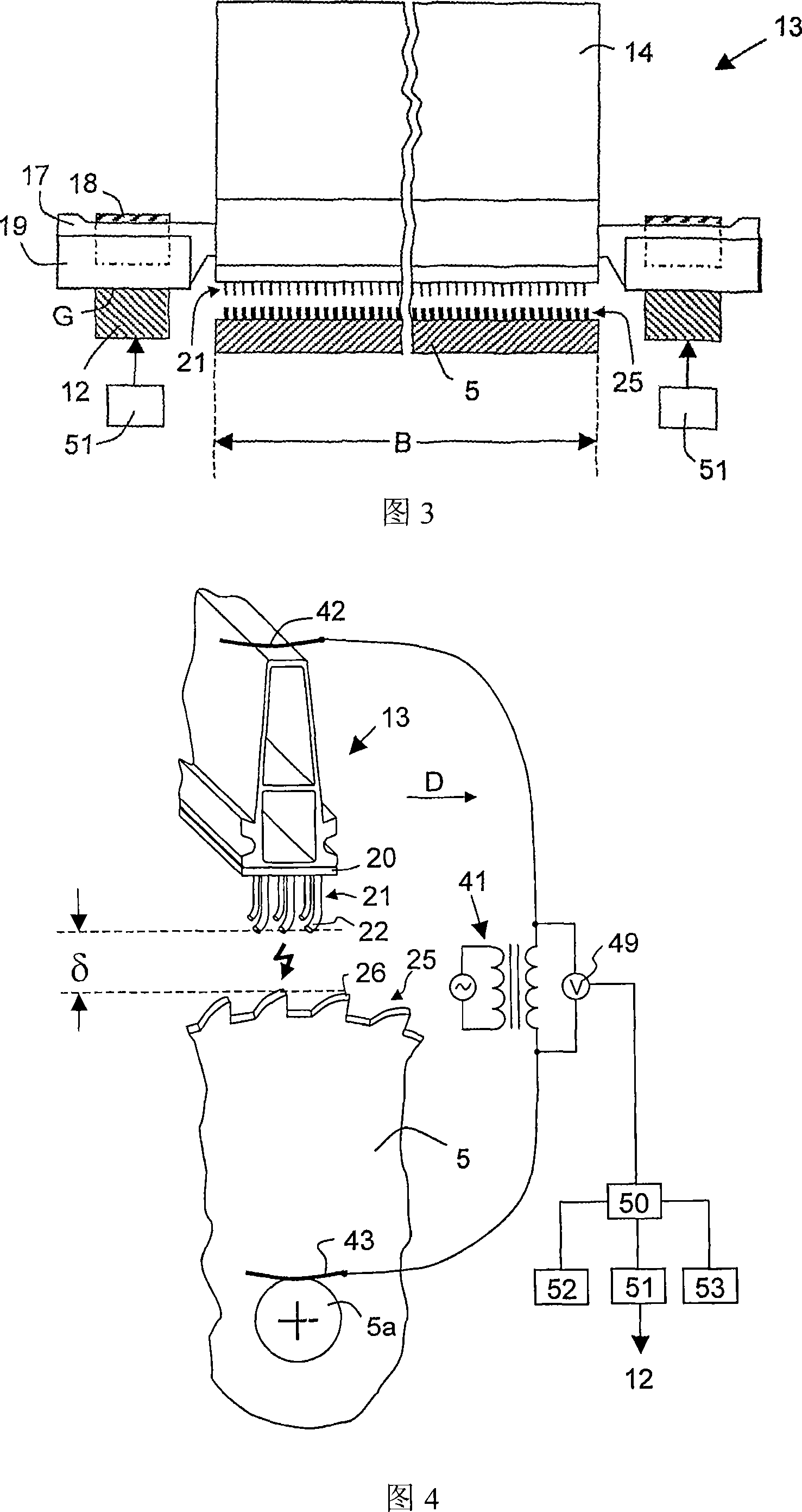

Spinning preparation machine and contactless measuring method

The present invention relates to a spinning preparation machine, such as e.g. a carding machine or a cleaner or the like. Said machine comprises a device for the contactless measurement and / or adjustment of parameters in two opposite card clothings (21, 25). The tips (22, 26) of said card clothings are configured so as to be electrically conducting, a voltage source (41; 101; 201, 206) is connected to the tips of at least one of the card clothings, and electrical discharges can be produced by applying a variable potential difference between the tips of the two card clothings. These discharges are indicative of the actual distance (d) and / or the distance to be adjusted between the card clothing tips and / or the degree of wear of at least one of the card clothings and / or the position of the one card clothing in relation to the other card clothing, especially the angle of inclination (T) relative each other. The invention also relates to a corresponding contactless measuring method.

Owner:MASCHINENFABRIK RIETER AG

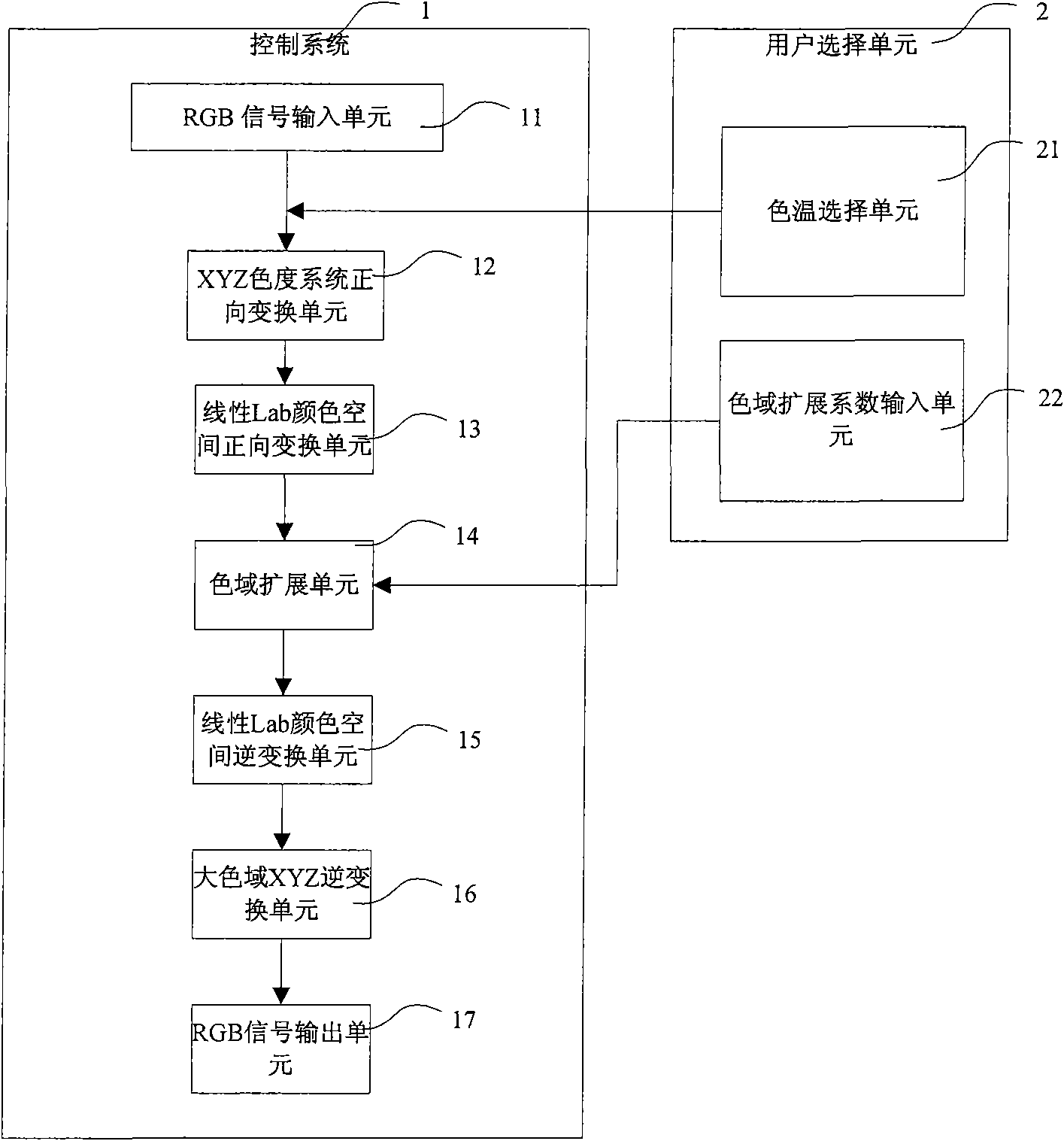

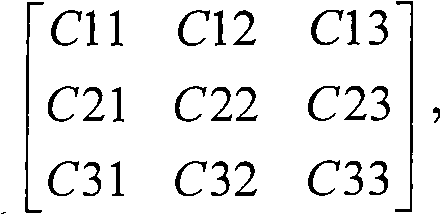

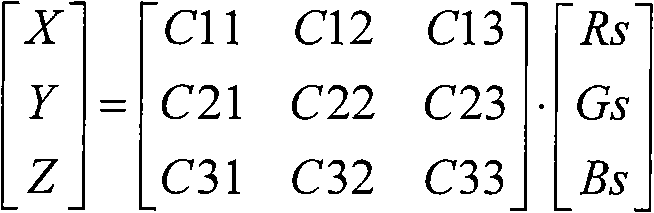

Color gamut expanding system and method

InactiveCN101594545ARealize continuous adjustmentImprove computing efficiencyColor signal processing circuitsCathode-ray tube indicatorsLab color spaceGamut

The invention provides a color gamut expanding system comprising a signal input unit, a forward conversion unit, a color gamut expanding unit, an inverse conversion unit and a signal output unit; wherein, the signal input unit is used for inputting pixel color information; the forward conversion unit is used for converting the pixel color information into values of L, a and b in liner Lab color space; the color gamut expanding unit is used for receiving color gamut expanding coefficients, and expands the values of L, a and b provided by the forward conversion unit into new values of L, a and b in the linear Lab color space according to the color gamut expanding coefficients; the inverse conversion unit is used for converting expanded values of L, a and b into the pixel color information of a large color gamut; the signal output unit is used for outputting the color information of the large color gamut. The invention also provides a corresponding color gamut expanding method. The invention can realize continuous adjustment, has high calculation efficiency, can better avoid the phenomenon of hue deviation, and has higher precision and accuracy.

Owner:PHOEBUS VISION OPTO ELECTRONICS TECH

Adjustable crank and rocker mechanism

InactiveCN101963217ARealize continuous adjustmentEasy to adjustGearingEngineeringMechanical engineering

The invention discloses an adjustable crank and rocker mechanism, which comprises an eccentric wheel, a ratchet wheel, a first connecting rod, a second connecting rod, a worm, a worm screw, an adjusting plate and a frame connecting rod, wherein one end of the first connecting rod is hinged on the eccentric wheel; the second connecting rod is connected with the other end of the first connecting rod and the ratchet wheel respectively; the worm screw is matched with the worm; one end of the adjusting plate is hinged on the worm; one end of the frame connecting rod is hinged with the adjusting plate, while the other end is hinged with the connected point of the first connecting rod and the second connecting rod; and the top end of the worm screw is provided with a hand wheel for driving the worm screw to rotate. The adjustable crank and rocker mechanism has the advantages that: (1) on the premise of not stopping the equipment, the swinging angle of the ratchet wheel can be adjusted continuously till a proper angle of the ratchet wheel, so the adjustment is convenient and the adjustment precision is high; and (2) in the adjustment, the equipment is not stopped, so the working efficiency of the equipment is improved.

Owner:SHANDONG YINYING COOKING MACHINERY

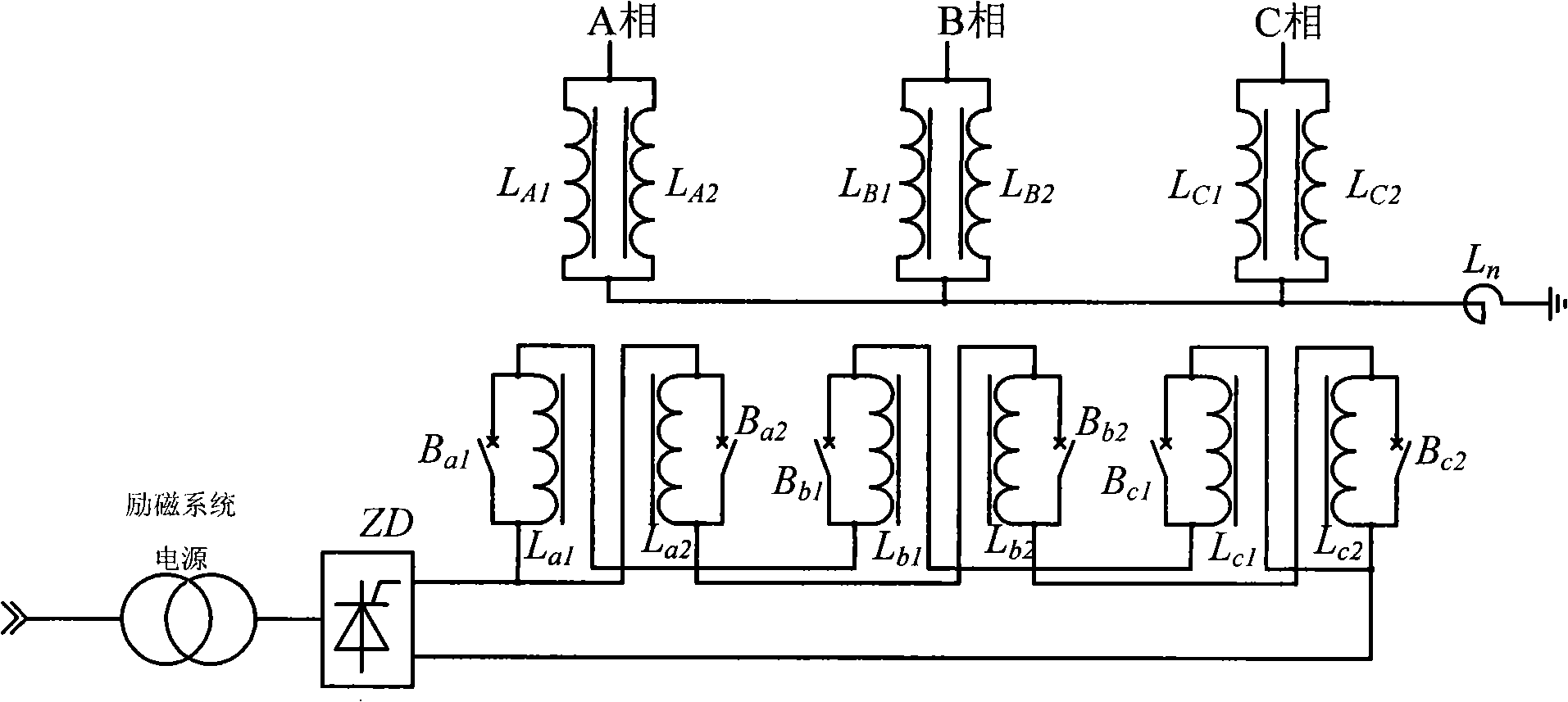

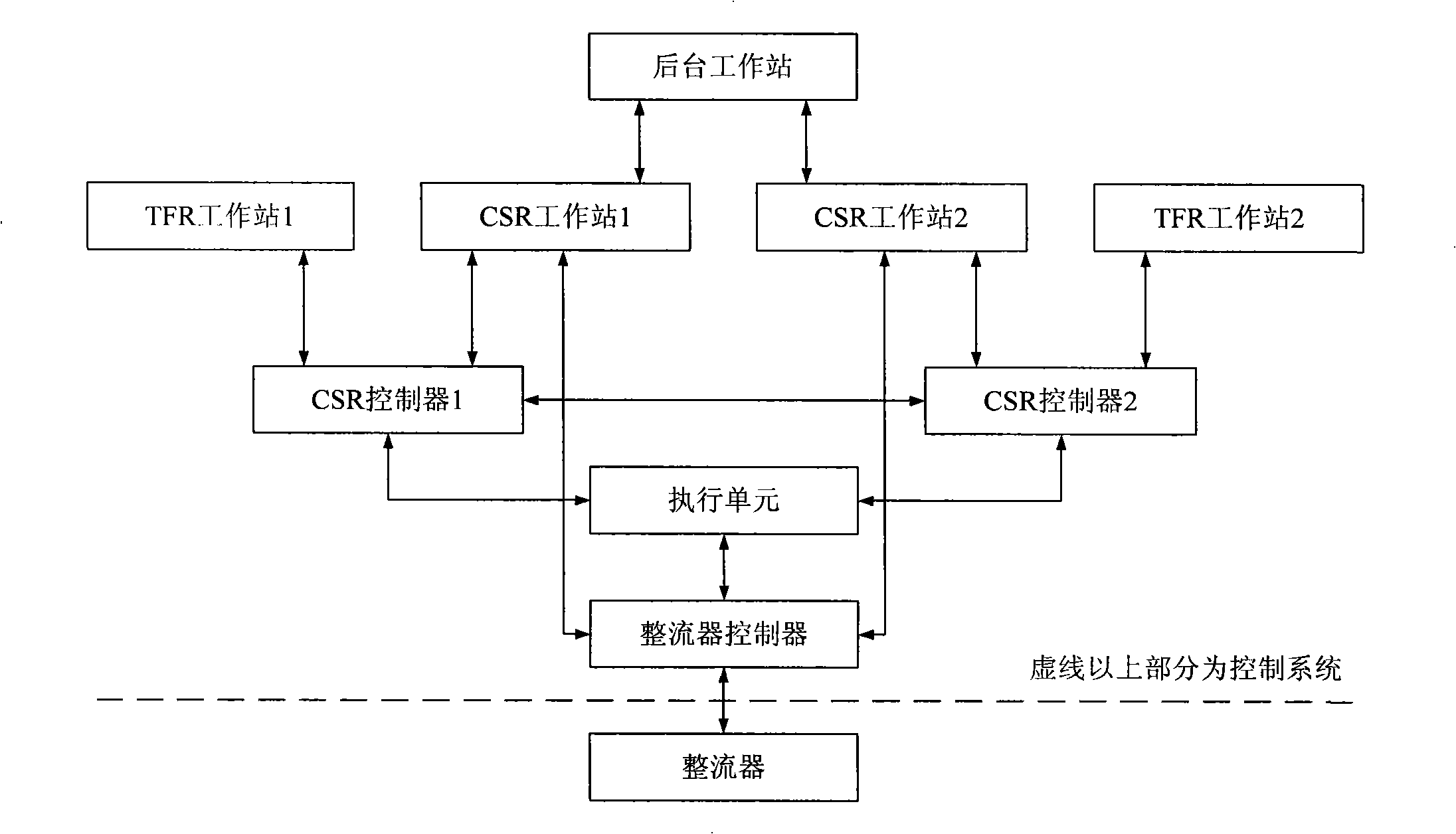

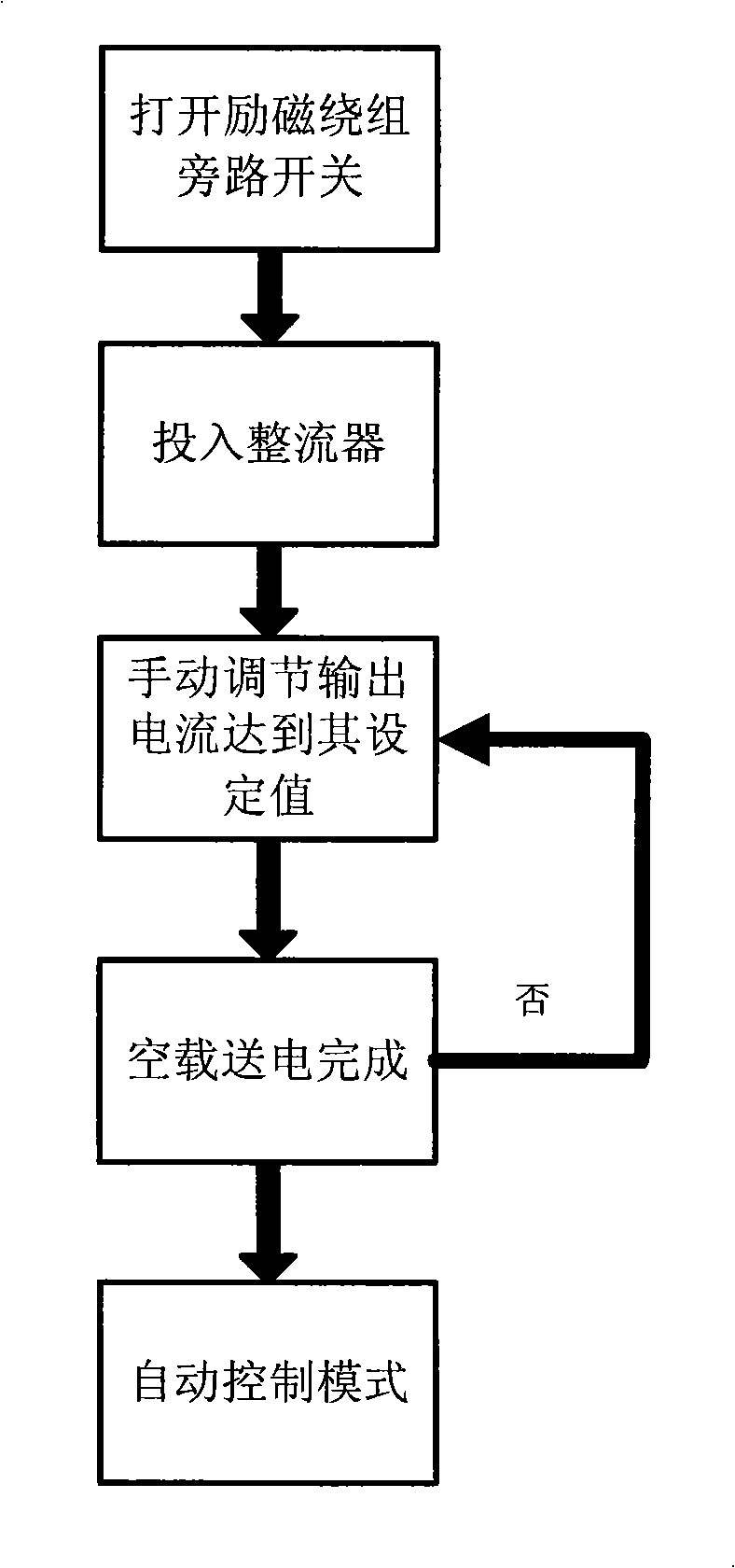

Control method for parellel reactor with ultra-high/extra-high voltage magnetic control type

ActiveCN101286723AImprove power supply reliabilityImprove transmission capacityEmergency protective circuit arrangementsConversion without intermediate conversion to dcShunt reactorElectric network

The invention relates to a control method for a supervoltage / extra-high voltage magnetically-controlled reactor in parallel, which is characterized in that: the control method is realized by controlling by-pass switches of a direct-current excitation system and an excitation winding of the magnetically-controlled reactor in parallel, and includes that a homeostatic control method and a transient control method: 1 the homeostatic control method is an automatic adjusting mode in a homeostatic condition, namely, when the voltage fluctuation of electric networks exceeds the set range, a controller automatically adjusts the capacity of the reactor to maintain the stability of the voltage of the electric networks or automatically adjusts the output current based on the set reactive capacity to maintain the constant reactive power output of the reactor in parallel; 2 the transient control method includes (1) a process control method for no-load power transmission; (2) a control method for a three-phase tripping of an onside breaker; (3) a control method for a single-phase tripping and single-phase grounding; (4) a circuit disconnection control method.

Owner:CHINA ELECTRIC POWER RES INST +1

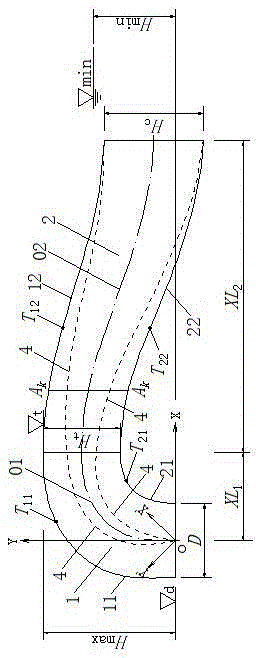

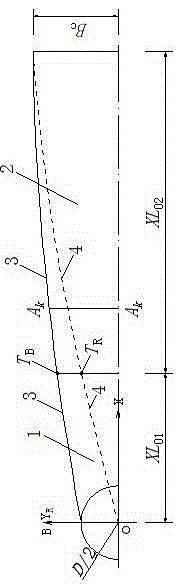

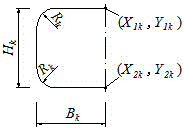

Shaping algorithm for quartic curvilinear equation of three-dimensional shape of low hump type water draining flow way and application of shaping algorithm

ActiveCN104615831AGood hydraulic performanceGuaranteed design qualitySpecial data processing applicationsWater flowThree dimensional shape

The invention relates to a shaping algorithm for a quartic curvilinear equation of a three-dimensional shape of a low hump type water draining flow way and application of the shaping algorithm, and belongs to the technical field of pump stations of water conservancy projects. The low hump type water draining flow way is designed by the shaping algorithm. The shaping algorithm is characterized in that an upper side line and a lower side line of a longitudinal section of the flow way, a width changing curve of the flow way and a transitional circle center track line of the cross section, which is changed into square from circle, of the flow way are respectively set into the quartic curvilinear equation; the flow way is divided into a rising turning section and a falling section, the rising turning section turns at an angle of 90 degrees, influences of a centrifugal force on water flow are reduced to a maximum extent, the height of the rising turning section is increased as much as possible under the condition of arrangement permission of a pump room, and a turning radius of the rising turning section is increased; the falling section guides the water flow to be connected with a water draining pond gently and orderly, so that the crest level of the cross section of an outlet of the flow way is lower than the minimum water level of the water draining pond by 0.5m; and the water flow of the designed low hump type water draining flow way turns orderly and is scattered uniformly, loss of a water head of the flow way is low, and the hydraulic performance is excellent.

Owner:YANGZHOU UNIV

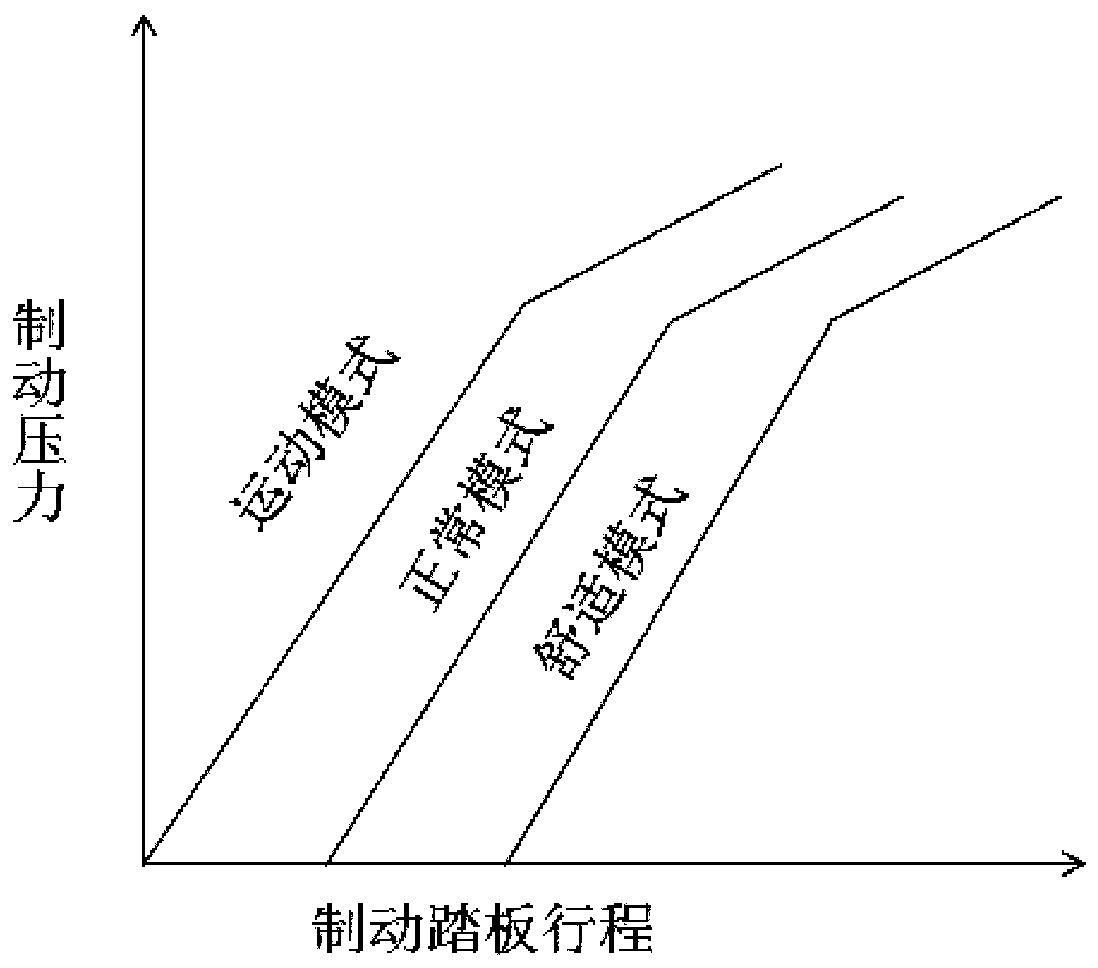

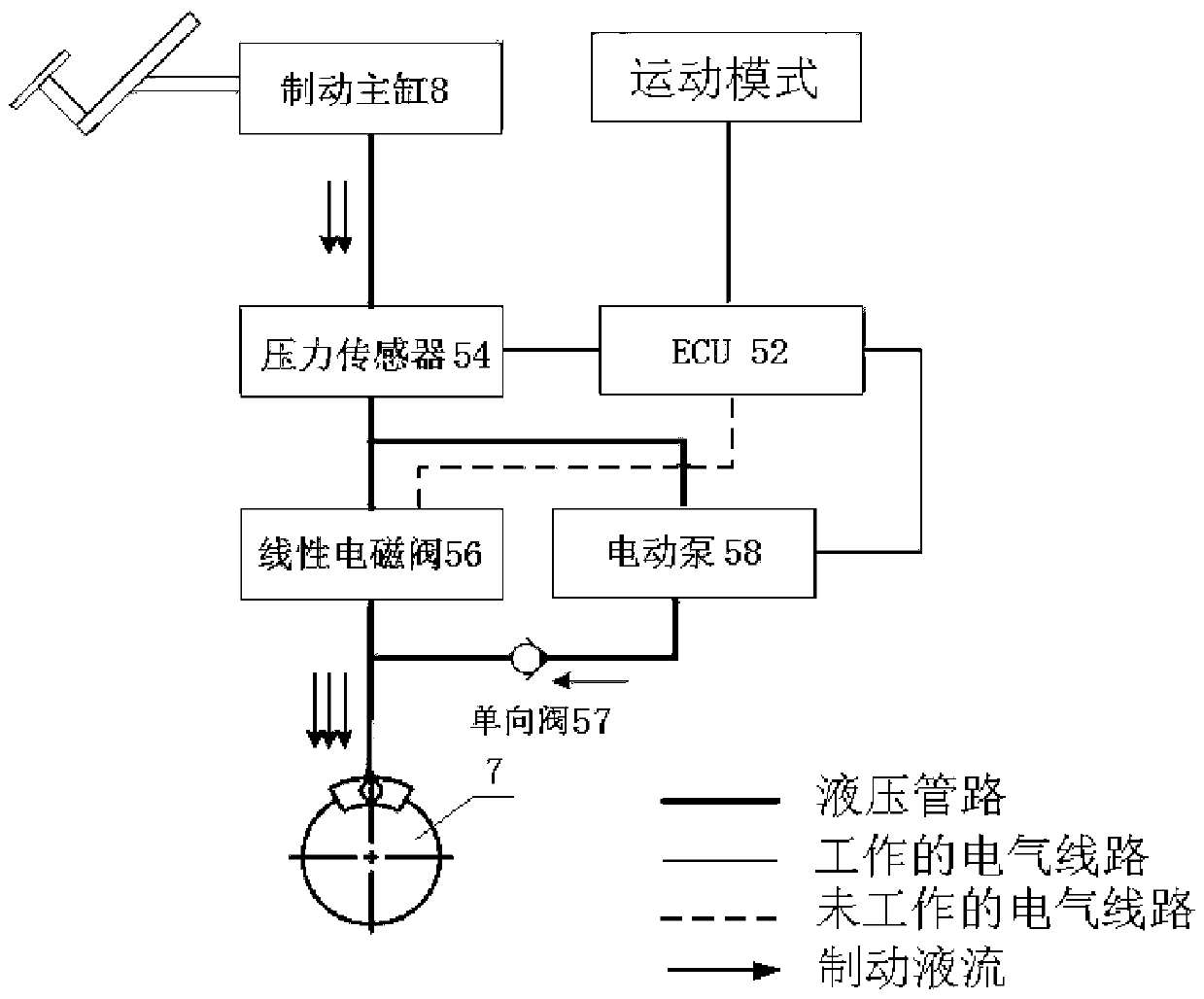

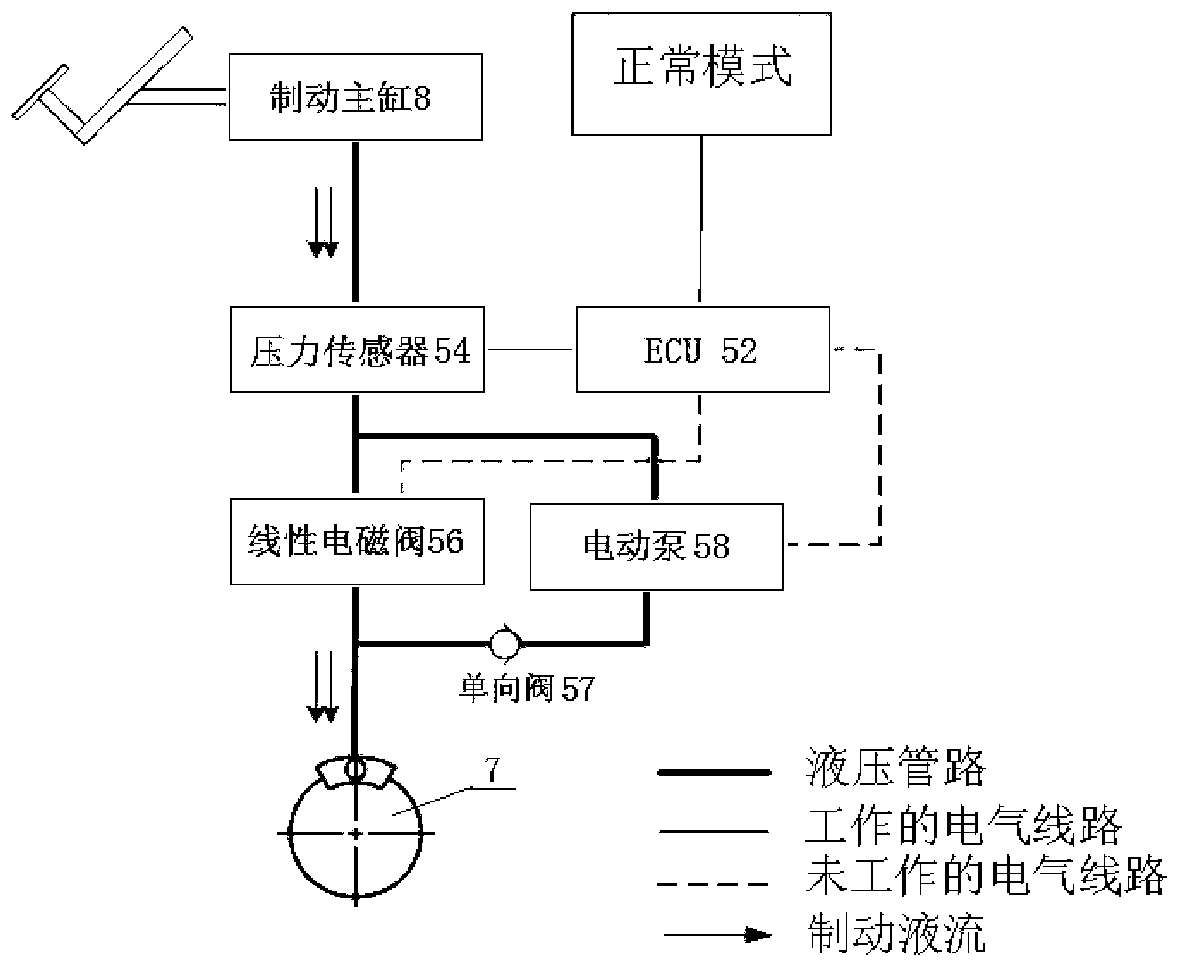

Vehicle braking sensitivity regulating and controlling system

InactiveCN110065482AComfortable brake operation experienceRealize continuous adjustmentBraking action transmissionInteraction deviceWheel cylinder

The invention discloses a vehicle braking sensitivity regulating and controlling system which comprises a man-machine interaction device, a brake pedal travel sensor and an electronic brake control module (EBCM). The man-machine interaction device is used for receiving an external input instruction; the brake pedal travel sensor is used for detecting the magnitude and speed of input of a brake pedal; the EBCM comprises an electronic control unit (ECU) and a braking force adjusting unit, and the ECU receives a braking sensitivity adjusting instruction input by the man-computer interaction device, receives input of the brake pedal travel sensor, and then sends a braking sensitivity regulating and controlling instruction; the braking force adjusting unit is used for carrying out delayed pressure building or rapid pressurization operation on a brake pipeline according to the regulating and controlling instruction of the ECU, so that the braking force borne by a brake wheel cylinder is correspondingly changed corresponding to the pressure change of the brake pipeline.

Owner:SAIC GENERAL MOTORS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com