Patents

Literature

44results about How to "Real-time monitoring size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

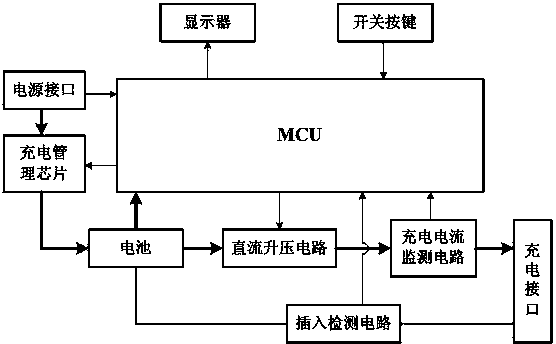

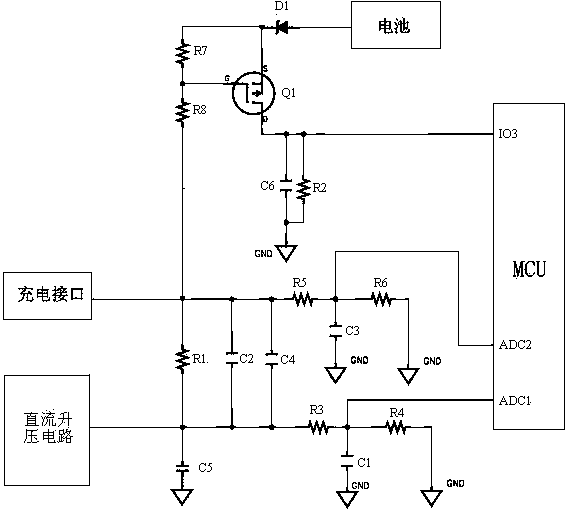

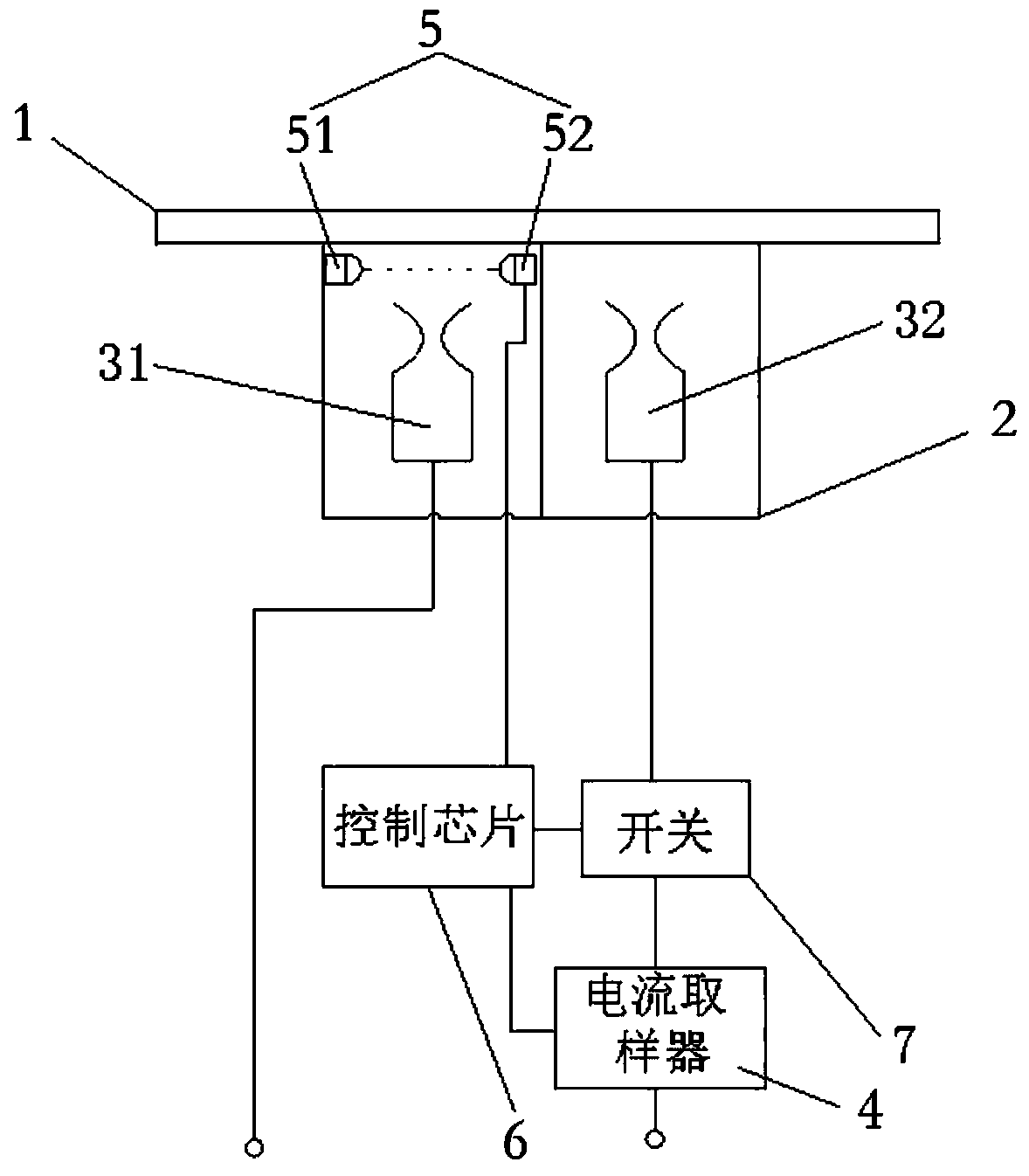

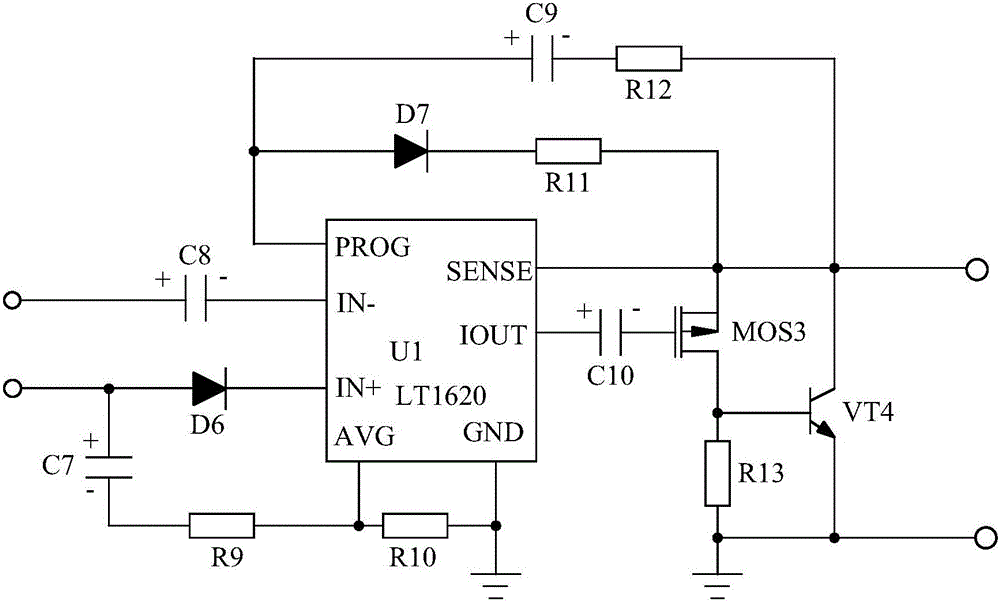

Intelligent charging detection circuit and movable power supply

ActiveCN103698640AReduce current consumptionExtended use timeBatteries circuit arrangementsCurrent/voltage measurementElectrical batteryCharge detection

The invention discloses an intelligent charging detection circuit and a movable power supply. The intelligent charging detection circuit comprises a power supply circuit, a controller, a charging interface and an insertion detection circuit; the insertion detection circuit is used for detecting the variation of electrical parameters of the charging interface, a switch element is controlled by the variation of the electrical parameters of the charging interface to be on and off, a corresponding command signal is generated by utilizing the variation of the on-off state of the switch element and is transmitted to a controller, and the command signal is used for recognizing the insertion state of a charging device. A charging device insertion detection circuit is additionally arranged in a movable power supply, so that the movable power supply is enabled to stay at a dormant state during the non-charging period, the current loss of the movable power supply can be reduced, and the use time of the movable power supply is prolonged. A current monitoring circuit is additionally arranged in the movable power supply, the size of the charging size can be monitored in real time, and the battery application efficiency of the movable power supply can be improved by reducing the constant-voltage charging time while the safety of the movable power supply and the charging device is guaranteed.

Owner:QINGDAO GOERTEK

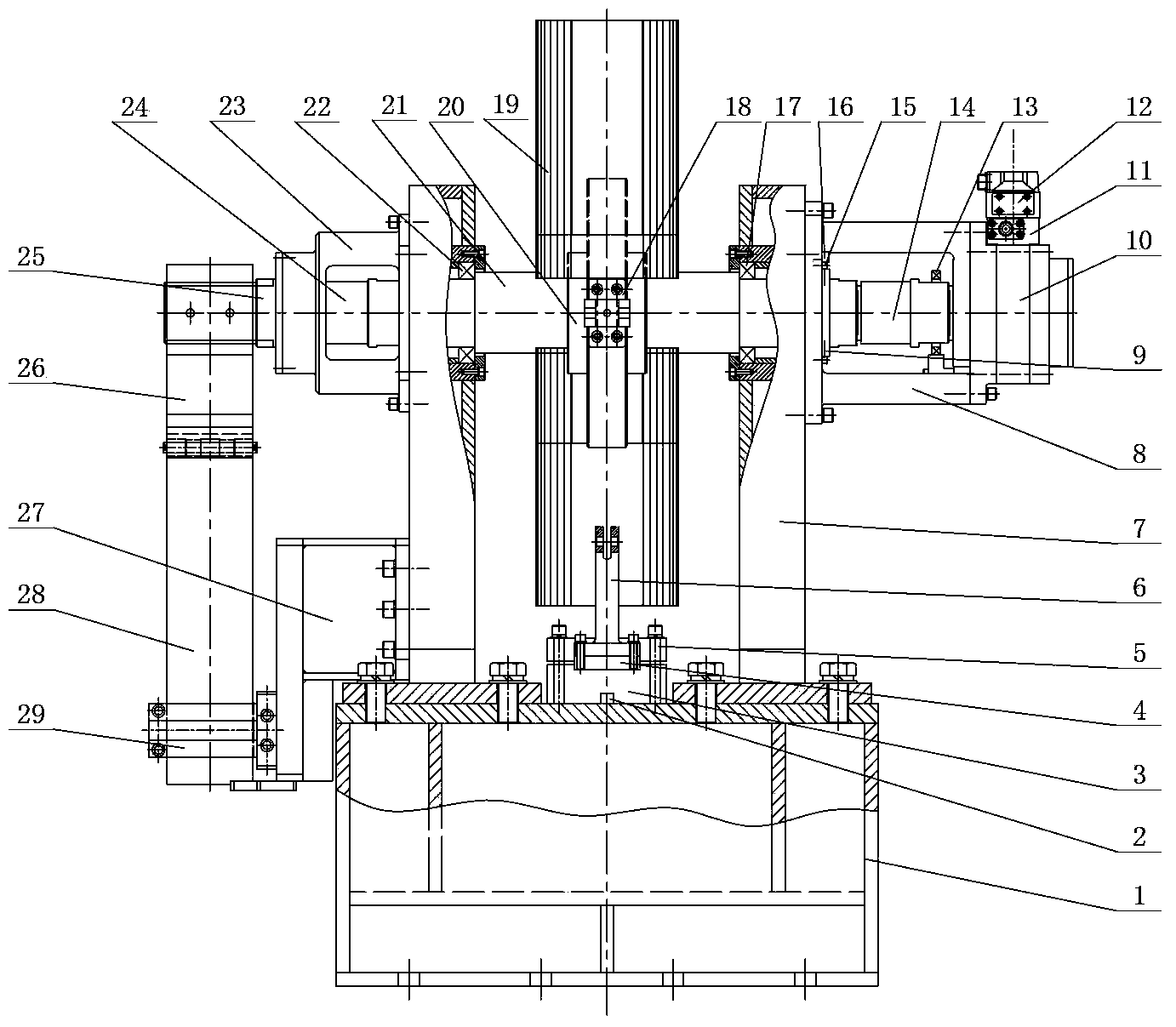

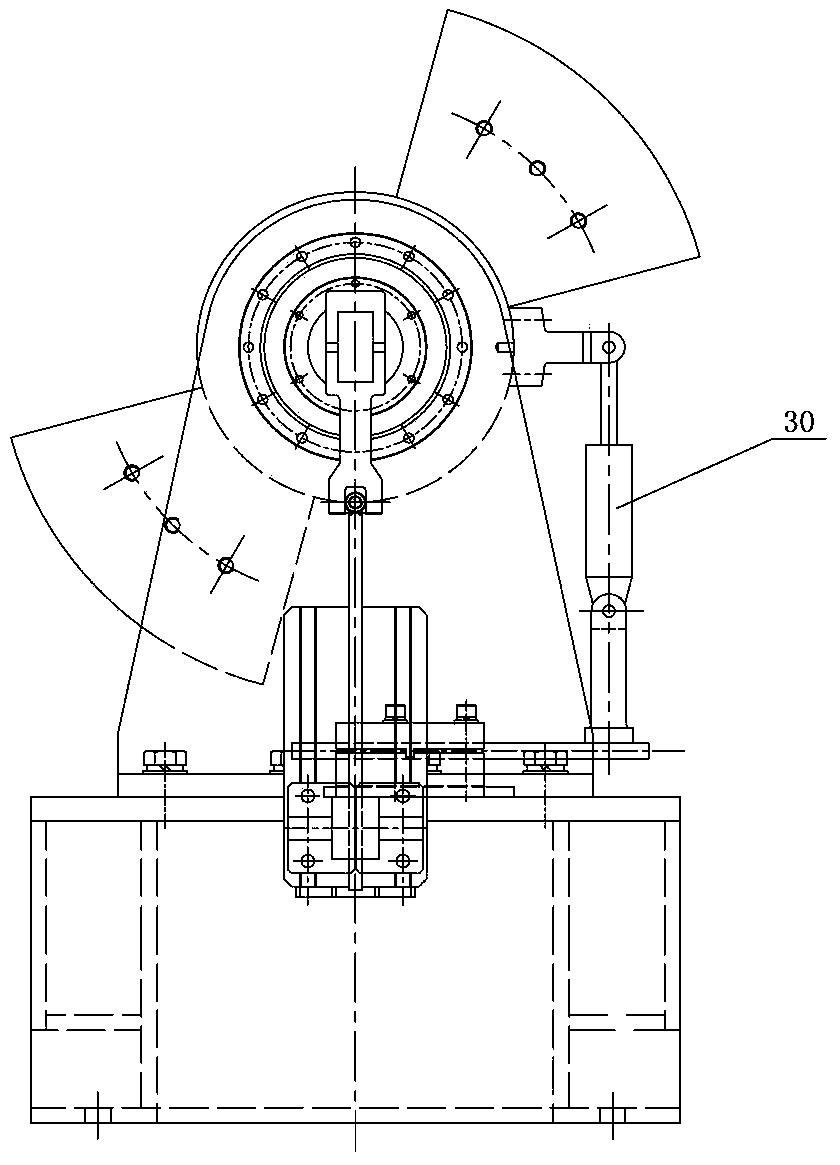

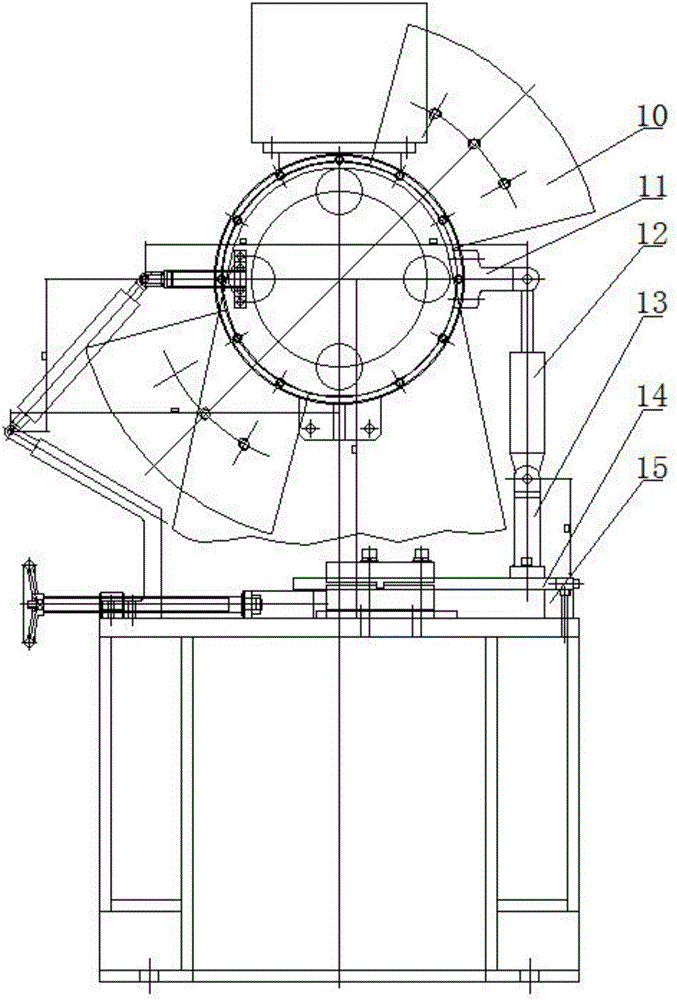

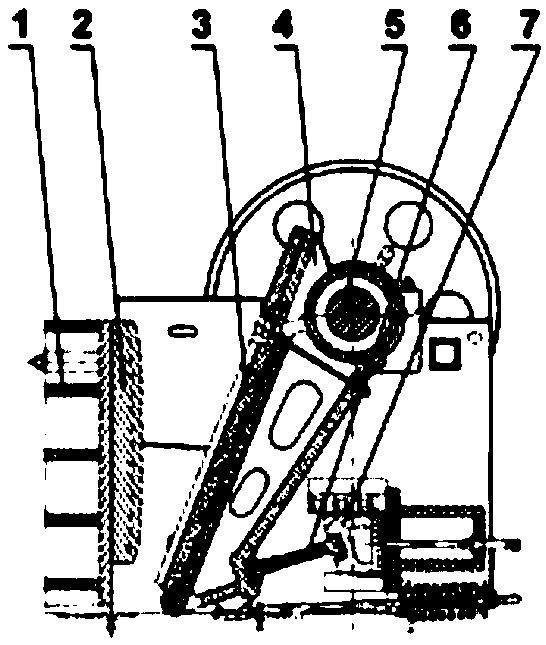

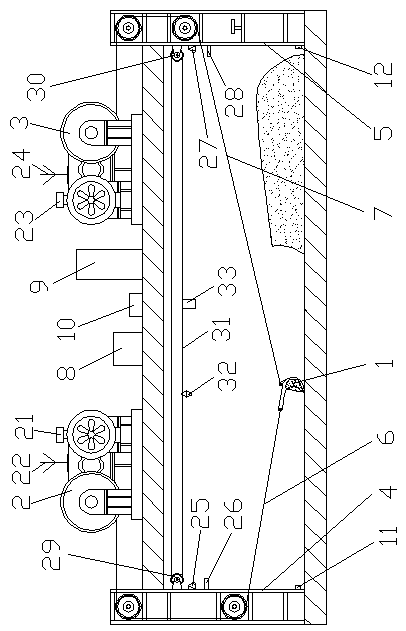

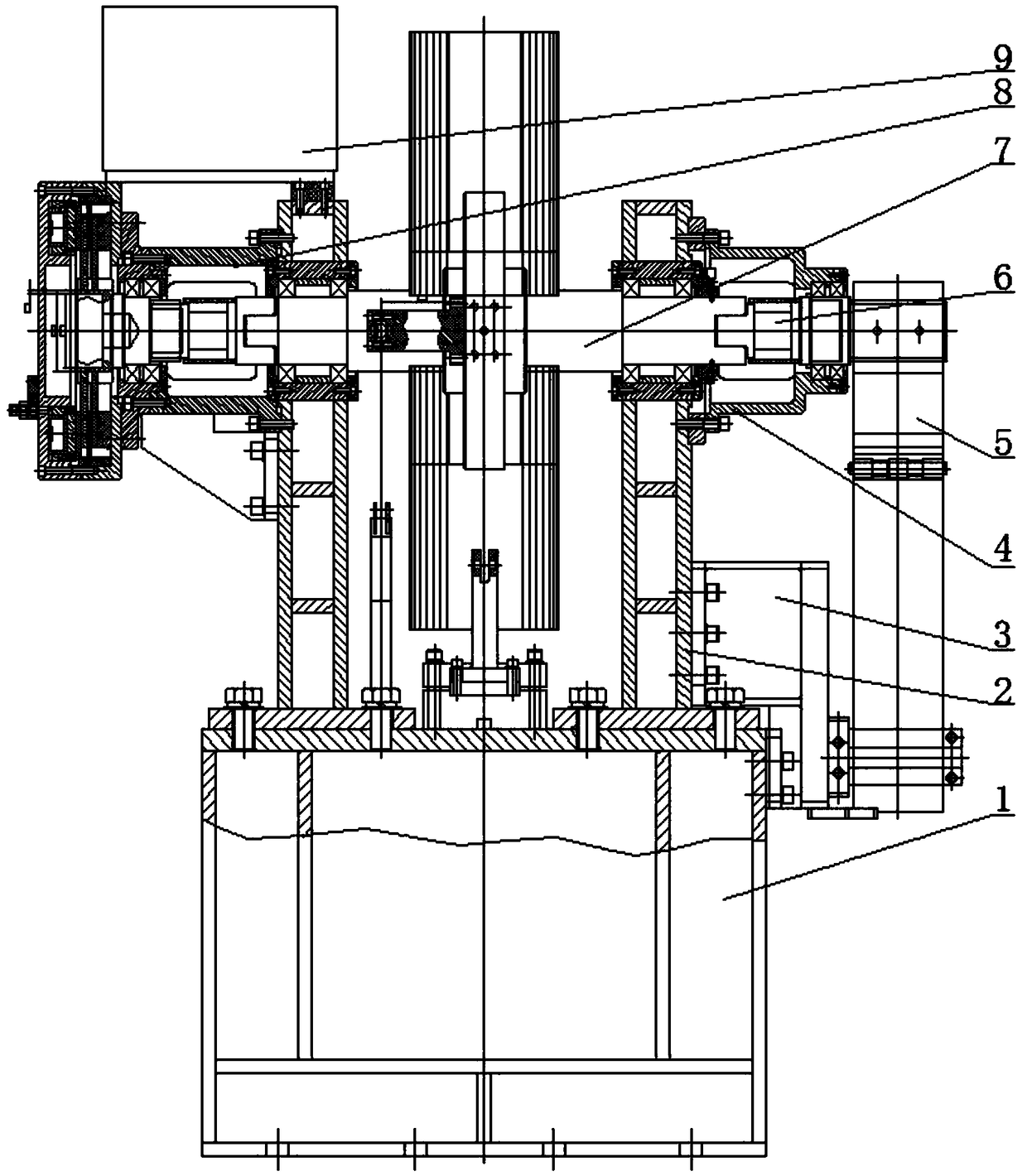

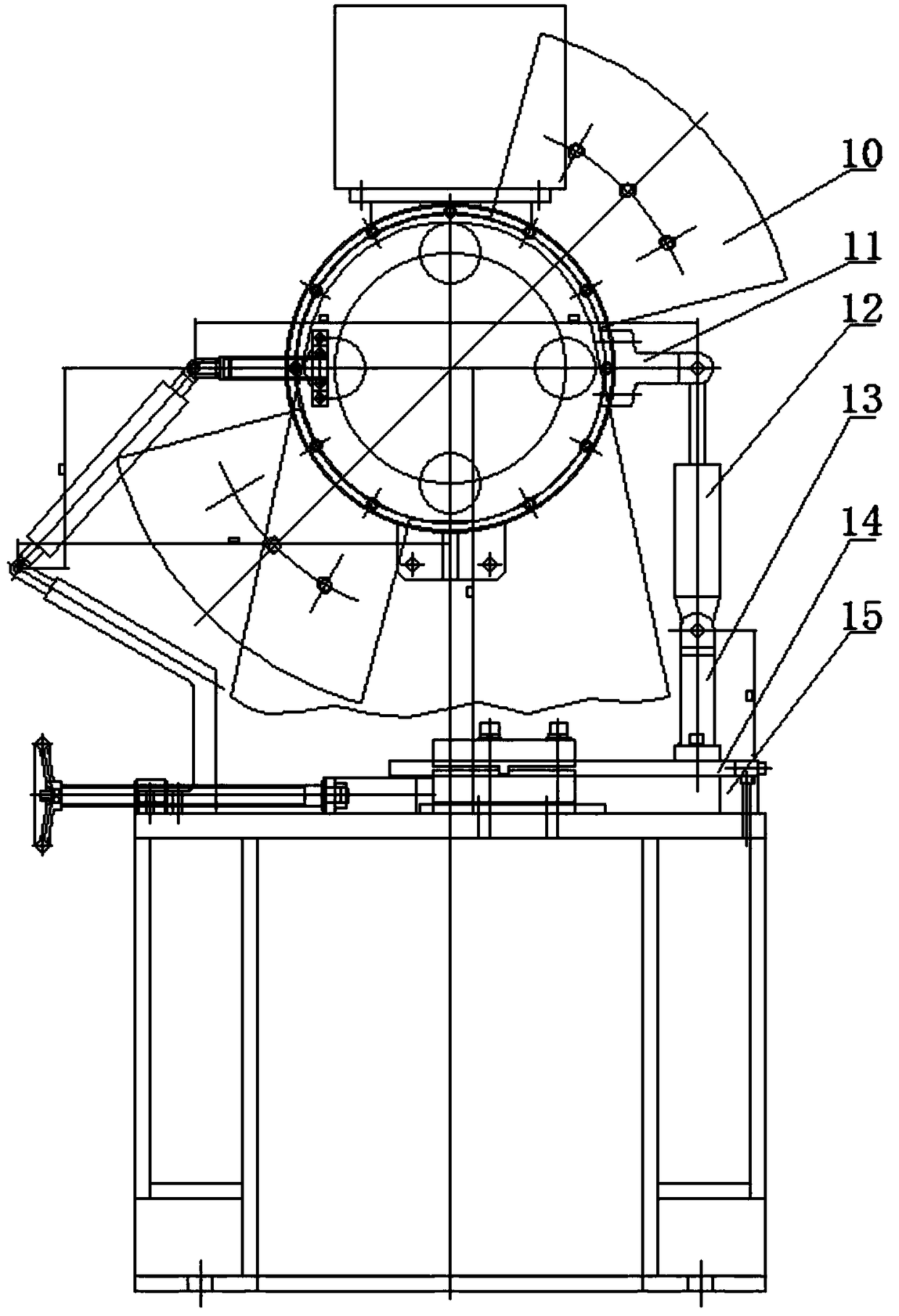

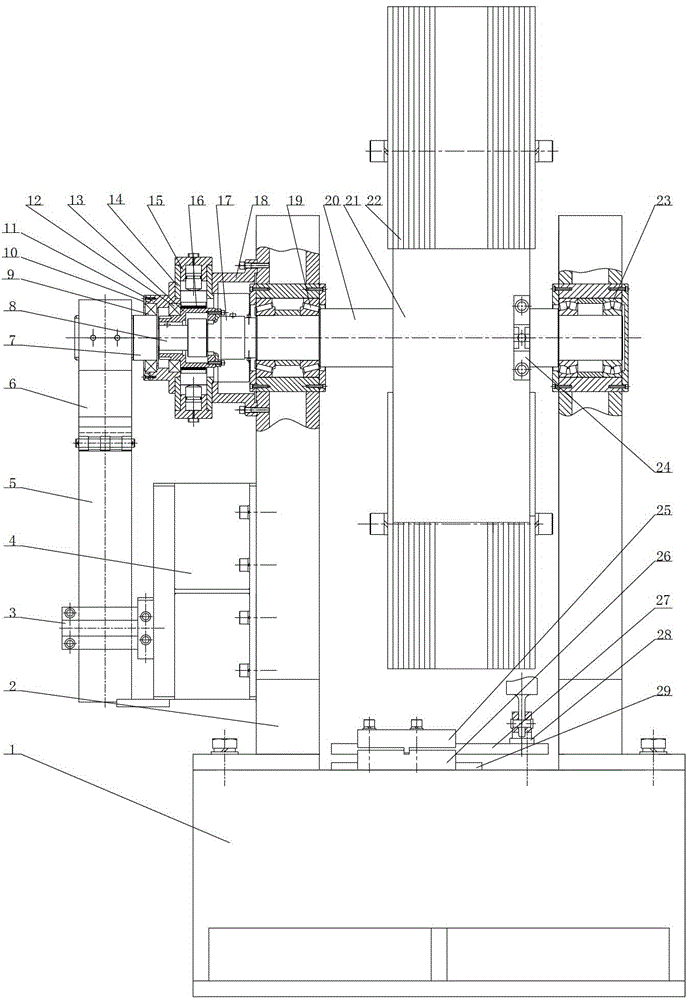

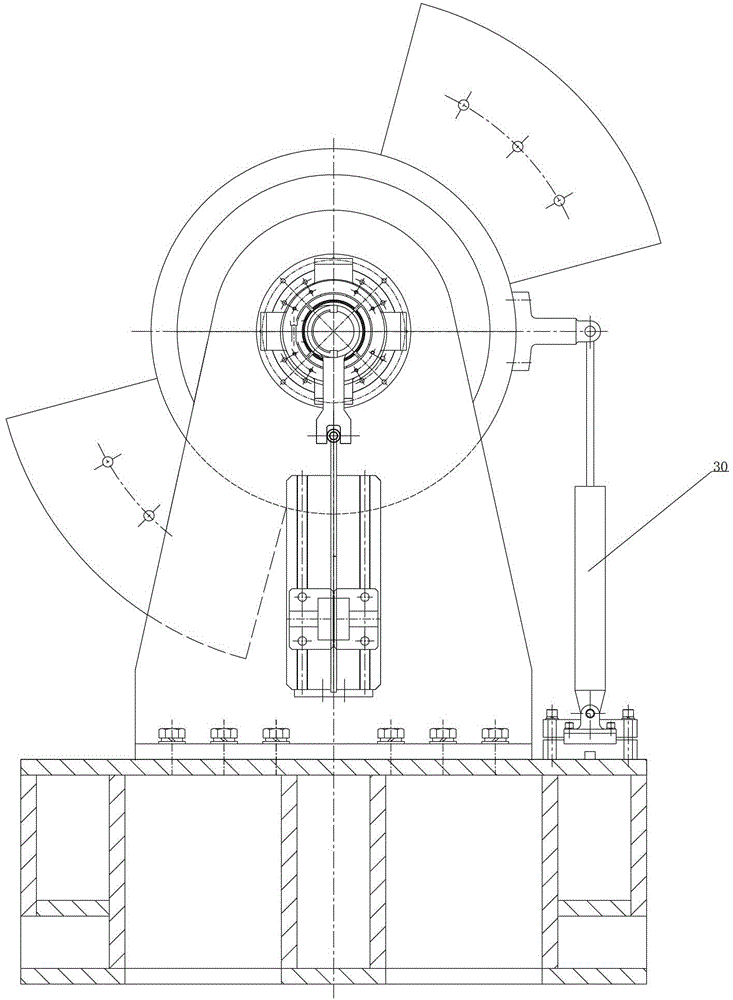

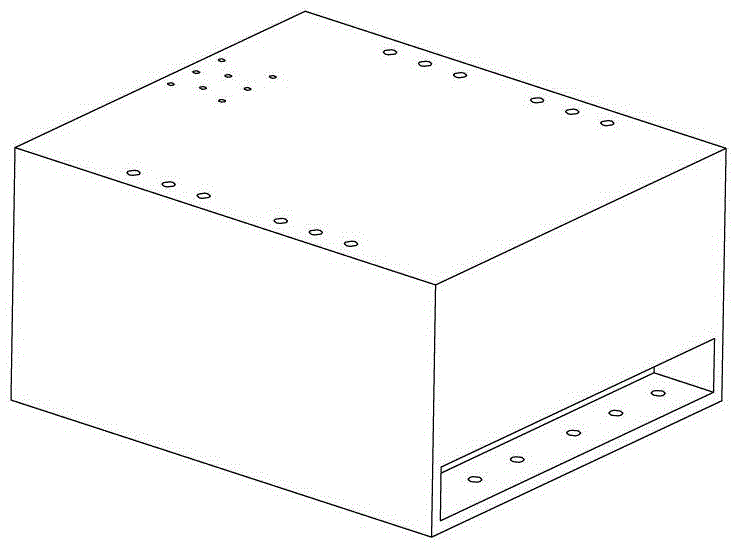

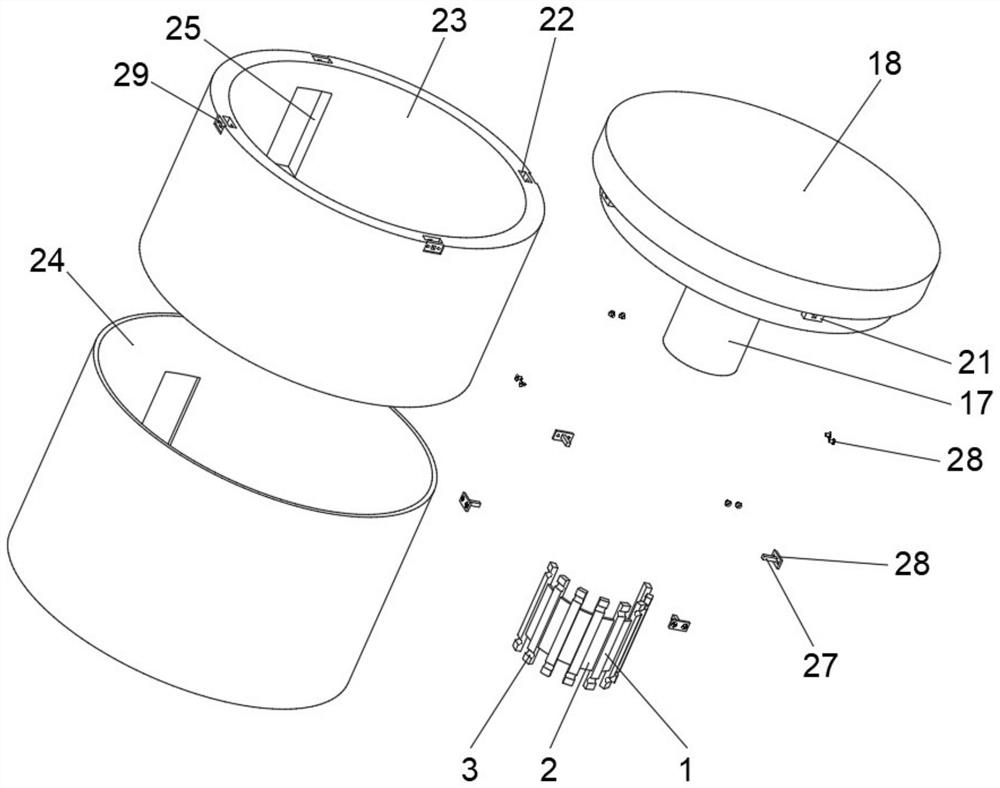

Torque servo control loading load simulator

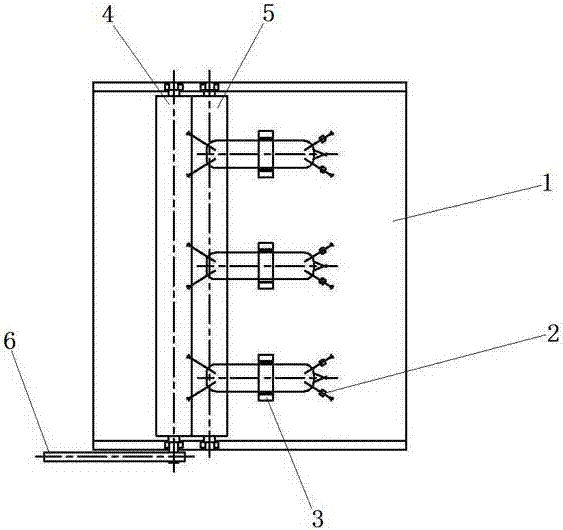

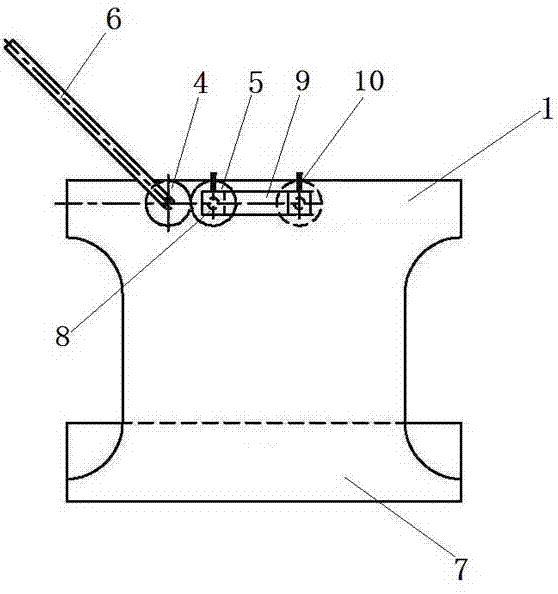

InactiveCN103413489AReal-time monitoring sizeContinuous regulationEducational modelsTorque sensorRocket

A torque servo control loading load simulator comprises a base, a guide strip, a supporting spring plate base, a supporting spring plate, a supporting spring plate cover plate, a lower supporting lug, a side vertical plate, a motor mounting seat, a photoelectric encoder mounting seat, a swing hydraulic motor, a valve block, a servo valve, a rolling bearing, a loading torque sensor, a photoelectric encoder, a probe, a ball bearing, an upper supporting lug, an inertia counterweight disk, an inertia base disk, a spindle, an elastic torque mounting support, an elastic torque sensor, an elastic torque rotating shaft, a swing shifting fork, an elastic torque loading support, an elastic torque spring plate and a spring torque spring plate clamping plate. The torque servo control loading load simulator can simulate the structural characteristics of a rocket exhaust nozzle, wherein the structural characteristics comprise inertia loads, elastic torque loads, set torque loads and supporting stiffness. The torque servo control loading load simulator has the advantages of being simple and compact in structure, flexible in servo loading torque, high in precision, and capable of better reproducing the structural characteristics of the actual rocket exhaust nozzle.

Owner:BEIHANG UNIV

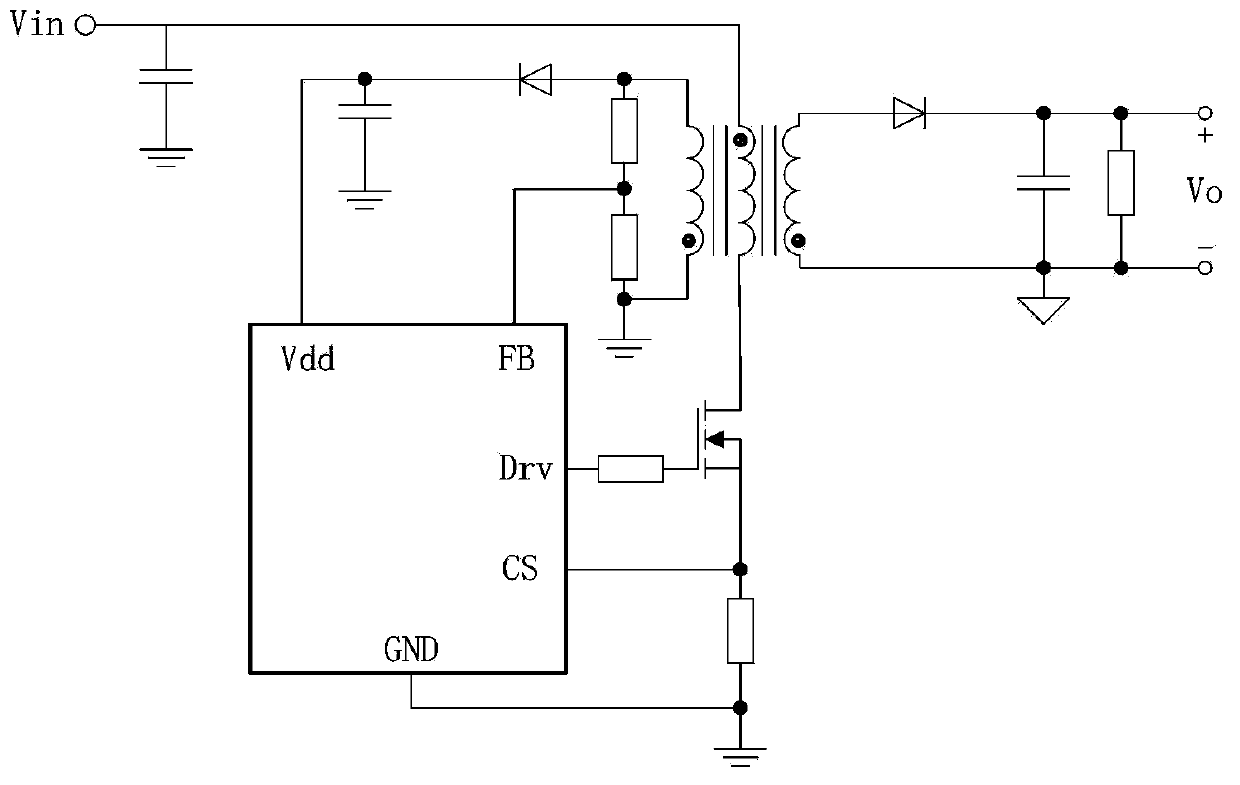

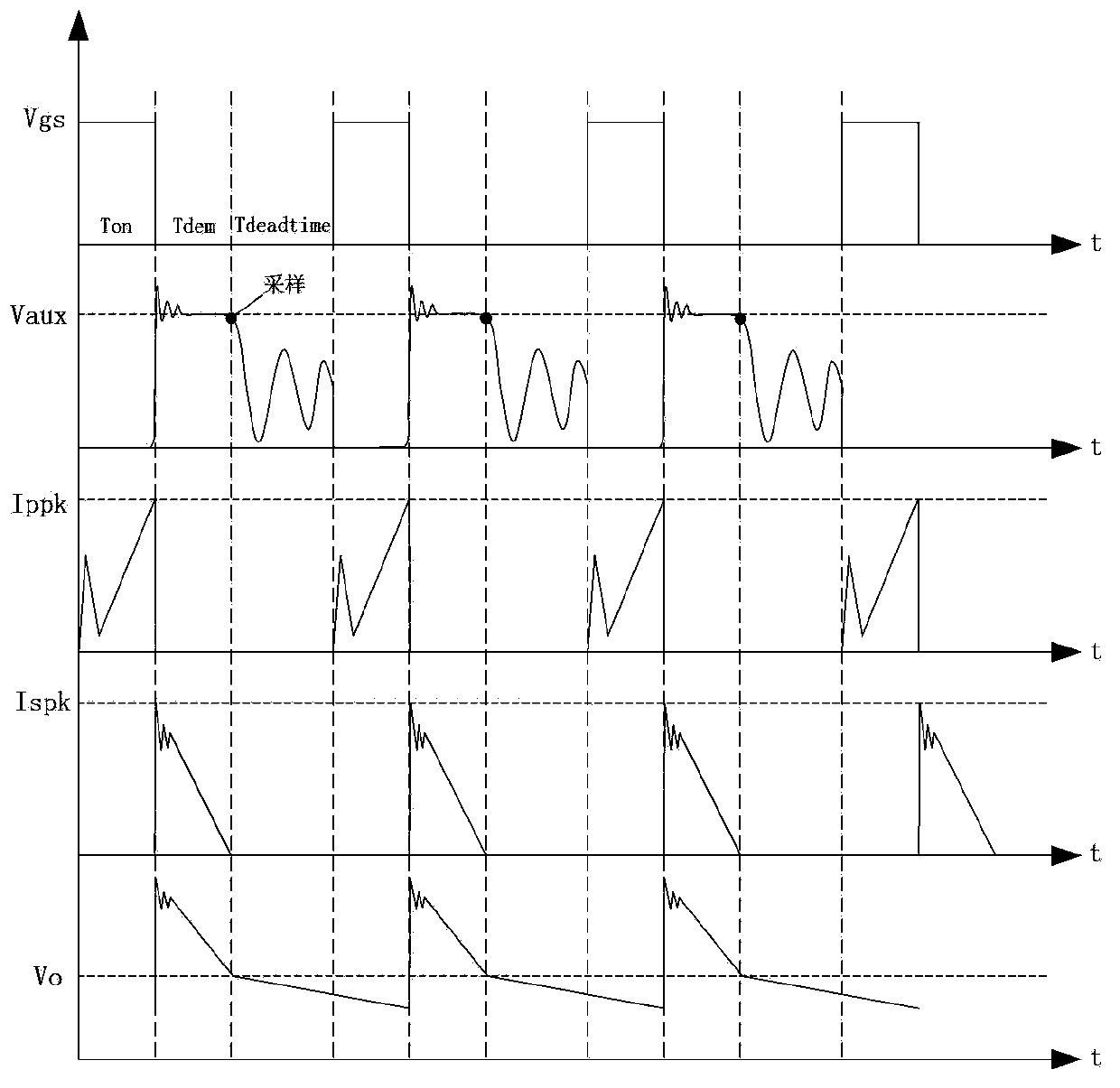

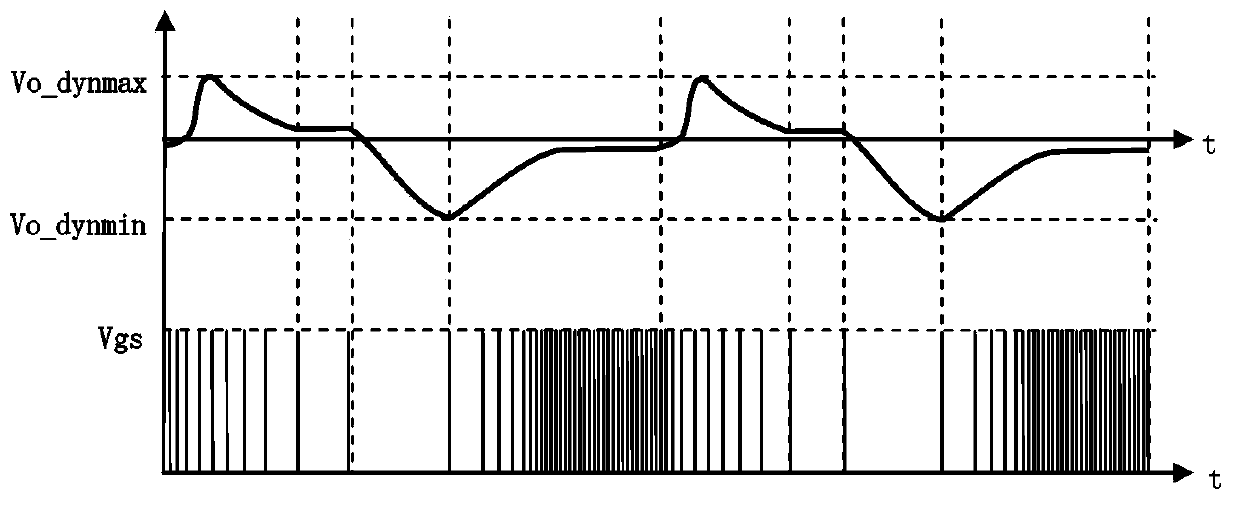

Control method and controller

ActiveCN103427655AReal-time monitoring sizeFast dynamic responseDc-dc conversionElectric variable regulationVoltage amplitudeSwitching cycle

The invention discloses a control method. The control method includes detecting a real-time output voltage of an output end of a converter of a switch power supply and sampling and outputting a feedback voltage signal relevant to the amplitude of the output voltage; comparing the feedback voltage signal to a reference voltage signal, judging whether the output voltage is higher than a set value or not in a dynamic load jumping procedure, and outputting a logic control level if the output voltage is higher than the set value; enabling the logic control level to trigger and output a pulse signal with a fixed pulse width and transmitting the pulse signal with the fixed pulse width from a secondary side to a primary side in an isolation manner; enabling the pulse signal which is transmitted to the primary side to trigger and output a quick reset signal, switching a working mode of a master control IC (integrated circuit) in an off-time modulation mode, quickly resetting an internal oscillator of the IC and enabling the circuit to quickly enter a next switch cycle. The control method has the advantage that the dynamic response speed of the converter of the switch power supply can be increased by the aid of the control method.

Owner:MORNSUN GUANGZHOU SCI & TECH

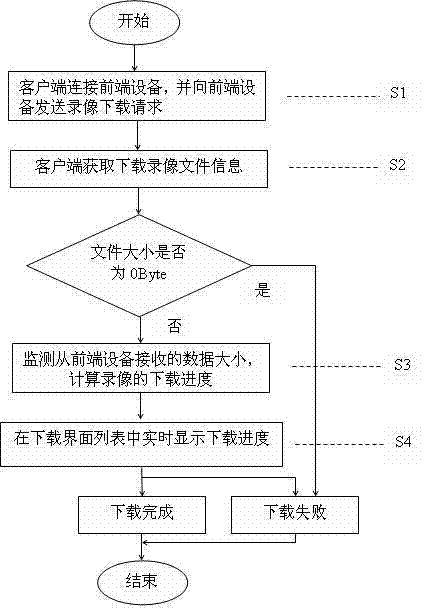

Method and system of displaying video download progress of front-end equipment in real time

InactiveCN103095807AReal-time monitoring sizeEasy to useTransmissionSpecific program execution arrangementsReal time displayReal-time computing

The invention relates to the technical field of network transmission, and discloses a method and a system of displaying video download progress of front-end equipment in real time. The method includes the following steps: first, a client terminal is connected with the front-end equipment, a video download interface is initialized, and a video file is downloaded, second, the client terminal obtains an address of the video file selected by the front-end equipment, third, the client terminal receives video data transmitted by the front-end equipment according to the download address, monitors the size of the video data received from the front-end equipment, and calculates download progress, and fourth, download progress is displayed on a download list page. The method and the system of displaying the video download progress of the front-end equipment in real time are capable of monitoring the size of the data received from the front-end equipment in real time, calculating download progress accurately according to the size of the downloaded video, and facilitating usage of a user.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

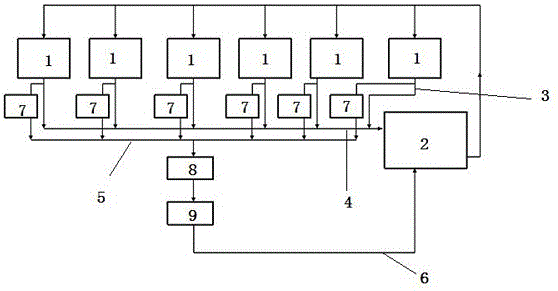

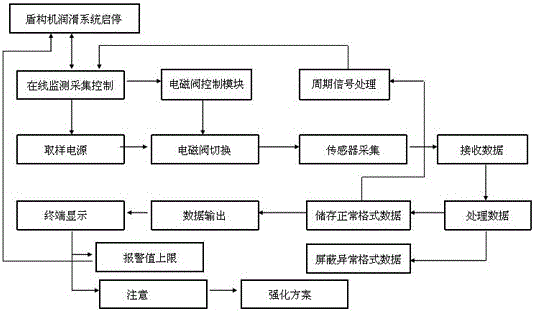

Shield TBM oil liquid state on-line automatic monitoring system

InactiveCN106525141AReal-time monitoring of moisture contentReal-time monitoring of viscosity changesMeasurement devicesLiquid stateSolenoid valve

The invention belongs to the technical field of shield machine lubrication condition monitoring, and proposes a shield TBM oil liquid state on-line automatic monitoring system. The proposed shield TBM oil liquid state on-line automatic monitoring system includes a planetary gear oil tank (1), a main bearing gear main oil tank (2) and an on-line monitoring acquisition control part (9); the on-line monitoring acquisition control part (9) has a plurality of solenoid valves (7); the plurality of solenoid valves (7) and a plurality of planetary gear oil tanks in a shield machine gear oil lubrication system are in one-to-one correspondence; the plurality of solenoid valves are cyclically opened in an on-line monitoring period, and only one is in a normally open state; the on-line automatic monitoring system is also provided with an oil liquid monitoring loop (5); the other ends of the plurality of solenoid valves (7) communicate with the oil liquid monitoring loop (5); and the oil liquid monitoring loop (5) is connected with the on-line monitoring acquisition control part (9). The shield TBM oil liquid state on-line automatic monitoring system provided by the invention ensures reliable lubrication of equipment and safe operation of a shield machine.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

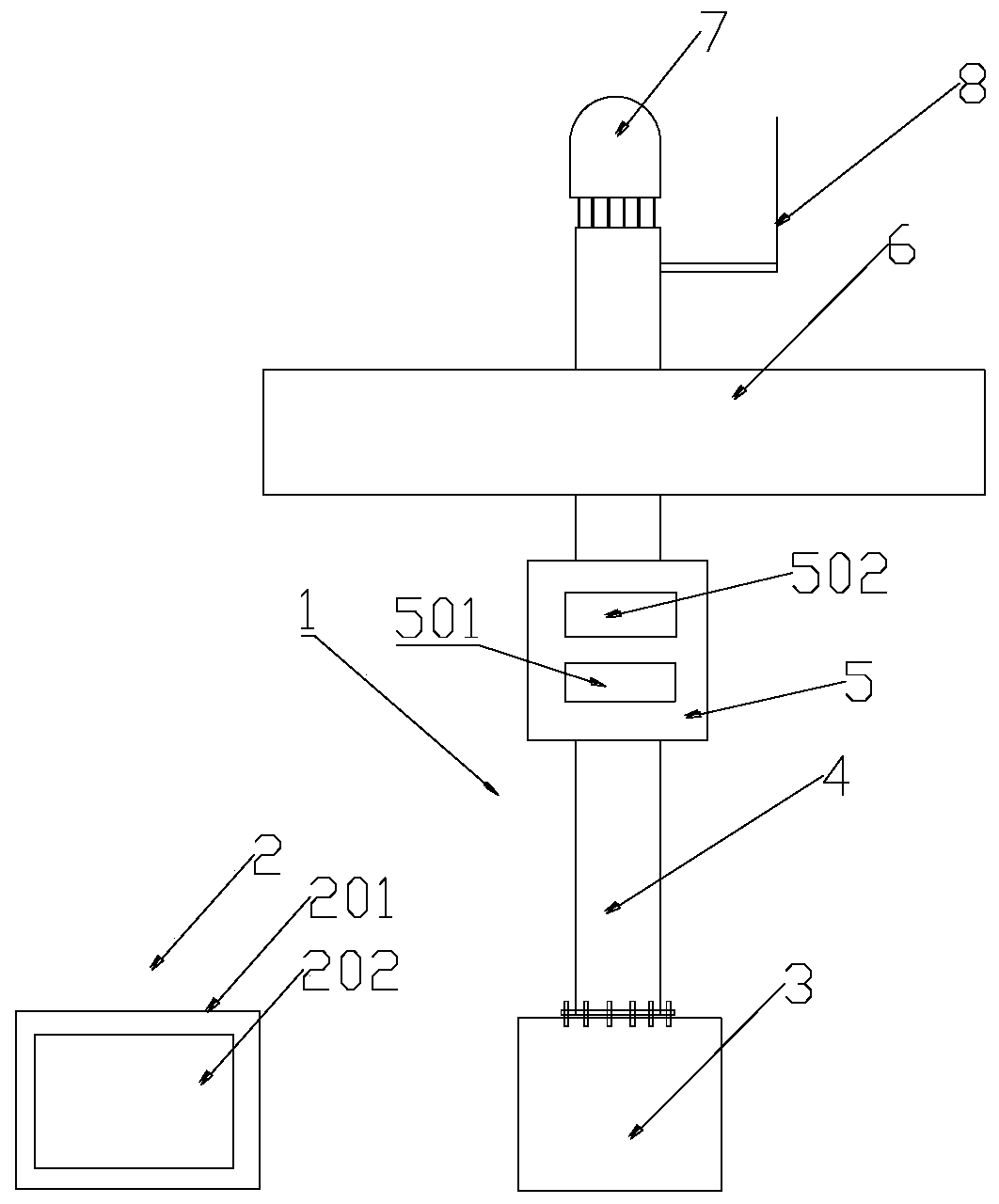

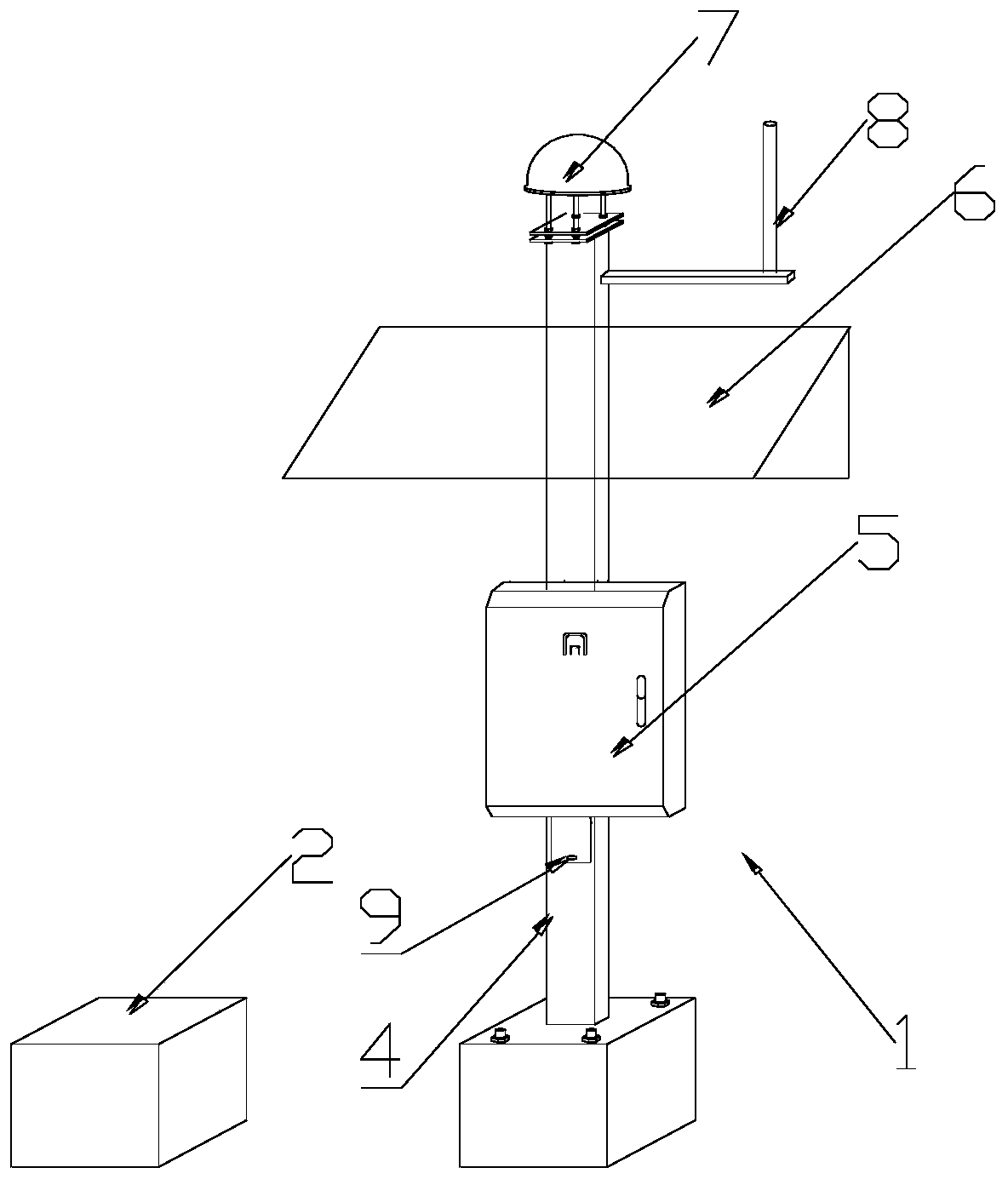

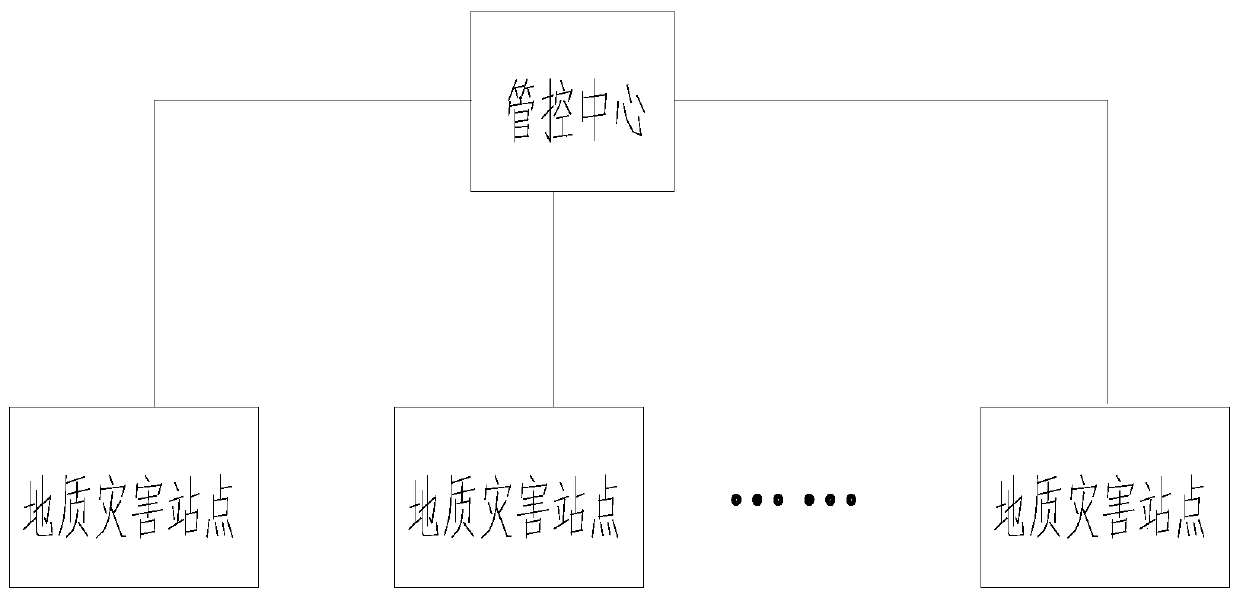

Geological disaster site and control system integrating warning and electricity storage functions

InactiveCN110648503AEasy to disassembleEasy to carry and installBatteries circuit arrangementsMeasurement devicesEnvironmental resource managementControl system

The invention relates to the technical field of geological equipment, and discloses a geological disaster site and control system integrating warning and electricity storage functions. The site comprises a monitoring body and a buried box which are arranged in a matched manner. The system comprises a control center and a plurality of geological disaster sites. According to the site and the system,the early warning of the danger can be realized, the displacement change information of the landslide mass can be mastered in real time, the landslide disaster can be predicated, the early warning self-control effect can be achieved, and higher practical value and wide application prospect are provided.

Owner:ANHUI TELECOMM ENG

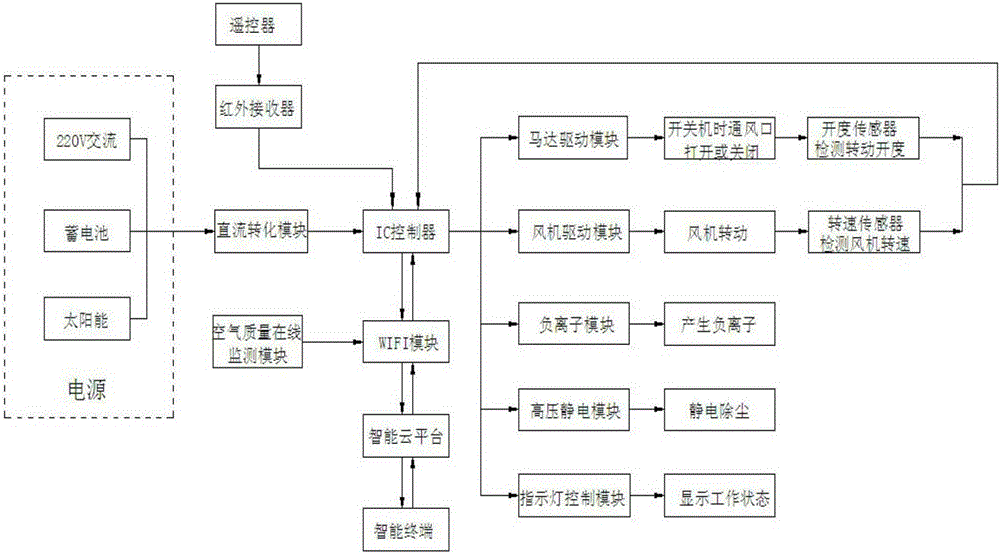

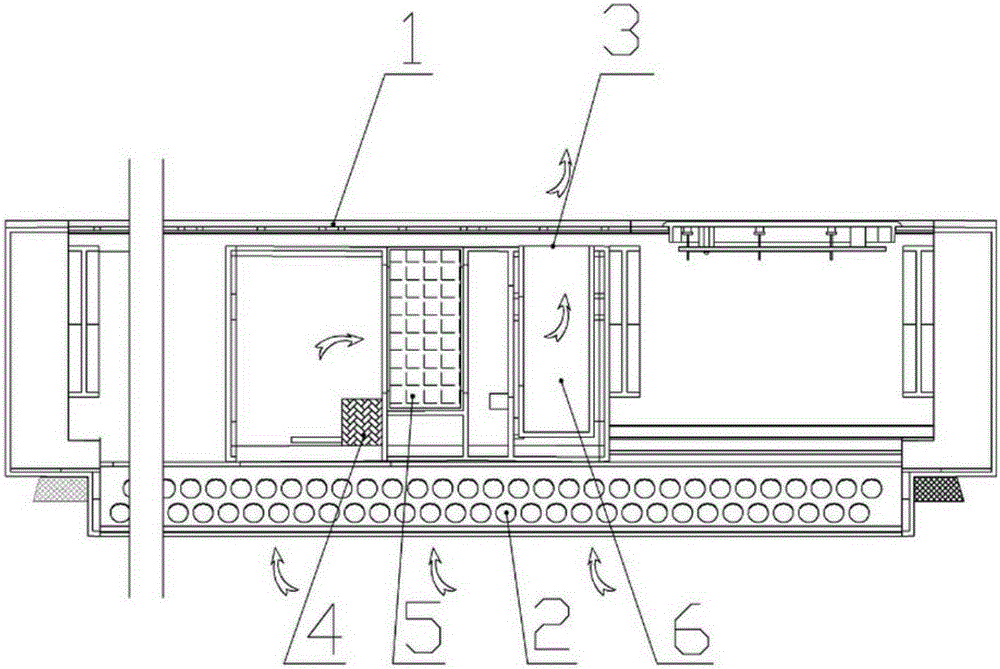

Ozone disinfection power ventilator for remotely and online monitoring air quality

InactiveCN105352096AReduce energy consumptionIncrease speedMechanical apparatusSpace heating and ventilation safety systemsMotor driveFresh air

The invention relates to an ozone disinfection power ventilator for remotely and online monitoring air quality. The ozone disinfection power ventilator comprises a ventilator shell which is provided with gas inlets and gas outlets. A plurality of air purification devices are arranged in the ventilator shell. Each air purification device comprises an ozone generator, an ozone removal filter screen and a draught fan. An air quality online monitoring and remote control system comprises a power supply, a direct-current conversion module, an air quality online monitoring module, a WIFI module, an intelligent cloud platform, an intelligent terminal, an IC controller, a draught fan drive module and a motor drive module. The air quality online monitoring module is connected with the WIFI module. The WIFI module is connected with the IC controller and the intelligent cloud control platform. The intelligent cloud platform is connected with the intelligent terminal. The power supply is connected with the IC controller. The IC controller is connected with the draught fan drive module and the motor drive module. By means of the ozone disinfection power ventilator, air quality can be monitored online, data can be remotely downloaded, ventilator ventilation is remotely controlled, people can completely breathe fresh air, and energy consumption can also be obviously lowered.

Owner:CHONGQING GREEN AKIRA TECH DEV

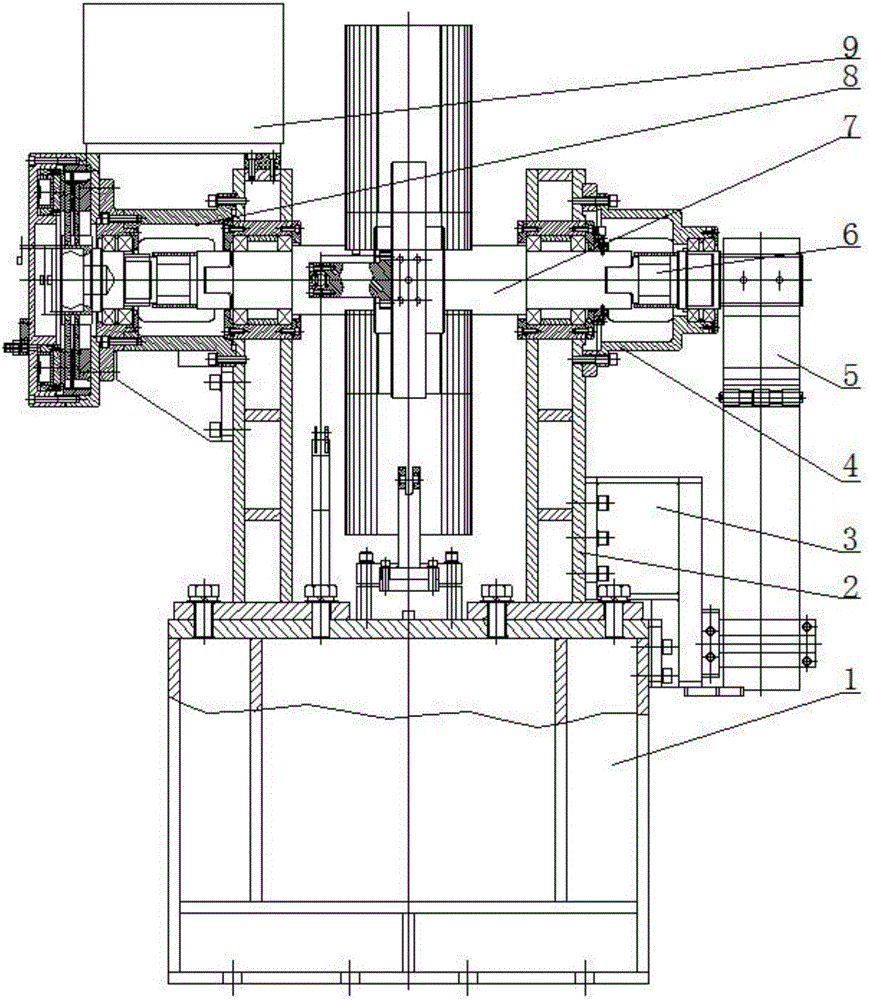

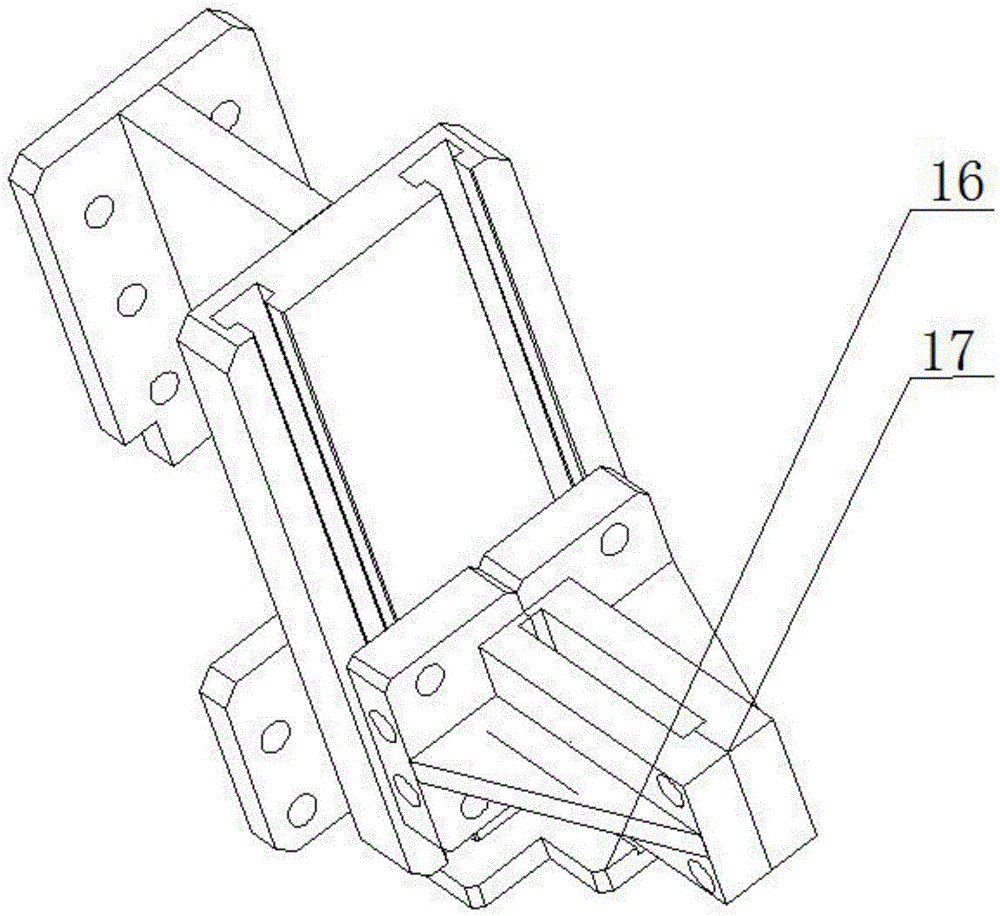

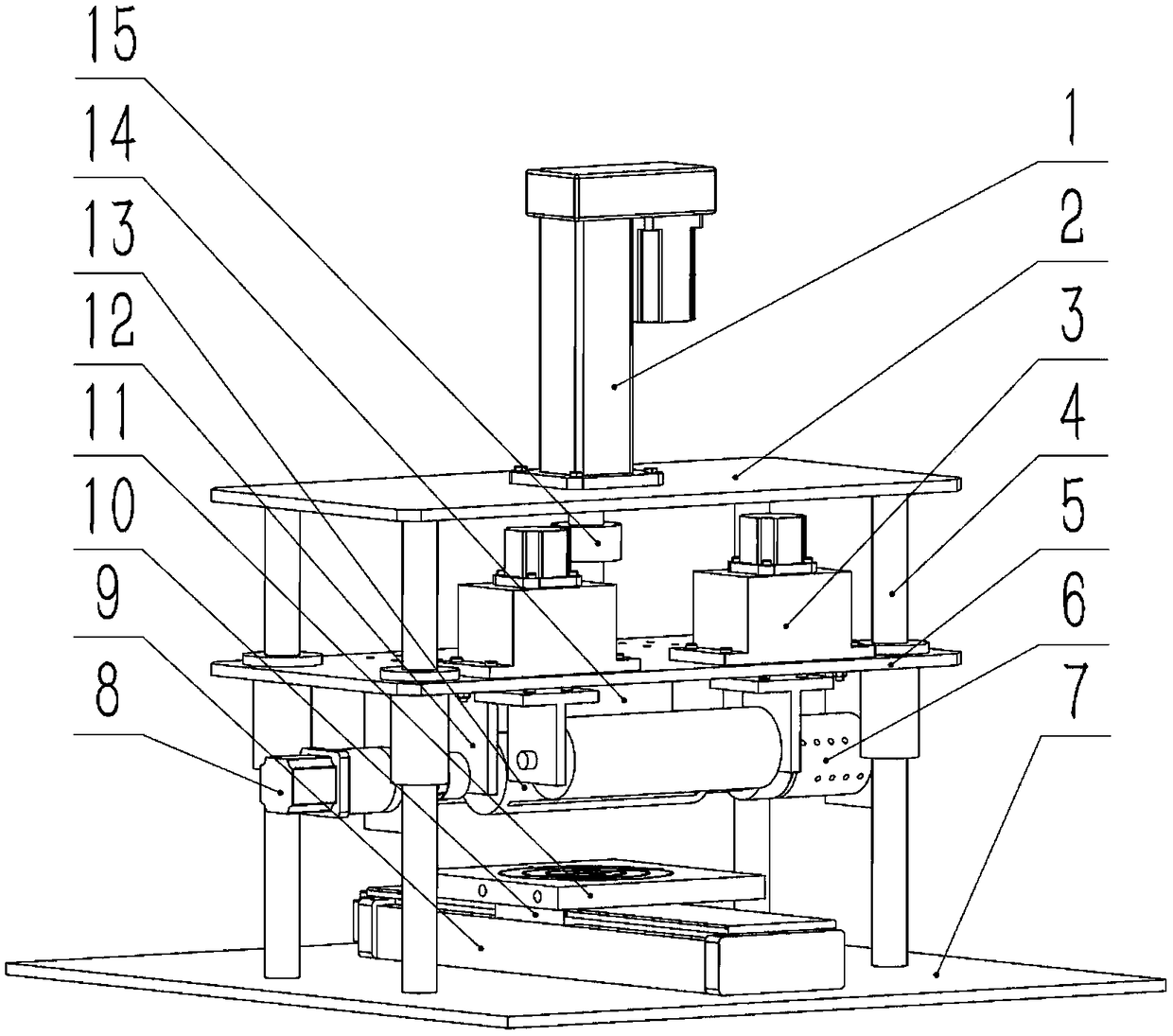

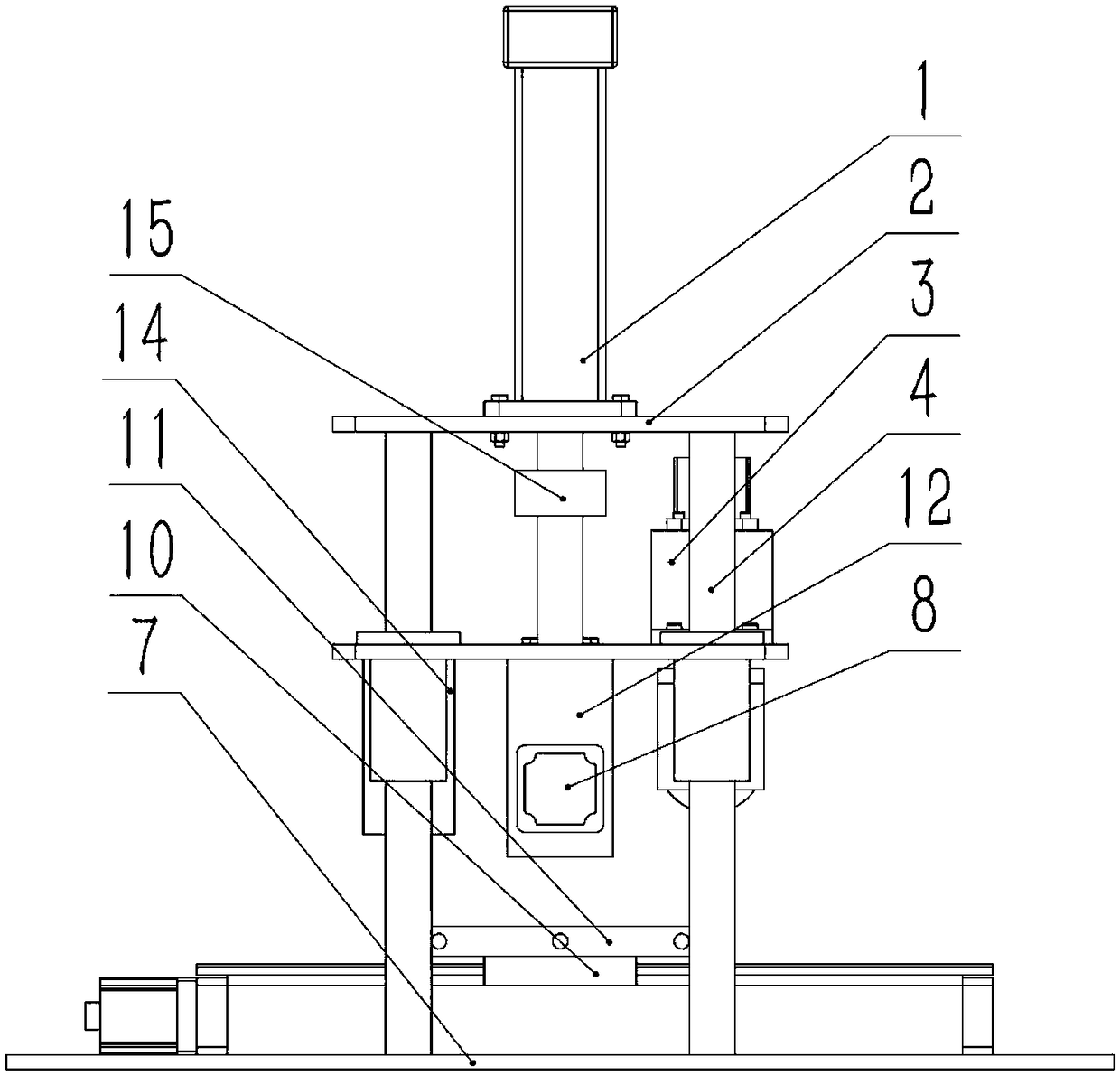

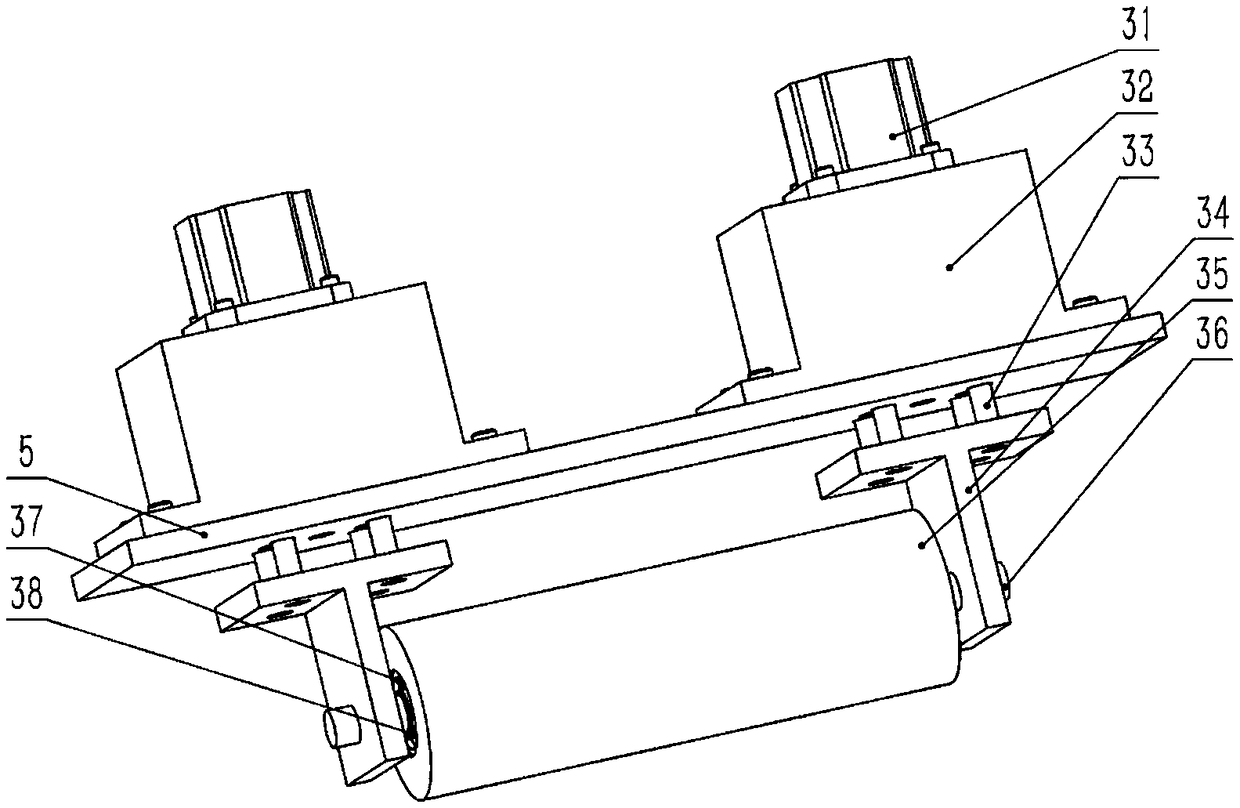

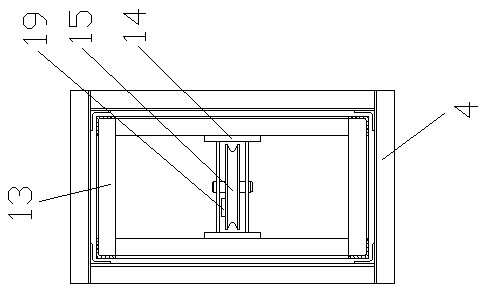

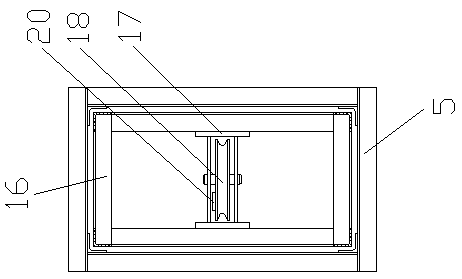

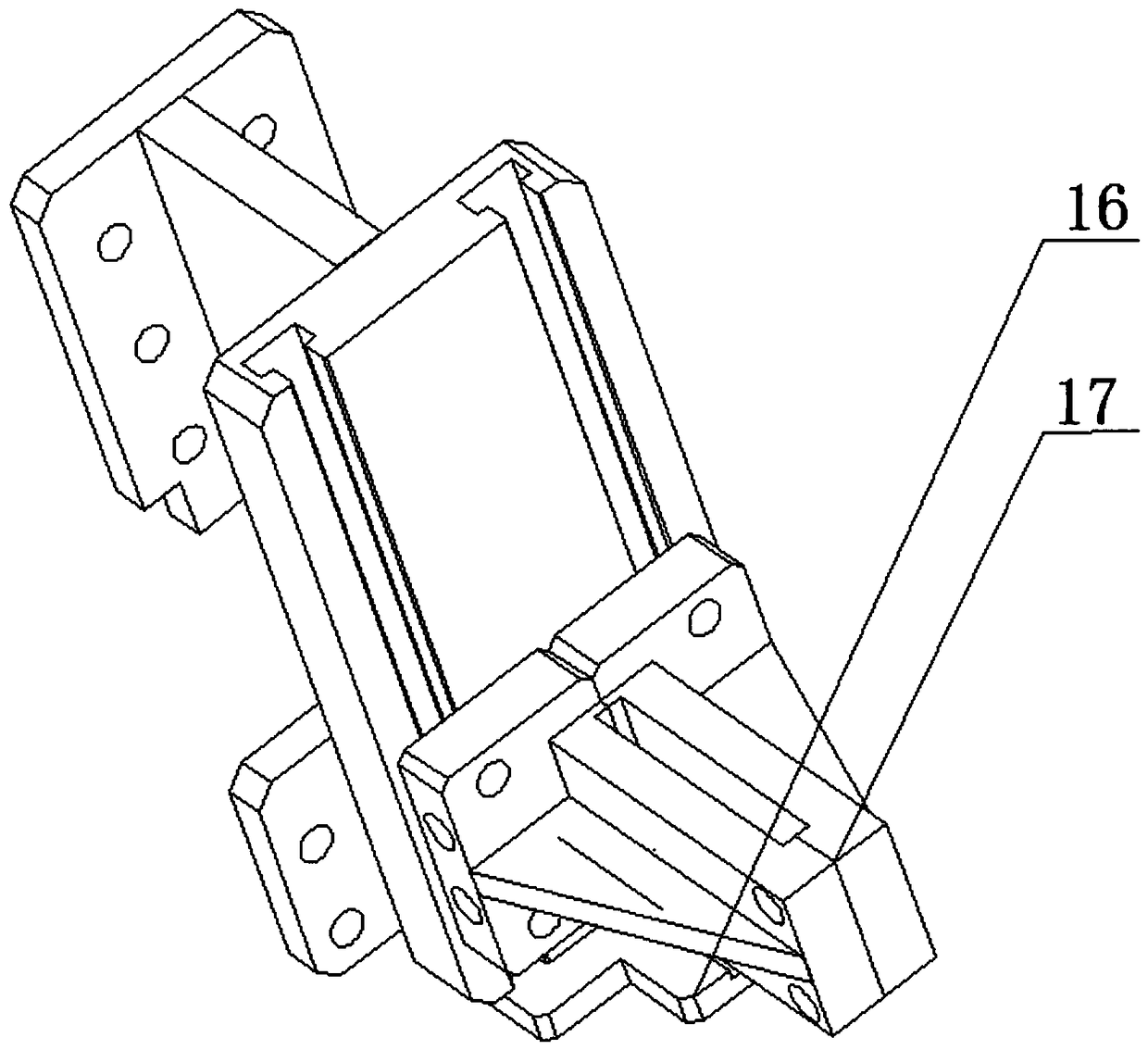

Servo mechanism force moment loading device

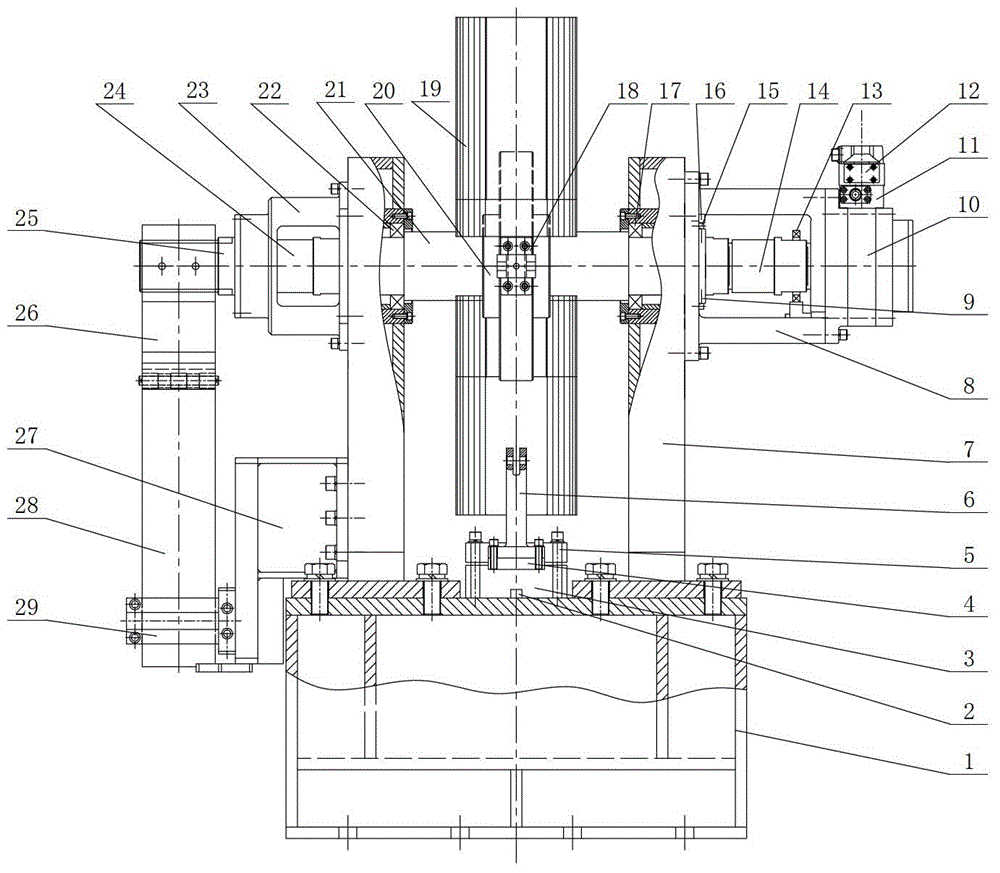

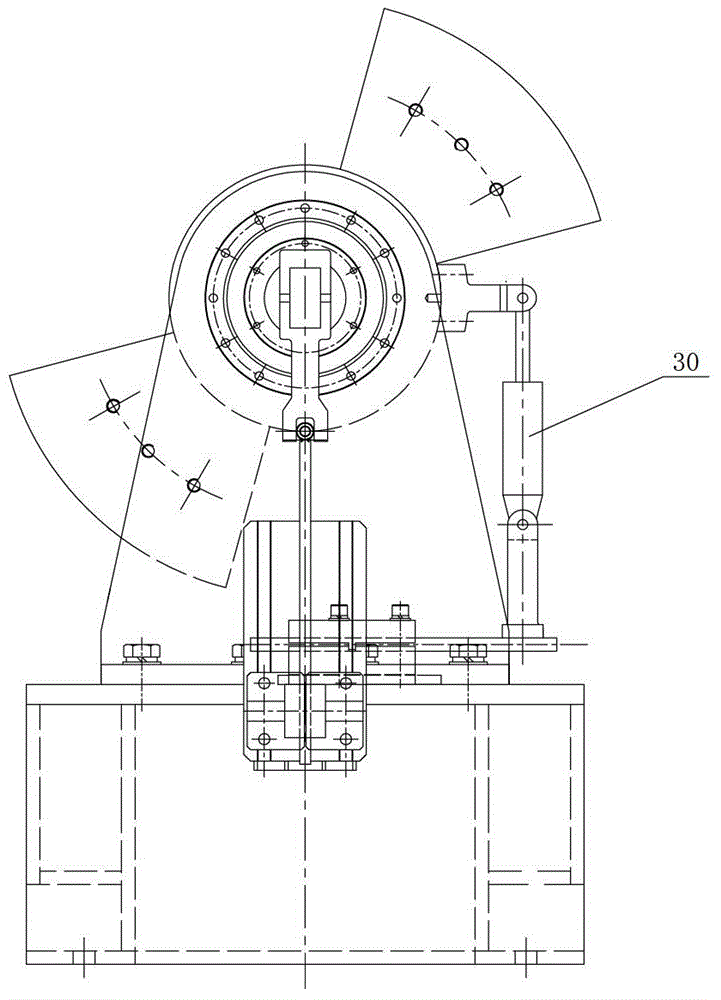

InactiveCN106840725AContinuous regulationReal-time monitoring sizeWork measurementStructural/machines measurementCantilevered beamFriction torque

The invention discloses a servo mechanism force moment loading device and belongs to the technical field of mechanical system test facilities. The friction moment loading of the device can be continuously adjusted by loading hydraulic oil, and meanwhile a loading moment can be monitored through a friction moment sensor in real time; elastic moment loading can be continuously adjusted, a supporting spring plate is used for achieving the supporting rigidity of a servo mechanism for overcoming the strength requirement of a spring moment spring plate, and continuous supporting rigidity adjustment can be achieved by adjusting the clamping position of the supporting spring plate. The servo mechanism force moment loading device has the advantages that compared with a traditional servo mechanism force moment loading device, the friction moment loading of the device can be continuously adjusted by loading the hydraulic oil.

Owner:BEIHANG UNIV

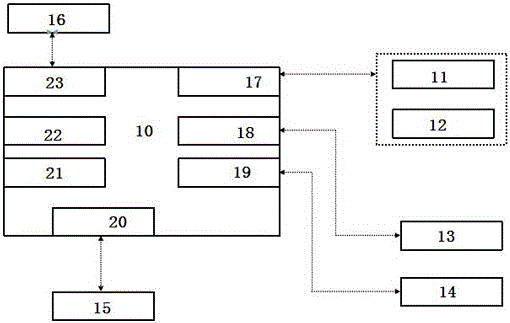

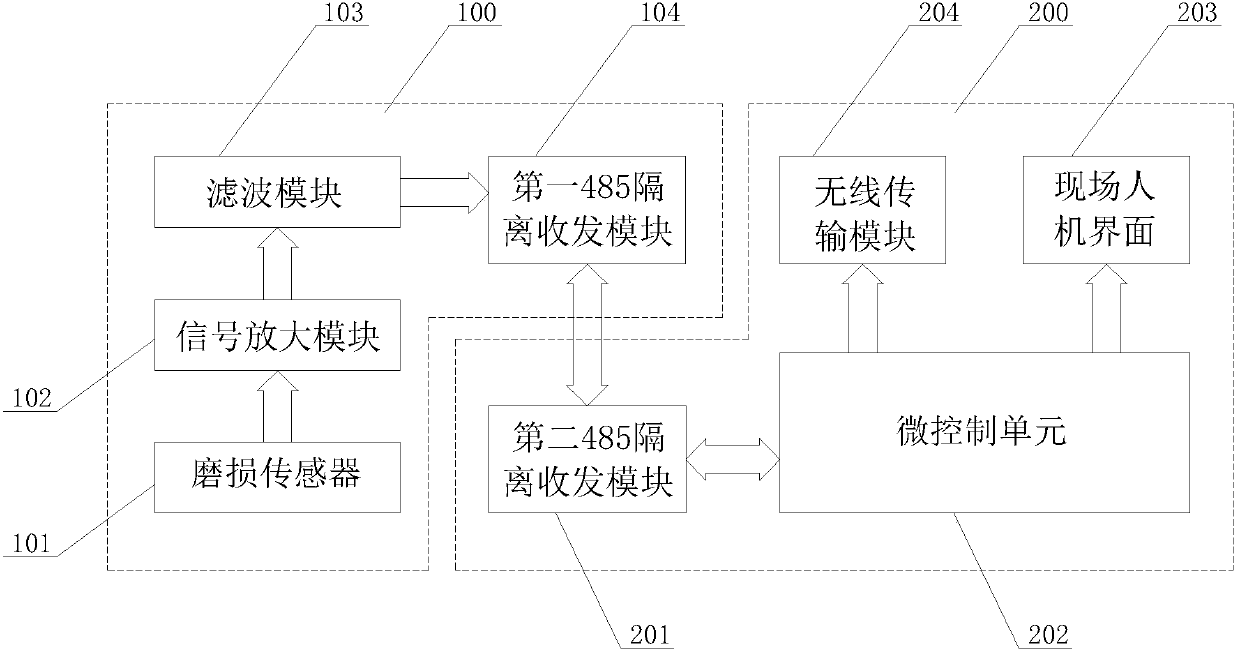

Discharge port size detecting system of jaw crusher

InactiveCN105498940AReal-time monitoring sizeGrasp the size information in timeMeasurement devicesGrain treatmentsHuman–machine interfaceTransmission technology

The invention relates to a discharge port size detecting system of a jaw crusher, and belongs to the sensing detection and signal processing transmission technology. The discharge port size detecting system of the jaw crusher comprises a front end sensor subsystem and a control and transmission subsystem; the front end sensor subsystem detects the wear extentsof a fixed jaw plate and a movable jaw plate of the jaw crusher through wear sensors, and outputs the wear extents in a wear signal mode; the wear signals are amplified, filtered and converted to send to the control and transmission subsystem; the control and transmission subsystem calculates the present discharge port size according to the delivery discharge port size and the received wear signals; and the present discharge port size is displayed on a field human-computer interface. The discharge port size detecting system of the jaw crusher can monitor the discharge port size in real time, can timely master the discharge port size information of the jaw crusher through the field human-computer interface or remote login, and guides operators to timely adjust the discharge port size when a discharge portincreases so as to guarantee the qualification of production technology.

Owner:SHANGHAI YUNTONG INFORMATION SCI & TECH CO LTD

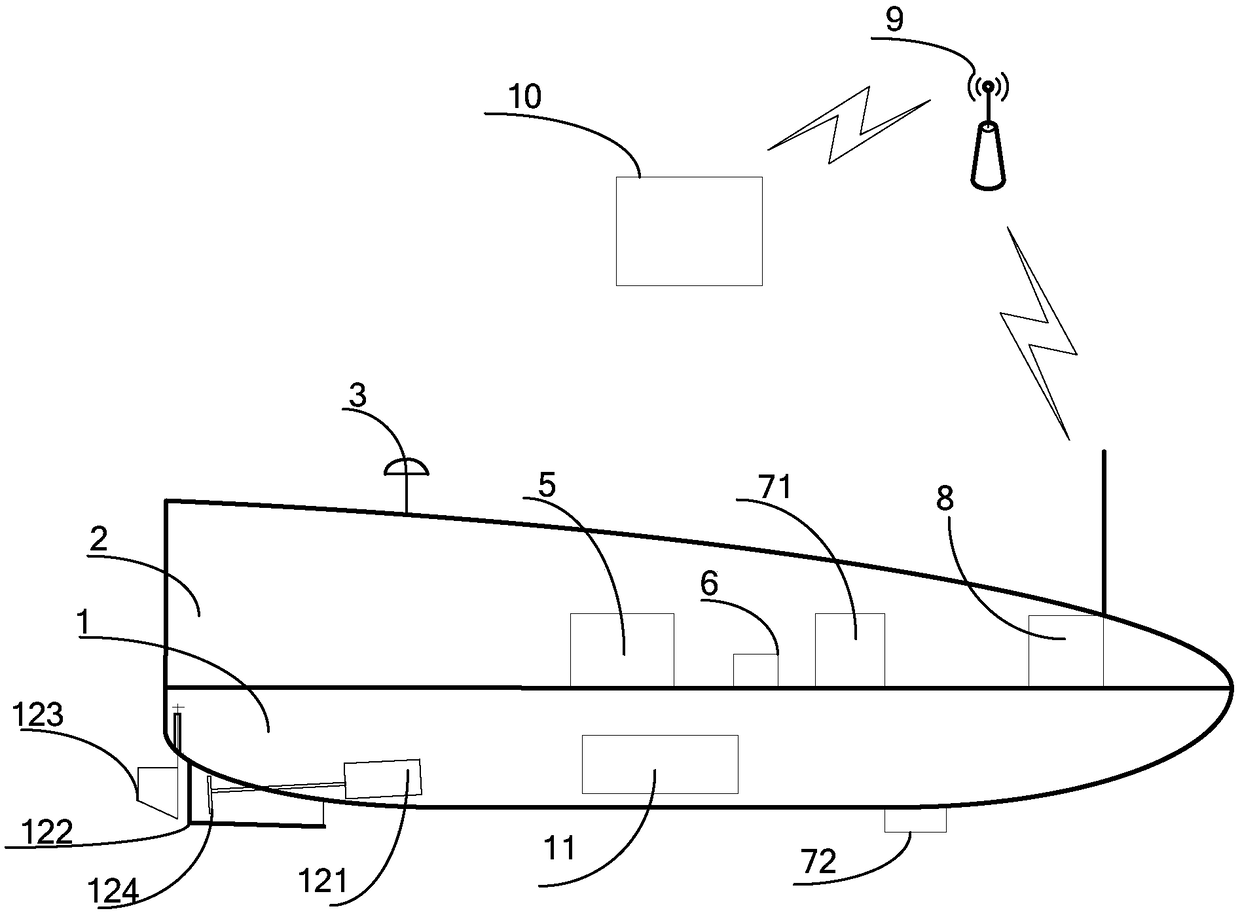

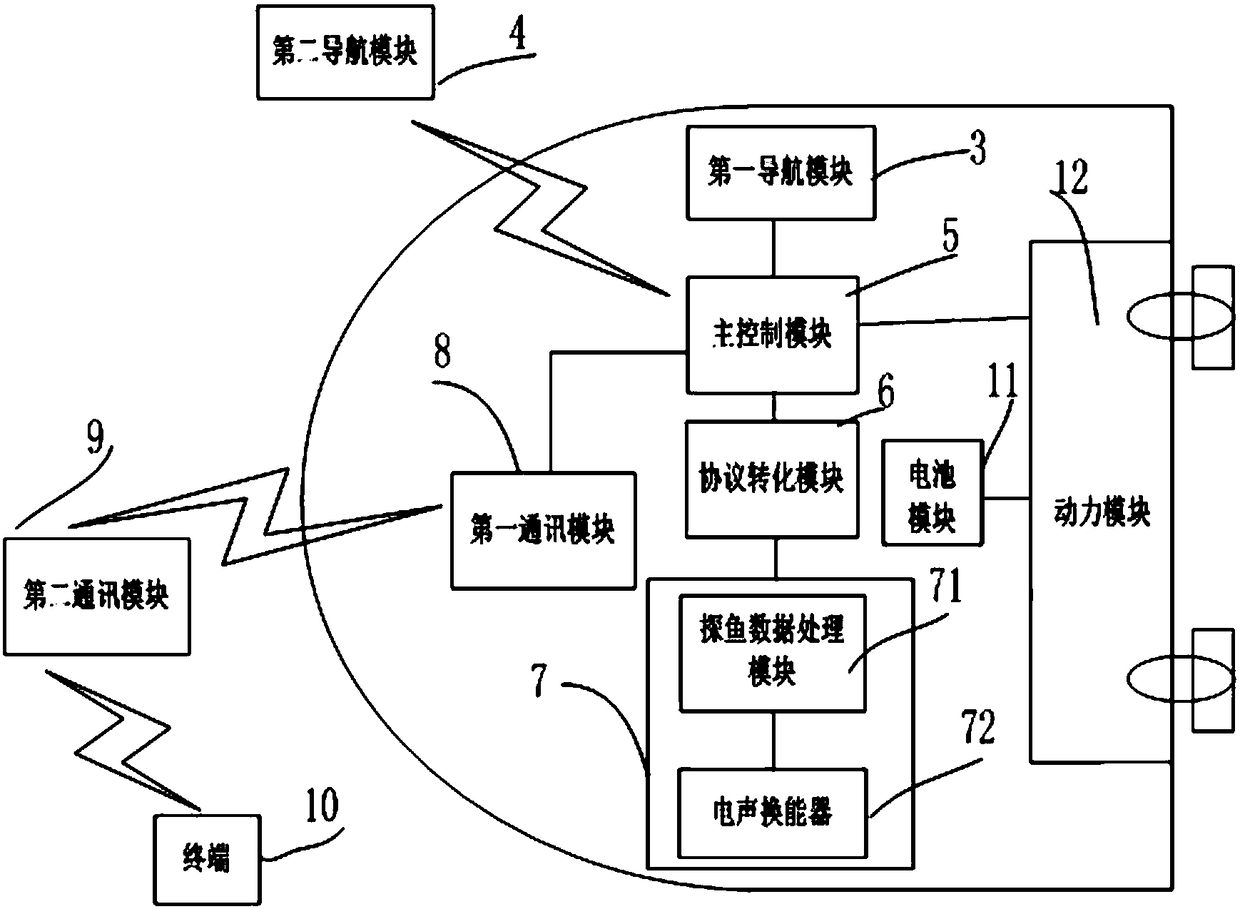

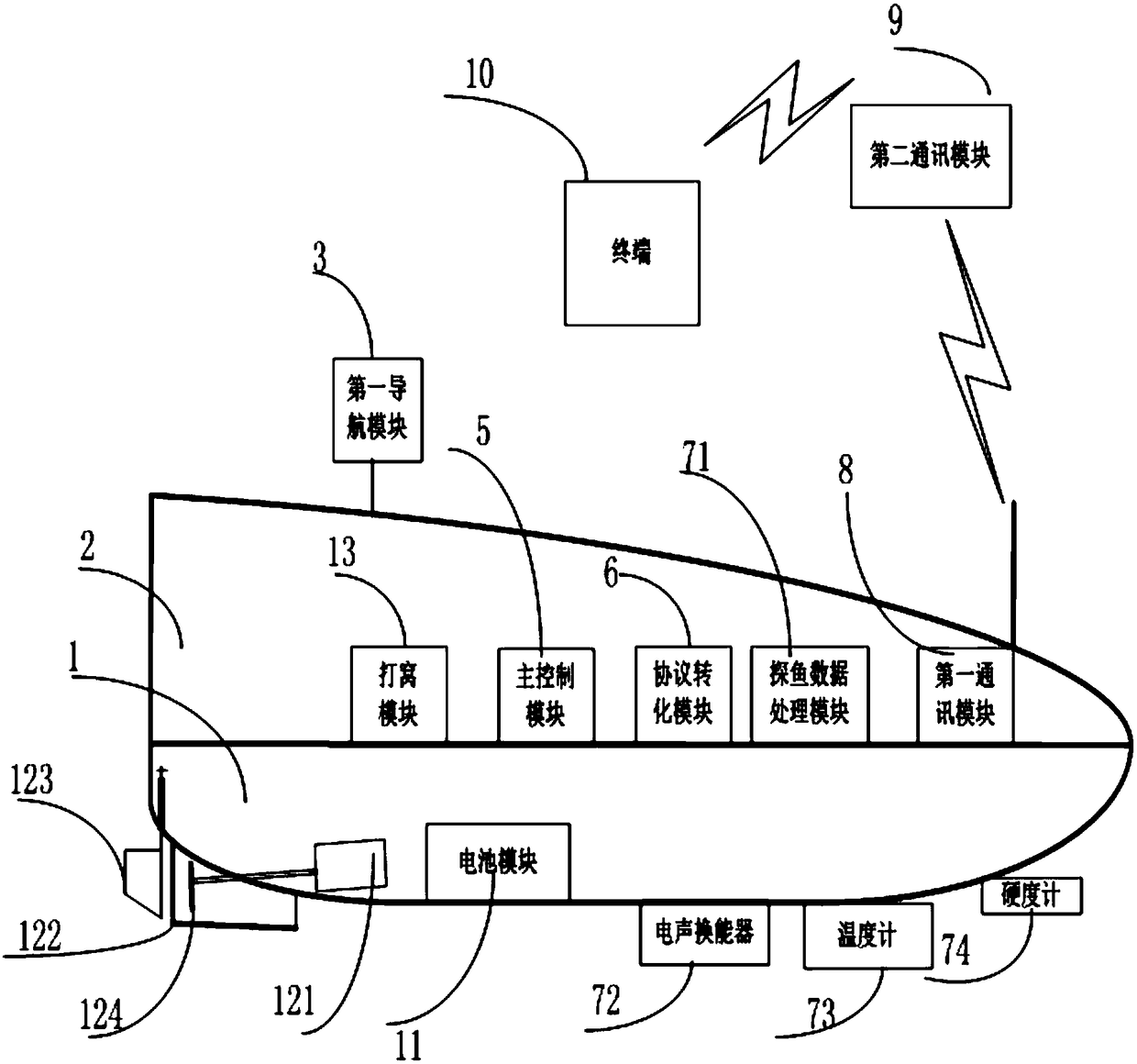

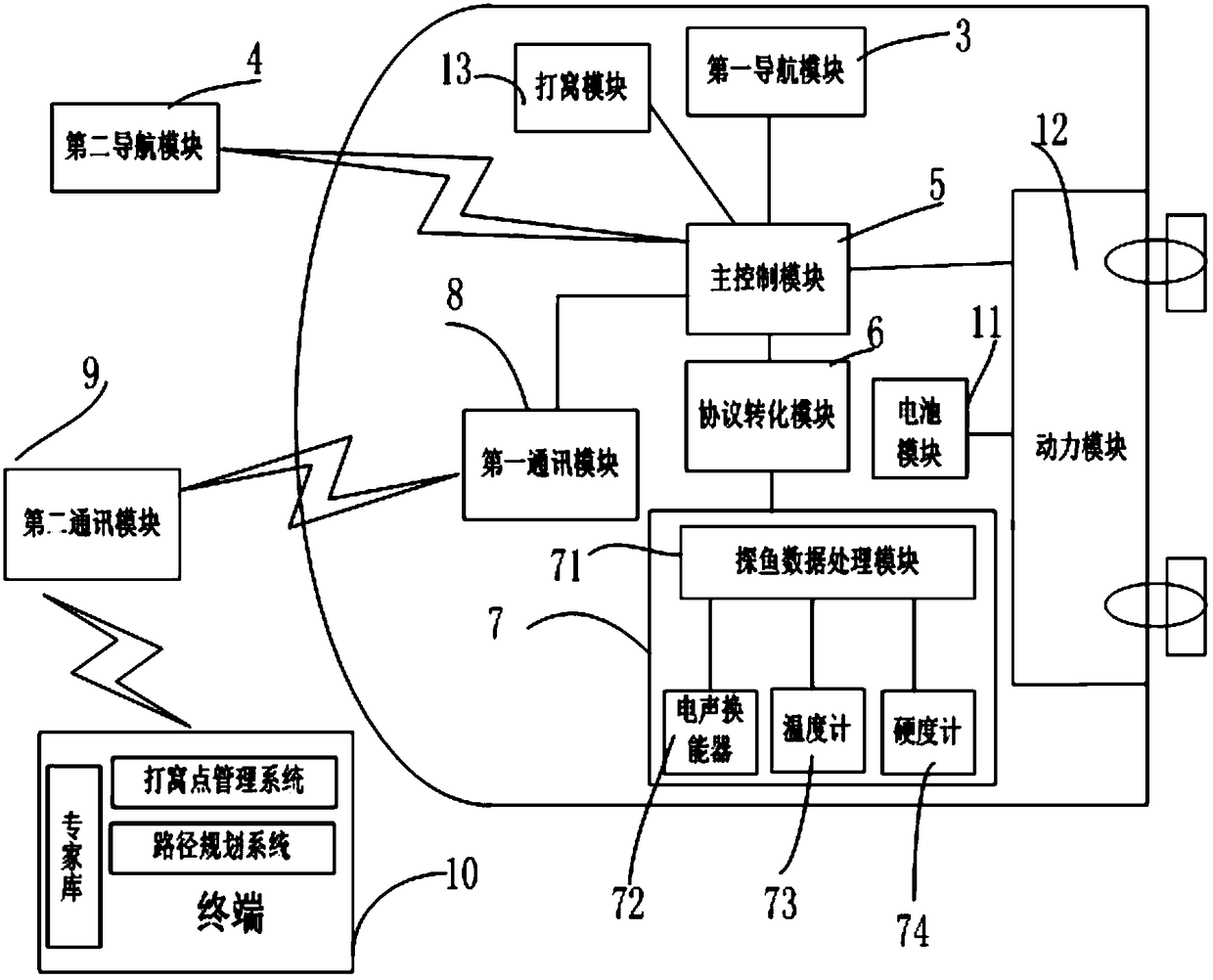

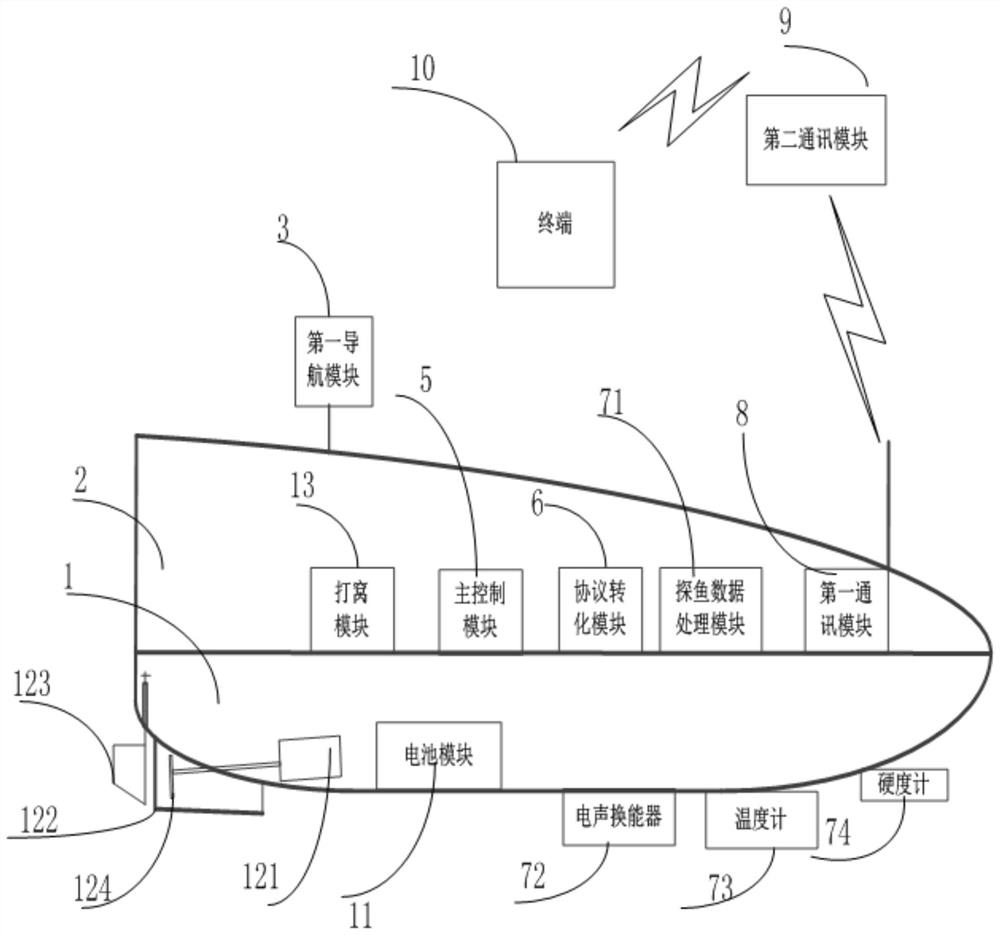

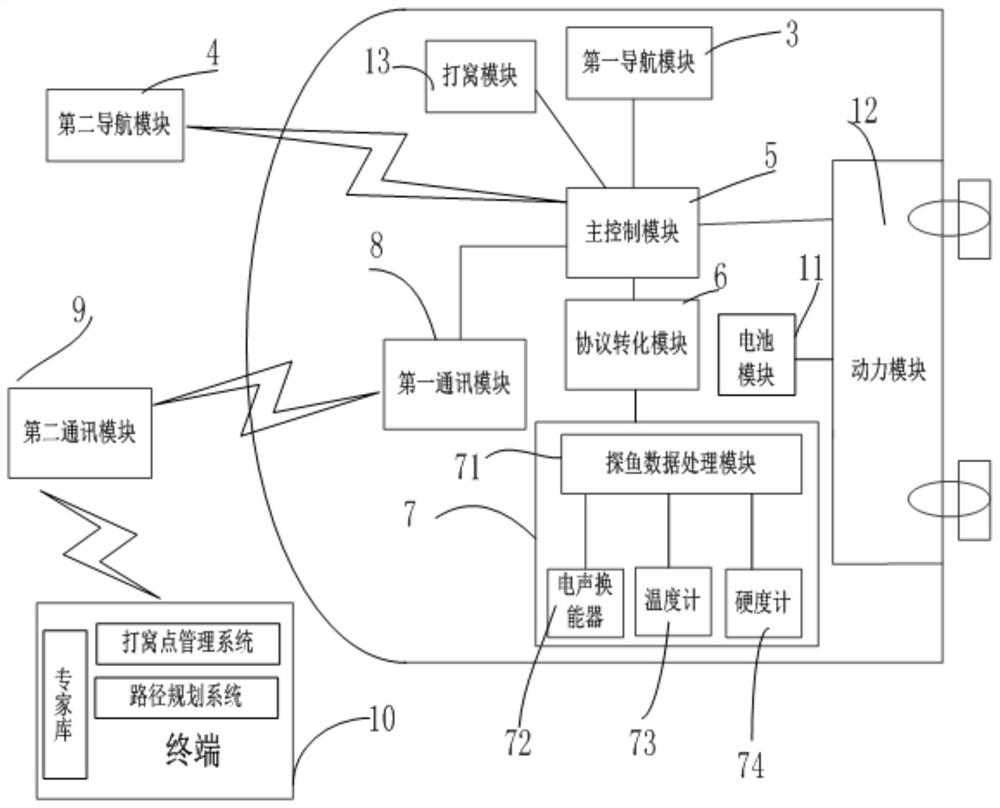

Control system of unmanned ship and unmanned ship

InactiveCN108646753AOvercome communication difficultiesImprove compatibilityPosition/course control in two dimensionsControl systemModularity

The invention relates to the field of overwater unmanned ships, in particular to a control system of an unmanned ship and the unmanned ship. The problems are solved that for existing unmanned ships, fish-finding modules and main control modules of different manufacturers have difficulty in communication and cannot be compatible. The control system of the unmanned ship comprises a protocol conversion module, the protocol conversion module can convert fish-finding protocols of different manufacturers into data protocols which can be identified by the main control modules, data is sent to the main control modules through serial ports or other bus modes, and the fish-finding modules of different manufacturers are compatible; modularization is achieved, and the fish-finding modules of differentmanufacturers are conveniently updated or replaced. Meanwhile, the invention further provides the unmanned ship.

Owner:安徽欣思创科技有限公司

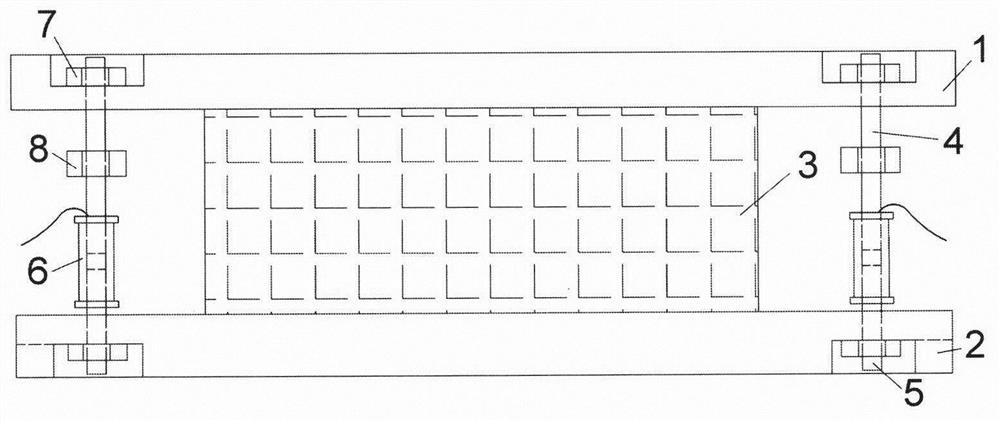

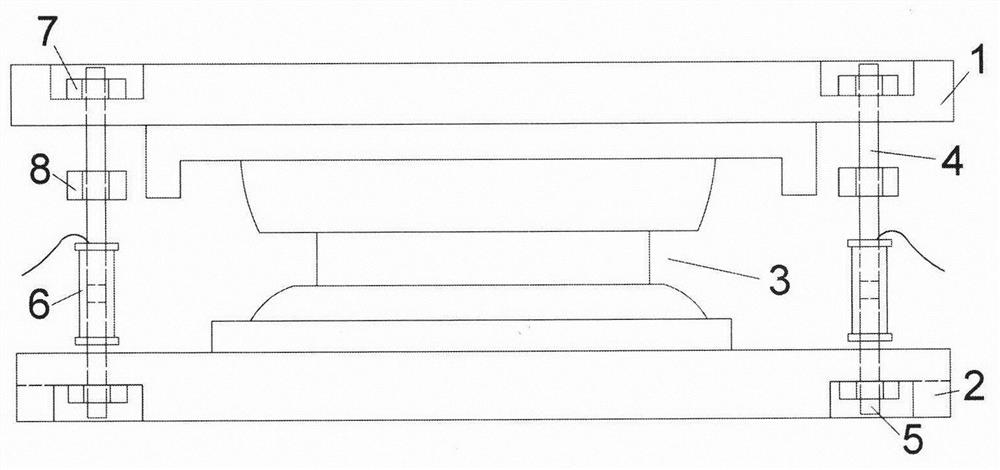

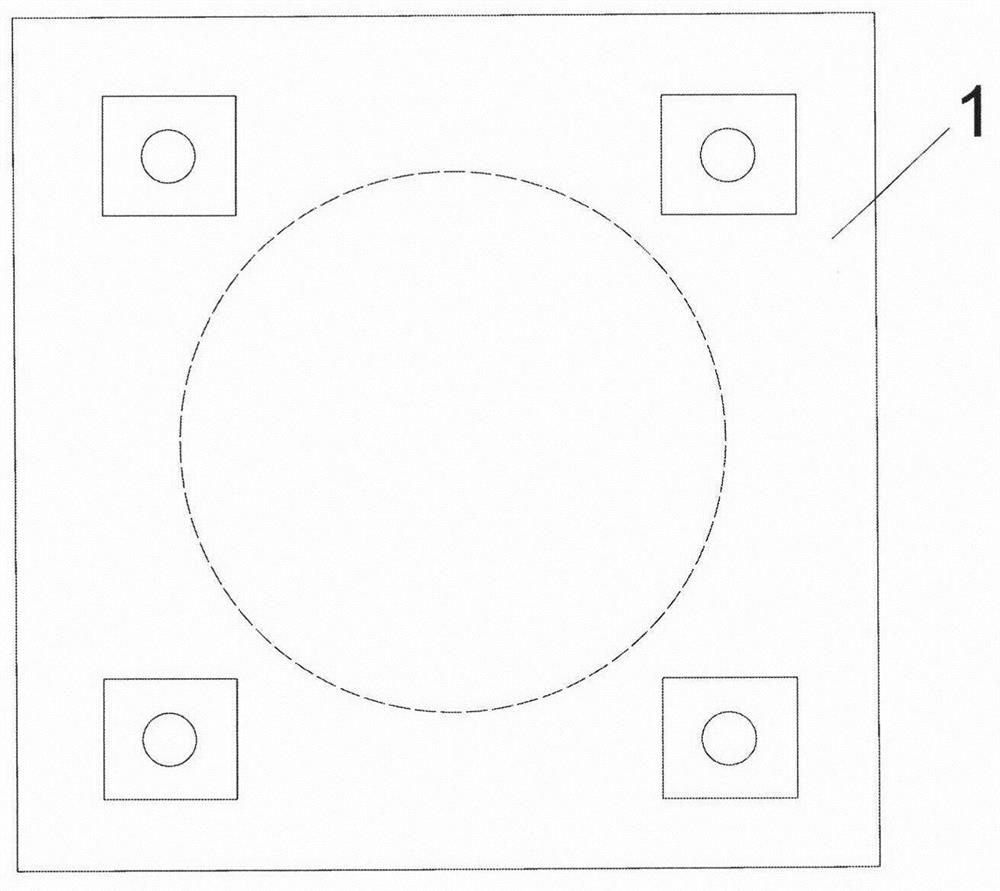

Device for manufacturing large-are micro-nanostructures in batches and working method of device

PendingCN108762001AEnsure consistencyHigh positioning accuracyPhotomechanical apparatusNanotechnologyMicro nanoComputer module

The invention discloses a device for manufacturing large-are micro-nanostructures in batches and a working method of the device. According to the device, the precision and the quality of imprinted patterns and the efficiency and the reliability of micro-nano imprinting equipment are improved, and the service life of a mold is prolonged. According to the technical scheme, the device comprises a base plate, vertical guide rods are fixedly arranged on the base plate, the tops of the guide rods are fixedly connected with a top plate, a support plate is arranged in the middles of the guide rods ina penetrating mode, a driving device is connected with the support plate to drive the support plate to move up and down, and a pressure detection module is arranged between the driving device and thesupport plate; and an auxiliary imprinting module, a main imprinting module and a solidification module are sequentially connected to the bottom of the support plate from front to back, the auxiliaryimprinting module comprises an imprinting roller, a roller shaft is arranged in the middle of the imprinting roller in a penetrating mode, the two ends of the roller shaft are connected with imprinting roller connecting frames, the tops of the imprinting roller connecting frames are connected with a reciprocating mechanism through auxiliary imprinting module guide rods, and the reciprocating mechanism can drive the imprinting roller to move up and down.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

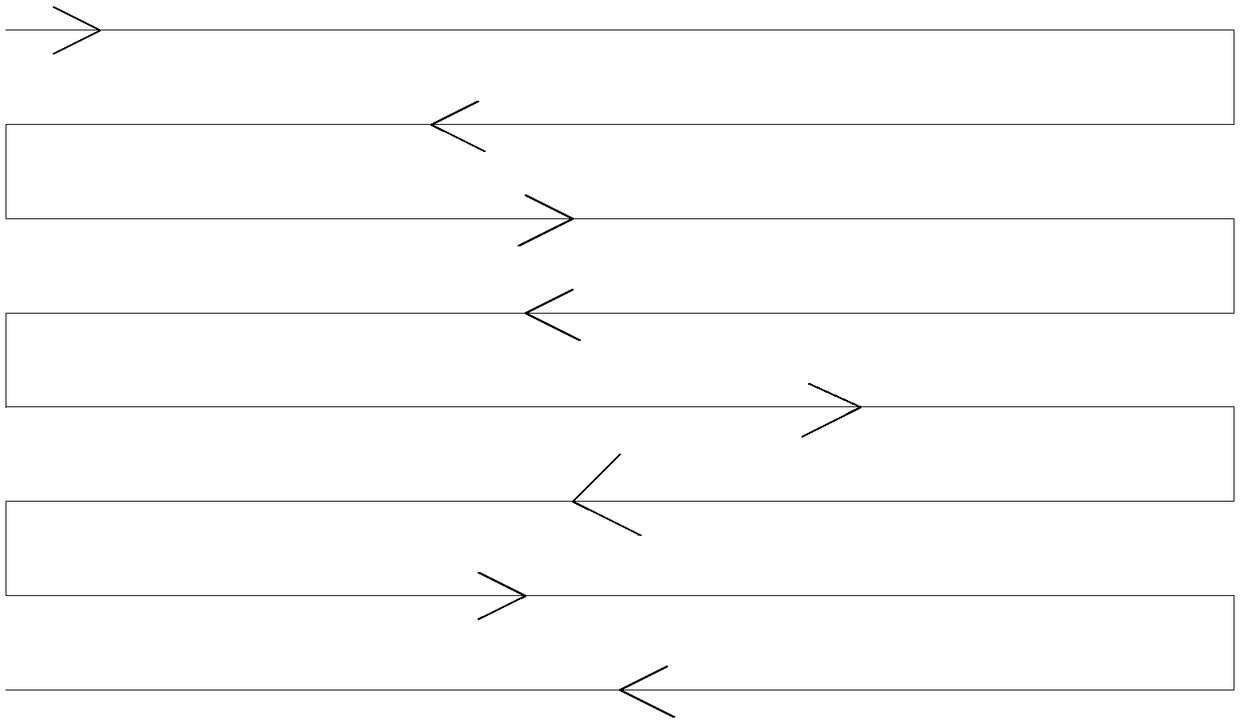

Buried culvert desilting system

InactiveCN110670708ARealize the function of stroke limit position controlImprove dredging efficiencySewer systemsFrequency changerReciprocating motion

The invention discloses a buried culvert desilting system, and belongs to the technical field of desilting equipment. The buried culvert desilting system comprises a scraper bucket and is characterized in that the buried culvert desilting system further comprises a main traction winch, an auxiliary traction winch, a main supporting frame, an auxiliary supporting frame, a main traction steel wire rope, an auxiliary traction steel wire rope, a PLC, a frequency converter and a displayer; a main proximity switch is fixed to the bottom of the main supporting frame, and an auxiliary proximity switchis fixed to the bottom of the auxiliary supporting frame; one end of the main traction steel wire rope is connected with the main traction winch, and the other end of the main traction steel wire rope is connected with the scraper bucket; one end of the auxiliary traction steel wire rope is connected with the auxiliary traction winch, and the other end of the auxiliary traction steel wire rope isconnected with the scraper bucket; and the scraper bucket is driven by the main traction winch and the auxiliary traction winch to do reciprocating motion in a culvert in the length direction of theculvert. Through the buried culvert desilting system, the desilting operation efficiency can be effectively improved, the operation process is visualized, thus, the operation situation of the interiorof the underground culvert can be monitored in real time, and deposits in the underground culvert can be advantageously removed to the greatest extent.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

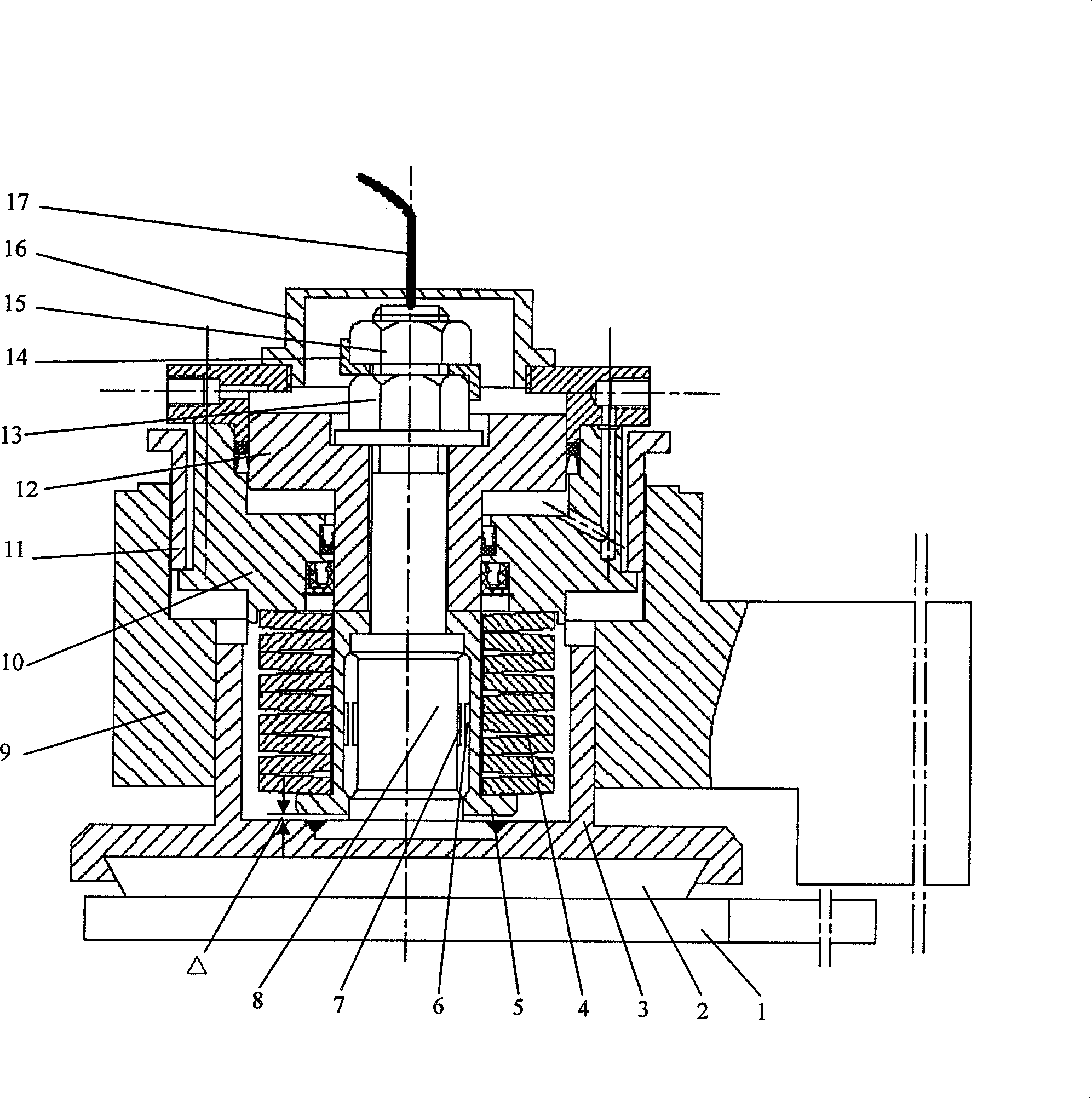

Disc type brake for monitoring braking positive pressure under braking state

InactiveCN100467899CReal-time monitoring sizeCompact structureBrake typesHydraulic cylinderPositive pressure

Owner:平顶山煤业(集团)有限责任公司 +1

Intelligent freely-compressible bridge replacement support

PendingCN112359714AReal-time monitoring sizeHigh degree of intelligenceBridge structural detailsClassical mechanicsStructural engineering

An intelligent freely-compressible bridge replacement support comprises an upper steel plate, a lower steel plate, a support body, an upper screw, a lower screw, a force sensor, a fixing nut and a force application nut. The support body is arranged in a space gap between the upper steel plate and the lower steel plate, the upper screw penetrates through a reserved hole channel of the upper steel plate, the upper end is fixed to the upper steel plate through a fixing nut, and the lower end extends into the force sensor; the lower screw penetrates through a reserved hole channel of the lower steel plate, the lower end is fixed to the lower steel plate through a fixing nut, the upper end extends into the force sensor, and the force application nut is arranged at the upper screw between the upper steel plate and the force sensor. According to the structure, relative movement between the upper steel plate and the lower steel plate is controlled by rotating the force application nut, compression and loosening of the support body are achieved, and meanwhile accurate monitoring of compression force in the operation process can be achieved through the force sensor. The structure is high inintelligent degree, the compression force can be freely adjusted according to actual needs, and the compression force can be monitored in real time.

Owner:NANJING FORESTRY UNIV

Intelligent bait throwing ship and method

ActiveCN108902068AOvercome communication difficultiesImprove compatibilityWaterborne vesselsOther angling devicesComputer terminalFishing

The invention discloses an intelligent bait throwing ship and method, and belongs to the technical field of fishing supplies. The intelligent bait throwing ship aims at solving the problem that the existing bait throwing ship cannot find the bait throwing point cannot automatically and accurately. The intelligent bait throwing ship includes a terminal, a communication module, a main control module, a fish detection module and a bait throwing module. The terminal is provided with a built-in expert library, and the terminal and the main control module communicate through the communication module. First data obtained by the fish detection module are compared with the expert library of the terminal. When the first data conform to growth habit data of certain fish in the expert library, the terminal sends a bait throwing command to the main control module through the communication module, and the main control module sends the bait throwing command to the bait throwing module for bait throwing, so that the bait throwing point can be found automatically and accurately. A bait throwing method is further provided.

Owner:安徽欣思创科技有限公司

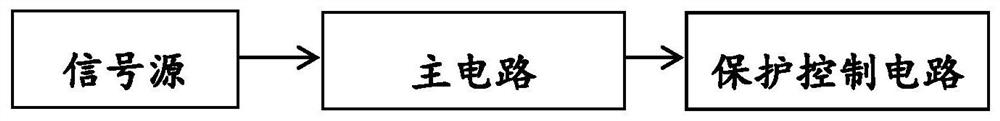

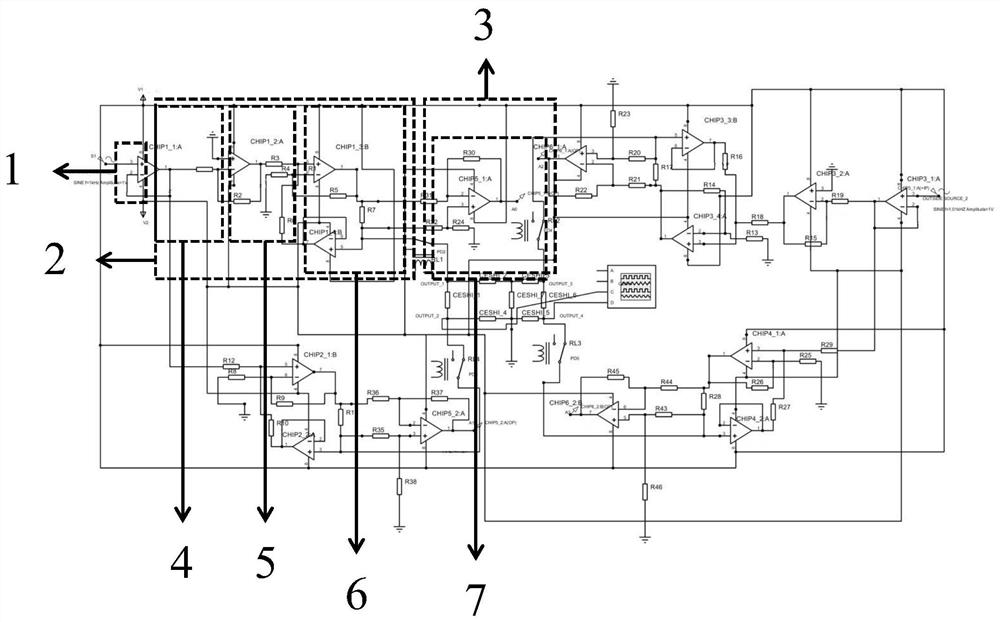

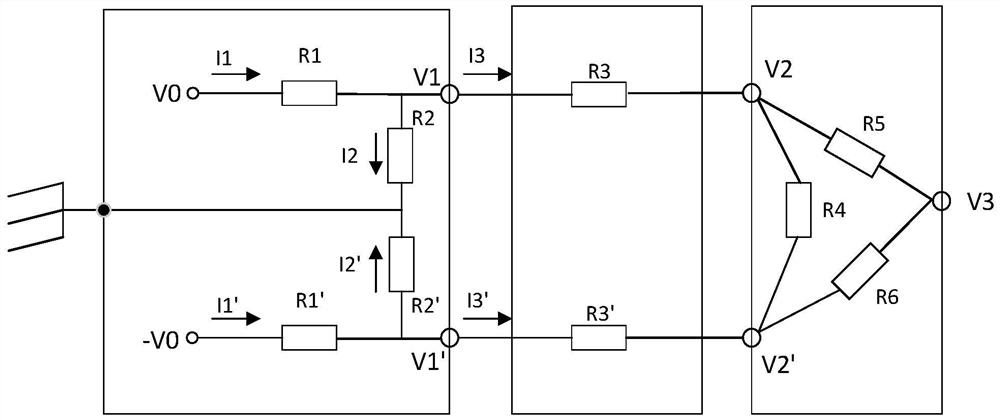

Non-invasive deep brain region electrical stimulation device

InactiveCN113599696AReal-time monitoring sizeIncrease irritationElectrotherapyArtificial respirationNon invasivePhysical therapy

The invention discloses a non-invasive deep brain region electrical stimulation device which comprises a signal source, a main circuit and a protection control circuit. The signal source is an external signal source and can generate sinusoidal voltage signals of any amplitude within a safe voltage limiting range and input the signals into the main circuit. The main circuit provides alternating current output with constant amplitude and reduces interference caused by current imbalance between the two electrodes. The protection circuit monitors the magnitude of the output current in real time, and when the current is too large, the single-chip microcomputer immediately controls the relay to be powered off to stop the stimulation process. By combining the signal source, the main circuit and the protection control circuit, a stable alternating current signal can be output, whether stimulation is carried out or different stimulation modes are determined according to a calculation result of an upper computer on electroencephalogram signal characteristics, and in addition, when the circuit detects that the current exceeds the human body safety current, the stimulation switch can be immediately switched off to ensure the safety of the subject.

Owner:安徽效隆科技有限公司

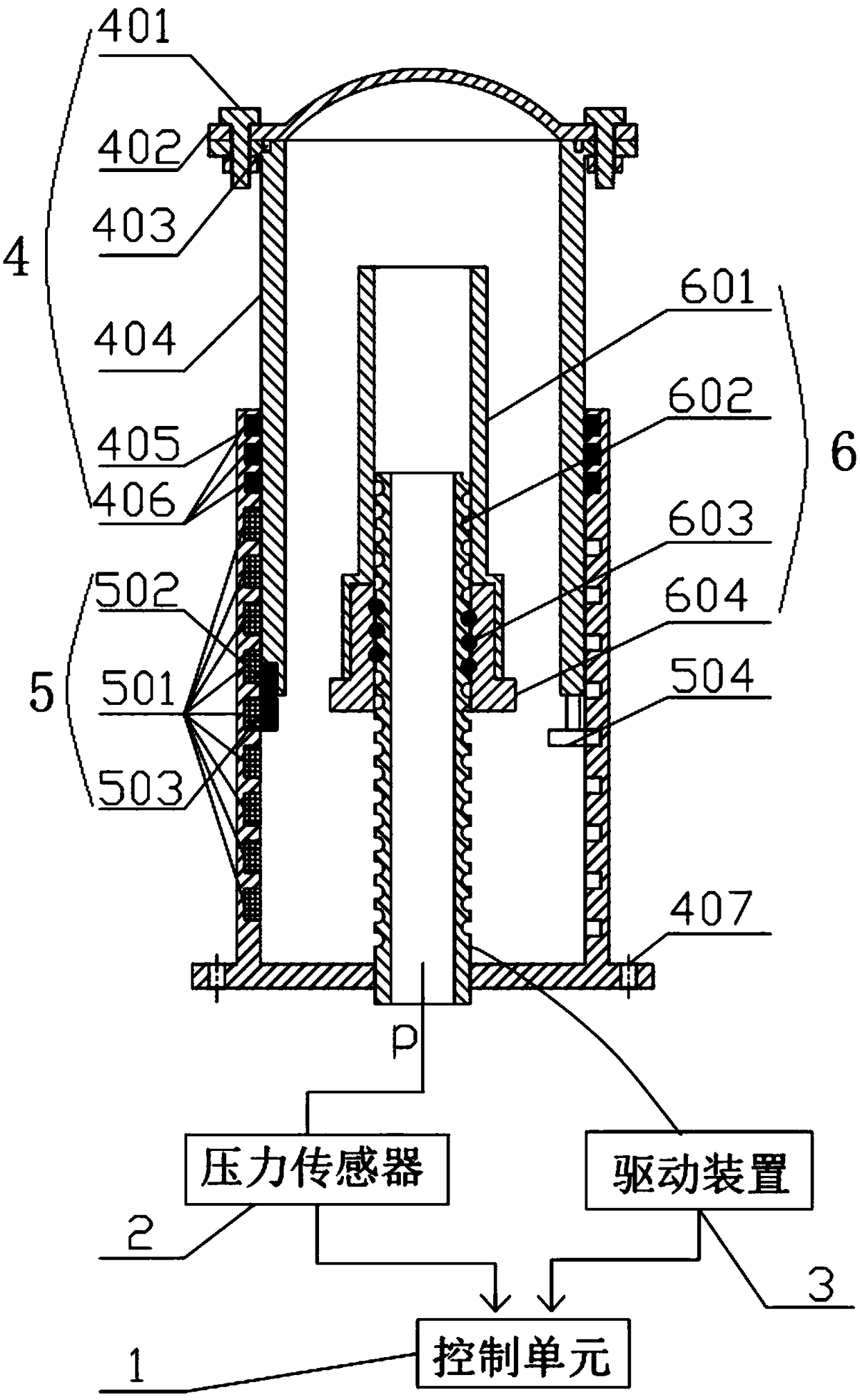

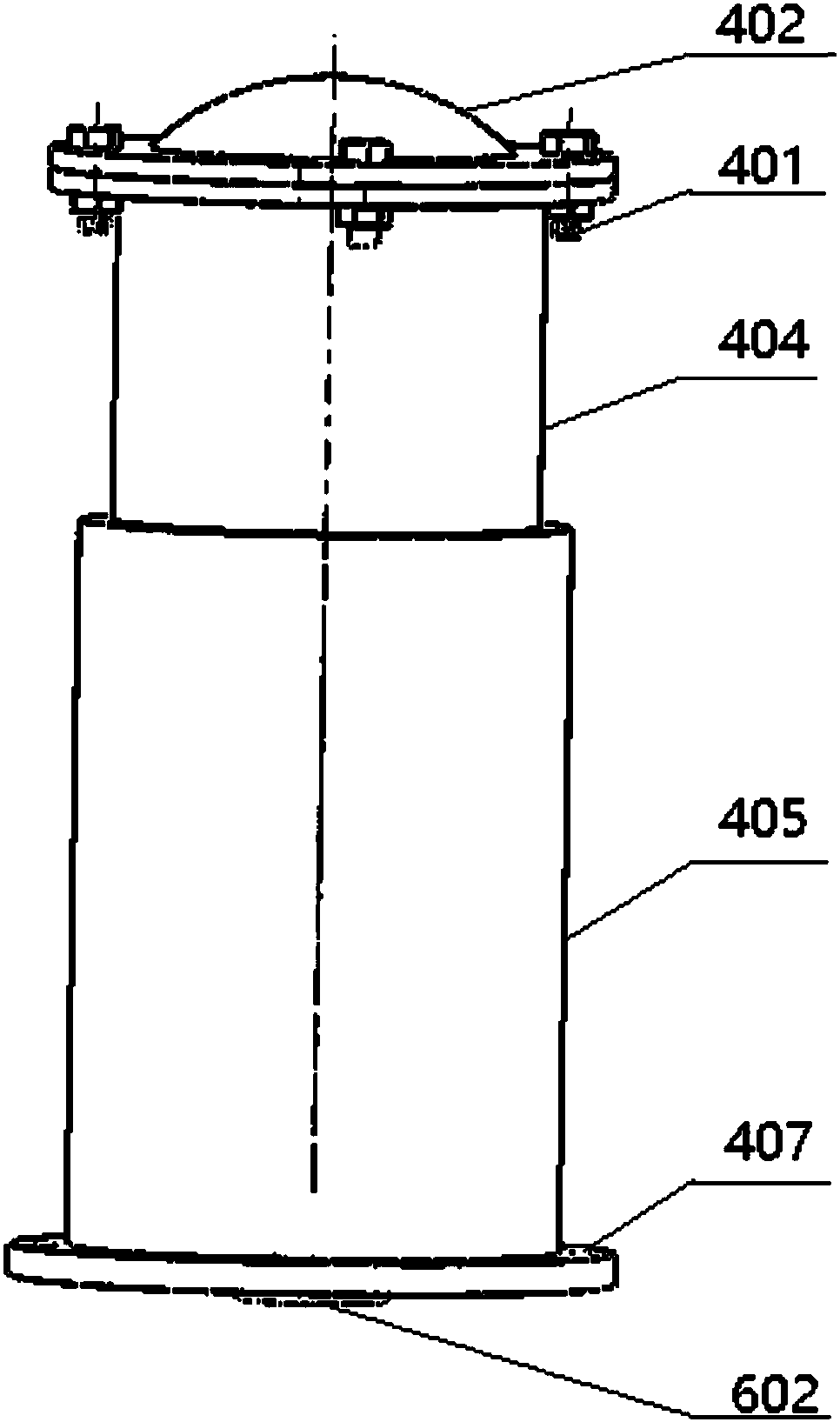

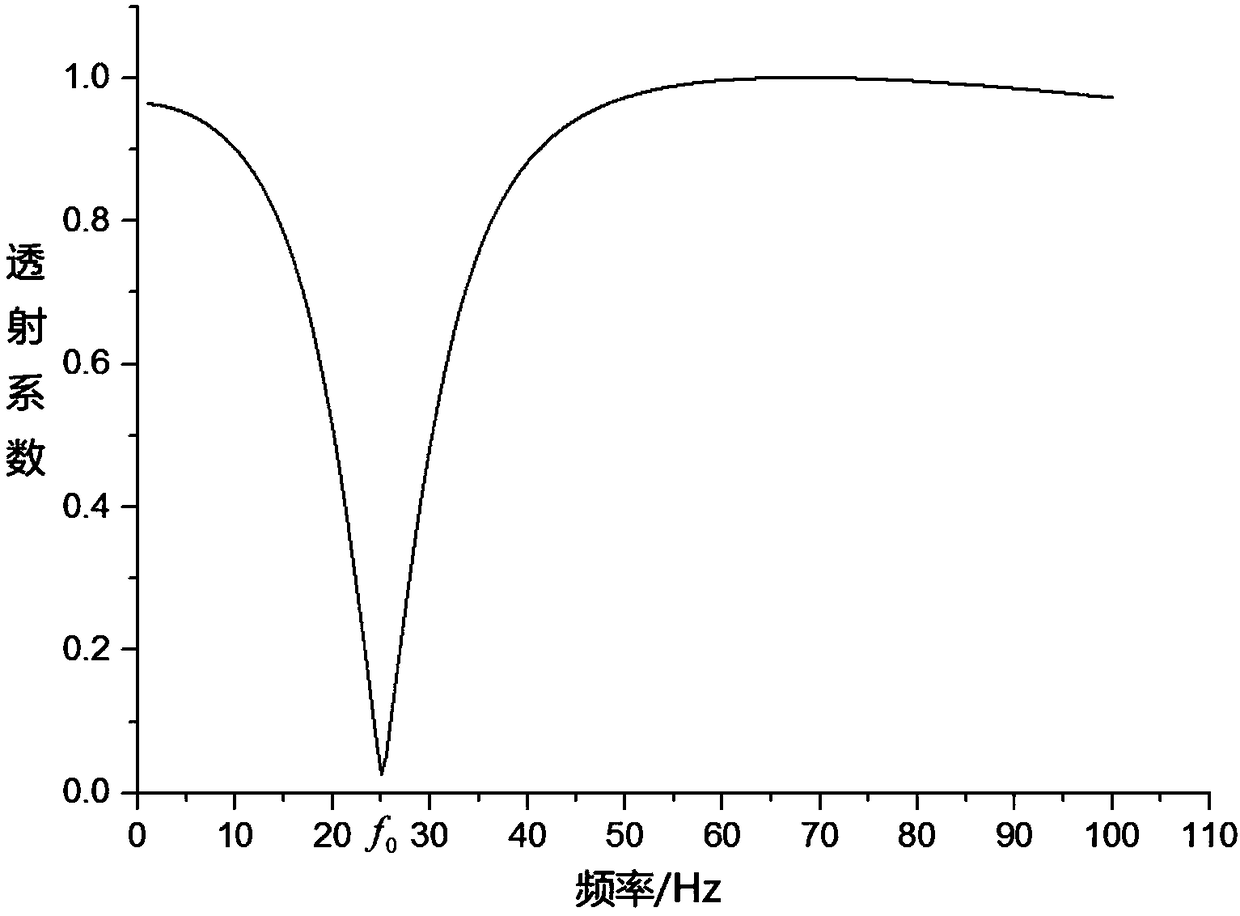

Self-regulating wide-frequency gas pulsation attenuator of variable-rotation-speed compressor and control method of self-regulating wide-frequency gas pulsation attenuator

ActiveCN108518334AImprove the operating environmentReduce air pulsationPositive displacement pump componentsPositive-displacement liquid enginesUltrasound attenuationGas compressor

The invention discloses a self-regulating wide-frequency gas pulsation attenuator of a variable-rotation-speed compressor and a control method of the self-regulating wide-frequency gas pulsation attenuator. The self-regulating wide-frequency gas pulsation attenuator consists of a self-stretching container, a rolling ball lead screw, a drive device and a control unit. The self-regulating wide-frequency gas pulsation attenuator is mounted on a valve cavity of the compressor through a mounting hole of a compressor gas valve; a container cavity communicates with the valve cavity of the compressorthrough a lead screw; resonance frequency of the attenuator can be automatically regulated by changing length of the stretching container and the lead screw; under a variable-rotation-speed working condition, main excitation frequency of a compressor system can be monitored in real time, and the dimension of the attenuator is automatically regulated, so that resonance frequency of the attenuator is ensured to be equal to the main excitation frequency of the compressor system in real time, active attenuation, on gas pulsation of the main excitation frequency in the valve cavity of the compressor, is realized in real time under the variable-rotation-speed working condition, and the defects that common attenuator is fixed in cut-off frequency and is not practical under the variable-rotation-speed working condition are solved; and moreover, the self-regulating function improves application efficiency and working reliability of the attenuator.

Owner:XI AN JIAOTONG UNIV

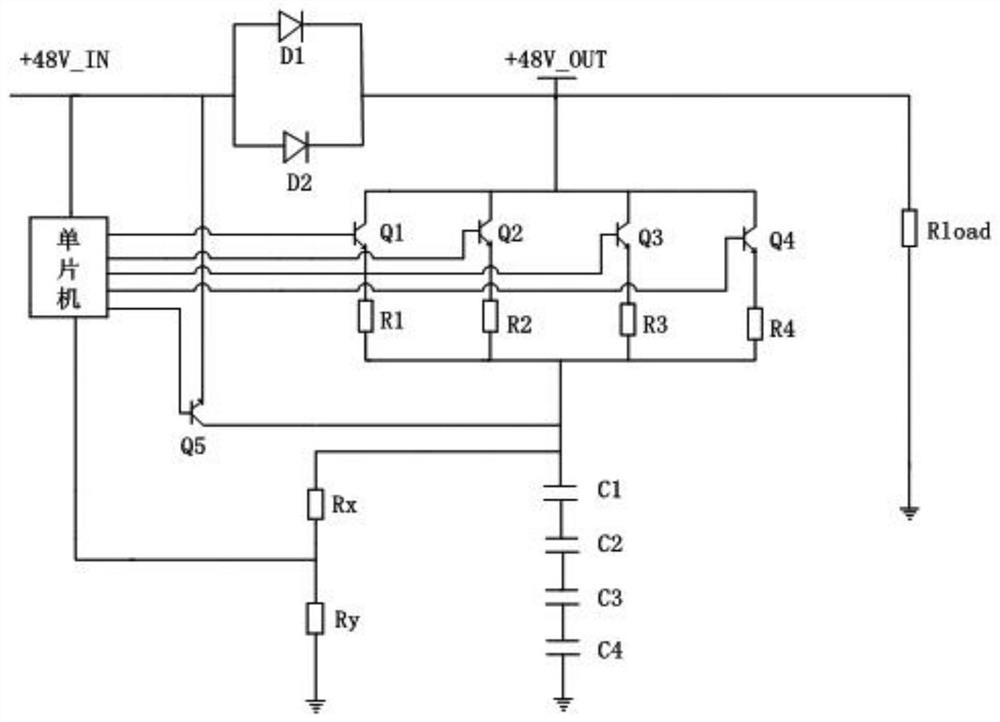

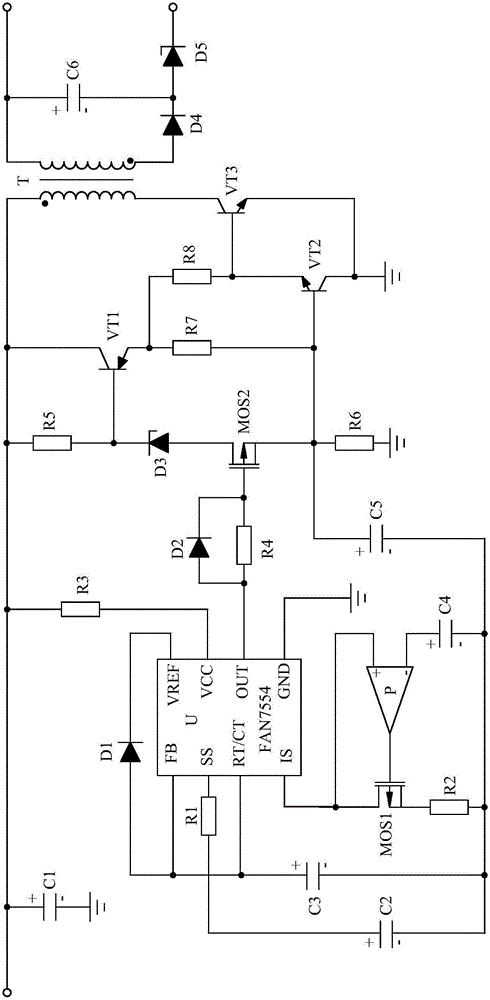

Super-capacitor self-adaptive charging and discharging control system and control method

ActiveCN112653228AChange the size of the currentEasy to controlElectric powerCharging/discharging current/voltage regulationCapacitanceControl system

The invention relates to a super-capacitor self-adaptive charging and discharging control system, which comprises a single-chip microcomputer, a charging and discharging circuit, and the super capacitor which are electrically connected in sequence, wherein a control module is arranged in the single-chip microcomputer, the control module is used for controlling the charging and discharging circuit to charge the super capacitor according to the change of the voltage, or controlling the charging and discharging circuit to enable the super capacitor to discharge to the load; when the voltage of the super capacitor is lower than a set value, the control module controls the charging and discharging circuit to charge the super capacitor; or, when the input voltage is lower than the set value, the control module controls the charging and discharging circuit to enable the super capacitor to discharge to the load. The invention further relates to a super-capacitor self-adaptive charging and discharging control method. According to the super-capacitor self-adaptive charging and discharging control system and the super-capacitor self-adaptive charging and discharging control method, intelligent control of different charging speeds is realized, and multistage conversion of the charging speeds can be realized; the single-chip microcomputer is connected into the circuit to monitor the voltage in real time; the current of each branch circuit can be controlled; and a super-capacitor charging mode, a maintaining mode and a discharging mode are freely switched.

Owner:SHANDONG ELECTRICAL ENG & EQUIP GRP XINNENG TECH CO LTD +1

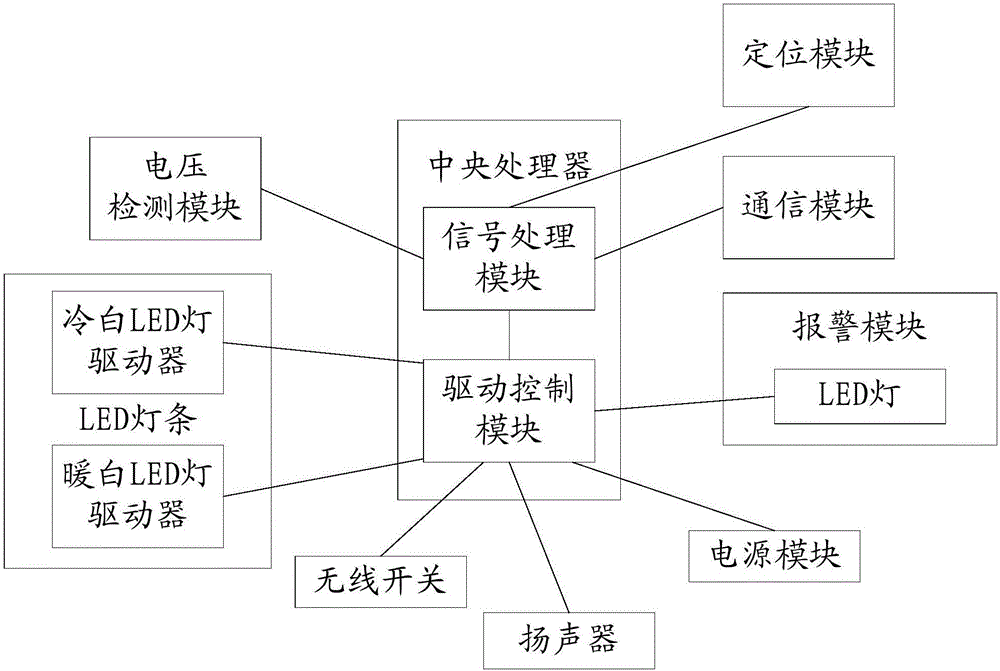

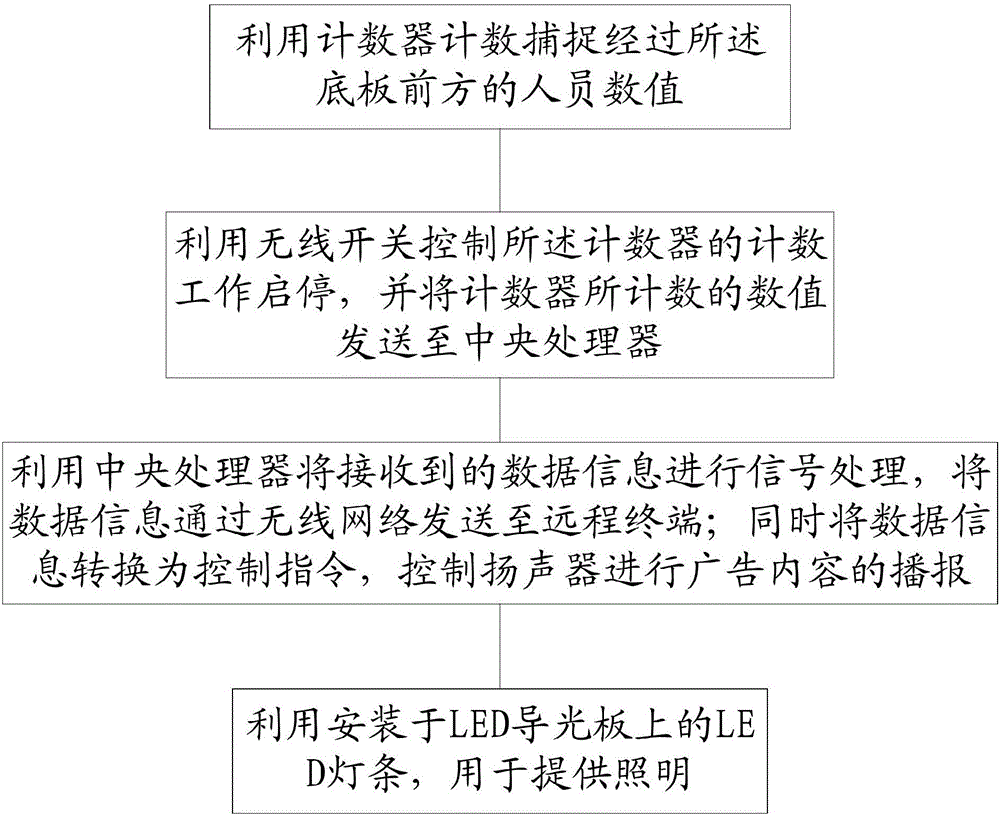

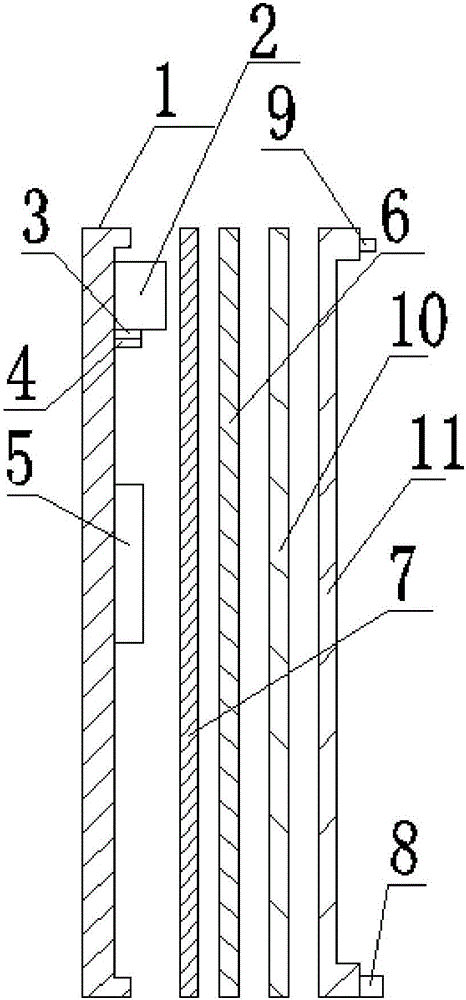

Frame medium advertising lamp box capable of emitting light

InactiveCN106782226AAddressing Poor PublicityImprove publicityElectrical apparatusElectroluminescent light sourcesMedia controlsData information

The invention relates to the field of lighting lamp boxes, in particular to a frame medium advertising lamp box capable of emitting light. The frame medium advertising lamp box capable of emitting light comprises a frame medium control system capable of emitting light, a counter, a wireless switch, a central processing unit, a power supply module, an LED lamp strip, a reflecting film and a loudspeaker, wherein the counter is mounted on a bottom plate and is used for counting the number of people passing through space in front of the bottom plate; the wireless switch is used for controlling starting and stopping of counting operation of the counter; the central processing unit is used for carrying out signal processing on received data information and controlling other components to be matched with one another; the power supply module is used for providing electric energy; the LED lamp strip is mounted on an LED light guide plate and is used for lighting; light rays emitted from the LED lamp strips are gathered to the same side by the reflecting film; and the loudspeaker is mounted on the outer frame and is used for broadcasting advertisements. An LED light guide plate is combined to the power supply module, and therefore, the problem of poor advertising content promotion caused by the reason that advertisements in a frame medium does not emit light at present is solved.

Owner:北京奥普莱特照明器材有限公司

A torque loading device for a servo mechanism

InactiveCN106840725BContinuous regulationReal-time monitoring sizeWork measurementStructural/machines measurementCantilevered beamFriction torque

The invention discloses a servo mechanism force moment loading device and belongs to the technical field of mechanical system test facilities. The friction moment loading of the device can be continuously adjusted by loading hydraulic oil, and meanwhile a loading moment can be monitored through a friction moment sensor in real time; elastic moment loading can be continuously adjusted, a supporting spring plate is used for achieving the supporting rigidity of a servo mechanism for overcoming the strength requirement of a spring moment spring plate, and continuous supporting rigidity adjustment can be achieved by adjusting the clamping position of the supporting spring plate. The servo mechanism force moment loading device has the advantages that compared with a traditional servo mechanism force moment loading device, the friction moment loading of the device can be continuously adjusted by loading the hydraulic oil.

Owner:BEIHANG UNIV

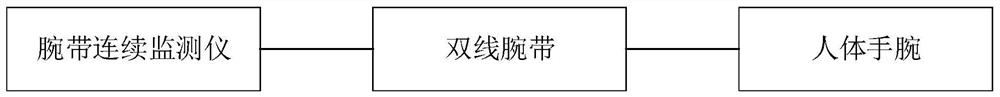

A two-wire anti-static wrist strap and real-time grounding monitoring device

ActiveCN108226648BReal-time monitoring sizeRaise the potentialEarth resistance measurementsVoltage measurements onlyPhysical medicine and rehabilitationMetallic electrode

The invention provides a two-wire type anti-static wrist strap. The two-wire type anti-static wrist strap comprises a wrist strap continuous monitor and a two-wire wrist strap. The two-wire wrist strap is used for being bound on the wrist of the human body, and a metal electrode making contact with skin of the wrist of the human body is arranged in the two-wire wrist strap. The wrist strap continuous monitor is used for being connected with the two-wire wrist strap to enable the two-wire wrist strap to be grounded, and meanwhile the voltage of the wrist of the human body is monitored. The invention further provides a real-time grounding monitoring device of the two-wire type anti-static wrist strap. By means of applying bipolar symmetrical voltages, the potential of measured staff can be prevented from being increased while the resistance is measured. The magnitude of the ground resistance can be monitored in real time and the voltage of the human body can be monitored in real time while the grounding function of the anti-static wrist strap is reserved.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

Animal Crushing Injury-Crush Syndrome Experimental Apparatus

InactiveCN105919690BReal-time monitoring sizeEasy to controlAnimal fetteringSurgical veterinaryEngineeringRepeatability

The invention relates to an experimental device for animal CI-CS (crush injury-crush syndrome). The experimental device comprises a base, wherein a fixing device and a crushing device are arranged on the base; the crushing device comprises a fixed roller and a movable roller which are horizontally arranged and capable of rolling in opposite directions; multiple groups of concave crushing structures are arranged on a crushing surface of the movable roller, multiple convex crushing structures are arranged on a crushing surface of the fixed roller, and the multiple concave crushing structures and the multiple convex crushing structures are matched with one another; rotating shafts are arranged at two ends of the fixed roller, and the fixed roller is arranged on the side wall of the base in a crossing manner; the movable roller is arranged in a guide rail groove in the side wall of the base in a crossing manner through a concentric shaft, the concentric shaft can slide in the guide rail groove, a clamping lock is arranged on the concentric shaft, and the concentric shaft and the clamping lock can control the movable roller to slide and get locked relative to the fixed roller. The experimental device for animal CI-CS simulates the injury caused by the fact that four limbs are crushed by the rollers in production practice, and a model is more practical; the experimental device is simple in overall structure, convenient to operate, high in measurement precision and good in experimental repeatability, and reliable experimental data can be obtained.

Owner:XIAN HONGHUI HOSPITAL

Torque servo control loading load simulator

InactiveCN103413489BReal-time monitoring sizeContinuous regulationEducational modelsHydraulic motorBall bearing

A torque servo control loading load simulator comprises a base, a guide strip, a supporting spring plate base, a supporting spring plate, a supporting spring plate cover plate, a lower supporting lug, a side vertical plate, a motor mounting seat, a photoelectric encoder mounting seat, a swing hydraulic motor, a valve block, a servo valve, a rolling bearing, a loading torque sensor, a photoelectric encoder, a probe, a ball bearing, an upper supporting lug, an inertia counterweight disk, an inertia base disk, a spindle, an elastic torque mounting support, an elastic torque sensor, an elastic torque rotating shaft, a swing shifting fork, an elastic torque loading support, an elastic torque spring plate and a spring torque spring plate clamping plate. The torque servo control loading load simulator can simulate the structural characteristics of a rocket exhaust nozzle, wherein the structural characteristics comprise inertia loads, elastic torque loads, set torque loads and supporting stiffness. The torque servo control loading load simulator has the advantages of being simple and compact in structure, flexible in servo loading torque, high in precision, and capable of better reproducing the structural characteristics of the actual rocket exhaust nozzle.

Owner:BEIHANG UNIV

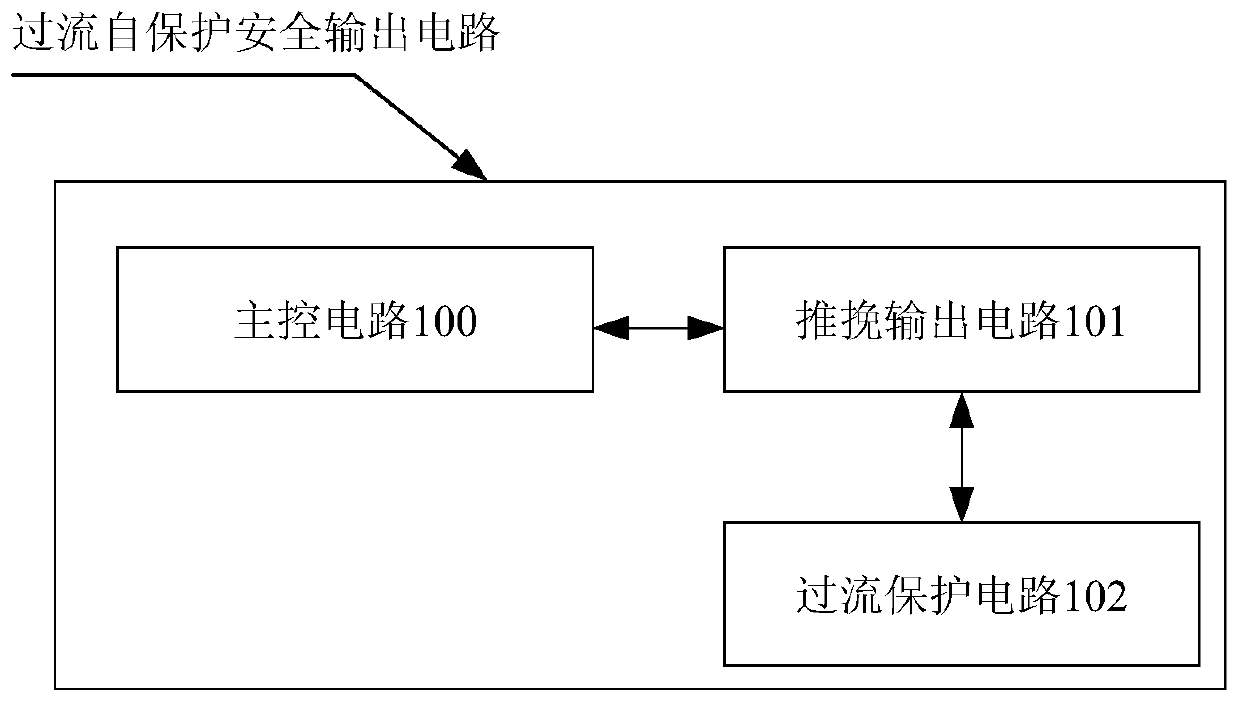

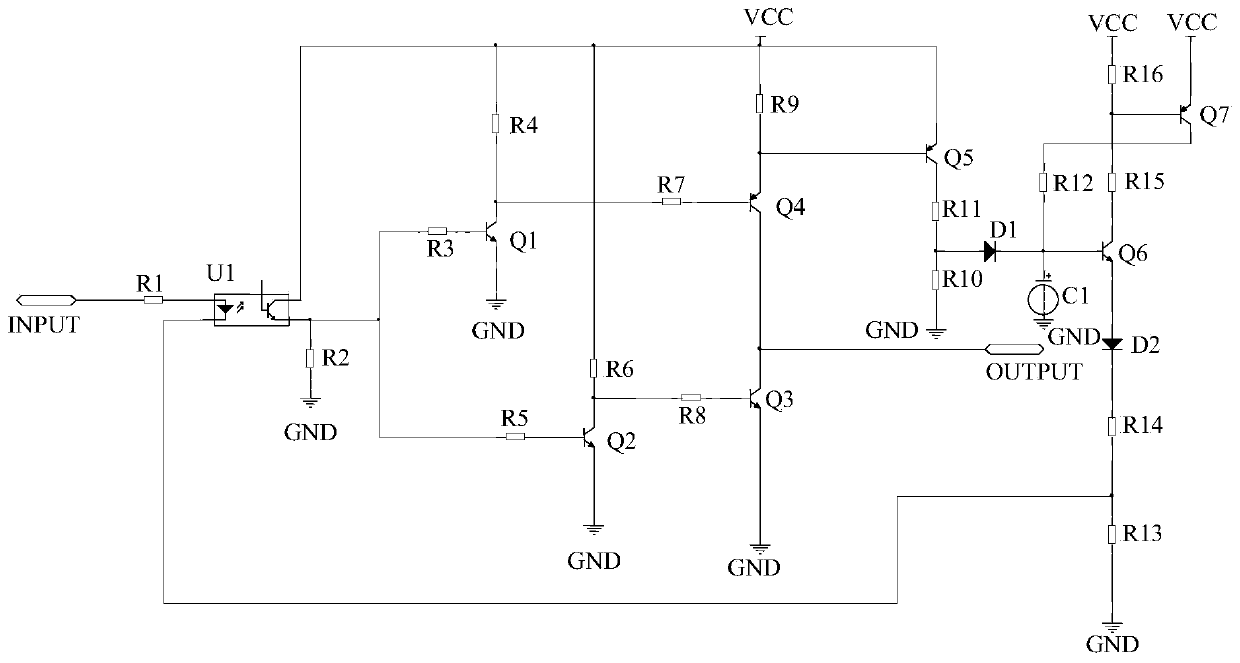

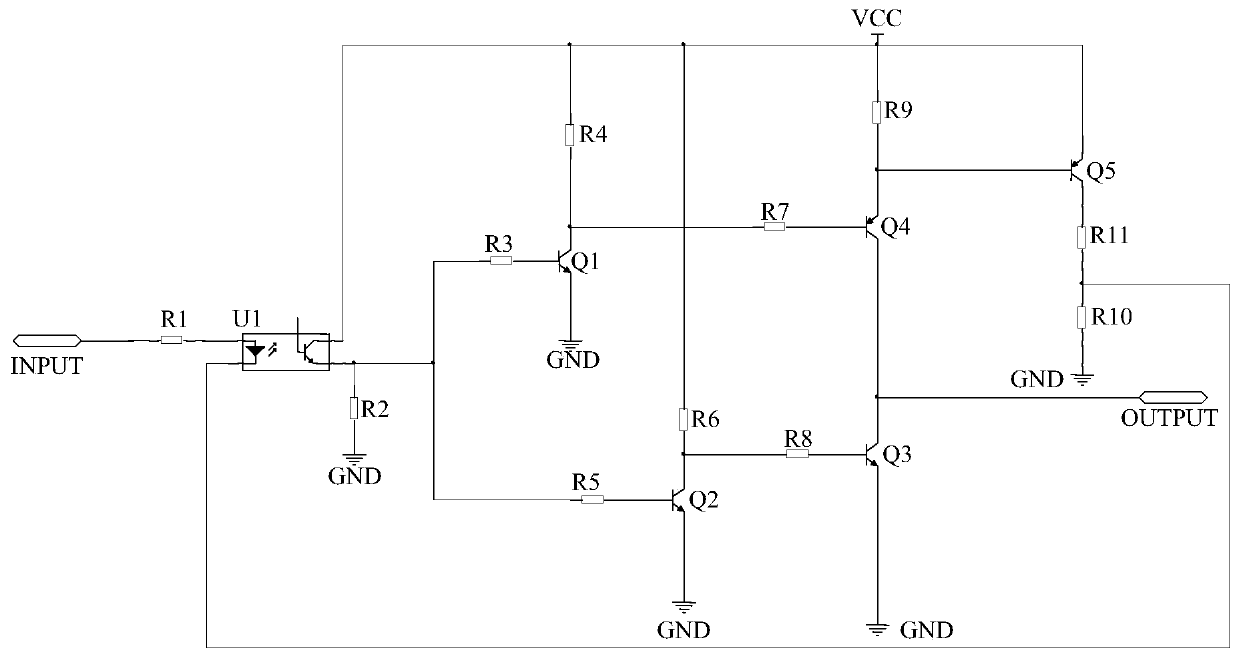

Overcurrent self-protection safety output circuit and its application method, laser radar

ActiveCN109546616BReal-time monitoring sizeImprove securityArrangements responsive to excess currentControl signalHemt circuits

Owner:WUHAN WANJI INFORMATION TECH

Servo mechanism load simulator

InactiveCN103413474BReal-time monitoring sizeContinuous regulationCosmonautic condition simulationsSimulatorsBall bearingFriction torque

A servo mechanism load simulator comprises a base, side upright plates, elastic moment spring plate clamping boards, an elastic moment loading support, an elastic moment spring plate, a swing shifting fork, an elastic moment rotary shaft, an elastic moment sensor, ball bearings, a bearing cap, a bearing seat, a friction shaft, a small oil cylinder seat, friction moment loading small oil cylinders, friction sheets, a friction moment sensor, an installation seat, roller bearings, a main shaft, an inertia basic disc, an inertia balance weight disc, self-aligning roller bearings, an upper supporting lug, a supporting spring plate cover plate, a supporting spring plate base, a supporting spring plate, a lower supporting lug, a guide bar and a servo mechanism to be measured. According to the servo mechanism load simulator, the structural characteristics, comprising the inertia load, the elastic moment load, the friction moment load and the supporting rigidity, of a rocket engine tail nozzle can be simulated; the elastic moment and the friction moment can be respectively measured through a torque sensor. The servo mechanism load simulator has the advantages of being simple and compact in structure and capable of enabling the structural characteristics of the actual rocket tail nozzle to well reappear.

Owner:BEIHANG UNIV

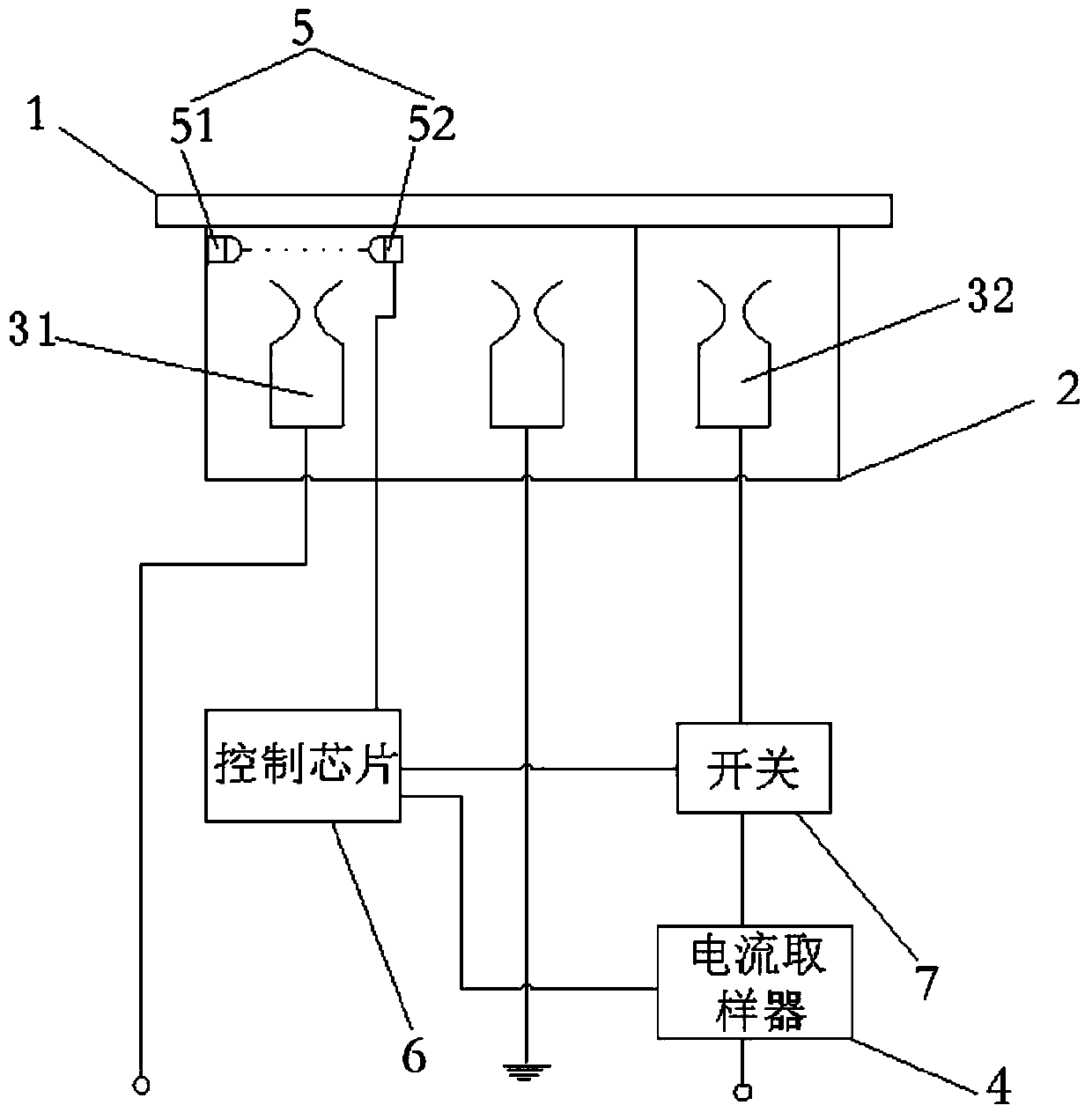

a safety socket

ActiveCN106329237BAvoid Electric Shock HazardImprove securityCoupling device detailsEngineeringElectric shock

The invention discloses a safety socket. The safety socket comprises a socket panel, a shell, a null line metal current-carrying part and a live wire metal current-carrying part, wherein the socket panel and the shell are embedded into a hollow structure; the null line metal current-carrying part and the live wire metal current-carrying part are mounted in the hollow structure oppositely; jacks corresponding to the null line metal current-carrying part and the live wire metal current-carrying part are formed in the socket panel; the null line metal current-carrying part is connected with a mains supply null line directly; the live wire metal current-carrying part is connected with a mains supply live wire through a switch; the safety socket is also provided with an infrared pair tube, a control chip and a switch, wherein the infrared pair tube is mounted on one side of the null line metal current-carrying part and connected with the control chip; the control chip is connected with the switch; and the live wire metal current-carrying part is connected with the mains supply live wire through the switch. According to the safety socket, the infrared pair tube is arranged on one side of the null line metal current-carrying part, so that electric shock caused by accidental touch can be avoided while safety is greatly improved.

Owner:广州帝能云科技股份有限公司

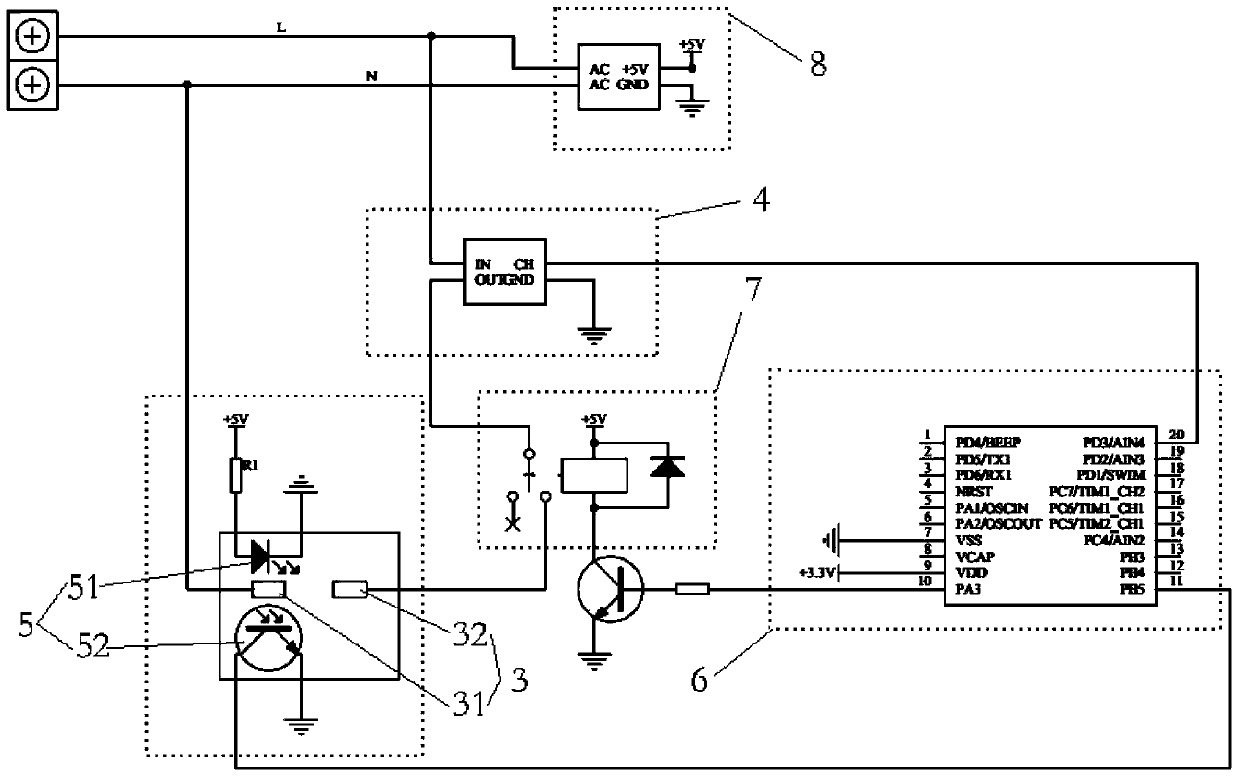

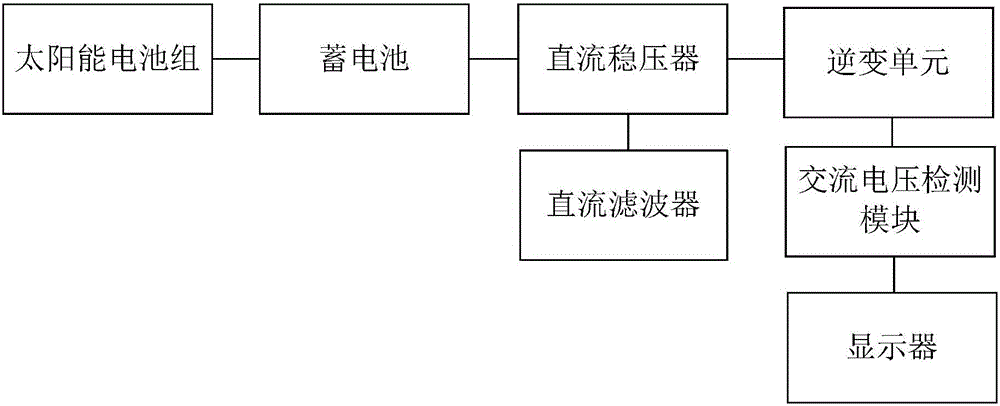

Output voltage detection-based solar inverter system

InactiveCN105846774ANo risk of depletionResources are widely distributedPhotovoltaicsEnergy storageLow voltageDisplay device

The invention discloses an output voltage detection-based solar inverter system. The output voltage detection-based solar inverter system is characterized by mainly comprising a solar battery pack, a storage battery, a DC stabilizer, a DC filter, an inverter unit, an AC voltage detection module and a display, wherein the storage battery is connected with the solar battery pack; the DC stabilizer is connected with the storage battery; the DC filter and the inverter unit are connected with the DC stabilizer respectively; the AC voltage detection module is connected with the inverter unit; and the display is connected with the AC voltage detection module. Power generation is carried out by solar energy; solar energy resources have no danger of exhaustion; resource distribution is wide; and the solar energy resources are environment-friendly to use and suitable for extensive promotion. The AC voltage detection module is arranged, so that the AC voltage output by the inverter unit can be detected and displayed through the display; and people can monitor the magnitude of the voltage output by the inverter unit in real time and prevent normal work of an electric appliance from being affected by an over-high or over-low voltage.

Owner:CHENGDU SIBOTE TECH CO LTD

An intelligent nest-making boat and a nest-making method

ActiveCN108902068BOvercome communication difficultiesImprove compatibilityWaterborne vesselsOther angling devicesFishingReliability engineering

The invention discloses an intelligent nest-making boat and a nest-making method, belonging to the technical field of fishing supplies. Aiming at the problem that existing nest-making boats cannot automatically and accurately find nest-making spots, the present invention provides an intelligent nest-making boat. It includes a terminal, a communication module, a main control module, a fish detection module and a nest making module. The terminal has a built-in expert library, the terminal and the main control module communicate through the communication module, and the first data obtained by the fish detection module is compared with the expert library of the terminal. When the growth habit data of the species of fish are consistent, the terminal sends the nesting command to the main control module through the communication module, and the main control module sends the nesting command to the nesting module for nesting, so as to automatically and accurately find the nesting point. The invention also provides a method for making nests.

Owner:安徽欣思创科技有限公司

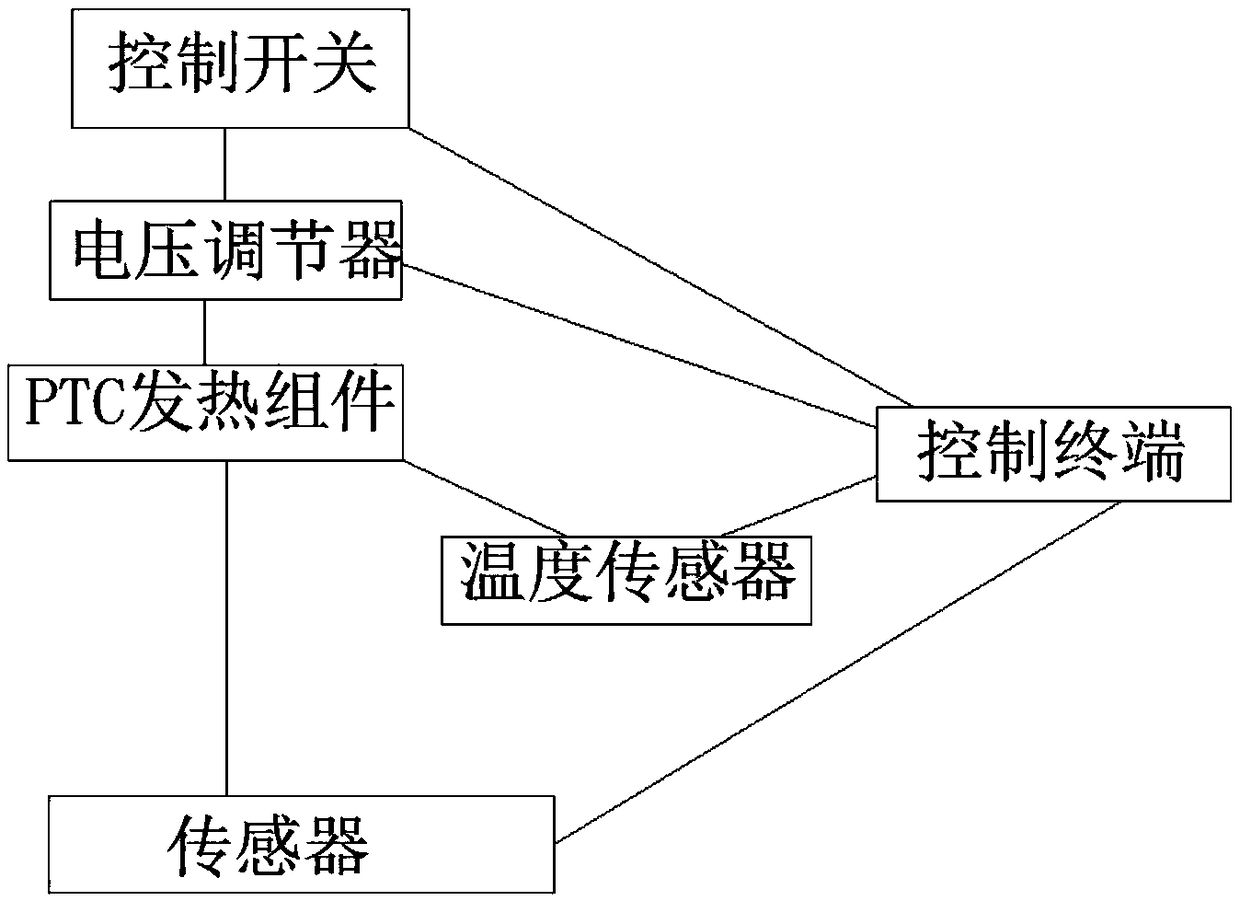

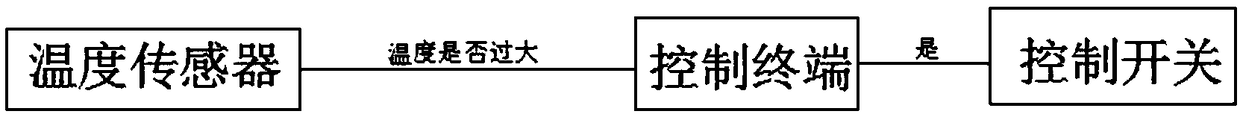

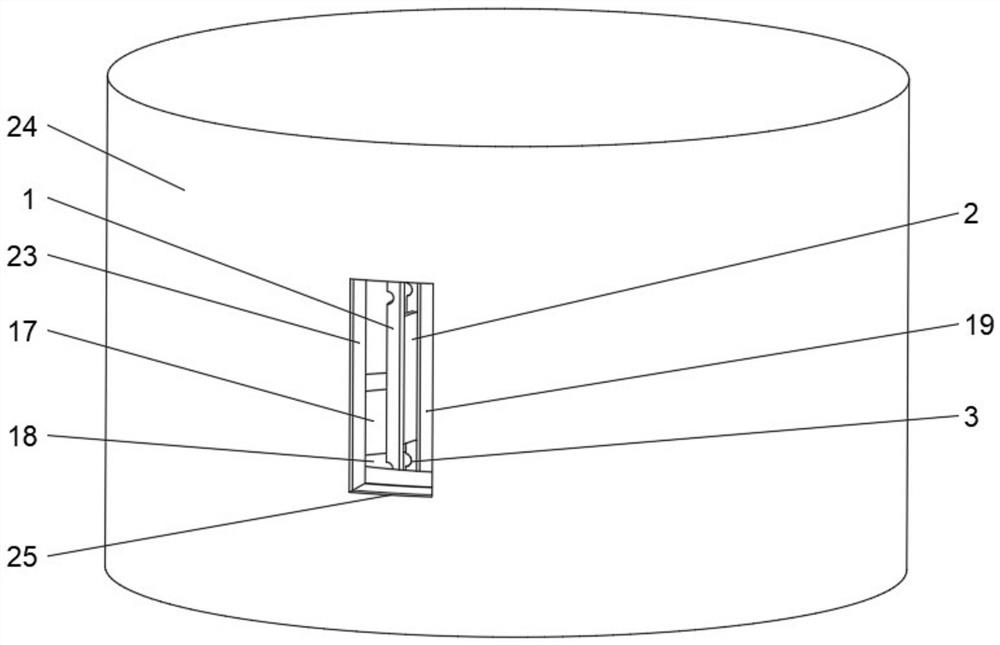

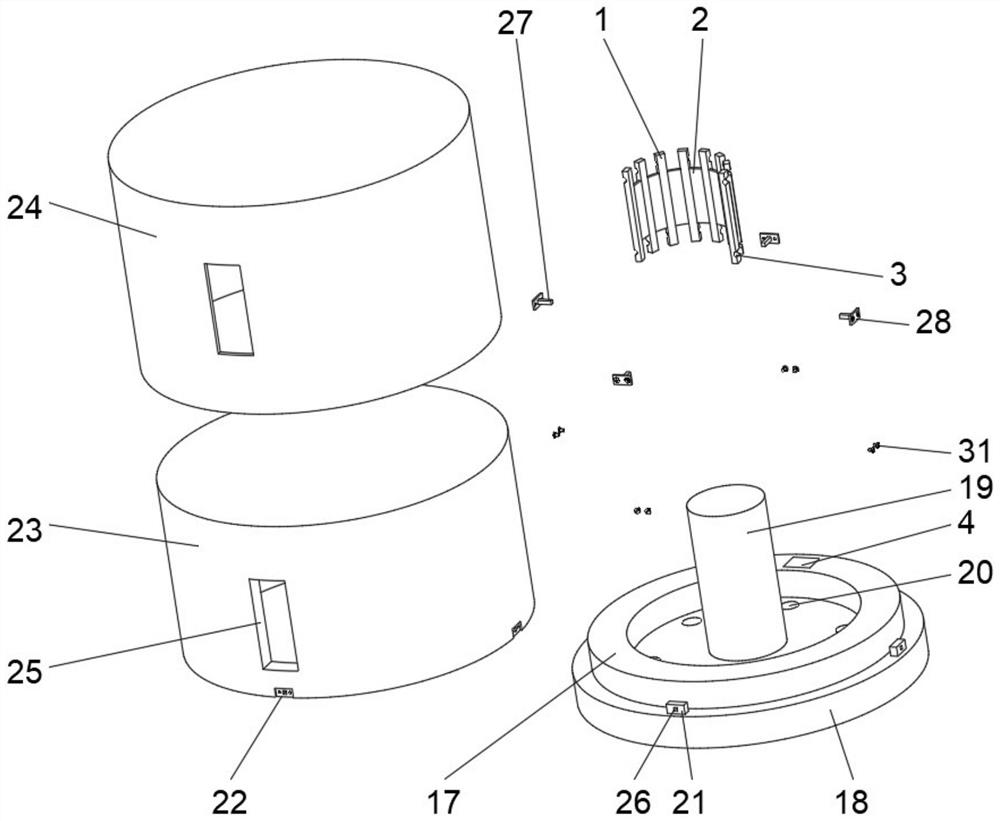

Control method for constant power of PTC heating assembly

InactiveCN108848574AReal-time monitoring sizeConstant power controlOhmic-resistance heatingVoltage regulationVoltage sensor

The invention discloses a control method for constant power of a PTC heating assembly. According to the control method, a control switch is used for controlling opening and closing of the PTC heatingassembly; the control switch is connected with the PTC heating assembly through a wire; a voltage regulator can be used for adjusting circuit voltage; and the PTC heating assembly is connected with apower supply through a wire. By means of the control switch, opening and closing of the PTC heating assembly circuit can be controlled; the magnitude of the current and voltage in the power supply circuit can be monitored in real time through a current sensor and a voltage sensor which are arranged, and the acquired information can be transmitted to a control terminal; and through the control of the control terminal, the voltage of the circuit is changed through the set voltage regulator, so that the magnitude the voltage and the current can be adjusted in time according to the demand change,the voltage and the current are in a relatively stable state, and power invariability can be controlled conveniently.

Owner:浙江欧兰顿电器科技有限公司

Protection device and system for improving safety of wharf bollard

InactiveCN114370032AImprove securityImprove structural strengthClimate change adaptationHydraulic engineering apparatusPull forceStrain gauge

The invention discloses a protection device and system for improving the safety of a wharf bollard, and the device comprises a pressure measurement strain gauge, a connecting sheet, a rope winding groove, a monitor, a limiting ring, a pedestal, a central reinforcing column, a protection housing, a buffer rubber sleeve, and a rope threading hole. A connecting piece is arranged between the pressure measuring strain gauges, rope winding grooves are formed in the top ends and the bottom ends of the side faces of the pressure measuring strain gauges, and the output ends of the pressure measuring strain gauges are connected with the input end of the monitor through a wireless network. The wharf bollard enhances the structural strength of the wharf bollard, is not prone to fracture and deformation, reduces the falling risk of the mooring rope, is reliable in work and long in service life, adopts an indirect fixing mode, is convenient to disassemble, assemble and replace, saves time and labor, reduces the maintenance cost of the bollard, has a pressure monitoring function, improves the safety of the bollard, and is suitable for popularization and application. The cable pulling force on the bollard is monitored in real time, the working state of the bollard is comprehensively released, and a wharf manager is reminded to take countermeasures in time.

Owner:虎鲸智能科技(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com