Self-regulating wide-frequency gas pulsation attenuator of variable-rotation-speed compressor and control method of self-regulating wide-frequency gas pulsation attenuator

A technology of airflow pulsation and compressor, which is applied in the field of variable speed compressors, can solve the problems of narrow adjustment range of adjustable attenuators, manual adjustment, time-consuming and labor-intensive problems, and achieve the effect of improving application efficiency and working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

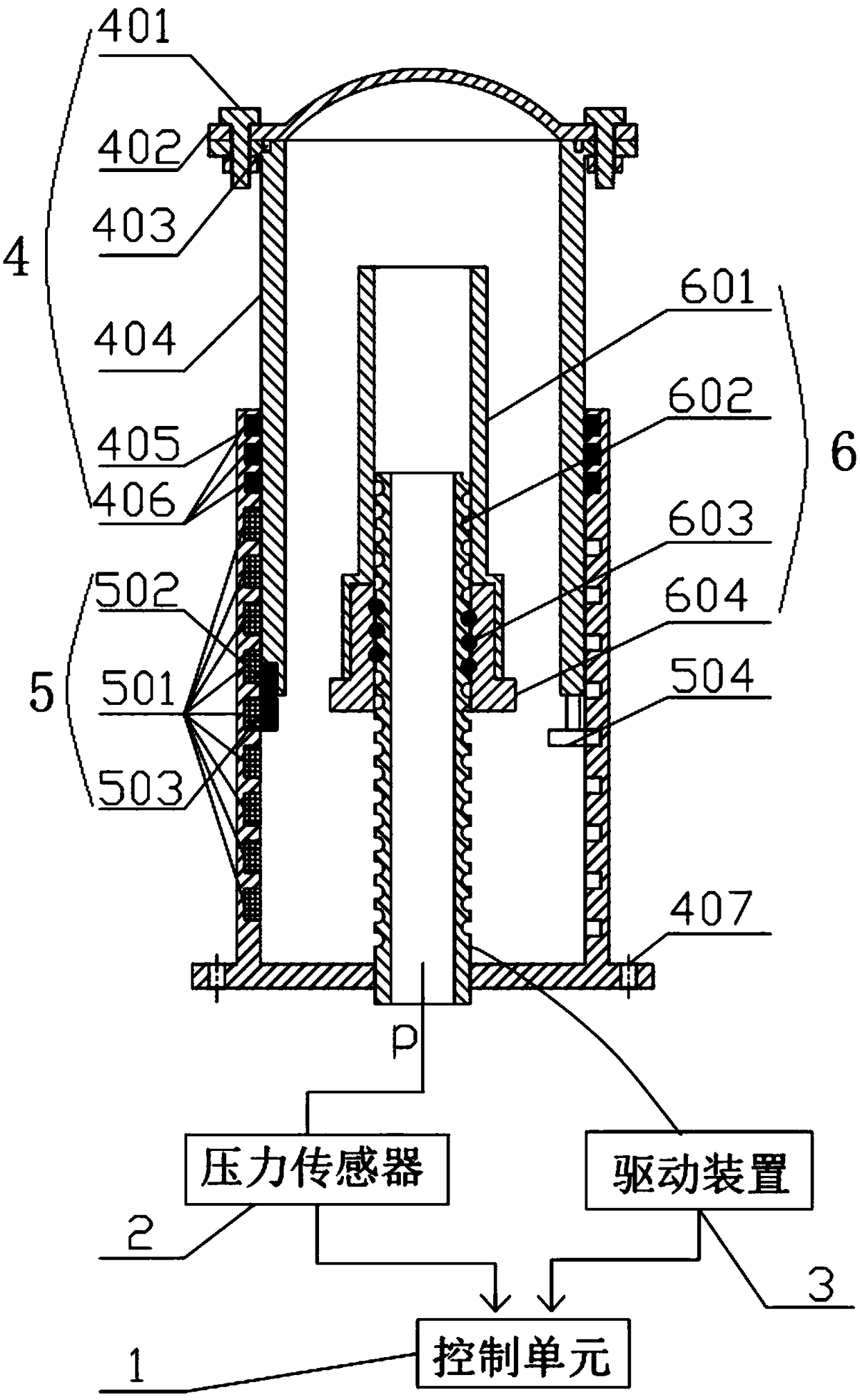

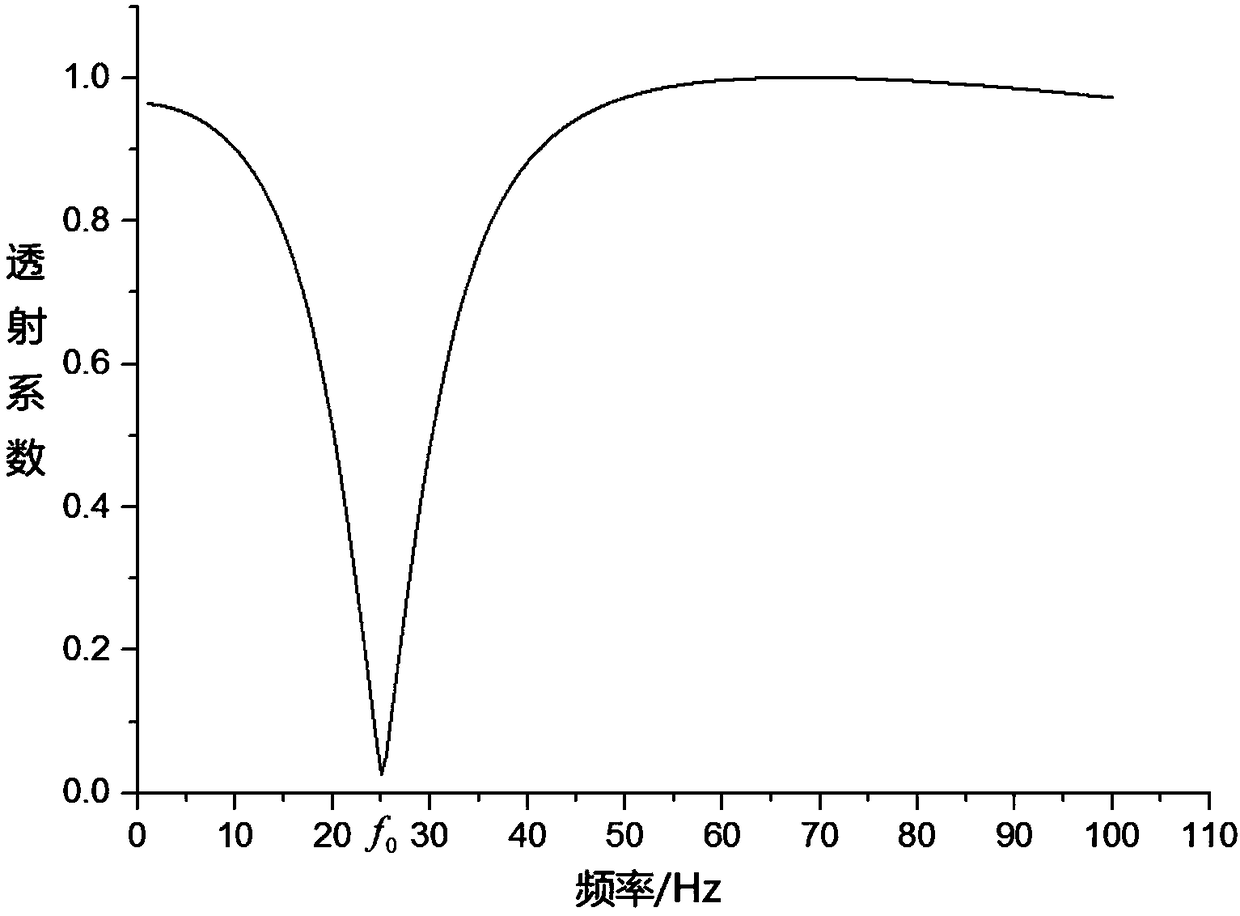

[0035] The variable speed compressor self-adjusting broadband airflow pulsation attenuator of the present invention has a structure such as figure 1 As shown, it includes a self-expanding container 4 , a ball screw 6 , a driving device 3 and a control unit 1 , and the self-expanding container 4 includes an adjustable container and a linear motor 5 .

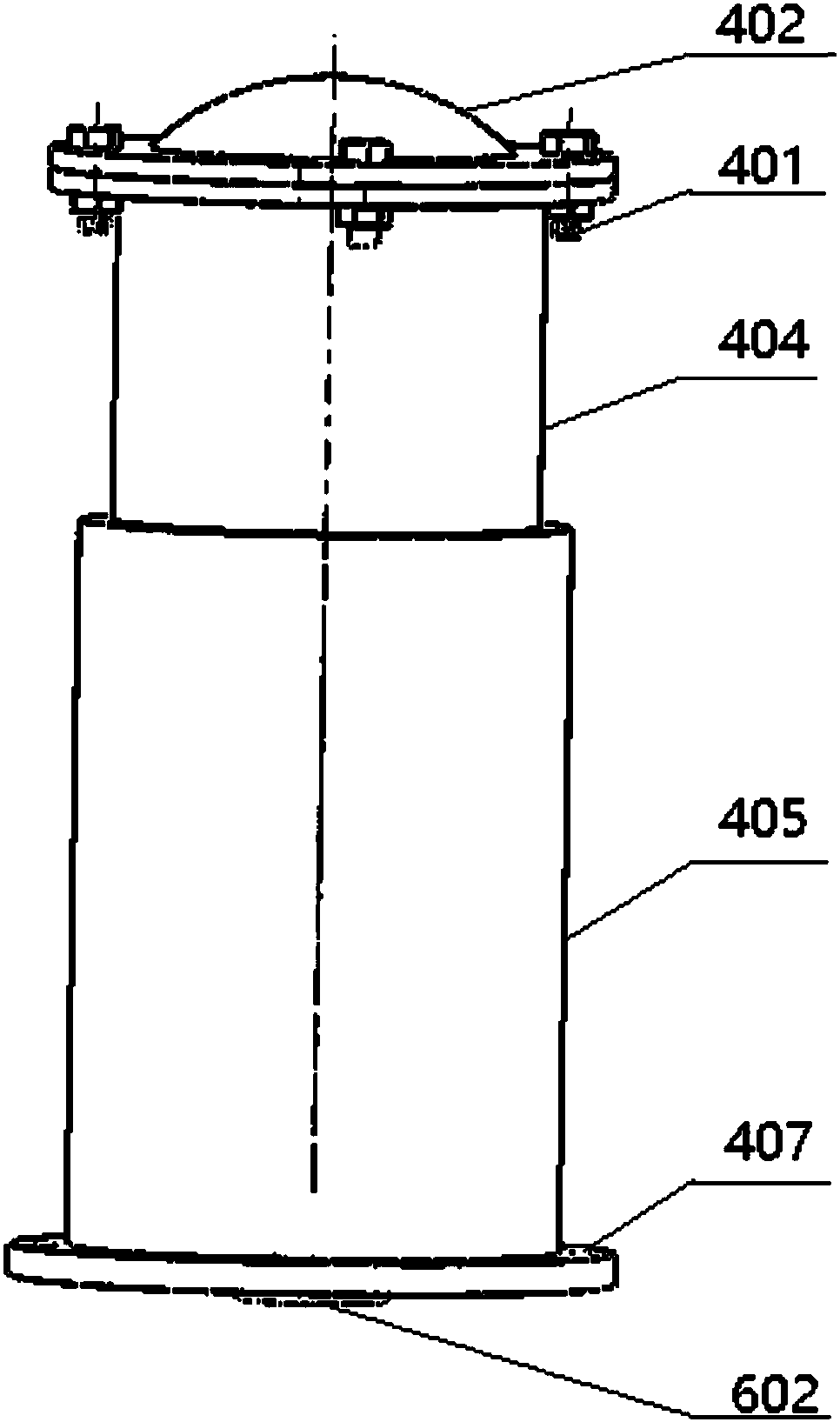

[0036] From top to bottom, the self-expanding container is provided with bolts 401, end caps 402, O-rings 403, first telescopic sections 404, second telescopic sections 405, piston rings 406, end caps 402, first telescopic sections 404 and second telescopic sections. The telescoping sections 405 are connected in sequence and jointly form a closed volume chamber. The upper opening of the first telescopic section 404 is flanged to the end cover 402 , fixed by bolts 401 and sealed by an O-ring 403 . The first telescoping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com