Stelmor line cooling method and cooling apparatus of high-speed rod-rolling mill

A high-speed wire rod and cooling device technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of lap joint organization and uneven mechanical properties, achieve uniform cooling, prevent steel jamming, and achieve unmaintainable The effect of multi-point air volume control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

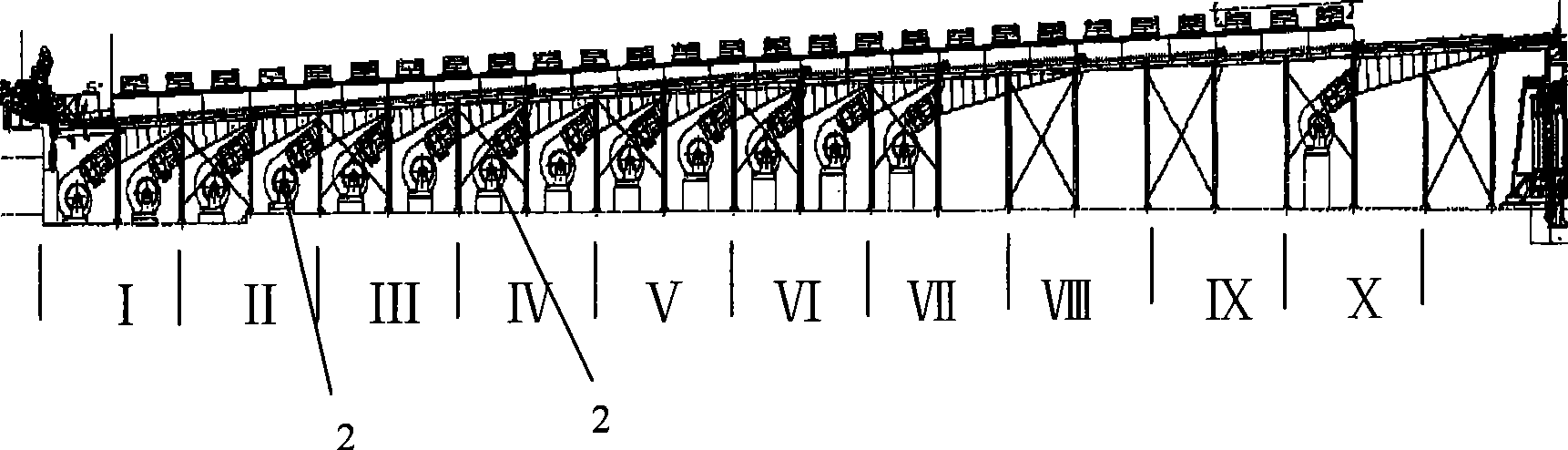

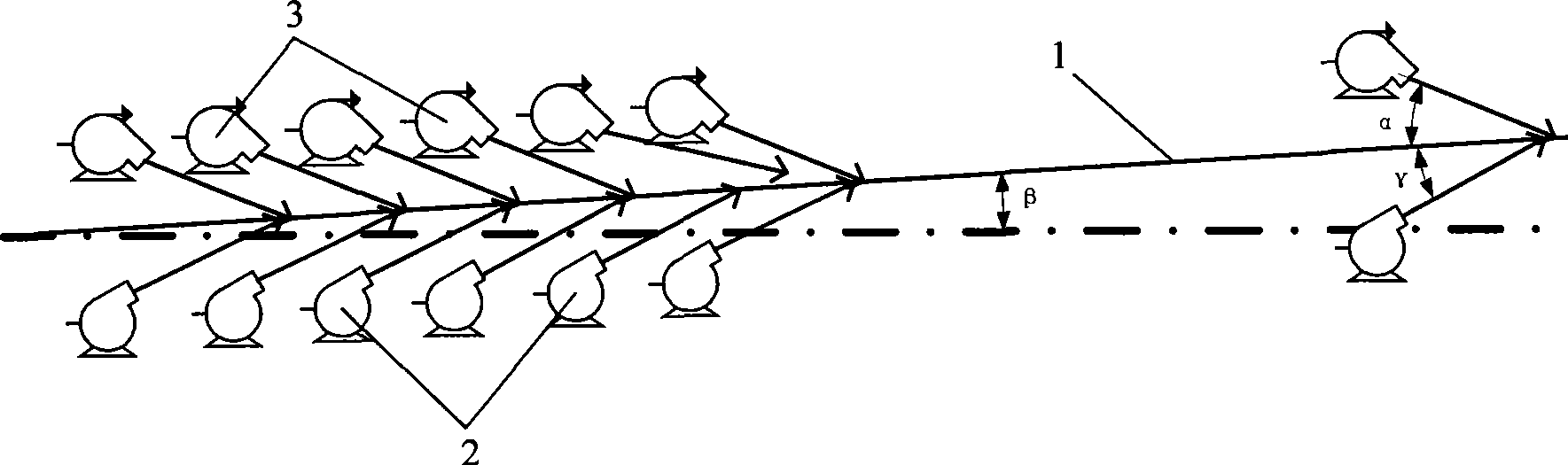

[0030] see figure 2 , a high-speed wire rolling mill Stelmore line cooling device, under the Stelmore line conveying roller table 1, a number of fans 2 are arranged in sequence along the direction of the conveying roller table 1, and on the Stelmore line conveying roller table 1 Along the direction of the conveying roller table 1 above, there are several fans 3 arranged in sequence. figure 2 Seven lower fans 2 and seven upper fans 3 are shown in the drawing, and the upper and lower fans 3 and 2 are in one-to-one correspondence, and the position along the transport roller way 1 direction is gradually improved. see figure 2 , the conveying roller table 1 forms an angle β with the horizontal line, and this angle exists in the prior art, and is generally 3° to 6°. The number of the upper fan 3 can be consistent with the number of the lower fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com