A torque loading device for a servo mechanism

A technology of servo mechanism and loading equipment, which is used in the testing of machine/structural components, torque measurement, instruments, etc., can solve the problems of large overall vibration, adverse effects of the surrounding test environment, and inconvenient inertia adjustment methods. Effects of theoretical and experimental support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

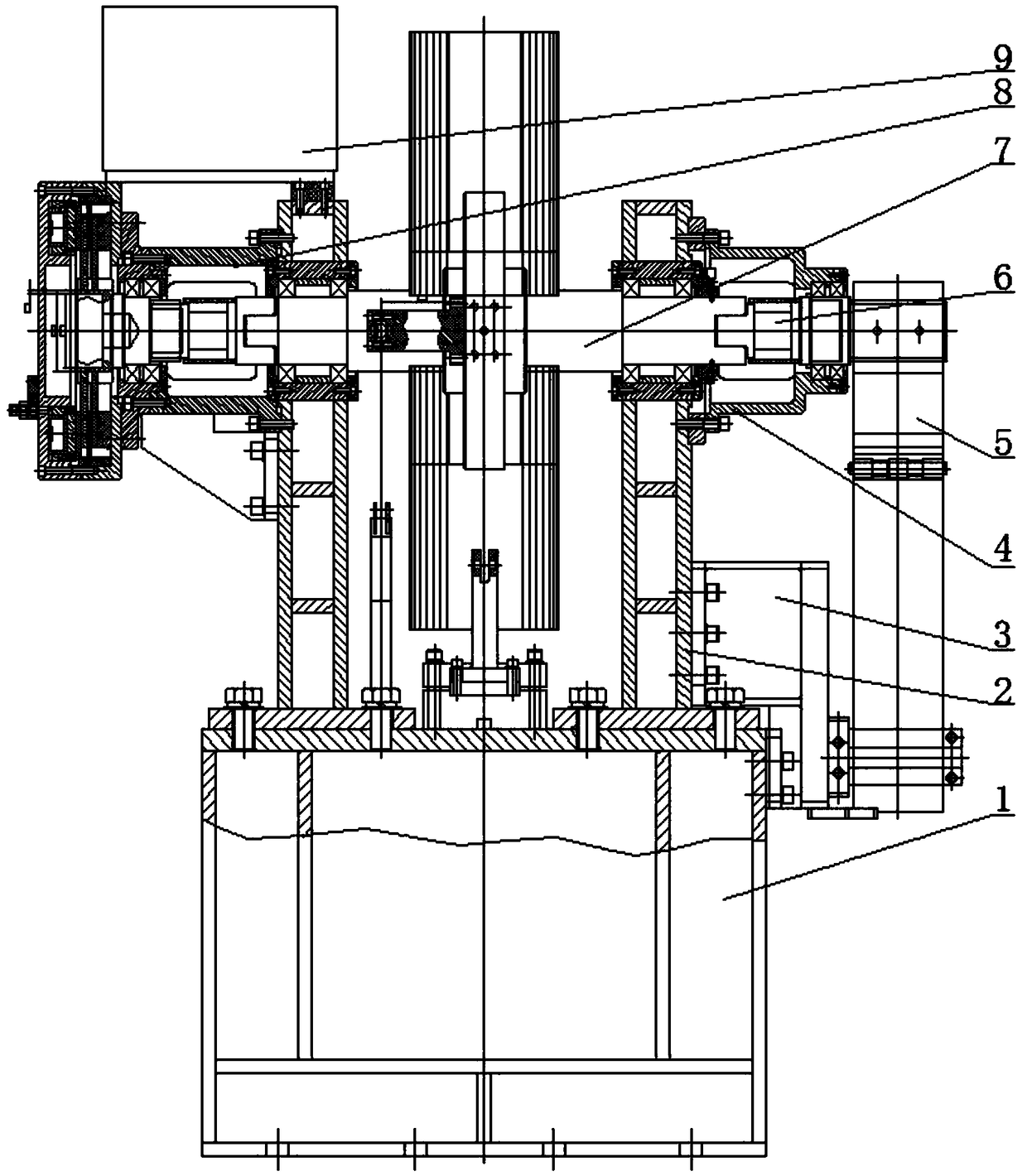

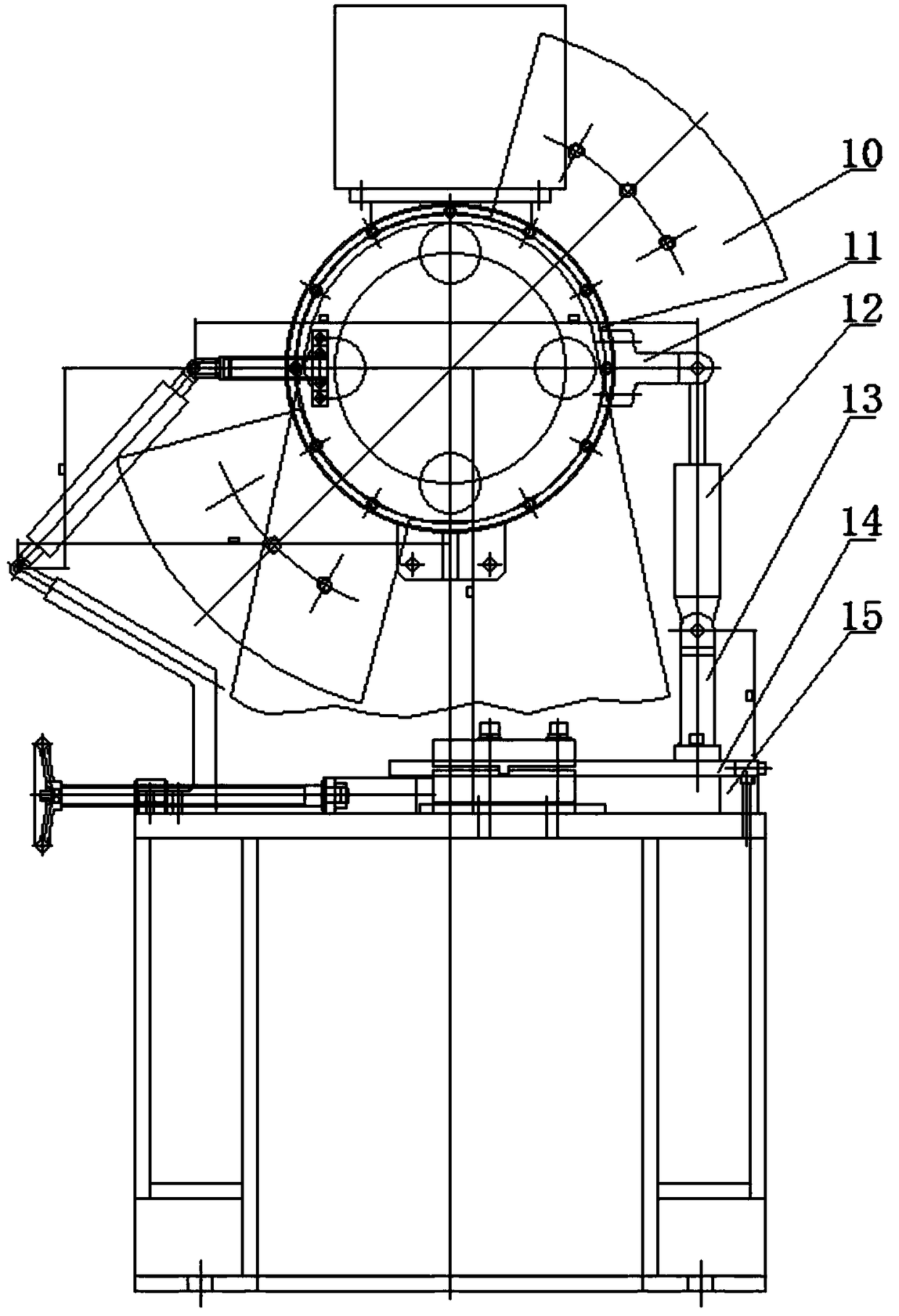

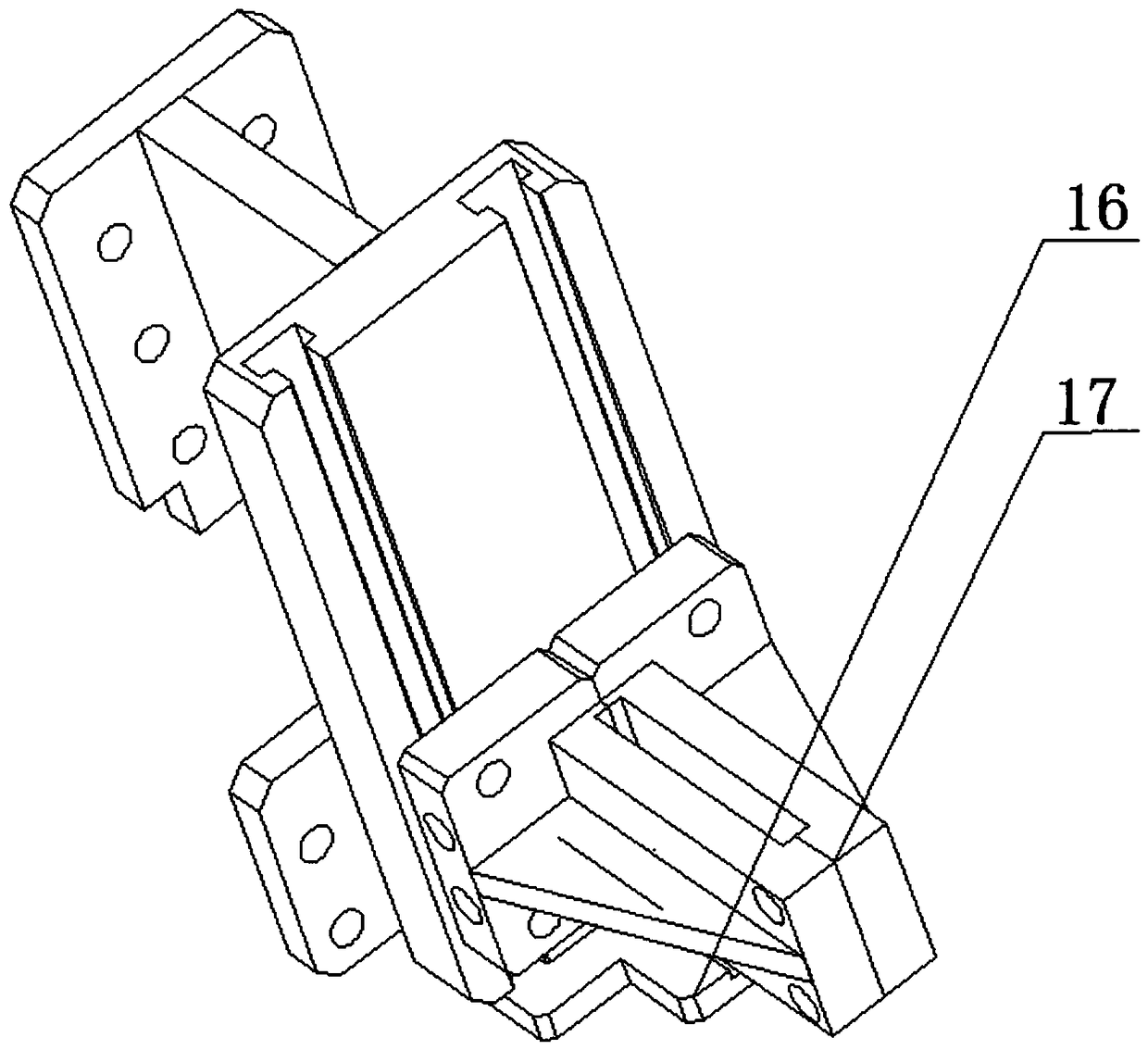

[0030] A servo mechanism torque loading device is composed of a base 1, a support 2, an elastic moment loading bracket 3, an elastic moment device support 4, an elastic moment loading device 5, an elastic moment sensor 6, a main shaft 7, a friction moment loading device 8, and a load Torque display instrument 9, inertia simulation disk 10, servo mechanism force arm 11, tested servo mechanism 12, servo mechanism support 13, support stiffness simulation device 14, fulcrum positioning plate 15, baffle plate 16, spring plate clamping frame 17, Elastic torque device mounting seat 18, swing shaft 19, spring plate 20, roller 21, swing shift fork 22, frictional moment device mounting seat 23, bearing (120) 24, spacer sleeve 25, bearing seat 26, loading inner seat 27, Loading outer seat 28, fixed disk holder 29, friction fixed disk 30, friction moving disk 31, fixed disk 32, friction shaft 33, friction torque sensor 34, joint mounting seat 35, joint 36, piston 37, bracket 38, support S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com