Shield TBM oil liquid state on-line automatic monitoring system

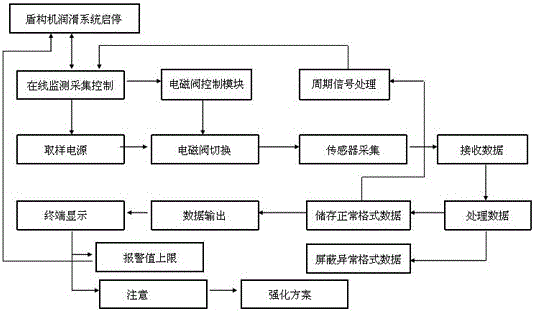

An automatic monitoring and oil monitoring technology, applied in measuring devices, instruments, etc., can solve the problems of main bearing and gear pair damage, shield construction loss, difficulty, etc., to ensure reliable lubrication, reduce maintenance downtime costs, prevent Effects of major equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

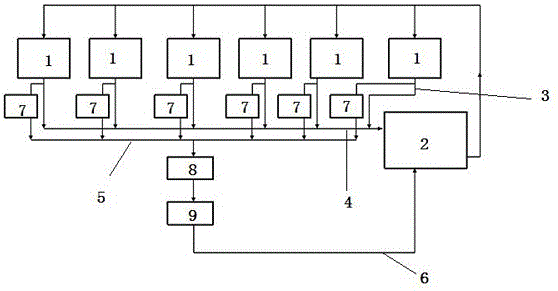

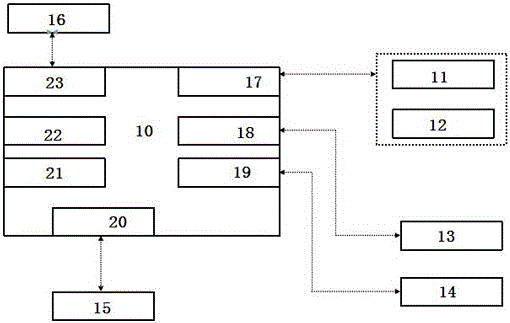

[0018] Such as figure 1 As shown, a shield machine TBM oil state online automatic monitoring system, the shield machine TBM oil state online automatic monitoring system includes a planetary gear oil tank 1 and a main bearing gear main oil tank 2; the planetary gear oil tank 1 is a plurality of , the oil inlets of a plurality of planetary gear oil tanks 1 communicate with the oil outlets of the main bearing gear main oil tank 2 respectively; 7 are connected; the online automatic monitoring system has an online monitoring acquisition control part 9; a plurality of the solenoid valves are cycled open in an online monitoring cycle, and only one is in a normally open state; the online monitoring acquisition control Part 9 has electromagnetic valves 7 corresponding to multiple planetary gear oil tanks in the gear oil lubrication system of the shield machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com