Pre-stored hopper processing and monitoring system and operation method of ready-mixed concrete mixer

A ready-mixed concrete and monitoring system technology, which is applied in the direction of unloading device, transportation and packaging, loading/unloading, etc., can solve the problems of continuous impact of aggregate on the side wall, slow production efficiency, dust pollution, etc., and increase the consumption Statistical accuracy, increase effective utilization, and reduce the effect of continuous impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The basic structure of the traditional commercial concrete mixing hopper, the working principle of the sensor, the principle of wireless signal transmission and other technologies will not be described repeatedly in the present invention, and the implementation mode of the structure and operation method of the present invention will be emphasized.

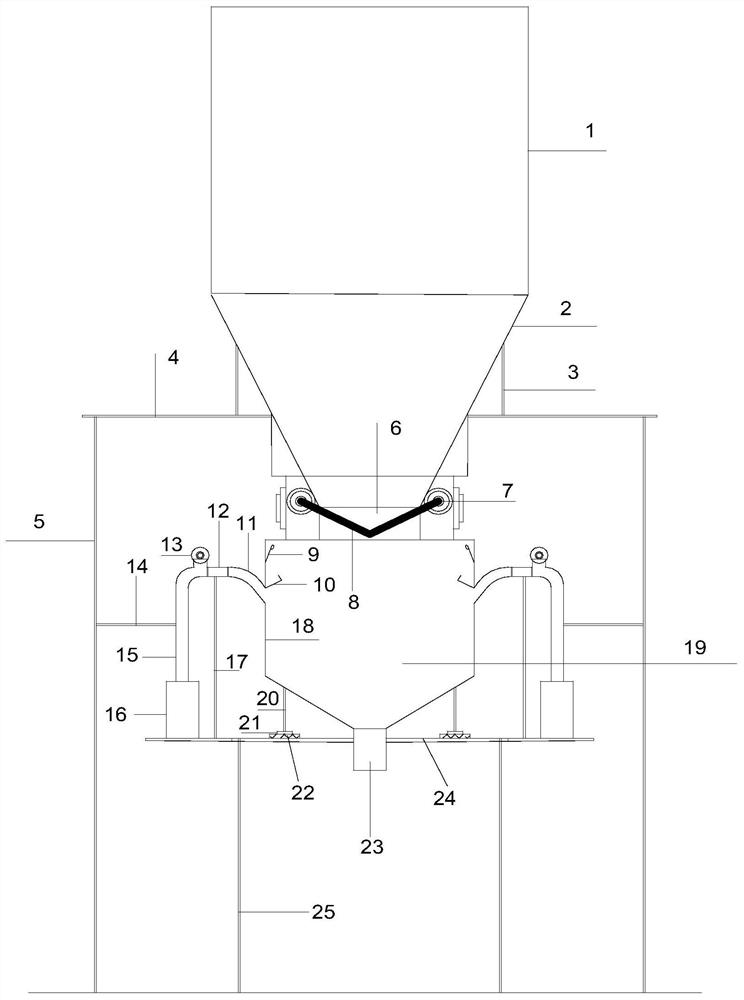

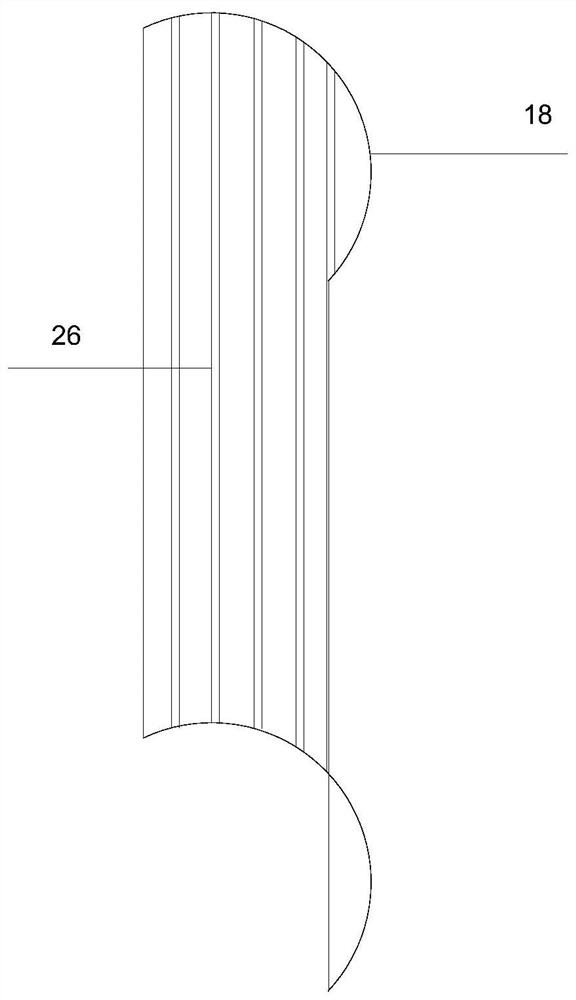

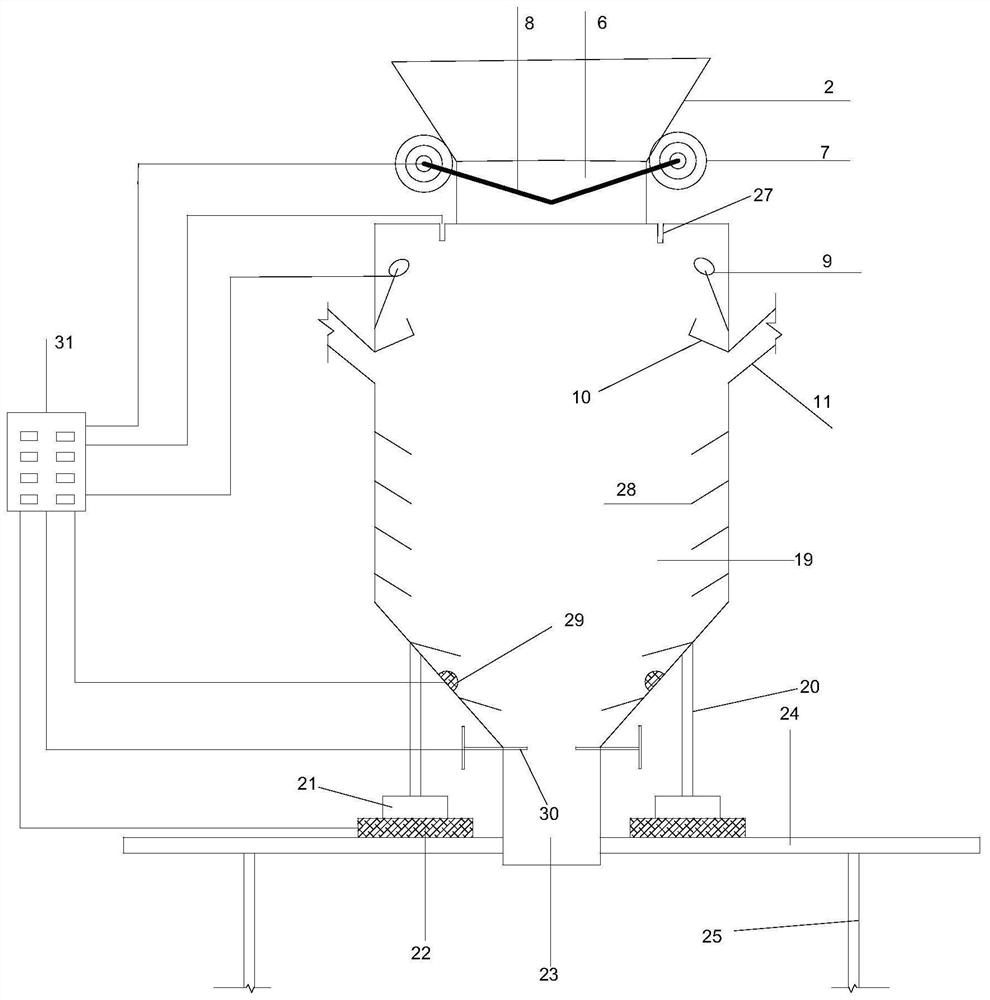

[0034] Such as Figure 1 to Figure 3 As shown, an embodiment of the present invention provides a pre-storage hopper processing and monitoring system for a ready-mixed concrete mixer, including an upper hopper body 1, a lower hopper body 2, a hopper fixed support 3, a hopper horizontal support 4, a hopper vertical Directional bracket 5, automatic control opening and closing feed inlet 6, rotating shaft 7, flat flap door body 8, hopper fog nozzle 9, dust removal device, inner wall of pre-storage hopper 18, pre-storage hopper 19, pre-storage hopper bearing bracket 20, backing plate 21, stress Sensing plate 22, automatic control o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com