Patents

Literature

48results about How to "Real-time monitoring of moisture content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

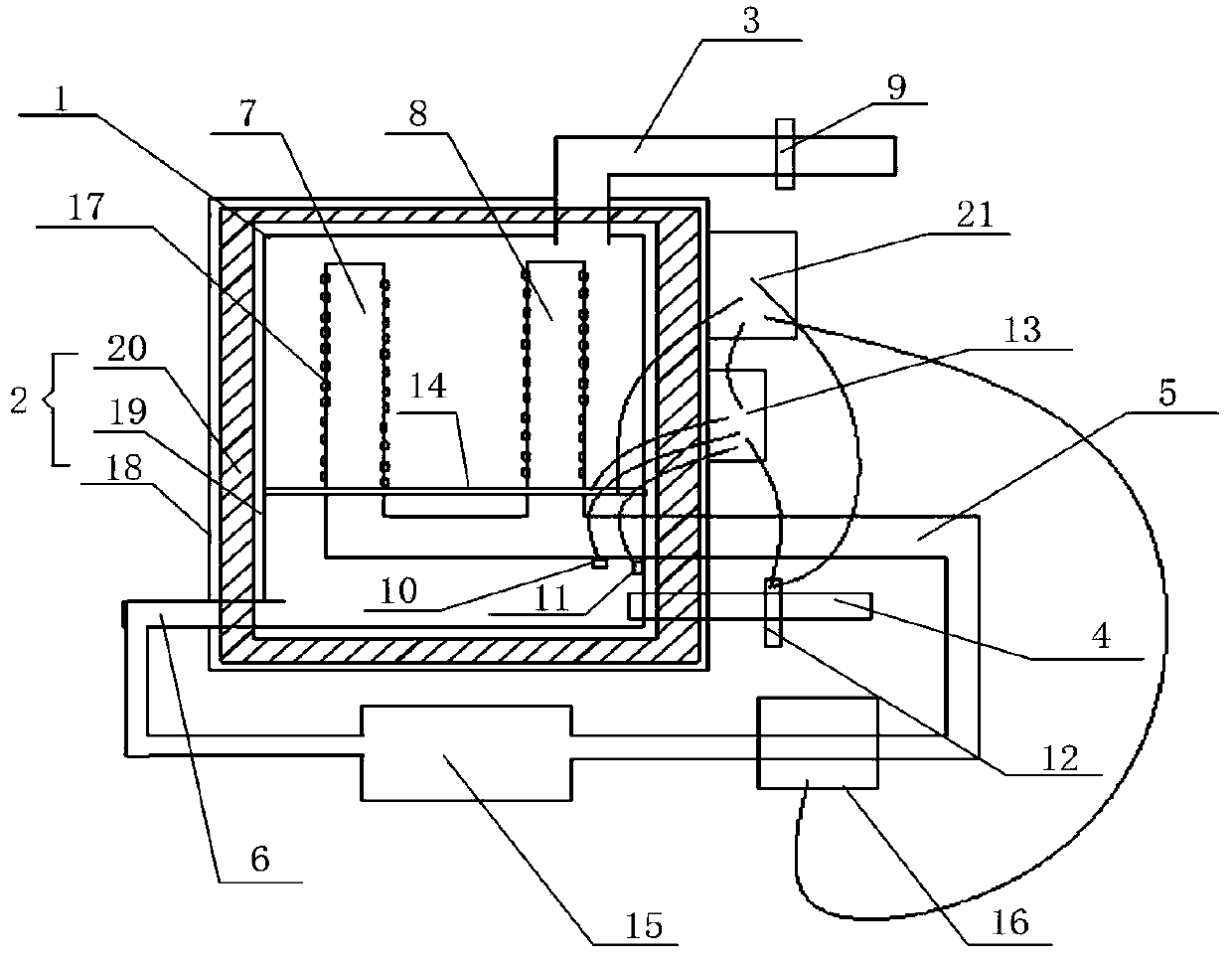

Soil horizontal frost-heaving visualization testing apparatus

InactiveCN107941574AMeet the test temperature requirementsImprove compactionPreparing sample for investigationEarth material testingPhysicsMoisture

The invention provides a soil horizontal frost-heaving visualization testing apparatus. The soil horizontal frost-heaving visualization testing apparatus comprises a sample cylinder, a loading system,a digital image measurement system, a water-supplementing system, and a temperature control system. The soil horizontal frost-heaving visualization testing apparatus can realize requirements of an experiment under different temperature conditions; performs real-time observation and analysis on moisture migration and temperature gradient change during a sample soil horizontal freezing process; performs real-time determination on frost-heaving displacement and stress during the sample soil horizontal freezing process, and realizes engraving of a horizontal segregated ice growth process in the horizontal freezing process.

Owner:BEIJING JIAOTONG UNIV

Control system of corrugated paper machine

InactiveCN106079832AHigh degree of automationSave manpower and material resourcesLamination ancillary operationsLaminationWater contentPaper sheet

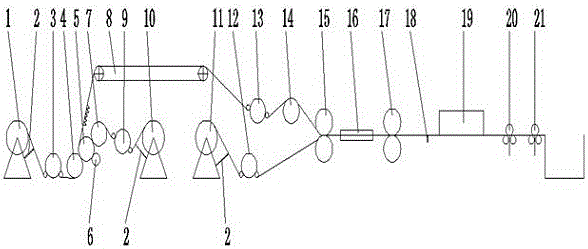

The invention discloses a control system of a corrugated paper machine. The control system comprises first facial tissue, a press roller, a lower corrugated roller, core paper, an electromagnetic heating and drying device and a printing device; an infrared sensor is fixedly installed below the first facial tissue, the infrared sensor and a line at the center position of the press roller are connected with a first facial tissue preheater, a first glue applicator is fixedly connected below the lower corrugated roller, and a paper passing bridge is rotationally connected to the lower corrugated roller; a core paper preheater is arranged at the left end of the core paper, a second facial tissue preheater line is connected with a single-face corrugated board preheater, a cooling device and a moisture detector are arranged at the right end of the electromagnetic heating and drying device in parallel, and a longitudinal cutting device and a transverse cutting device are arranged at the right end of the printing device in parallel. The control system of the corrugated paper machine is provided with an assembly controller and multiple rotating rollers, is high in automation degree, saves time and labor and avoids waste; water content of finished paper is monitored in real time through a water detector, and unqualified paper is avoided.

Owner:HENAN ZHONGYA PAPERMAKING EQUIP

Water circulation irrigation and drainage system for Hetao irrigation area field

InactiveCN106386407AEasy to manageEasy to useSoil lifting machinesWatering devicesWater storage tankEngineering

The invention relates to the technical field of irrigation and drainage systems, and discloses a water circulation irrigation and drainage system for a Hetao irrigation area field. The system comprises a saline-alkali land. A water drainage underground pipe is arranged in the saline-alkali land body. A filtering device is connected to the left end of the water drainage underground pipe. A water storage tank is connected to the left side of the filtering device. A float ball switch is arranged on the left sidewall of the inner cavity of the water storage tank. The top of the water storage tank is at a same level with the top of the saline-alkali land. Two sets of electric water pumps are arranged on the top of the saline-alkali land. The two sets of the electric pumps are respectively positioned on the left and right sides of the top of the water storage tank. Water inlet ports of the electric water pumps are both connected with the inner cavity of the water storage tank through water pipes. Supporting rods are arranged between the water pipes and the inner wall of the water storage tank. A drainage pipe is connected to the left end of the water outlet port of the left electric water pump. With the system, water is recycled, and water usage and distribution are reasonable. An automatic sprinkler irrigation technology is adopted, such that the intelligence degree is high.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Method for measuring water content of dried object, vacuum drying device and control method thereof

ActiveCN107014156AEasy to implementLarge measuring rangeDrying using combination processesDrying solid materials without heatEvaporationPulp and paper industry

The invention provides a method for measuring the water content of a dried object, a vacuum drying device and a control method of the vacuum drying device. The method for measuring the water content of the dried object is used for calculating the water content of the dried object in a drying container in the vacuum drying process. The method calculates the water evaporation amount of the dried object at the drying temperature according to the system parameter values of the drying container in the closed state and calculates the current water content of the dried object according to the water evaporation amount. The method for measuring the water content of the dried object is simple, convenient to use and easy to achieve, efficient in the measuring process, and wide in measuring range and reliable in measuring result. The invention further provides the vacuum drying device and the control method of the vacuum drying device. The vacuum drying device controls the drying process by conducting real-time measurement on the water content of the dried object, the control method can meet the requirements for rapidness and continuity, manual intervention is not required, and the preset target water content of the dried object can be accurately and rapidly achieved.

Owner:常州广建仪器科技有限公司

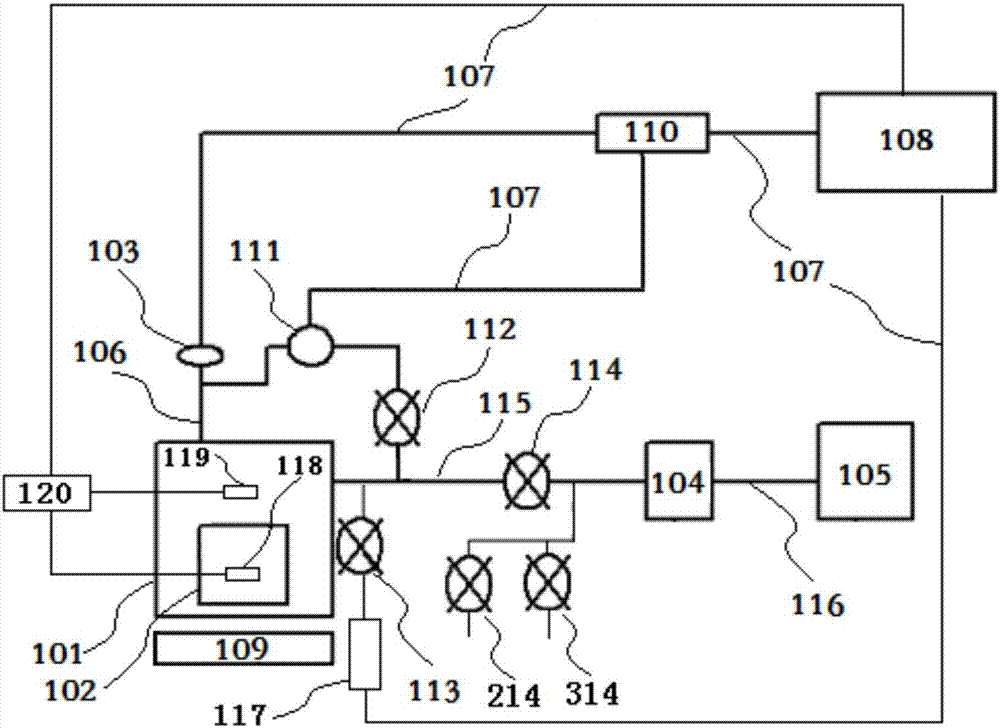

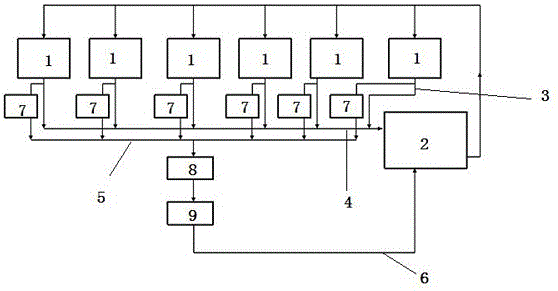

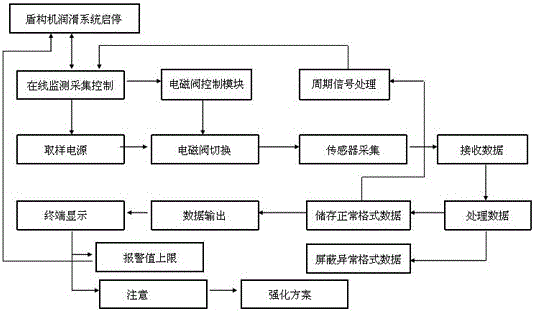

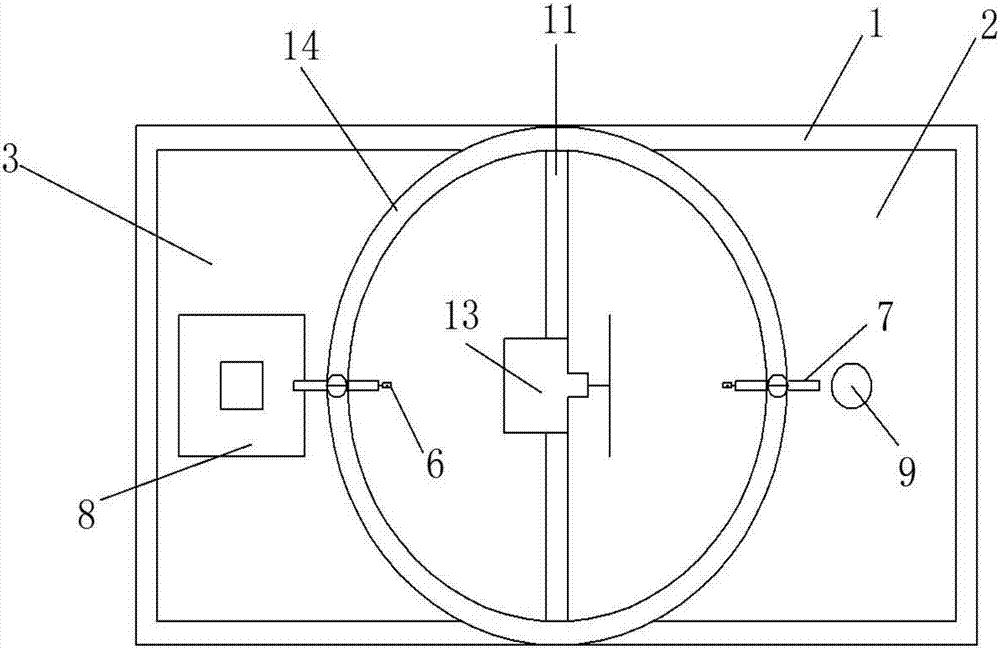

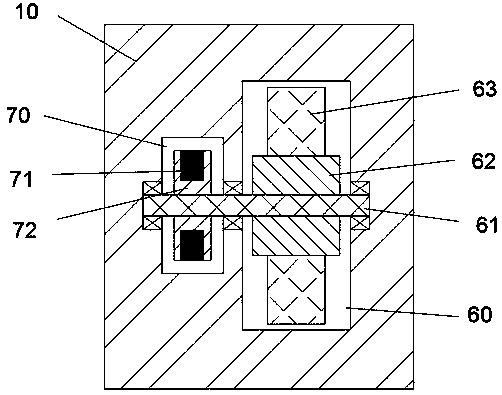

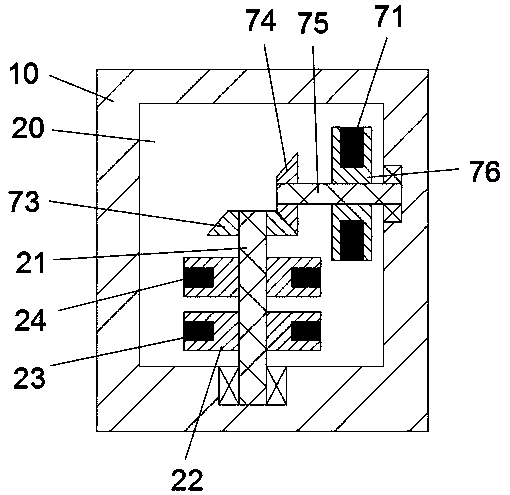

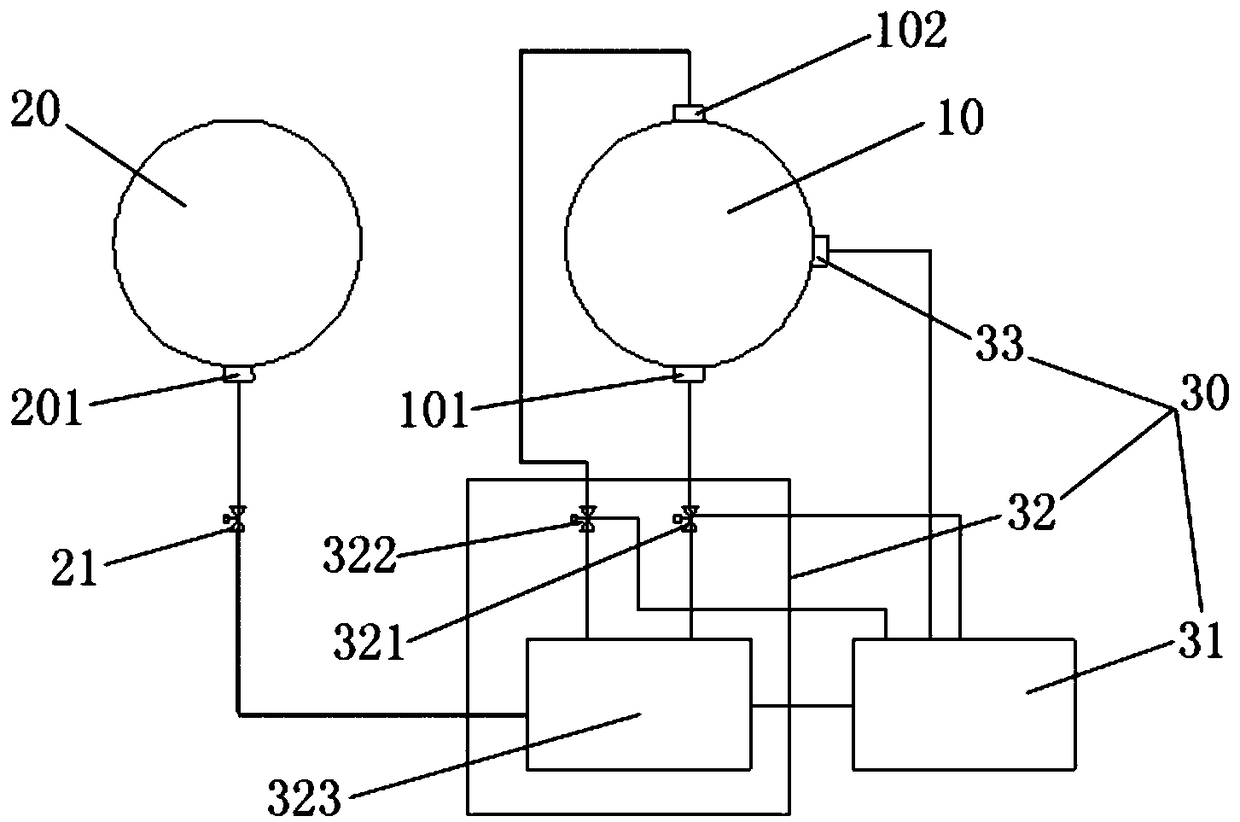

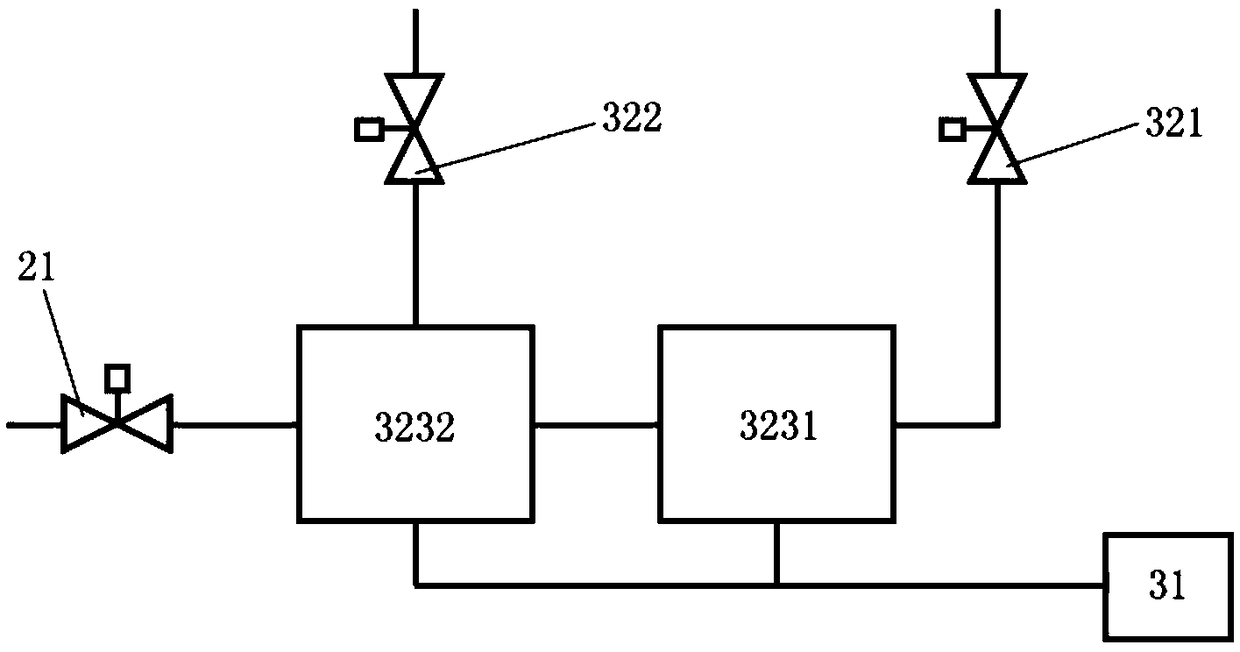

Shield TBM oil liquid state on-line automatic monitoring system

InactiveCN106525141AReal-time monitoring of moisture contentReal-time monitoring of viscosity changesMeasurement devicesLiquid stateSolenoid valve

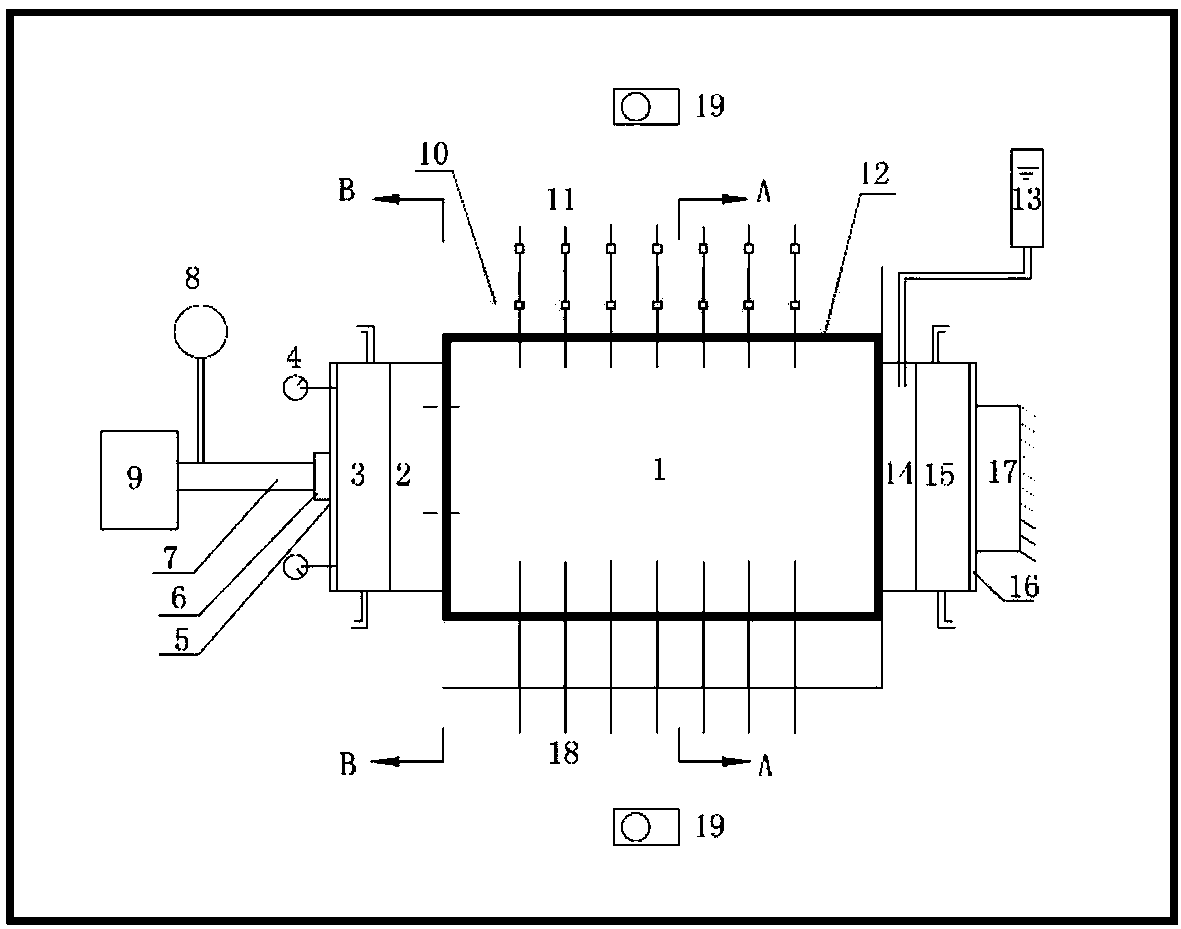

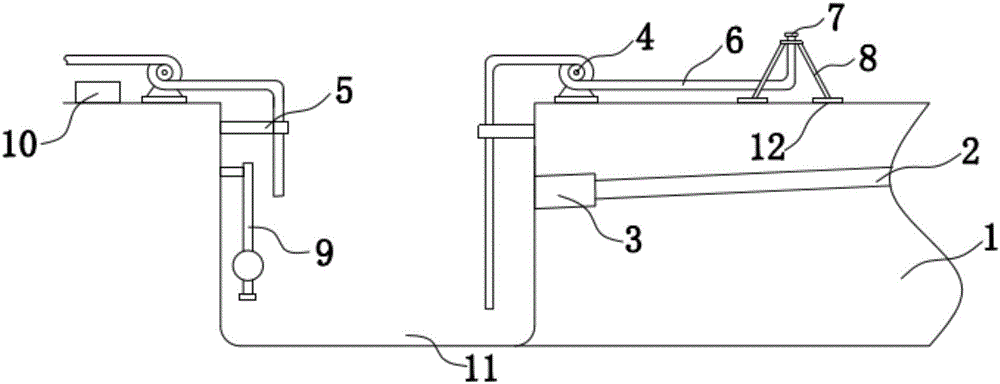

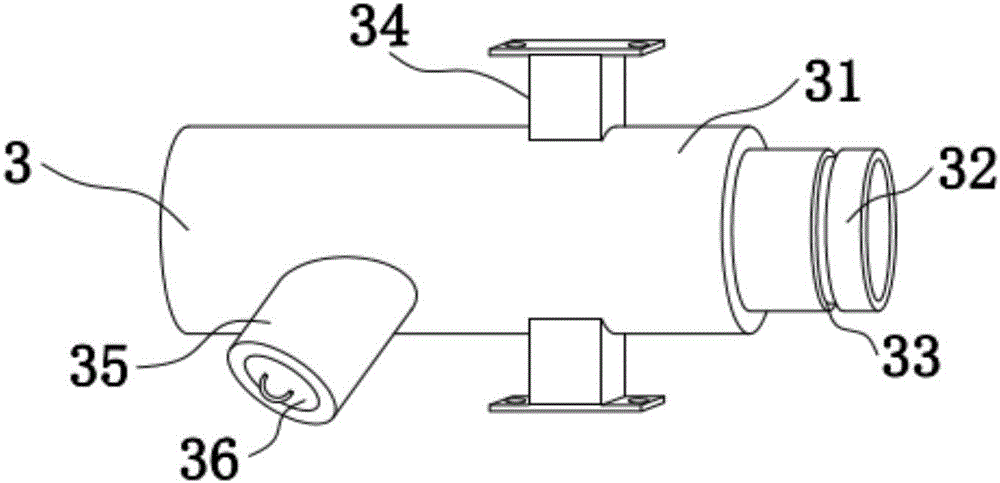

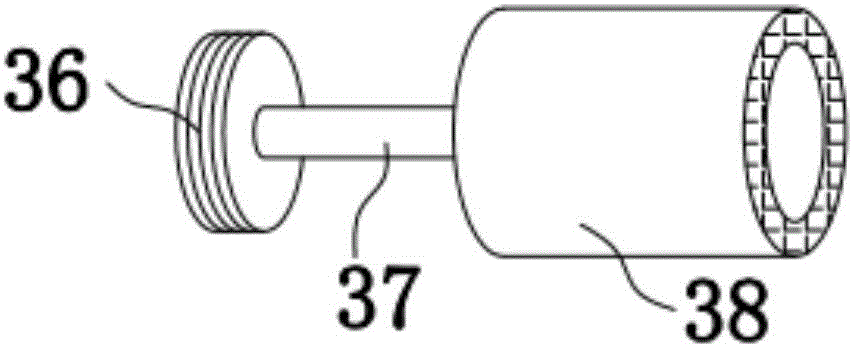

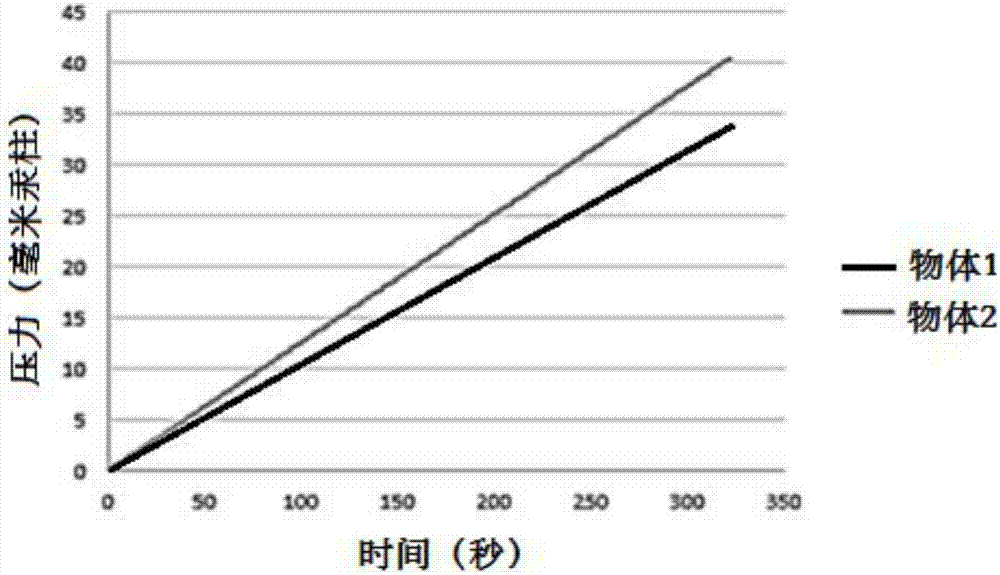

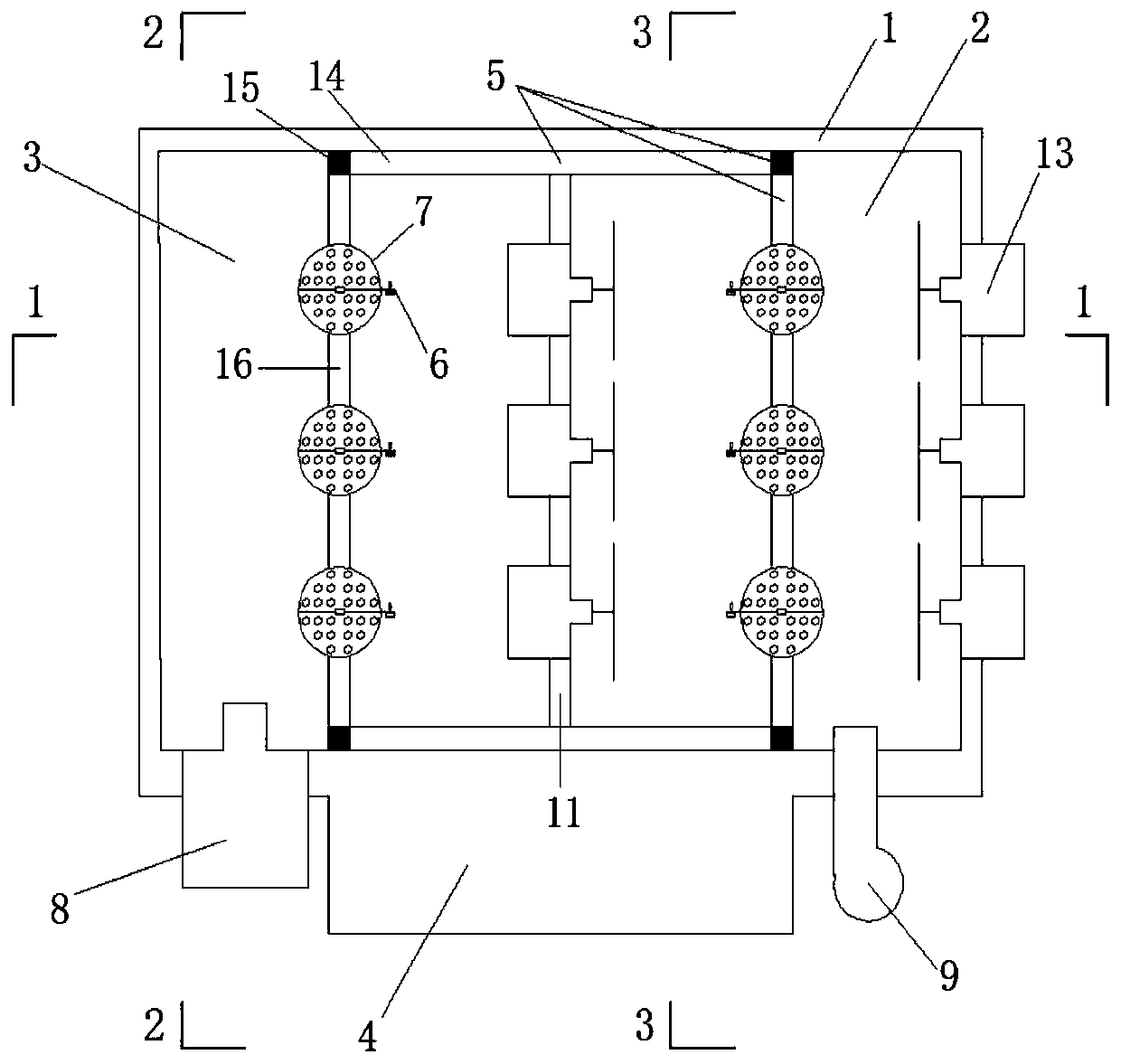

The invention belongs to the technical field of shield machine lubrication condition monitoring, and proposes a shield TBM oil liquid state on-line automatic monitoring system. The proposed shield TBM oil liquid state on-line automatic monitoring system includes a planetary gear oil tank (1), a main bearing gear main oil tank (2) and an on-line monitoring acquisition control part (9); the on-line monitoring acquisition control part (9) has a plurality of solenoid valves (7); the plurality of solenoid valves (7) and a plurality of planetary gear oil tanks in a shield machine gear oil lubrication system are in one-to-one correspondence; the plurality of solenoid valves are cyclically opened in an on-line monitoring period, and only one is in a normally open state; the on-line automatic monitoring system is also provided with an oil liquid monitoring loop (5); the other ends of the plurality of solenoid valves (7) communicate with the oil liquid monitoring loop (5); and the oil liquid monitoring loop (5) is connected with the on-line monitoring acquisition control part (9). The shield TBM oil liquid state on-line automatic monitoring system provided by the invention ensures reliable lubrication of equipment and safe operation of a shield machine.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

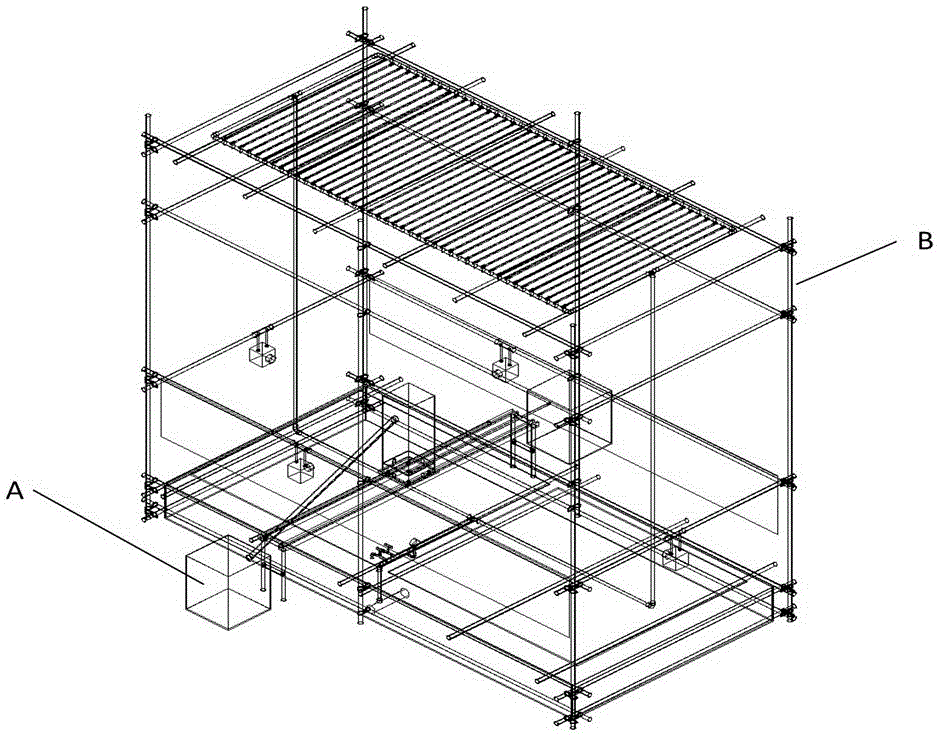

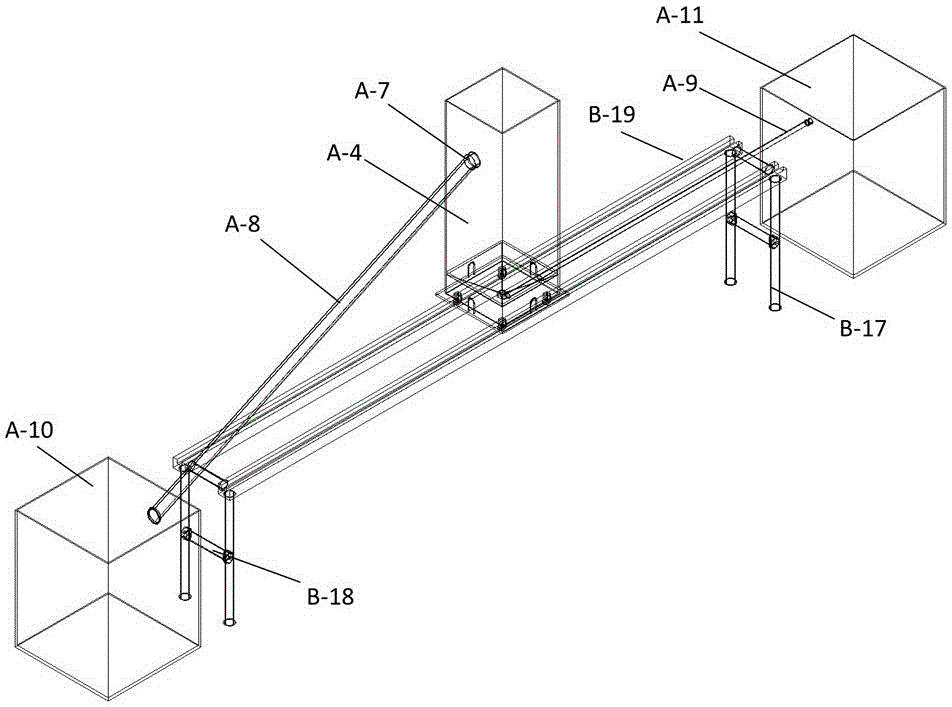

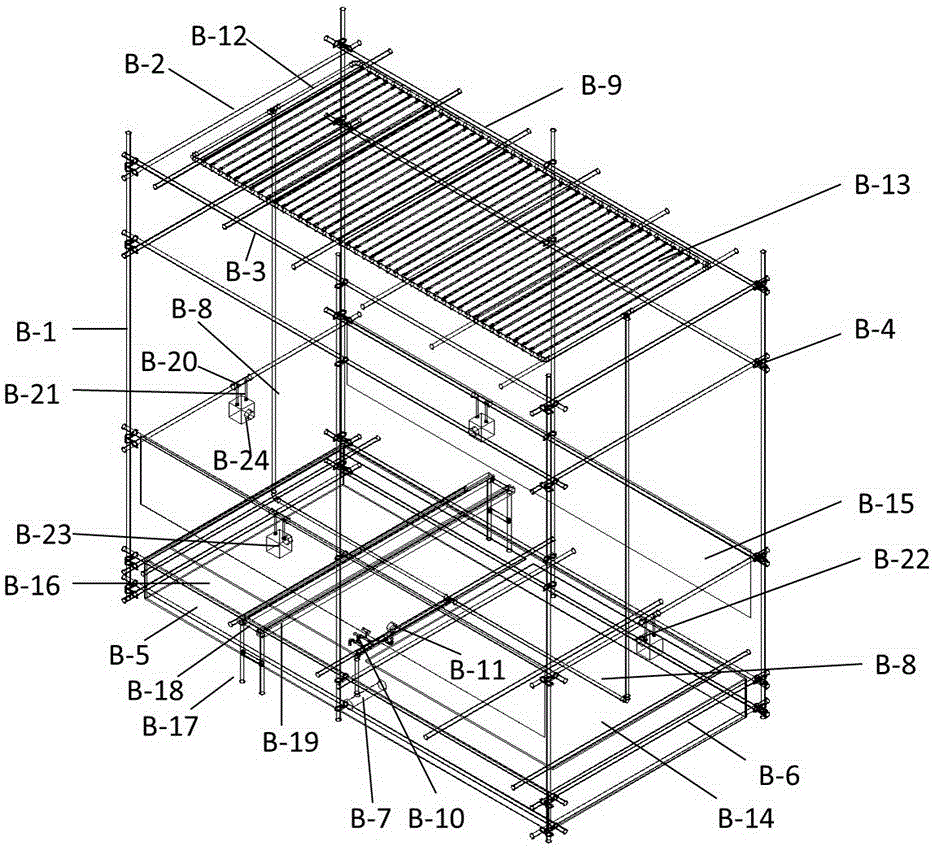

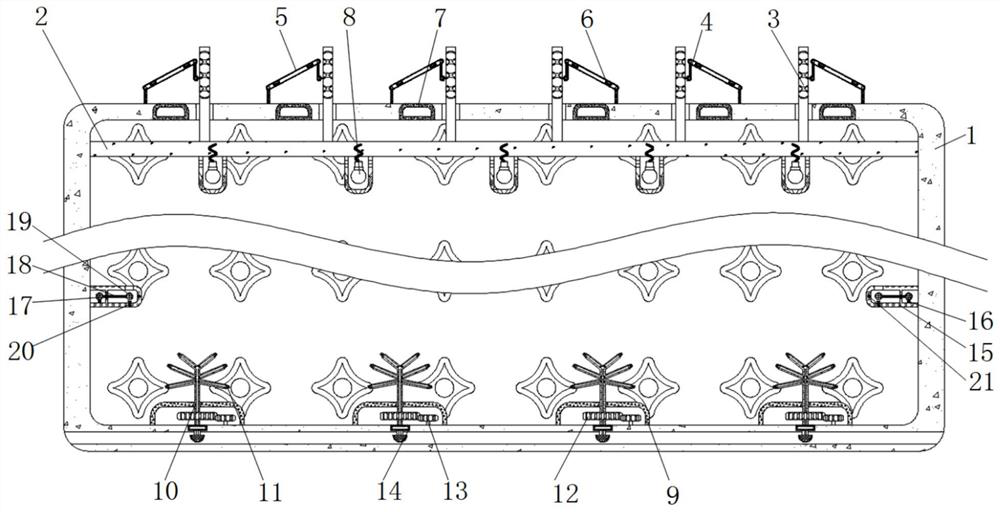

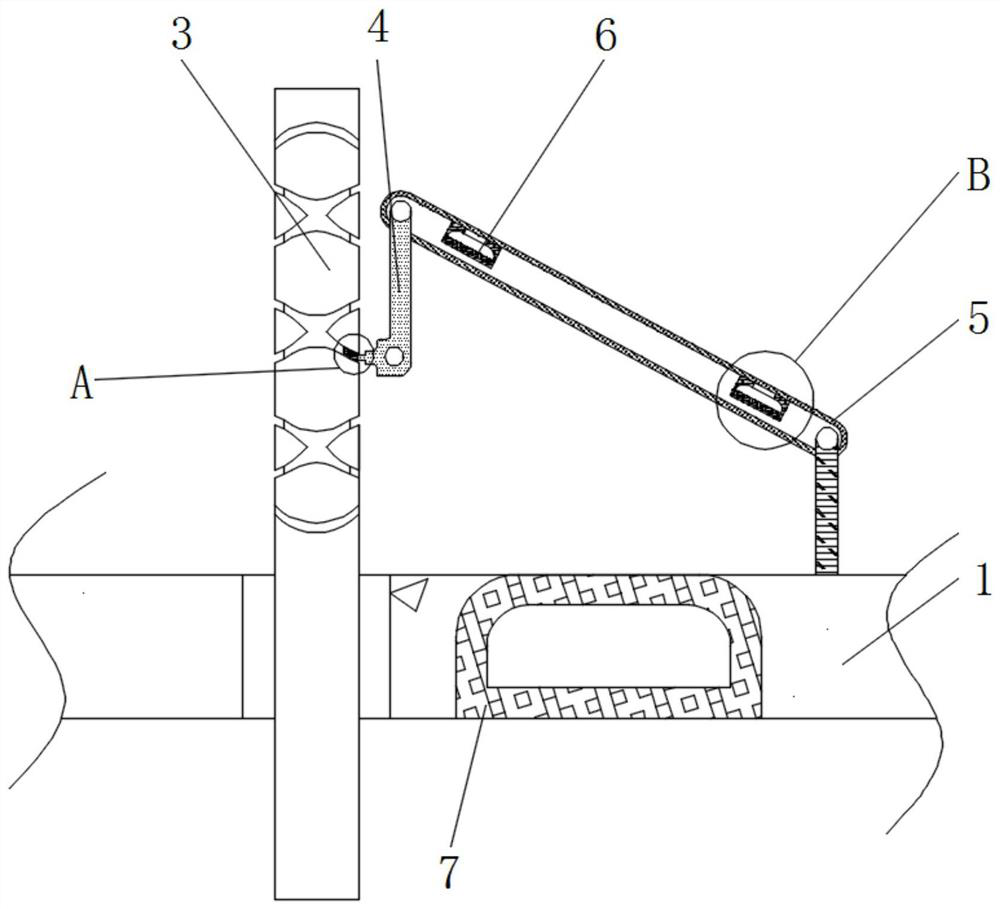

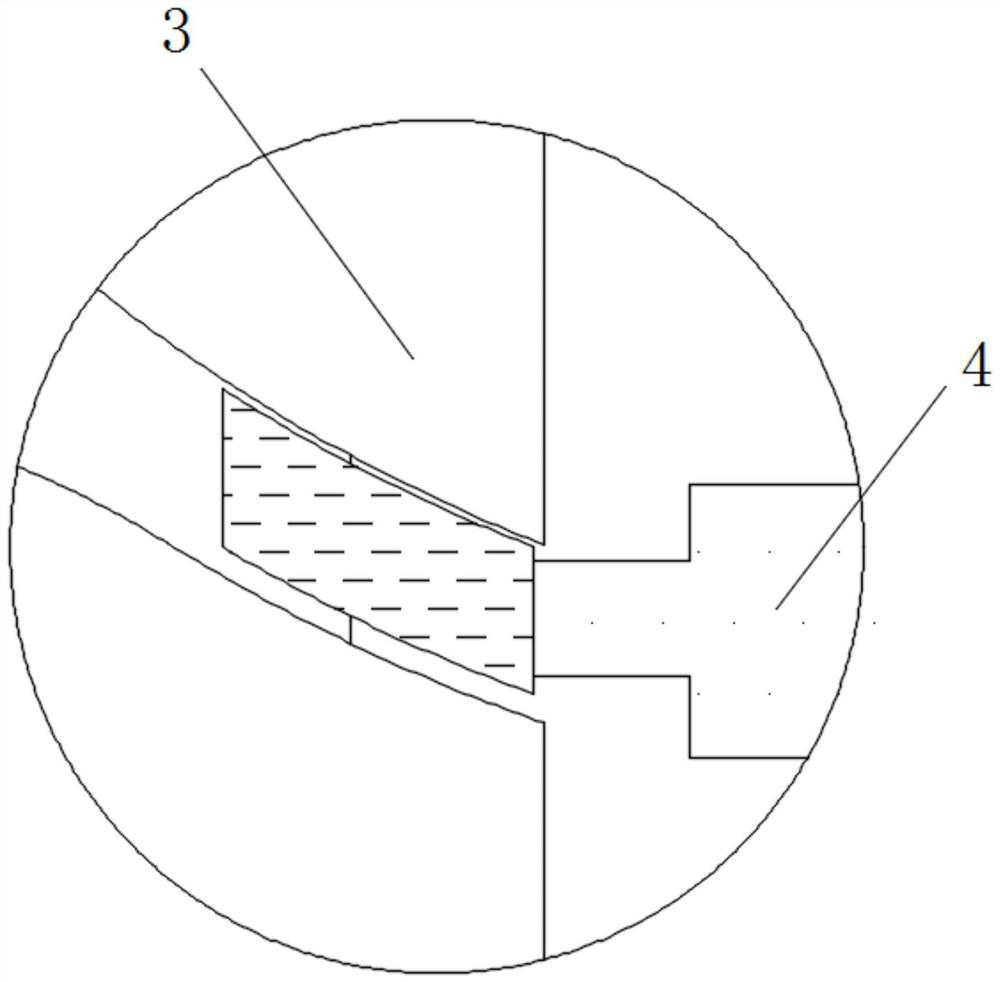

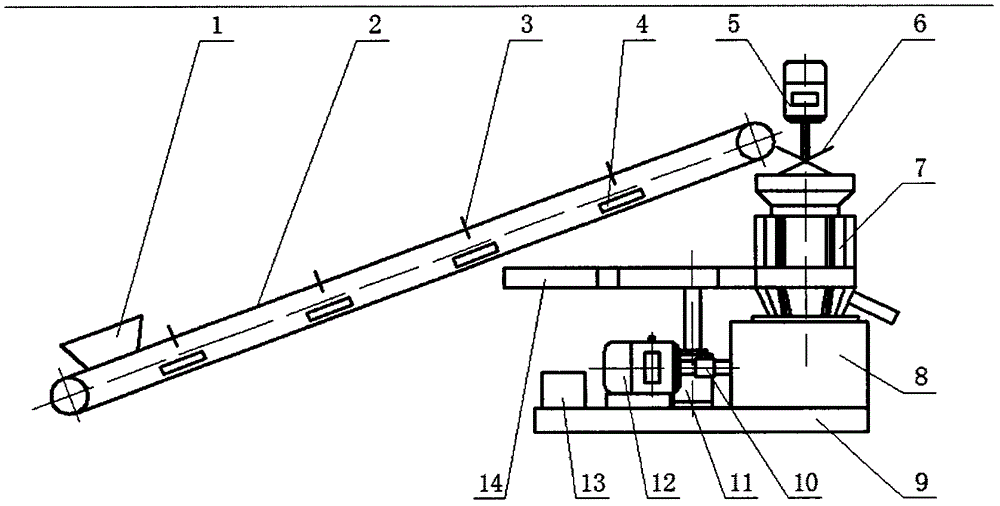

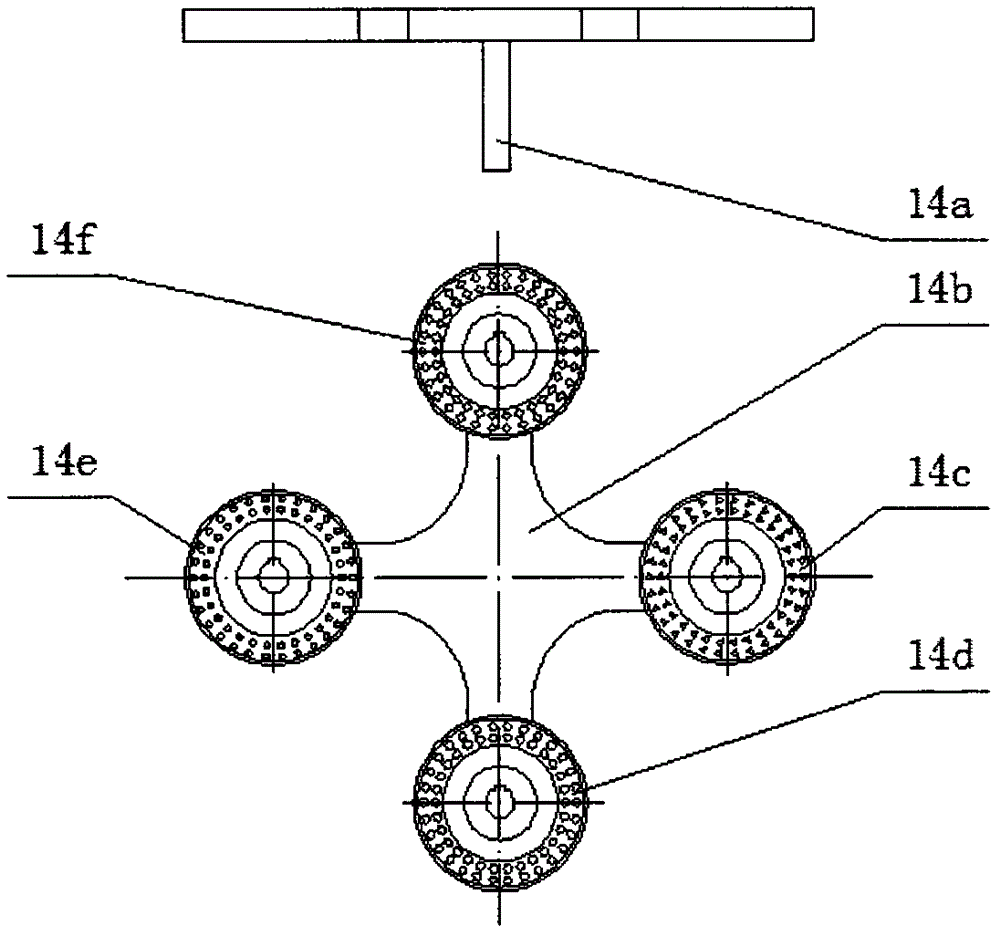

Device for batch experiment of soil body rainwater infiltration characteristics and use method thereof

InactiveCN106596378ARealize self-recyclingRecord moisture content in real timePermeability/surface area analysisSupporting systemSoil science

The invention discloses a device for batch experiment of soil body rainwater infiltration characteristics and a use method thereof. The device is divided into two parts, wherein the first part is a soil body infiltration characteristic measuring device which comprises a soil body infiltration characteristic model box, a slope runoff measuring box and a bottom surface seepage flow measuring box; and the second part is a rainfall device which comprises a rainfall system, a self-circulating water supply system, a supporting system, a real-time observing system, an operating platform and a movable soil body infiltration characteristic model bearing device. The device disclosed by the invention not only can recycle rainwater and monitor a spatial distribution rule of rainwater infiltration in a visual manner, but also can monitor the content of moisture in a soil body, the pressure of pore water and the change in soil pressure in the rainfall process in real time; as a plurality of soil body infiltration characteristic model boxes of the same experiment batch can be arranged on the operating platform, a rainwater infiltration characteristic experiment on soil bodies with different slopes, compaction degrees, initial moisture contents and stone contents under the condition of different rainfall intensities and rainfall durations can be developed in batch in a short term, so that the experiment efficiency and reliability are greatly improved.

Owner:HUNAN CITY UNIV

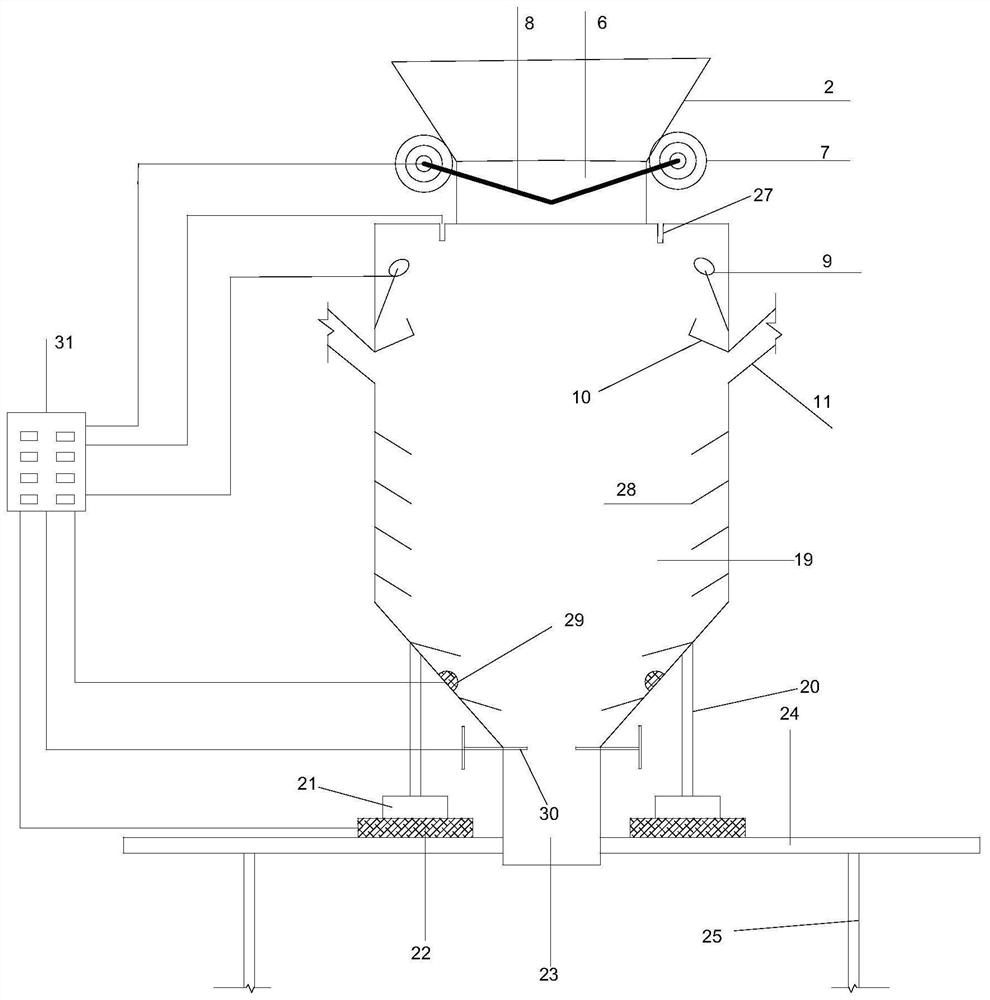

Mold electric-switch intelligent biomass forming machine

ActiveCN103386277AReal-time monitoring of moisture contentGuaranteed moisture contentGranulation by pressingTemperature controlMotor control

The invention relates to a mold electric-switch intelligent biomass forming machine comprising a humidity sensor, a temperature controller, heating wires, a material delivery hopper, a material conveyor belt, a stirring device, a granulation machine, a mold-changing disc, and a mold-changing disc motor. With the humidity sensor, biomass powder water content can be subjected to real-time measuring, such that the temperature controller can change heating current of the heating wires of the conveyor belt, such that the water content of the biomass powder can be adjusted. With the stirring device, biomass powder can be continuously stirred, such that caking is prevented, and forming machine normal work can be ensured. A plurality of molds with different hole sizes and through hole depths are arranged on the mold-changing disc. The mold-changing disc motor controls the mold-changing disc such that the mold-changing disc rotates, such that mounting of different flat molds can be realized according to requirements. According to the biomass forming machine provided by the invention, through realizing flat mold switch, water content control, and biomass powder stirring, forming machine normal work can be ensured. Biomass formed particles can be prepared according to requirements, such that adaptability and versatility of the application of the forming machine are improved.

Owner:安徽省蓝天能源环保科技有限公司

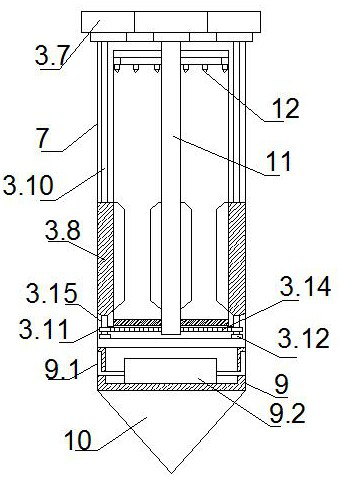

Building foundation exploration sampling detection device

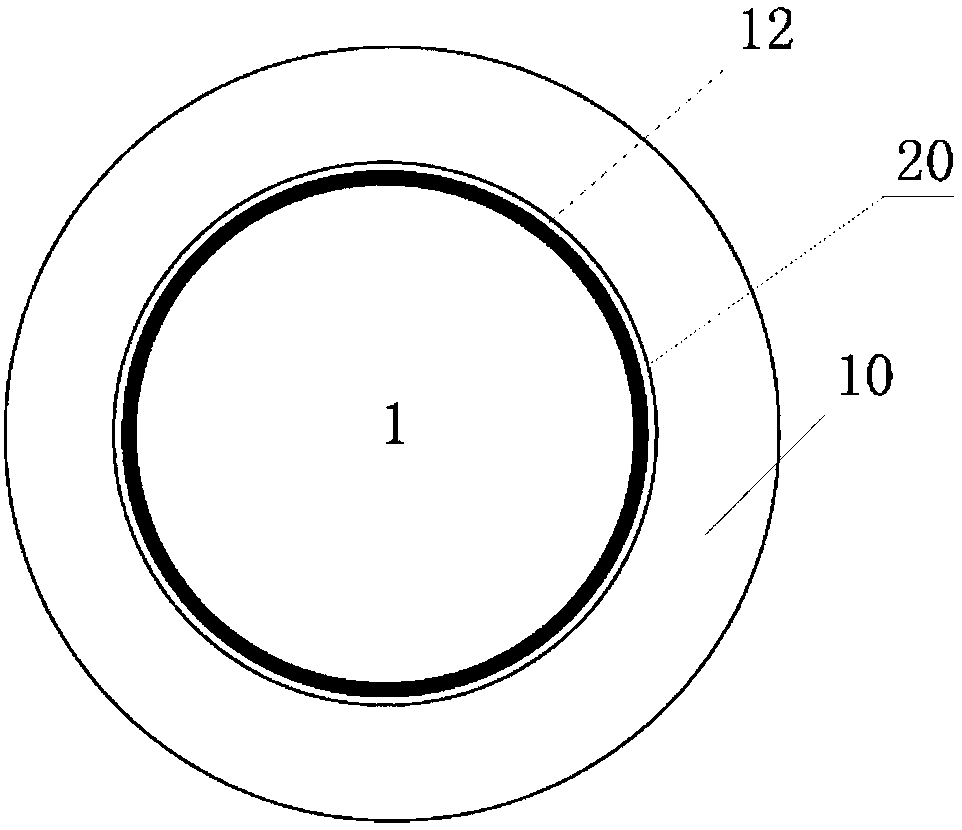

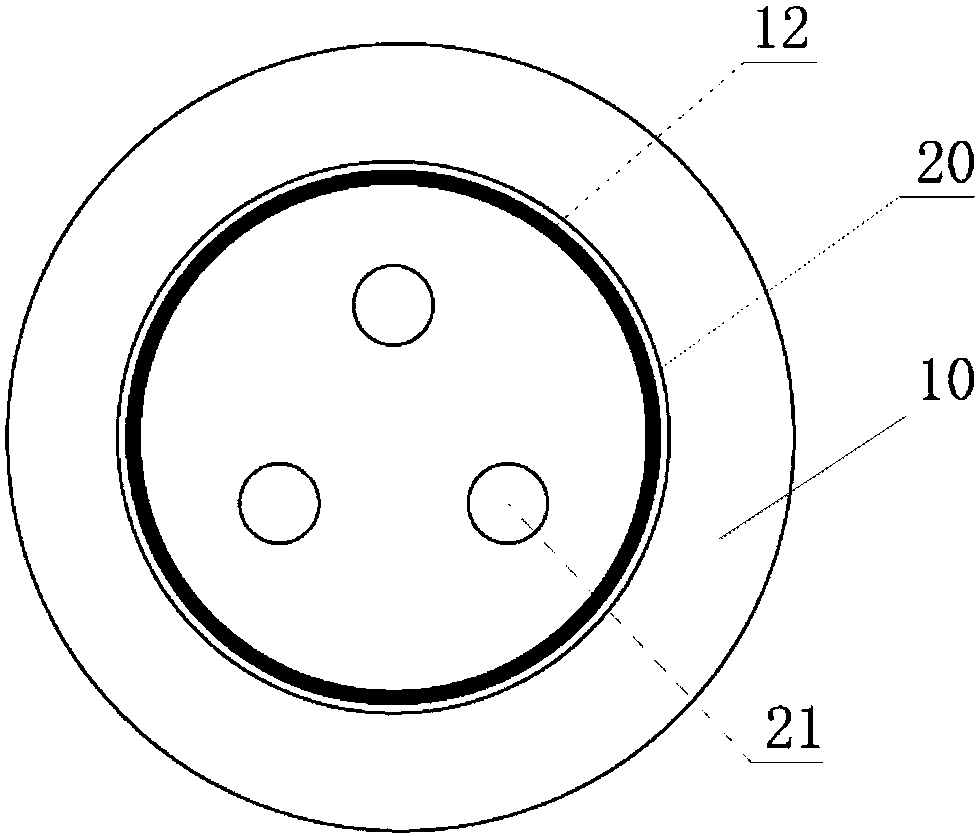

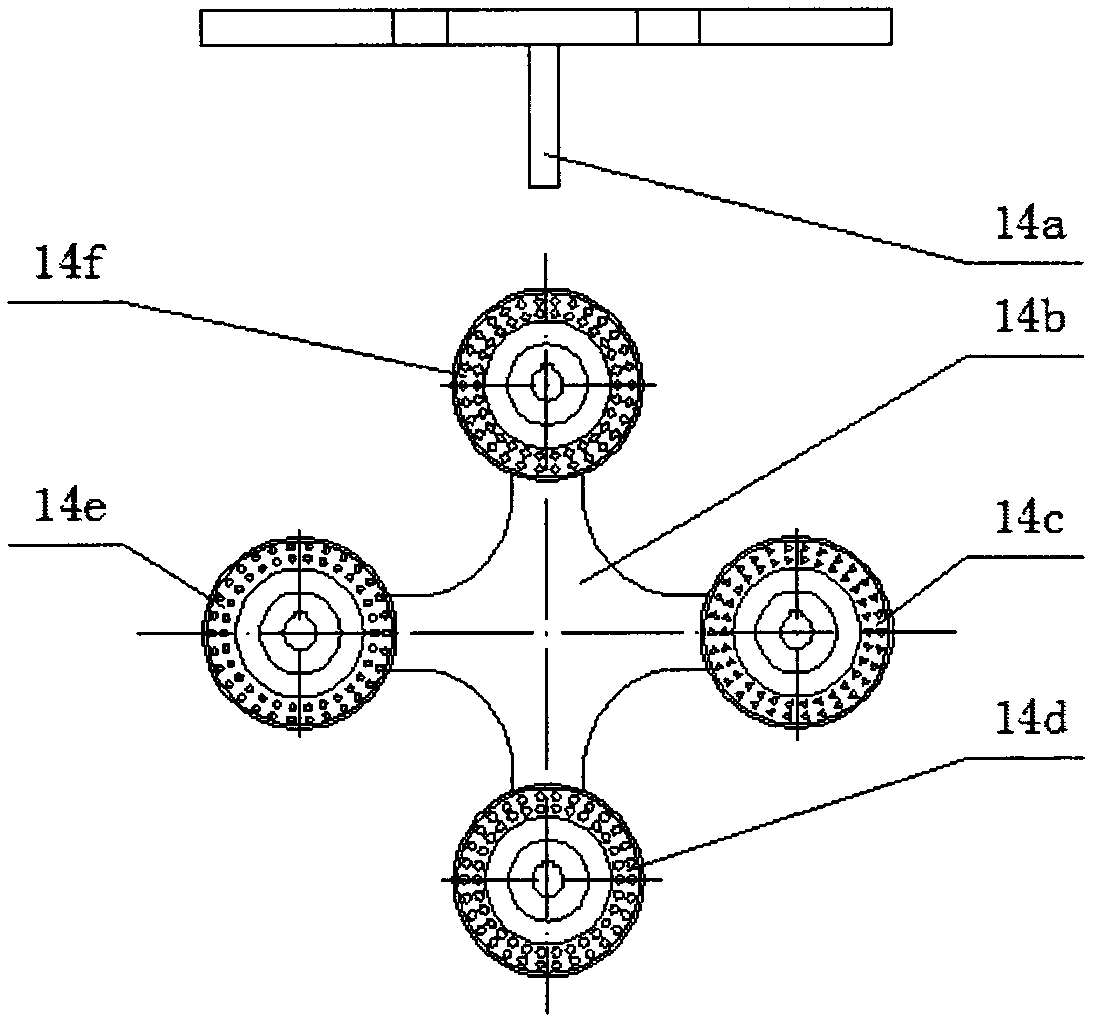

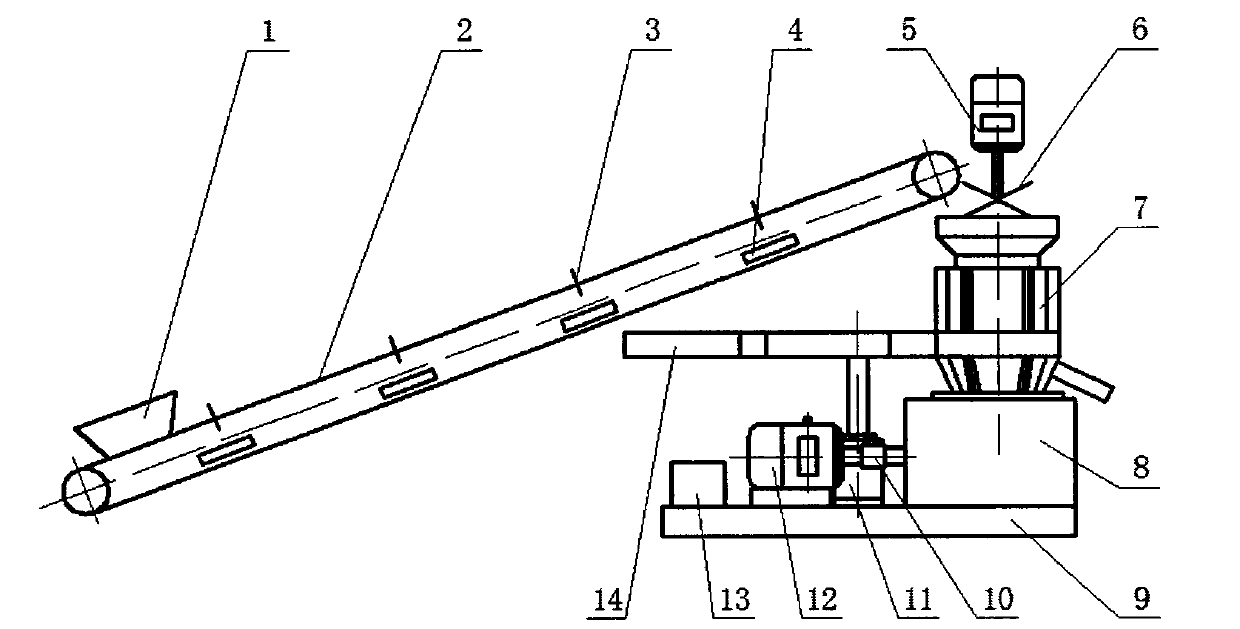

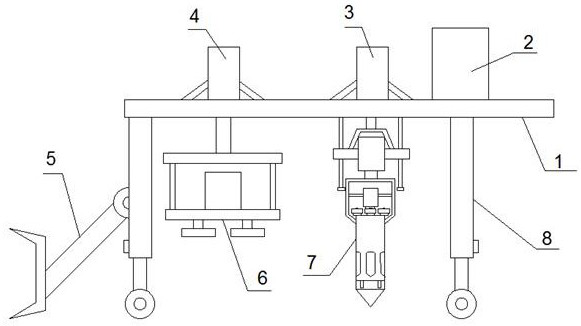

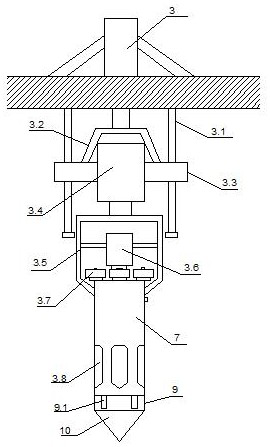

PendingCN111964957AConvenient and fast geological detectionReal-time monitoring of moisture contentWithdrawing sample devicesEarth material testingElectric machineStructural engineering

The invention discloses a building foundation exploration sampling detection device, which comprises a moving trolley; the moving trolley is provided with a roof flat plate; a controller, a storage battery, an electric push rod I and an electric push rod II are arranged on the roof flat plate; the lower end of the electric push rod I is connected with a geological radar; the lower end of a rotating motor I is connected with a sampling cylinder; a cylindrical sampling cavity is formed in the sampling cylinder; a plurality of cylindrical rod penetrating cavities are evenly formed in the side wall of the upper portion of the sampling cylinder in the axis direction; and a sampling opening communicated with the rod penetrating cavities and the sampling cavity is formed in the side wall, under each rod penetrating cavity, of the sampling cylinder. The device has the advantages that geological detection can be conveniently and rapidly conducted on a building foundation, soil can be sampled, the water content of the soil can be monitored in real time, sampling can be conducted on a soil layer with the specific water content, sampling is convenient and rapid, and cleaning is convenient.

Owner:张栋

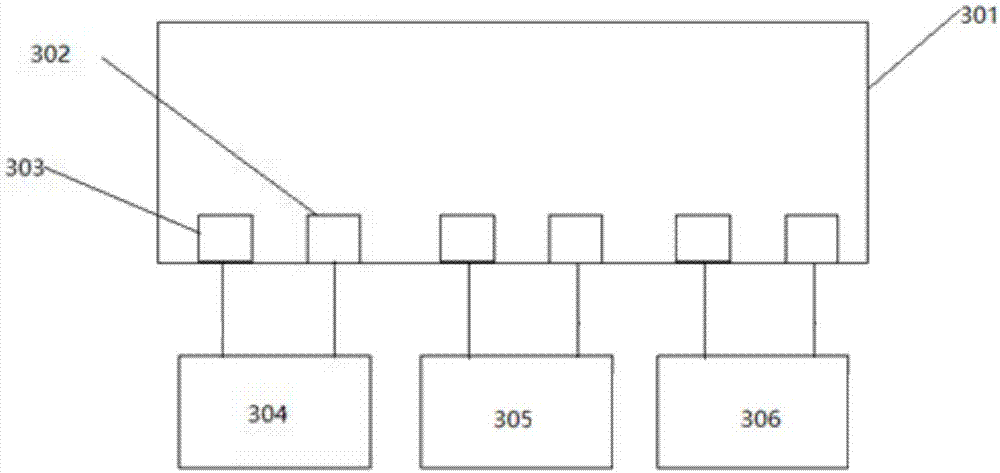

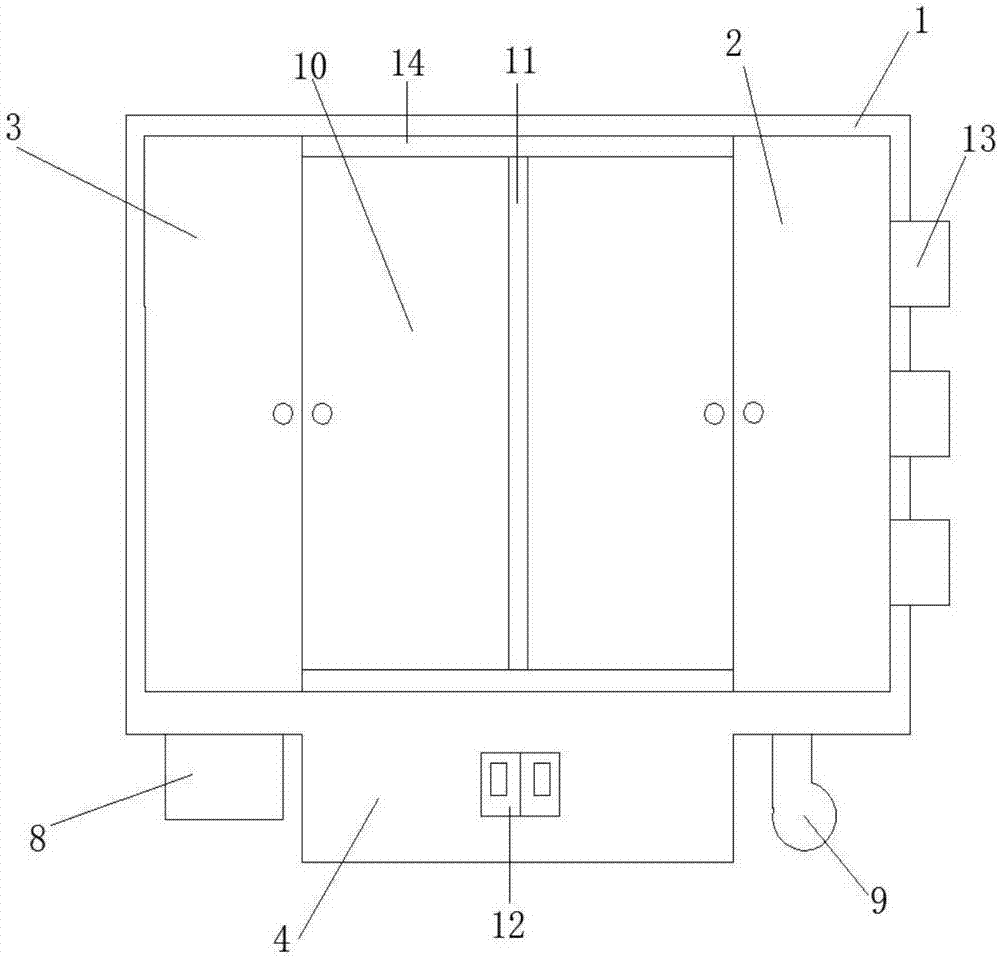

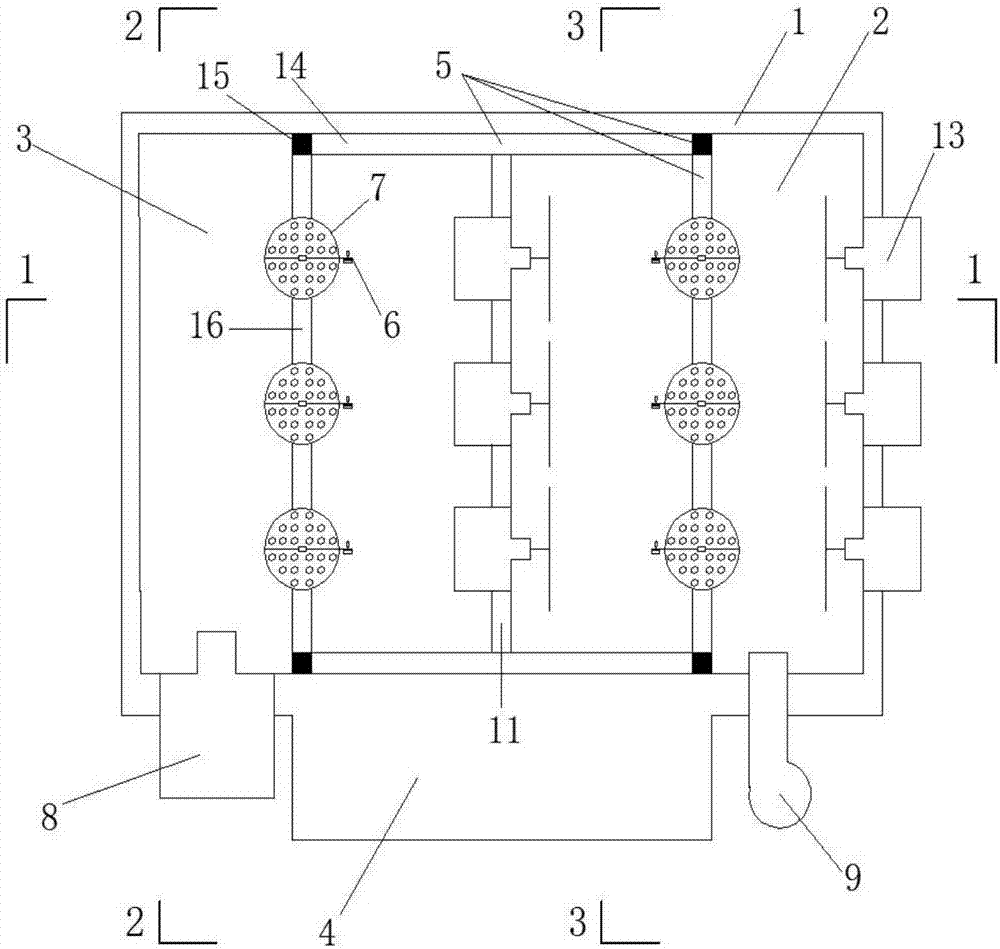

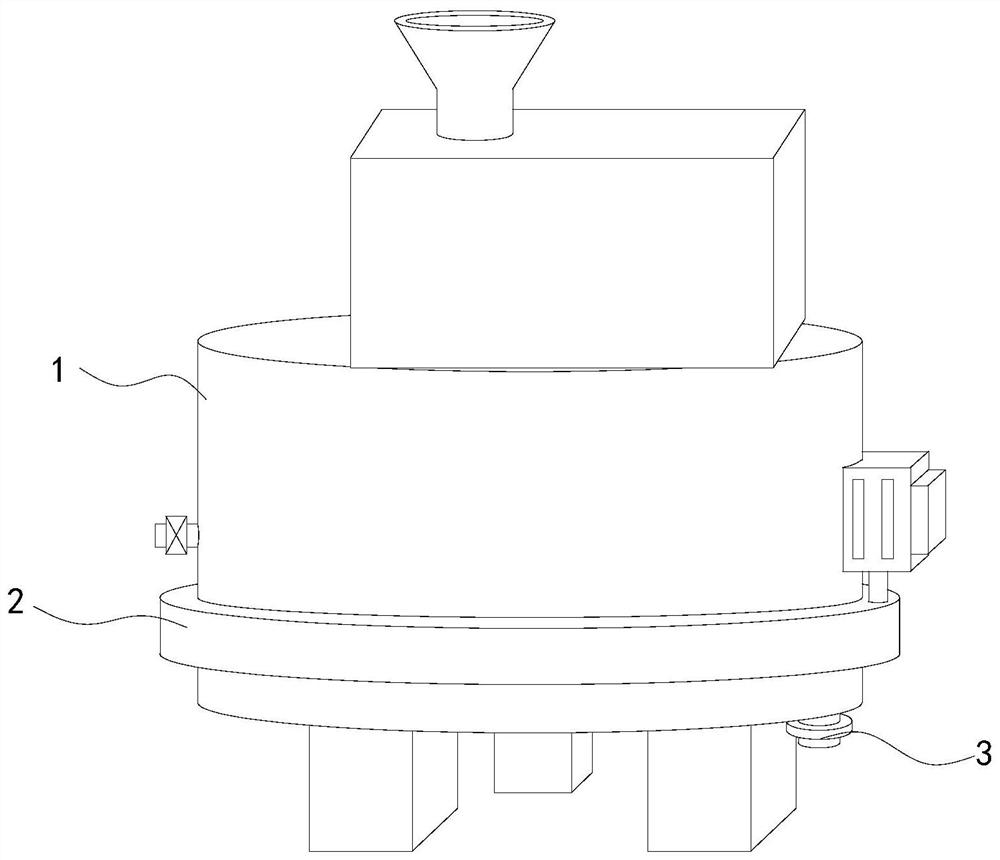

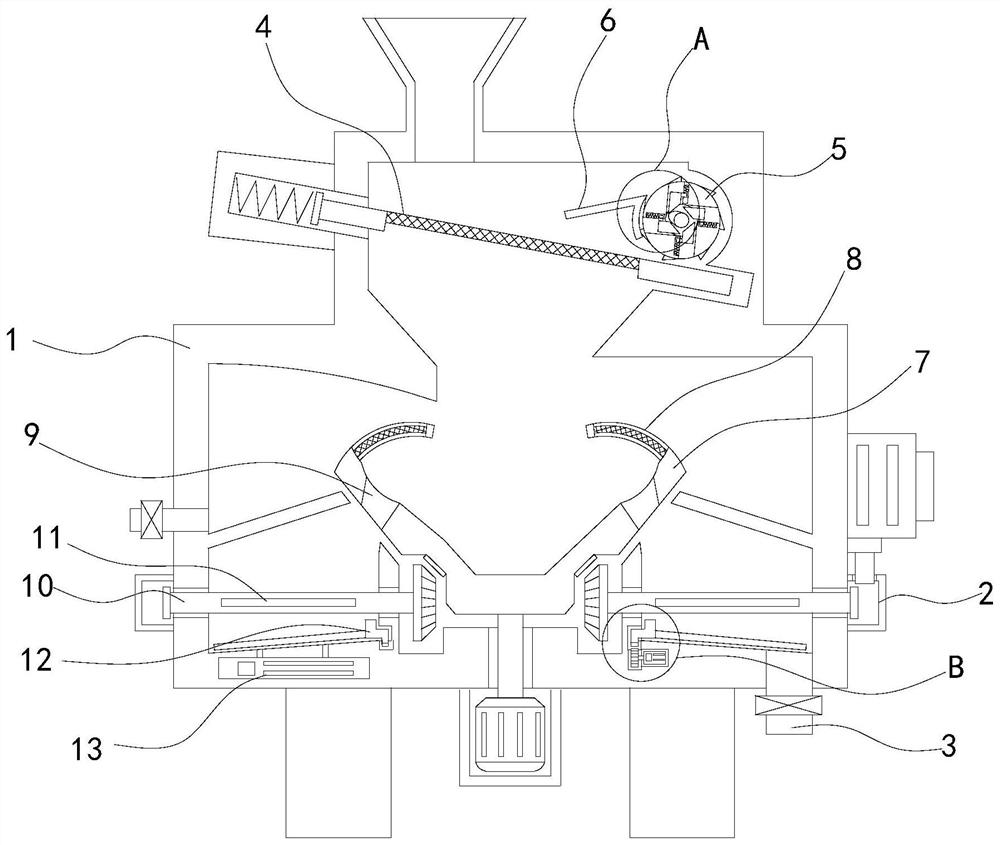

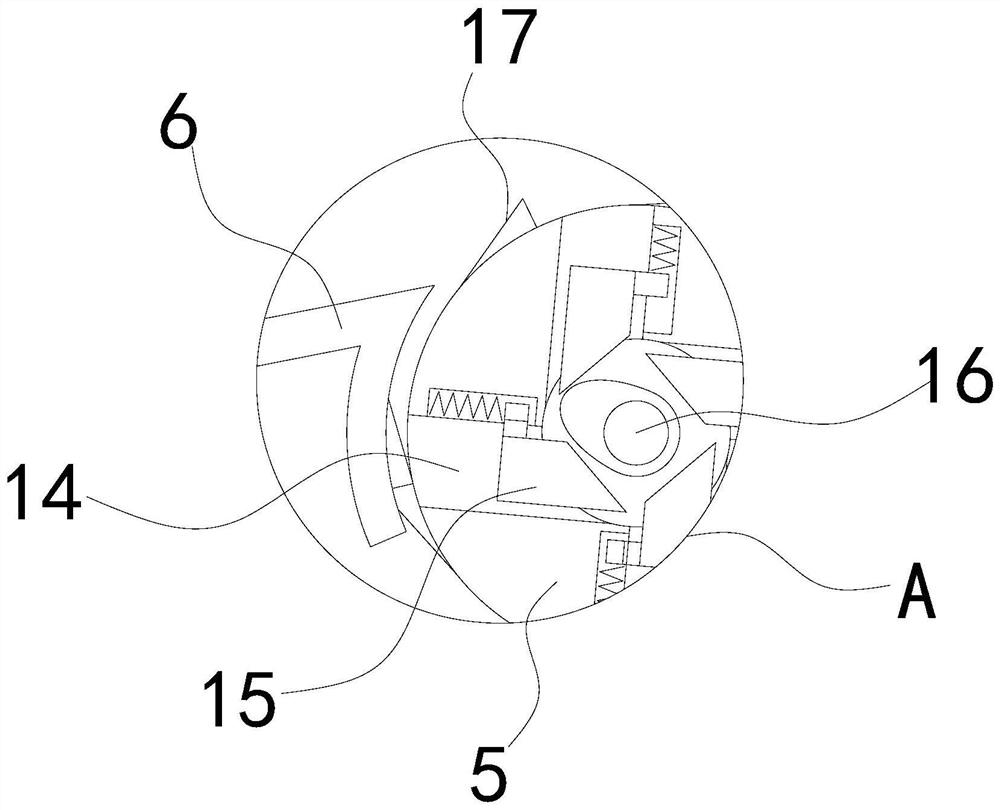

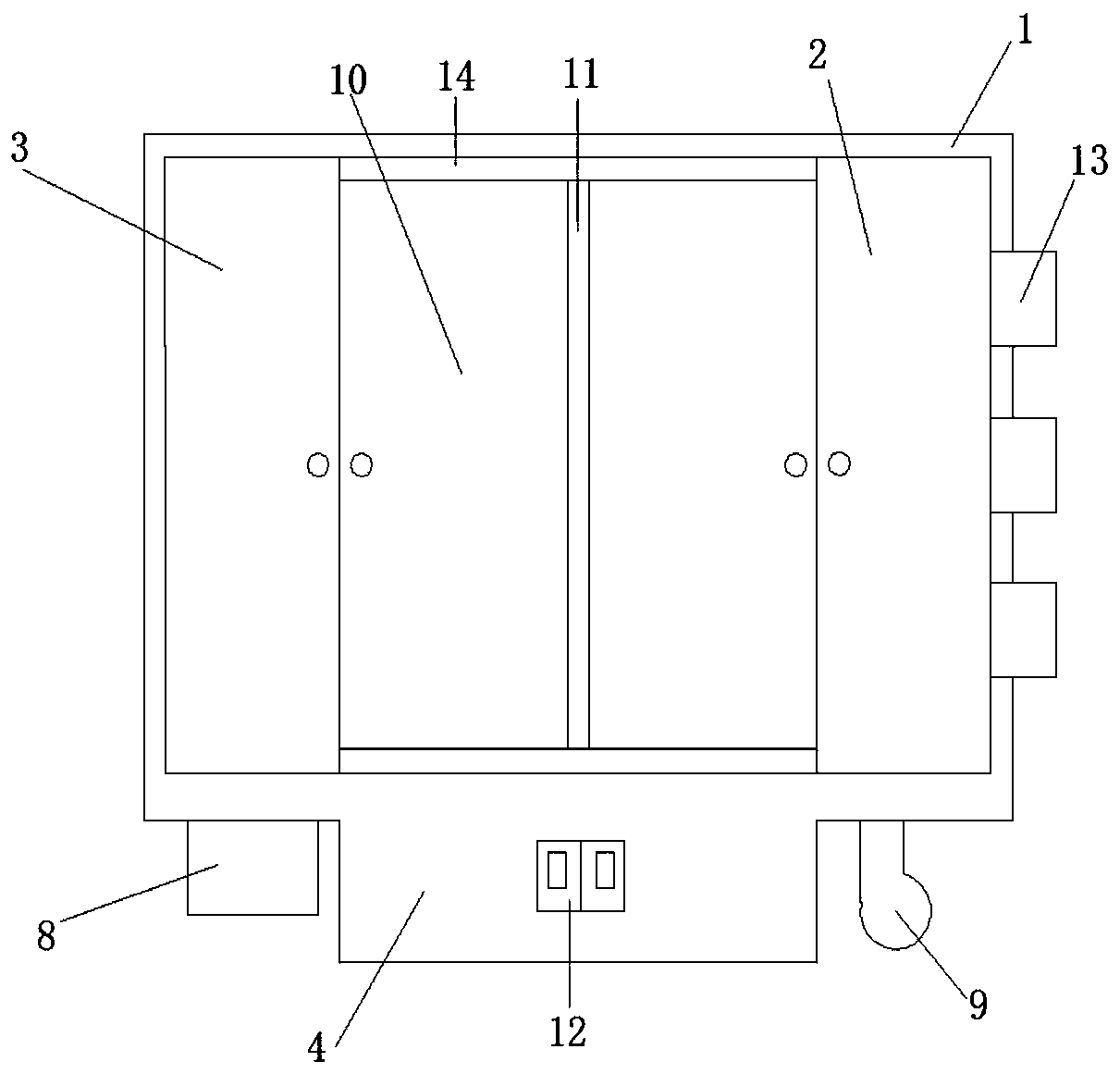

Dry-wet cycle testing device capable of monitoring moisture content of soil in real time

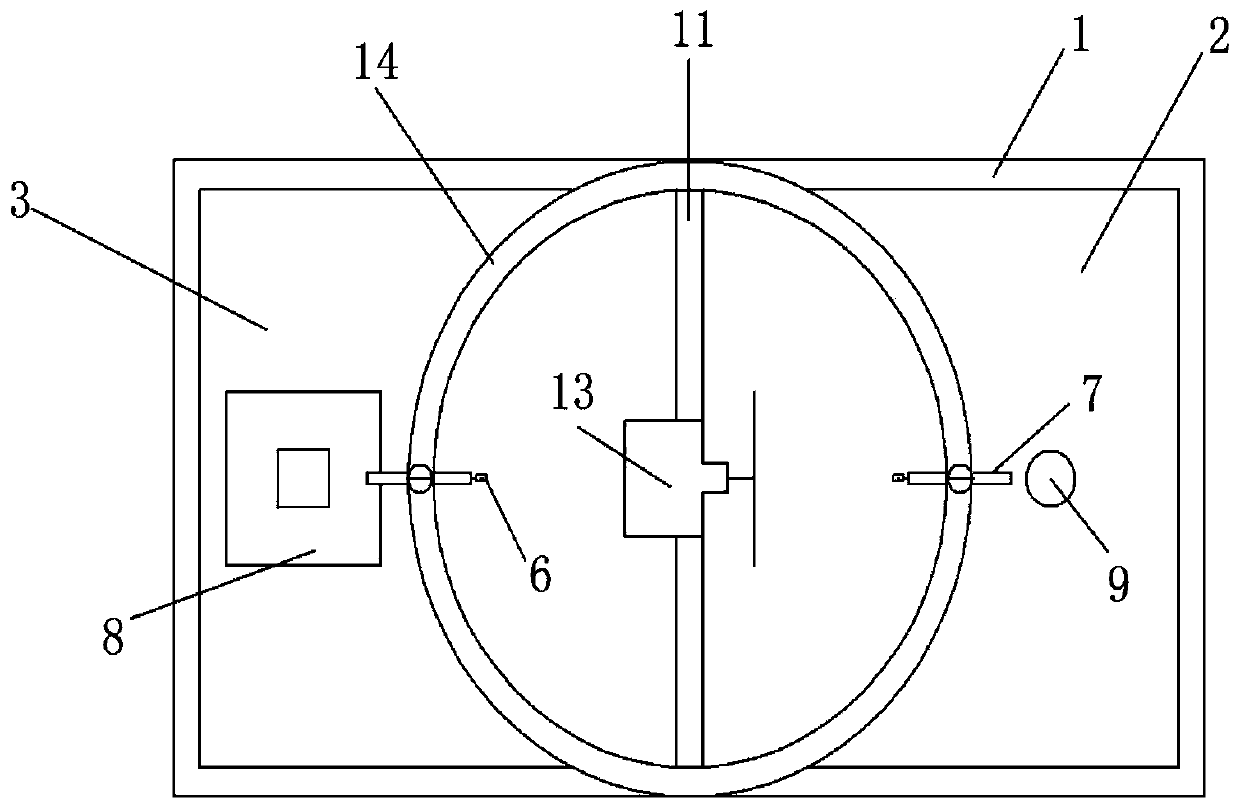

A dry-wet cycle testing device capable of monitoring moisture content of soil in real time comprises a drying tank, a saturation tank, a power supply tank, a rotating device and a reading control device, wherein the drying tank promotes drying of soil samples by means of fans and a blower; the saturation tank performs humidification saturation on the soil samples by means of a humidifier; the power supply tank is located at the bottom of the device; the rotating device is divided into a self-rotating device and an around-circular-ring-track rotating device; the reading control device monitors the moisture content of the soil samples in real time. The dry-wet cycle testing device has the advantages that dry-wet cycle can be performed on the multiple soil samples with different water content ranges simultaneously, saturation and drying are more uniform by means of the special rotating device in the dry-wet cycle process, the moisture content of the soil samples can be monitored at any time, indication lamps can be lightened when preset moisture content is reached, and the dry-wet cycle on the soil samples is performed precisely.

Owner:GUANGXI UNIV

Measuring instrument and measuring method based on dielectric method for water content of flour or similar substance

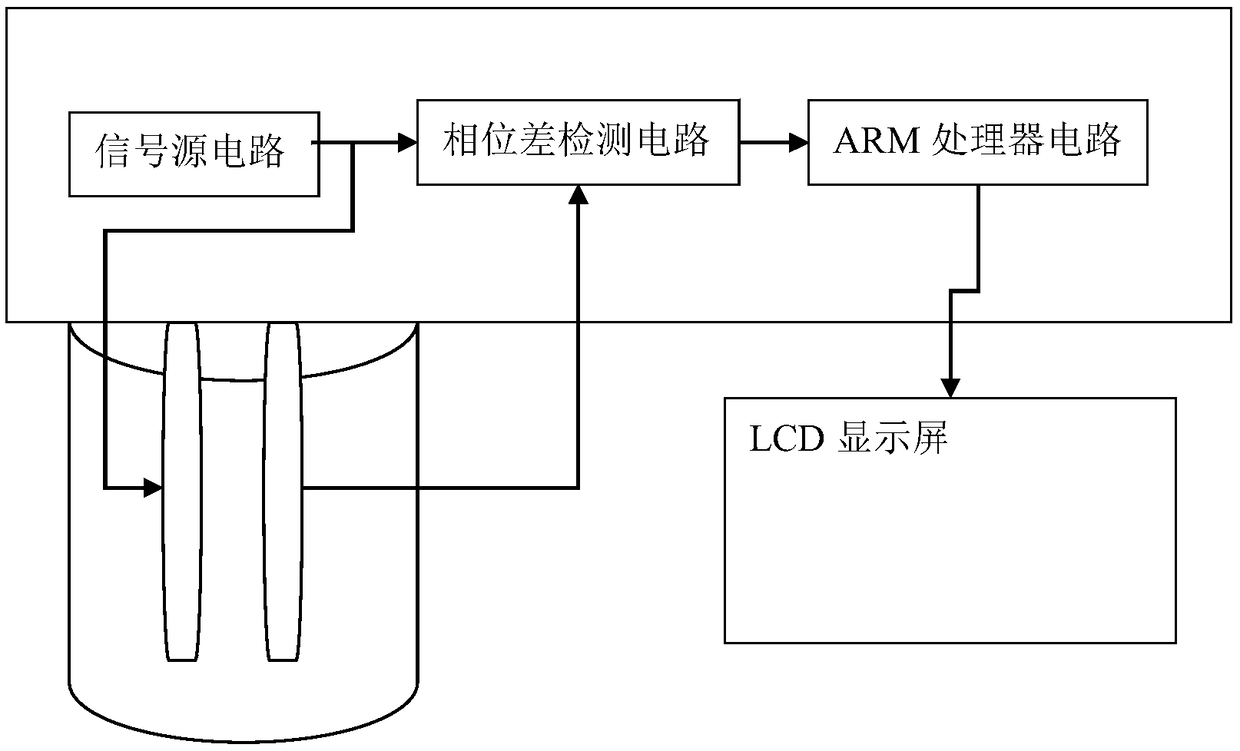

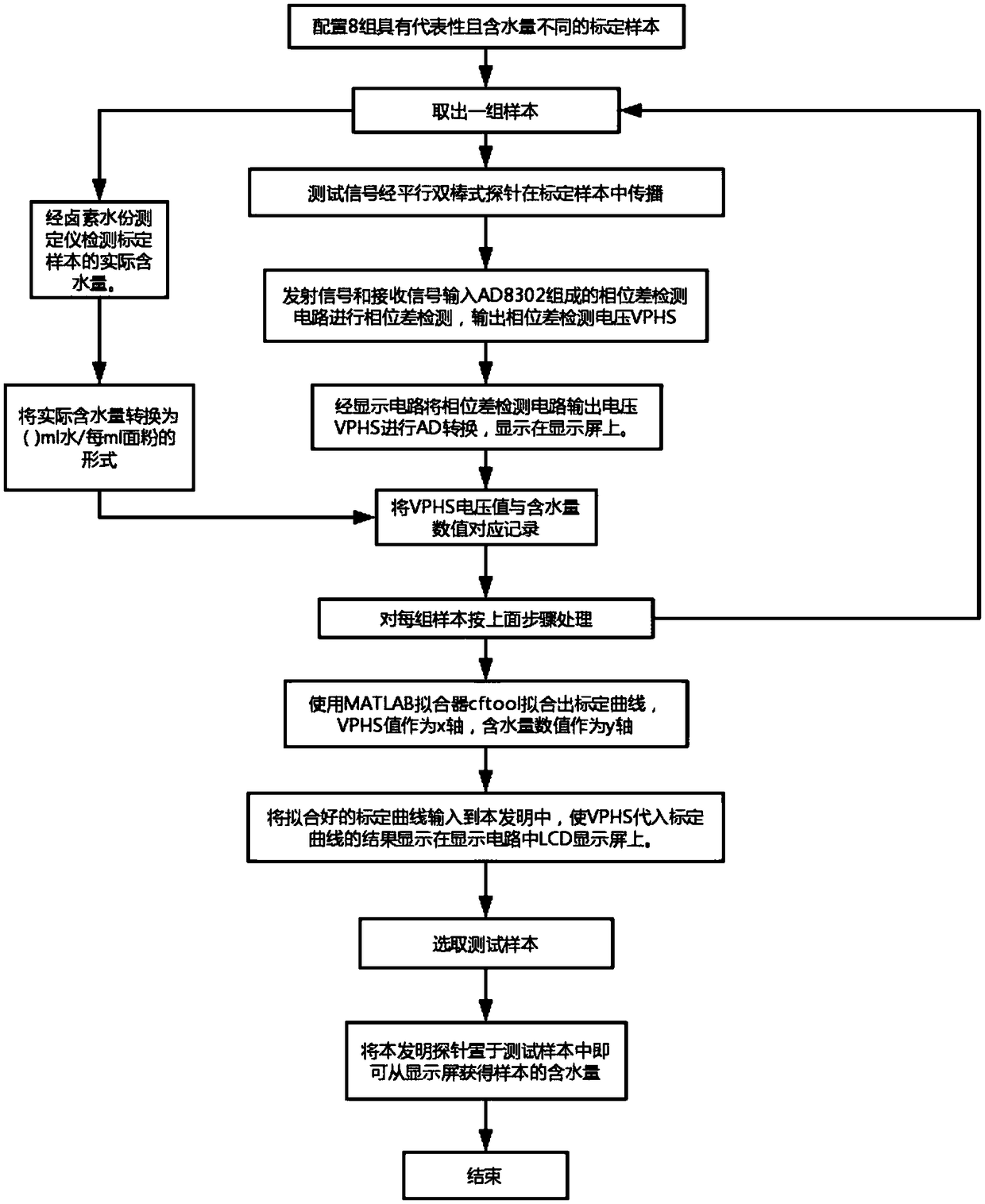

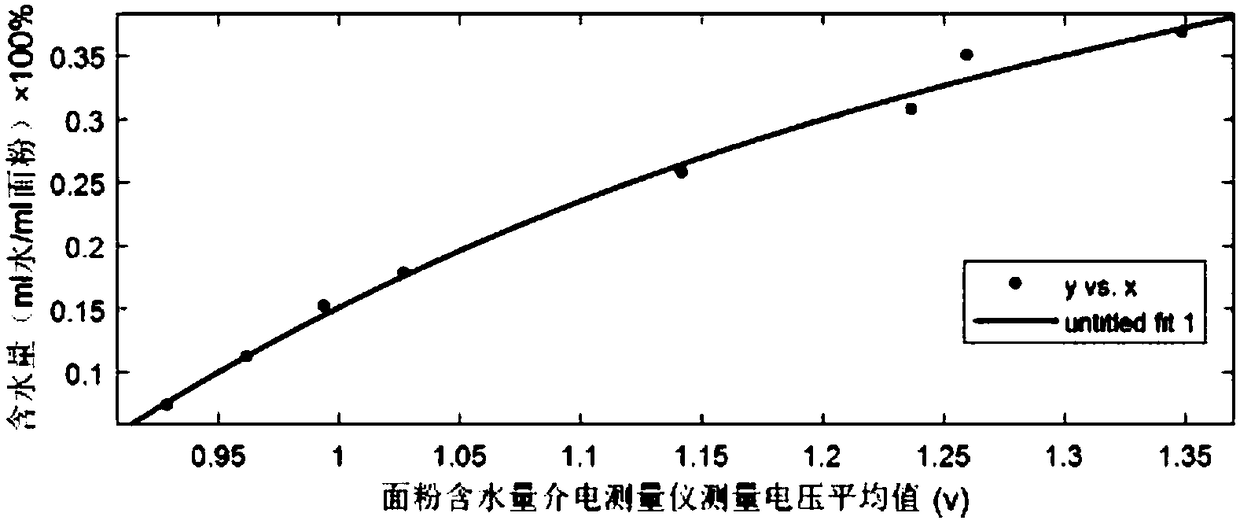

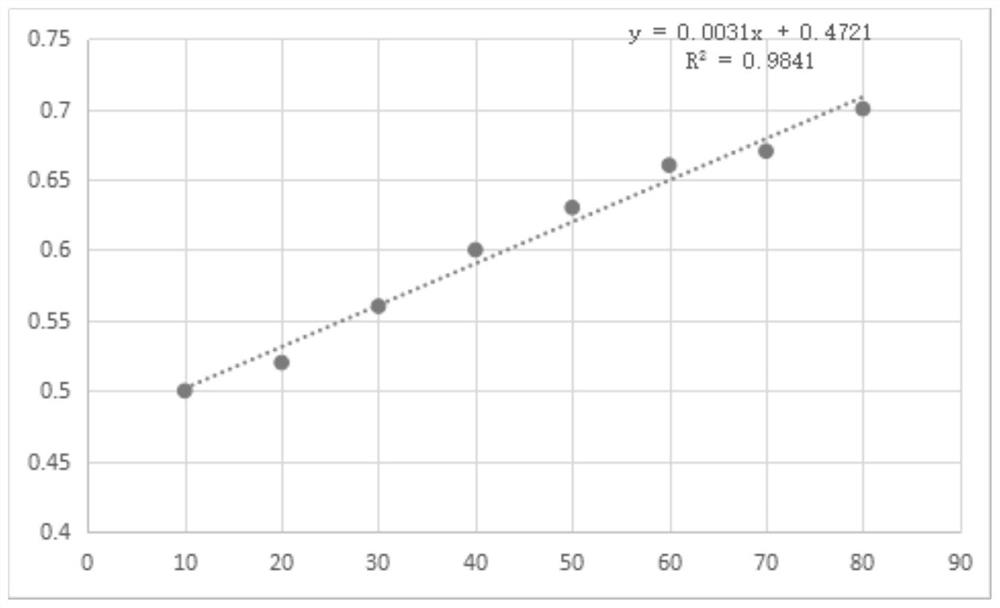

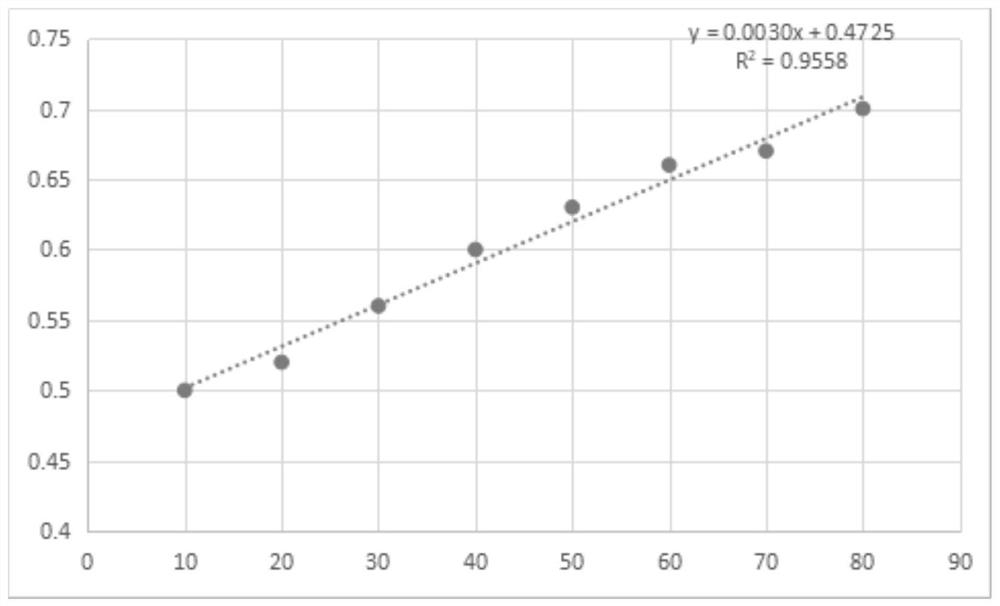

PendingCN109187669AReal-time monitoring of moisture contentPrice advantageMaterial capacitanceCalibration curveWater content

The invention discloses a measuring instrument and a measuring method for the water content based on a dielectric method to measure the water content of the flour or the similar substance. The measuring instrument for water content comprises a test circuit and a display circuit. The test circuit mainly comprises a signal source circuit, a parallel double rod probe, and a phase difference detectioncircuit using an AD8302. The display circuit comprises an ARM processor circuit and an LCD display screen. The measuring method comprises the steps: that parallel double rod probe is placed in the flour or the similar substance; a signal is generated by an oscillator employed by the signal source circuit; the signal is transmitted in a sample of the flour or the similar substance through the parallel double rod probe; the signal generated by the signal source and the signal transmitted by the probe are respectively detected by the phase difference detecting circuit; the phase difference is obtained; a calibration curve is drawn; and the water content value corresponding to the VPHS value on the calibration curve is calculated. According to the measuring instrument and the measuring methodbased on dielectric method for the water content of the flour or the similar substance, the rapid non-destructive detection of water content can be realized, the measuring instrument and the measuring method are not only economical and efficient, have high application value, and are worthy of popularization and application.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

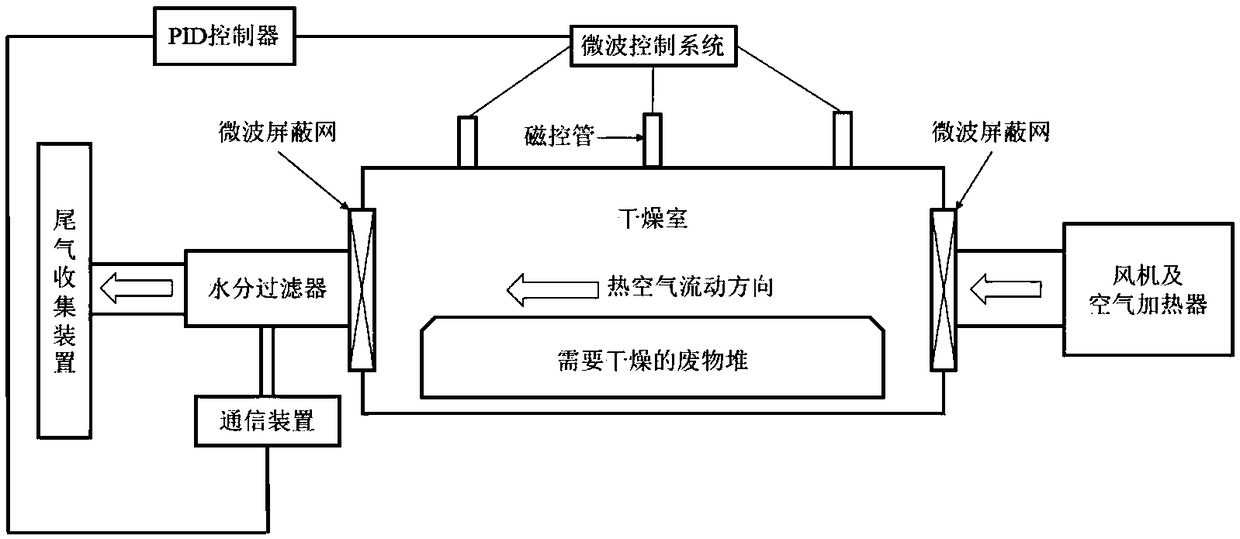

Radioactive waste drying method and system

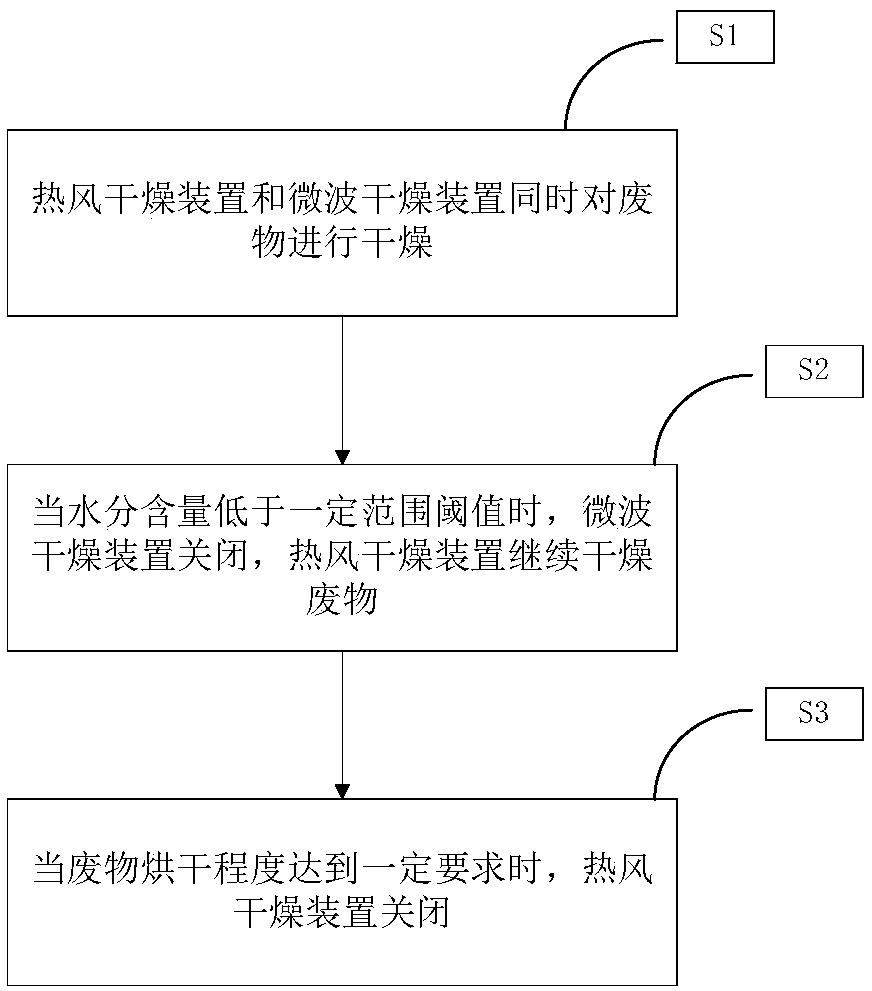

InactiveCN109237868AReal-time monitoring of moisture contentImprove drying efficiencyDrying using combination processesRadioactive decontaminationMicrowavePulp and paper industry

The invention provides a radioactive waste drying method and system. Radioactive wastes are dried by using a hot air drying device and a microwave drying device, the water content of the radioactive wastes is monitored in real time, when the water content is lower than a certain range threshold, the microwave drying device is shut down, the hot air drying device continues to dry the radioactive wastes, when the drying degree of the radioactive wastes meets certain requirements, drying is finished, and the hot air drying device is shut down. By means of the method, two different drying ways aremutually combined, the time required for drying is shortened, energy consumption is reduced, and the disposal risk caused when the local temperature is overhigh in the drying process can be avoided.

Owner:BEIJING JIAOTONG UNIV

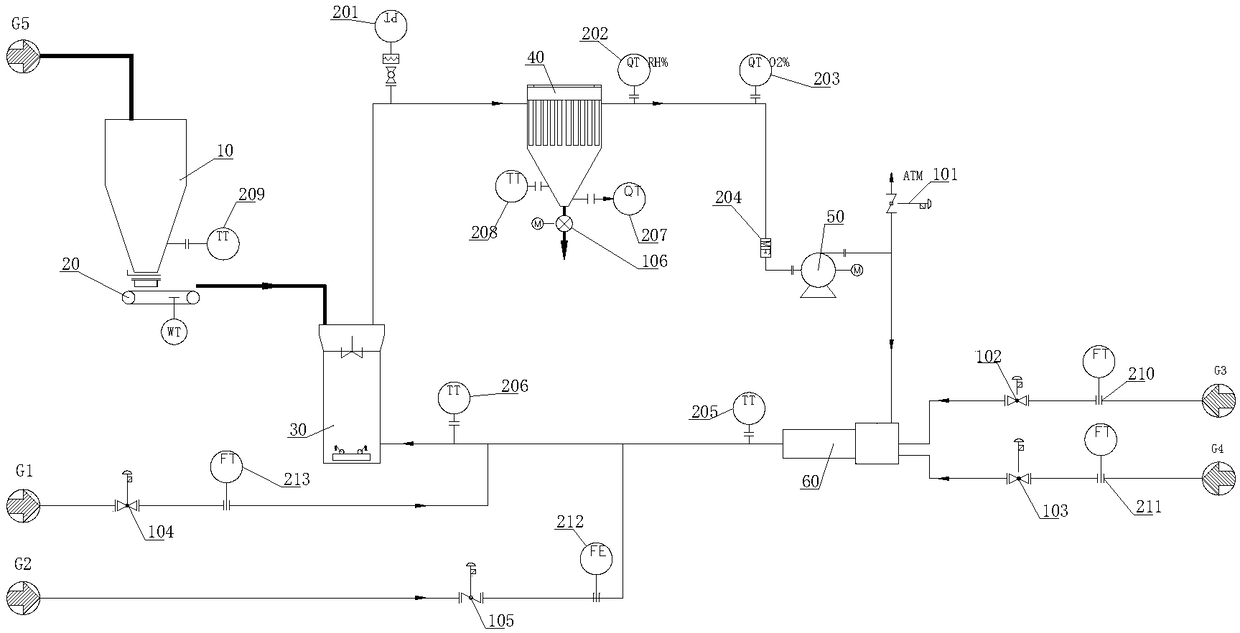

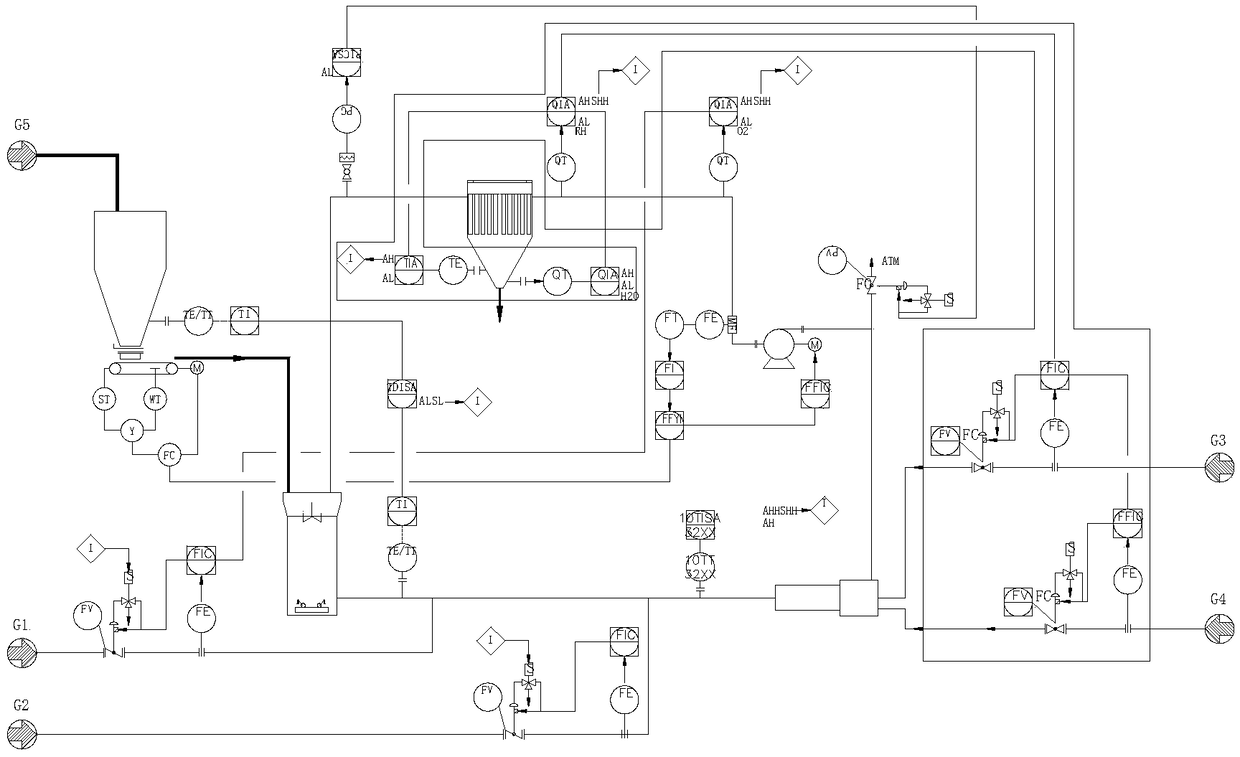

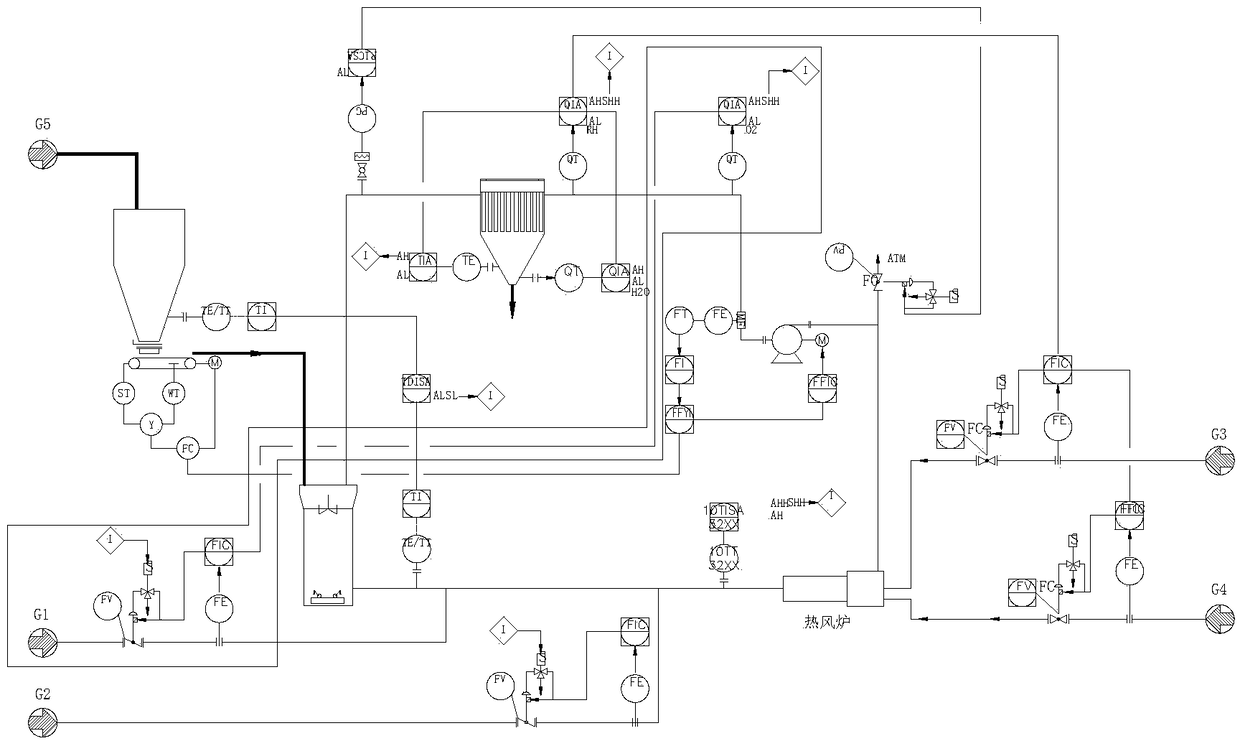

Control system and method of high-volatility-component pulverized coal preparation and drying technology

ActiveCN109340809AEnergy efficient drying processReal-time monitoring of moisture contentDrying gas arrangementsSolid fuelsControl systemNitrogen

The invention discloses a control system and method of a high-volatility-component pulverized coal preparation and drying technology. The control system comprises a raw coal bin, wherein a weighing and coal feeding machine is arranged at a discharging port of the raw coal bin; the output end of the weighing and coal feeding machine is connected to a feeding port of a coal grinding machine; a discharging port in the top part of the coal grinding machine communicates with a feeding port of a pulverized coal collector through a pipeline; an air inlet of the coal grinding machine is connected to an air outlet of a hot blast heater through a pipeline; a circulating fan is arranged between an air inlet of the hot blast furnace and an air outlet of the pulverized coal collector; a low-pressure nitrogen channel and a dry fresh air pipeline are arranged on a pipeline through which the air outlet of the hot blast furnace is connected to the air inlet of the coal grinding machine; and the controlsystem further comprises a relative humidity control unit, an oxygen content control unit and an assistant control unit. Compared with a traditional production technology, the control system and method have the advantages of being efficient and energy saving; and meanwhile, the environmental pollution is reduced.

Owner:EAST CHINA ENG SCI & TECH

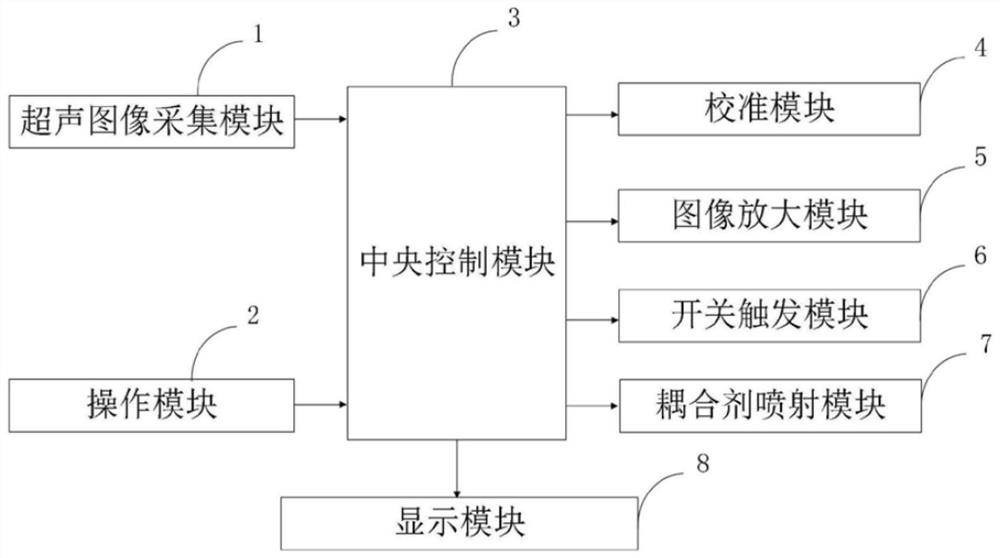

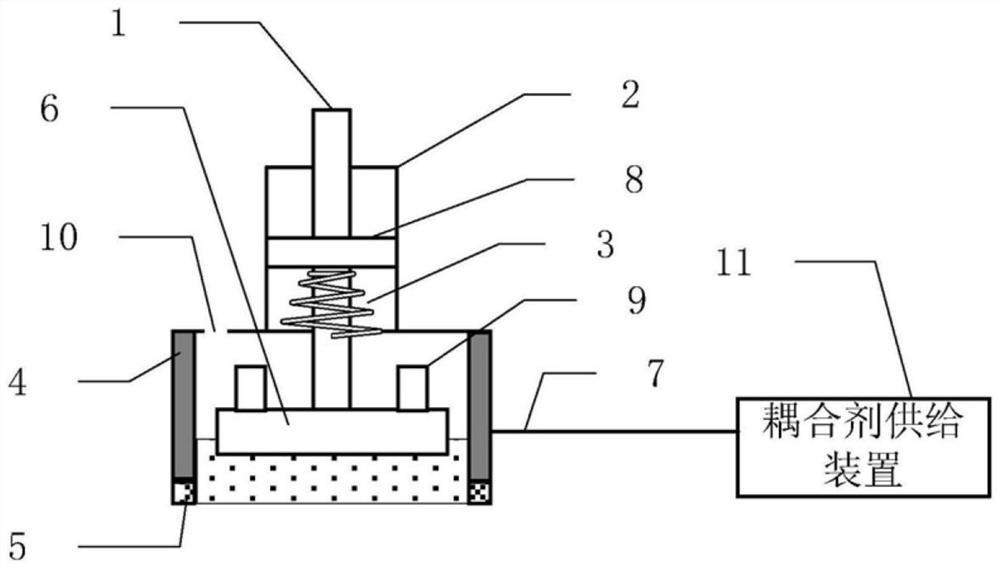

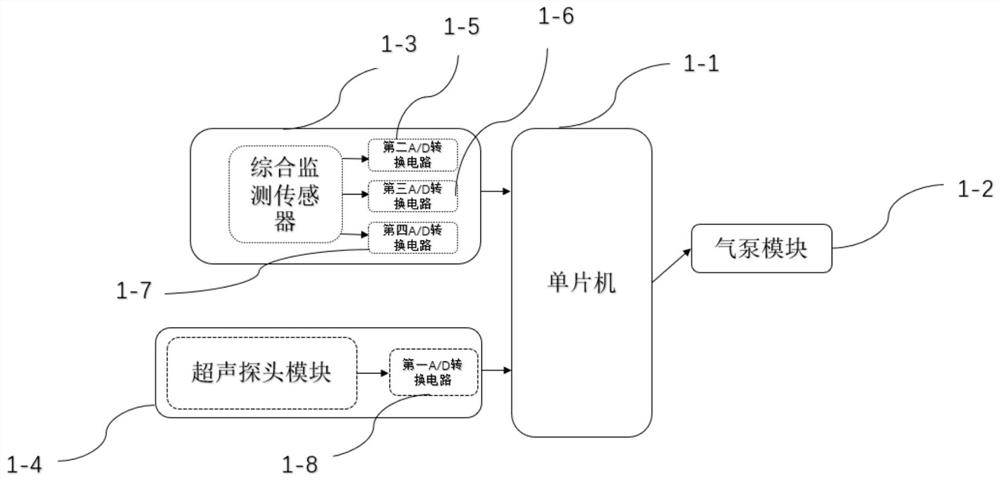

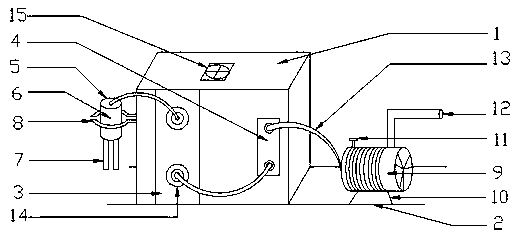

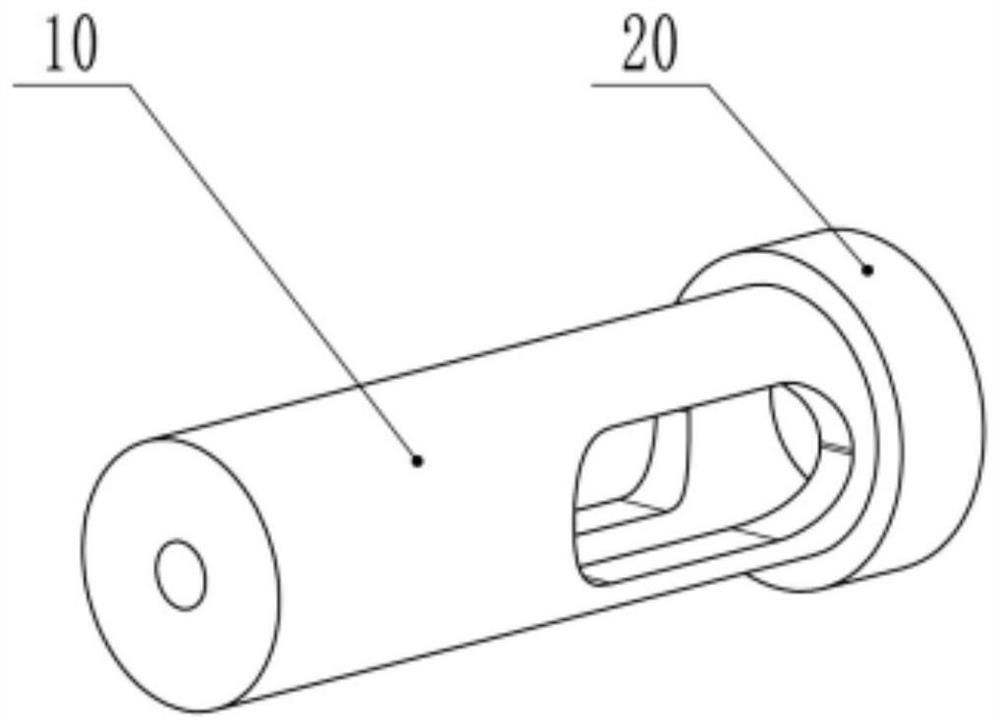

Device capable of automatically smearing coupling agent on ultrasonic probe

InactiveCN112807020AReal-time monitoring of body temperatureReal-time monitoring of moisture contentOrgan movement/changes detectionMedical applicatorsAir pumpSingle chip

The invention provides a device capable of automatically smearing a coupling agent on an ultrasonic probe. The device capable of automatically smearing the coupling agent comprises an ultrasonic probe module, a comprehensive monitoring sensor, a single chip microcomputer, an air pump module and a nozzle, wherein the ultrasonic probe module, the comprehensive monitoring sensor and the air pump module are all connected with the single chip microcomputer. and the air pump module is connected with the nozzle through a hose. By monitoring different patients in real time and automatically and comprehensively judging the amount required for spraying the coupling agent, the workload of doctors can be reduced, and the working efficiency is improved.

Owner:赵晓辉

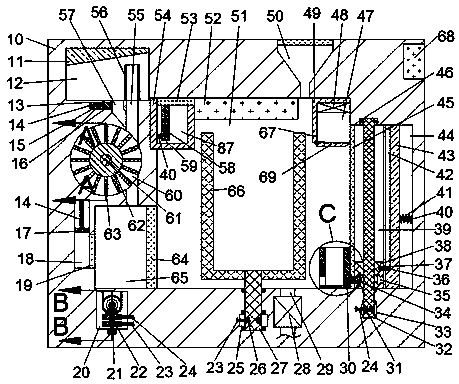

Dryer capable of self-detecting water obtained after drying

ActiveCN111578643AReal-time monitoring of moisture contentAvoid mass scrappingDrying solid materialsDrying machines with non-progressive movementsEngineeringProcess engineering

The invention discloses a dryer capable of self-detecting water obtained after drying. The dryer comprises a dryer body. A drying cavity is formed in the dryer body, a lifting mechanism is arranged onthe inner wall of the right side of the drying cavity, a heating plate is fixedly arranged on the inner top wall of the drying cavity, a feeding hole located in the right side of the heating plate isformed in the inner top wall of the drying cavity in a penetrating manner, a sealing plate capable of being opened and closed is arranged in the feeding hole, and a detection box located on the rightside of the feeding hole is fixedly arranged on the inner top wall of the drying cavity. Internal materials are stirred while drying of the dryer is carried out, all the internal materials can be fully dried, the water content of the materials can be monitored in real time after the drying operation is completed, production technicians can visually judge whether the materials reach producible technical standards or not, and following batched scrapping of products caused by the disqualified water content of the materials is avoided.

Owner:山东瑞谱检测技术有限公司

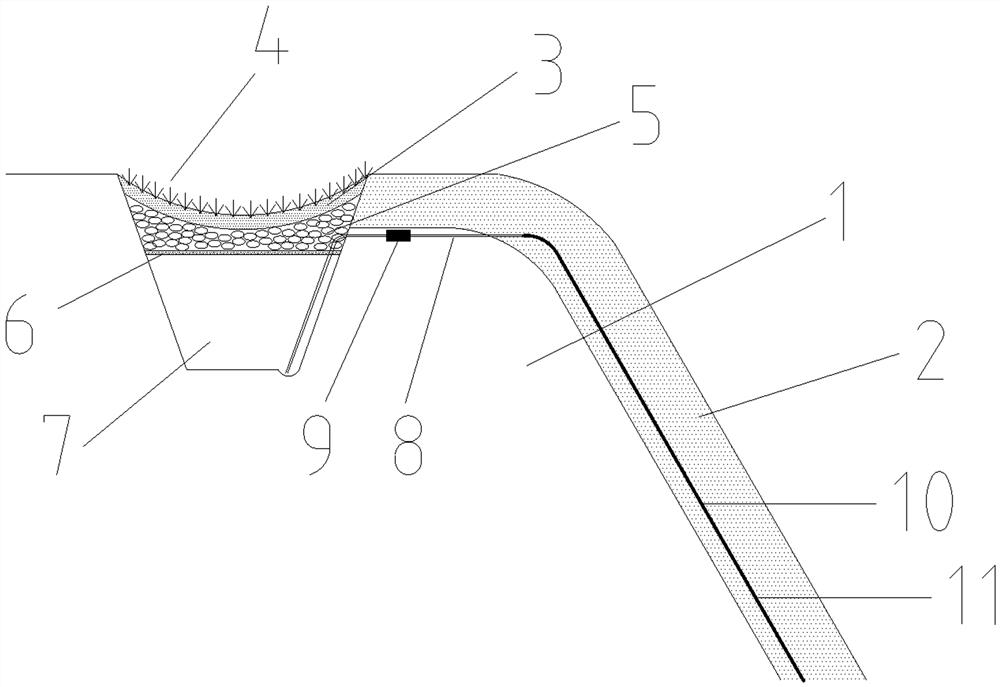

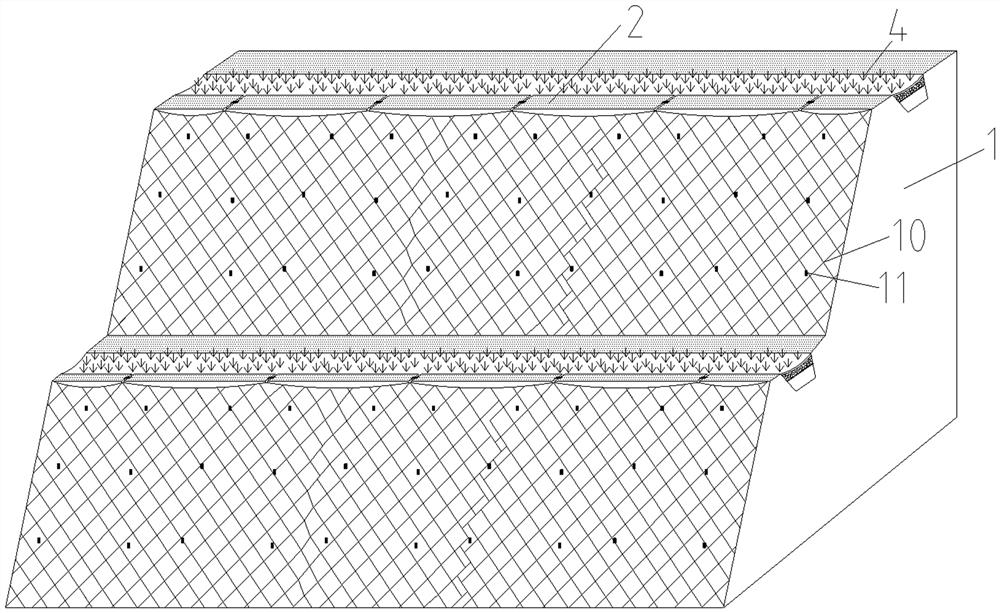

Intelligent maintenance system and maintenance method for ecological slope protection

PendingCN113186945AReal-time monitoring of moisture contentMoisture content automatic adjustmentWatering devicesExcavationsWater storageEnvironmental resource management

The invention discloses an intelligent maintenance system and maintenance method for ecological slope protection. The intelligent maintenance system comprises a monitoring system, a water storage system and a water supply system; the monitoring system comprises a controller and a plurality of humidity sensors; the water storage system comprises a water storage groove formed in a side slope, and a shallow slope protection base material is arranged on the upper surface of the water storage groove; the water supply system comprises a micro-seepage net and a water supply pipeline. According to the intelligent maintenance system, monitoring control equipment is matched with a micro-infiltration technology, a slope surface is automatically maintained, water sources are saved and the cost is controlled through a method of wetting plant root systems, and water waste and base material erosion caused by a traditional maintenance mode are avoided.

Owner:CHINA THREE GORGES UNIV

Liquid gasification device

PendingCN111035947AGasification trueImprove gasification efficiencyUsing liquid separation agentEvaporator accessoriesEngineeringHeating effect

The embodiment of the invention provides a liquid gasification device. According to the device, air enters a device body through a gas inlet pipeline, and under the pressurization effect of a gas pressurization device, the air moves from top to bottom; a liquid enters from a liquid inlet pipeline, and is sprayed out from a first water outlet structure and a second water outlet structure, and the sprayed liquid is vaporized under the heating effect of a heating net; the vaporized liquid is mixed with the air to form mixed gas; a temperature sensor arranged in the device body is used for monitoring the temperature in the device body in real time, a humidity sensor arranged in the device body is used for monitoring the moisture content of the generated mixed gas in real time, and the temperature sensor and the humidity sensor send the values sensed by the temperature sensor and the humidity sensor to a controller; and when the humidity value reaches the standard, the controller controls an automatic valve to be opened, the mixed gas is discharged out of the device body from a gas discharge pipeline. According to the invention, the humidity sensor is arranged in the device body to real-timely monitor the humidity value of the mixed gas, so that the gasification magnitude is effectively controlled, the liquid is truly gasified, and the gasification effect is good.

Owner:西安森兰科贸有限责任公司

Intelligent processing equipment for bio-organic fertilizer

PendingCN112657826AImprove screening efficiencyImprove fertilizer use efficiencySievingScreeningAgricultural engineeringStructural engineering

The invention relates to the field of intelligent fertilizer processing equipment, in particular to intelligent processing equipment for a bio-organic fertilizer. The intelligent processing equipment comprises a device main body, wherein the upper end inside the device main body is movably equipped with a screening board; the right side of the upper end of the device main body is movably equipped with an extruding device; a throwing device is movably mounted at the lower end inside the device main body; an extruding cavity is arranged inside the extruding device; an extruding block is movably mounted inside the extruding cavity; a guide plate is fixedly mounted inside the device main body relative to the left side of the extruding device; the right side of the guide plate is in the shape of an arc fitted to the outer side of the extruding device; the left side of the guide plate is arranged in an inclined mode, so that a caked fertilizer moving rightwards can enter the extruding cavity; when the extruding device moves upwards, the extruding block moving outwards is matched with the guide plate for extruding; and finally, the extruding cavity returns onto the screening board along the inclined surface of the guide plate while the extruding block moves to a position above the extruding device, so that the effect of automatically returning the caked fertilizer to improve fertilizer utilization efficiency is achieved.

Owner:杨文兰

Smart watering device

InactiveCN108849433AReal-time monitoring of moisture contentTo achieve the purpose of intelligent wateringWatering devicesCultivating equipmentsMicrocontrollerMicrocomputer

The invention discloses a smart watering device. The smart watering device comprises a body box and a ground fixing frame, a single chip microcomputer and a motor driving module are installed in the body box, multiple I / O interfaces are formed in the single chip microcomputer and the motor driving module respectively, a soil moisture detector is connected to one side of the body box and comprisesa data collector and a moisture sensor, a water pumping motor is connected to the other side of the body box and is fixed to the ground fixing frame through a bottom supporting frame, a switch is arranged at one end of the water pumping motor, a water outlet pipe is installed at the other end of the water pumping motor, all electrical appliance elements are connected through data wires, and an external power interface is reserved in the top of the body box. The content of moisture in soil can be automatically detected, water can be supplemented in time, human monitoring is not needed, and thesmart watering device can execute watering in time and turn off a command at appropriate time automatically, and is suitable for all kinds of planting projects, simple, convenient to use and high in accuracy.

Owner:苏州沃古斯电子商务有限公司

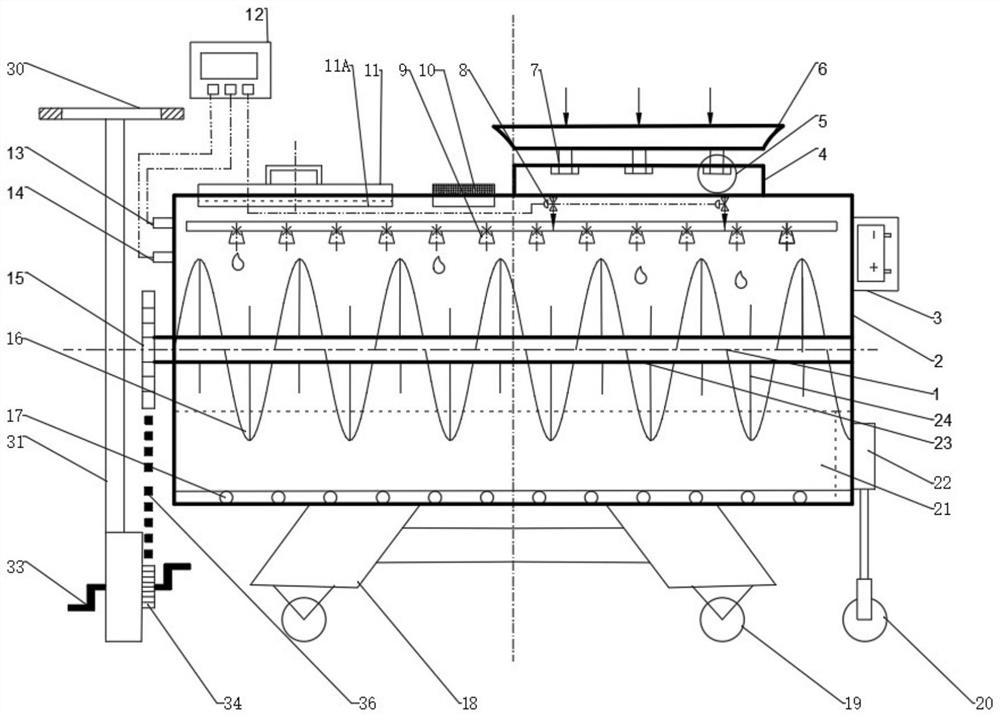

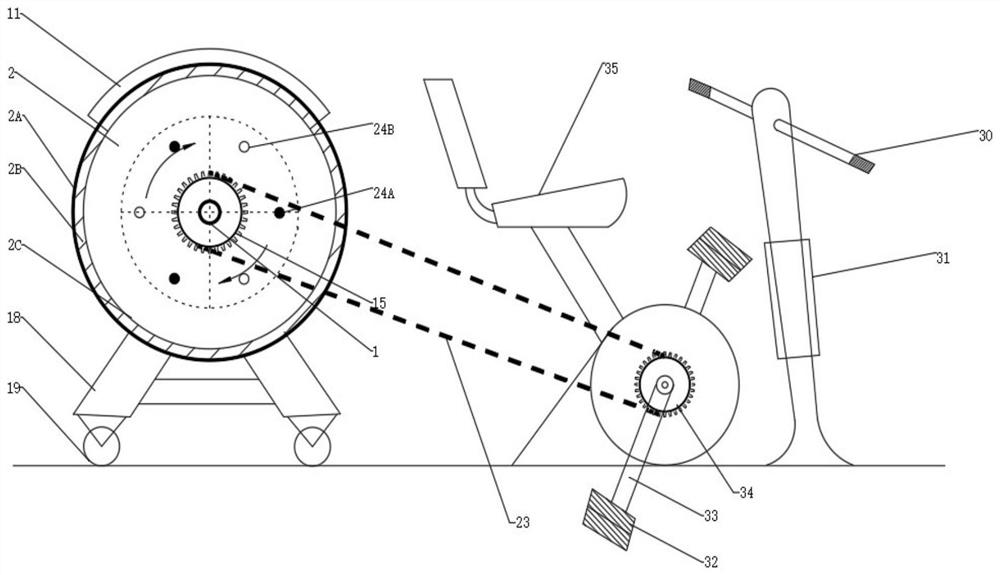

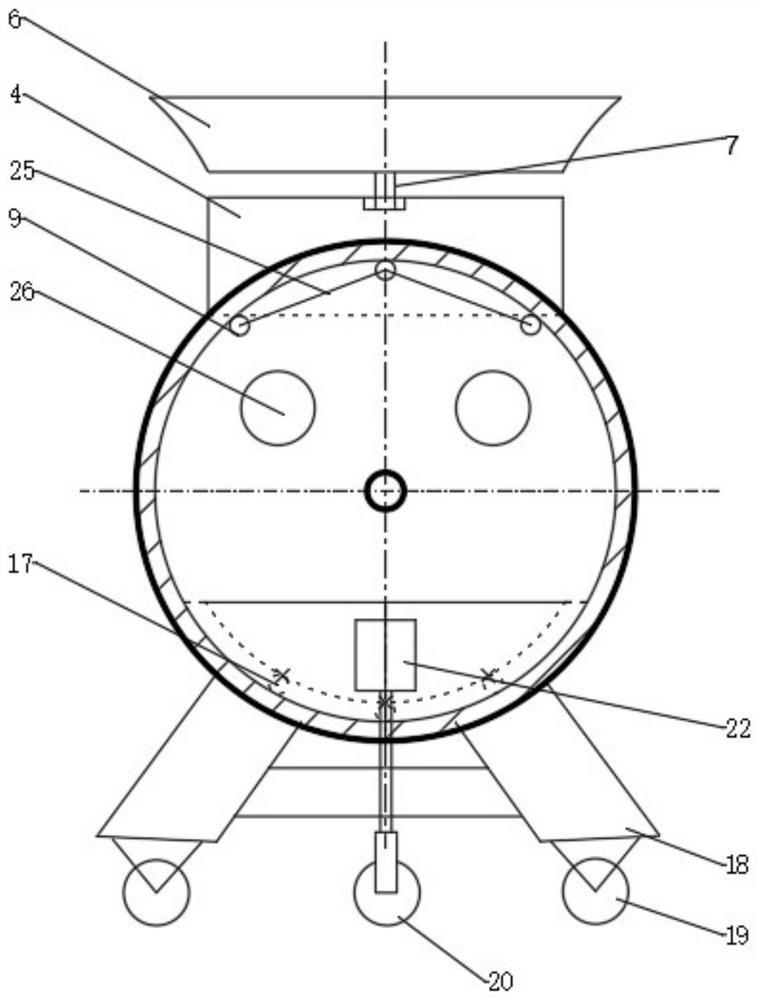

Composting reactor

PendingCN112209758AIn-place processingFacilitate reuse in placeBio-organic fraction processingOrganic fertiliser preparationProcess engineeringAgitator

The invention discloses a composting reactor. The composting reactor comprises a roller device, a feeding device, a discharging device, a driving device, a stirring device and an automatic flow storage and humidification device, the device is mainly applied to parks, fallen leaves, grass clippings and the like in the parks are collected and directly added into the reactor to be subjected to on-site composting treatment, residents use the foot-operated fitness equipment to exercise, and generated power is used for driving the stirring shaft in the composting reactor to rotate. The stirrer is ofa novel screw rod type and comprises the stirring rods and the screw rods, the stirring rods comprise the long stirring rod and the short stirring rod, and the screw rods are sequentially and spirally arranged at the top end of the long stirring rod, so that materials are fully mixed in the axial direction and the radial direction. Meanwhile, the automatic flow storage and humidification device is arranged at the top of the reactor, the temperature and humidity change condition of the reactor body can be monitored in real time, and collected rainwater is used for humidifying the reactor body.

Owner:清华苏州环境创新研究院

Greenhouse energy-saving water spraying device based on solar power generation

InactiveCN112425427AGuaranteed water demandSave watering timePhotovoltaic supportsSolar heating energyGreenhouseAtmospheric sciences

The invention relates to the technical field of solar energy, and discloses a greenhouse energy-saving water spraying device based on solar power generation. The device comprises a shell, a supportingplate is fixedly connected to the interior of the shell, a screw rod is movably connected to the exterior of the supporting plate, a push rod is movably connected to the exterior of the screw rod, and a photovoltaic panel is movably connected to the exterior of the push rod. The interior of the photovoltaic panel is fixedly connected with a photosensitive assembly, the interior of the shell is fixedly connected with a storage battery, the exterior of the supporting plate is fixedly connected with a fluorescent lamp, under the interaction of all structures of the device, flowers can be wateredin time through a water spraying rod when the sun rises, according to different angles of the sun, the angle of the photovoltaic panel is adjusted in time, so that the photovoltaic panel can be in contact with sunlight in the maximum area, the water content in the air can be monitored in real time after irrigation is started, flower irrigation is stopped in time when the water content reaches a certain degree, and the device conforms to the energy-saving manufacturing concept.

Owner:陆俊达

Dry-wet cycle test device that can monitor soil moisture content in real time

ActiveCN107290505BEvenly saturatedMeet testing needsEarth material testingSoil scienceEnvironmental engineering

Owner:GUANGXI UNIV

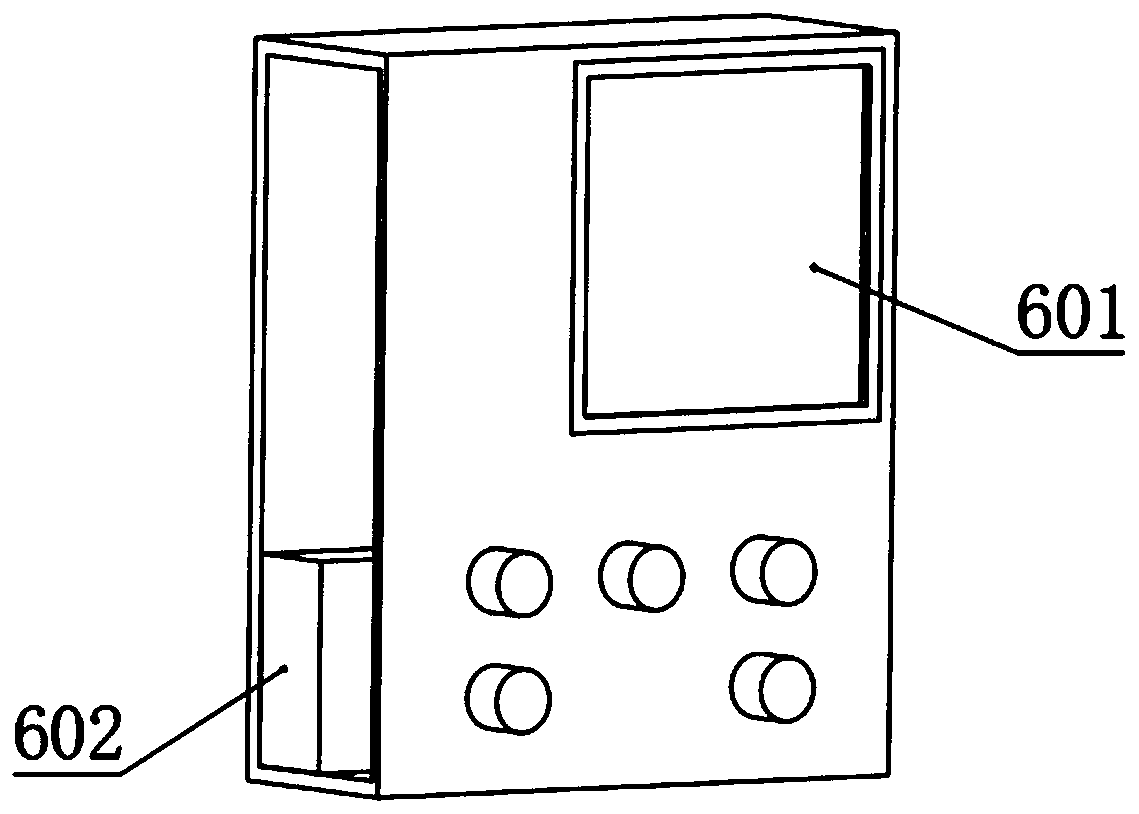

Nut drying device with moisture content real-time monitoring function

PendingCN111219962AReal-time monitoring of moisture contentImprove yieldDrying gas arrangementsDrying machines with non-progressive movementsAutomatic controlProcess engineering

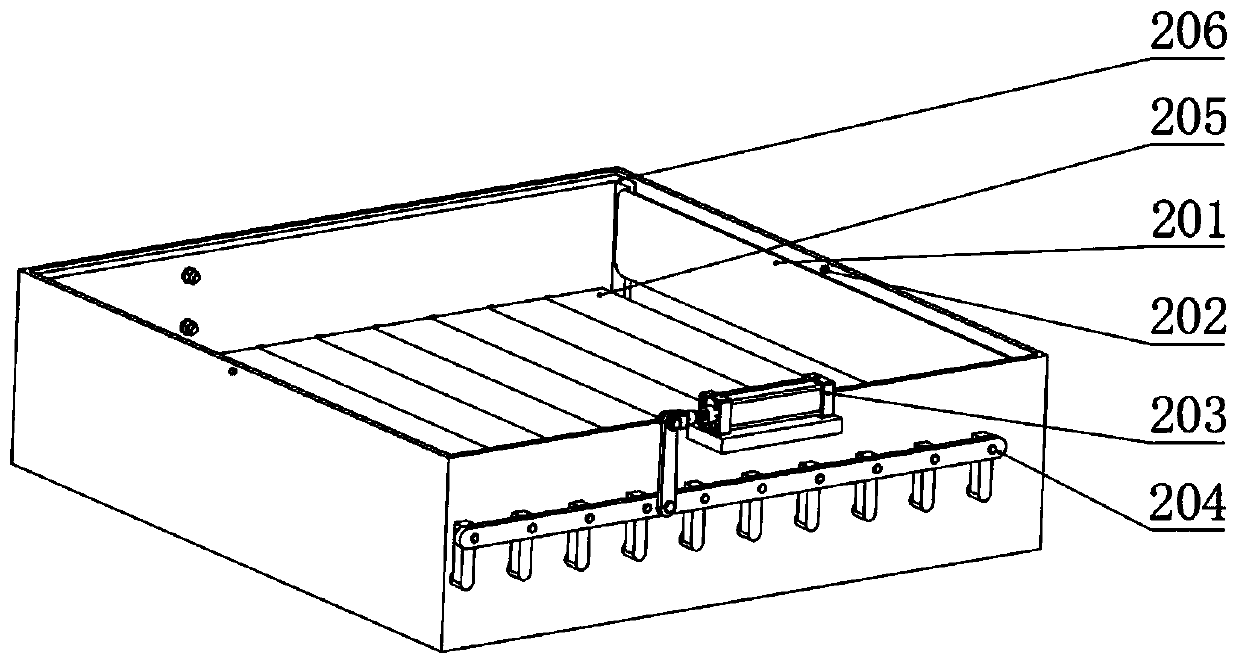

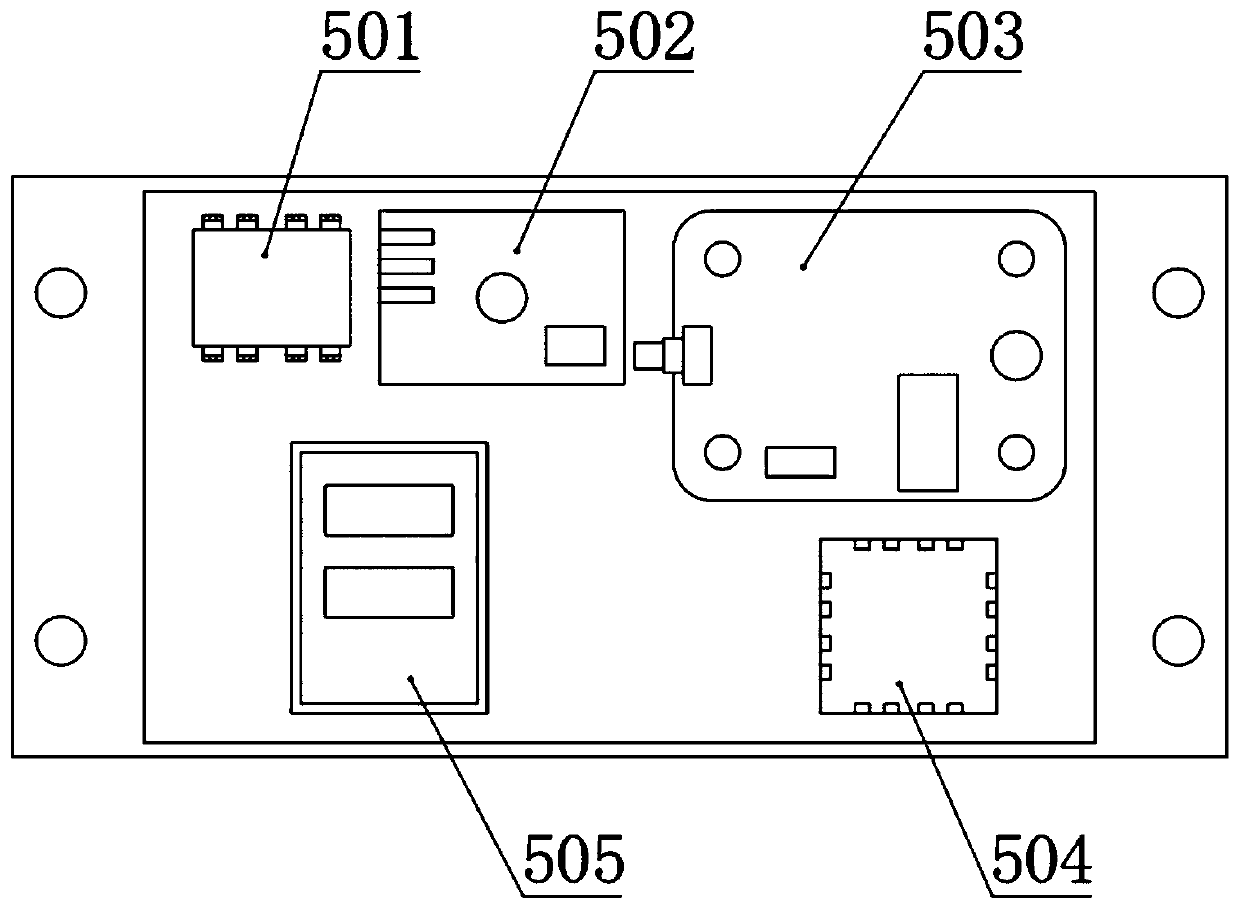

The invention belongs to the field of food processing, and discloses a nut drying device with a moisture content real-time monitoring function. The nut drying device with the moisture content real-time monitoring function comprises a moisture content monitoring device and a drying box body. The moisture content monitoring device is connected with the top end of the drying box body, a hot air channel is formed inside the drying box body, and a discharging outlet is formed in the bottom of the drying box body. The moisture content monitoring device comprises a working box body, a display panel and a working box body feeding device. A testing circuit integration type module is arranged on the side wall of the working box body. The moisture content change in the nut drying process is convertedto the electric capacity change, the real-time monitoring of the moisture content in the whole working process and the automatic control over nut feeding and discharging operation are achieved, the feeding and discharging process of products is changed in real time along with the change of the moisture content, the problem that an existing drying device is high in product quality randomness is solved, and the rate of finished products is greatly increased.

Owner:XINGTAI TIANYUANXING FOOD EQUIP +1

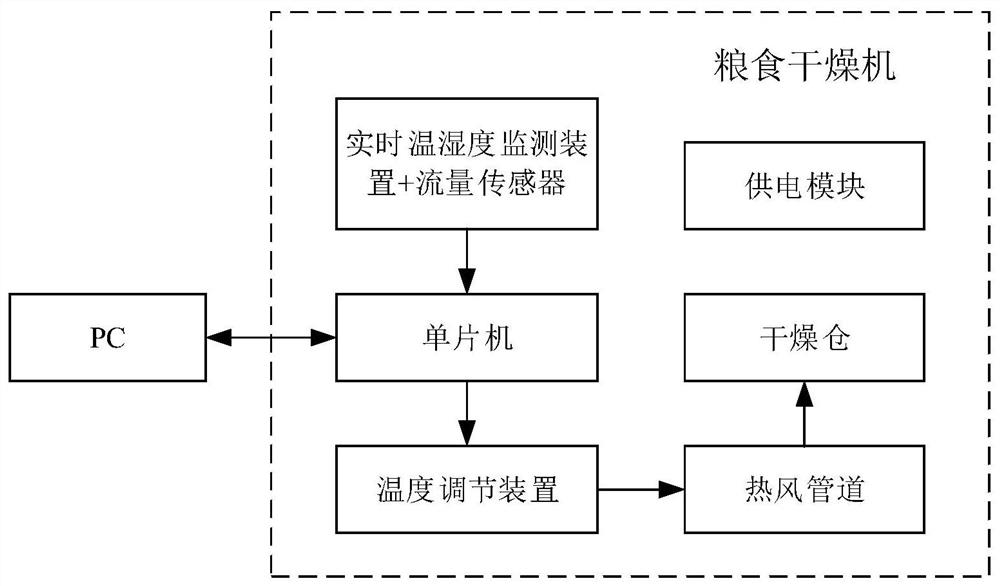

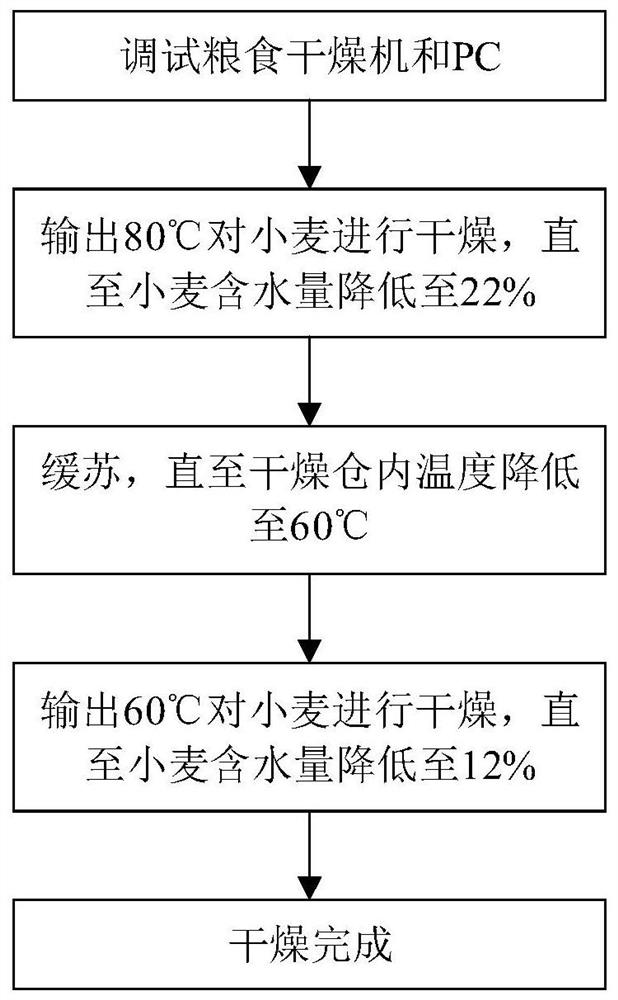

Grain drying method and system

InactiveCN112179125AEfficient dryingGuaranteed qualityDrying gas arrangementsDrying solid materialsMetallurgyGrain quality

The invention belongs to the technical field of grain drying, and particularly relates to a grain drying method and system. The method comprises the following steps of monitoring the water content ofgrains in real time, drying the grains to be dried at a set initial high temperature, and controlling to reduce the water content of the grains; when the water content of the grain is reduced to the set tempering starting water content, stopping the drying operation until the grain temperature is reduced to the set tempering finishing temperature; and when the grain temperature is reduced to the set tempering finishing temperature, drying the grain at the set tempering finishing temperature until the water content of the grain is reduced to the set drying finishing water content, thereby finishing grain drying. According to the grain drying method, rapid drying is conducted at a high temperature, tempering is conducted, drying continues to be conducted at a low temperature, the phenomenonof excessive drying is prevented, the grain quality is guaranteed, energy is saved, consumption is reduced, and grain drying is completed efficiently.

Owner:HENAN UNIV OF SCI & TECH

Method for measuring humidity of cable by two-way infrared spectrum analysis method

ActiveCN112557336AQuick balanceReal-time monitoring of moisture contentMaterial analysis by optical meansPhoto irradiationFt ir spectra

The invention relates to a method for measuring the internal humidity of a cable by using a two-way infrared spectrum analysis method, which comprises the following steps of: irradiating the same position of a test material by using two-way infrared light, testing the intensity of reflected light, calculating the absorbance, and calculating the internal humidity of the cable according to a linearrelation formula of an absorbance-humidity standard curve, wherein the test material is formed by coating a hydrophobic base material with a water absorbing material. The humidity is detected by adopting infrared light of double light paths, the reaction is sensitive, rapid water-vapor balance can be achieved by adopting a high-water-absorption material, the absorbance is calculated by adopting anoptical cable, convenience and rapidness are achieved, and the water content condition in the cable can be conveniently monitored in real time. The established linear relation between the humidity and the absorbance is excellent, the sensitivity is good, and when graphene oxide is adopted as a water absorbing material, the corresponding sensitivity to the humidity change is 0.0065 (absorbance)%-1.

Owner:中电保力(北京)科技有限公司

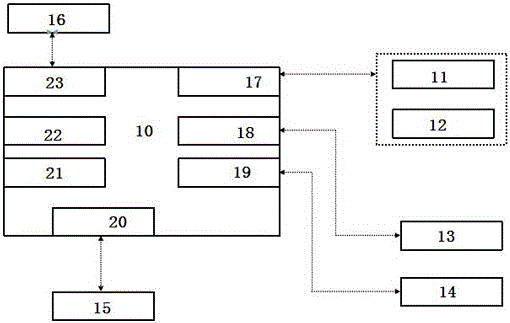

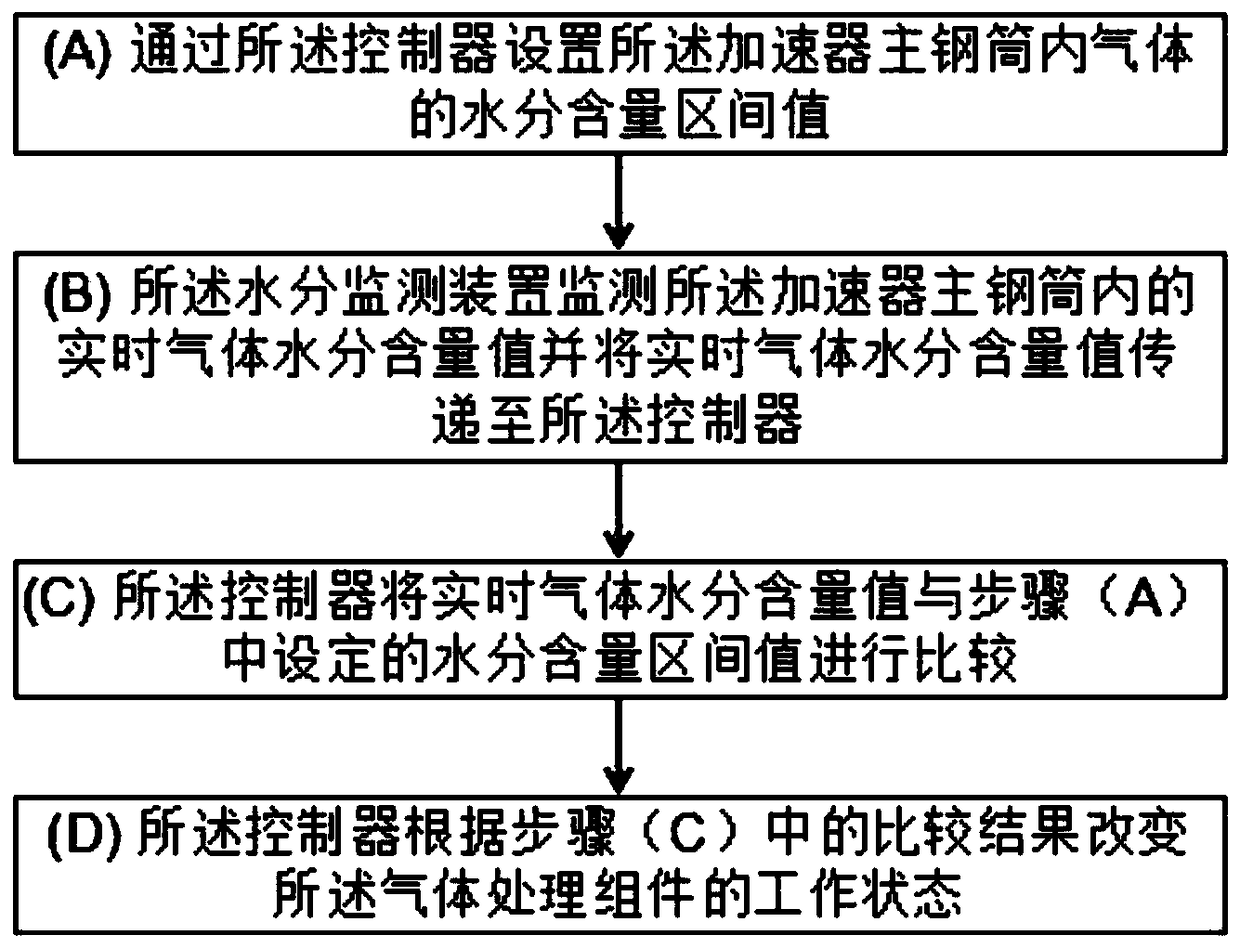

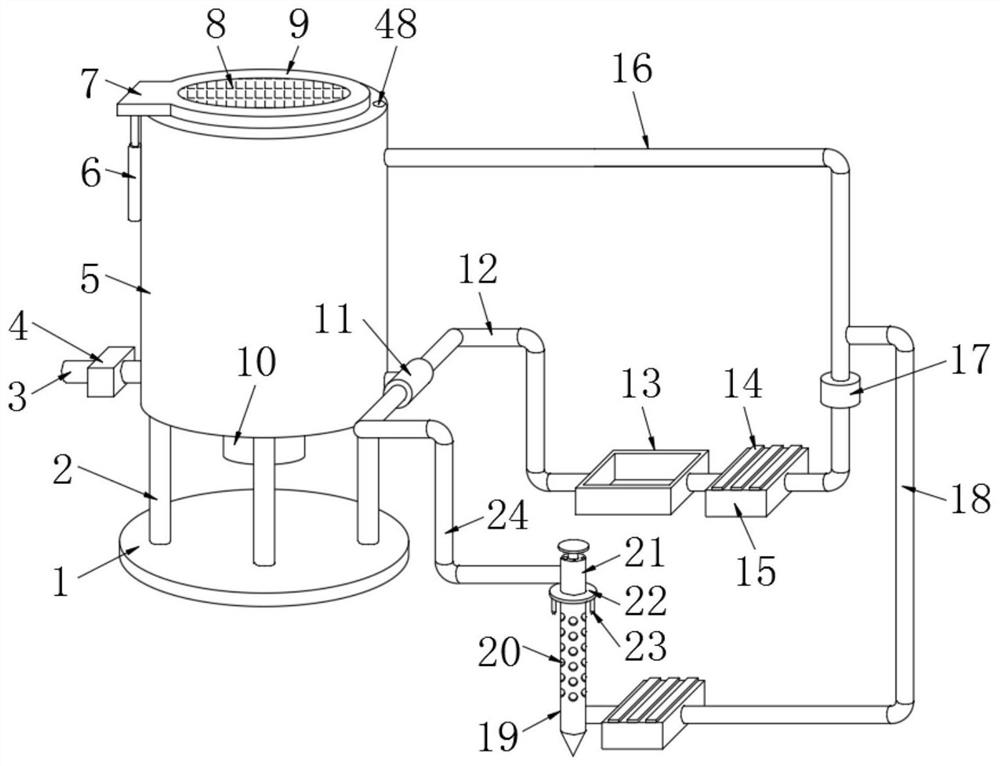

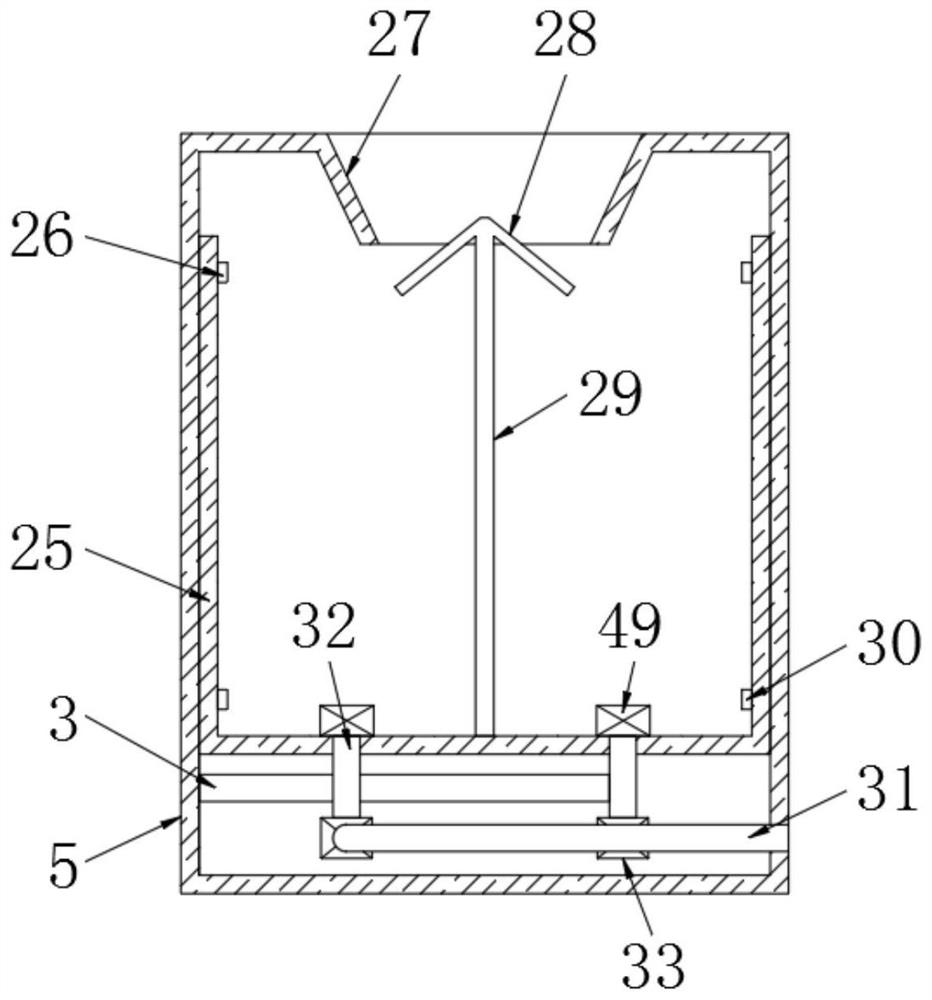

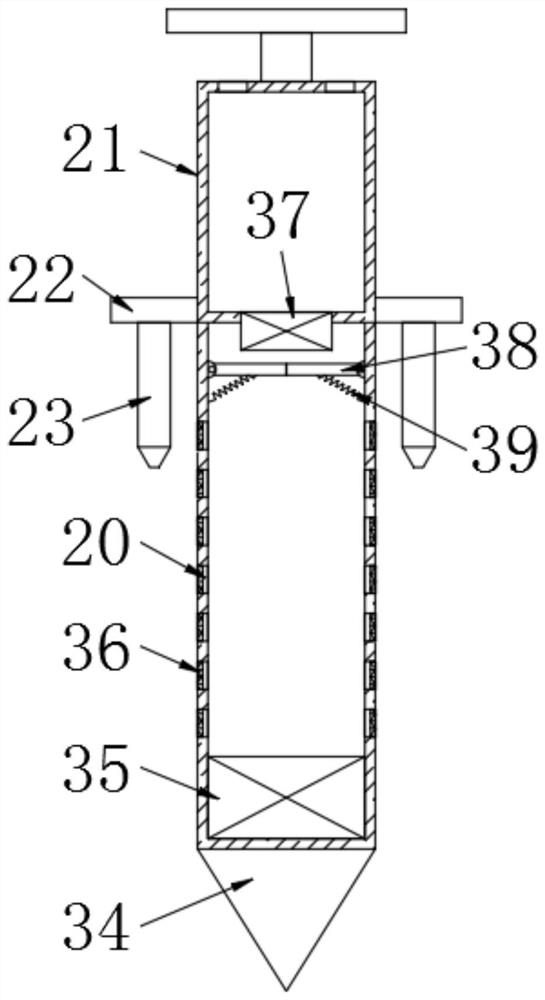

Insulated gas moisture monitoring system and method used for accelerator

PendingCN109406736ALow failure rateReal-time monitoring of moisture contentControlling ratio of multiple fluid flowsMaterial analysisElectricityMonitoring system

The invention discloses an insulated gas moisture monitoring system for an accelerator. The system is combined with a main steel cylinder of the accelerator. The insulated gas moisture monitoring system for the accelerator includes a gas treatment component, a moisture monitoring device and a controller. The gas treatment component and the moisture monitoring device are electrically connected withthe controller, the moisture monitoring device is combined with the main steel cylinder of the accelerator to monitor the moisture content, the gas treatment component is connected with the main steel cylinder of the accelerator through a pipeline, and the gas treatment component is controlled by the controller to drying the gas in the main steel cylinder of the accelerator in cycle. The invention further discloses an insulating gas moisture monitoring method for the accelerator, and the control device centrally monitors the moisture content in gas and controls the gas treatment component forcyclic drying.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

A water recycling system for garden landscape

ActiveCN113529853BAchieve recyclingReal-time monitoring of moisture contentClimate change adaptationWatering devicesWater useWater storage tank

The invention relates to the technical field of water for garden landscapes, and discloses a circulating water system for garden landscapes. A water tank, a partition plate is fixed at the center of the lower surface of the water storage tank, a discharge pipe is symmetrically fixed at the bottom of the water storage tank, a first solenoid valve is fixed at the bottom ends of the two discharge pipes, and two The top of the discharge pipe is fixed with a fourth solenoid valve; the present invention can collect rainwater, and can supply the collected rainwater to the water device and the sprinkler irrigation device, and when the water device is not in use, the water in it can be in the water. Under the action of the second pump body, it enters the high-level water tank again through the second return pipe, and can continue to supply the water device and the sprinkler irrigation device for use next time, and the moisture sensor at the bottom of the sprinkler irrigation device can monitor the moisture content in the soil in real time.

Owner:ZHOUKOU NORMAL UNIV

An intelligent biomass molding machine with electric mold switching

ActiveCN103386277BReal-time monitoring of moisture contentGuaranteed moisture contentGranulation by pressingTemperature controlMolding machine

The invention relates to an intelligent biomass molding machine with electric mold switching, including a humidity sensor, a temperature controller, a heating wire, a feeding hopper, a feeding belt, a stirring device, a granulator, a die changing plate, and a die changing plate motor, The humidity sensor can measure the moisture content of the biomass powder in real time, and control the temperature controller to change the heating current of the heating wire of the conveyor belt to adjust the temperature to control the moisture content of the biomass powder. The stirring device continuously stirs the biomass powder to prevent agglomeration and ensure the normal operation of the molding machine. There are multiple molds with different hole diameters and through-hole depths installed on the die changing plate, and the rotation of the die changing plate is controlled by the die changing plate motor to realize the installation of different flat dies according to requirements. The present invention is a biomass molding machine with automatic mold switching. By realizing flat mold switching, moisture content control, and biomass powder stirring, the normal operation of the molding machine is ensured, and biomass molding particles are produced according to requirements, which improves the adaptability of the molding machine. and versatility.

Owner:安徽省蓝天能源环保科技有限公司

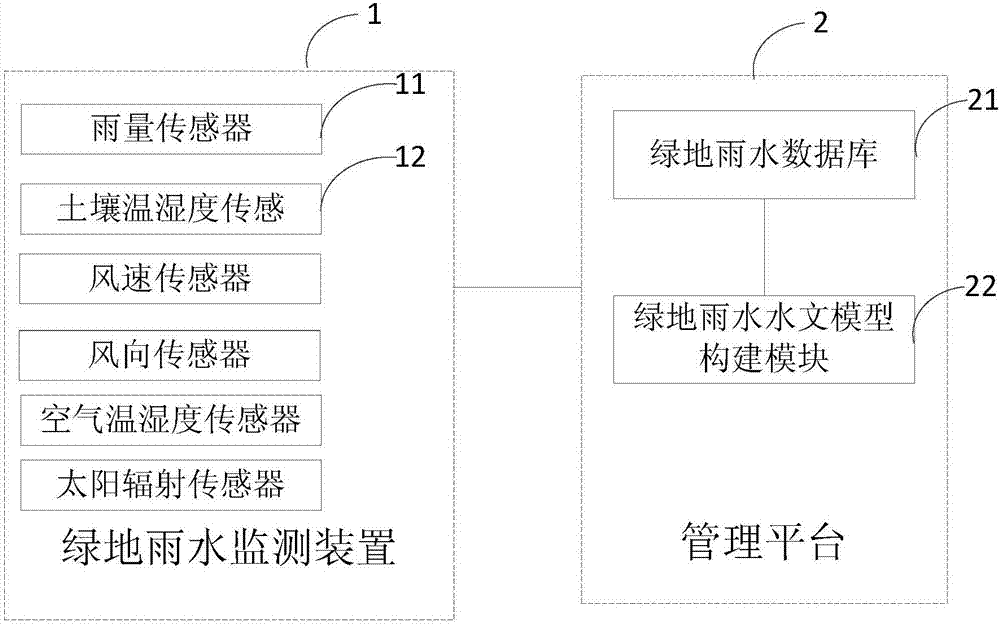

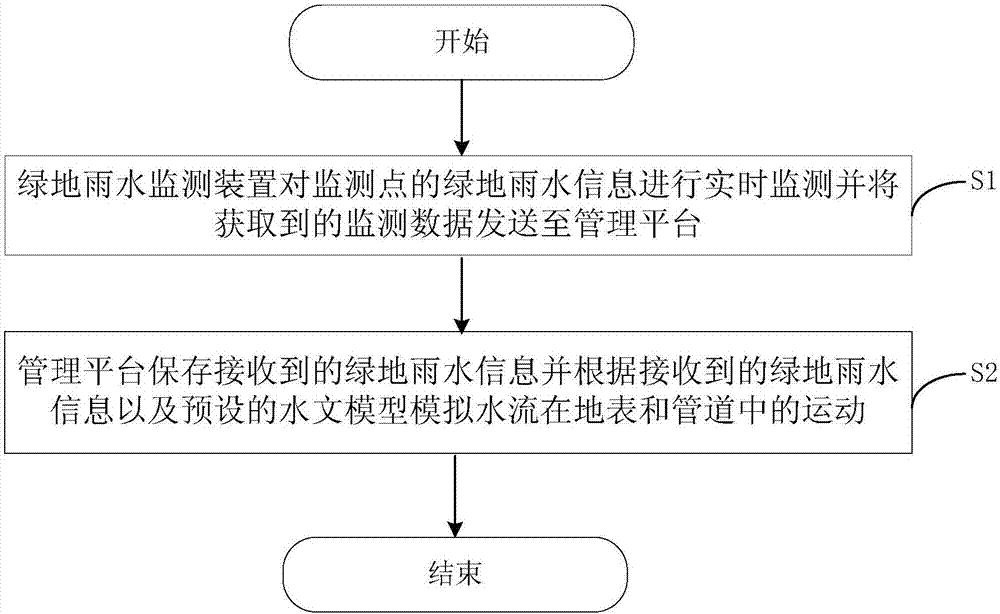

Green land rainwater ecological management system and method

InactiveCN107167177ARealize intelligent managementReal-time monitoring of moisture contentMeasurement devicesMonitoring dataEcological environment

The present invention relates to the field of green space rainwater ecological management, and provides a green space rainwater ecological management system and method. The system includes: a green space rainwater monitoring device for real-time monitoring of green space rainwater information at monitoring points and sending the obtained monitoring data to Management platform; the management platform at least includes a green space rainwater hydrological model building block, which is used to simulate the movement of water flow on the surface and in the pipeline according to the received green space rainwater information and a preset hydrological model. The technical solution proposed by the invention monitors the precipitation and soil moisture content of the green space in real time through the green space rainwater monitoring device, manages the data through the management platform and realizes the construction of the rainwater hydrological model, and realizes the intelligent management of the urban green space ecological environment.

Owner:成都华兴众智工程项目管理咨询有限公司

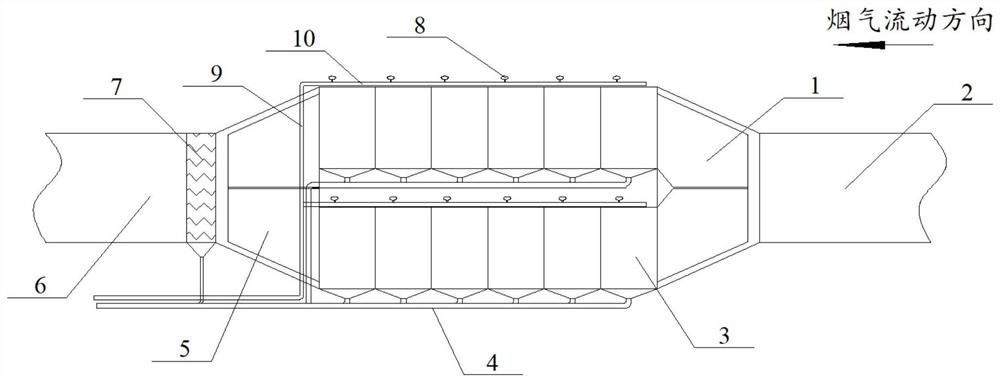

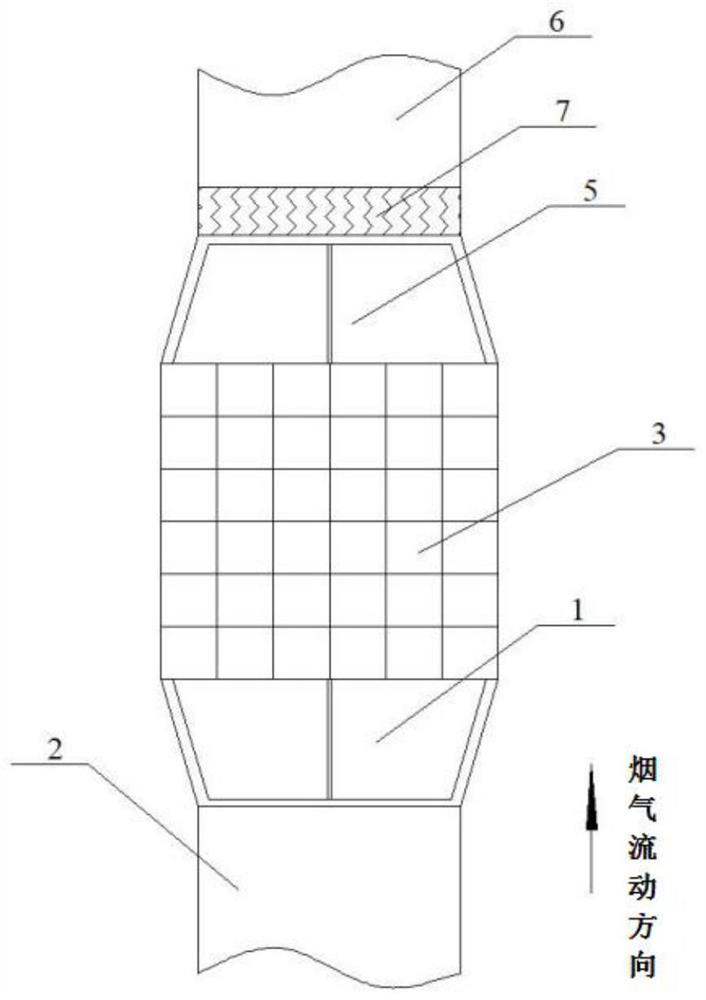

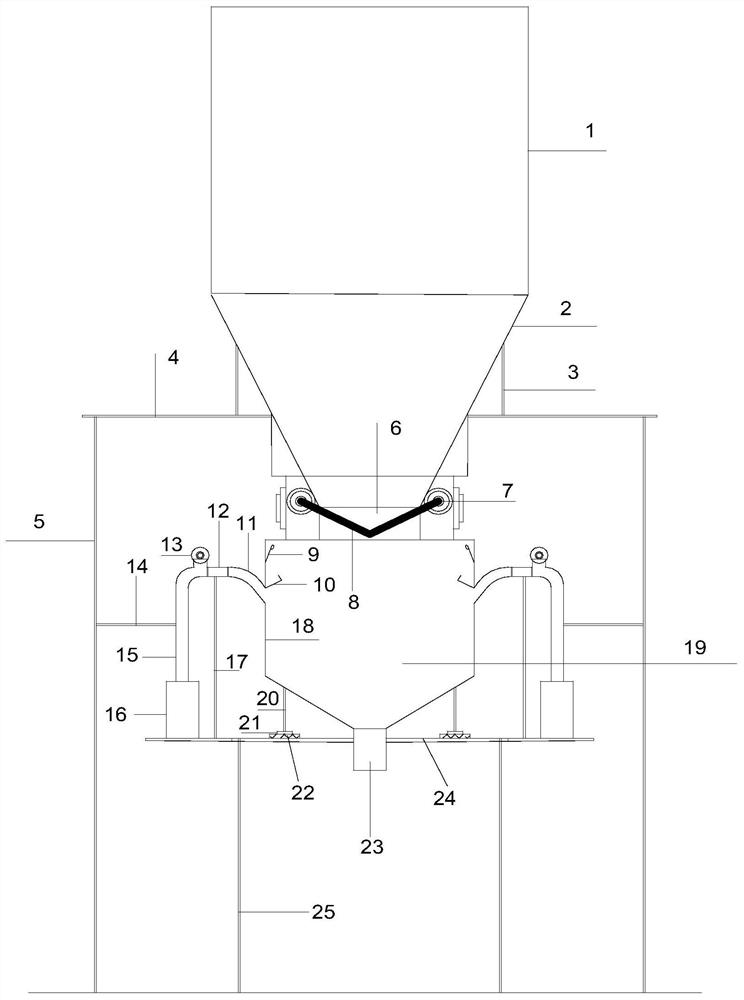

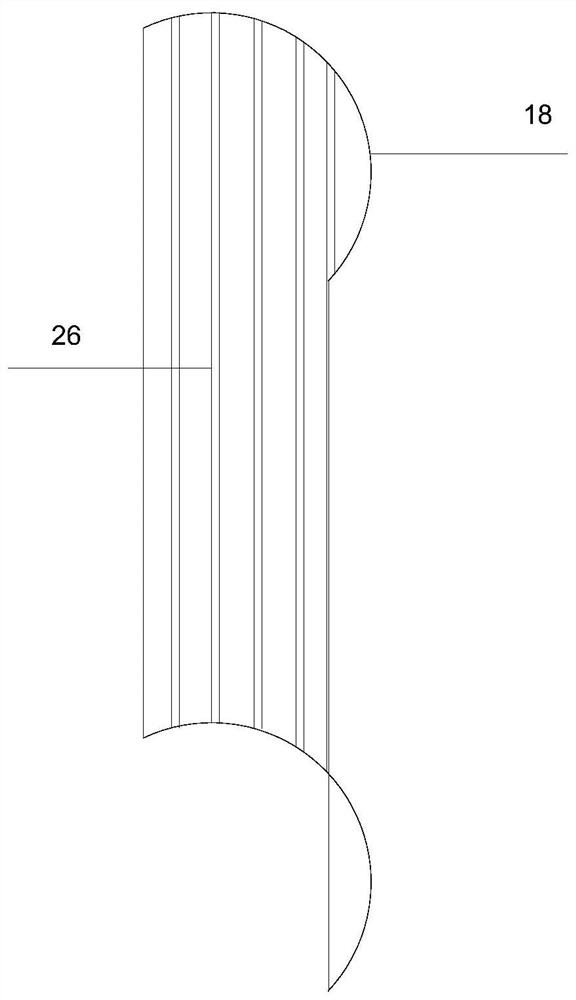

Modular limestone wet-desulphurization reaction device and desulphurization process

PendingCN112495177AReal-time monitoring of sulfur contentReal-time monitoring of moisture contentGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses a modular limestone wet-desulphurization reaction device and a desulphurization process, belonging to the technical field of flue gas desulphurization. The device comprises a flue gas inlet channel, a desulphurization reaction module unit arranged between and connected with an inlet and an outlet, and a flue gas outlet channel, wherein the desulphurization reaction module unit is formed by vertically arranging a plurality of groups of independent reaction module channels layer by layer, and each group of reaction module channel is of a channel structure which is formedby connecting a plurality of reaction modules that are detachably connected in pairs in series and are communicating along the flowing direction of flue gas; vertical slurry spraying pipes are arranged at four corners of an inner cavity of any reaction module, the bottom of each reaction module communicates with a reaction slurry collecting pipe, and a plurality of slurry nozzles which are vertically arranged at intervals are arranged on each slurry spraying pipe; an inlet adjusting baffle is arranged at the inlet of the device; and an outlet adjusting baffle is arranged at the outlet of the device. According to the invention, one-time construction of a desulphurization system can basically meet the requirement on the whole operation life of a set, transformation investment is reduced, andthe purification requirement of high-sulfur flue gas can be met.

Owner:HUANENG CHAOHU POWER GENERATION

Pre-stored hopper processing and monitoring system and operation method of ready-mixed concrete mixer

ActiveCN109436850BReduce frictionReduce sustained shockDischarging apparatusLoading/unloadingReady mixed concreteDust control

The invention relates to a pre-storage hopper processing and monitoring system and operation method of a ready-mixed concrete mixer. A pre-storage hopper is arranged under the hopper, and an automatic control opening and closing material inlet and an automatic control opening and closing discharge port are arranged on the upper and lower sides of the pre-storage hopper; the inner wall of the pre-storage hopper Set a negative pressure air duct, and set a dust removal device on its upper part; set a stress sensing plate at the lower part of the pre-storage hopper, and monitor the feeding amount and stocking amount in the pre-storage hopper through the stress sensing plate; set a humidity sensor at the lower part of the inner wall of the pre-storage hopper, The moisture content of concrete is monitored in real time, and a water inlet is set on the top of the pre-storage hopper. The present invention relates to a pre-storage hopper processing and monitoring system and operation method of a ready-mixed concrete mixer, which performs corresponding buffering of concrete to avoid the risk of material spilling out, and at the same time monitors the moisture content state of the concrete in the pre-storage hopper as well as the amount of stored material and the amount of material used in real time. Monitoring, reducing the waiting time of vehicles, improving transportation efficiency, has good economic and technical benefits.

Owner:眉山市城投建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com