Method for measuring water content of dried object, vacuum drying device and control method thereof

A technology of a vacuum drying device and a measurement method, which is applied in the directions of drying solid materials, drying solid materials without heating, and drying solid materials by method combination, can solve the problems of difficulty in meeting the speed and continuity, measurement results being easily affected, and measurement methods. Long cycle and other problems, to achieve reliable measurement results, easy to achieve, meet the speed and continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

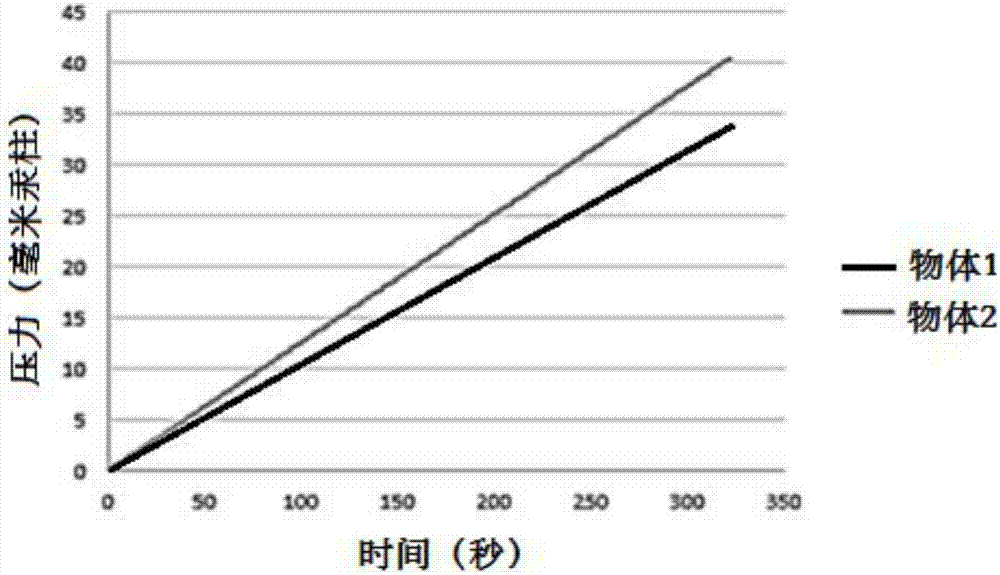

[0044] In the drying process, for a closed drying container, as a closed system, its system volume is a constant, so its thermodynamic state is an isochoric process.

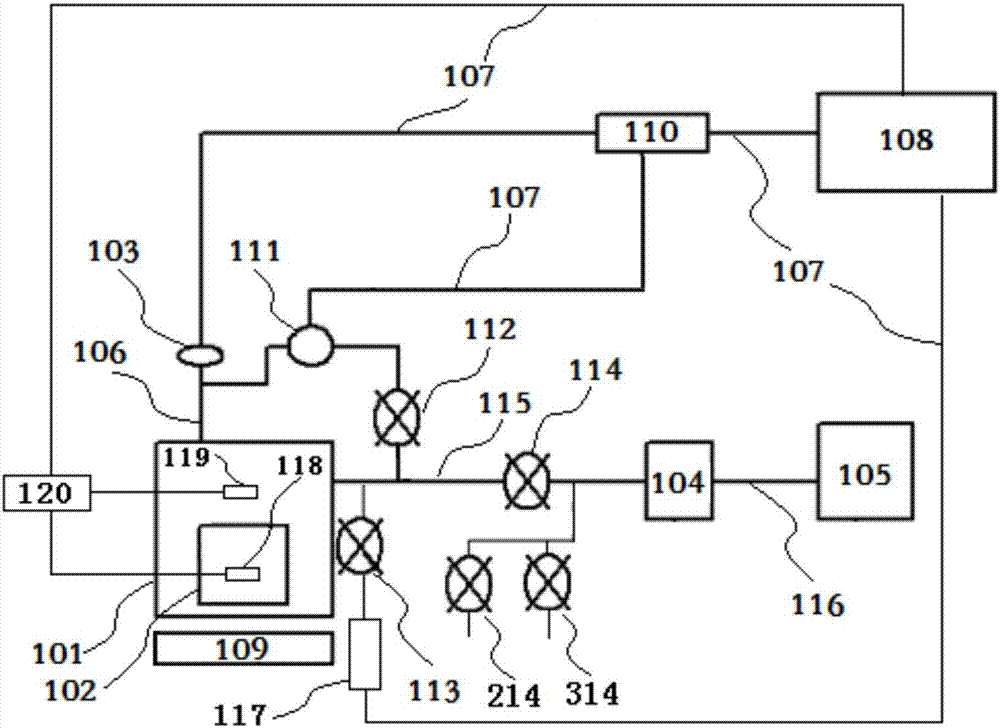

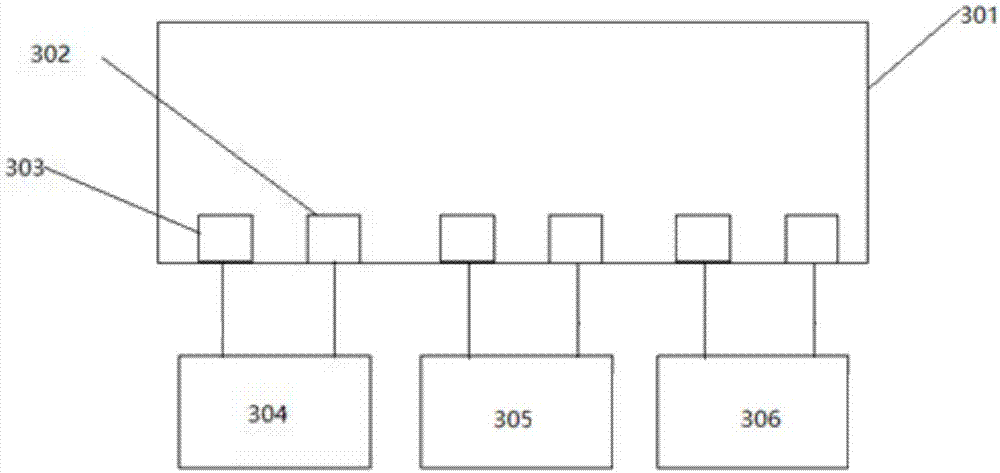

[0045] The invention provides a method for measuring the moisture content of the dried object during the vacuum drying process, that is, by timely sealing the drying container during the vacuum drying process, so that the drying system enters an isovolumic state, and based on the isovolumic process Thermodynamic state, a new method for real-time measurement of the moisture content of the dried material established.

[0046] The method for measuring the moisture content of the dried object according to the present invention is used to calculate the water content of the dried object in the drying container during the vacuum drying process, and the water content of the dried object is based on the system parameters of the drying container in a closed state to calculate.

[0047] Specifically, the water content M1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com