Dry-wet cycle testing device capable of monitoring moisture content of soil in real time

A technology of soil moisture content and dry-wet cycle, applied in the direction of measuring devices, soil material testing, material inspection products, etc., can solve the problems of inability to dry-wet cycle, insufficient saturation, inability to accurately monitor the water content of soil samples at any time, etc. problems, achieve the effect of shortening time, uniform drying and saturation, and convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

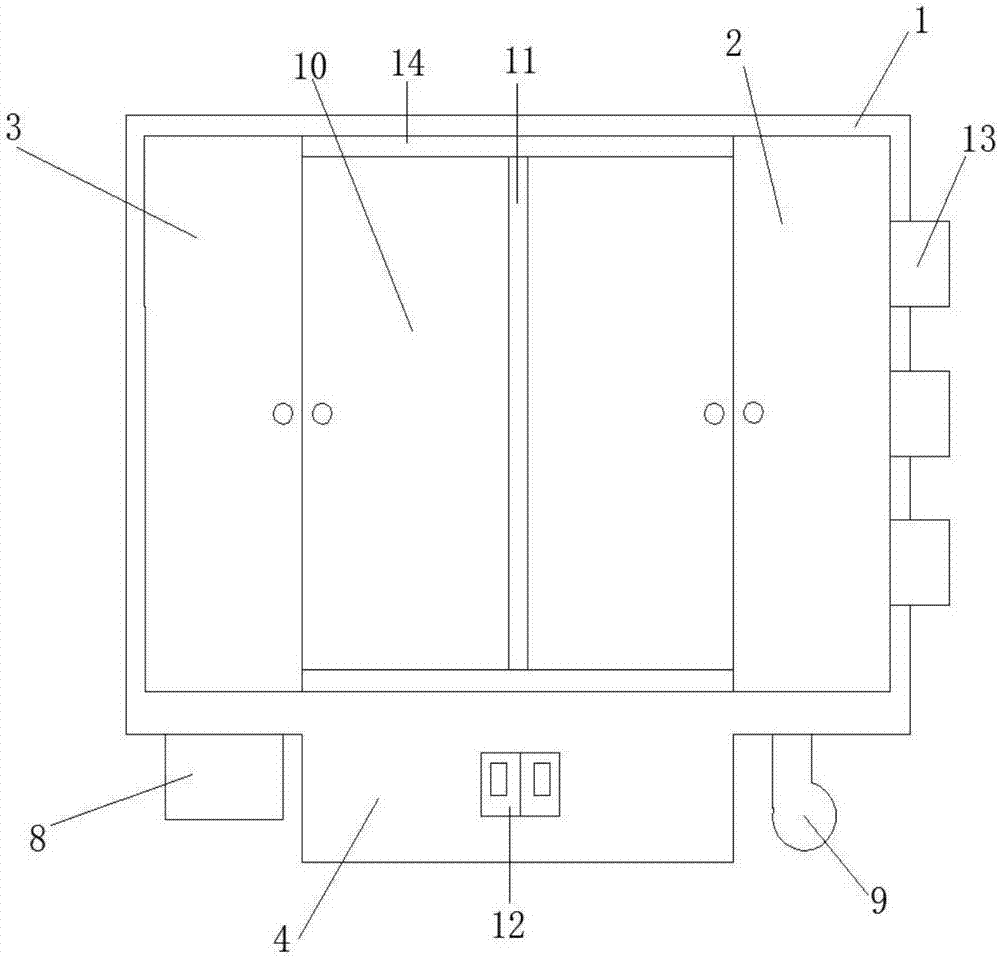

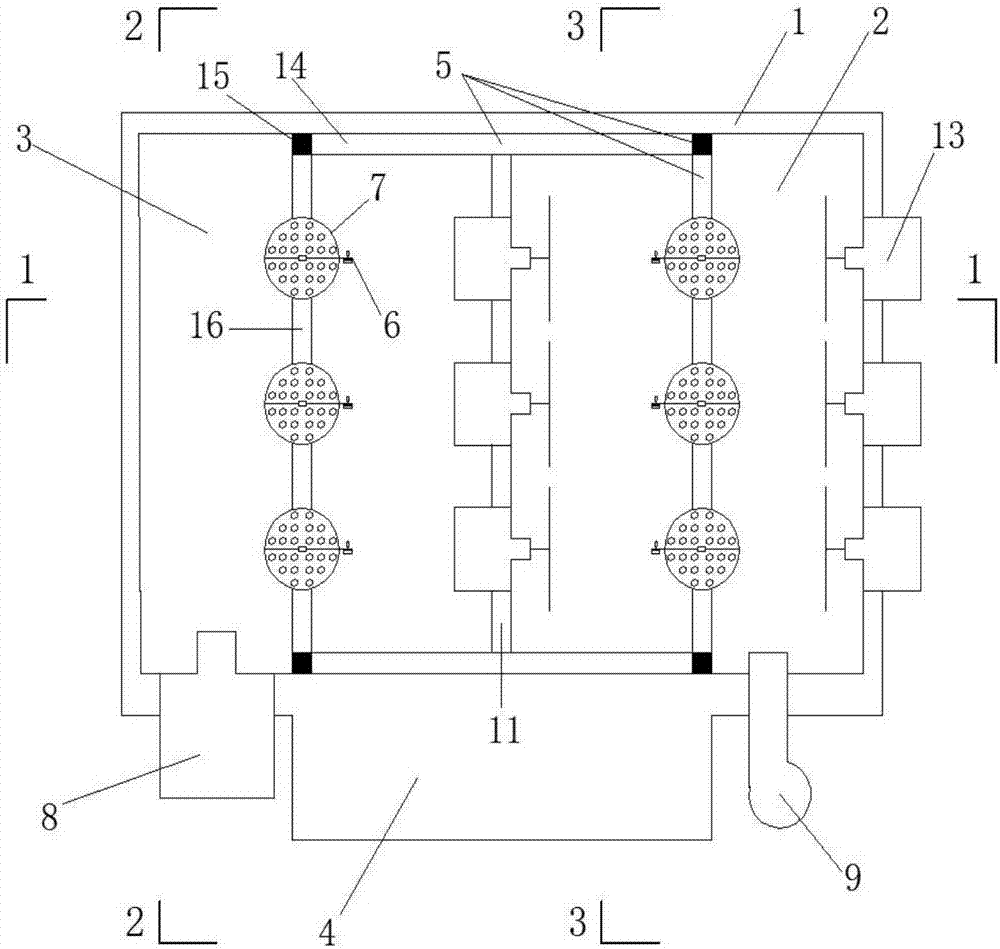

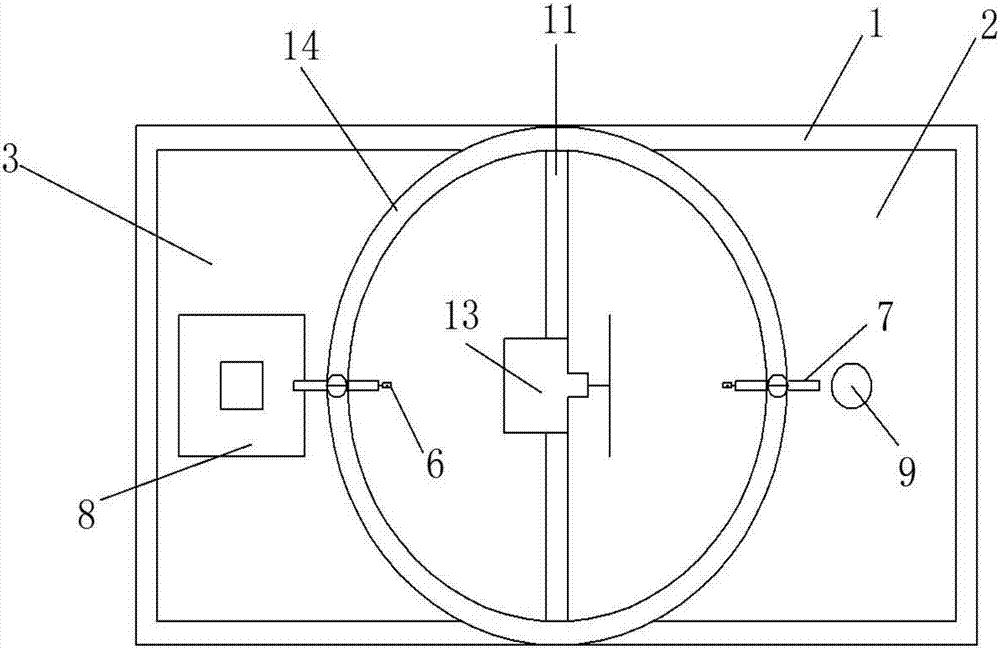

[0046] as attached Figure 1 to Figure 6 As shown, the dry-wet cycle test device capable of monitoring the moisture content of soil in real time according to the present invention includes a dry-wet cycle box 1 , a drying box 2 , a saturation box 3 , a power supply box 4 , a rotating device 5 and a reading control device 6 . The specific structure and connection relationship are: the dry-wet cycle box 1 includes a sliding glass door 10, a baffle plate 11 between the drying box 2 and the saturation box 3, and a main switch 12 of the control device. Described drying box 2 comprises fan 13 and small blower 9, and fan 13 is located at drying box 2 left and right sides, and each fan 13 center is aligned with porous soil box 7 centers, and small blower 9 conveys warm air in drying box 2. The saturation box 3 includes a hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com