Liquid gasification device

A gasification device and liquid technology, applied in the direction of using liquid separating agent, chemical instruments and methods, spray evaporation, etc., can solve the problems of sewage affecting construction and slag removal transportation, low dust removal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0018] In order to solve the problem in the prior art that when the staff maintain the flowers or vegetation placed on the flower stand, they cannot reach the greenery or flowers at a high place and the maintenance is inconvenient, the embodiment of the present invention provides an environmental protection field. Lifting flower stand.

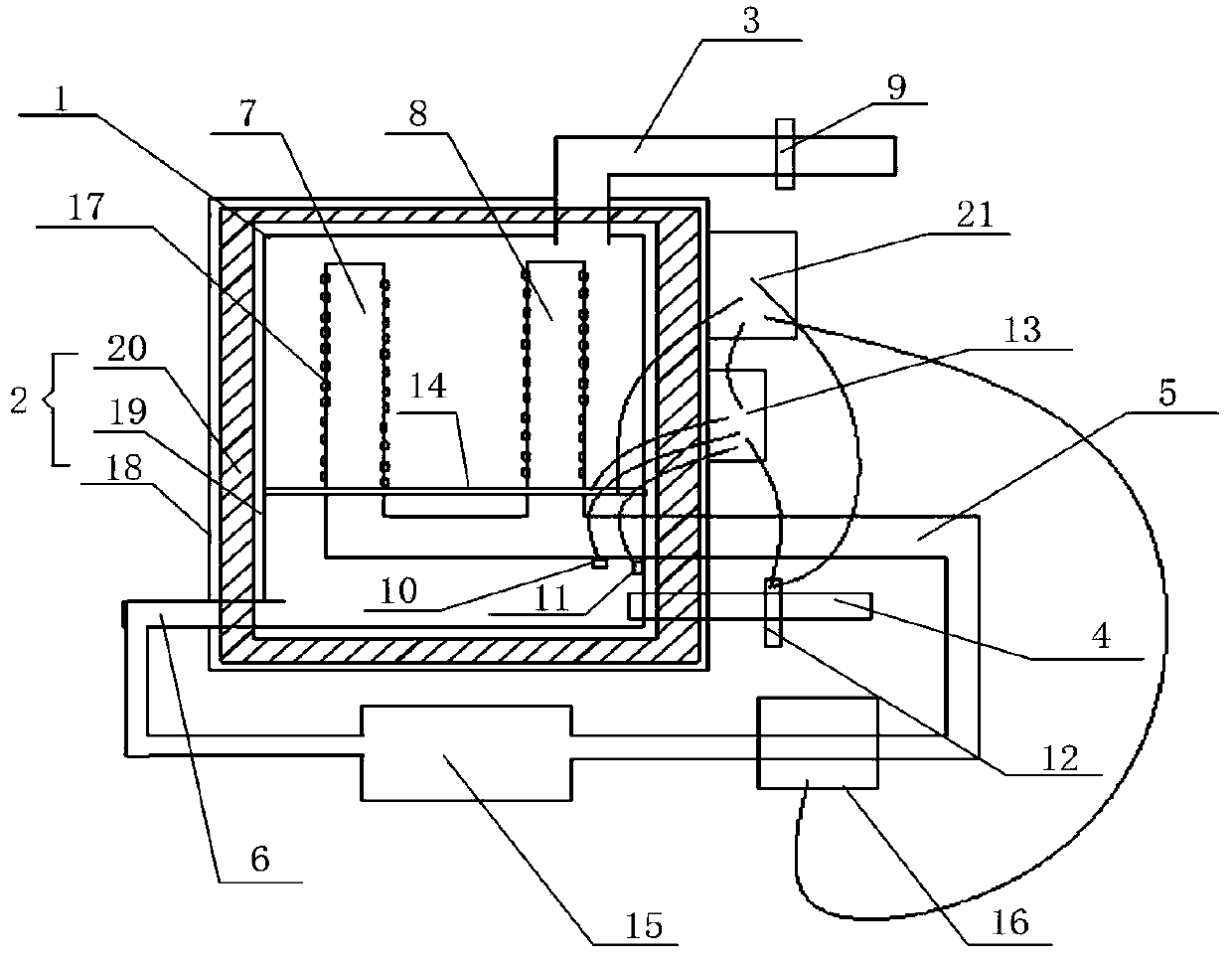

[0019] See figure 1 , the embodiment of the present invention provides a liquid gasification device, including: a device body 1, a coating layer 2, an air inlet pipe 3, an exhaust pipe 4, a liquid inlet pipe 5, a liquid discharge pipe 6, and a first water outlet structure 7 , second water outlet structure 8, gas pressurization device 9, temperature sensor 10, humidity sensor 11, automatic valve 12, controller 13, heating network 14, water storage tank 15, liquid pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com