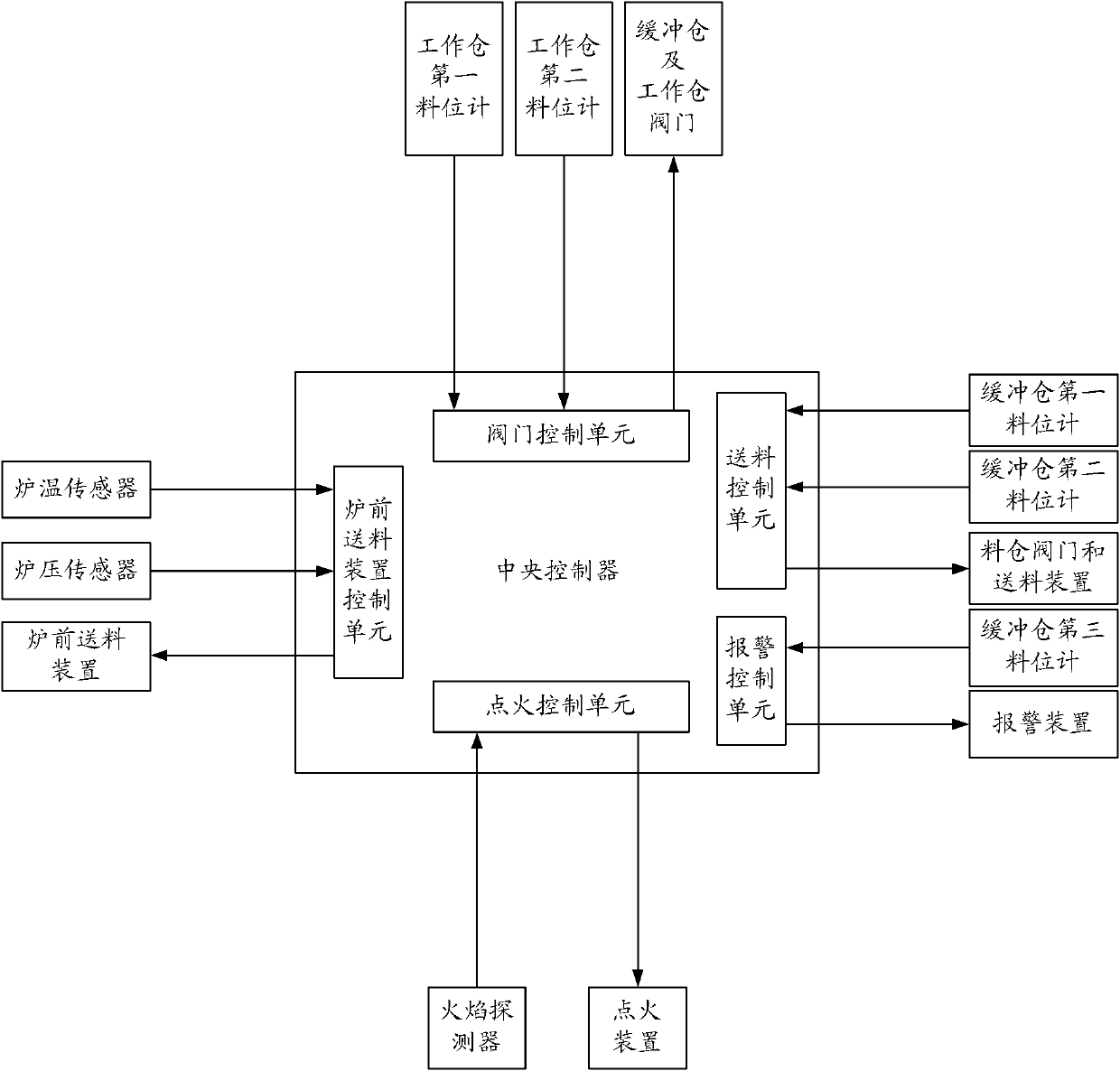

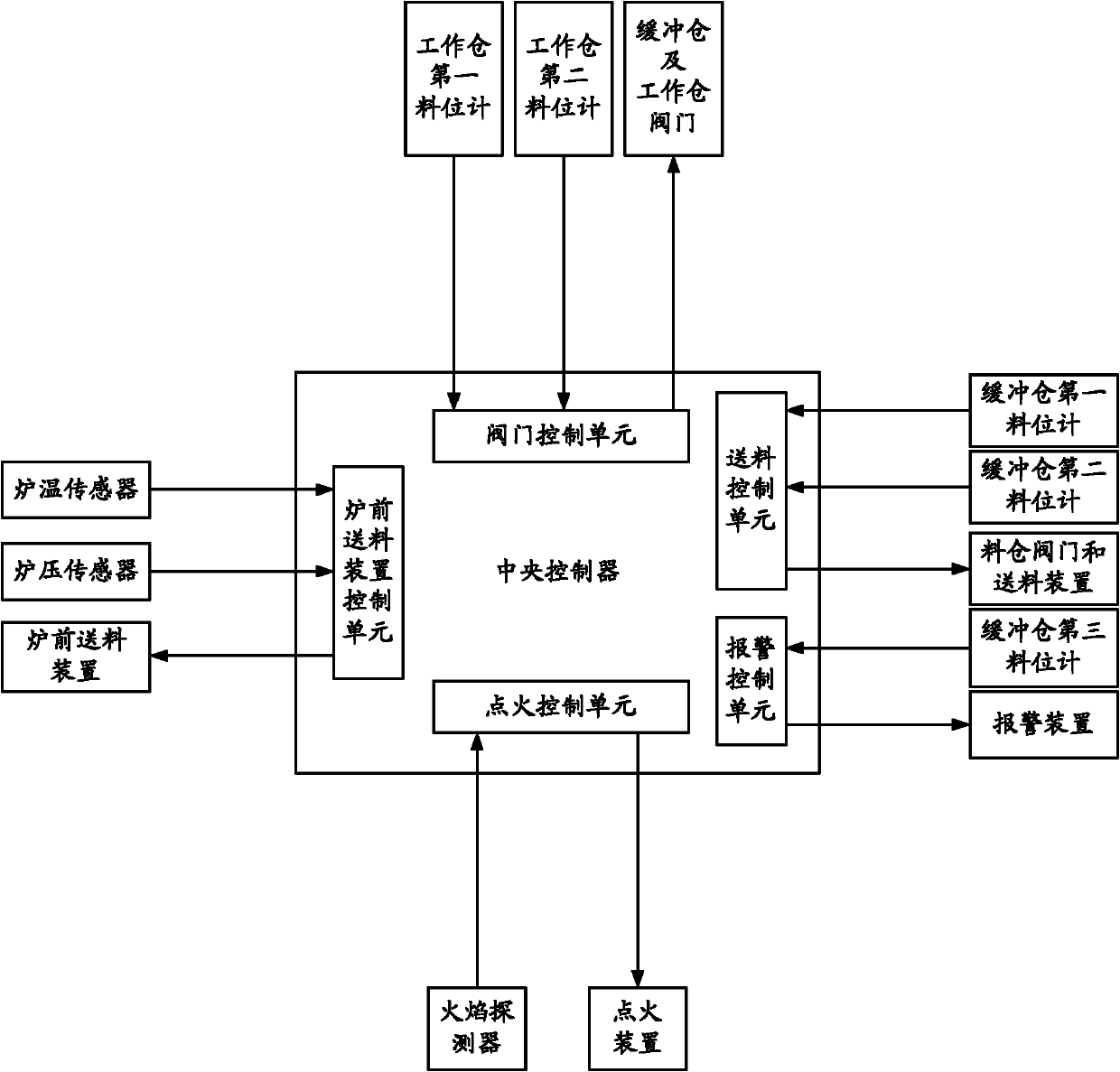

Automatic biomass gas feeding and diffusing control system and biomass gasification reaction system

An automatic control system, biomass gas technology, applied in electrical program control, granular/powder fuel gasification, program control in sequence/logic controllers, etc., can solve energy waste, low energy utilization, gas storage, etc. Problems such as rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

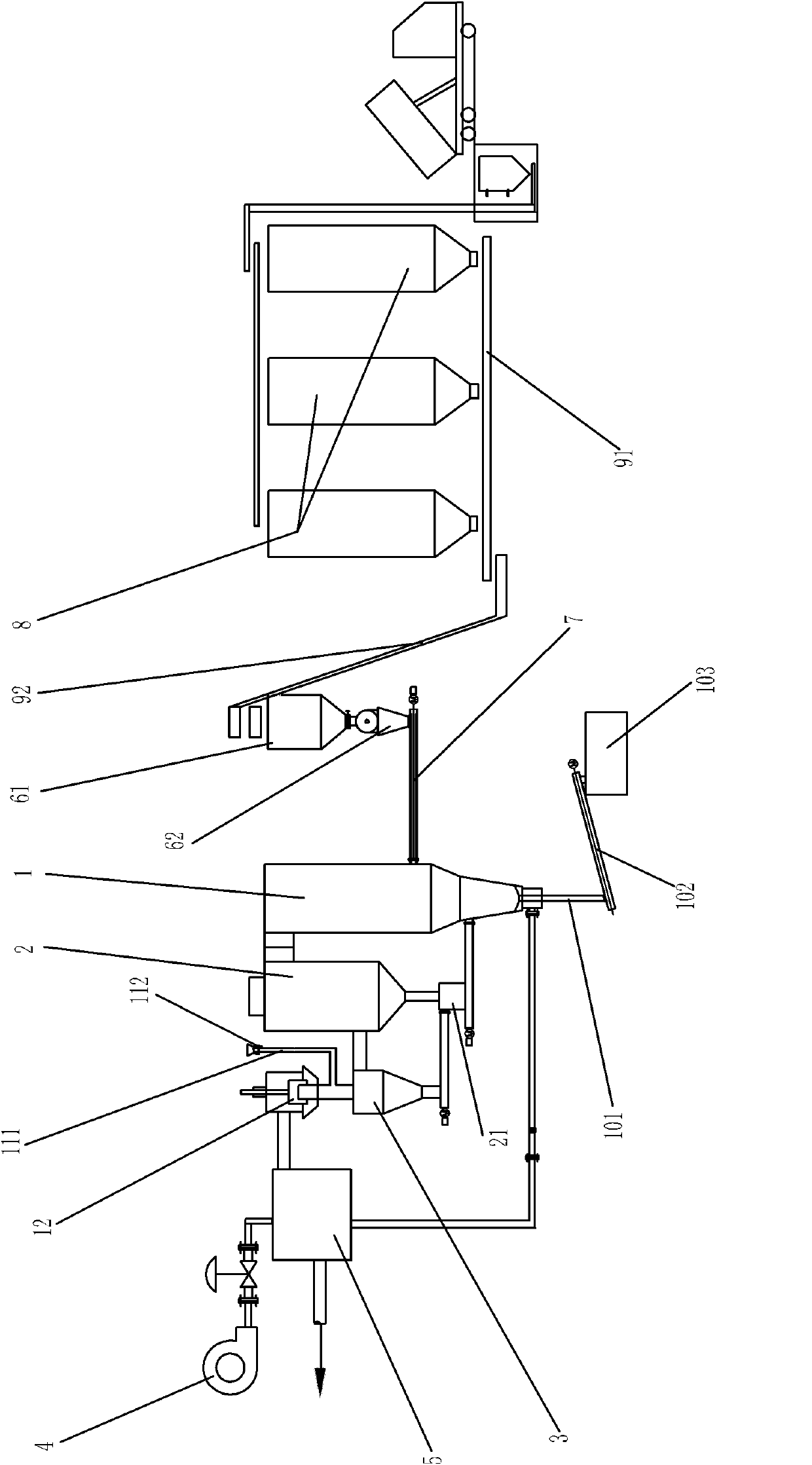

[0057] The biomass gasification reaction system applicable to this embodiment includes a fluidized bed gasification reactor, a furnace front material storage device, a furnace front feeding device, a silo and a feeding device, and a release device; the furnace front material storage device includes a buffer bin and The working bin, the buffer bin and the working bin respectively include a material inlet and an outlet, and the inlet of the working bin is connected to the outlet of the buffer bin; the feeding device in front of the furnace sends the raw materials from the outlet of the working bin into the fluidized The feed port of the bed gasification reactor; the buffer bin and the bottom discharge port of the working bin are equipped with valves; the feed bin includes a top feed port and a bottom discharge port, and the bottom discharge port of the feed bin is provided with a valve; The feeding device includes a horizontal conveyor belt and an elevator. The horizontal conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com