Fixed bed straw gasification process with tar backflash

A fixed bed, tar technology, applied in the field of straw gasification technology, can solve the problem of tar secondary pollution, etc., achieve the effect of increasing calorific value, avoiding inconvenience, and improving gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

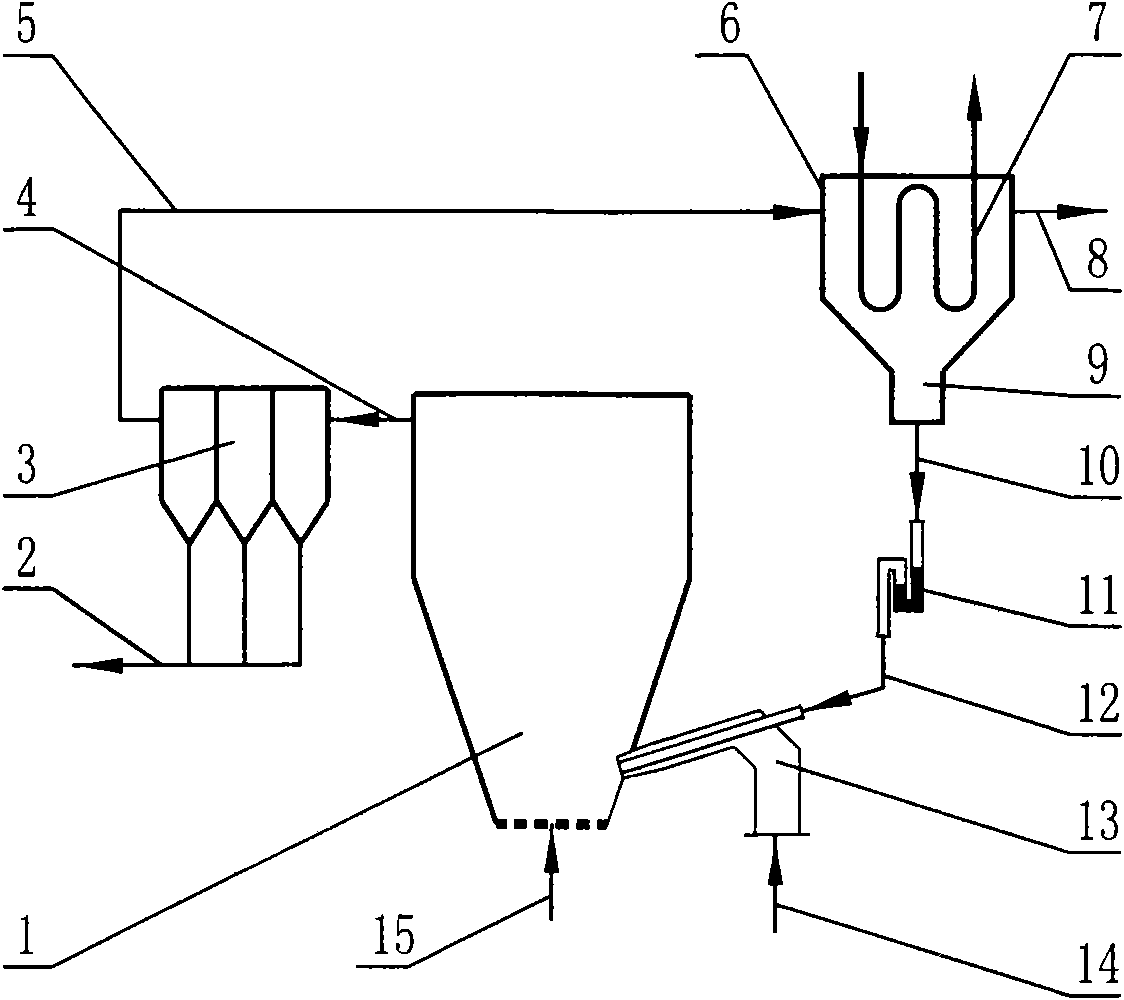

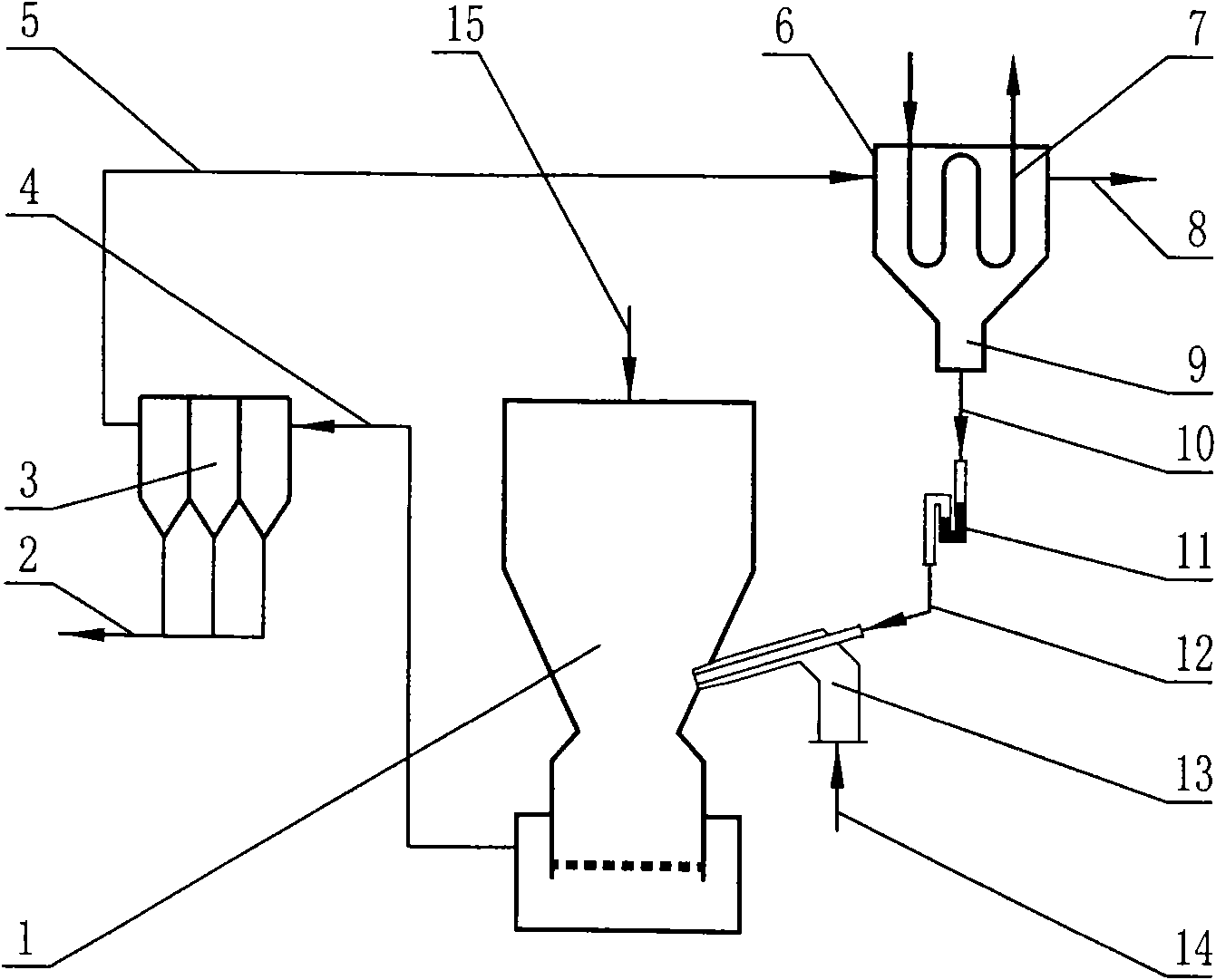

[0010] In the figure, in this process, there is a cylindrical gasifier 1, which is divided into a downdraft fixed-bed gasifier ( Picture 1-1 ) and the updraft fixed-bed gasifier ( diagram 2-1 ); on the side wall of the gasification furnace 1, an ejector 13 for ejecting airflow is installed, and through the upper and lower parts of the side wall, the air guide pipe 4, the filter dust remover 3, the air guide pipe 5, and the tar trap are connected in sequence. device 6, coke collection tank 9, backfire pipe 10, liquid-sealed elbow 11, backfire pipe 12 and pilot burner 13, so that the collected tar is injected into the gasifier 1 to continue burning; among them, the tar is discharged through the gasifier 1 Keep the reaction temperature between 500°C and 1500°C. In the filter and dust collector 3, the high-temperature gas generated by the gasifier is firstly dedusted, and in the tar trap 6, it is collected by a combination of inertia and cooling. The tar in the gas, the capture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com