Cracking and gasifying reforming furnace

A technology of cracking gasification and reforming furnace, which is applied in the direction of granular/powdered fuel gasification, coking oven, chemical industry, etc. It can solve the problems of low gasification efficiency, low heat utilization rate, and low calorific value of gas, and achieves High gasification efficiency, high calorific value of gas, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

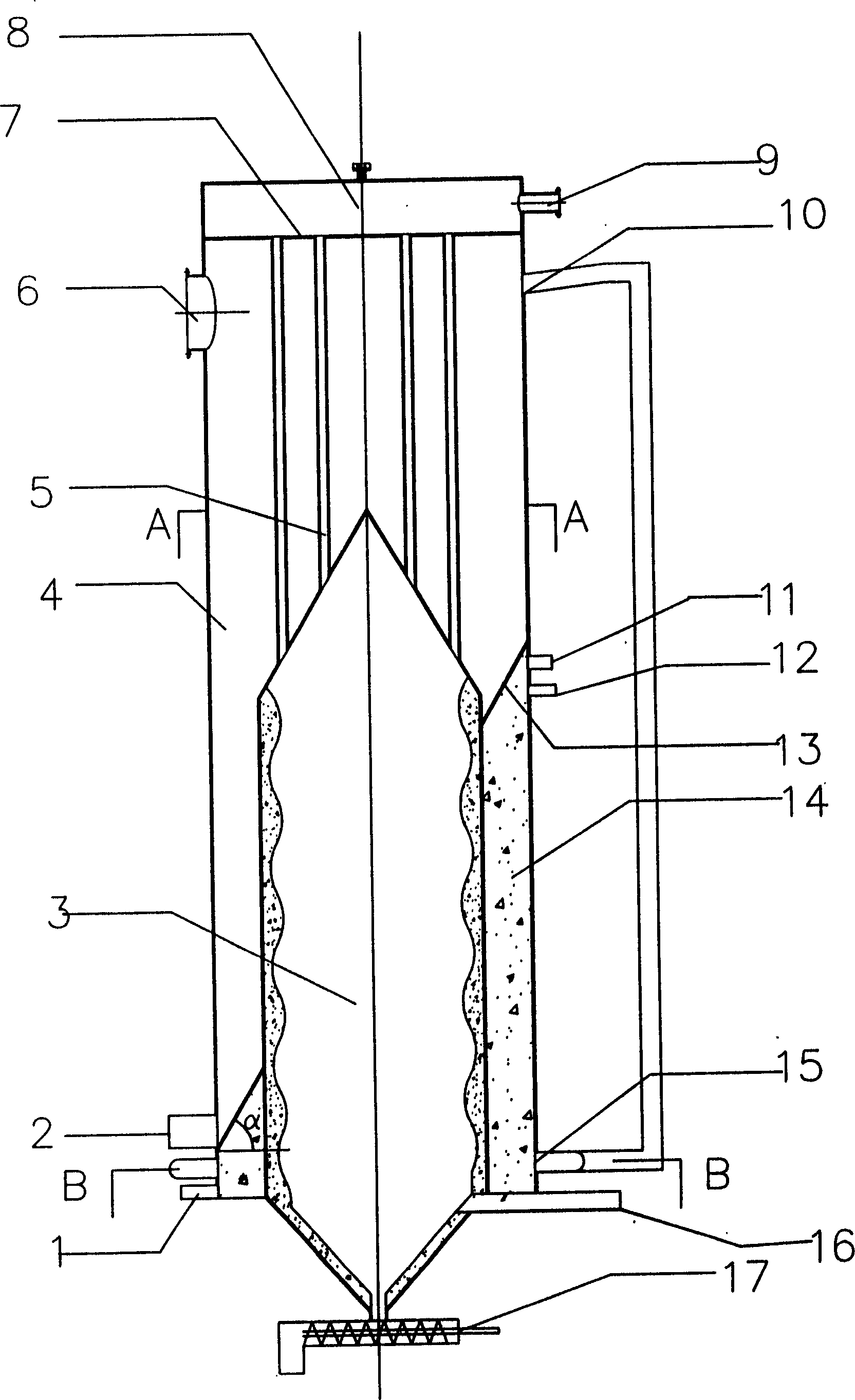

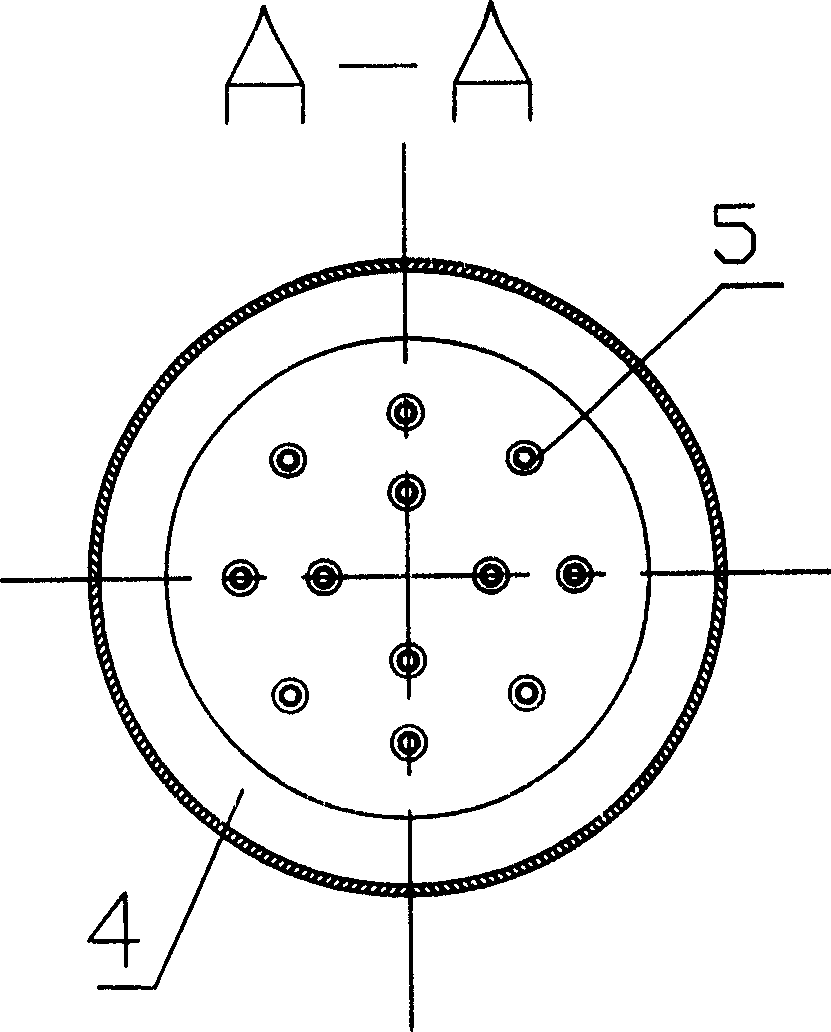

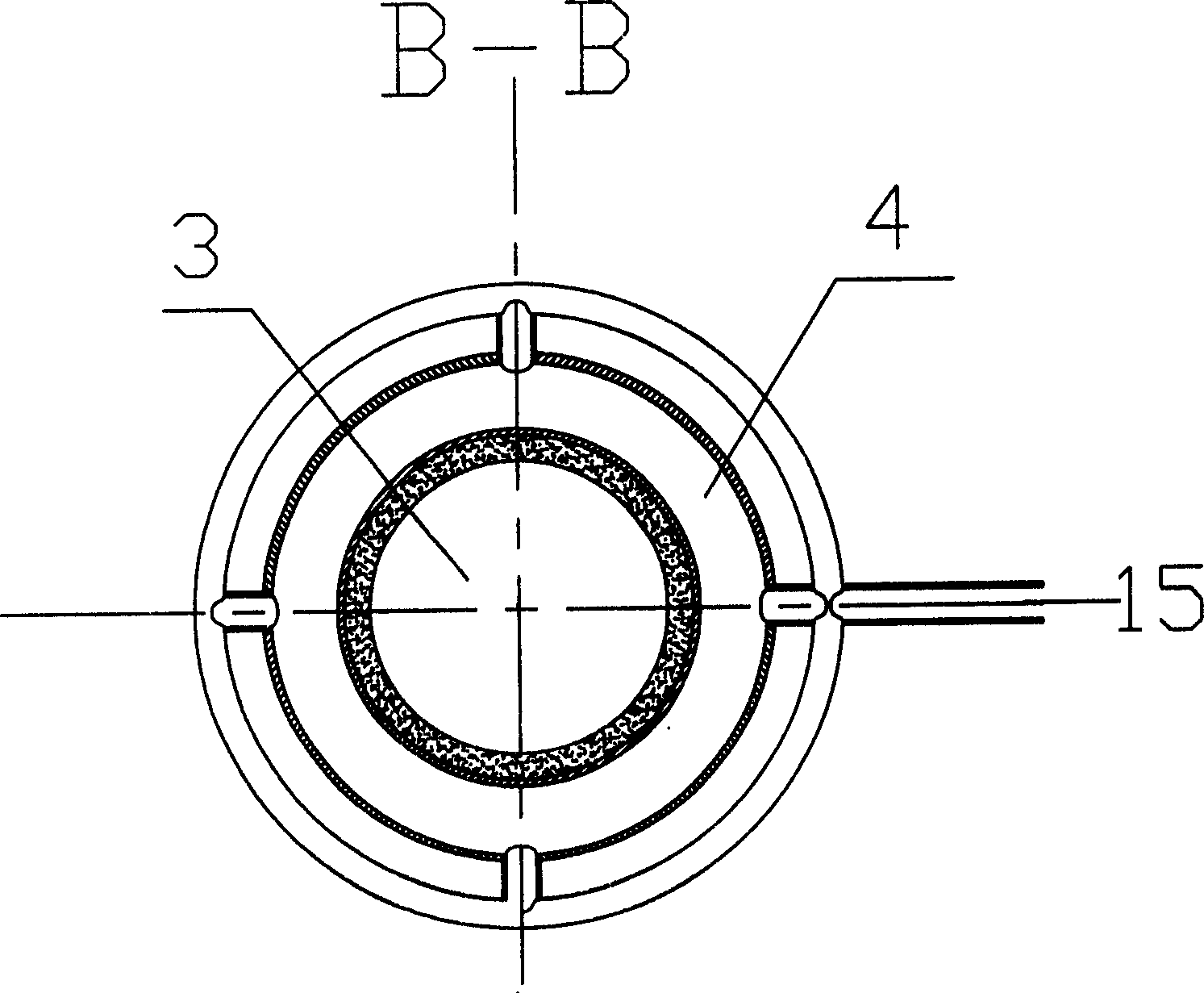

[0025] Depend on Figure 1 ~ Figure 3 As shown, a pyrolysis gasification reforming furnace, the furnace body is vertical, the dust cloud combustion chamber 3 is located at the bottom of the furnace body, the upper part of the dust cloud combustion chamber 3 is a cone with a small upper part and a larger lower part, and the lower part is a large cone with an upper part. , lower small cone, have residue outlet 17 at the bottom of dust cloud combustion chamber 3, have fuel feed inlet 16 at the lower end of dust cloud combustion chamber 3, be provided with and body of heater side wall at the upper part of body of heater The first dividing plate 7 that joins, the top of the first dividing plate 7 is the gas collection chamber 8, has the flue gas outlet 9 on the gas collecting chamber 8, the lower end of the flue gas column tube 5 is positioned at the dust cloud combustion chamber 3, and It communicates with the dust cloud combustion chamber 3. The upper end of the flue gas column t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com