Patents

Literature

269 results about "Integration Type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Location of the integration of the engineered gene e.g. random or targeted.

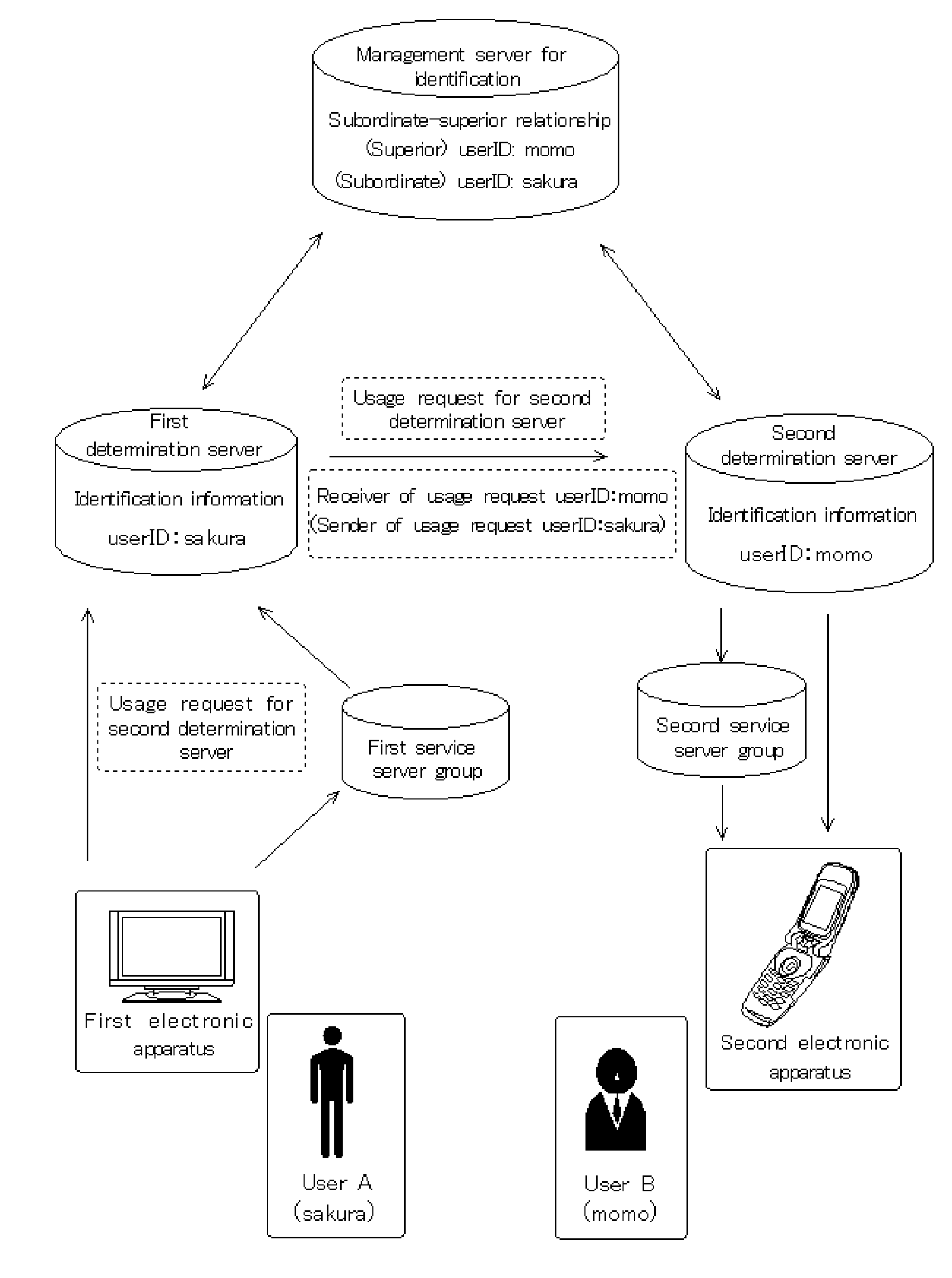

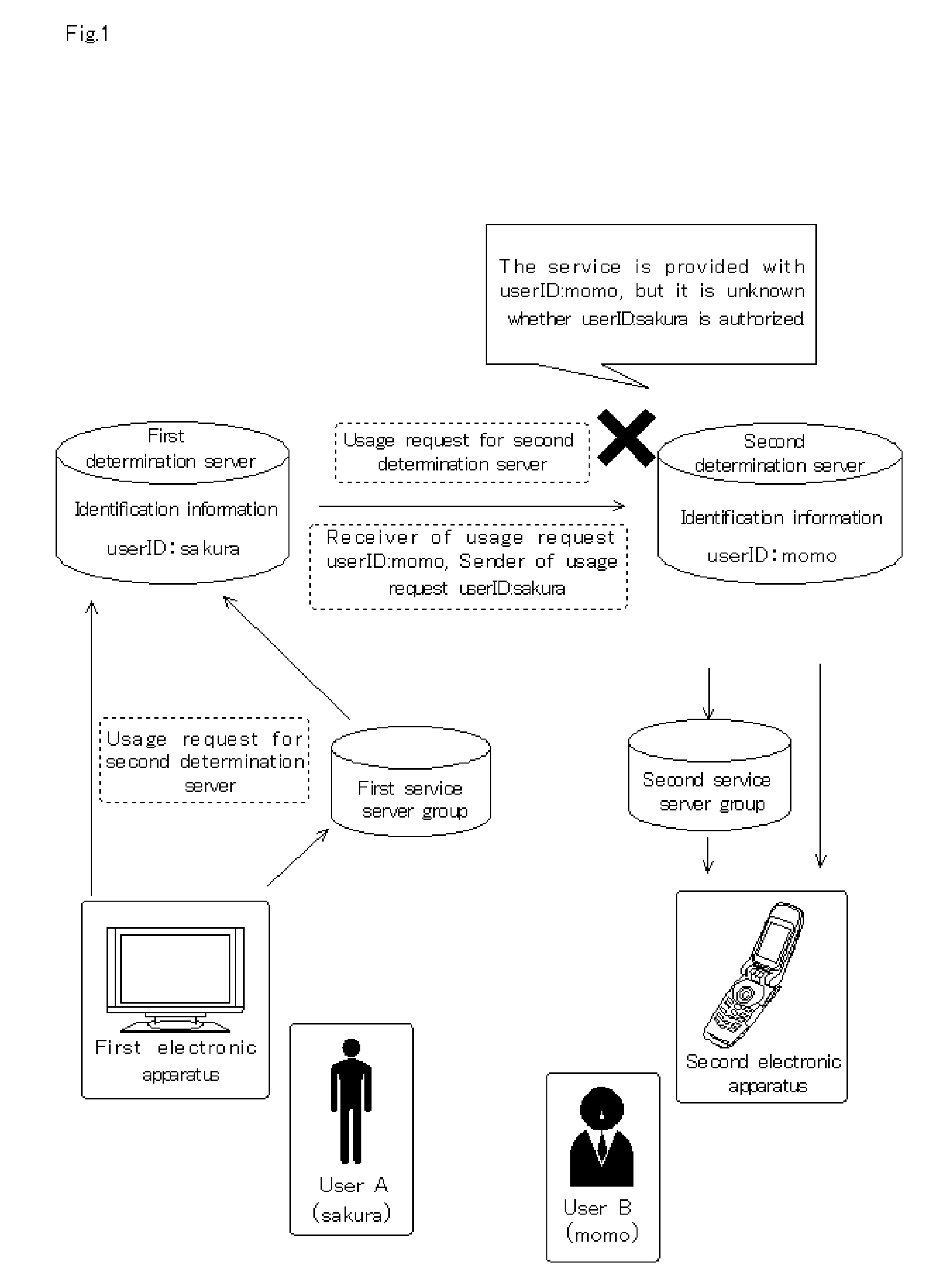

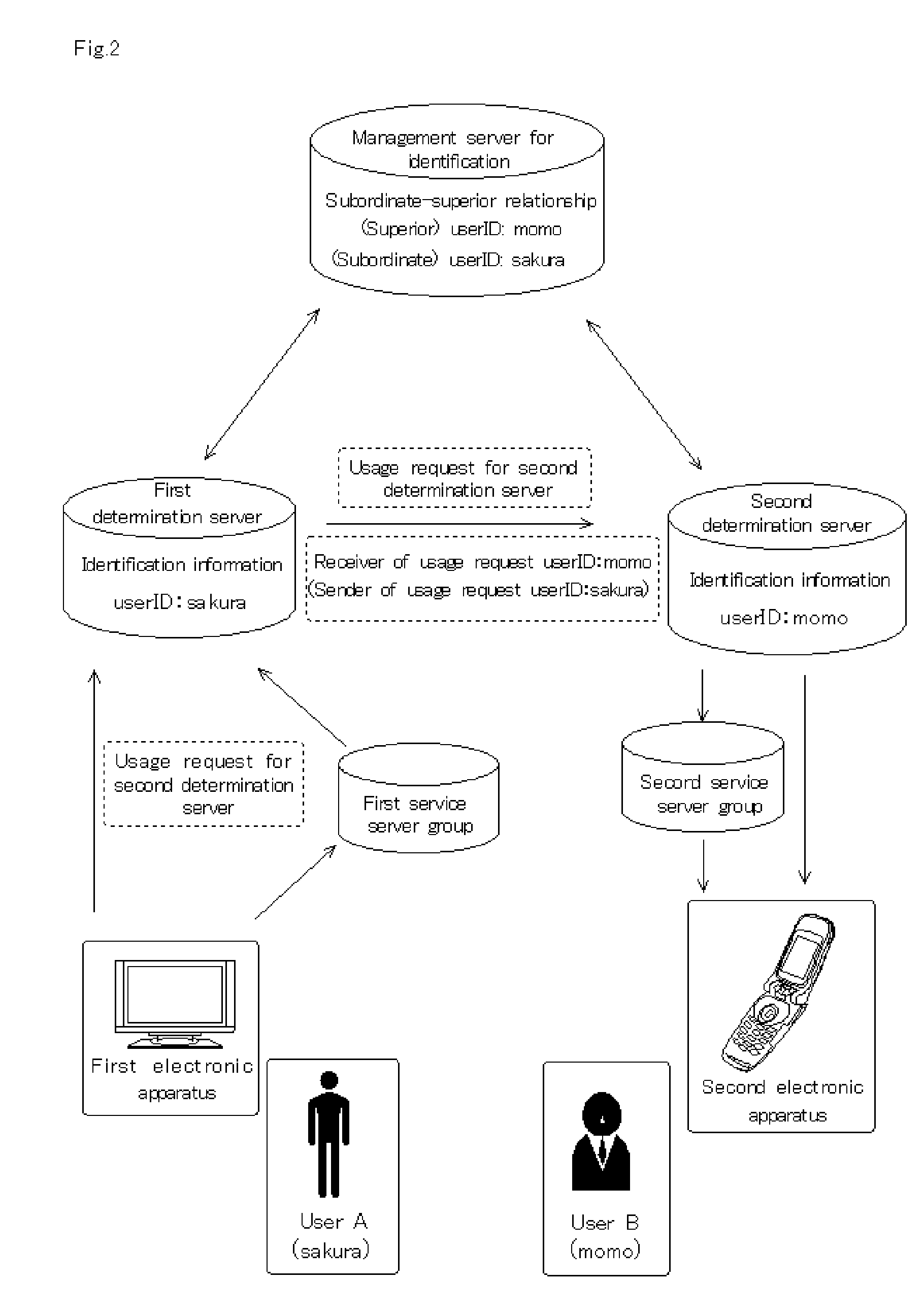

Identification managment system for electronic device authentication

InactiveUS20090165107A1Improve user friendlinessDigital data processing detailsUser identity/authority verificationSystems managementComputer science

The conventional vertical integration system management form has a problem that a first user cannot receive a service provided by a second user belonging to another service system. To cope with this, a following system is suggested. That is, according to a second judgment server use request from a first electronic device used by a first user, an identification management server which has received a guarantee request outputted from a first judgment server searches for master-slave relationship information based on a common identifier. According to the search result, a guarantee is outputted. According to the guarantee, the first judgment server outputs a guaranteed service request to the second judgment server. Thus, the first user can receive the service used by the second user belonging to other vertical integration type system.

Owner:PANASONIC CORP

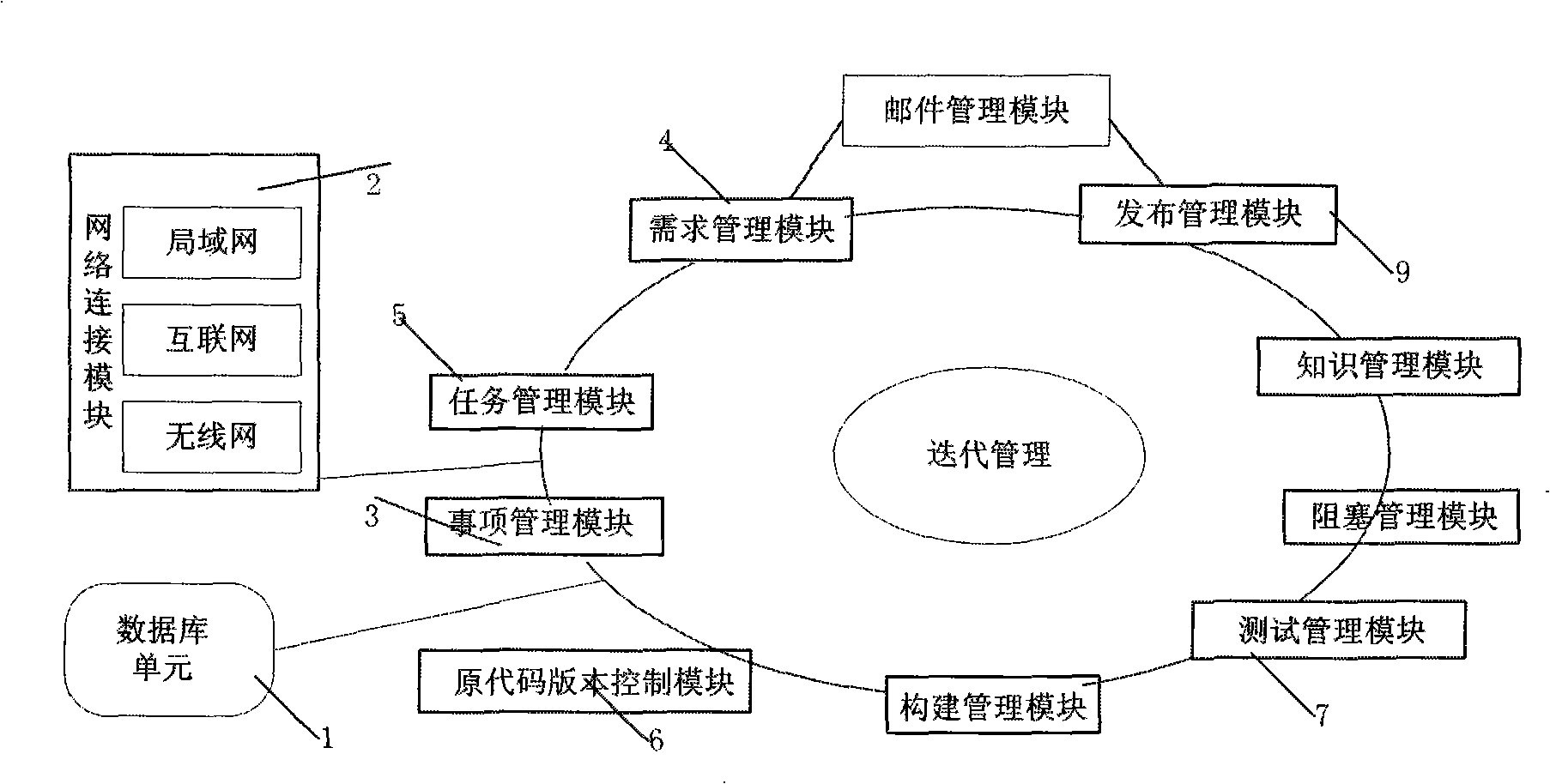

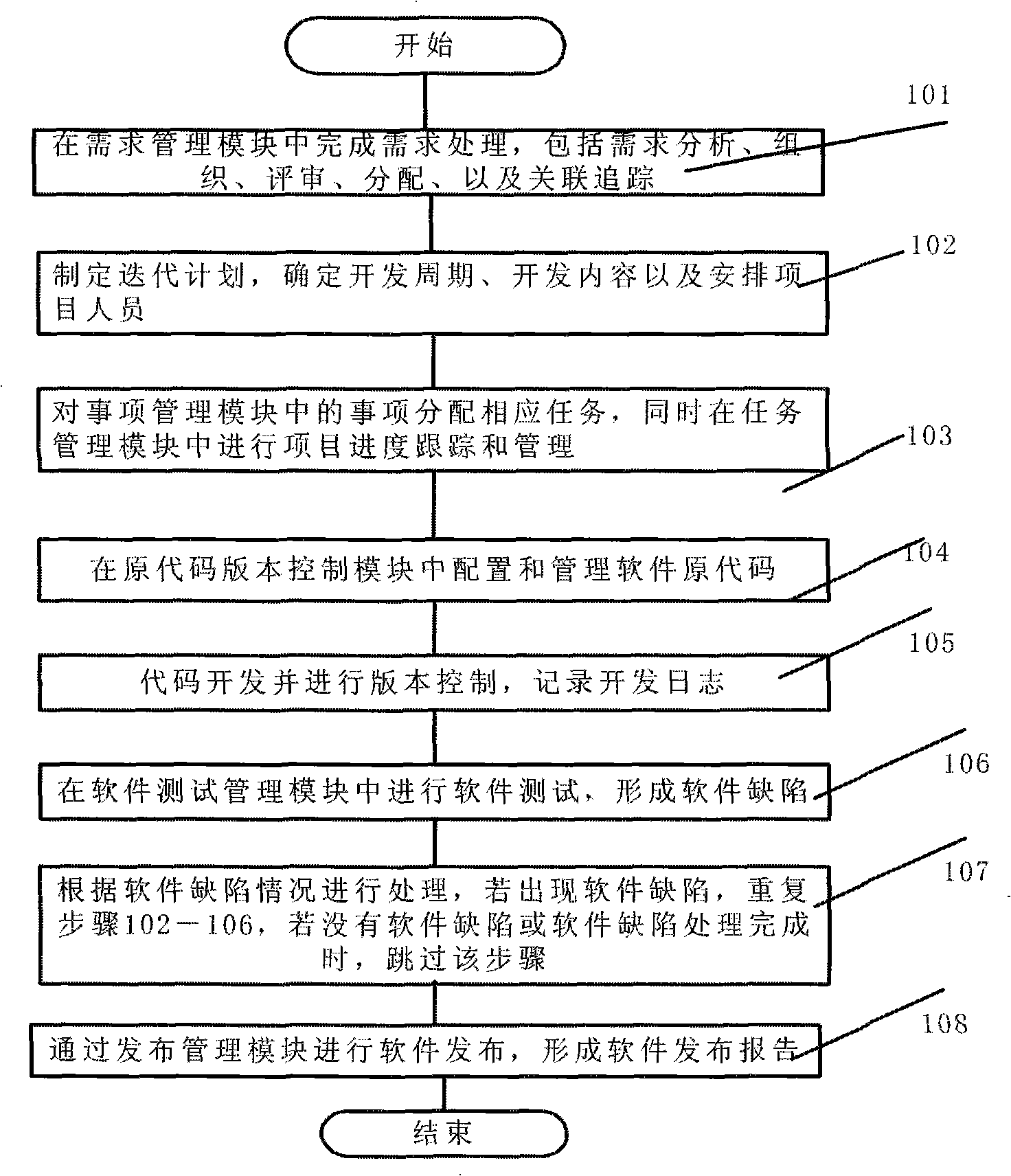

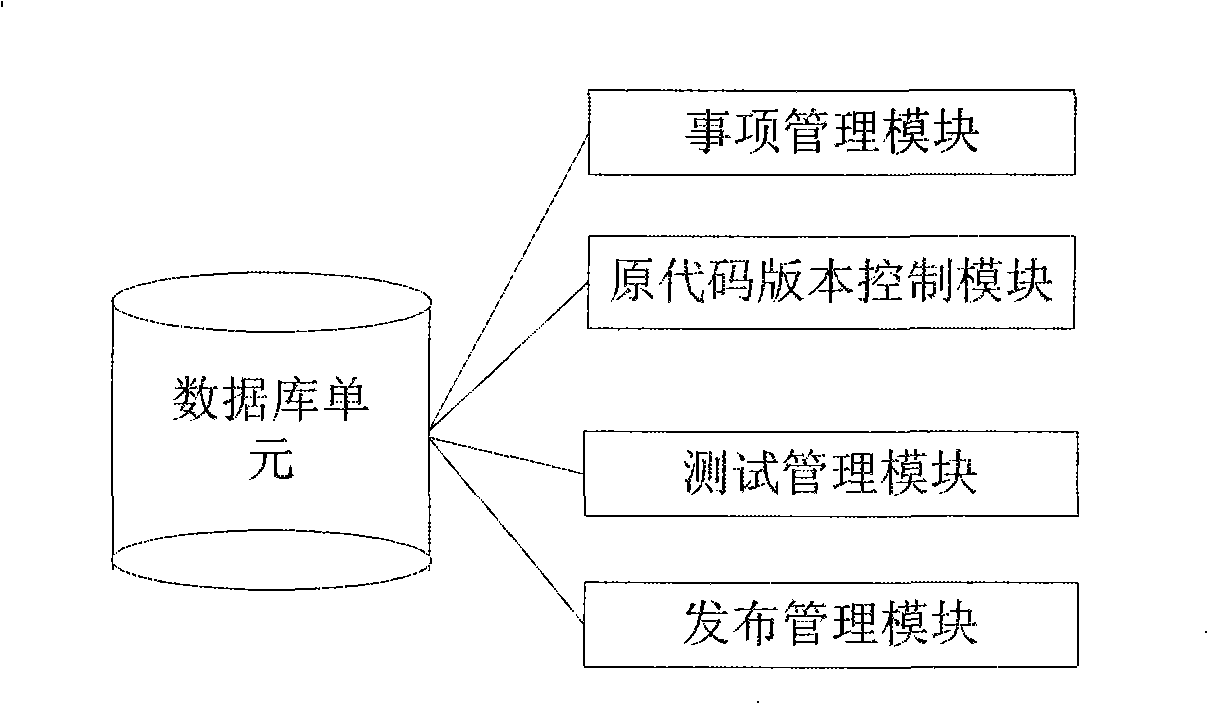

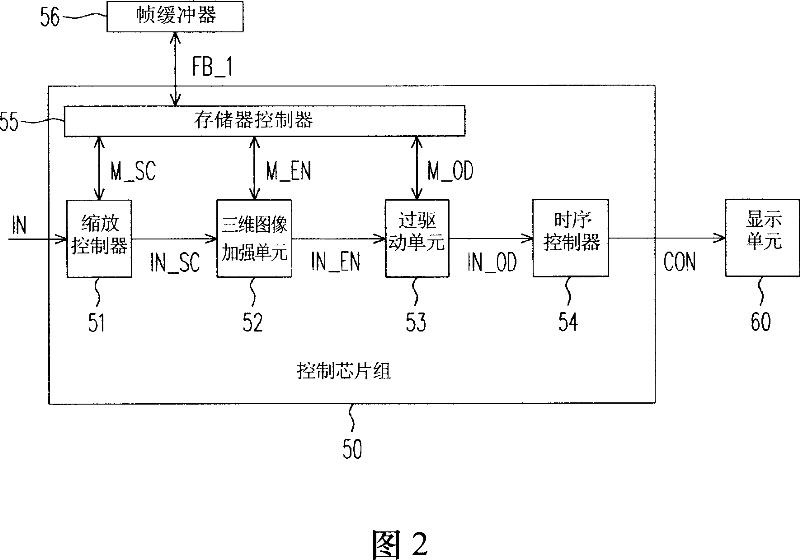

Integration type iteration software development process control system and method

InactiveCN101403965AImprove good performanceEasy maintenanceSpecific program execution arrangementsChange managementRequirements management

The invention relates to the field of software development process control and discloses a control method of the integrated iteration software development process and a method thereof. The system comprises a database unit, a demand management module, a task management module, a primary code version control module, a test management module, an item management module and a release management module; the control of the project progress is carried out under the uniform iteration development management by the relation among modules, and the software quality is ensured and the project process is controlled. The invention has the advantages that the progress of the whole software development process can be controlled, the quality is ensured and the software which can be developed is easy to expand and maintain; and the difficult problems of the integrated project changing management are solved really, especially the uniform difficult problems which exist through the software life cycle are solved in the process of iteration development management including software requirements, project progress, primary software code, software configuration, software test, software building and software release and maintenance.

Owner:SICHUAN SEVENUC SOFTWARE

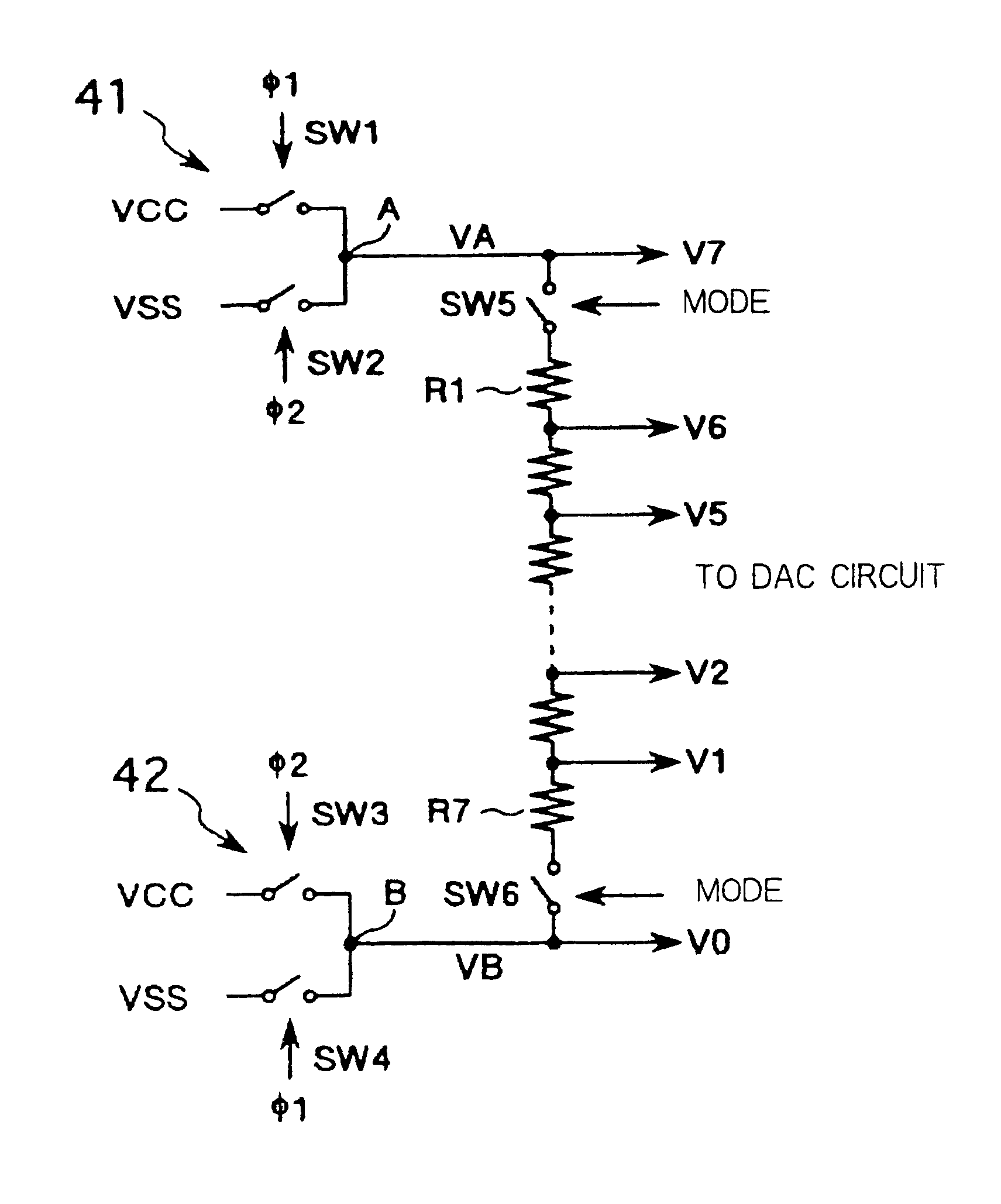

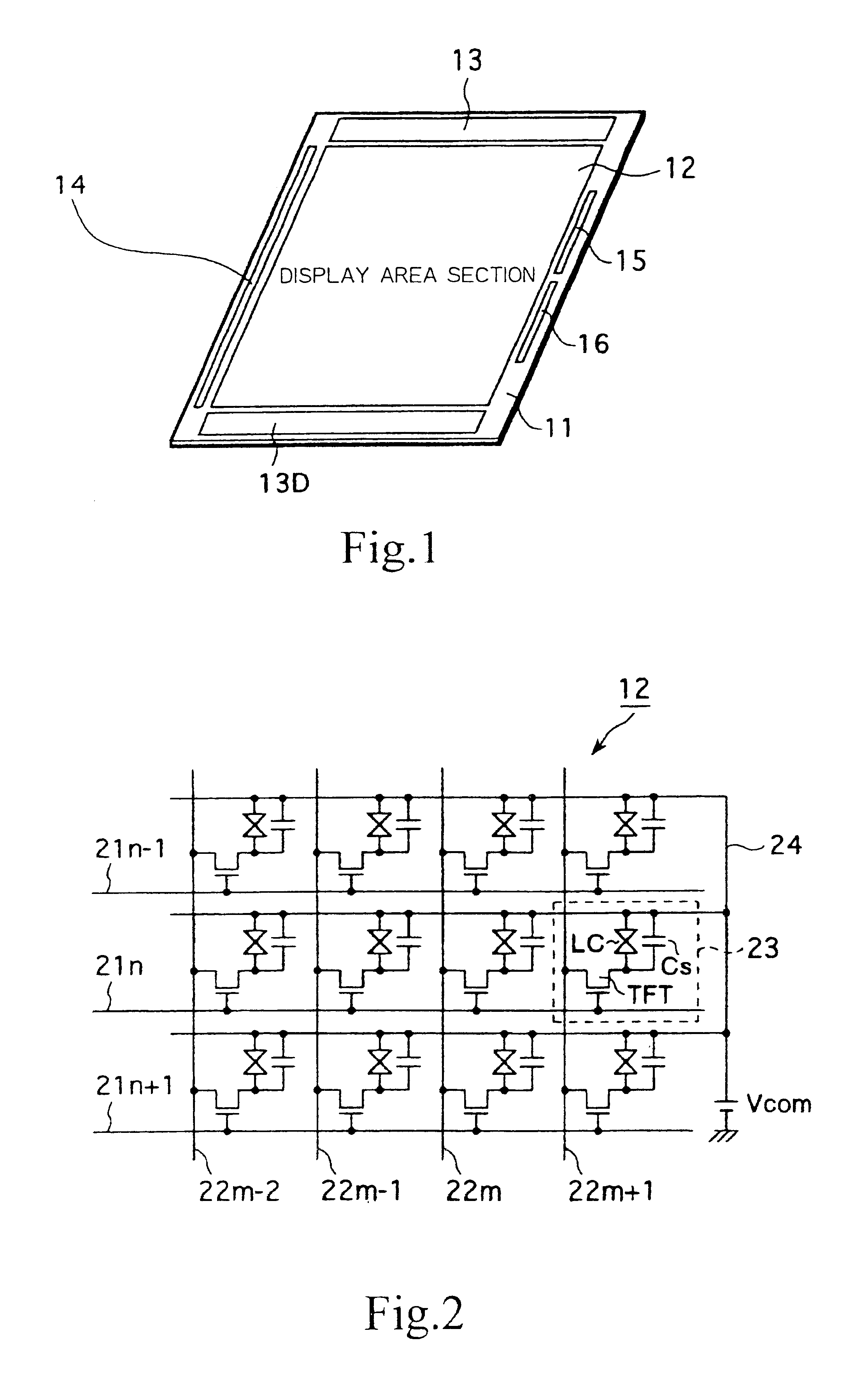

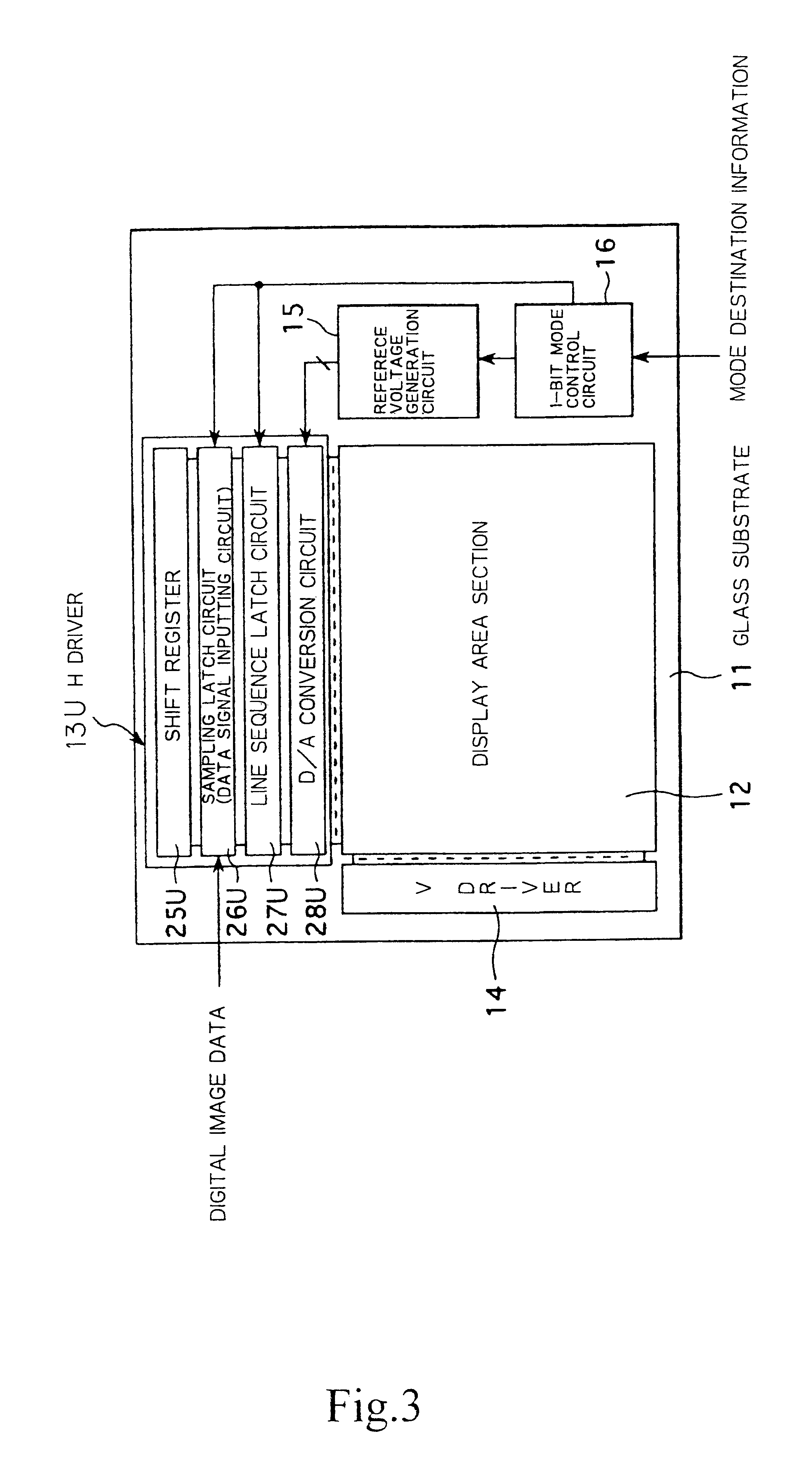

Active matrix type display apparatus and portable terminal using the same

InactiveUS6839043B2Reduce power consumptionNot consume powerStatic indicating devicesNon-linear opticsLiquid-crystal displayMode control

Owner:JAPAN DISPLAY INC

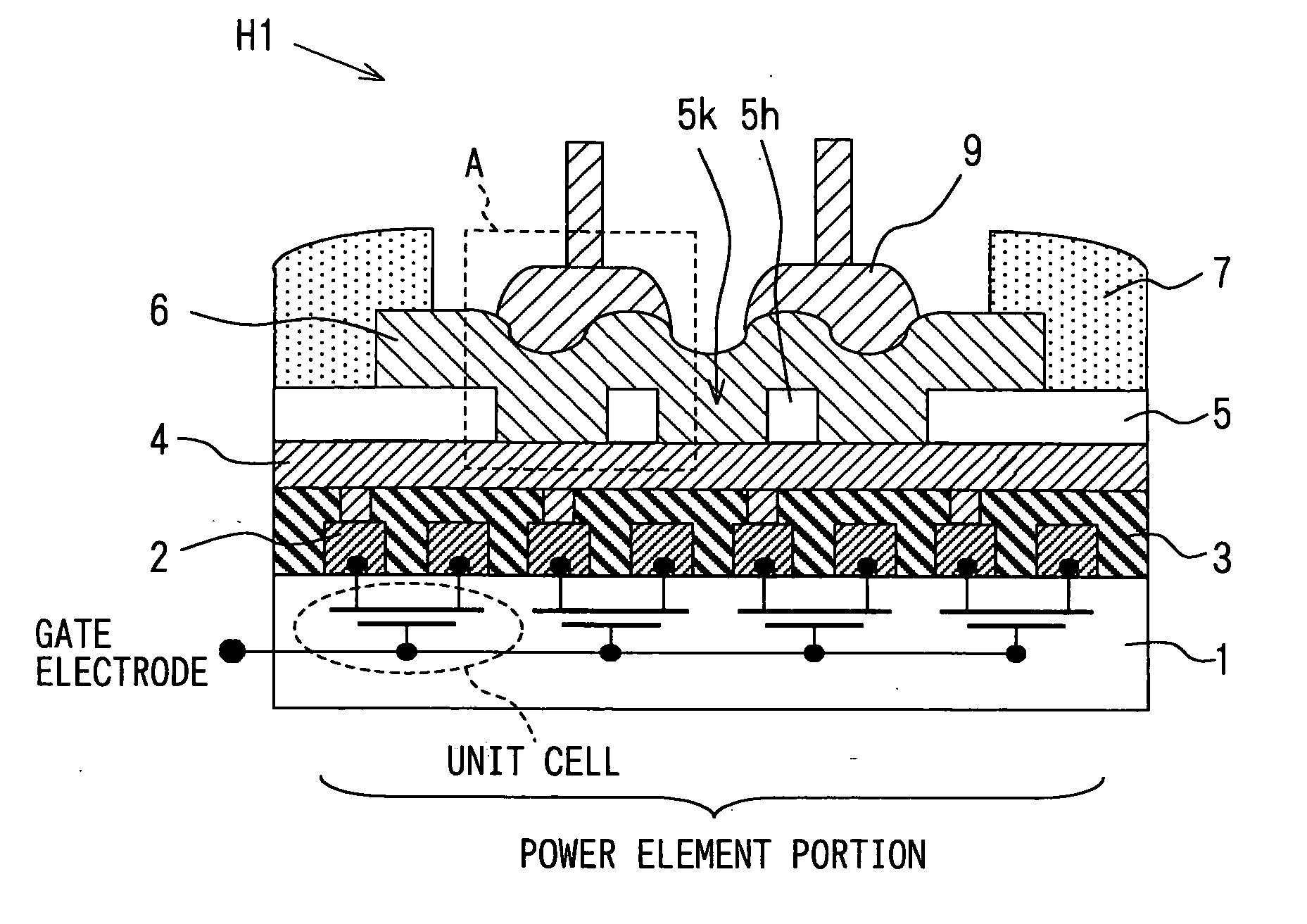

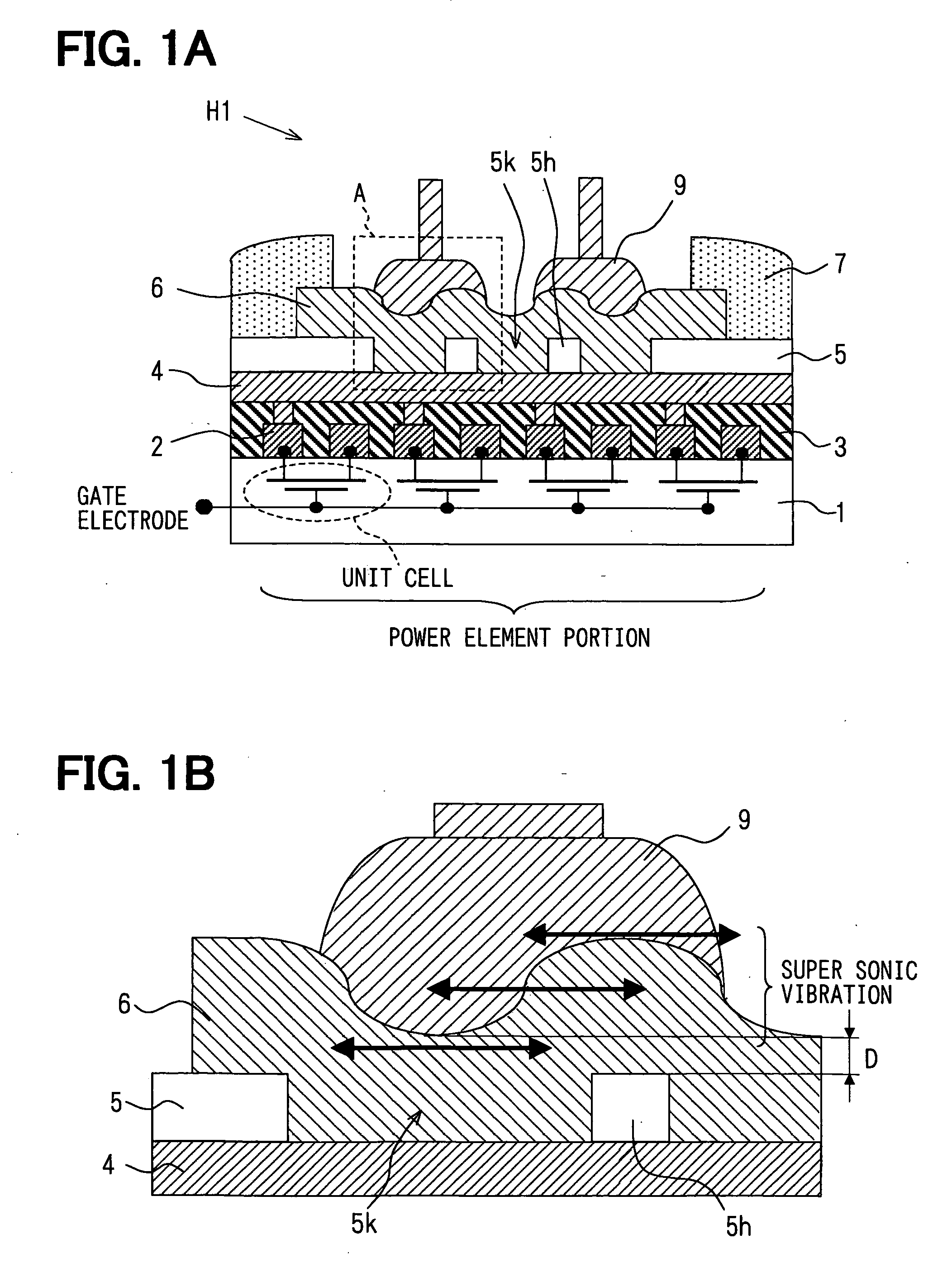

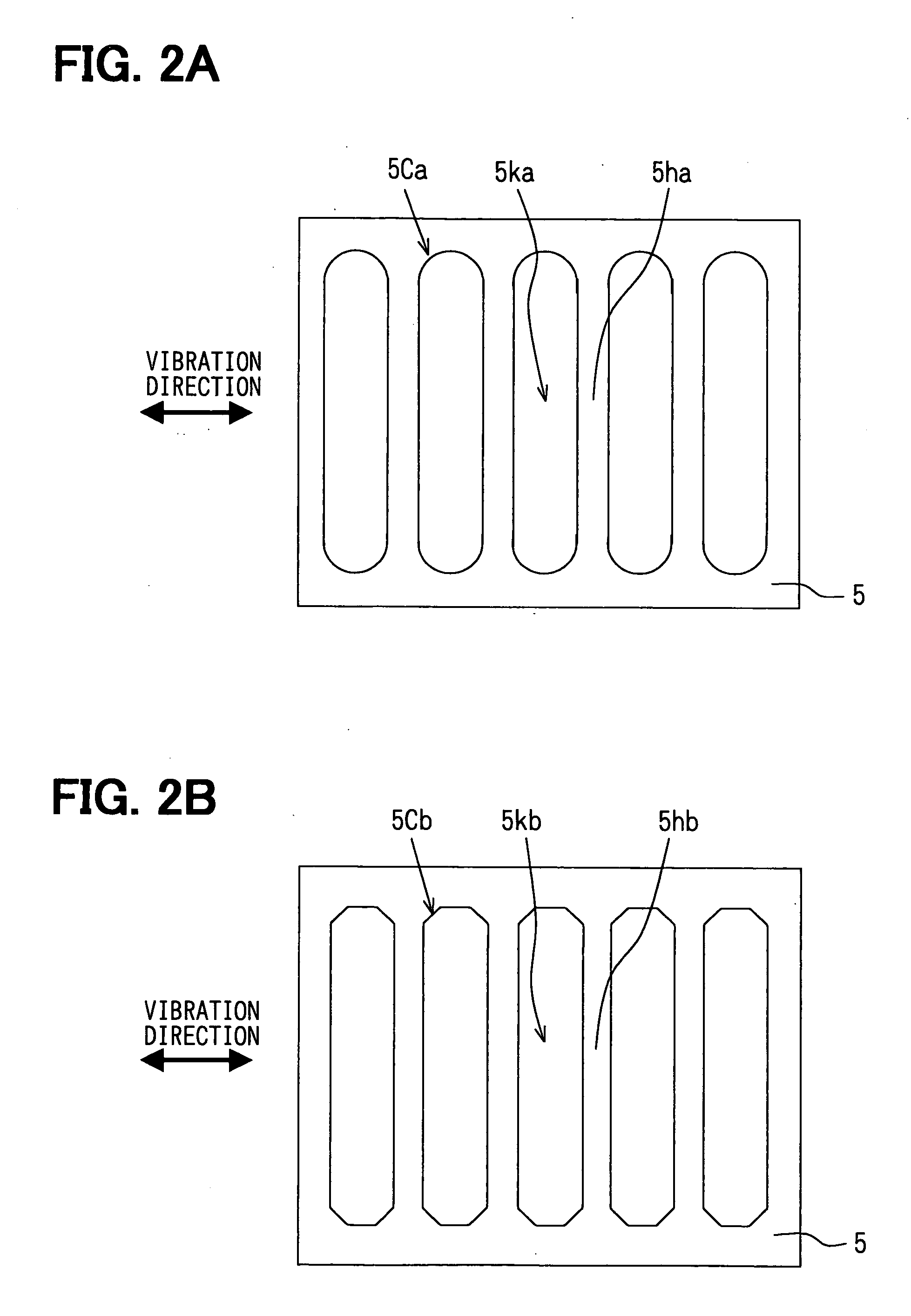

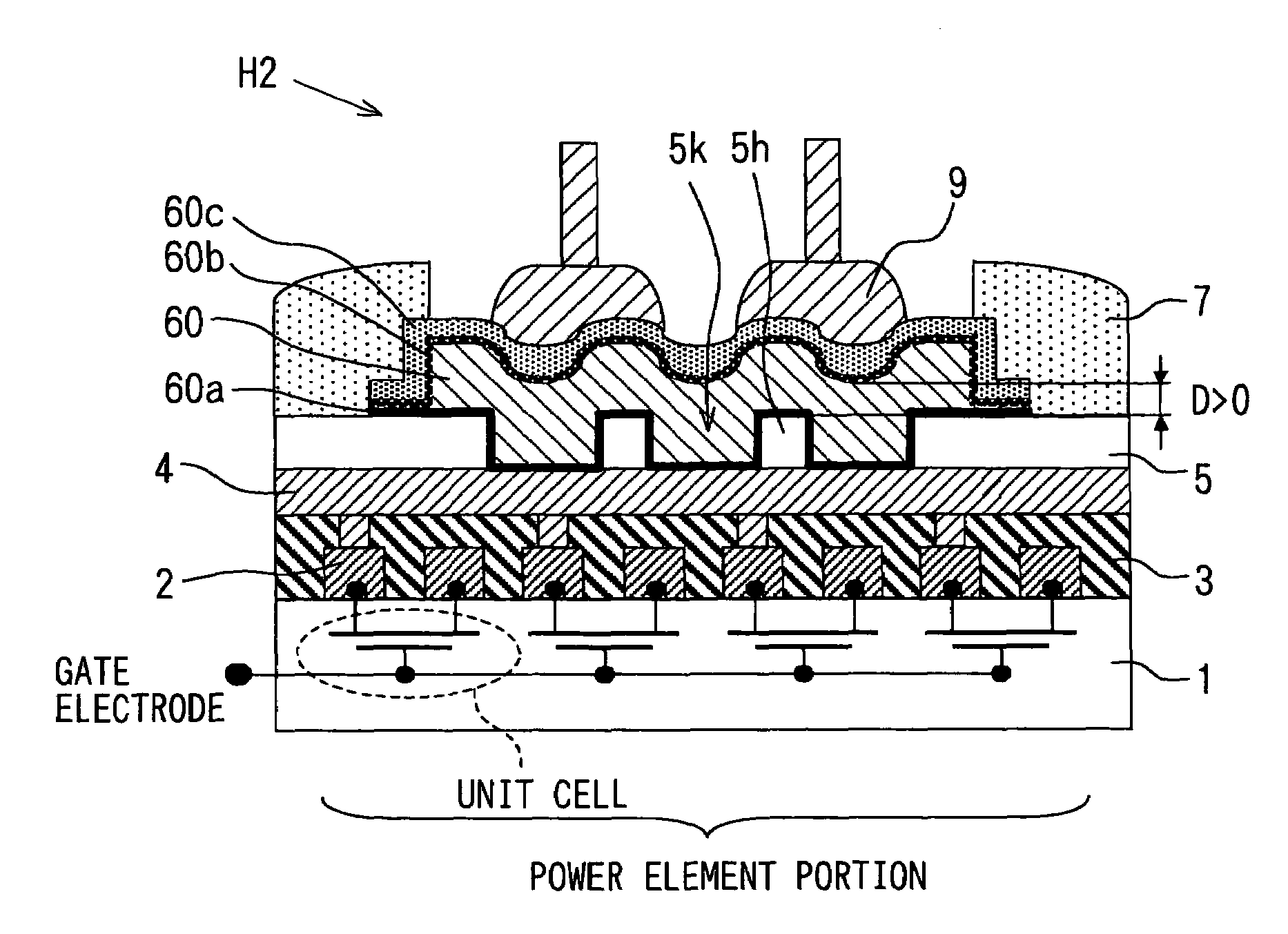

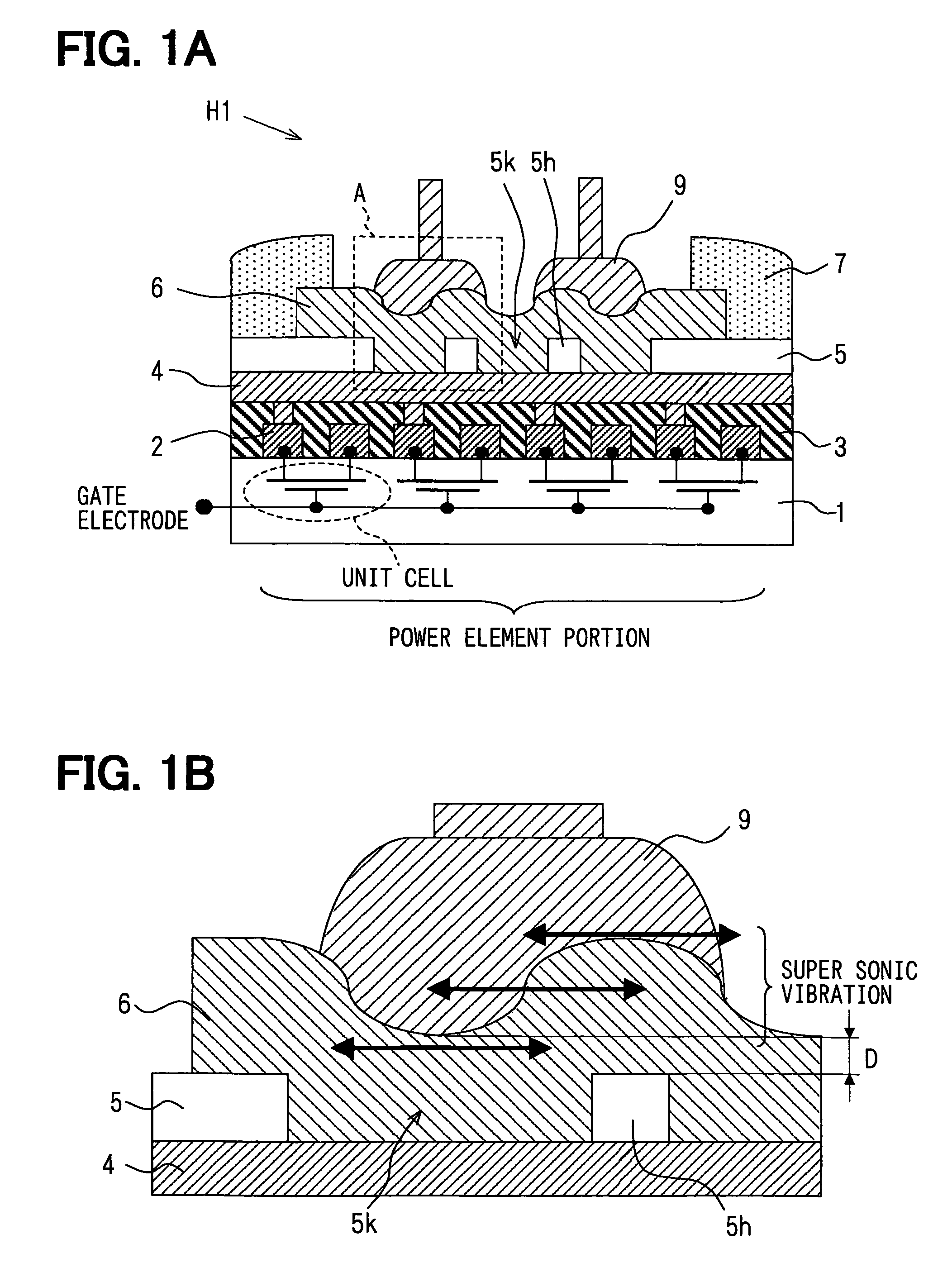

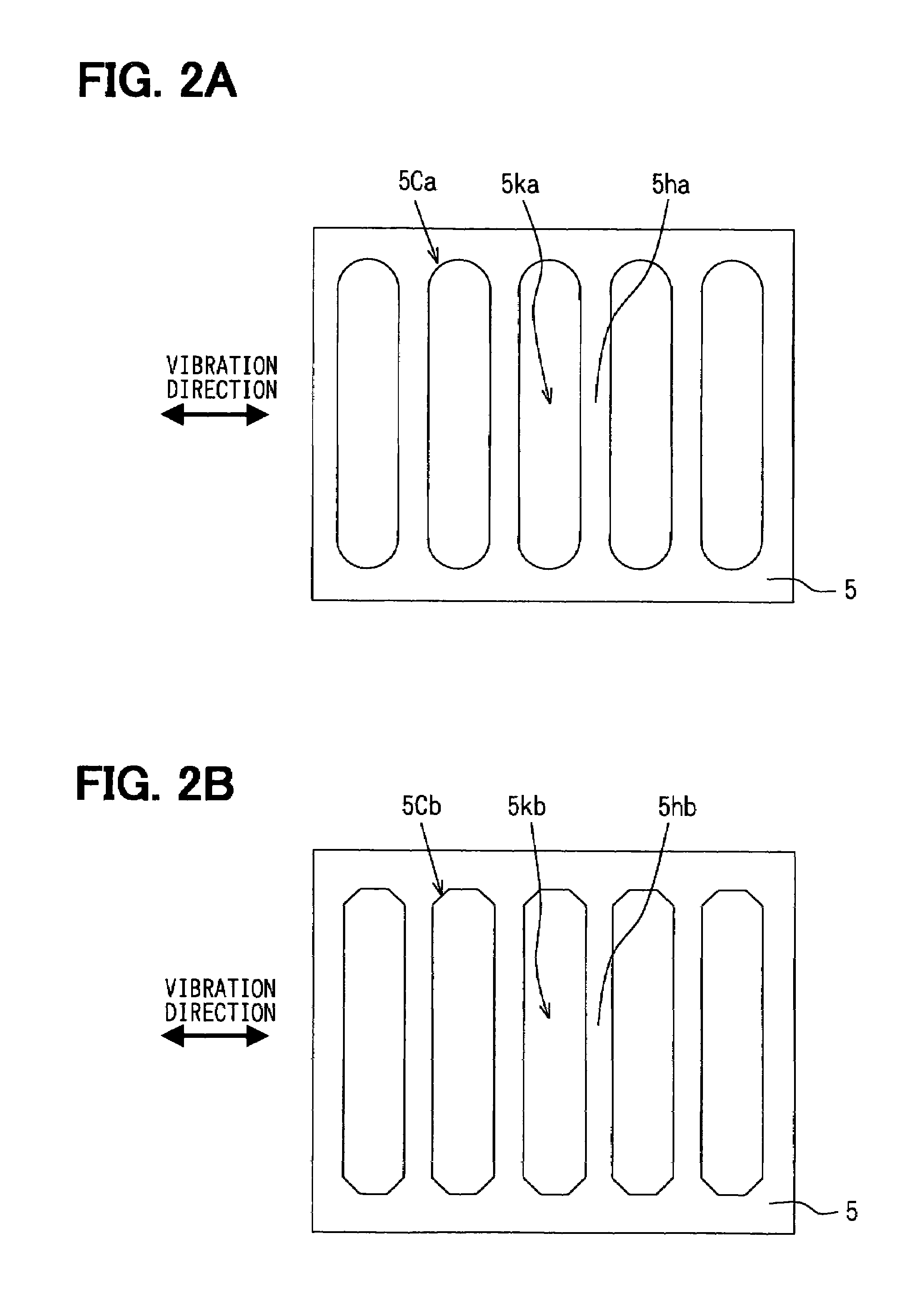

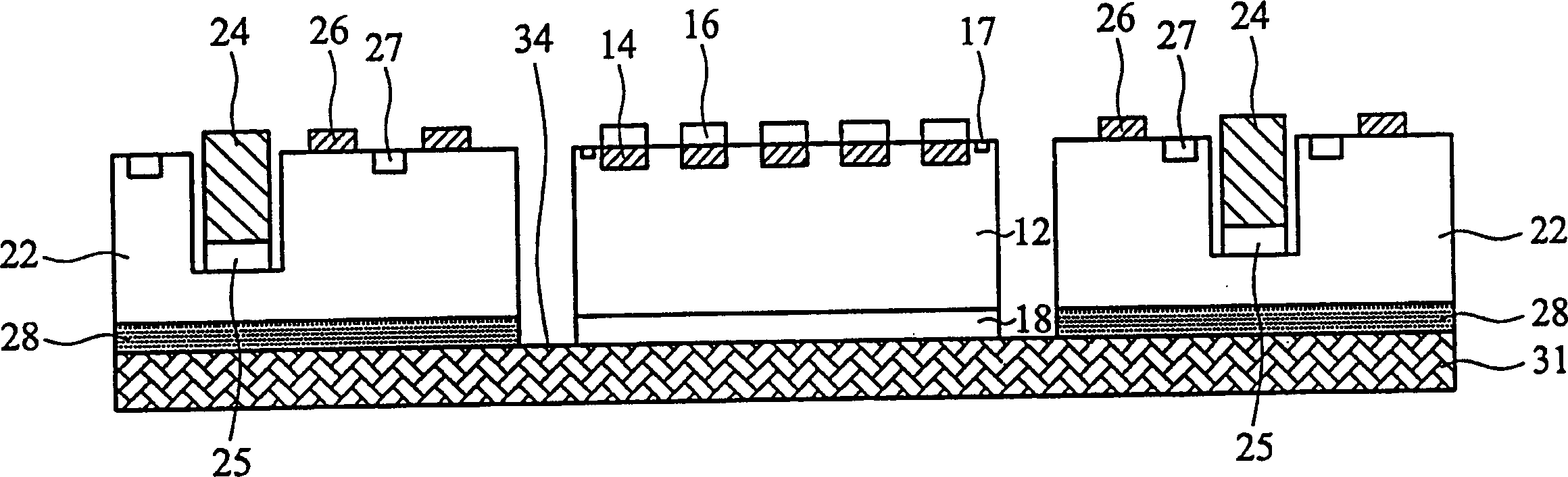

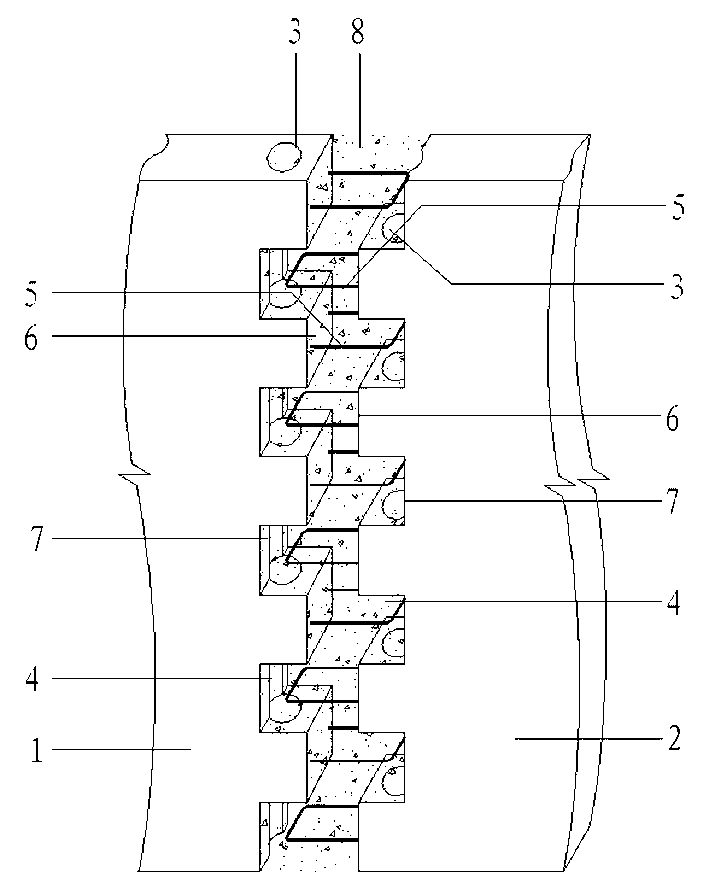

Integration type semiconductor device and method for manufacturing the same

InactiveUS20060097407A1AdhesivenessHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneEngineering

A semiconductor device includes: a plurality of power MOS cells on a semiconductor substrate; a plurality of lead wires connecting to a source and a drain of each power MOS cell through a contact hole; a plurality of collecting electrodes connecting in parallel with the lead wires through a via hole; an interlayer protection film on the collecting electrode; a thick film electrode connecting to the collecting electrode through the opening; and a terminal protection film having an opening for bonding connection. The openings are formed in the interlayer protection film such that a portion between the openings becomes a beam shape

Owner:DENSO CORP

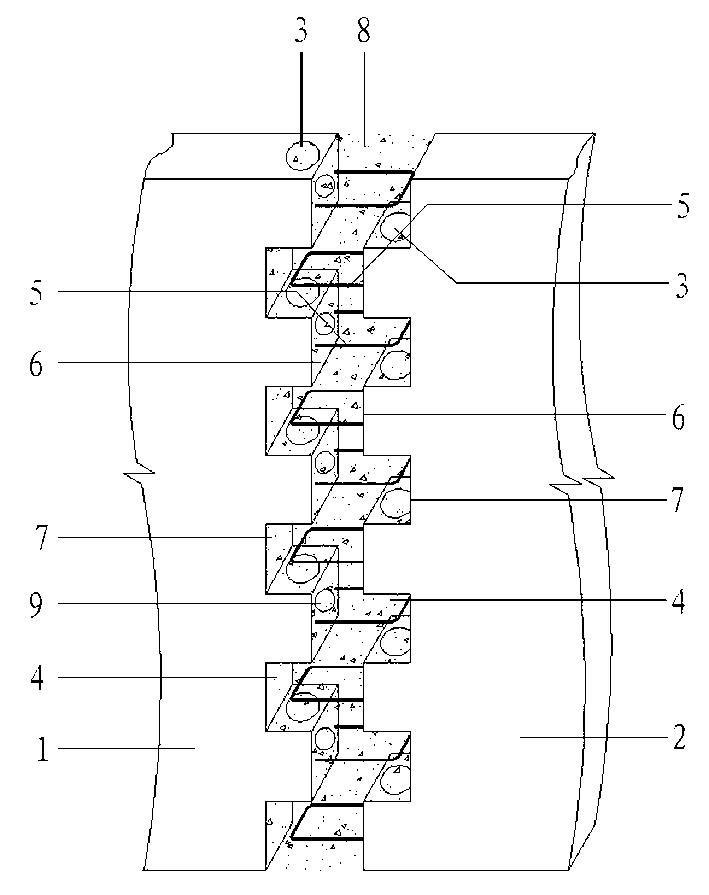

Integration type semiconductor device and method for manufacturing the same

InactiveUS7420283B2AdhesivenessHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneSemiconductor

A semiconductor device includes: a plurality of power MOS cells on a semiconductor substrate; a plurality of lead wires connecting to a source and a drain of each power MOS cell through a contact hole; a plurality of collecting electrodes connecting in parallel with the lead wires through a via hole; an interlayer protection film on the collecting electrode; a thick film electrode connecting to the collecting electrode through the opening; and a terminal protection film having an opening for bonding connection. The openings are formed in the interlayer protection film such that a portion between the openings becomes a beam shape

Owner:DENSO CORP

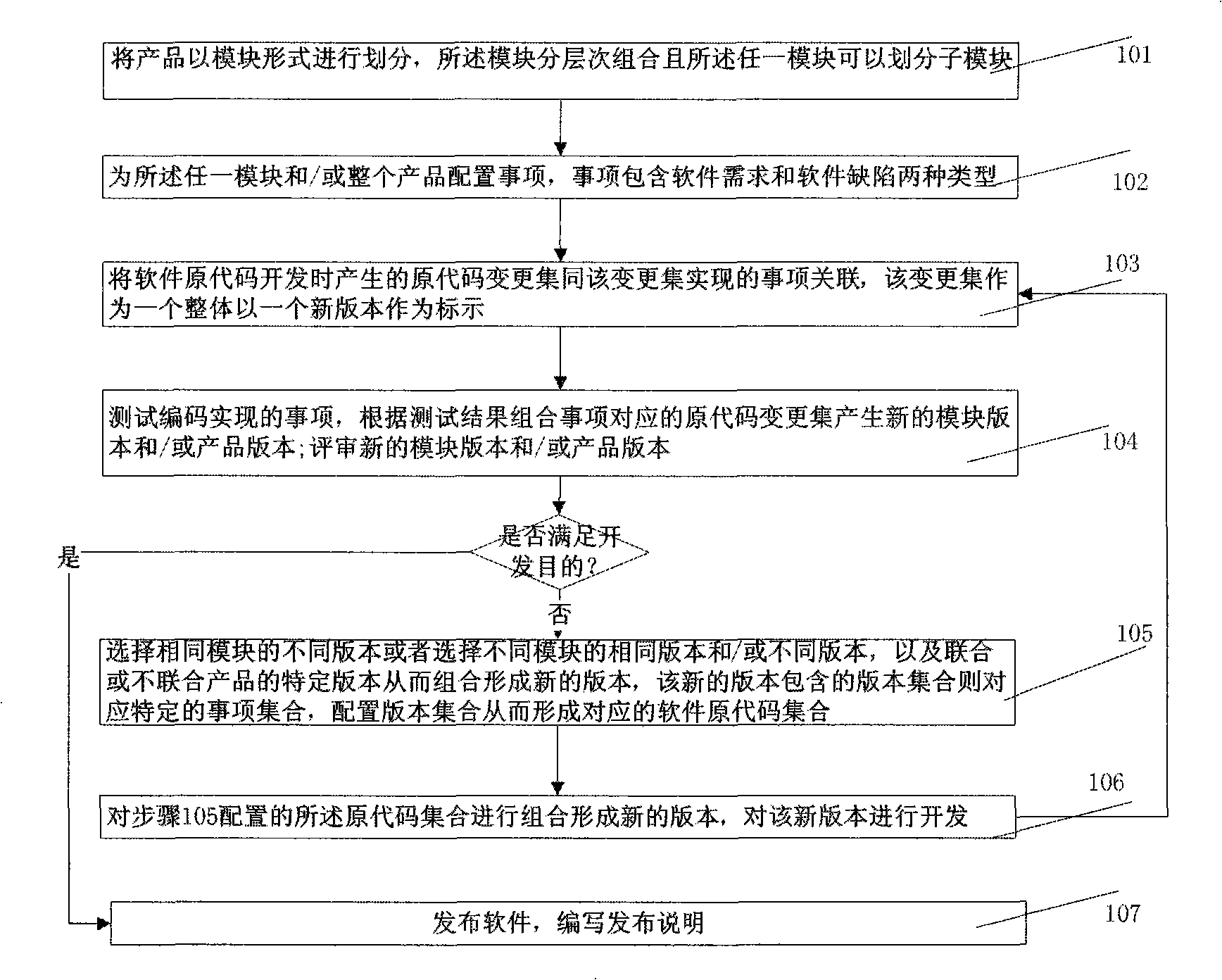

Integration type software configuration management method based on transaction management

InactiveCN101403964AEfficient testingImprove good performanceSpecific program execution arrangementsTransaction managementSoftware configuration management

The invention relates to the field of software development process control and discloses an integrated software configuration management method based on items. The method comprises the following steps: a product is divided in a form of the module; a combination product and / or a module edition form(s) a new edition, and the new edition is corresponding to specific item set; primary code changing set produced by development is related with the items realized by the changing set; the items realized by testing codes produce a new module edition and / or a new product edition; the software is released. The method has the advantages that the software configuration management is carried out by the method and the problem that the software primary code is lack of item process knowledge is solved, thus leading the developed software primary code to be easy to manage, test and release; the development process is easy to trace back and the primary code is easy to expand and maintain, the software quality can be controlled; meanwhile, the efficiency of the software development is improved, and the development cost and the maintenance cost are reduced.

Owner:SICHUAN SEVENUC SOFTWARE

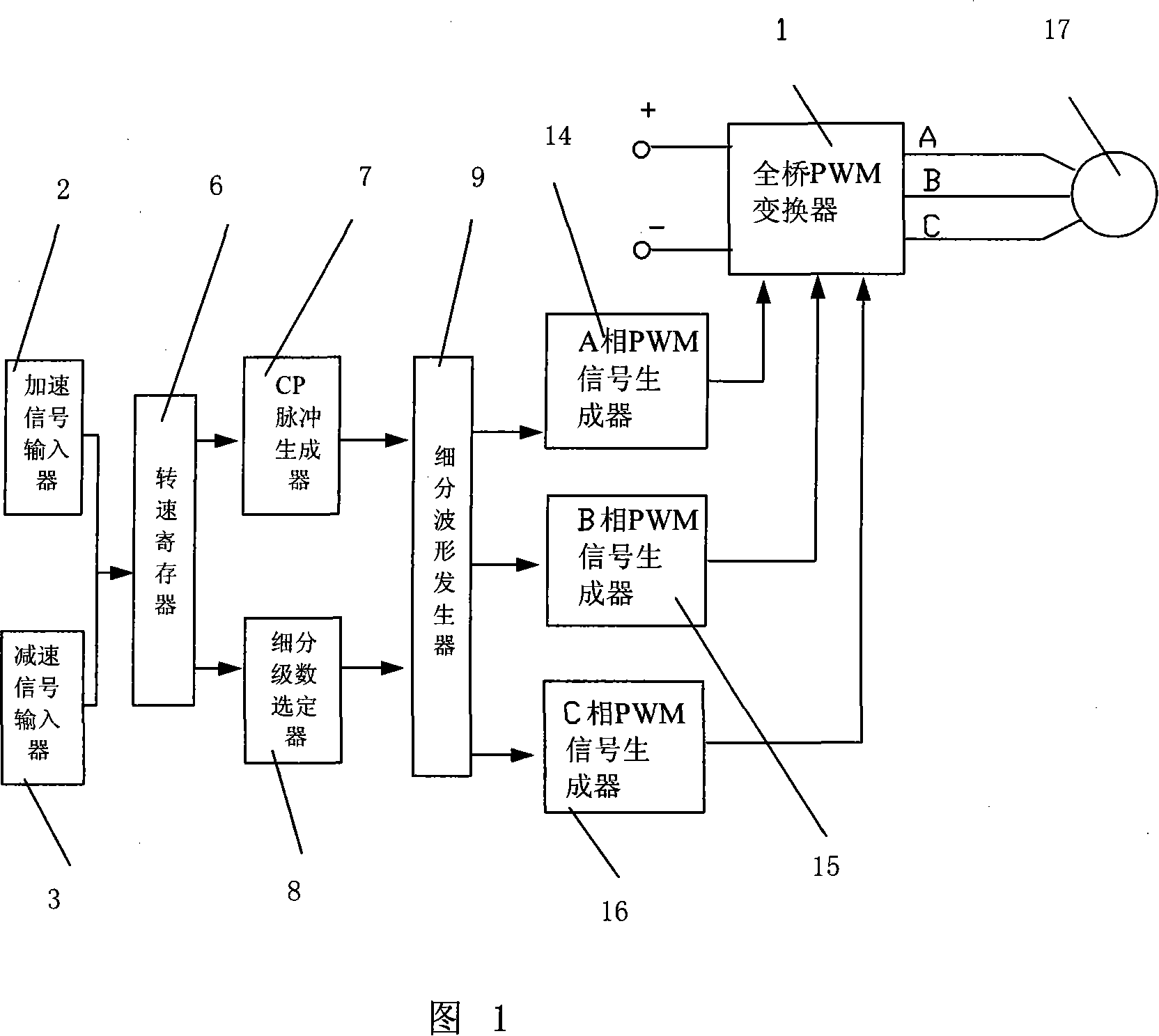

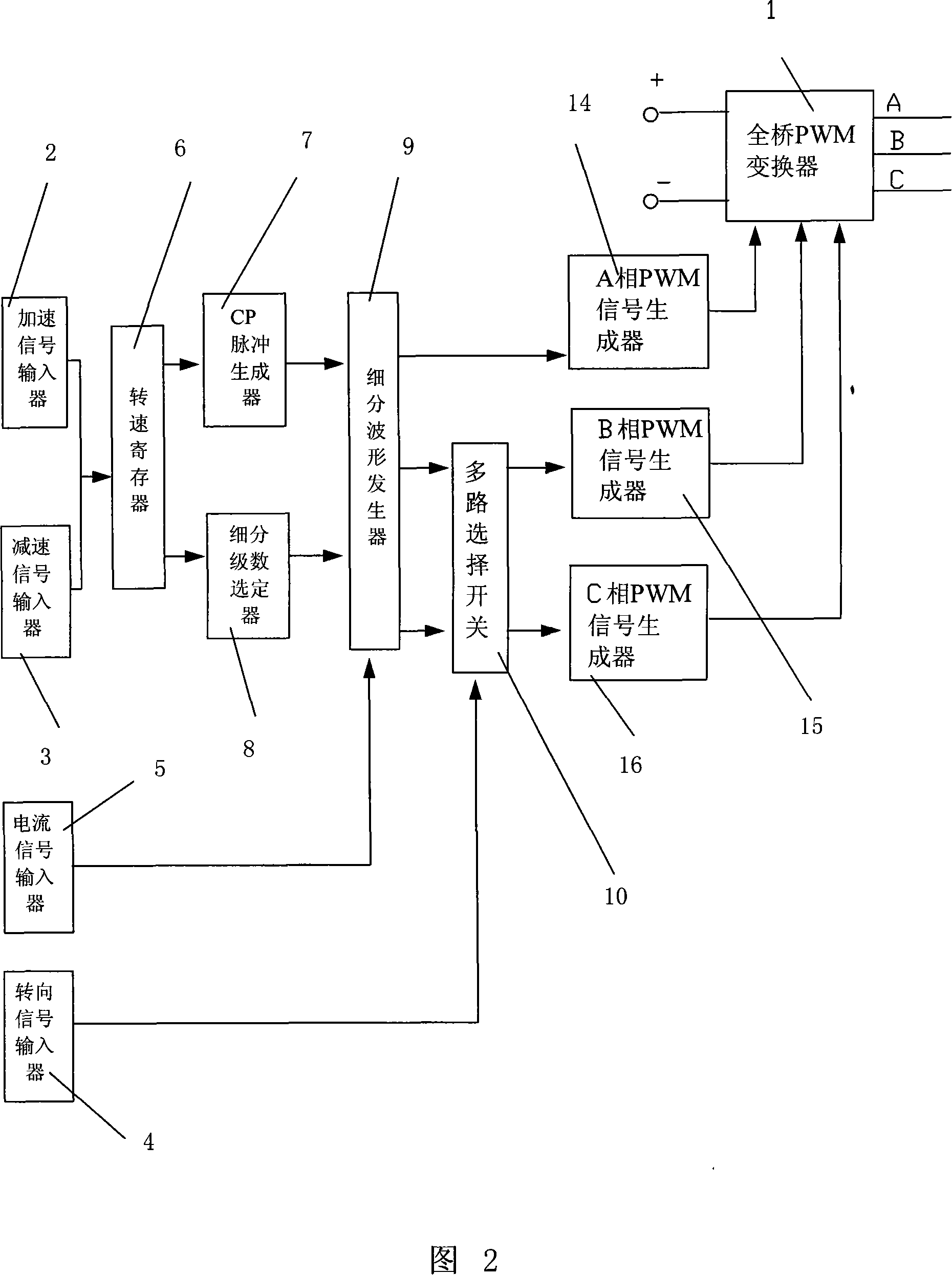

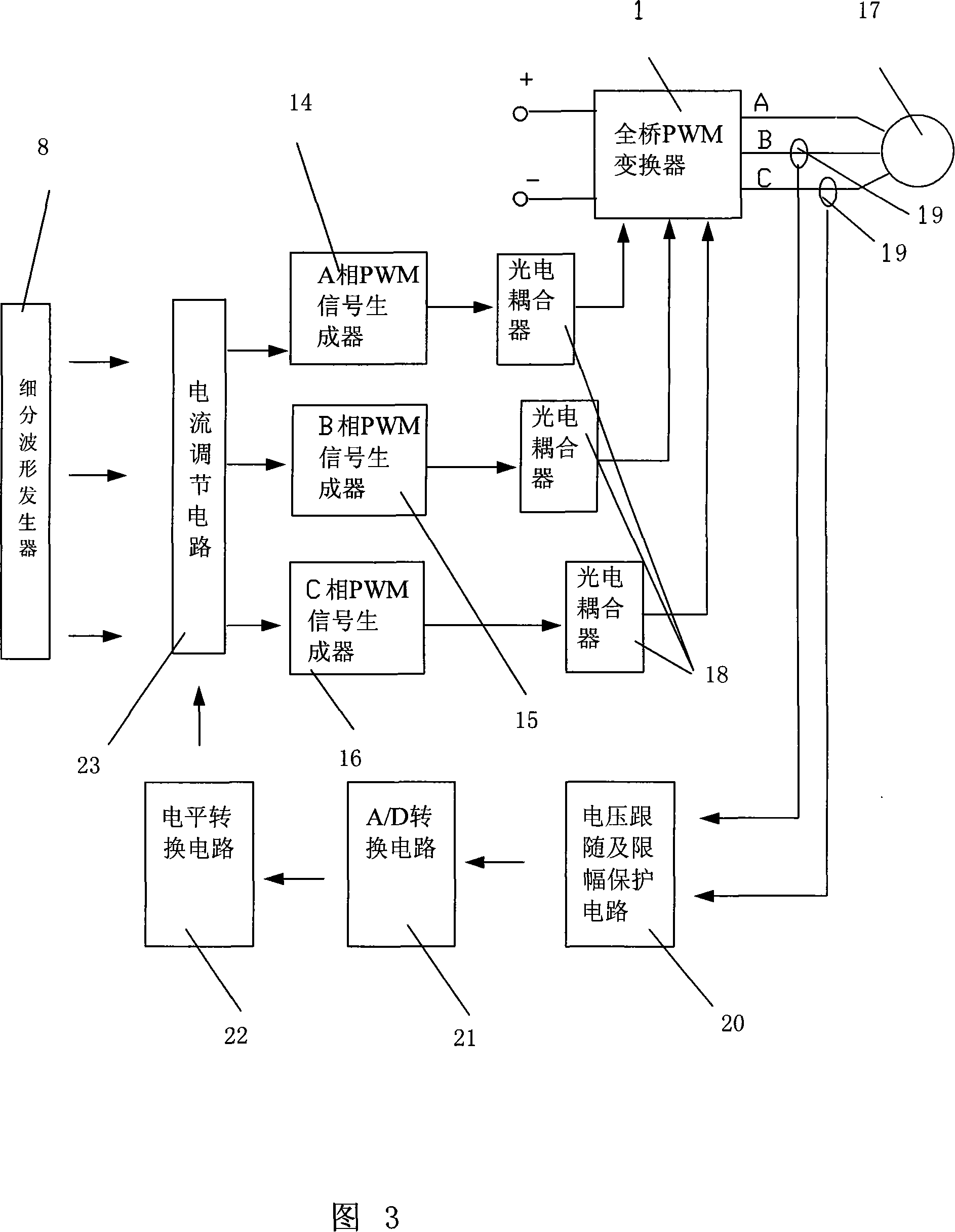

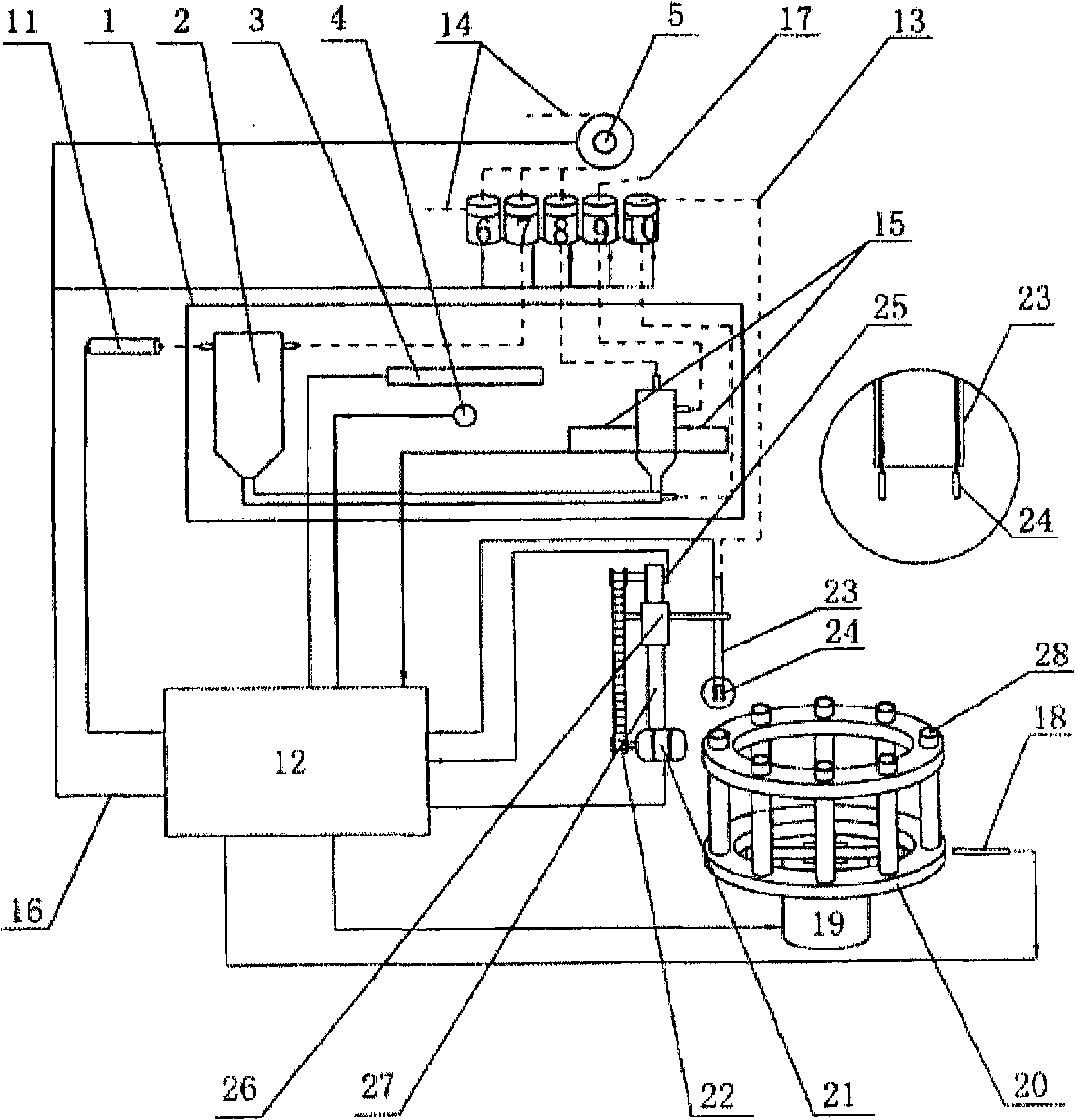

High subdivided integration type stepper motor driver

InactiveCN101119092AImprove reliabilityHigh precisionDynamo-electric converter controlPhase currentsFpga implementations

The present invention discloses a high-subdivision integrated stepper motor that relates to the drive machine of stepper motor. The present invention overcomes the shortages of low resolving capability of angular elongation caused by low subdivision, low frequency vibration and desynchronizing. The present invention consists of a full-bridge PWM converter, a speed acceleration signal input device, a speed reducing signal input device, a rotate speed register, a CP pulse generator, a subdivision wave generator and a PWM signal generator. The speed accelerating signal input device and the speed reducing signal input device choose rotate speed through adding and subtraction of numbers and choose the CP pulse frequency and motor through rotate speed and the subdivision grades of phasing current sinusoidal waveform, the subdivision waveform generator output each phasing current sinusoidal waveform after divided by chosen subdivision grades according to the arriving frequency of CP pulse. Then each phase of PWM signal is formed. The above control circuit is formed on the basis of FPGA and the division of the sinusoidal waveform according to time order is from 16 to 4096.

Owner:HARBIN INST OF TECH

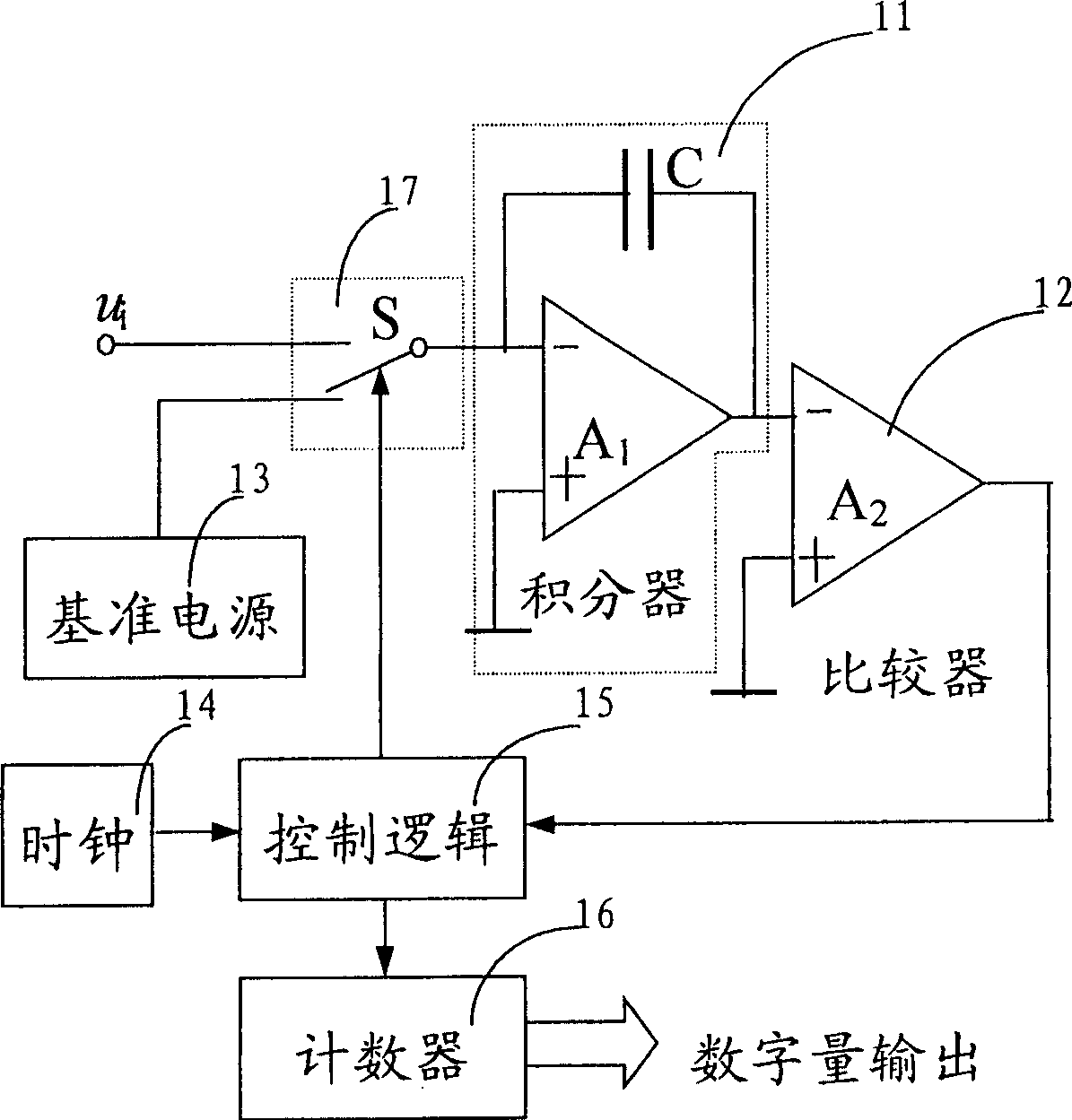

Integrating A/D convertion method and its A/D converter

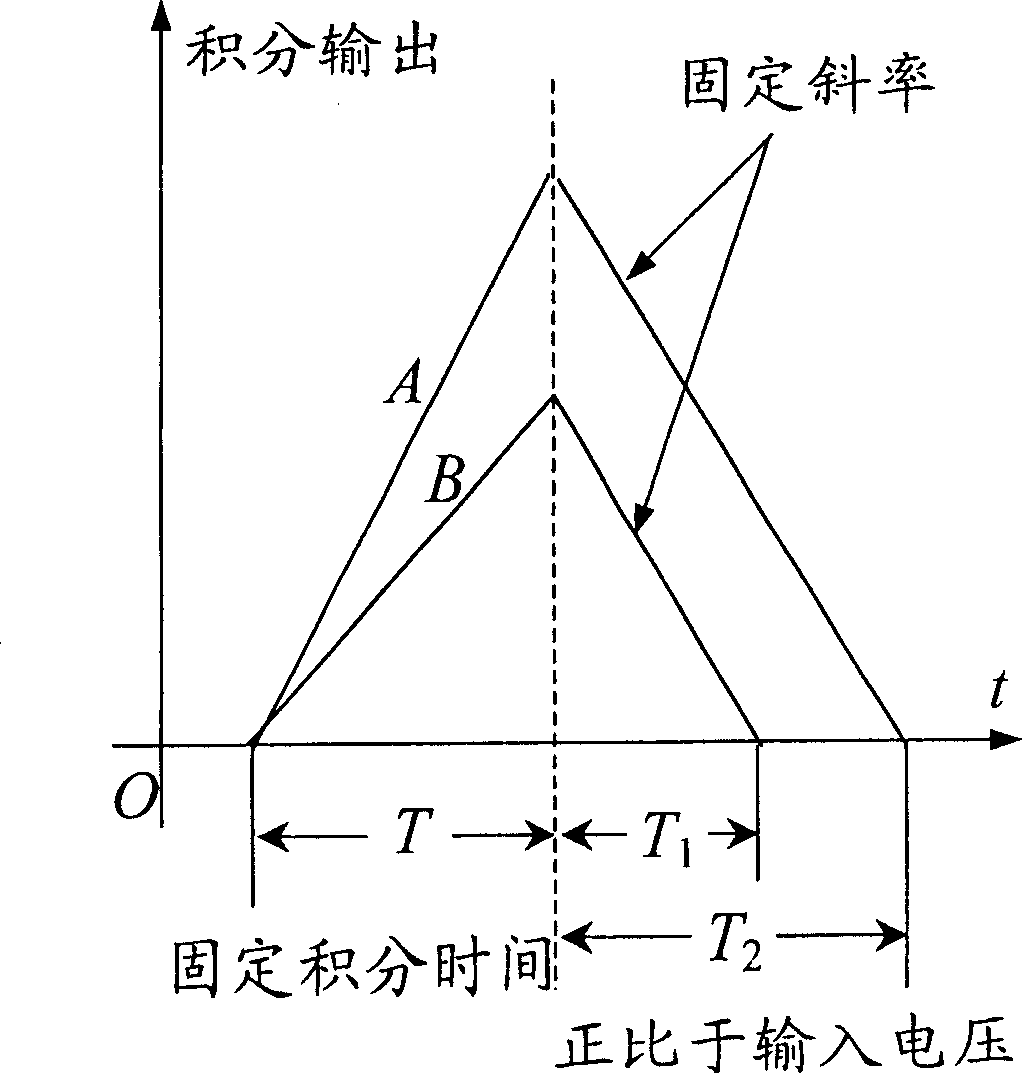

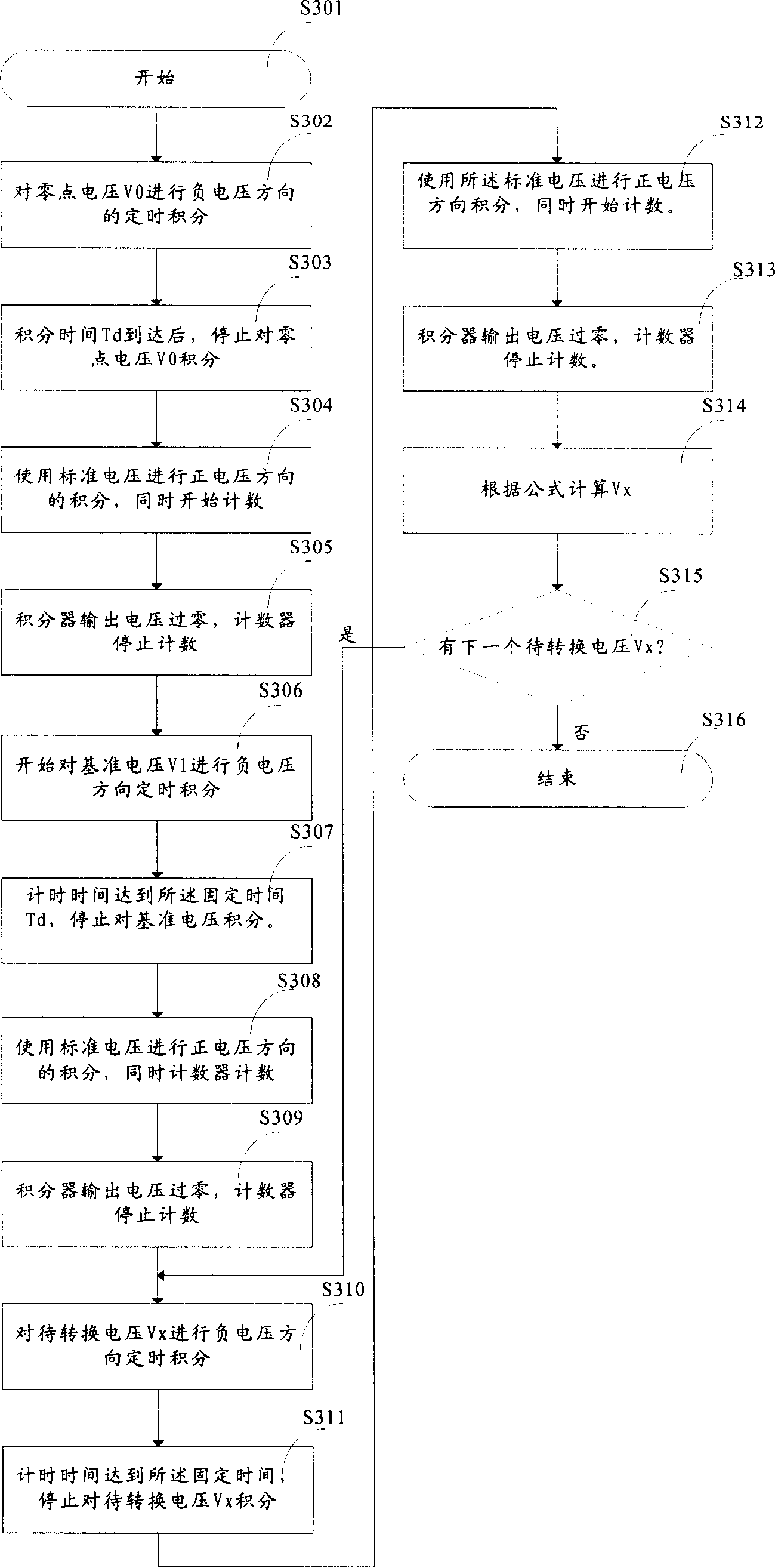

InactiveCN1822506AAvoid differencesExclude positive integral countsElectric signal transmission systemsAnalogue-digital convertersIntegratorBuck converter

An integration type A / D converting method includes 11 ) making bidirectional integration to zero voltage V 0 and standard voltage Vb, obtaining count value T0, 12 ) making bidirectional integration to reference voltage V 1 and standard voltage Vb, obtaining count value T1, 13 ) making bidirectional integration to switching voltage Vx and standard voltage Vb, obtaining count value Tx, 14 using formulae Vx = ( V 1- 1- V 0 ) ( Tx - t 0 ) / ( t 1- 1- t 0 ) + V 0 to calculate switching voltage Vx value. Bidirectional integration in Above-mentioned steps includes following steps: 1, to proceed positive direction timing integration to 0 or V 1 or Vx, timing time being the fixed time Td when integrating circuit output voltage passing zero, 2, stopping integration when reaching integration time Td, beginning reversal integration to integrator adopting standard voltage Vb, at the same time counter beginning counting, 3, when integrator output voltage passing zero, generating triggering signal to stop counter counting, respectively obtaining count value T0, T1 or Tx corresponding to voltage V 0, V 1 or Vx. Said invention also discloses A / D converter to realize above-mentioned method.

Owner:SUPCON GRP +1

Internal fiber integration type miniature Michelson interferometric sensor and manufacturing method thereof

ActiveCN101614601AEasy to makeLow costThermometers using physical/chemical changesCoupling light guidesInterferometric sensorElectromagnetic interference

The invention discloses an internal fiber integration type miniature Michelson interferometric sensor and a manufacturing method thereof. The sensor comprises two single mode fibers with different external diameters and the same core diameters; the single mode fiber with small external diameter is fusion-jointed on the single mode fiber with large external diameter by axis dislocation; the core parts of the two single mode fibers are overlapped; the uncovered part of the end face of the core of the single mode fiber with large external diameter is the reflecting surface of a reference arm; the core end of the exposed end of the single mode fiber with small external diameter is the reflecting surface of a measuring arm; the cores of the two fibers are made of SiO2. The sensor has the beneficial technical effects of simple manufacturing, low cost, small volume, good electromagnetic interference resistance, good high temperature resistance and good electric insulativity.

Owner:SICHUAN GUANGSHENG IOT TECH CO LTD

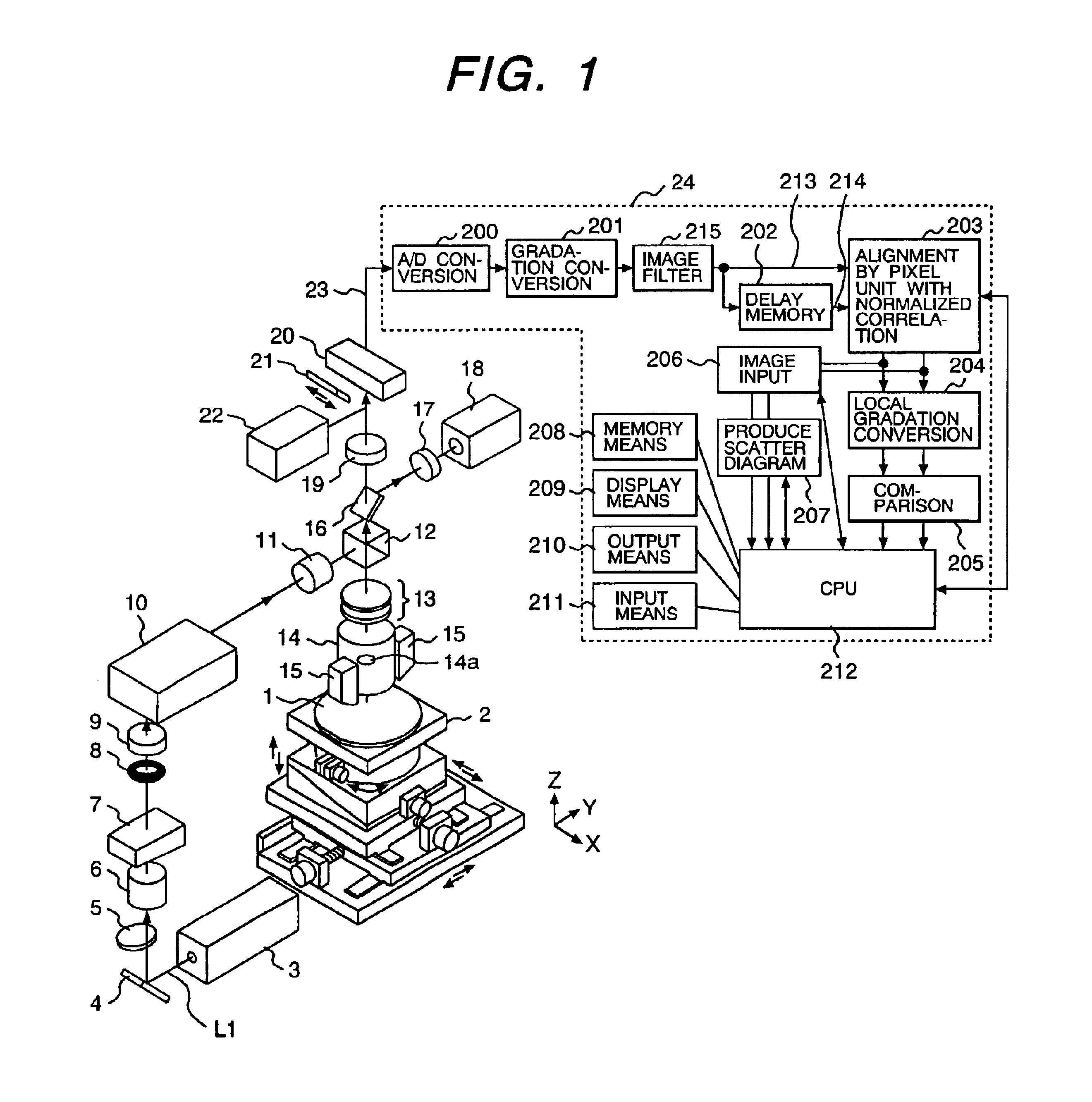

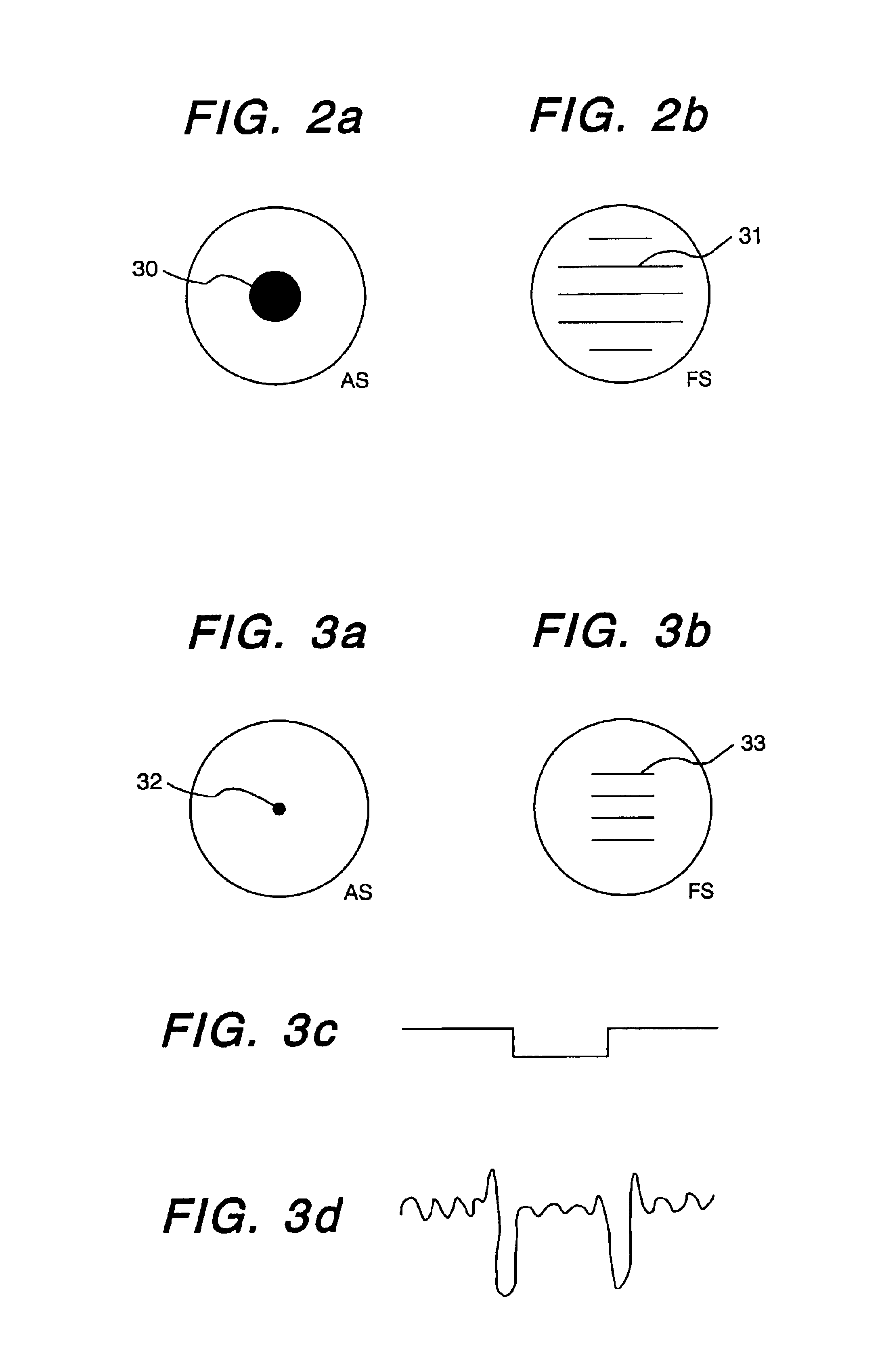

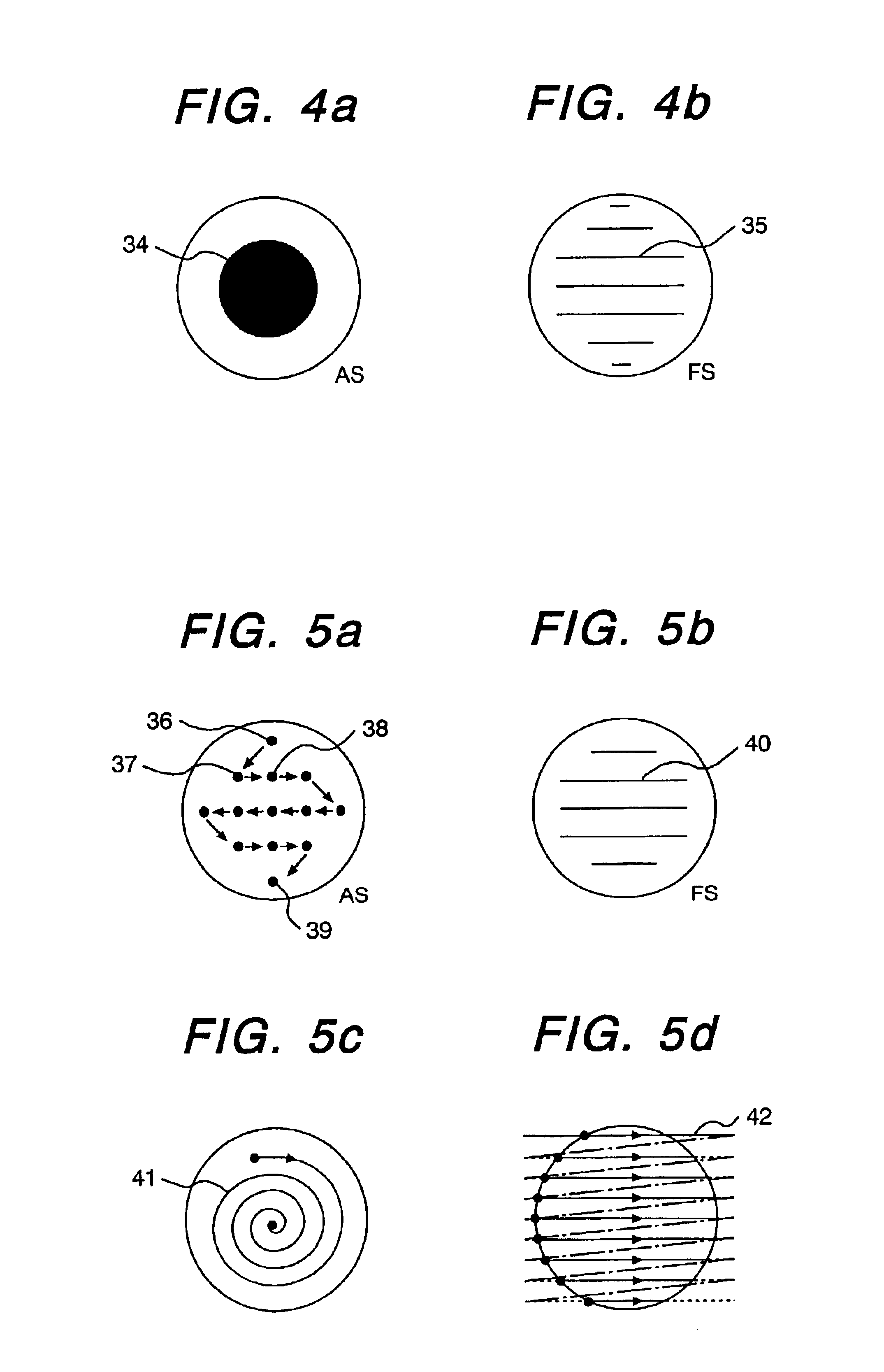

Method and apparatus for inspecting pattern defects

An apparatus for inspecting pattern defects on microscopic circuit patterns, with high resolution, comprises: an objective lens for detecting an image of a sample; a UV laser beam illumination arrangement for illuminating onto a pupil of the objective lens; am arrangement for lowering coherency of the UV laser illumination; a detector of integration type; and an arrangement for processing detected signal thereof.

Owner:HITACHI LTD

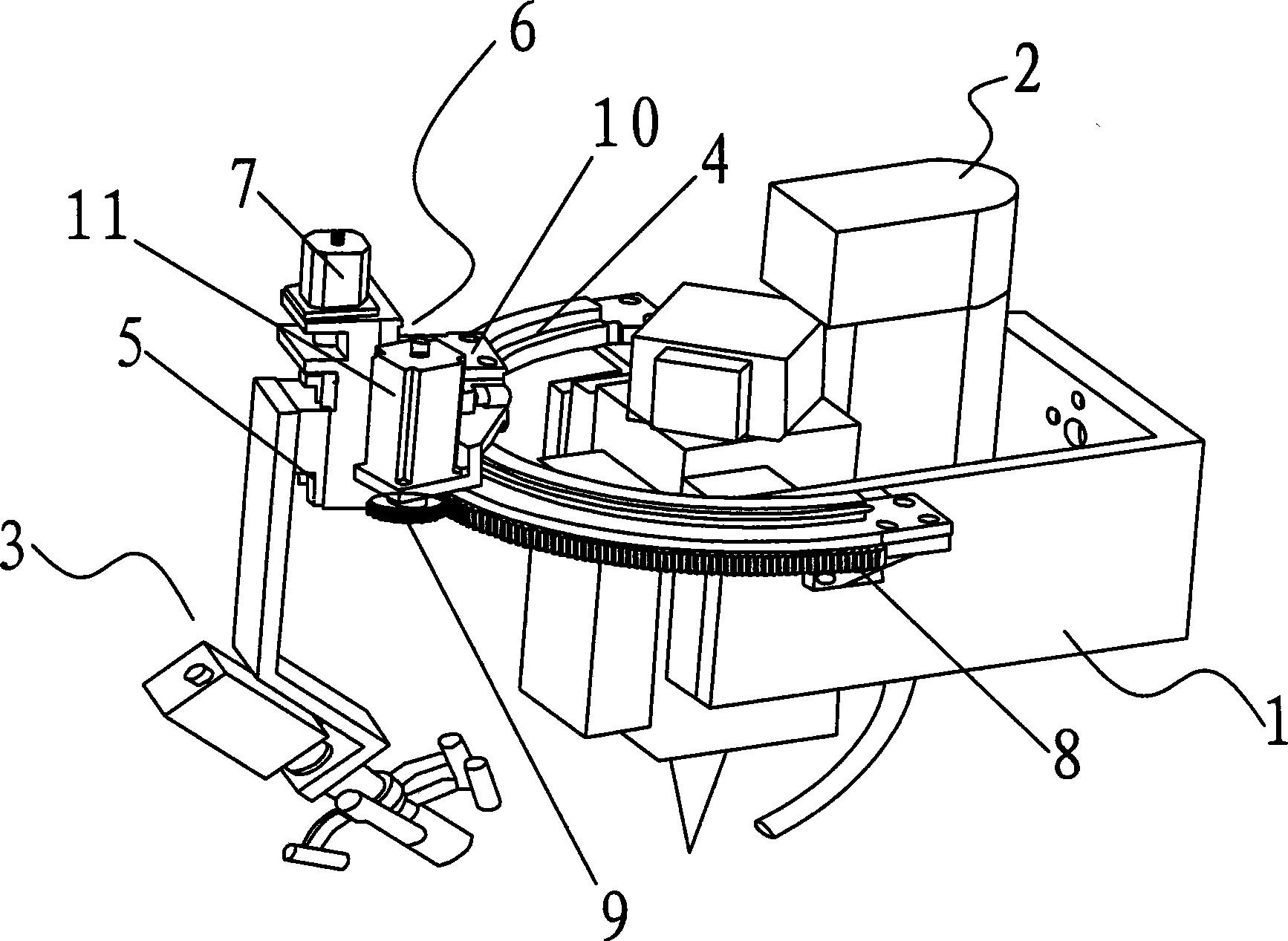

Integrated type laser welding and measurement integrated device

ActiveCN101372069AAchieve shape controlImplement performance controlMeasurement/indication equipmentsLaser beam welding apparatusNumerical controlMeasurement device

The invention belongs to the technical field of laser welding measurement device, and relates to an integration-typed laser welding measurement integrated device which comprises a welding head installation base, a welding head which is arranged on the welding head installation base, a camera device and an arc guideway which is arranged at the welding head installation base; the camera device is connected with a beeline guideway and the camera bracket; the beeline guideway is also connected with a numerical control rotation shaft which drives the beeline guideway; the camera bracket is connected with the welding head installation base by the arc guideway; the arc guideway is provided with a semi-round gear ring and a small gear which is engaged to the semi-round gear ring; the small gear is connected with a numerical control rotation shaft which is connected with the camera bracket; the camera bracket is also connected with a manual adjusting platform which is used for slightly adjusting the relative distance of the camera device and the welding head; the integrated device can realize the shape control and performance control of the laser welding of three-dimensional complex structure light alloy components.

Owner:DG HUST MFG ENG RES INST +1

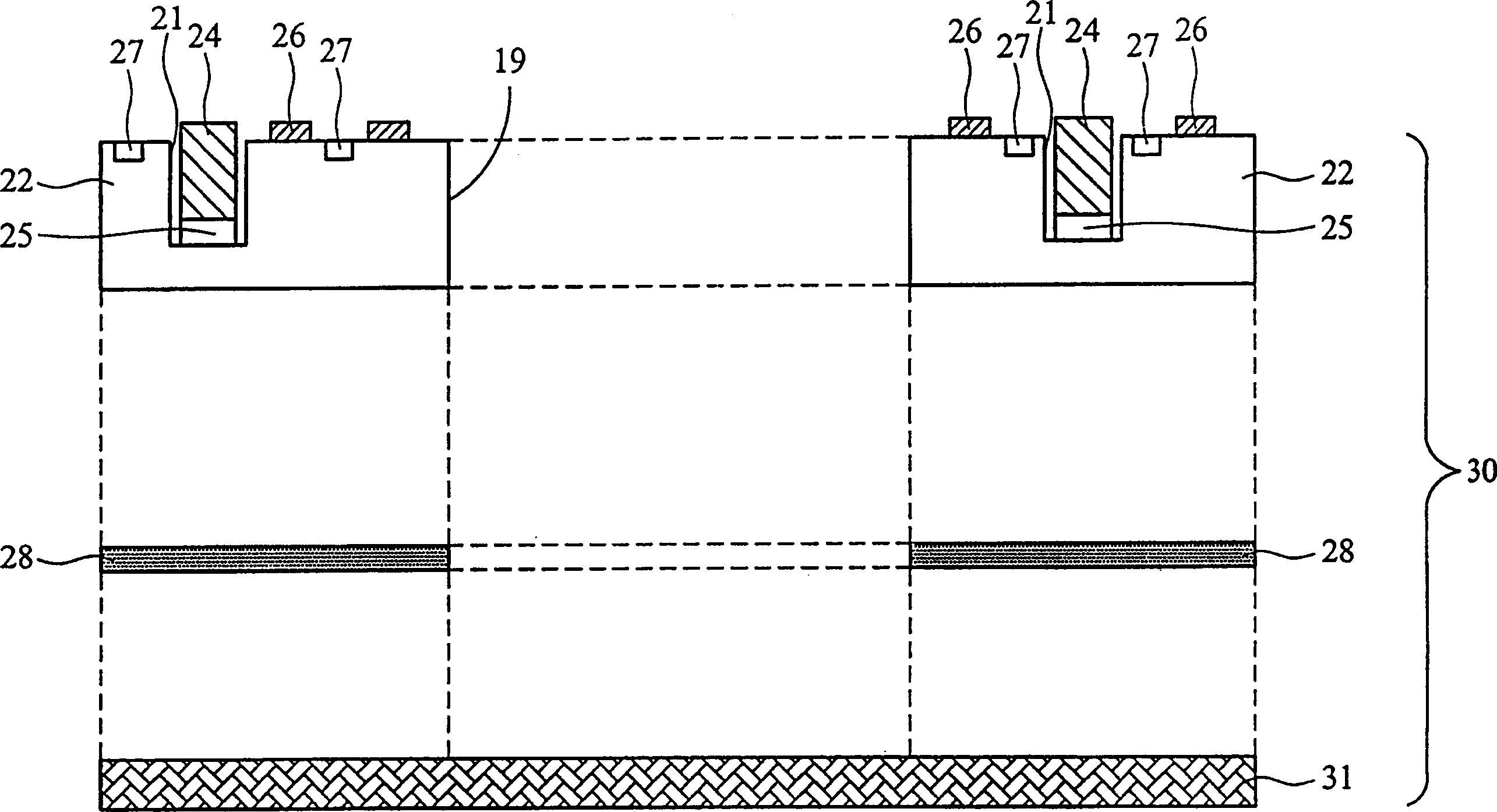

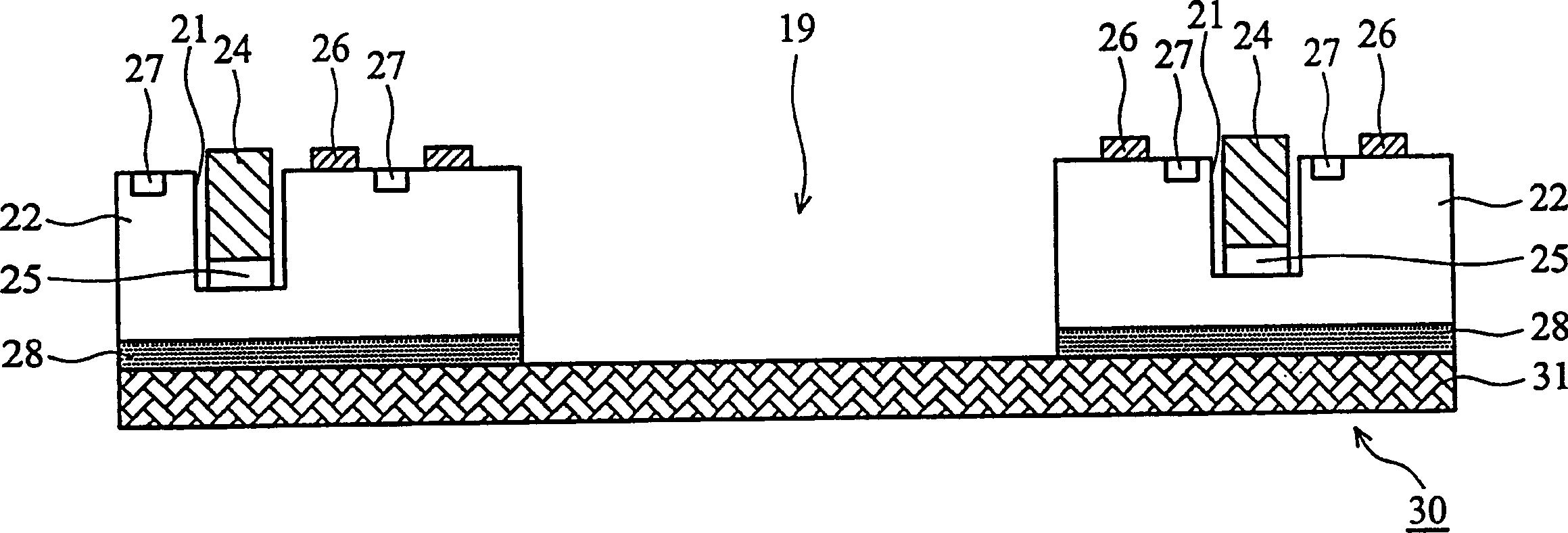

Integrated module board with embedded IC chip and passive element and its production method

InactiveCN1395461AReduce volumeSolid-state devicesPrinted circuit manufactureDielectricAdhesive glue

The integration type module board includes following parts. The base plate contains the multiple large openings and the small opening where the passive component is positioned in. The first adhesive glue film adhibits the bottom of the base palte to the heat sink base plate to form the integration type module board. The IC chip is adhibited in the large opening of the module board by use of the second adhesive glue film. The dielectric packed layer covers the whole surface of the module board and fills in the all gaps on the surface of the module board.

Owner:VIA TECH INC

Electric motor unit with controller

InactiveUS20060181166A1Increased durabilityImprove reliabilityAssociation with control/drive circuitsGearing controlElectricityGear wheel

An object of the present invention is to provide an electric motor unit with a controller of a machinery and electricity integration type for eliminating variations due to mechanical factors and obtaining excellent operation reliability. A magnet member is attached to a gear on the side of a gear case, and a sensor for sensing the magnet member and detecting a rotational angle of the gear in a controller case, and a cylindrical opening concentric with the rotational center of the gear is installed on the gear case, and a cylindrical part fitting into the cylindrical opening is installed on the controller case, and the controller case is positioned and mounted on the gear case by the fitting between the cylindrical part and the cylindrical opening.

Owner:HITACHI LTD +1

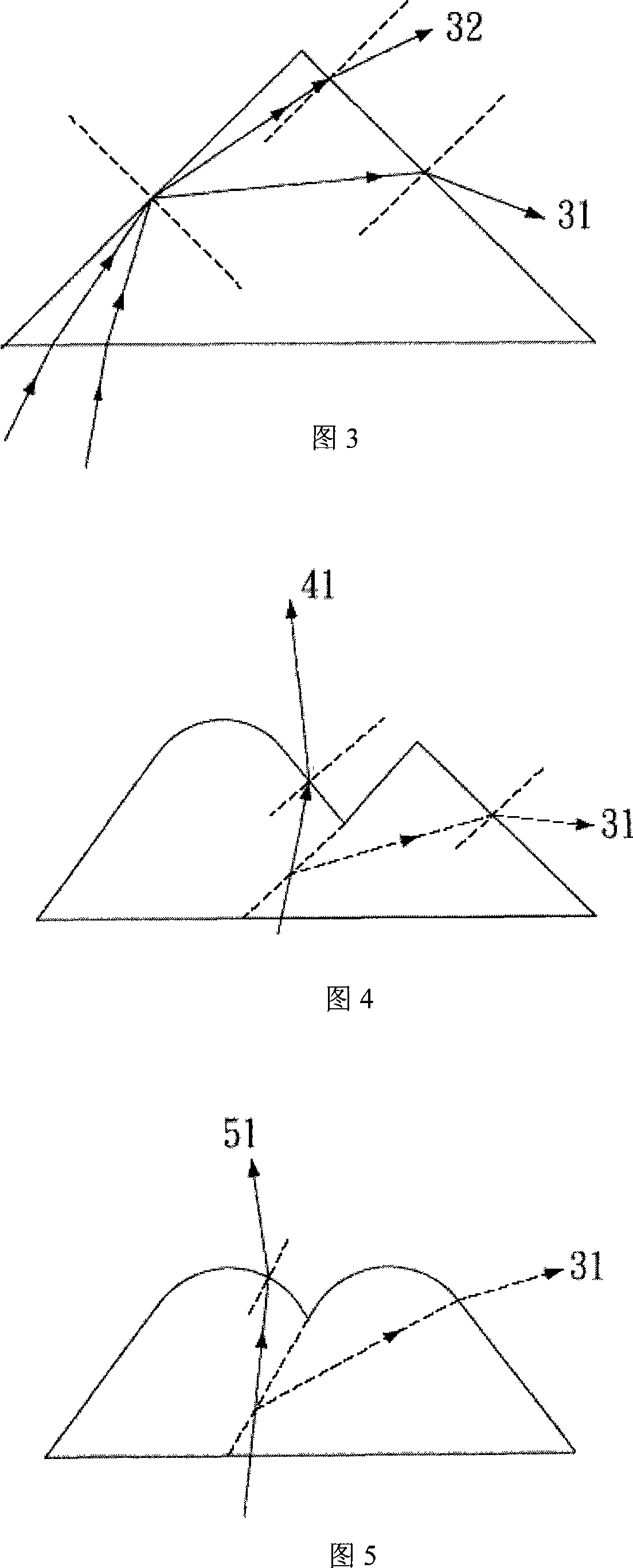

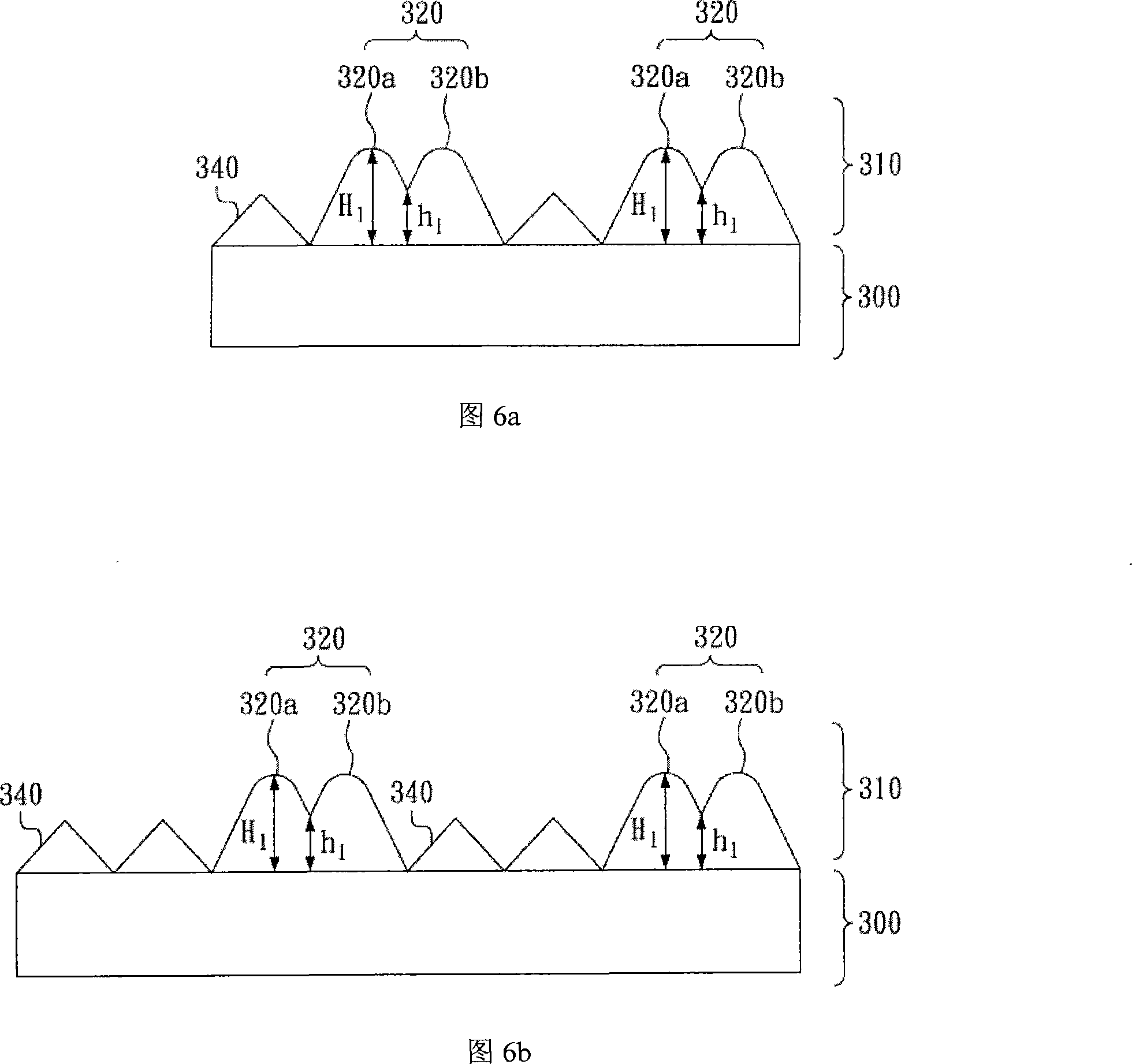

Integration-type optical film

The invention discloses an integrated optical film, which belongs to the field of optical film. The optical film comprises a substrate and a microstructure layer positioned on one surface of the substrate, wherein the microstructure layer includes one or more first regions, each including at least one multi-peak columnar structure consisting of at least two columnar structures overlapping each other to form a joint structure and an arc-shaped columnar structure formed at the maximal height position; and the microstructure layer optionally includes one or more second regions, each including at least one single-peak prism columnar structure. The optical film of the invention can suppress the optical interference and can prevent scratch of the optical film due to contacting with other optical films or panels, thus obviating the cost of an upper diffusion film or a protection film and achieving good scratch resistance and high brightness gain.

Owner:长兴光学材料(苏州)有限公司

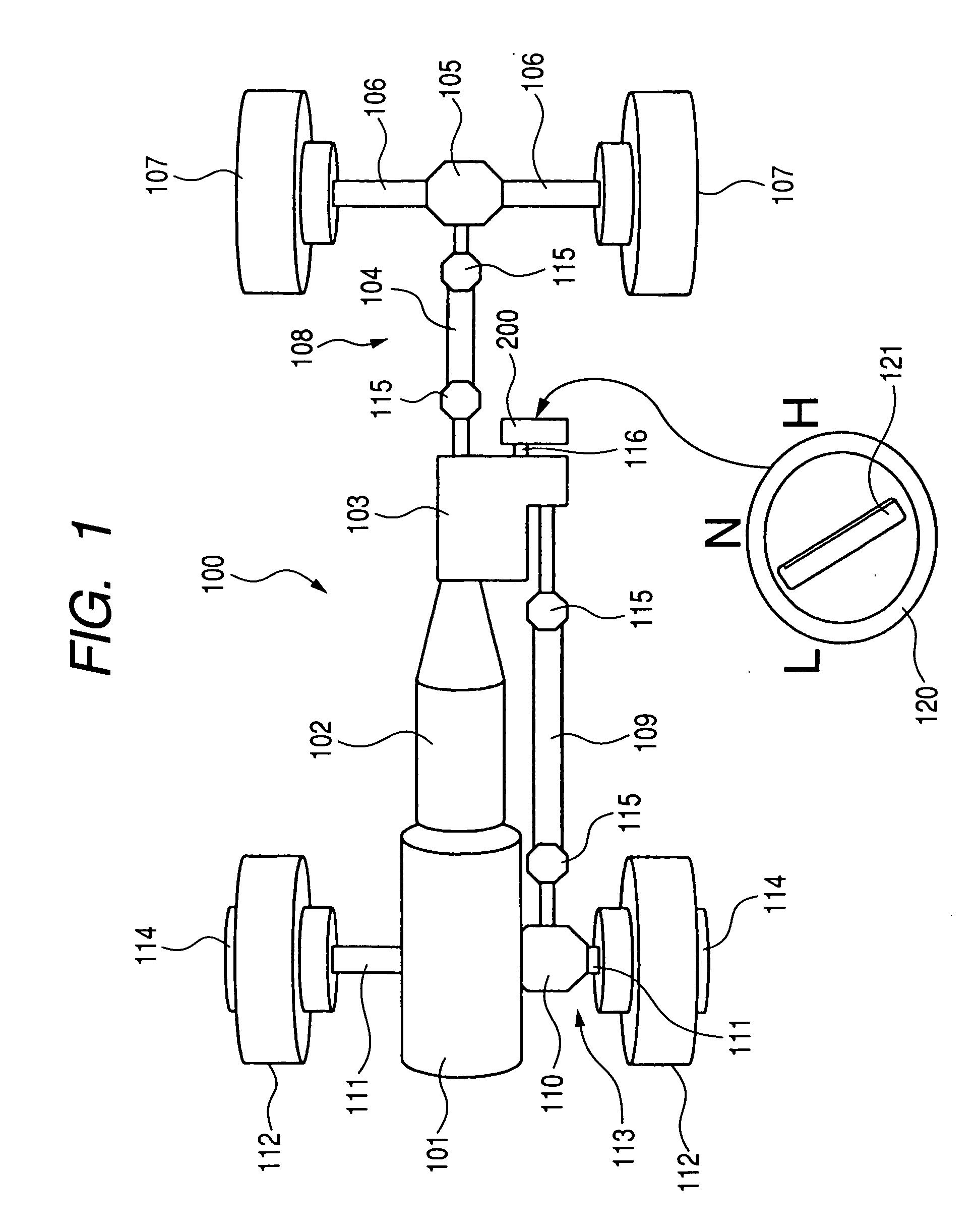

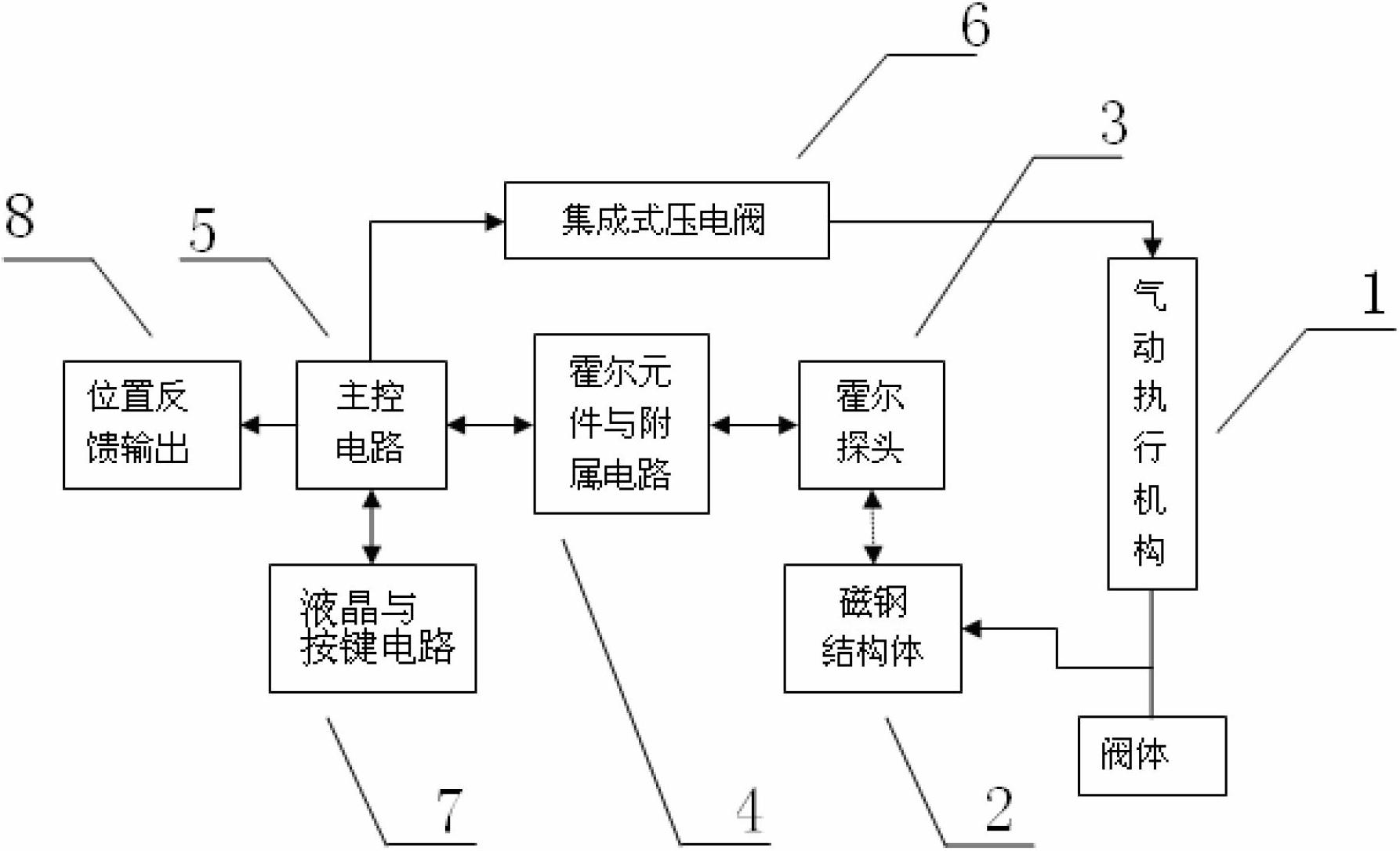

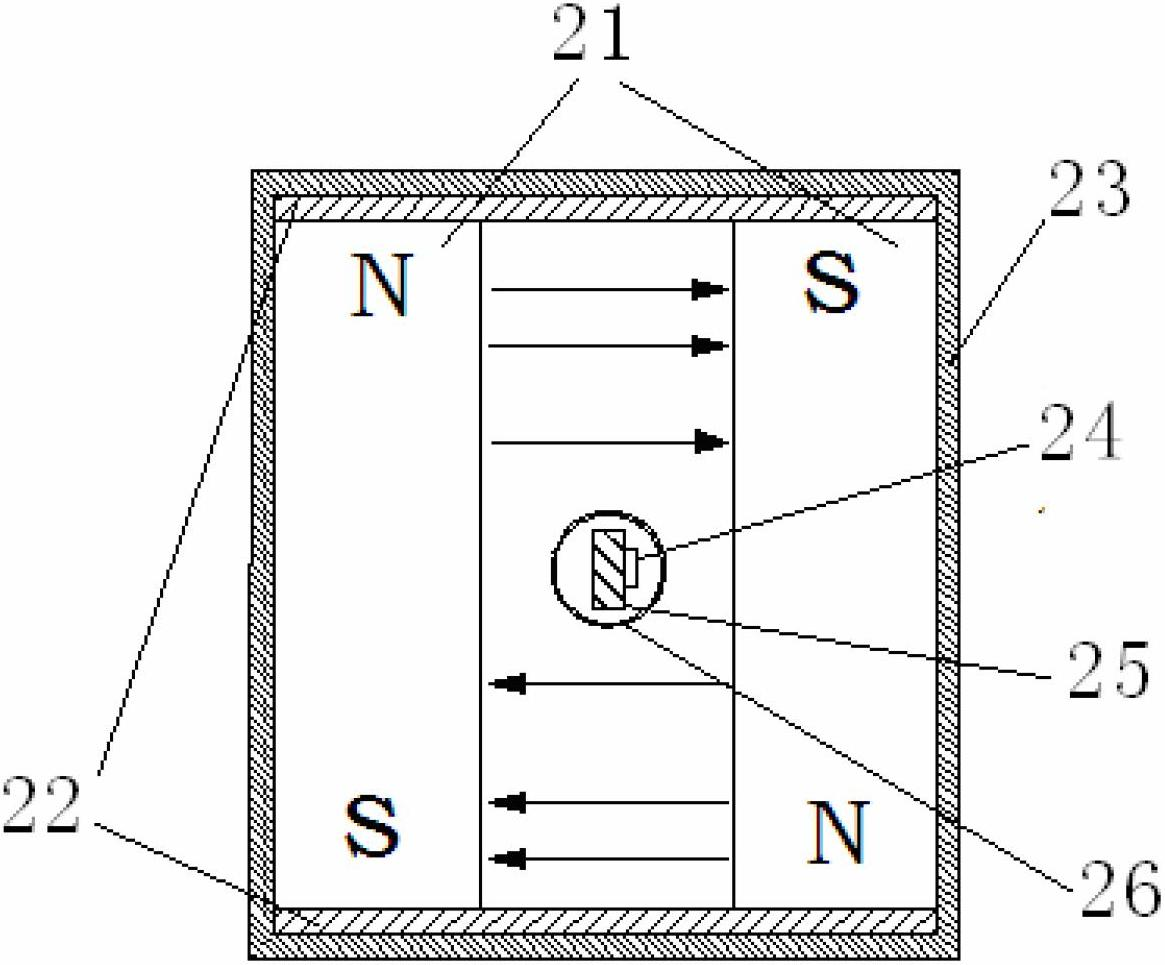

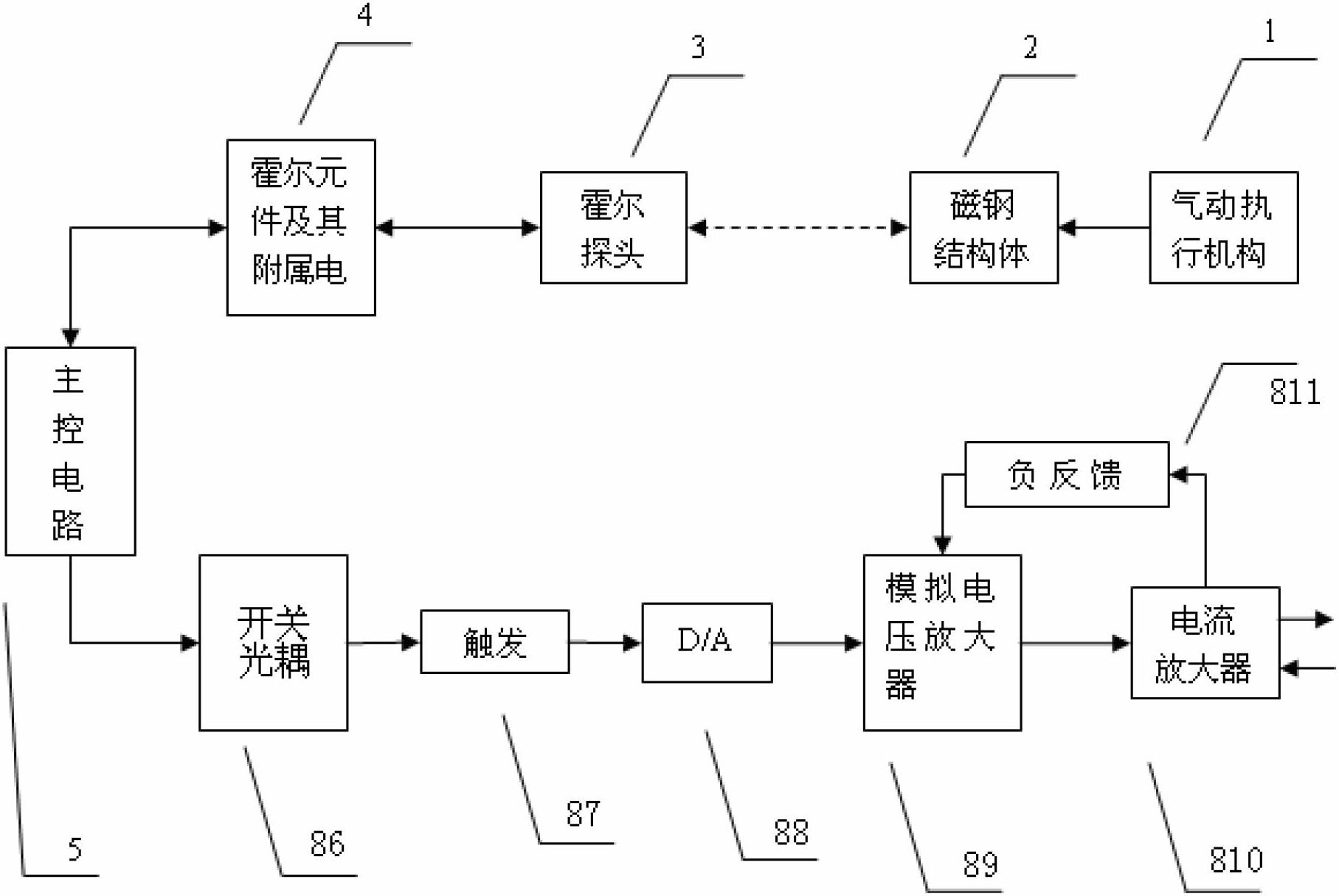

Hall type intelligent valve positioner

InactiveCN102661436ARealize measurementImprove dynamic and static performanceValve arrangementsHall elementSpecific function

The invention discloses a Hall type intelligent valve positioner. The valve positioner comprises a magnetic steel structural body, a Hall probe, a Hall element and an accessory circuit thereof, a main control circuit, and an integration type piezoelectric valve, wherein the magnetic steel structural body is designed and packaged into a groove shape; the Hall element and the accessory circuit thereof are arranged and sealed in the Hall probe, and an input / output port of the Hall accessory circuit is connected with the main control circuit; the Hall probe is arranged in a center position among magnetic steel structural body grooves, when a valve body moves, the Hall probe outputs an analog voltage signal which forms a specific function relation with motion displacement; and the signal is sent into the main control circuit through the Hall accessory circuit. The valve positioner can overcome the defects that a displacement sensor in the positioner has the defects of great mechanical corrosion and lag, is easy to be influenced by environment shock, is in low precision, is in low structural life and the like, and meanwhile the dynamic and static properties of the intelligent valve positioner are improved.

Owner:北京京仪海福尔自动化仪表有限公司

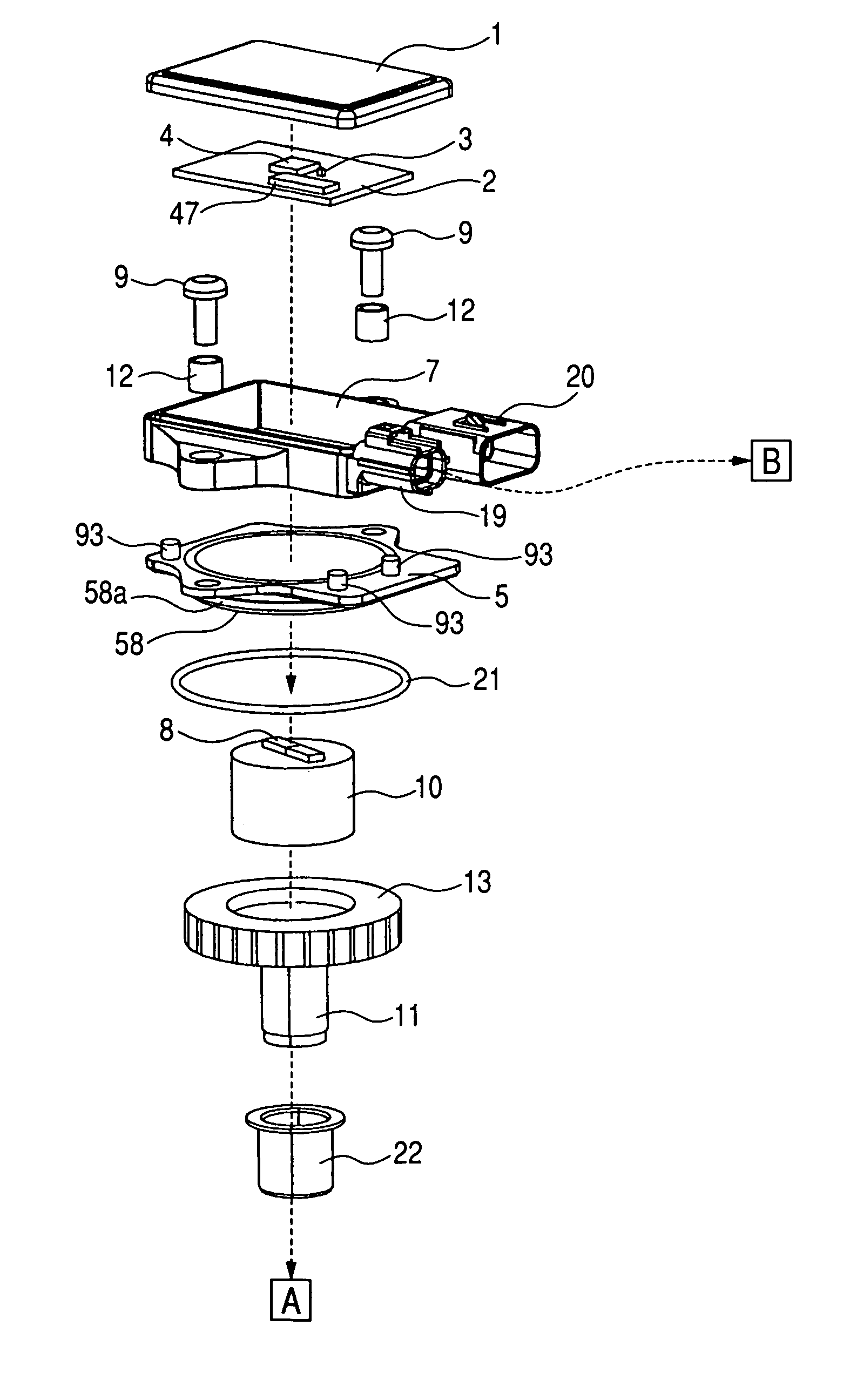

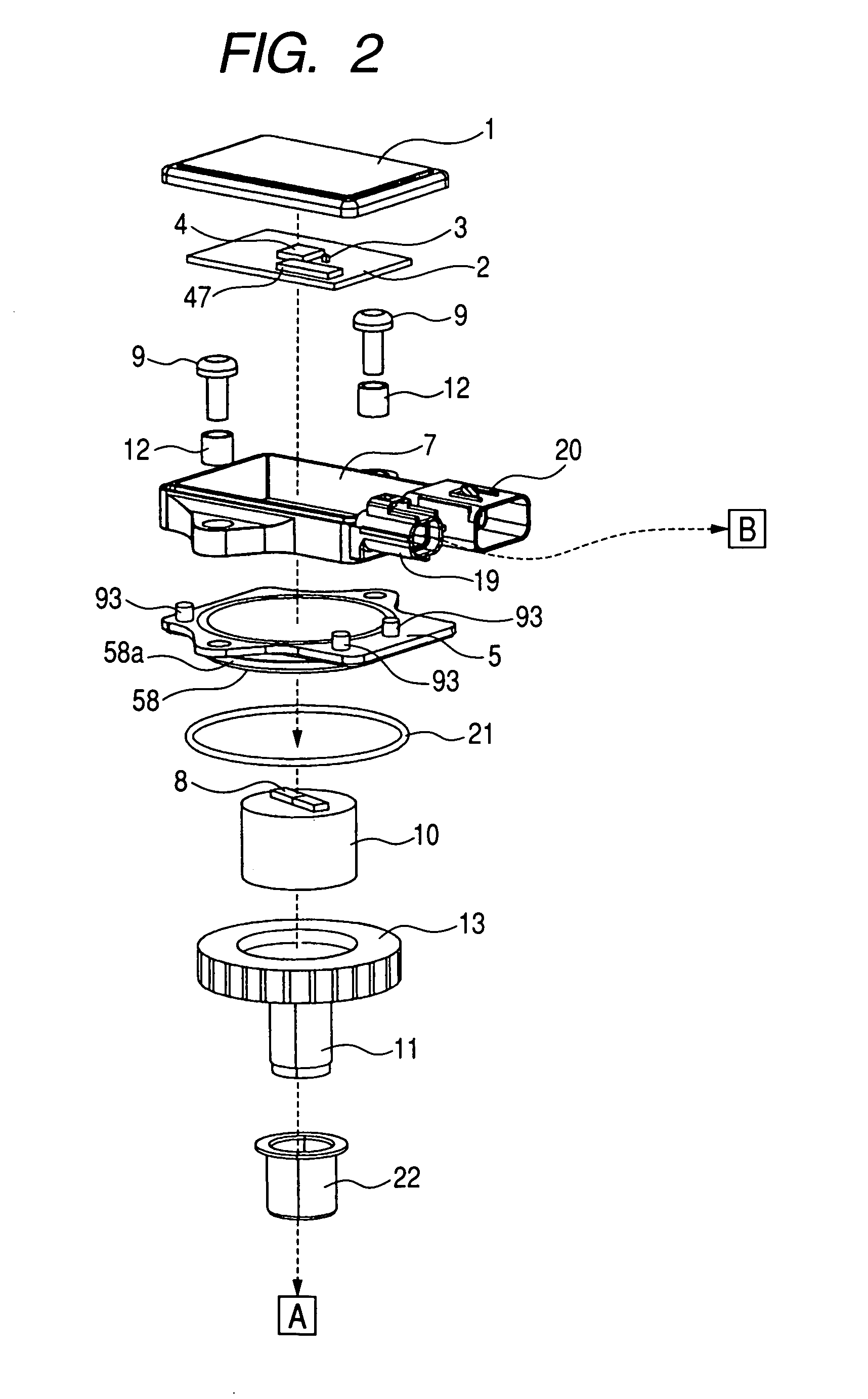

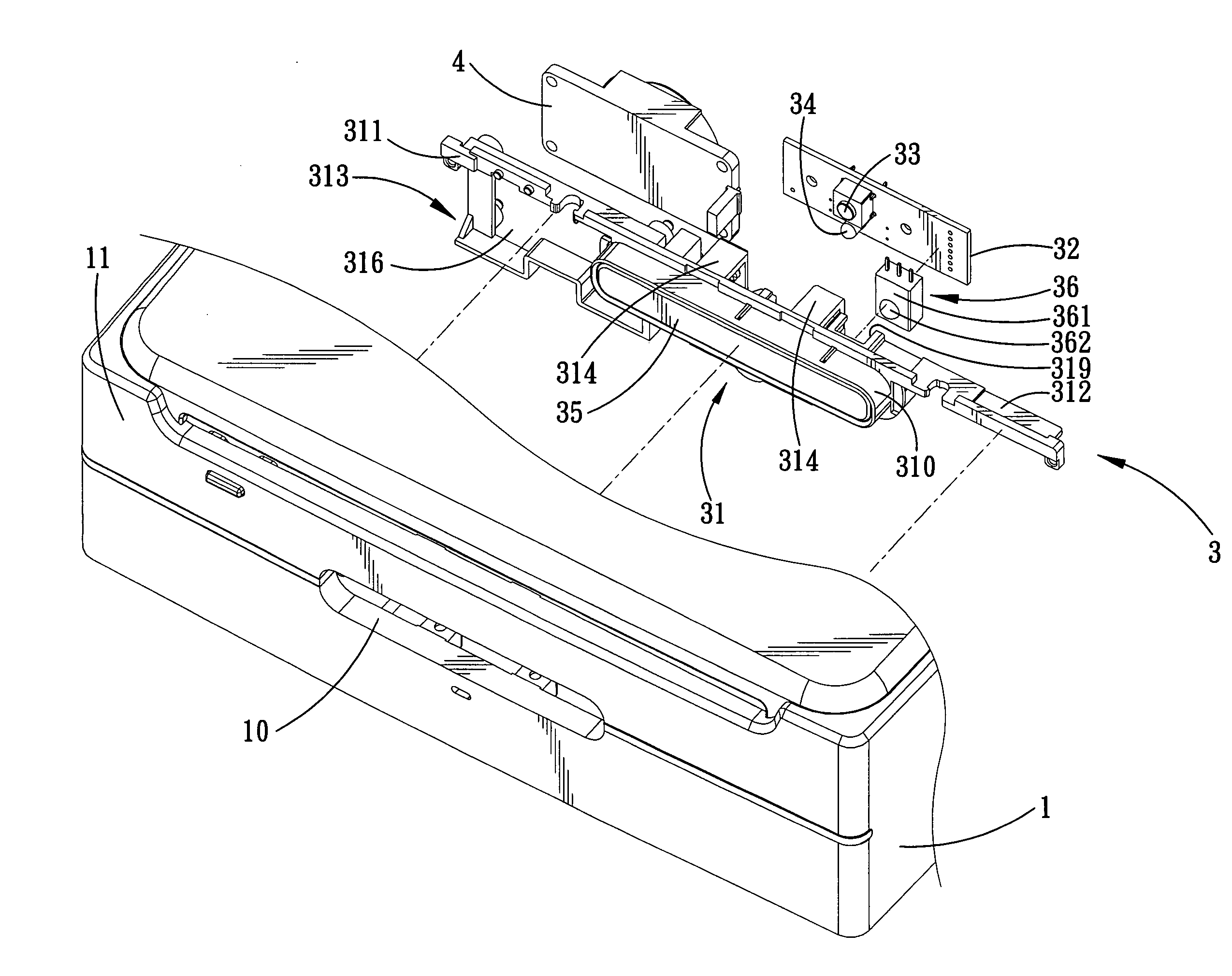

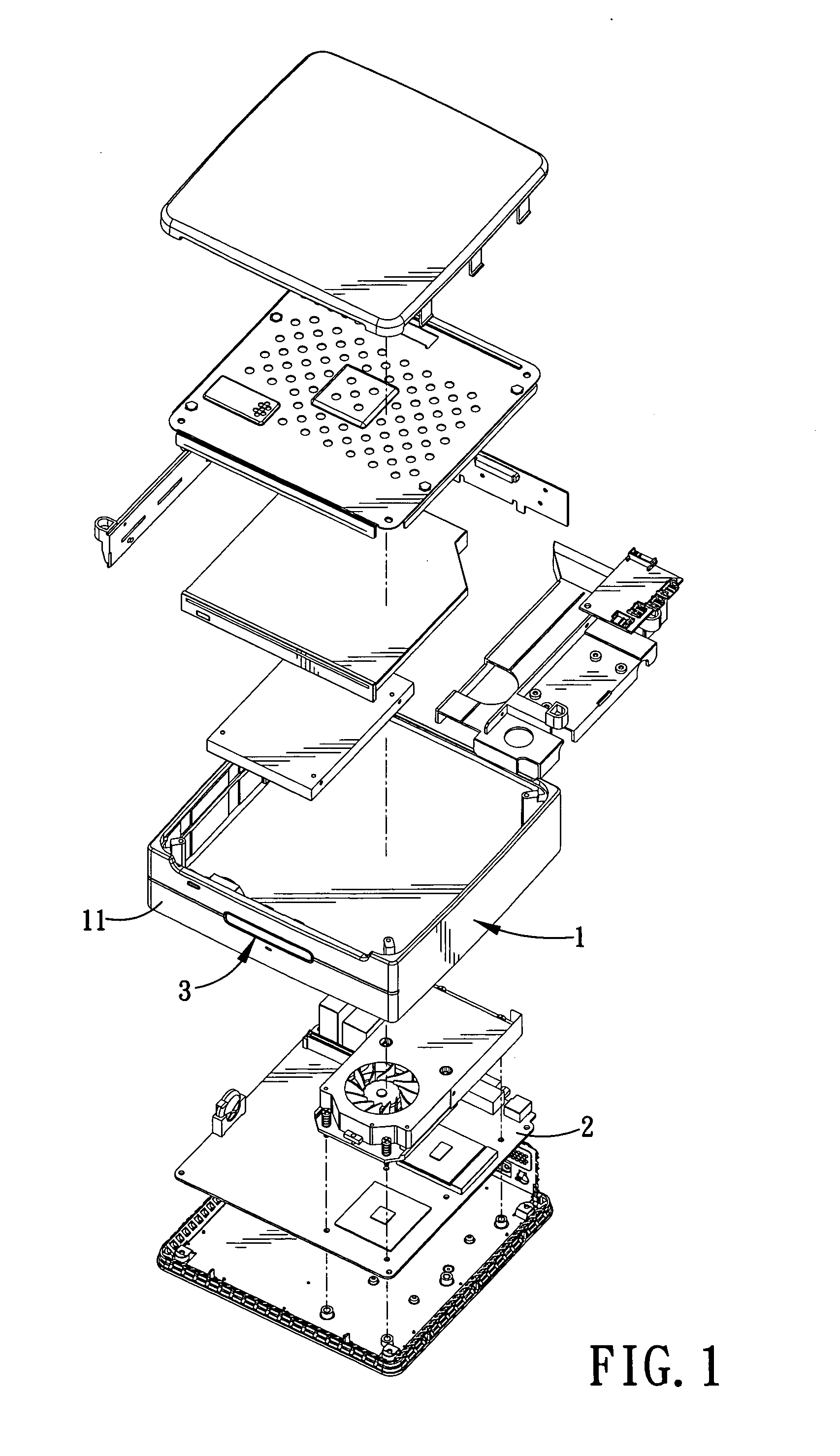

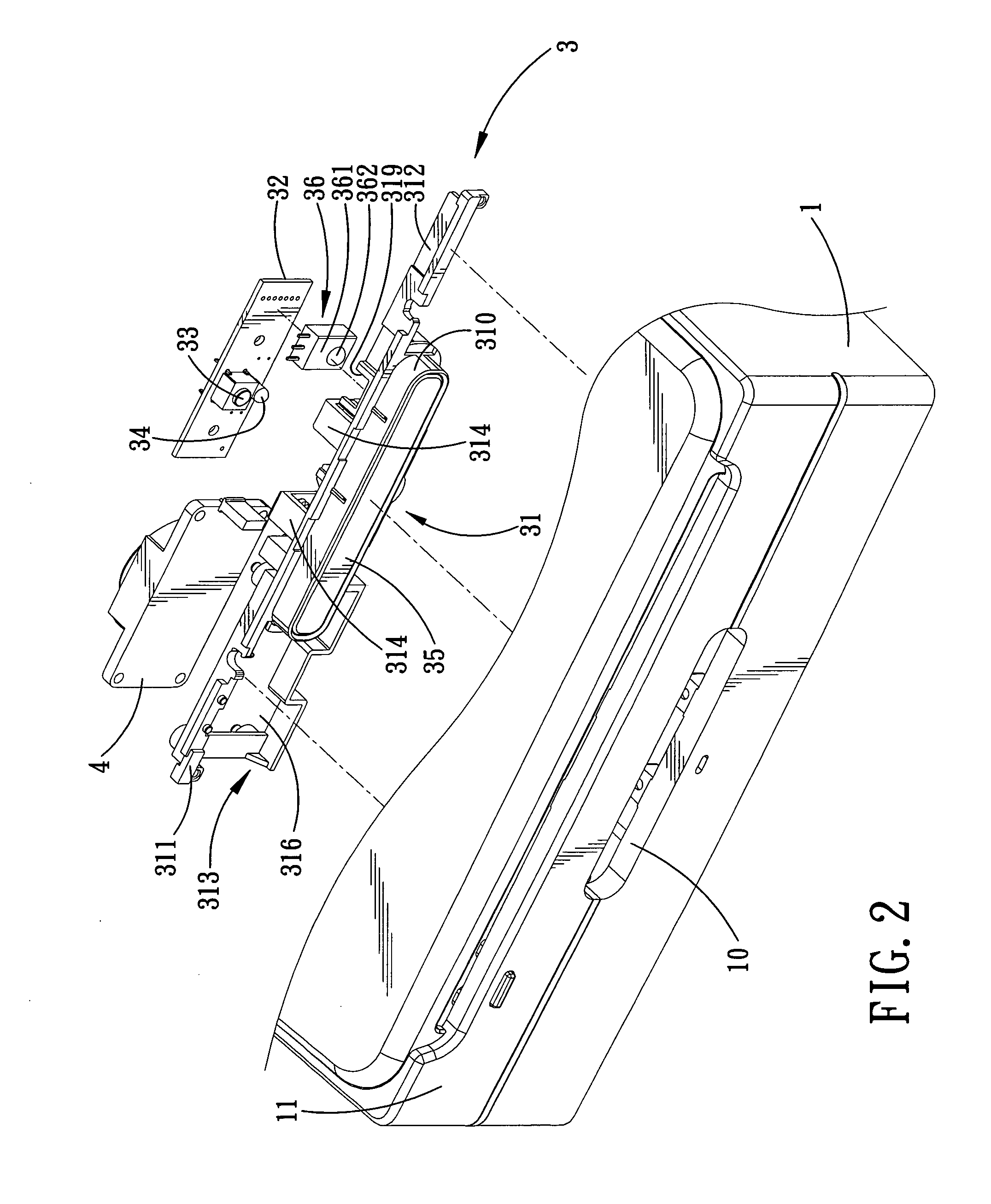

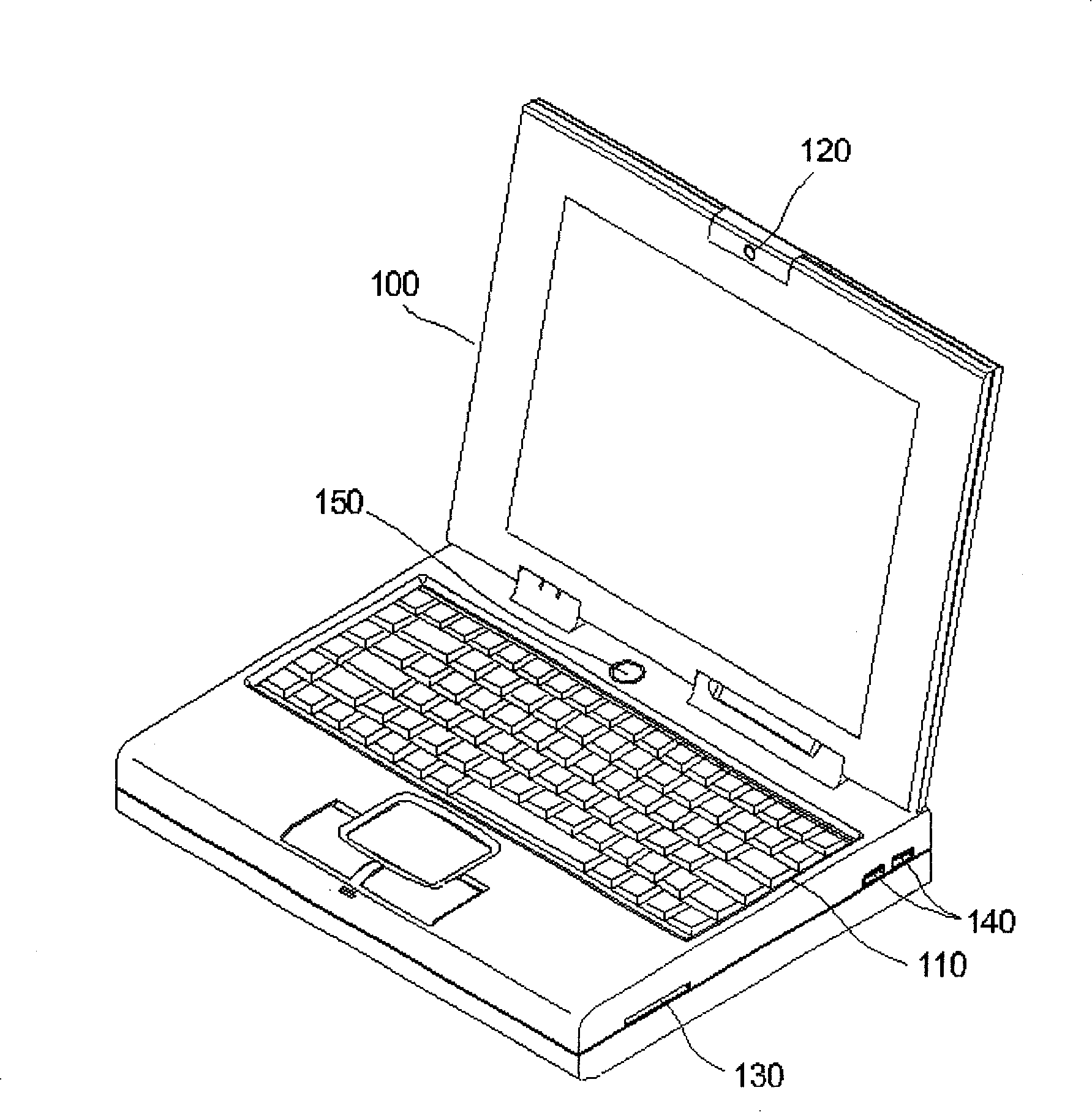

Computer with integration type switch device

InactiveUS20070227864A1Reduce in quantityContact operating partsCoupling contact membersIntegration Type

Owner:AOPEN

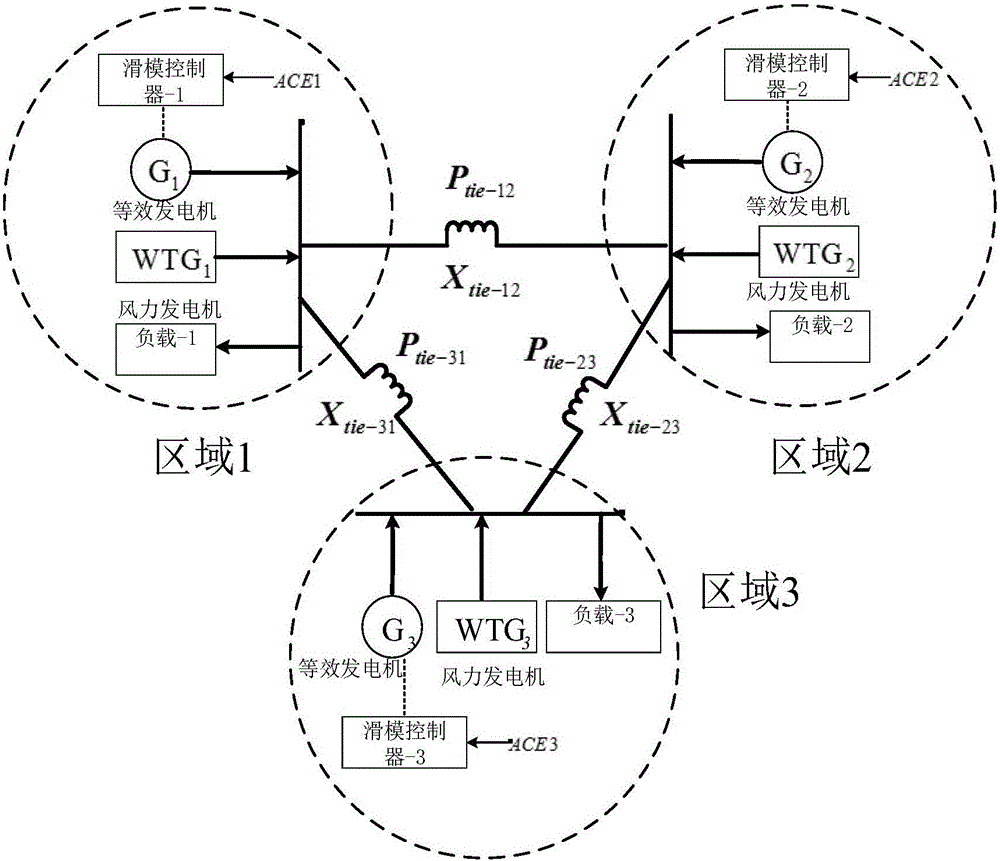

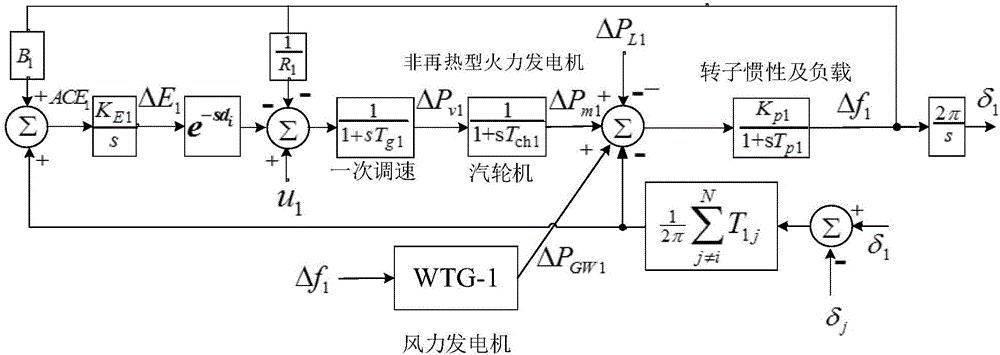

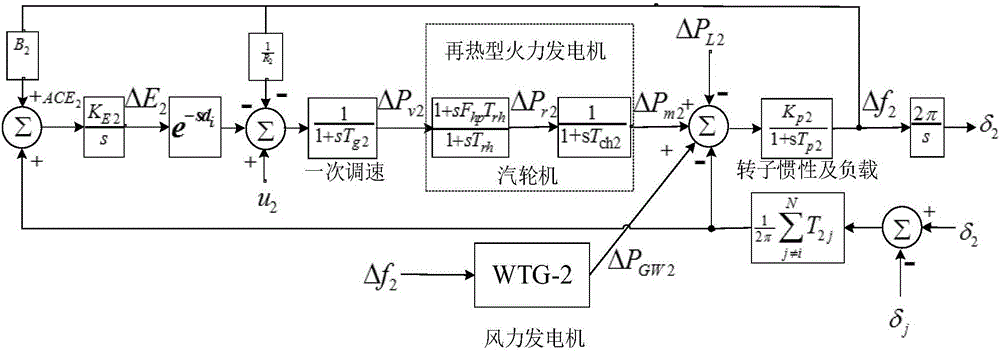

Load-frequency control method of multi-domain time-lag electric power system with high wind energy permeability

ActiveCN105958512AReduce incrementReduce frequency deviationPower oscillations reduction/preventionWind drivenElectric power system

The present invention relates to a load-frequency control method of a multi-domain time-lag electric power system with high wind energy permeability. The method comprises the following steps: S1, establishing a time-lag electric power system with multiple domains, and establishing the mathematics model of each generation system; S2, establishing state models with uncertain items corresponding to each domain according to the mathematics model of a generator; S3, designing an integration type sliding mode surface [Sigma]I (t) according to the state models with uncertain items; S4, designing the sliding mode load frequency controller according to the integration type sliding mode surface [Sigma]I (t); and S5, taking a controller ui(t) obtained in the step S4 as a controlling instruction, and optimizing the load frequency offset of the electric system. Compared with the prior art, a wind driven generator participates the regulation of the system frequency to tightly cooperate the wind power generation with the traditional fire power generation, and the increment of the output power of each generator is evenly reduced to ensure the power supply and demand balance of each area and effectively reduce the frequency offset of each area.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

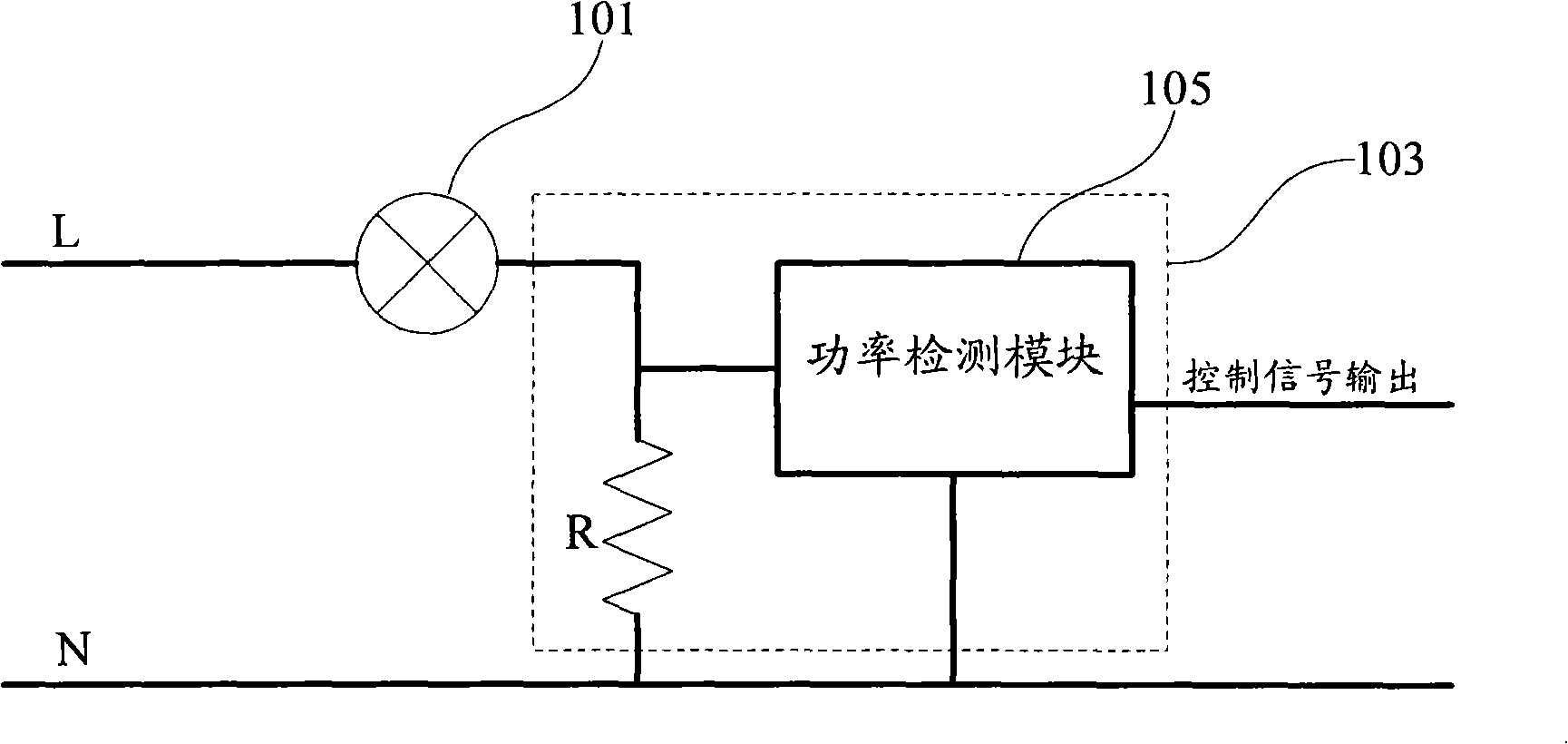

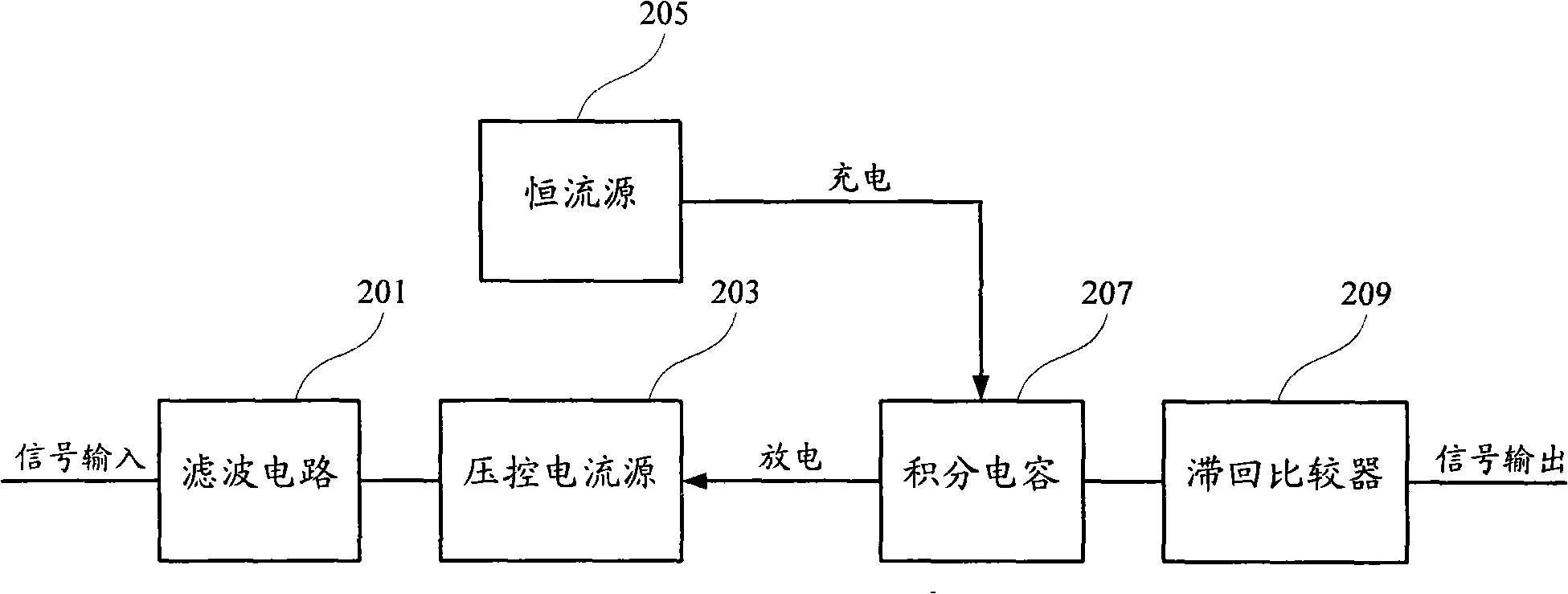

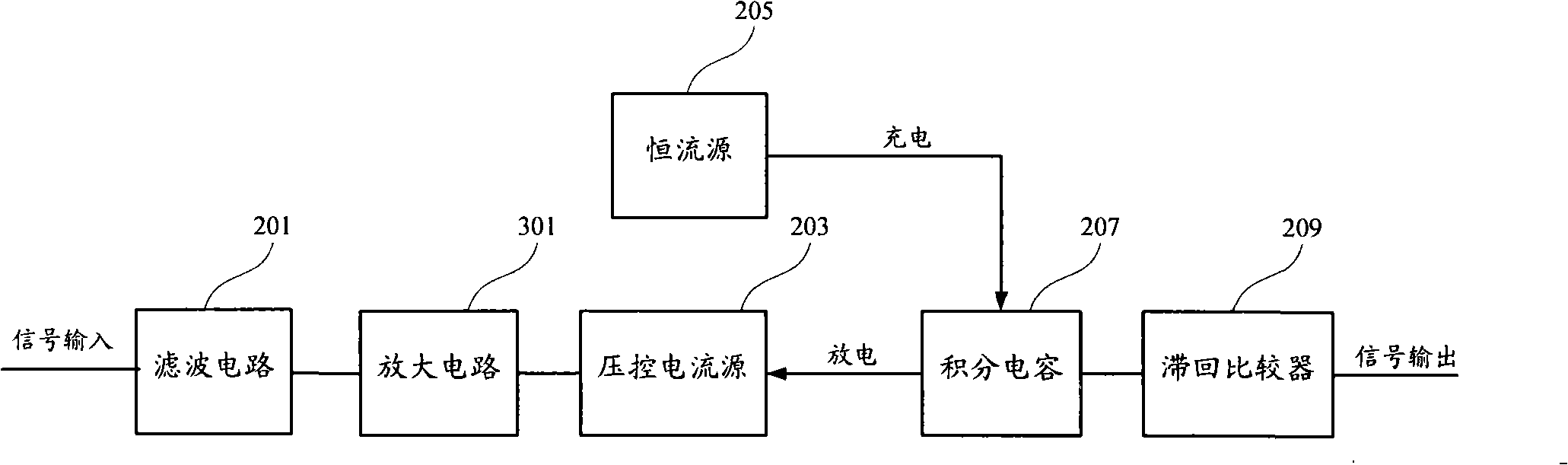

Current integration -type power detection device and power checking module

InactiveCN101308172AAccurate detectionLow costElectric devicesEffective value measurementsHysteresisCapacitance

The invention provides a current integration type power detection device and a power detection module, and the current integration type power detection device comprises a current sampling resistor and the power detection module. The current sampling resistor is connected in an AC loaded circuit loop in series. The power detection module is in parallel connection with the current sampling resistor and also includes a filter circuit, a voltage-controlled current source, a constant current source, an integrating capacitor and a hysteresis loop comparator. The filter circuit is connected with the current sampling resistor in parallel. The voltage-controlled current source is connected to the filter circuit. The integrating capacitor is connected with the voltage-controlled current source and the constant current source respectively. The hysteresis loop comparator is connected to the integrating capacitor. The power detection device and module have the advantages of high detection precision and low costs.

Owner:HANGZHOU ZHENGU TECH

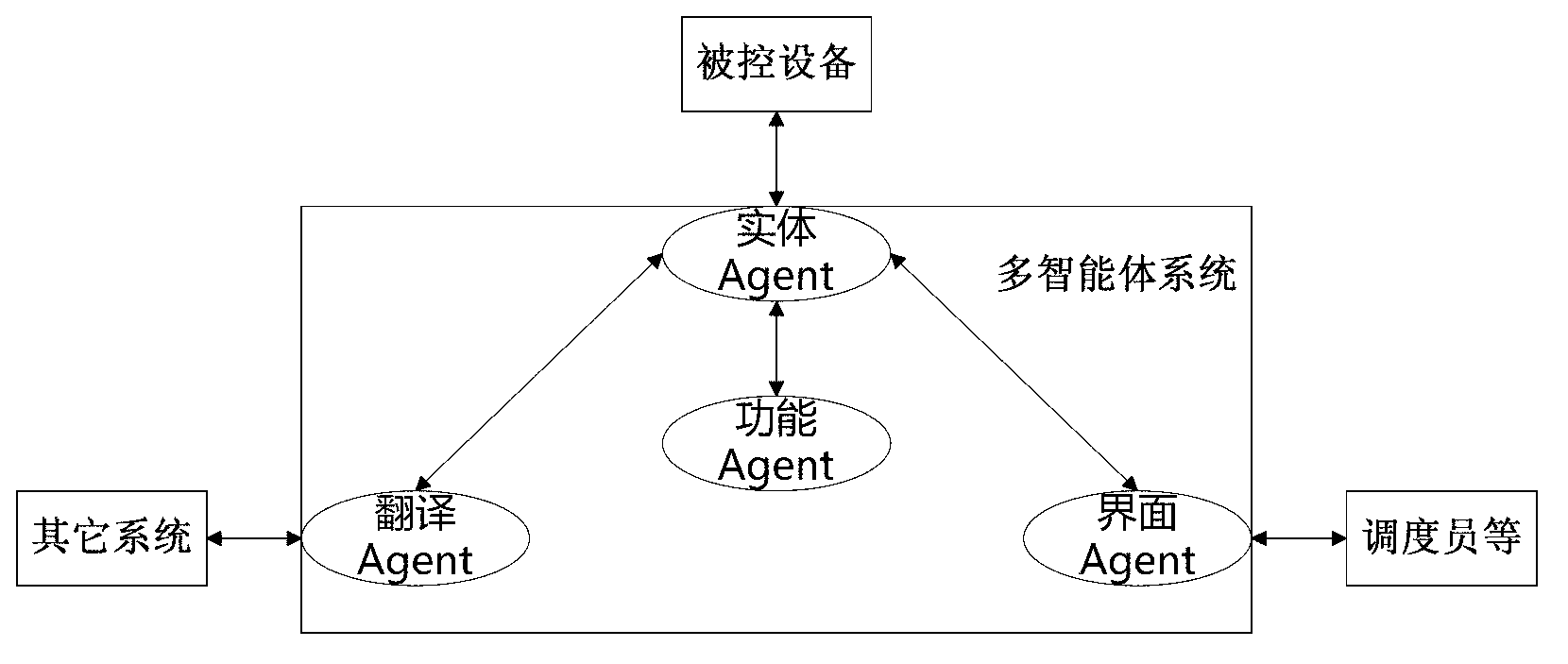

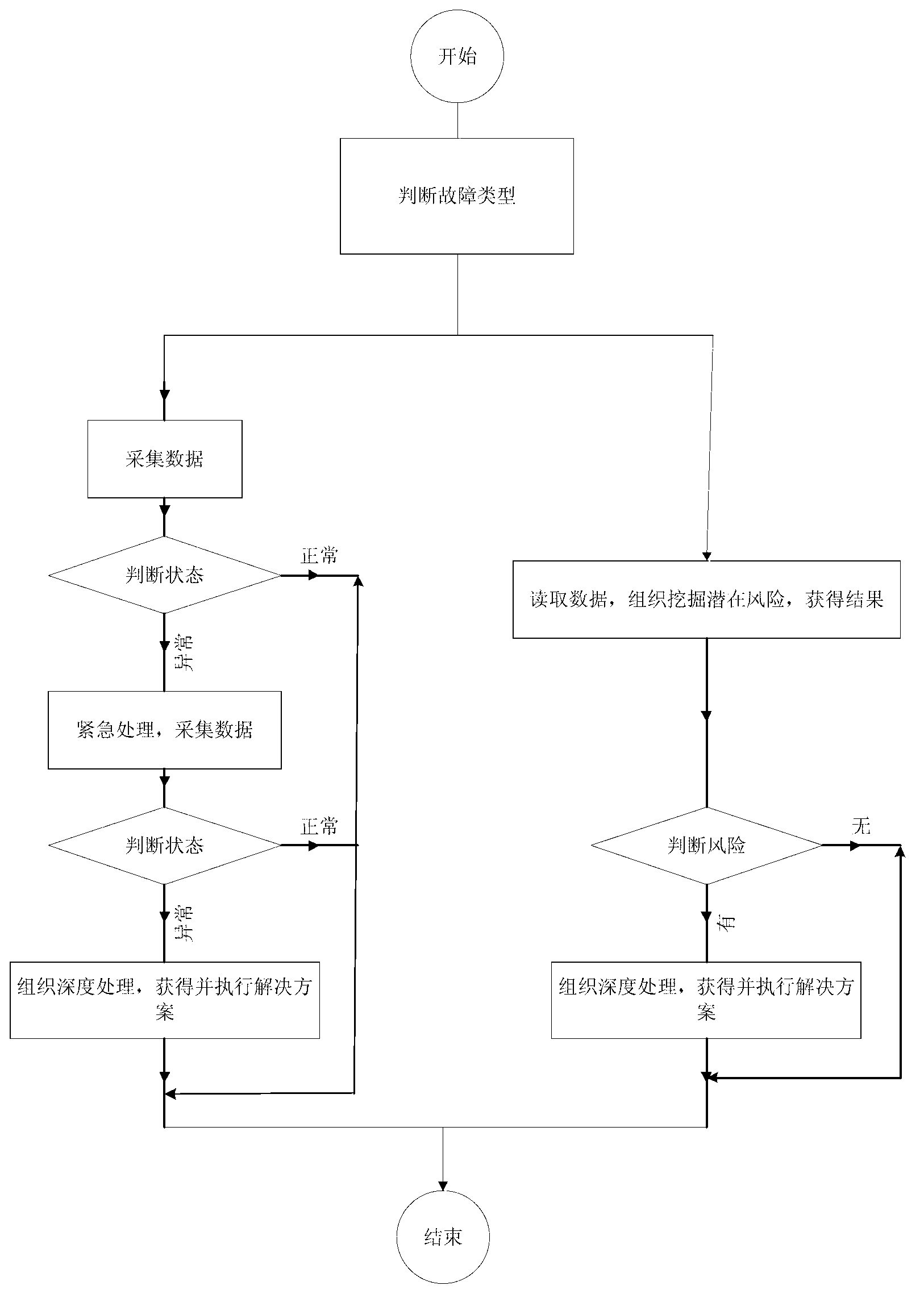

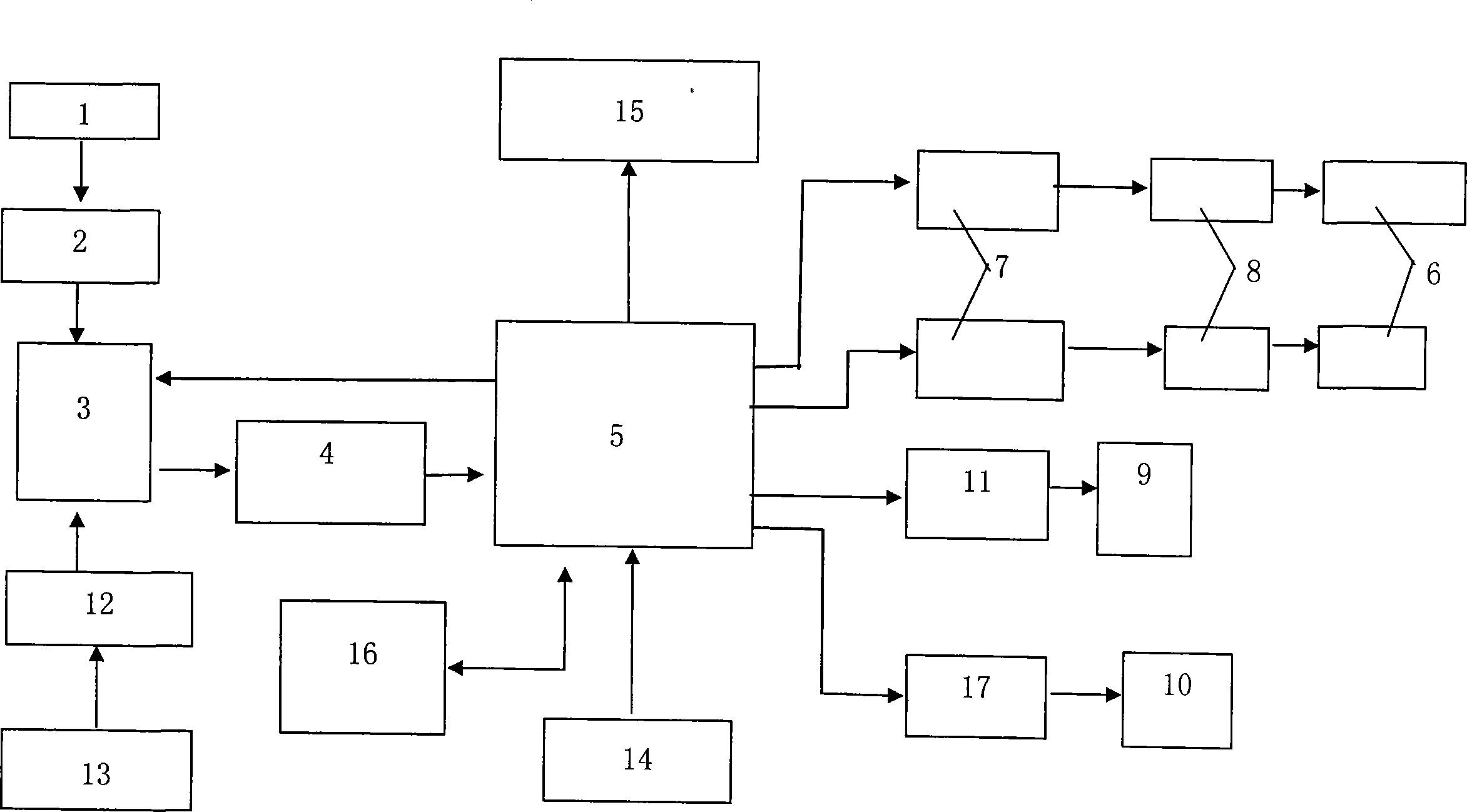

Distribution grid self-healing control system and implementation method thereof

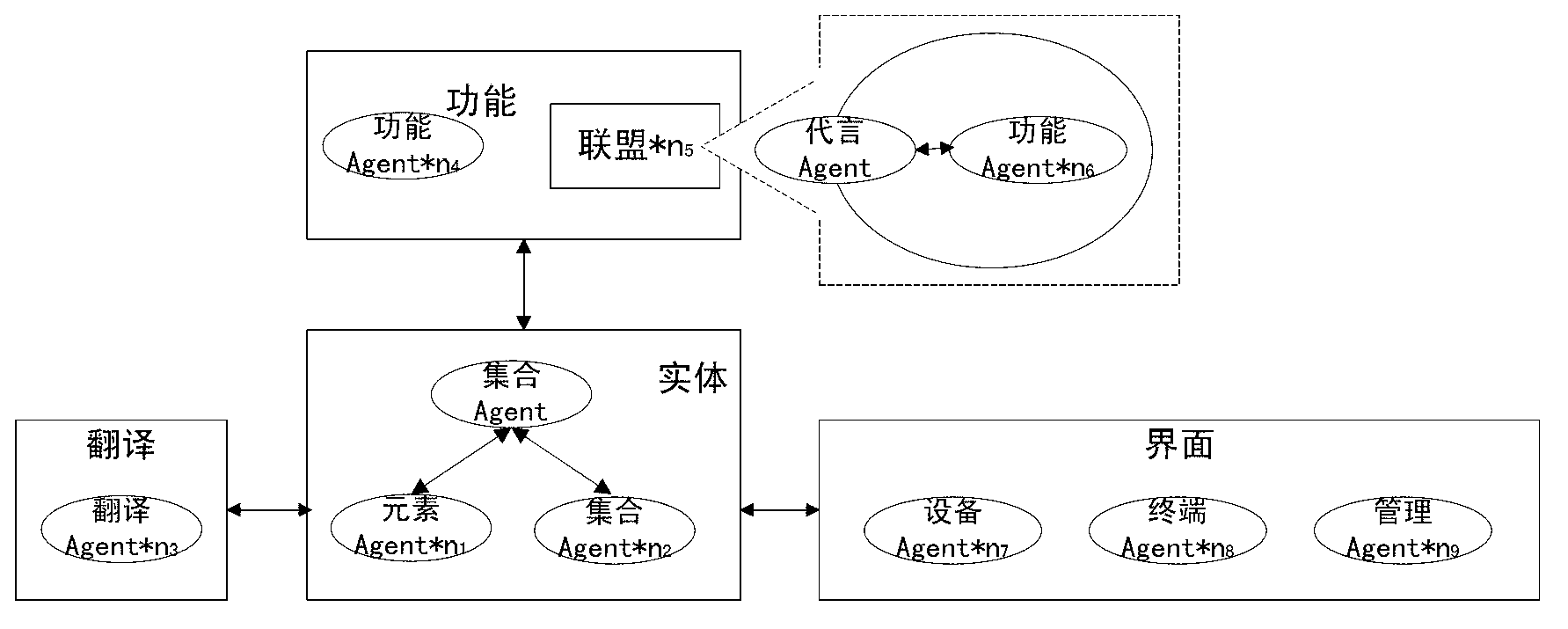

ActiveCN102841582AImprove real-time response performanceImprove reusabilityTotal factory controlSustainable buildingsSelf-healingControl system

The invention discloses a distribution grid self-healing control system which is characterized by comprising an entity Agent, a function Agent, an interface Agent and a translation Agent; the entity Agent comprises two types including an element type and an integration type; the element-type entity Agent is embedded in a controlled apparatus; the interface Agent is embedded in a control terminal; the integration-type entity Agent, the function Agent and the translation Agent are embedded in a server; the entity Agent is connected with other systems by the translation Agent, connected with a scheduler by the interface Agent and used for ensuring the normal running of the controlled apparatus via the processing task of the function Agent. The problems in the development of the distribution grid self-healing control system are solved by adopting the multifunctional intelligent system provided by the invention.

Owner:CHINA ELECTRIC POWER RES INST +1

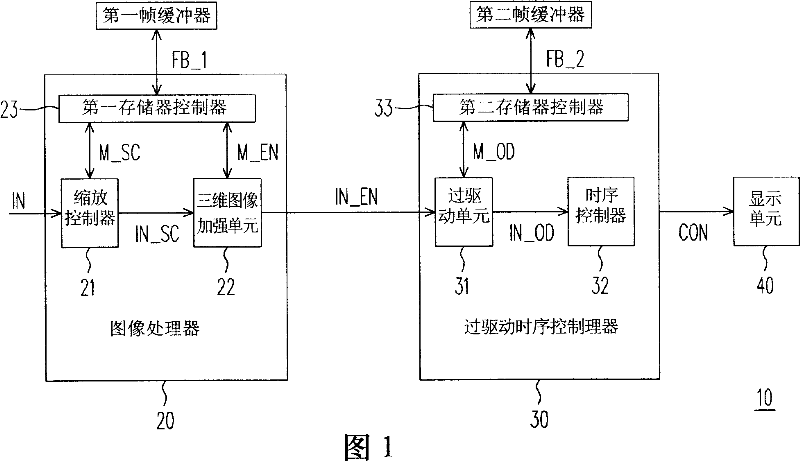

Integration-type image control chip group

The invention provides a synthesized image control chip group used for an image display device and capable of reducint component cost, packaging cost and system plate ling-winding cost. The synthesized image control chip group is connected to a share frame buffer and a display unit. A synthesized image control chip comprises: a zoom controller, a three-dimensional image strengthening unit, a passed driving unit, a time sequence controller and a memory controller. The zoom controller, the three-dimensional image strengthening unit and the passed driving unit access the share frame buffer via the memory controller. When accessing the share frame buffer, the passed driving unit compresses a reading / writting data to reduce operation frequency of the frame buffer.

Owner:HIMAX TECH LTD

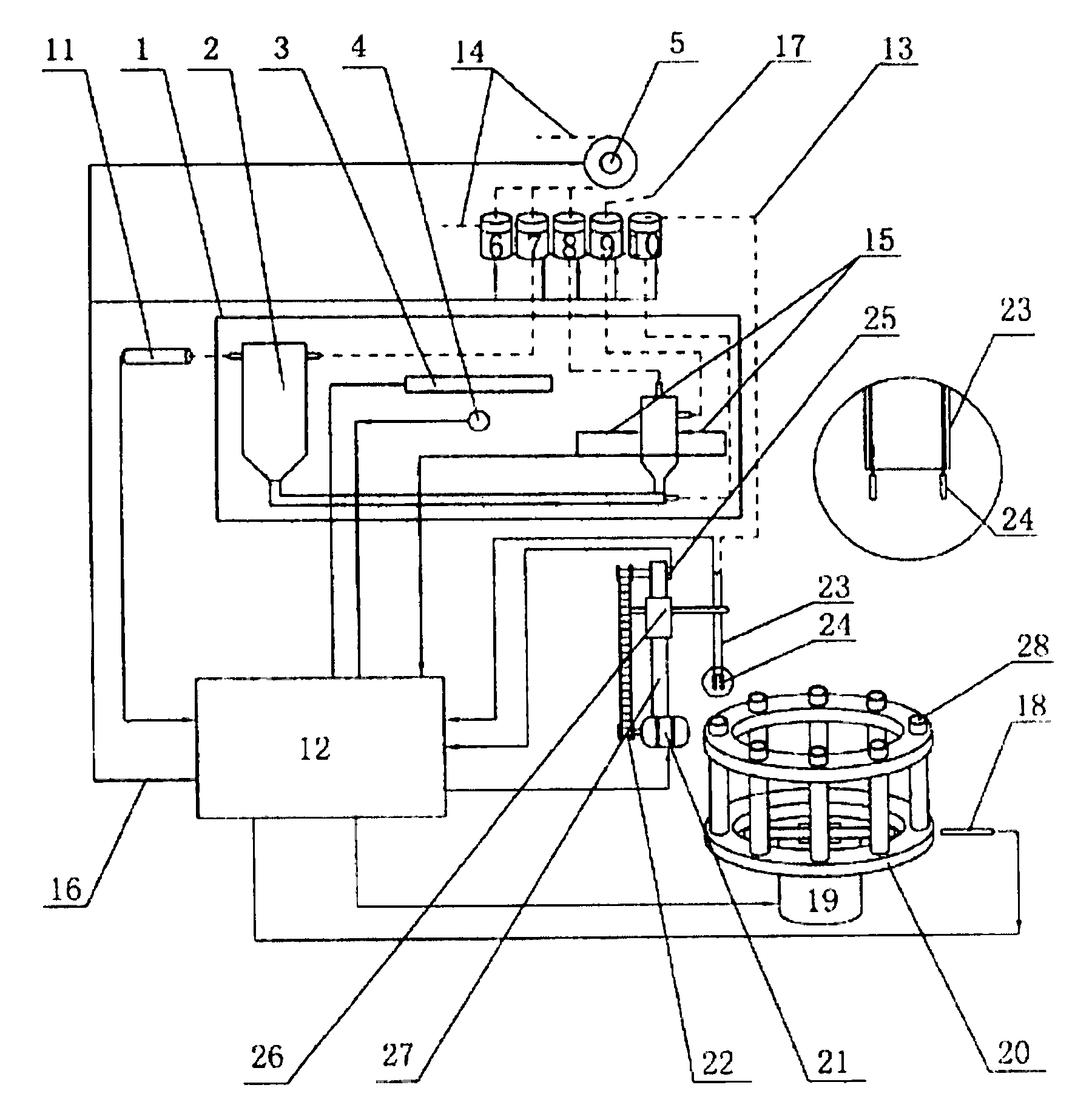

Integration type programmable crystal growth control system

The invention provides an integrated programmable crystal growth control system, comprising a temperature sensor, a microprocessor, a heater, a seed rod rotation step motor, a crystal drawing step motor and a weighing sensor. The temperature sensor and the weighing sensor are connected with a two-way signal switch respectively through an amplifier arranged in front of the temperature sensor and a weighing sensor amplifier; the two-way signal switch, an A / D converter and the microprocessor are connected with each other; the heater is divided into at least two ways, each of which is connected with the microprocessor; the seed rod rotation step motor and the crystal drawing step motor are connected with the microprocessor through a respective driver. The invention integrates temperature control and motor speed control into a whole, and can control fluctuation speed of temperature, rotational direction of motors, rotational speed and rotational time accurately by programming, and the invention can confirm the crystal growth situation by weighing the crystal weight and control temperature, speed and rotational direction during the growth process of the crystal in time, thus ensuring the growth quality of the crystal.

Owner:SHANDONG UNIV

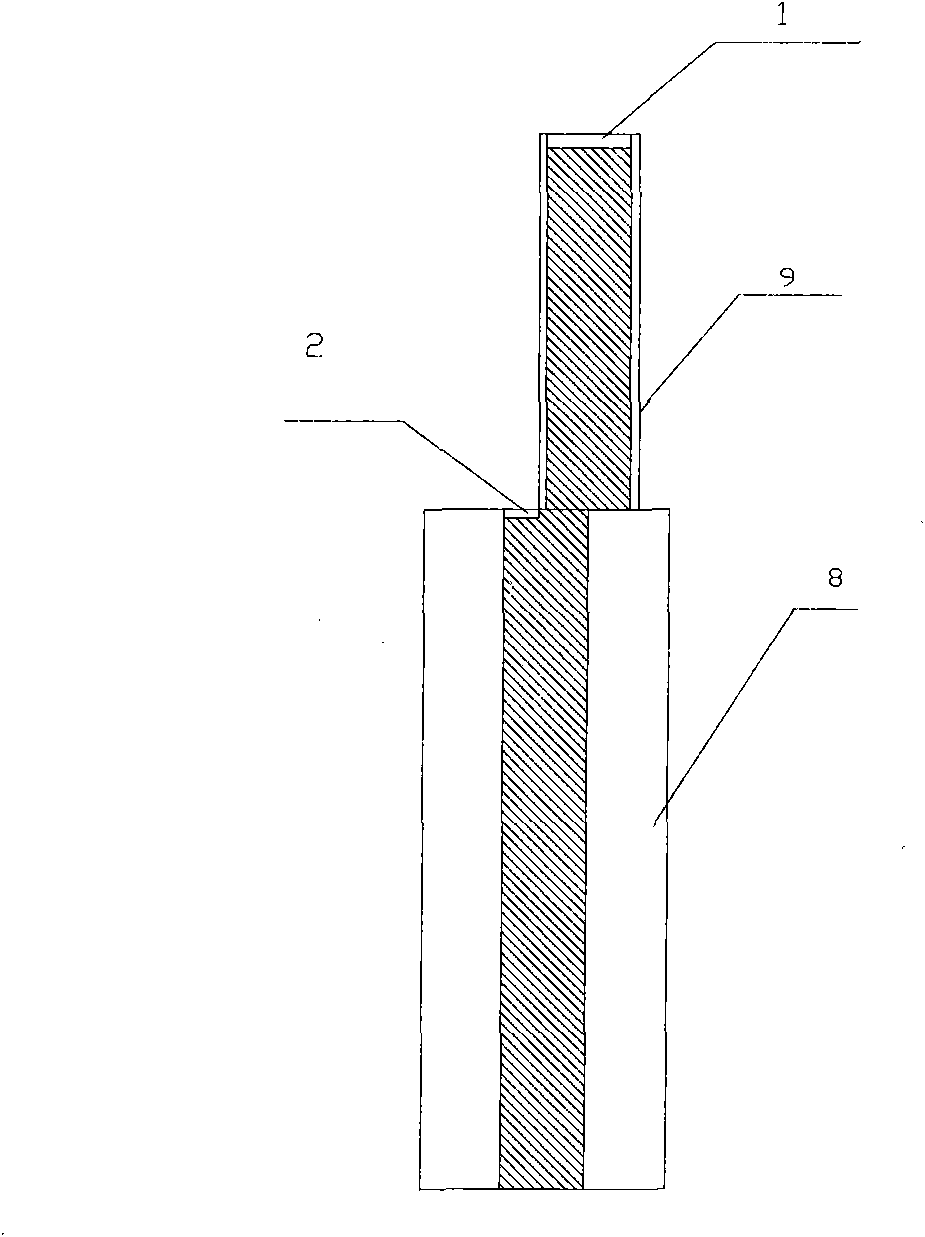

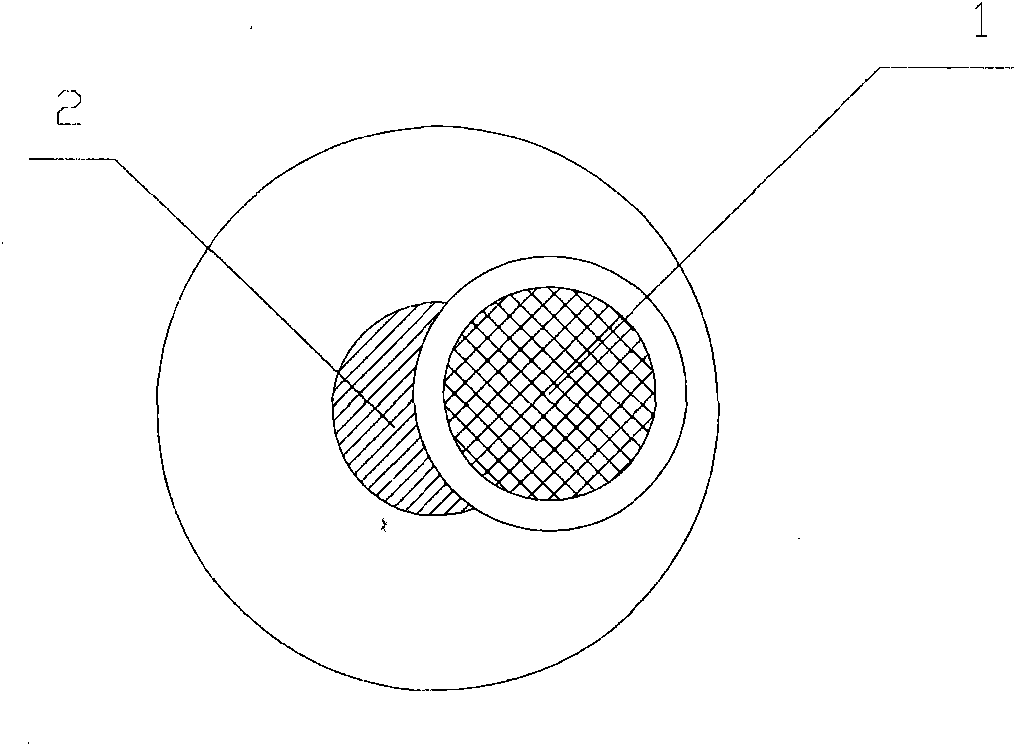

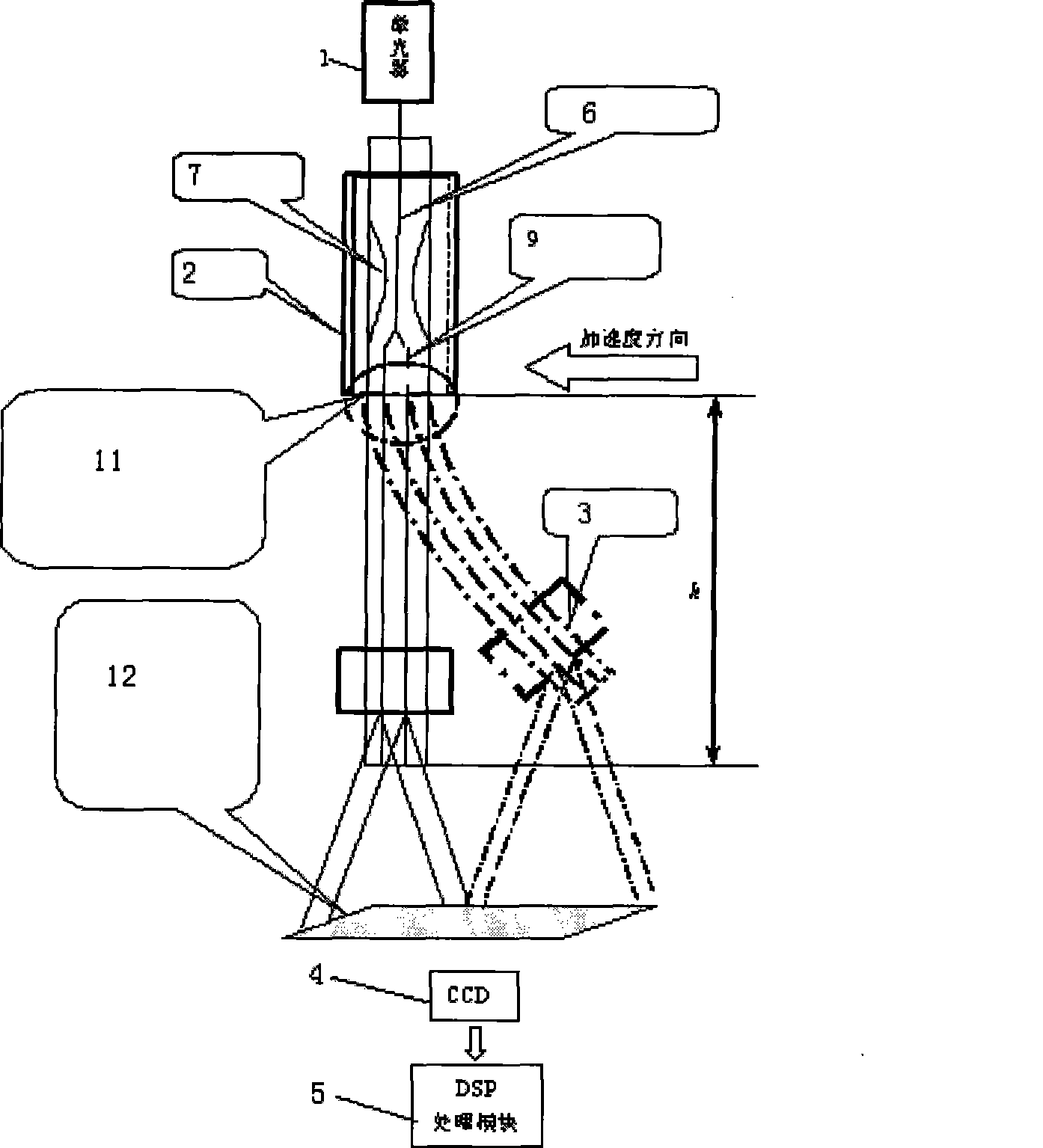

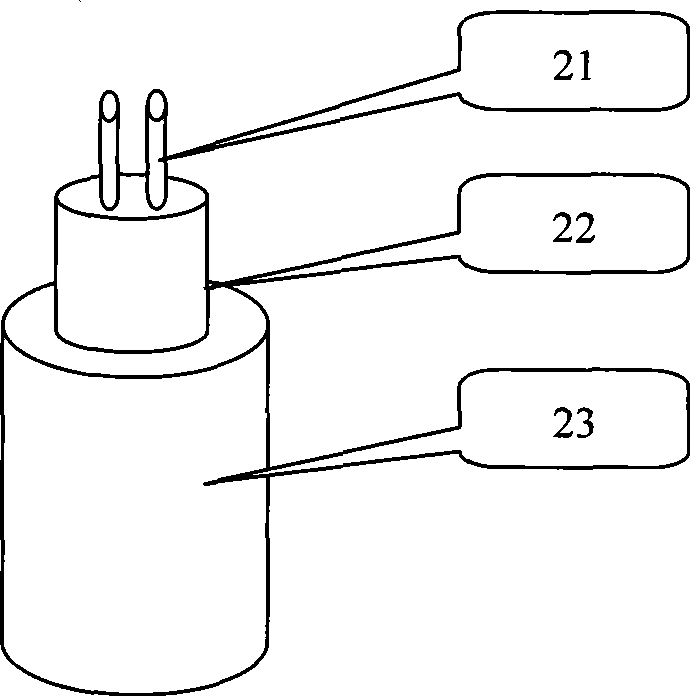

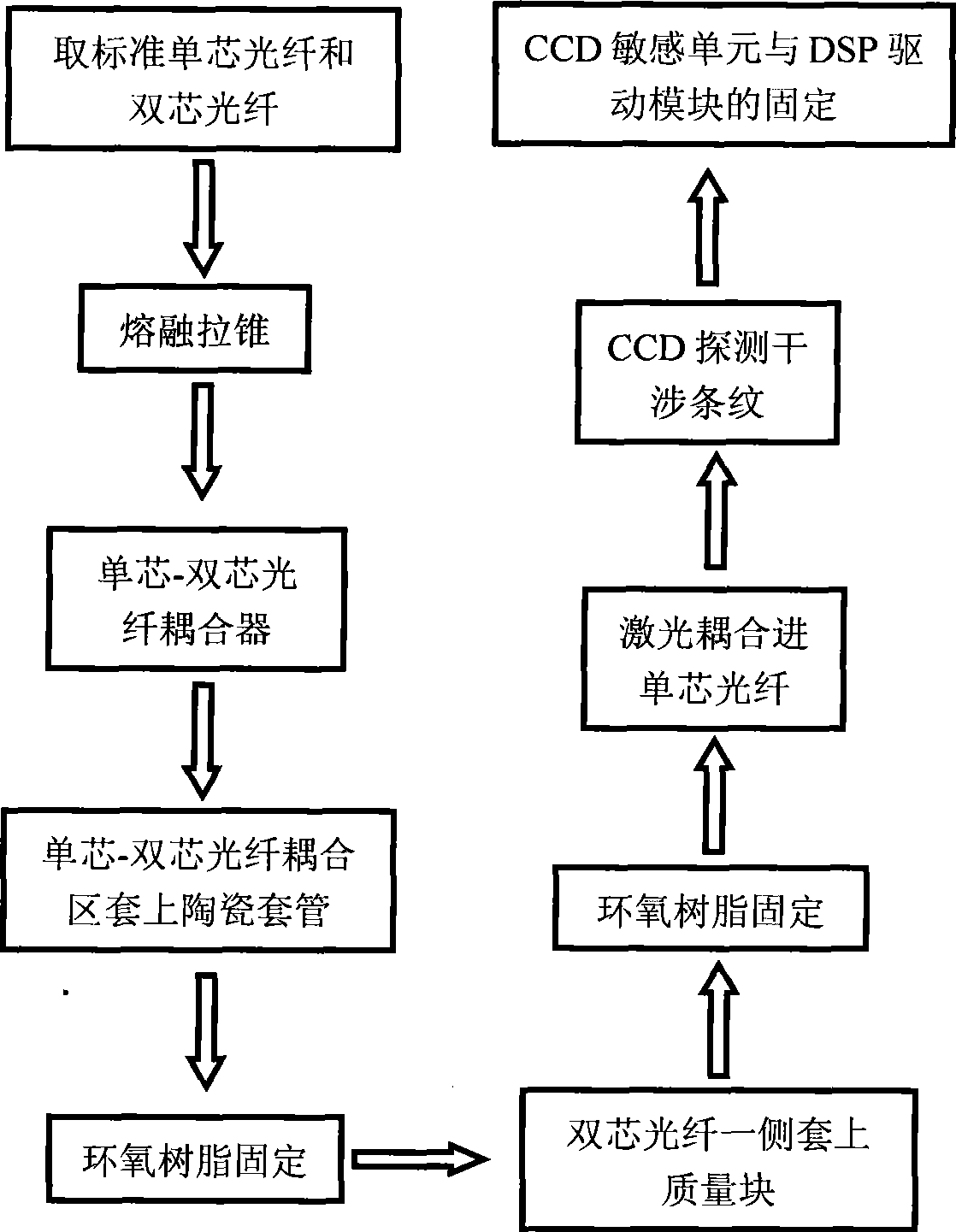

Double-core optical fiber integration type accelerometer and measuring method

InactiveCN101368978AReduce volumeRealize automatic compensationAcceleration measurement using interia forcesAccelerometerDual core

The invention provides a dual-core optical fiber integrated accelerometer and a measuring method thereof. A semiconductor optical laser device 1 is coupled at one end of a single-core optical fiber 6, a dual-core optical fiber 9 is coupled at the other end of the single-core optical fiber 6, a sleeve 8 is nested outside the coupled region 7 of the single-core optical fiber and the dual-core optical fiber, the sleeve 8 is rigidly connected with an exterior shell 2, a metal sleeve which is provided with a hole in the middle is nested at the other side of the dual-core optical fiber 9 as a weight block 3, a receiving device 4 with a plurality of interference fringes and a data processing module 5 are arranged in the exterior shell 2, and the receiving device 4 and the data processing module 5 are rigidly connected with the exterior shell 2, a data line and a power supply line are fetched out through a wire hole 10. The accelerometer has the advantages that the structure is simple and compact, the automatic compensation can be achieved, the accelerometer is suitable for various measuring occasions, and the measuring sensitivity is high.

Owner:HARBIN ENG UNIV

Automatic blood rheometer

The invention discloses an automatic blood rheometer comprising an integration type temperature controlling module, a measuring module, a dynamic module, an infrared liquid level quantification module and a signal processing and controlling circuit. The integration type temperature controlling module comprises a temperature sensor and a heating panel. The measuring module comprises a U-shaped glass tube and a pressure sensor. The dynamic module comprises a direct-current peristaltic pump, a solenoid valve set and a silica gel pipeline. The heating panel, the temperature sensor and the U-shaped glass tube are arranged in a sealed heat-insulating box. The pressure sensor is connected to the U-shaped glass tube through the silica gel pipeline. Signals outputted by the pressure sensor are transmitted to the signal processing and controlling circuit, and is subject to a sampling treatment. Treatment data is delivered to a computer. With the blood rheometer provided by the invention, rapid measuring can be carried out upon whole blood apparent viscosity and a relation thereof with shear rate. The blood rheometer can also be used in the measurement of blood plasma absolute viscosity. With the blood rheometer, a plurality of samples can be automatically detected within one time. Therefore, operation processes of operators can be greatly simplified. The blood rheometer is advantaged in stable performance, high automation degree, and improved efficiency.

Owner:SHANGHAI ANCAI INTELLIGENT TECH

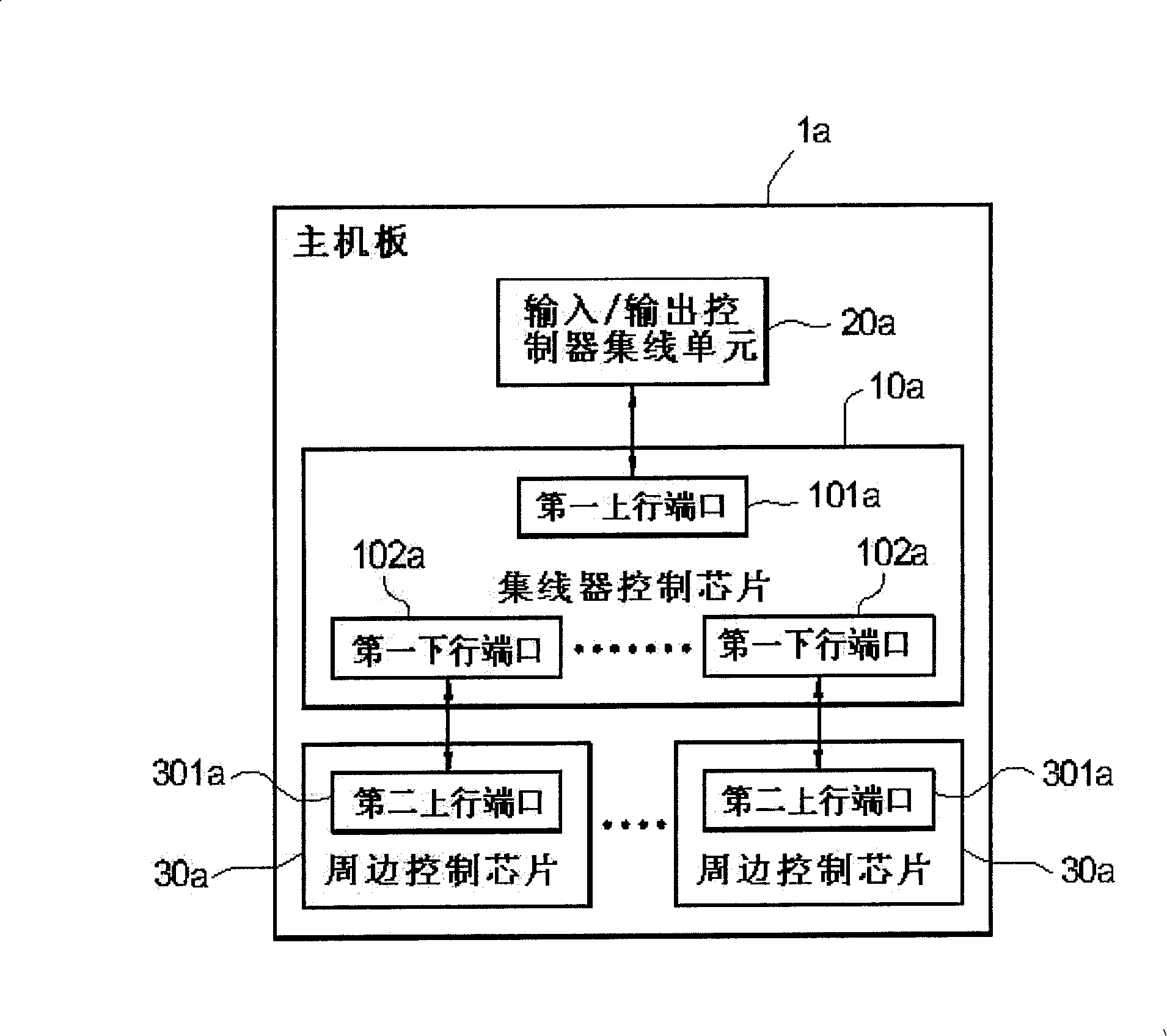

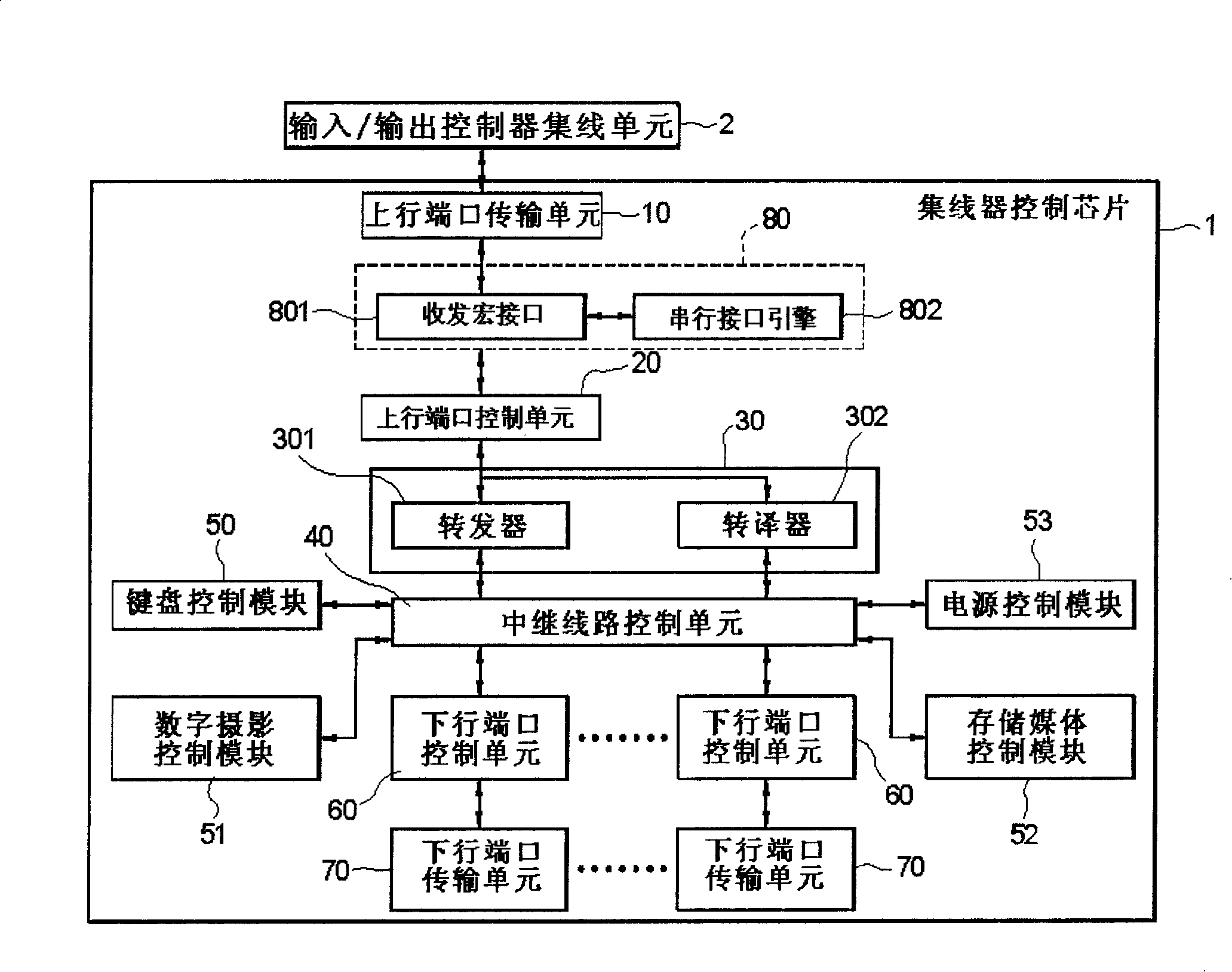

Integration type concentrator control chip

InactiveCN101206628ALow costImprove versatilityProgram loading/initiatingMedia controlsData transmission

An integrated type hub control chip applied to a mainboard of an application system comprises an upstream port transmission unit, an upstream port control unit, a relay line unit, a keyboard control module, a digital photography control module, a storage media control module and a relay line control unit, wherein, the keyboard control module, the digital photography control module and the storage media control module are directly connected through the relay line control unit; transmission paths in the relay line unit are switched according to the data transmission speed of the control modules; the upstream port control unit controls the transmission direction of the upstream port transmission unit so as to transmit data with the mainboard. Therefore, the present invention achieves the objectives of saving the circuit space of the mainboard, reducing hardware cost and increasing the versatility and extendibility of hub control chips.

Owner:ALCOR MICRO CORP

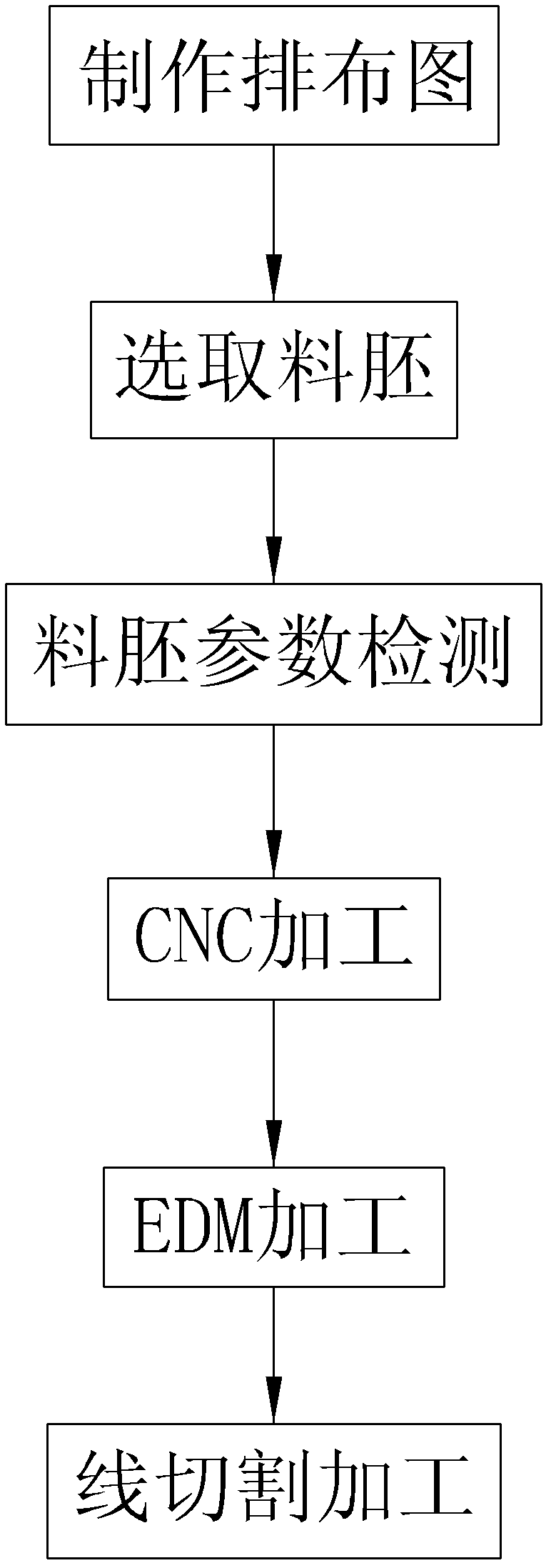

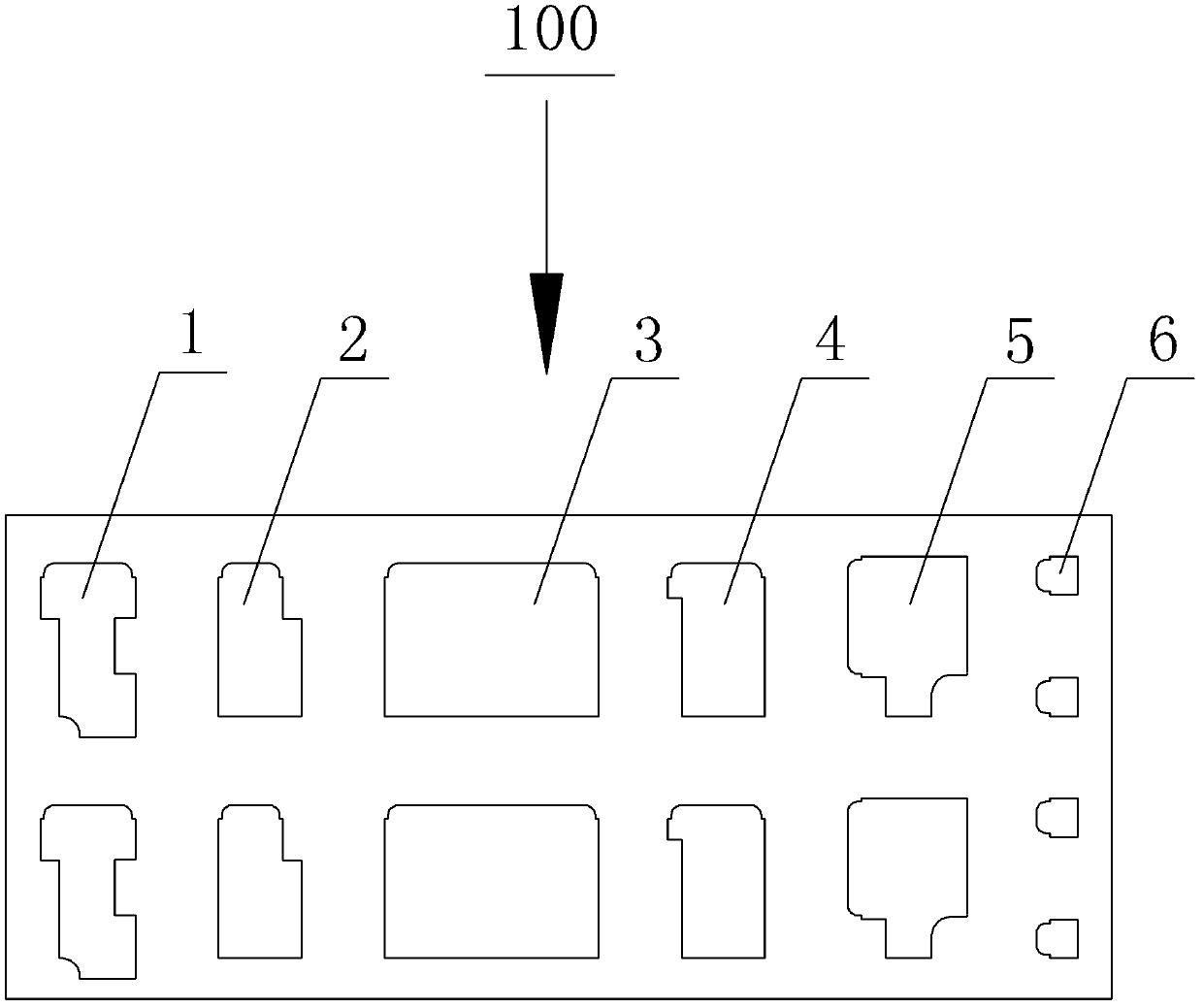

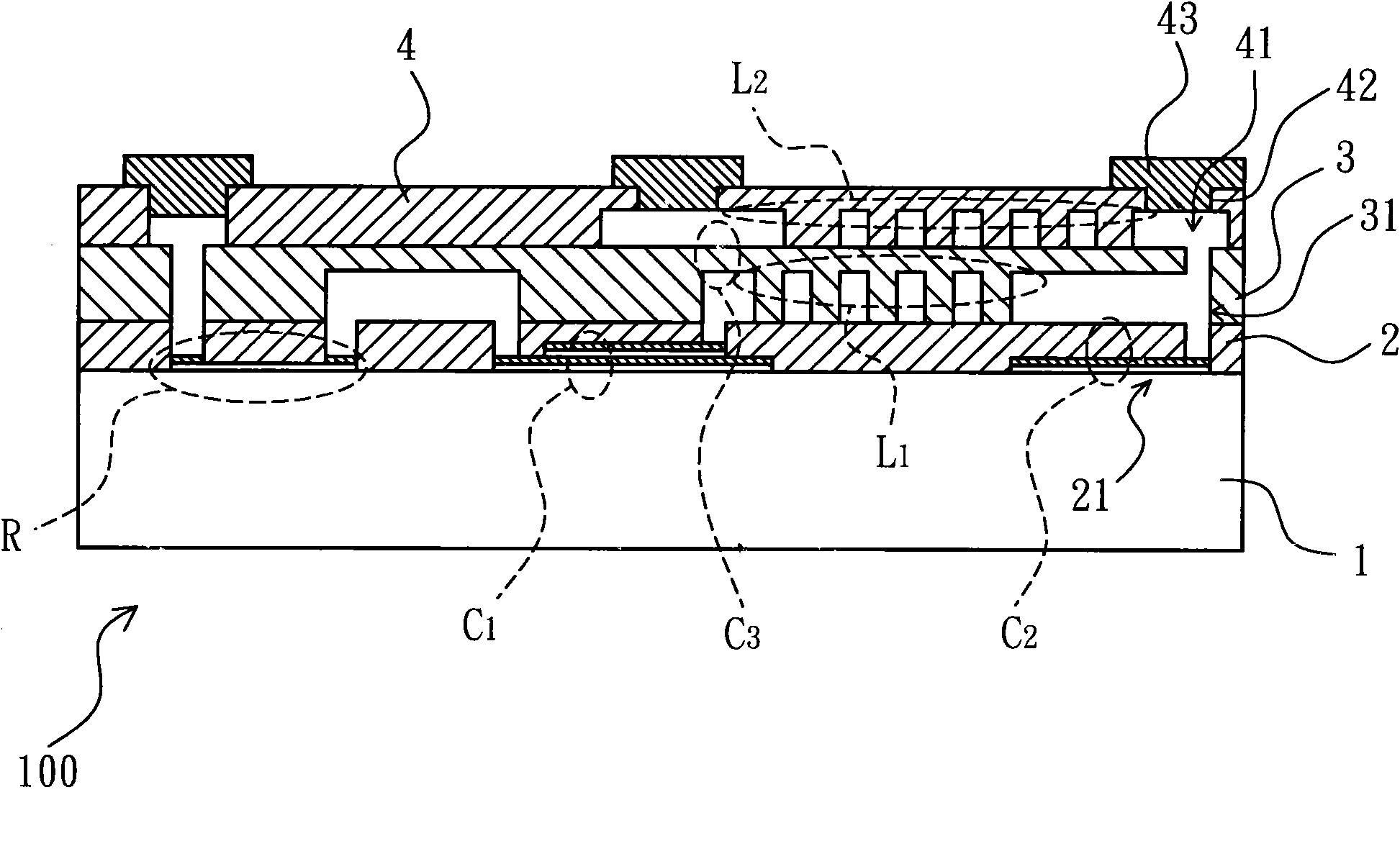

Insert integration type processing process

The invention discloses an insert integration type processing process. The insert integration type processing process comprises a first step of drawing a drawing with a plurality of insert outer contour maps according to the size and the shape of every to-be-processed insert; a second step of determining the size of needed blank according to the arrangement maps, and selecting the blank; a third step of detecting whether the squareness, the length, the width, the height and the tolerance of the blank meet the standard; a fourth step of performing computer numerical control (CNC) processing on the position of every to-be-processed insert, and forming every insert; a fifth step of performing electrical discharge machining (EDM) processing on every insert; and a sixth step of enabling the blank having undergone EDM processing to be clamped on a wire cutting machine tool to undergo wire cutting processing, and obtaining single inserts. The insert integration type processing process has the advantages that a plurality of inserts are integrated on one piece of blank to be integrally formed, clamping time of the single inserts is reduced, processing efficiency is improved, deformation of small inserts in processing can be effectively avoided, and the problem of difficulty in clamping special-shaped inserts and small single inserts is solved.

Owner:亿和塑胶电子制品(深圳)有限公司

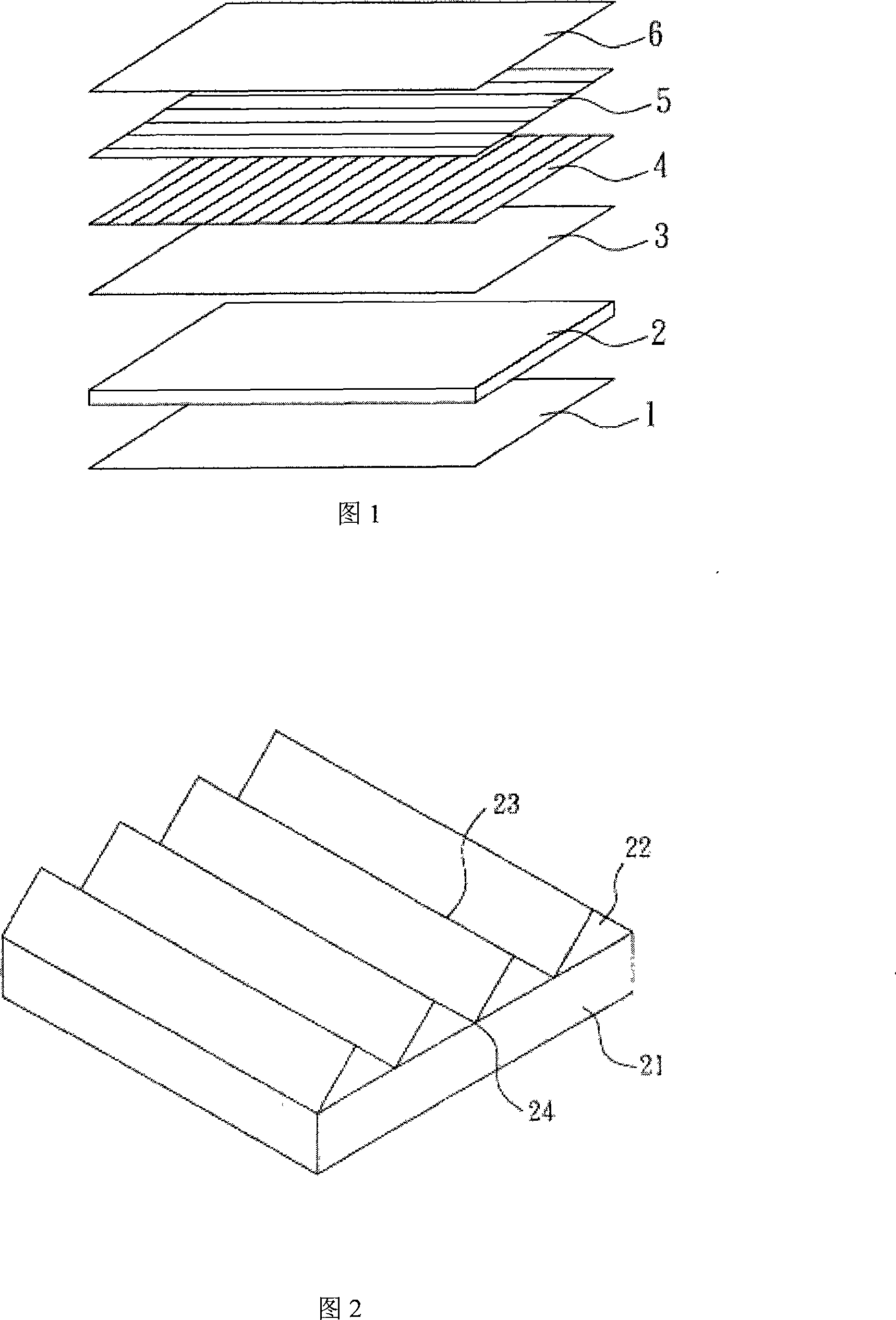

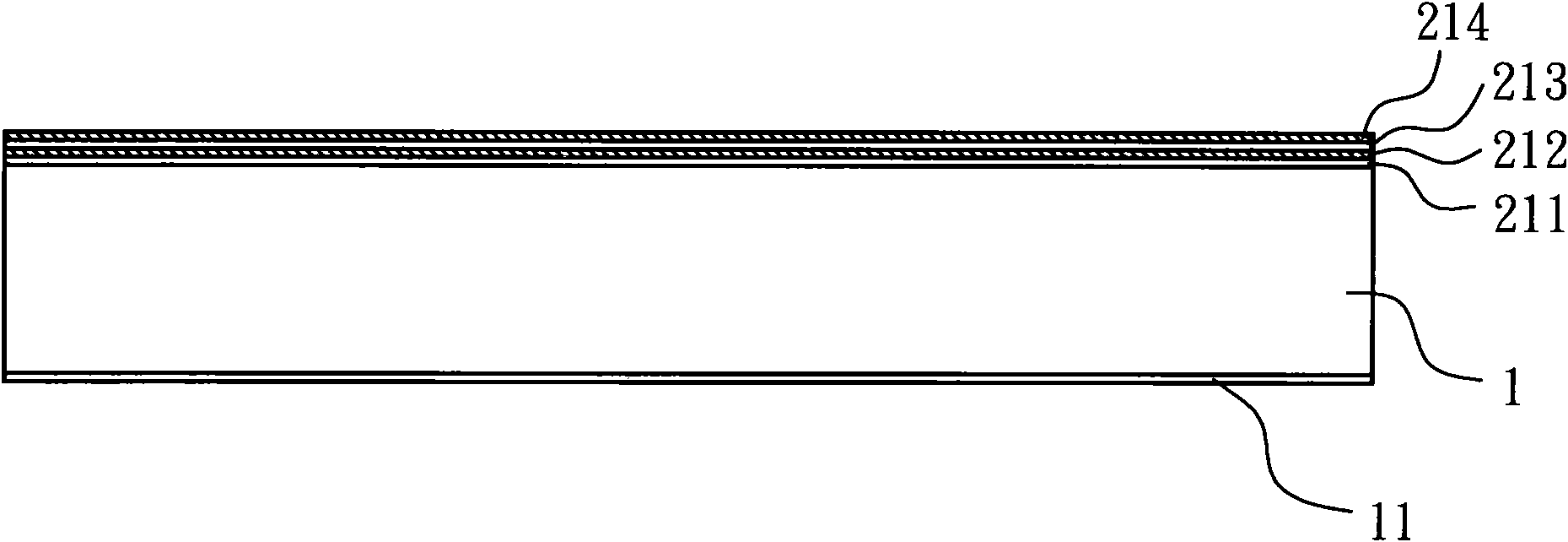

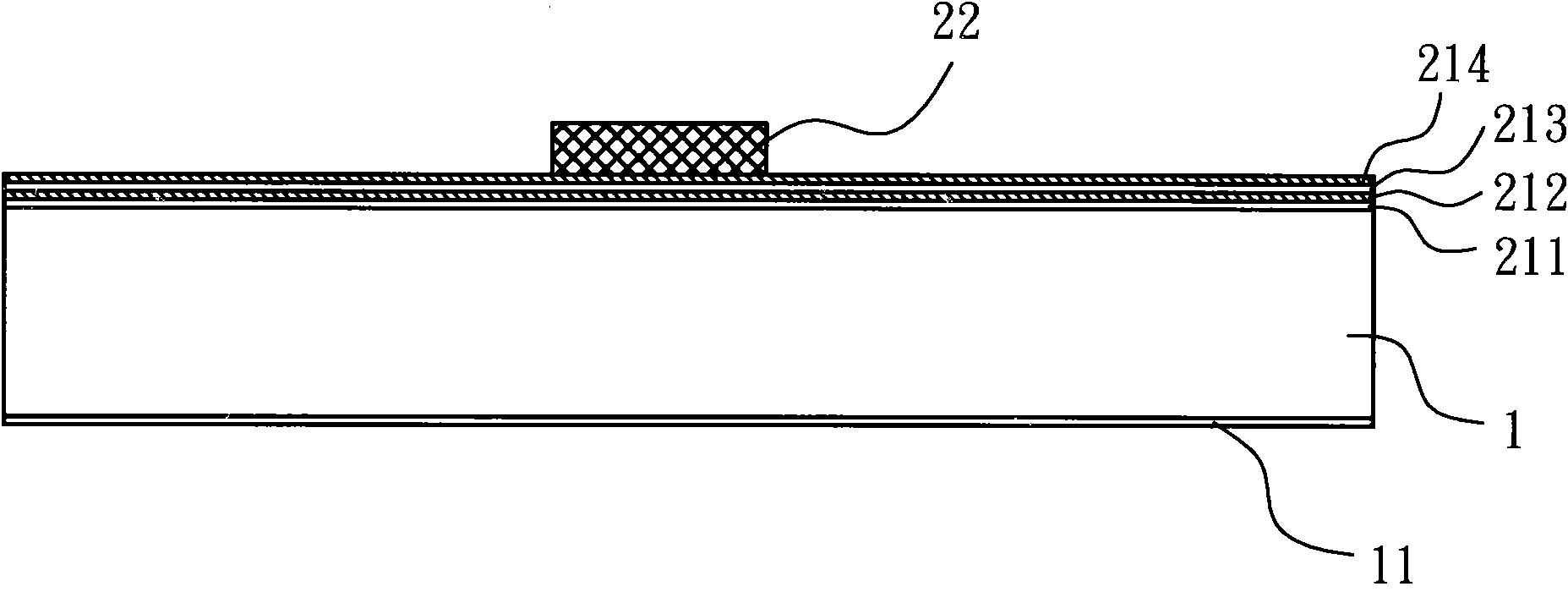

Integration-type passive element and manufacturing method thereof

ActiveCN101834178AIncrease integration densityReduced inductance lossSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInsulation layer

The invention discloses an integration-type passive element and a manufacturing method thereof. The integration-type passive element is sequentially stacked with a first insulation layer, a second insulation layer and a third insulation layer on the upper surface of a substrate; a first circuit layer is arranged in the first insulation layer and comprises at least one capacitor structure and at least one resistor structure; a second circuit layer is arranged in the second insulation layer, has the thickness within 5 to 50 microns and forms at least one first inductor structure; and a third circuit layer is arranged in the third insulation layer, has the thickness within 5 to 25 microns and forms at least one second inductor structure. The integration-type passive element can be manufactured by adopting a semiconductor rear section encapsulation substrate device, has the capacitor structure with the thickness more than 5 microns, is further beneficial to reducing the inductor loss and improving the inductor efficiency and can improve the integration density of the passive element and reduce the element size.

Owner:ADVANCED SEMICON ENG INC

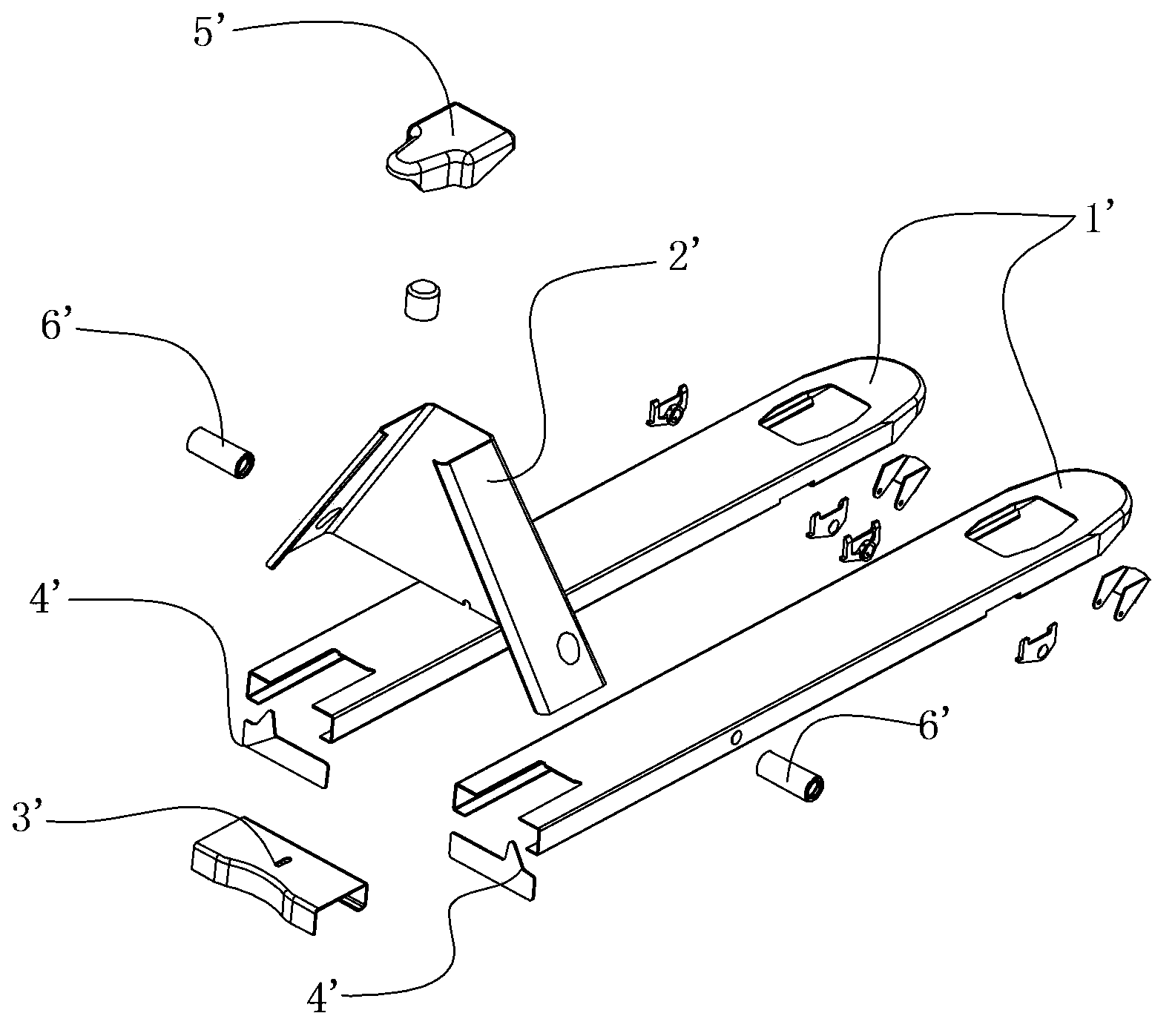

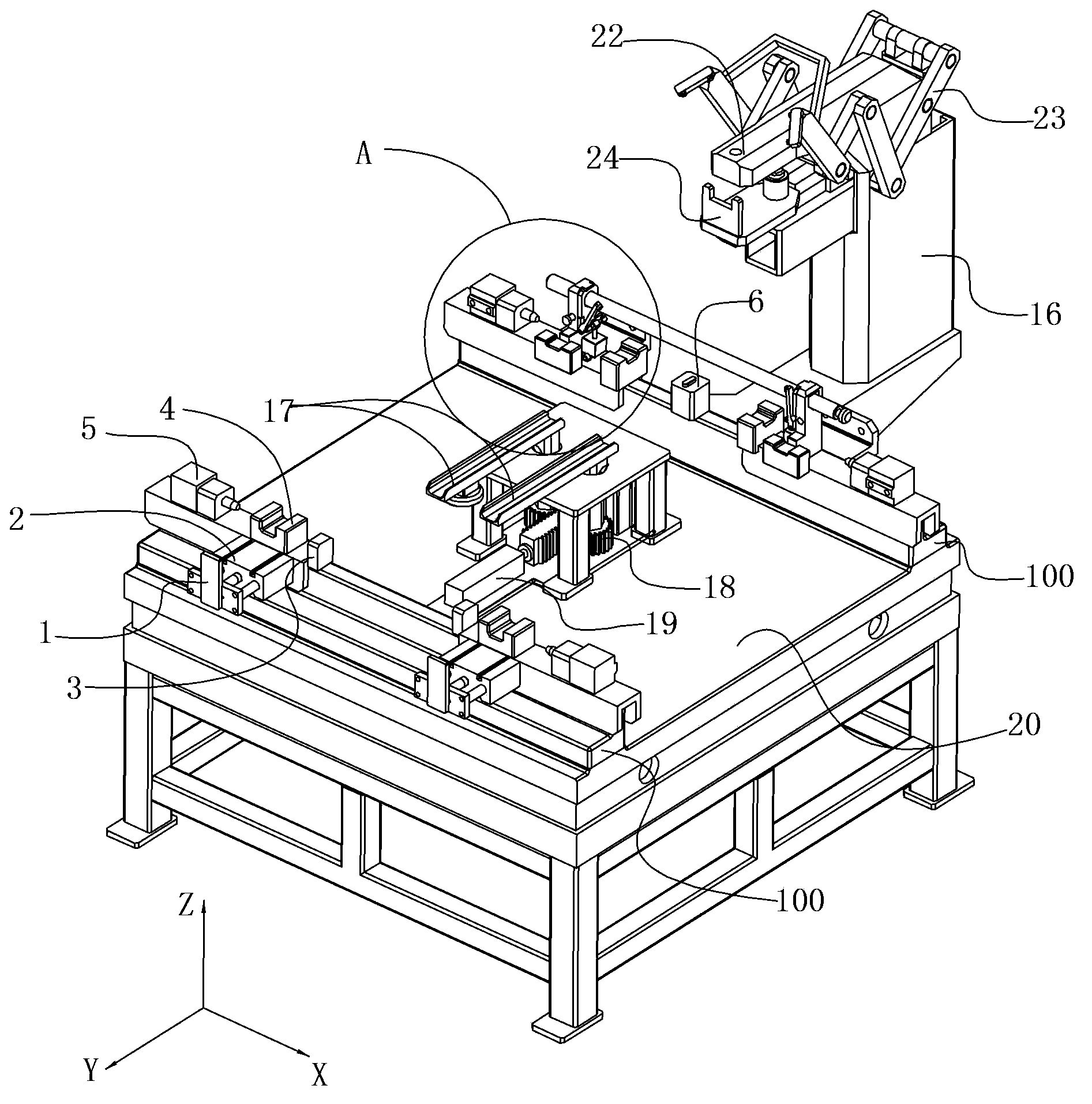

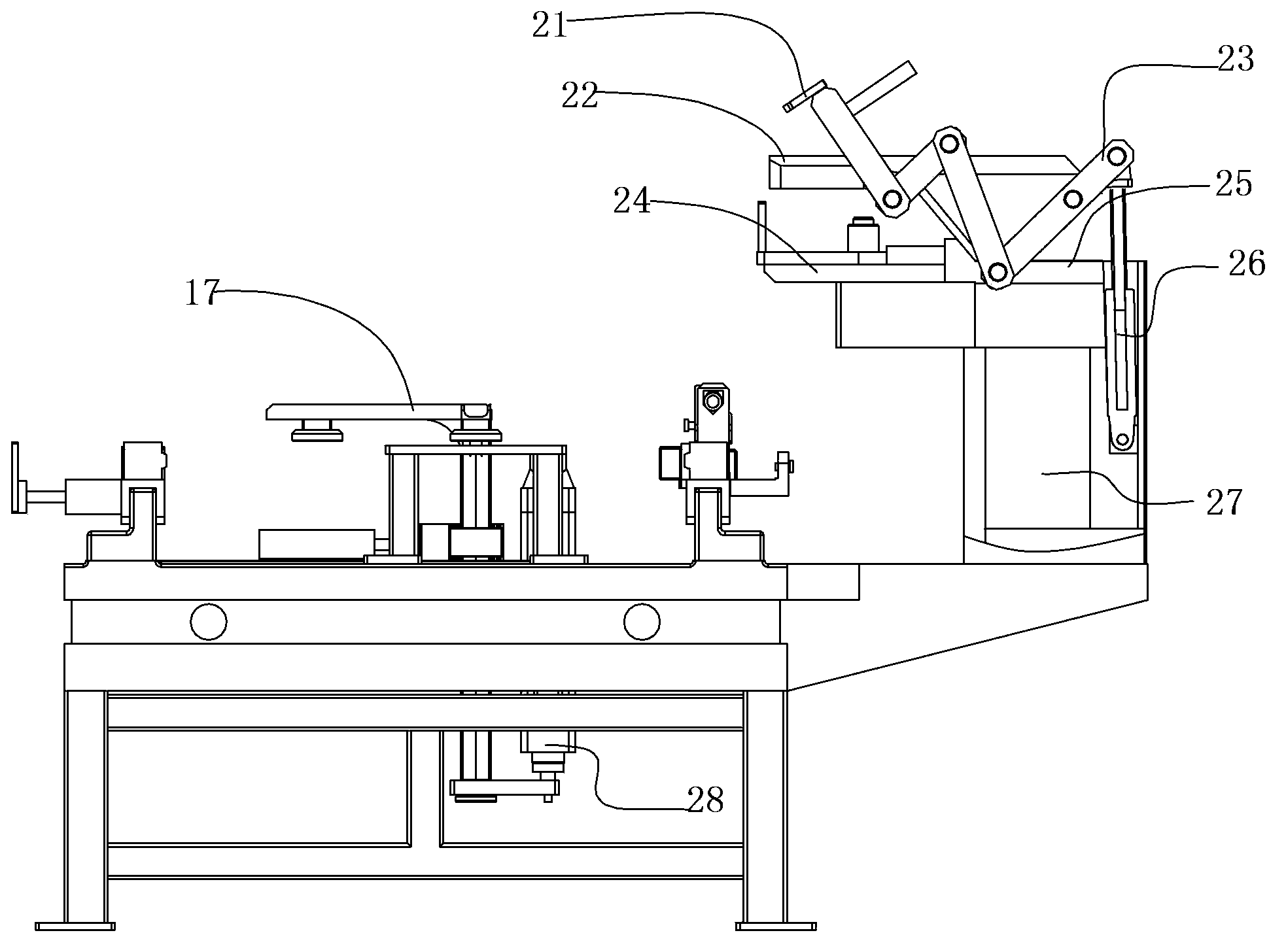

Manual tray carriage welding device

ActiveCN103801872AReduce welding processIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesTopology optimizationEngineering

The invention provides a manual tray carriage welding device, which comprises a base and an auxiliary installing base, wherein the base is in horizontal arrangement, the auxiliary installing base is positioned in the middle position of one side of the base and vertically and upwards extends, an x-direction positioning clamping module of a cargo fork of a manual tray carriage, a y-direction positioning clamping module of the cargo fork, a z-direction positioning clamping module of the cargo fork, a positioning clamping module of a top cover of the manual tray carriage and a positioning clamping module of a middle gear of the manual tray carriage, a positioning clamping module for a long shaft sleeve and a triangle of the manual tray carriage and a tooling mechanism of a back cover plate of the cargo fork are arranged on the base and the auxiliary installing base. The manual tray carriage welding device adopts the methods such as automation control technology, structural optimization design and space topology optimization for building the work procedure integration type manual tray carriage flexible welding device, the welding processing work procedures of the manual tray carriage are reduced, the processing site area is reduced, the production efficiency and the processing quality of the welding processing of the manual tray carriage are improved, the welding processing specifications of the manual tray carriage are increased, and the worker number and the work intensity are reduced.

Owner:NINGBO RUYI

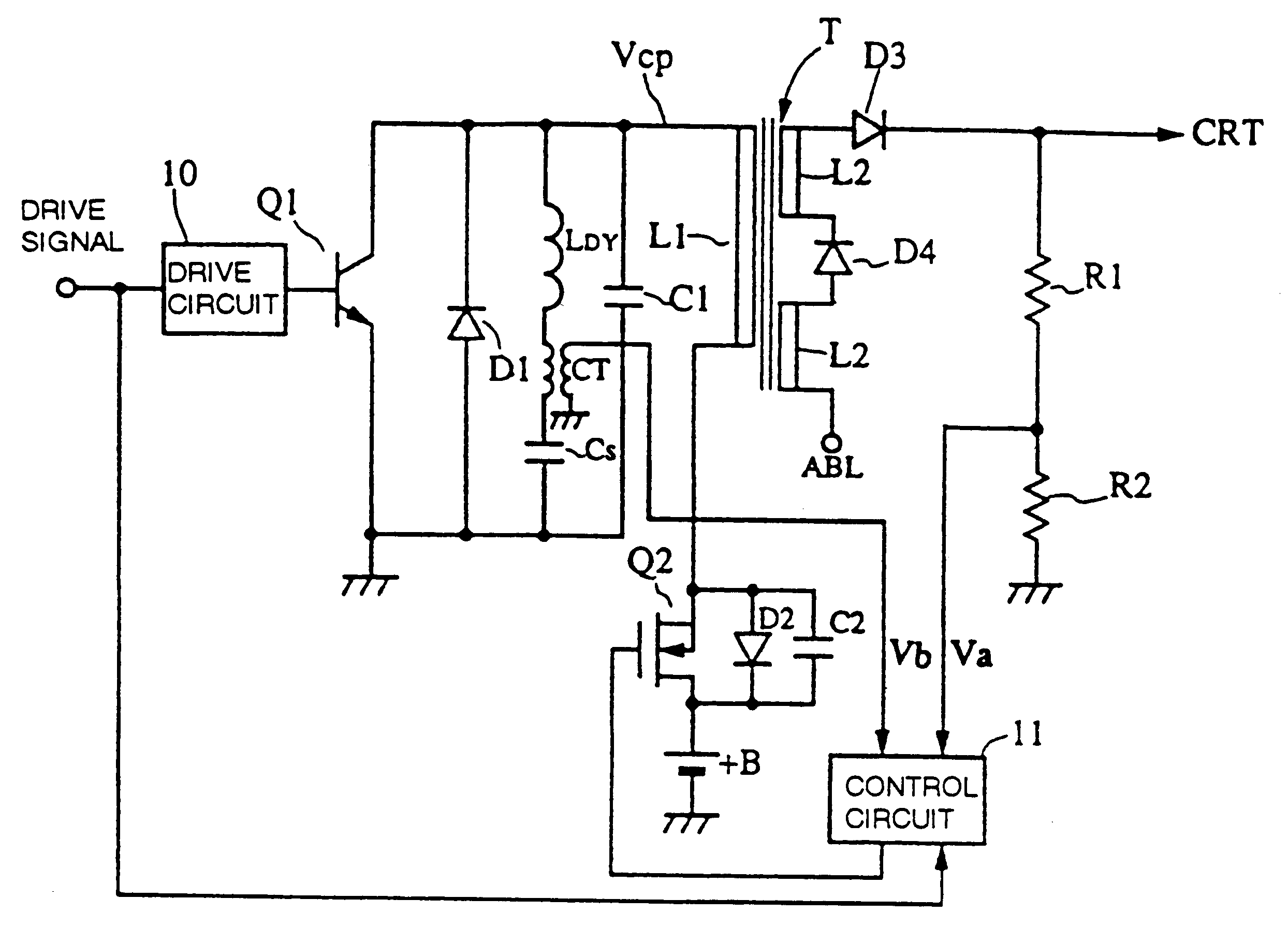

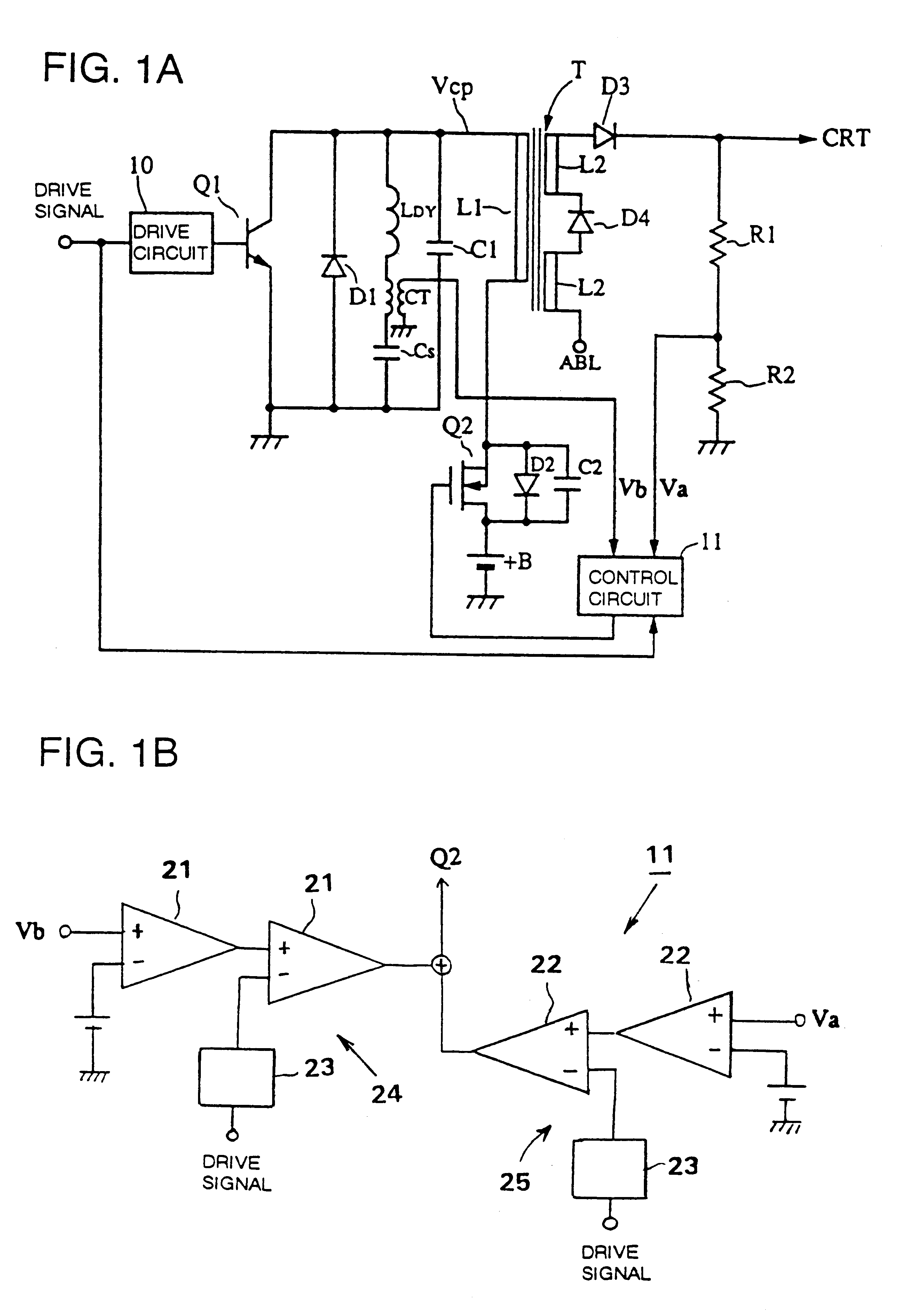

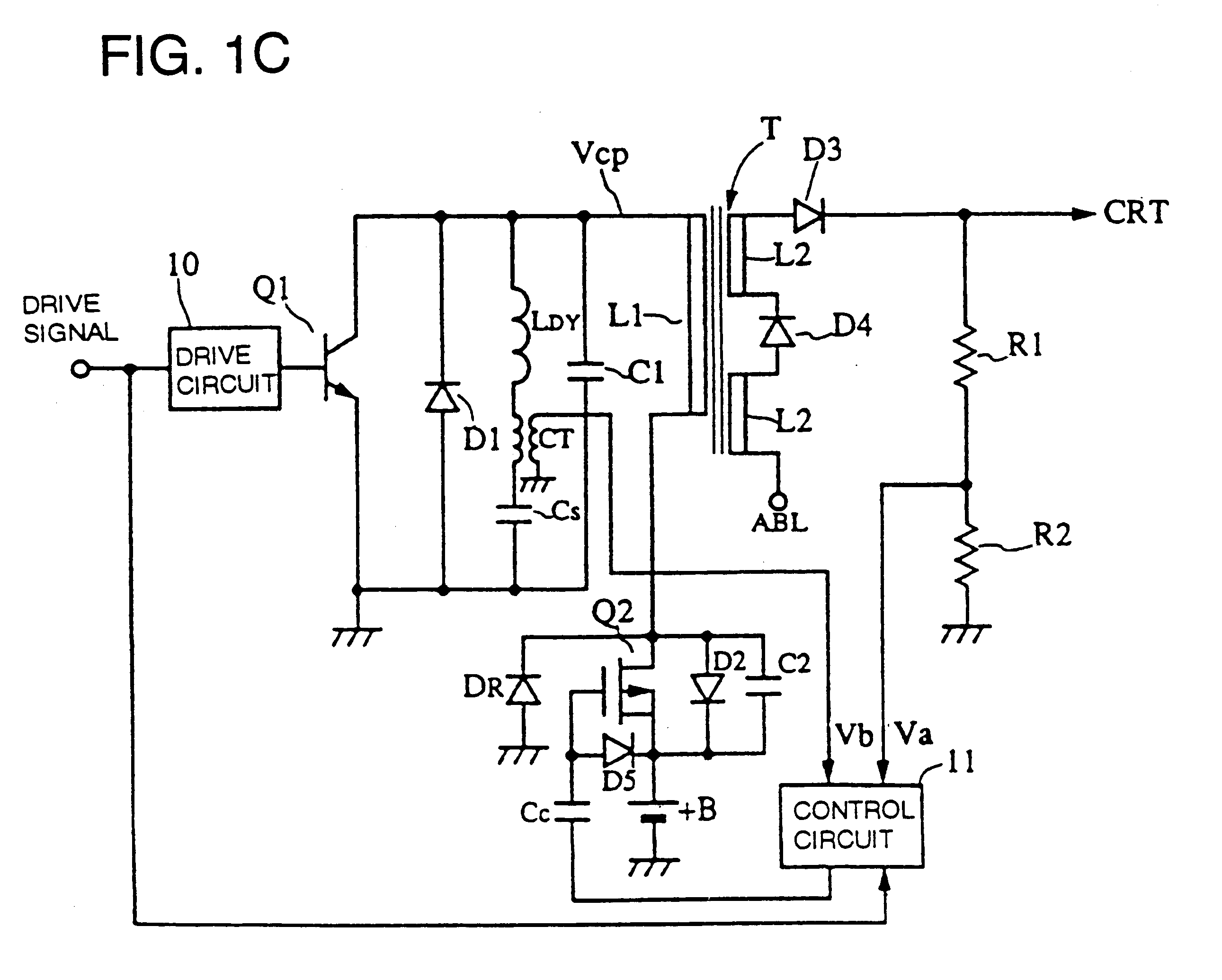

Deflection current/high voltage integration type power supply

A deflection current / high voltage integration type power supply has a flyback transformer having a primary winding and a secondary winding; a series circuit of a deflection coil and a first capacitor, connected in series to the primary winding of the flyback transformer; a resonance capacitor connected in parallel to the series circuit of the deflection coil and the first capacitor; a first switching element, connected in parallel with the series circuit of the deflection coil and the first capacitor, to be turned on / turned off by a drive signal so that a high voltage is generated at the secondary winding of the flyback transformer and a deflection current flows in the deflection coil; a parallel connection circuit of a second switching element and a second capacitor, connected in series to the primary winding of the flyback transformer; and a switching control means to control the deflection current flowing in the deflection coil and the high voltage generated at the secondary winding of the flyback transformer by controlling the on-timing and the off-timing of the second switching element in approximate synchronism with the drive signal.

Owner:MURATA MFG CO LTD

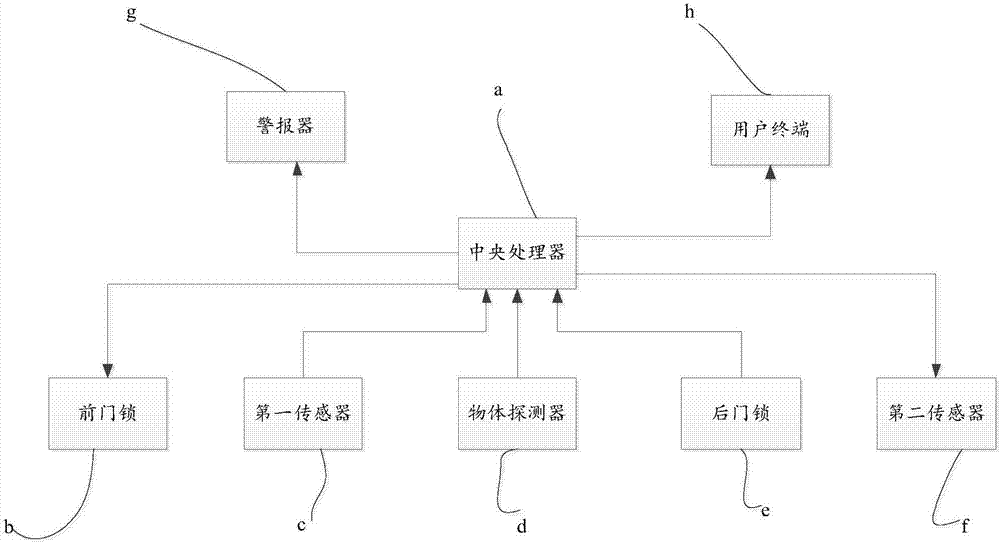

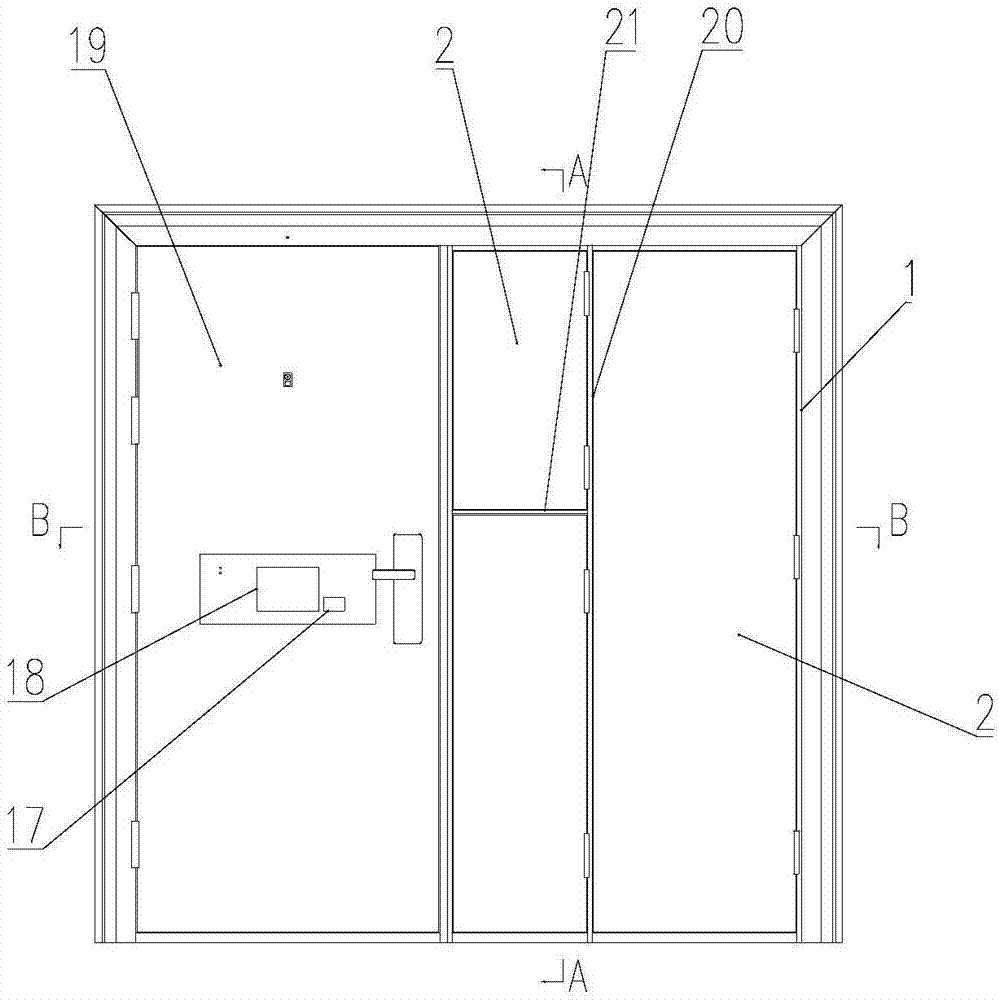

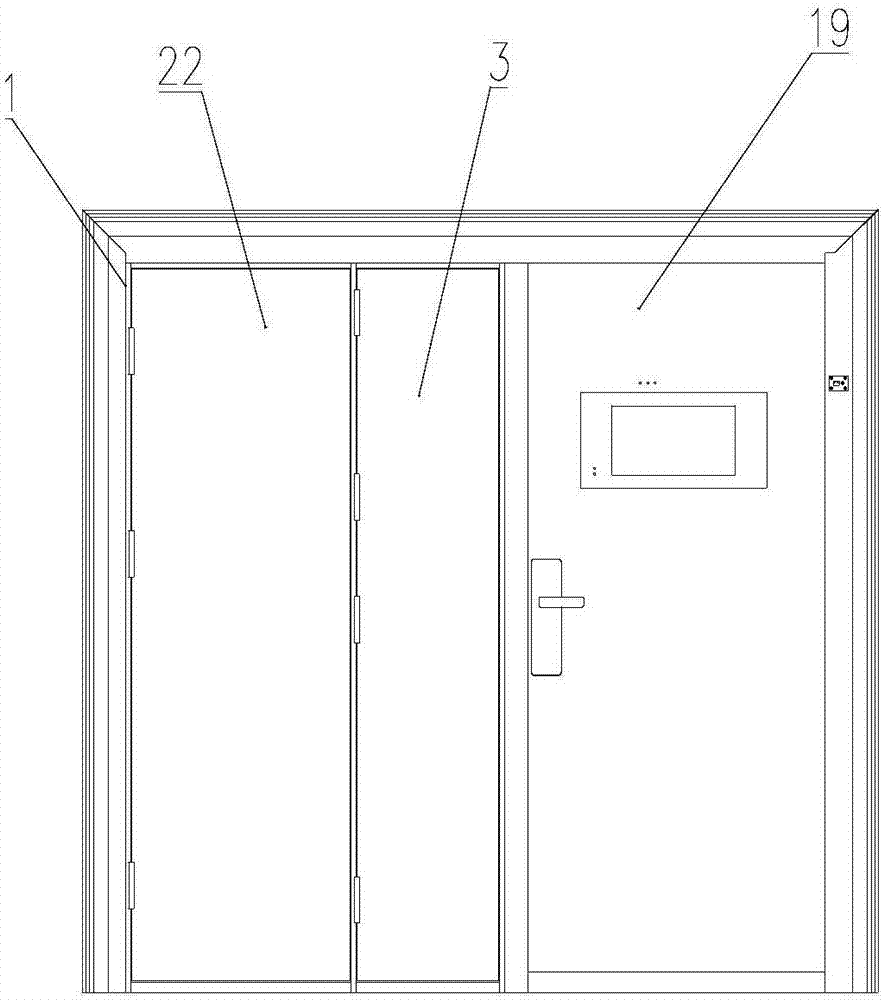

Combining integration type intelligent express container

ActiveCN107369265AShorten the timeImprove delivery qualityApparatus for meter-controlled dispensingLogistics managementEngineering

The invention belongs to the technical field of logistics transportation and particularly relates to a combining integration type intelligent express container. The combining integration type intelligent express container comprises a container body and an anti-theft door, the container body is used for storing express items and is integrated on the outside part of the anti-theft door, a first partition is vertically arranged in the container body and partitions the container body into a first chamber and a second chamber, a plurality of second partitions are horizontally arranged in the first chamber, the second partitions partition the first chamber into a plurality of storage rooms, one of a front door and a first back door of each storage room can be selectively opened, and one of a front door of the second chamber and a second back door of the second chamber can be selectively opened. By the arrangement, multiple express items can be delivered through one express container, convenience and reliability are achieved; in addition, one of the front door of each storage room and the back door of the container body can be selectively opened, security in delivery of the express items can be ensured, and user home security is guaranteed.

Owner:武汉未远金易科技有限公司

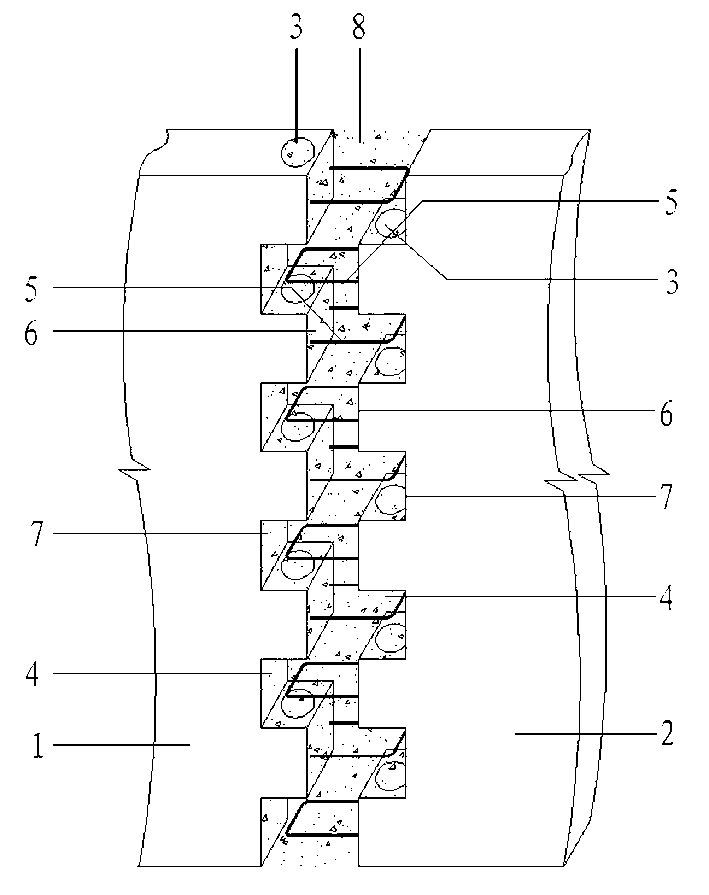

Connecting structure of prefabricated concrete wall body

ActiveCN102797307ASolve the problem of weak seam connectionImprove performanceWallsRebarPrecast concrete

The invention discloses a connecting structure of a prefabricated concrete wall body, and belongs to the technical field of a building structure. The connecting structure of the prefabricated concrete wall body comprises a first prefabricated concrete wall body and a second prefabricated concrete wall body, wherein the positions of the first prefabricated concrete wall body and the second prefabricated concrete wall body, which are close to the end surfaces, are provided with longitudinal communicating holes; the end surfaces are provided with a plurality of horizontal grooves; horizontal grooves of the first prefabricated concrete wall body and the second prefabricated concrete wall body are distributed in a staggering manner; the end surfaces of the first prefabricated concrete wall body and the second prefabricated concrete wall body are provided with U-shaped steel bars which are convex outwards from the inner part of the wall body, and the U-shaped steel bars extend to the positions close to the top surfaces of the horizontal grooves of the second prefabricated concrete wall body and the first prefabricated concrete wall body; and the horizontal grooves, the longitudinal holes and the space between the end surfaces of the prefabricated concrete wall bodies are filled with cast-in-place concrete. The connecting structure disclosed by the invention has the advantages that the integrity of the assembling integration type concrete structure can be improved and the performance of the building structure can be improved.

Owner:初明进

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com