Manual tray carriage welding device

A manual pallet truck, welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of small internal space of the triangle, long auxiliary time, affecting processing accuracy and processing quality, etc., to reduce the number of workers and The effect of labor intensity, increasing specifications, improving production efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

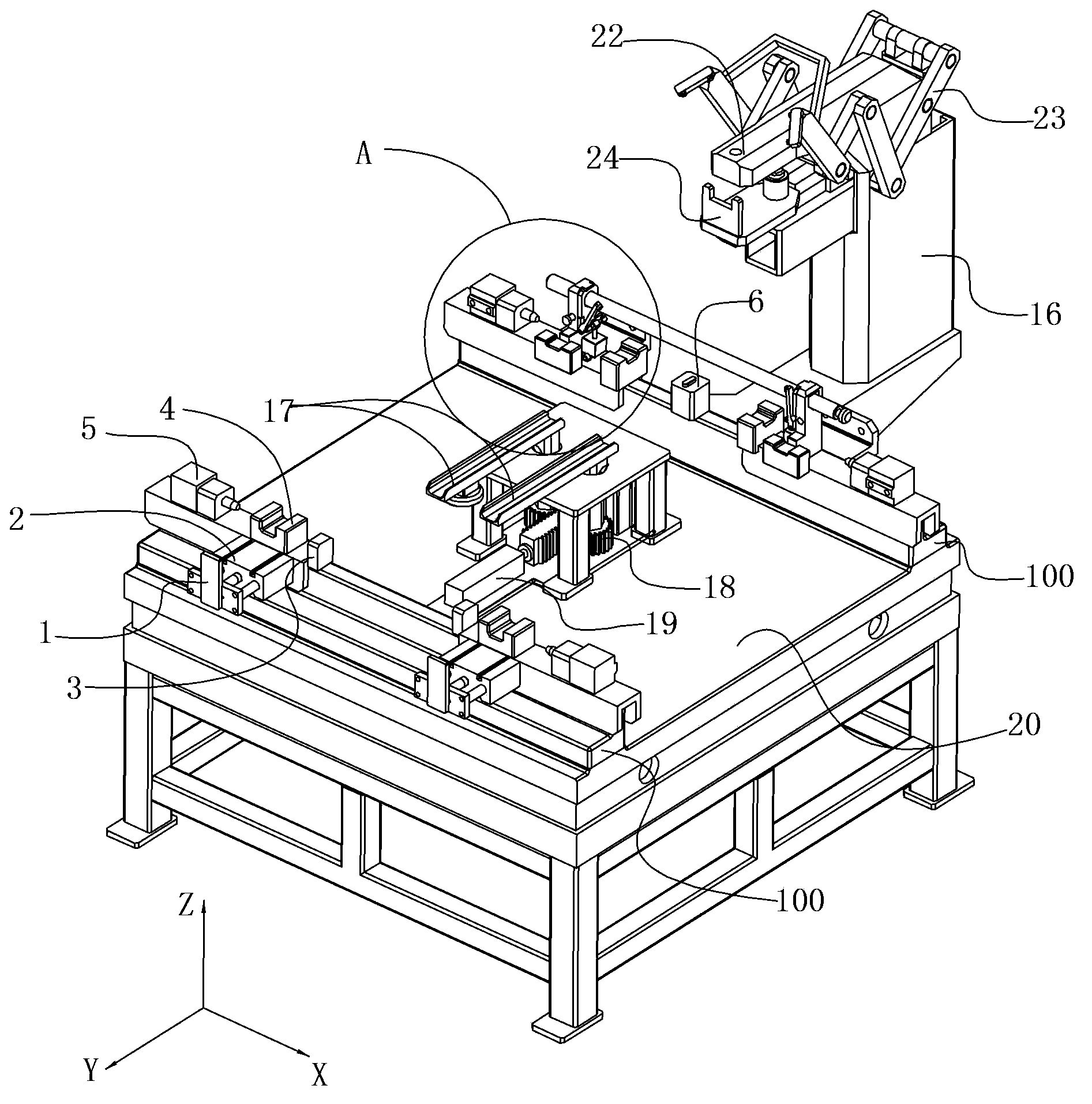

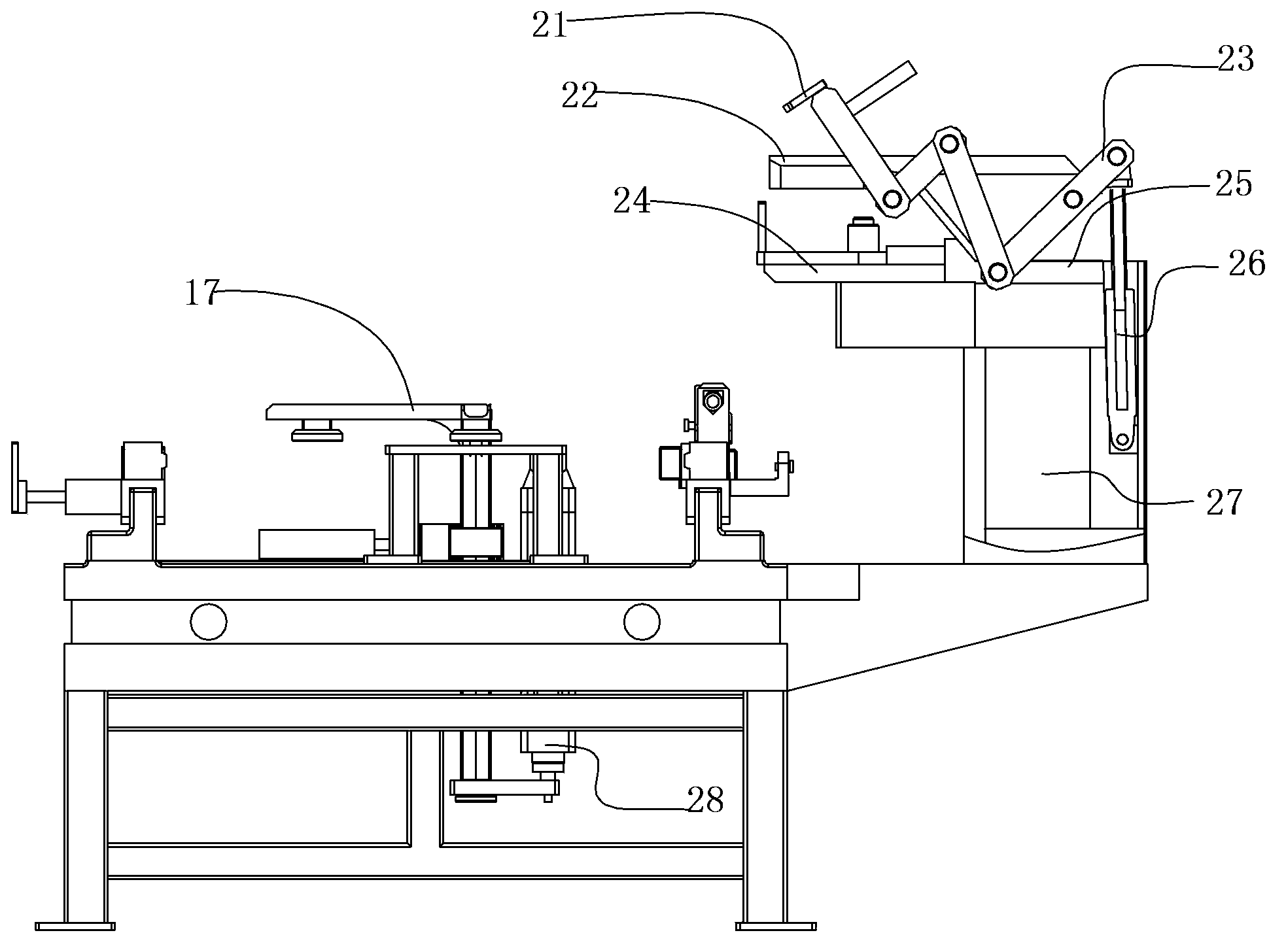

[0021] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

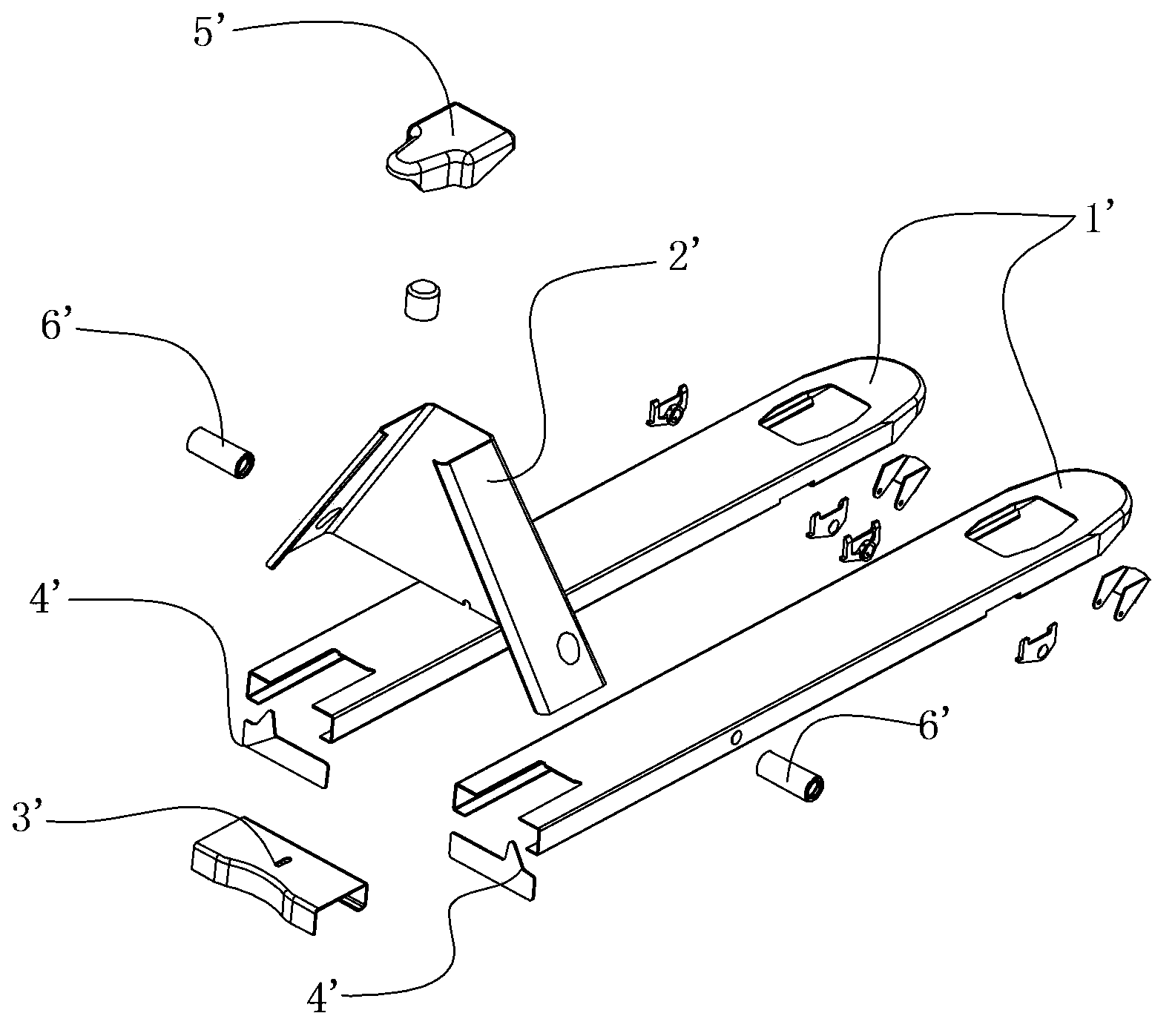

[0022] The manual pallet truck welding device of the present invention, such as Figure 2-4 As shown, it includes a base 20 and an auxiliary installation base 16 located on one side of the base 20. The auxiliary installation base 16 is located in the middle of one side of the base 20 and is perpendicular to the base 20. In the following description process, such as figure 2 As shown, assuming that the extension direction of the auxiliary mounting base 16 is the Z direction, the direction extending from one side of the auxiliary mounting base 16 to the other on the base 20 is the Y direction, and the direction perpendicular to the Y direction on the base 20 is X direction. The base 20 is provided with a mounting platform 100 extending along the direction of the base 20x.

[0023] The manual pallet truck welding device also includes 4 x-direction fork posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com