Integration-type passive element and manufacturing method thereof

A technology of passive components and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem that the Q value of the inductance structure cannot be further improved, and the application value of integrated passive components is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

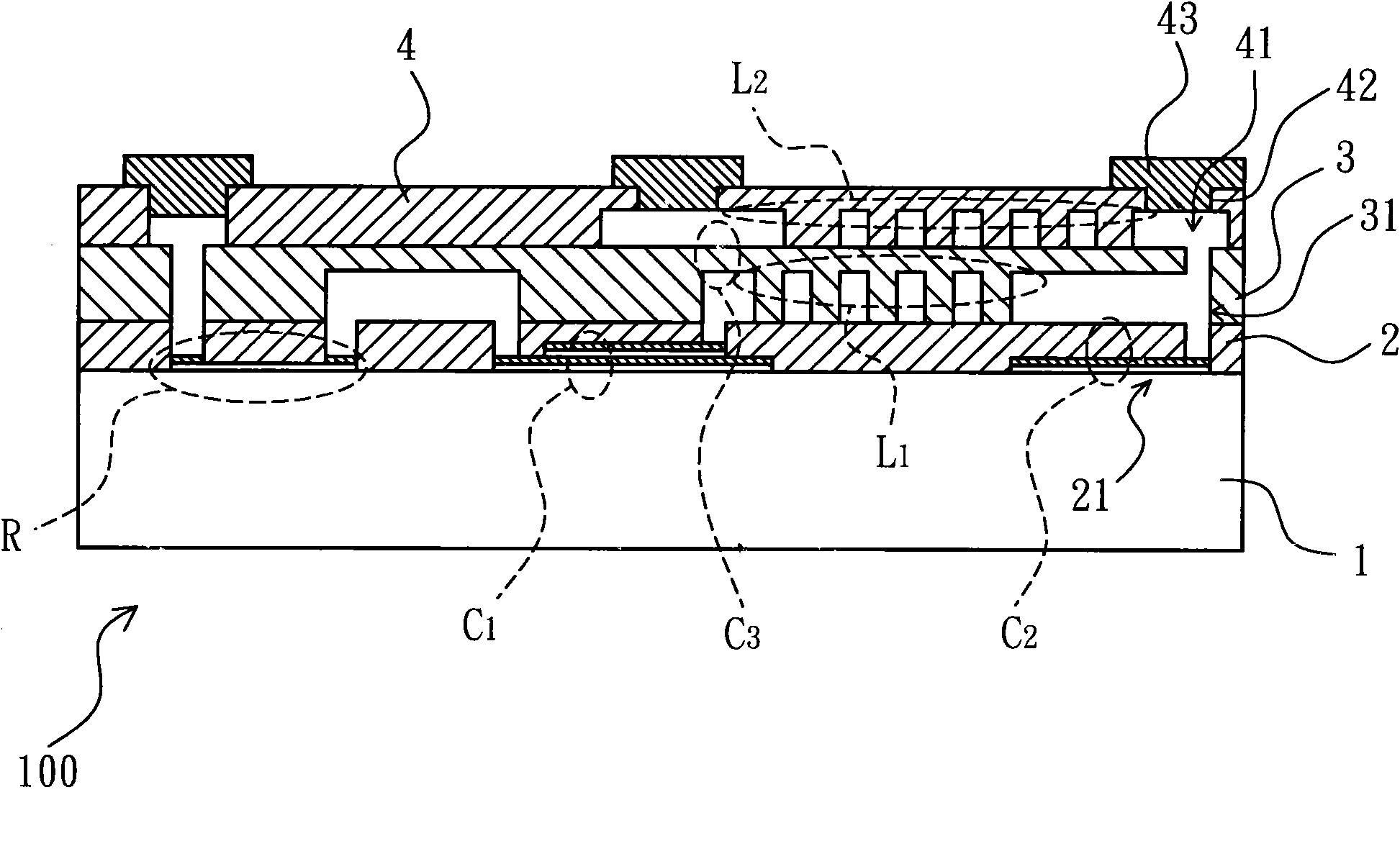

[0024] Please refer to figure 1 As shown, the integrated passive device (IPD) of the first embodiment of the present invention is similar to the existing thin film technology integrated passive device manufactured by physical phase deposition equipment in the semiconductor front-end wafer foundry industry, but the present invention changes to The semiconductor back-end packaging substrate equipment is used to manufacture integrated passive components, so that it has an inductive structure with a thickness greater than 5 microns, which is beneficial to reduce inductive loss and improve inductive efficiency, and can be applied to system-in-package (SIP) packaging. structure to impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com