Integrated module board with embedded IC chip and passive element and its production method

A technology of passive components and manufacturing methods, applied in the direction of electrical components, electrical components, electrical solid devices, etc., can solve the problems of long layout circuit lines, inability to meet lightness, thinness, affecting electrical quality, etc., and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

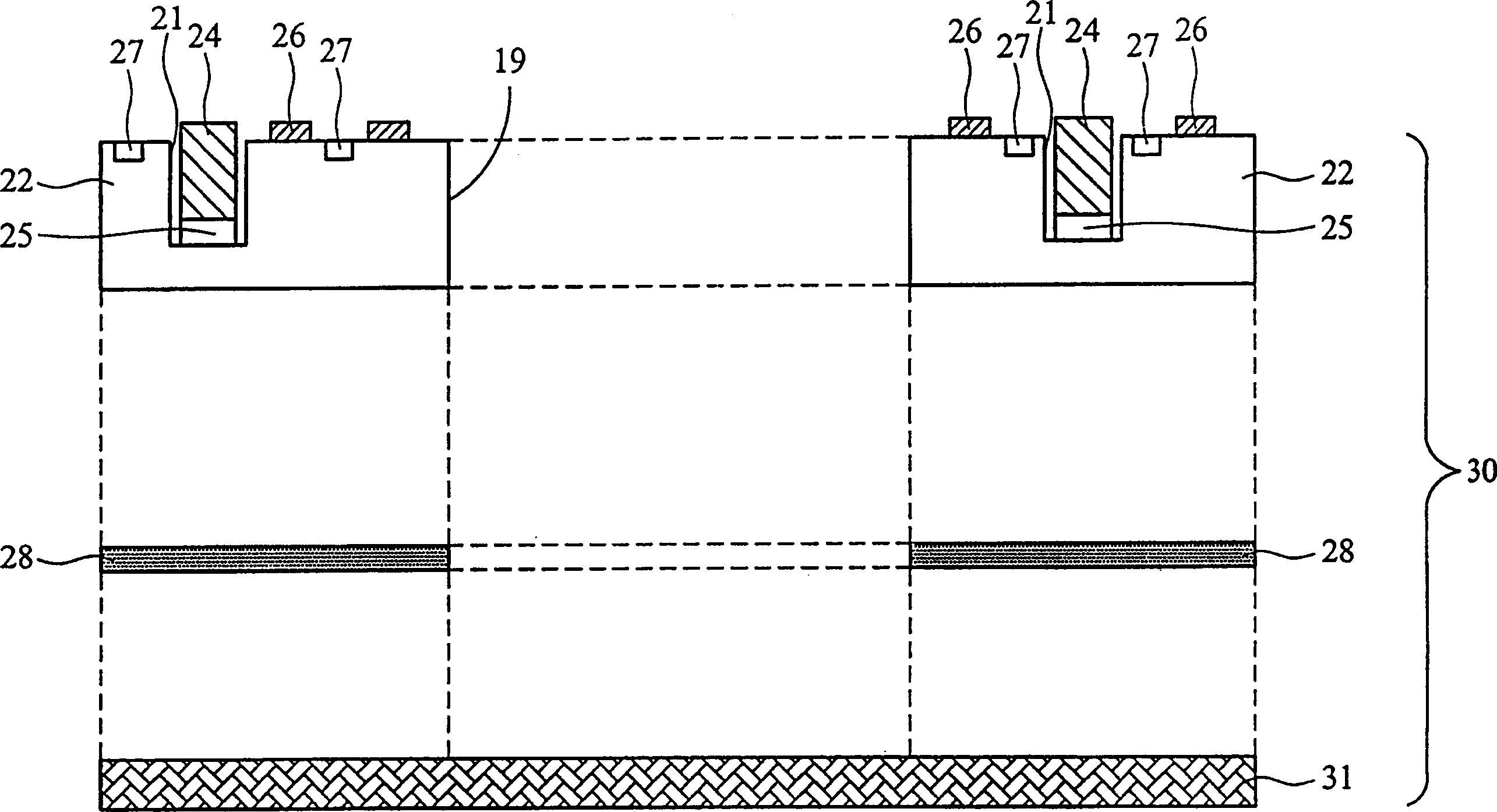

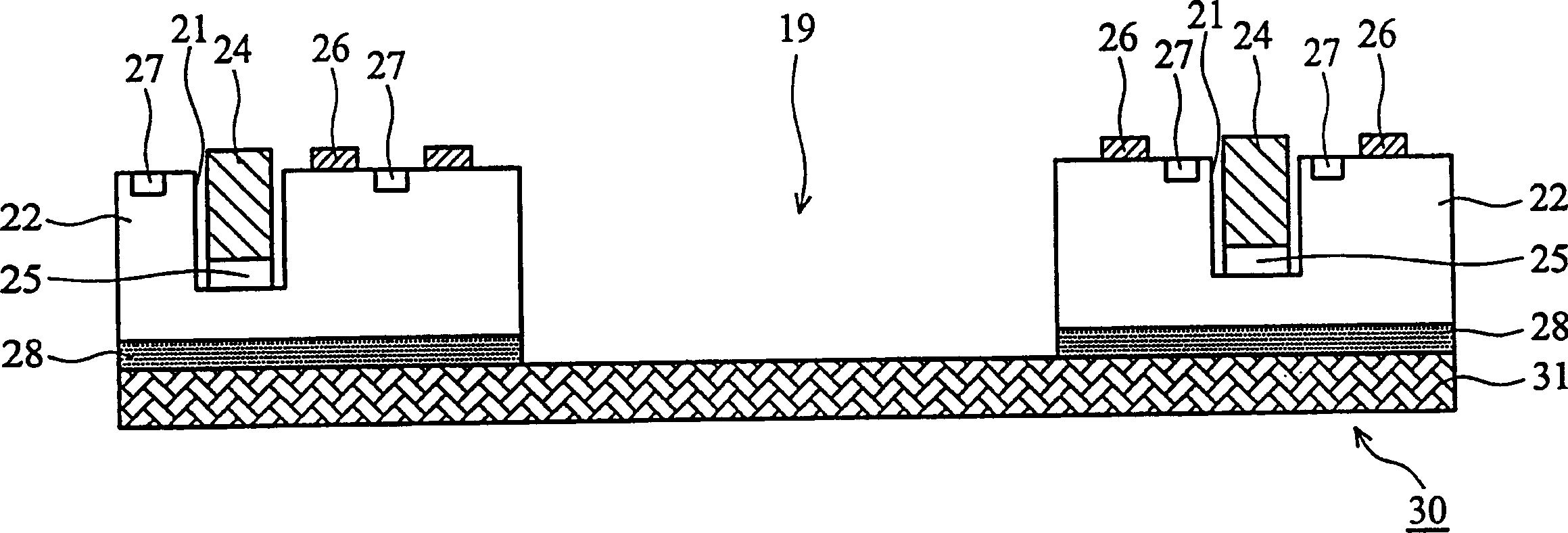

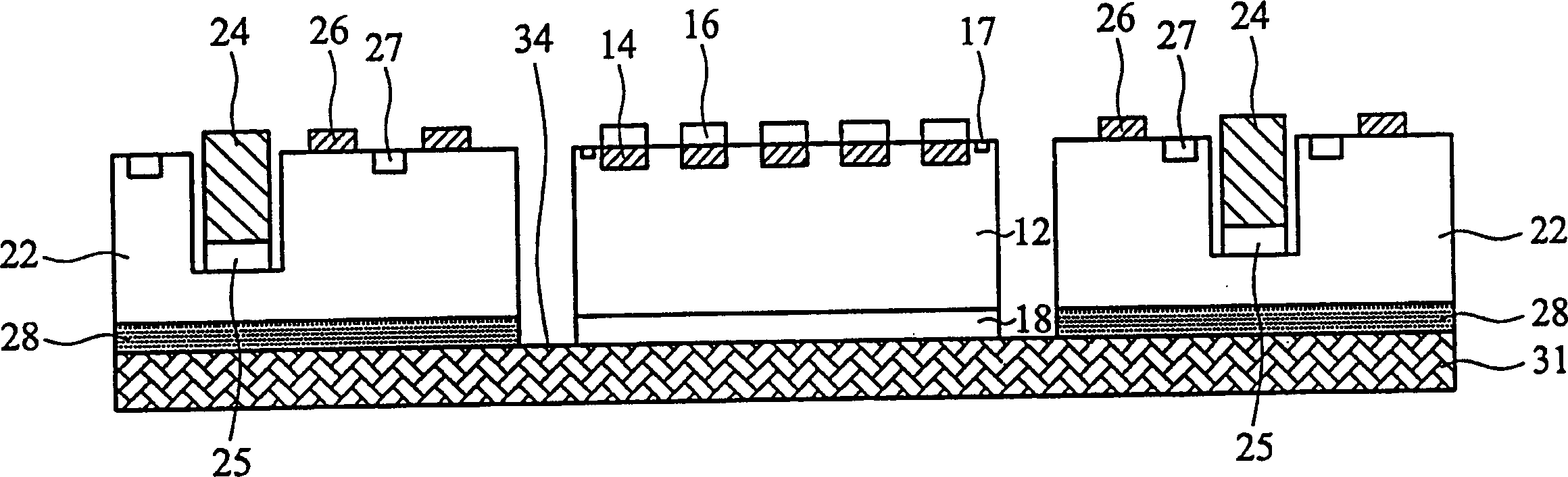

[0020] The invention provides a plastic solder ball array (CD-PBGA) with openings downwards or a modular substrate with multiple openings and a manufacturing method thereof. Passive components are directly fabricated on the substrate, and the substrate is Bonding with the cooling plate to form an integrated module board, and then bonding the IC chip in the opening of the integrated module board. Then, the multi-layer interconnection process can be carried out, so that the IC chip and passive components can be electrically connected to the integrated module board, and directly applied or connected to the surface solder ball array according to the demand, so that the integrated module board can be opened to Combine with other circuit boards in the following way. Therefore, according to the number of IC chips and the application of the modularization process, the integrated module board of the present invention can be regarded as a modular component, a multi-chip module (MCM) sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com