Connecting structure of prefabricated concrete wall body

A technology of precast concrete and connection structure, applied in the direction of walls, building components, building structures, etc., can solve the problems of affecting the mechanical performance, affecting performance, complex structure, etc., to improve performance, improve integrity, and continuous force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

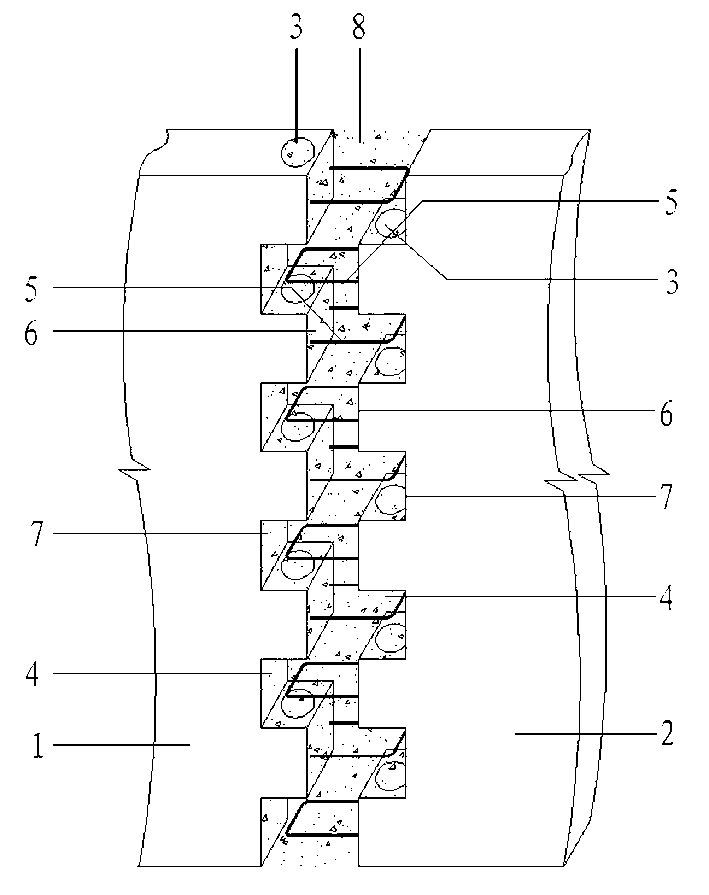

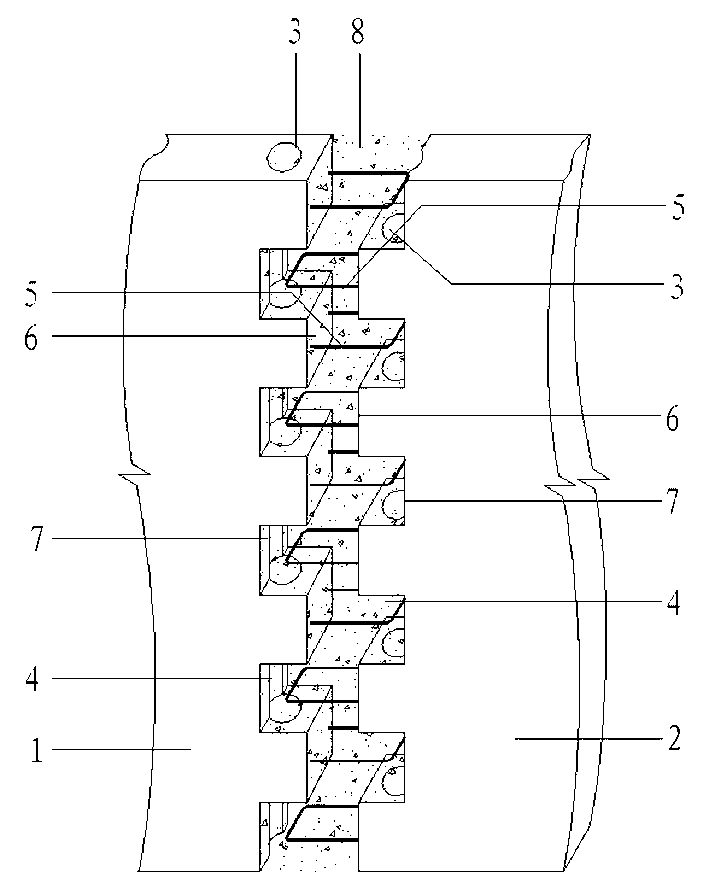

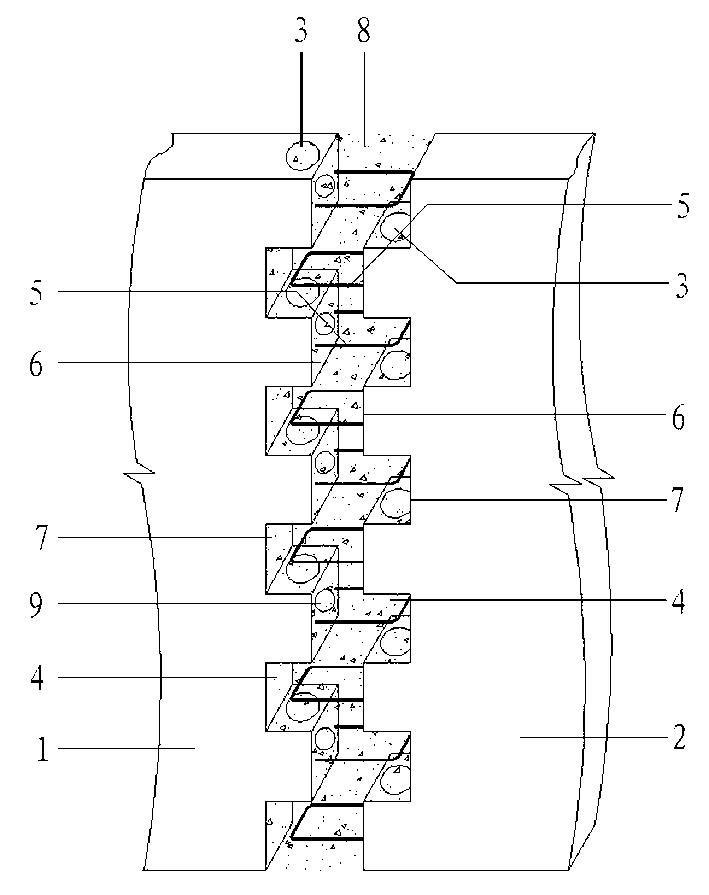

[0029] Such as figure 1 In the shown embodiment, the connection structure of the precast concrete wall includes a first precast concrete wall 1 and a second precast concrete wall 2, and the distance between the end faces 6 of the two walls can be negative 200mm to 50mm; the first precast concrete wall 1 and the second precast concrete wall 2 are provided with a longitudinal through hole 3 near the end face 6, the cross section of the hole is circular or rectangular, or other shapes, and the maximum dimension of the cross section is the wall thickness minus 50 mm; the first precast concrete wall There are several transverse grooves 4 at the end faces 6 of the body 1 and the second precast concrete wall 2, and the transverse grooves of the first precast concrete wall 1 and the second precast concrete wall 2 are arranged alternately, that is, the first precast concrete The wall 1 is provided with a transverse groove, and the corresponding second prefabricated concrete wall 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com