Prefabricated channel plate

A grooved plate and groove technology, which is applied in building materials, building components, buildings, etc., can solve problems such as affecting normal use, affecting mechanical performance, and being prone to cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

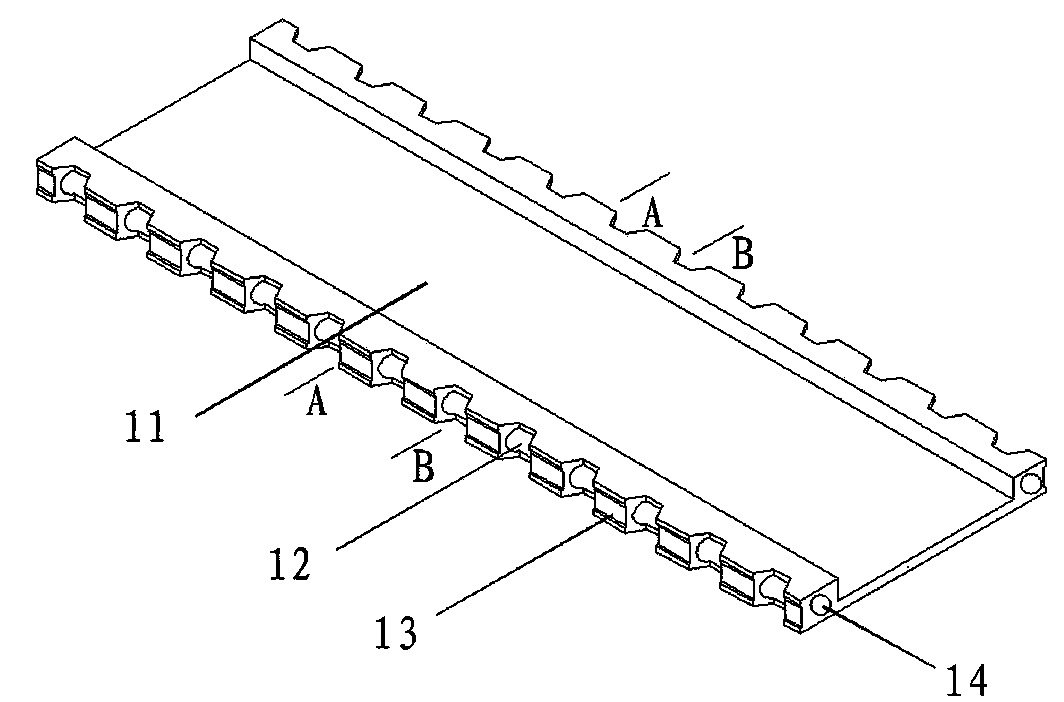

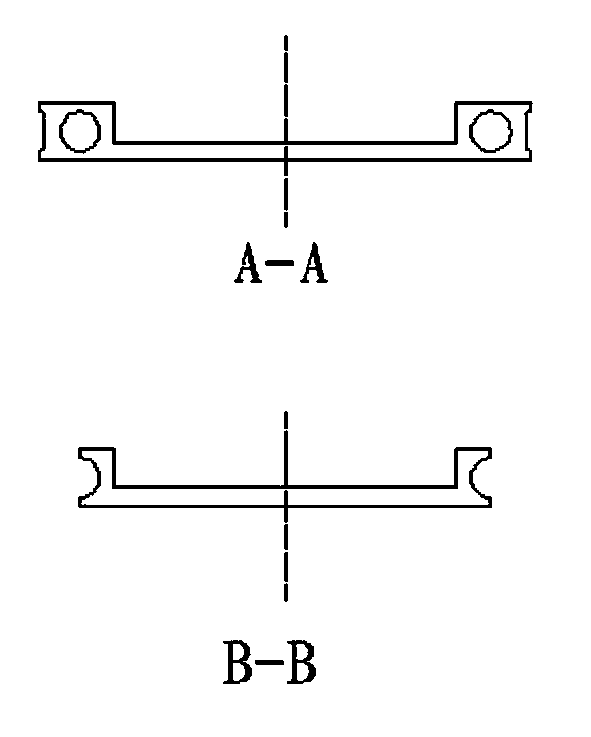

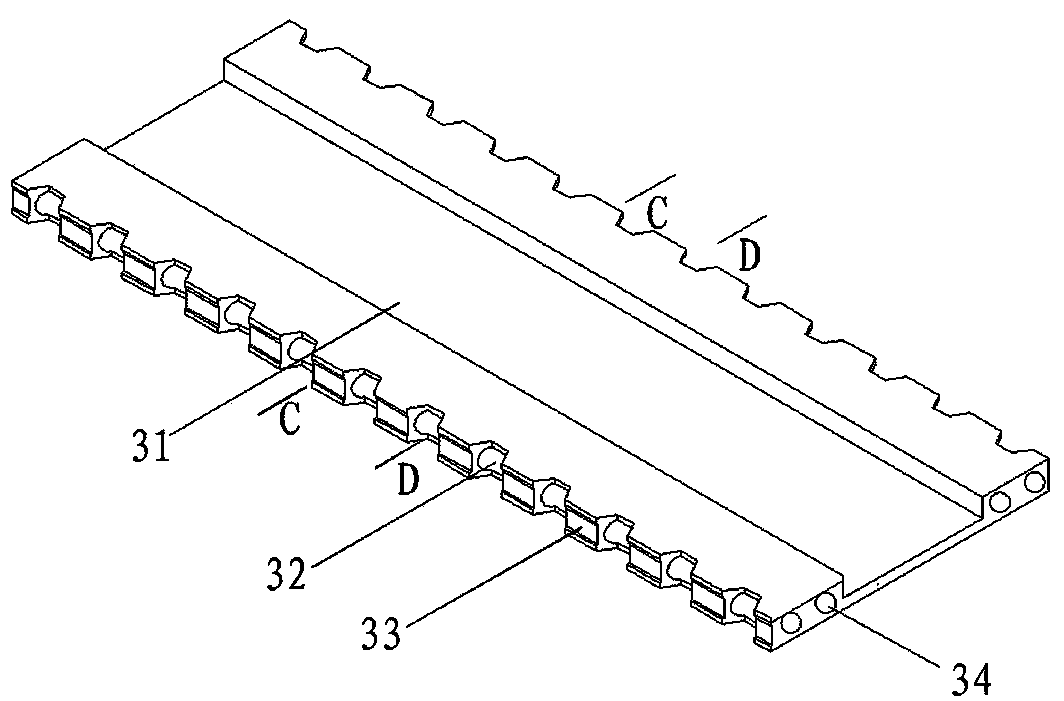

[0055] like figure 1 , figure 2 As shown, there is at least one longitudinal through-hole 14 parallel to the surface in the longitudinal rib of the prefabricated grooved plate 11, and the diameter of the longitudinal hole is generally between 60mm and 400mm (generally, the diameter of the longitudinal hole is the height of the longitudinal rib section or the width minus 60mm); a transverse groove 12 is arranged on the outer side of the longitudinal rib, intersecting with the outer longitudinal through hole, and the depth of the transverse groove is generally the distance from the center of the outer longitudinal hole to the side of the longitudinal rib; the transverse groove 12 and the protrusion 13 Staggered arrangement. An installation ring (not shown in the figure) is also provided on the prefabricated grooved plate.

[0056] The manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com