Straw wall body-based frame column/beam template-less construction technology

A construction technology and frame column technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of uneven surface of beam body, high construction cost, long construction time, etc. High, reduce construction difficulty and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

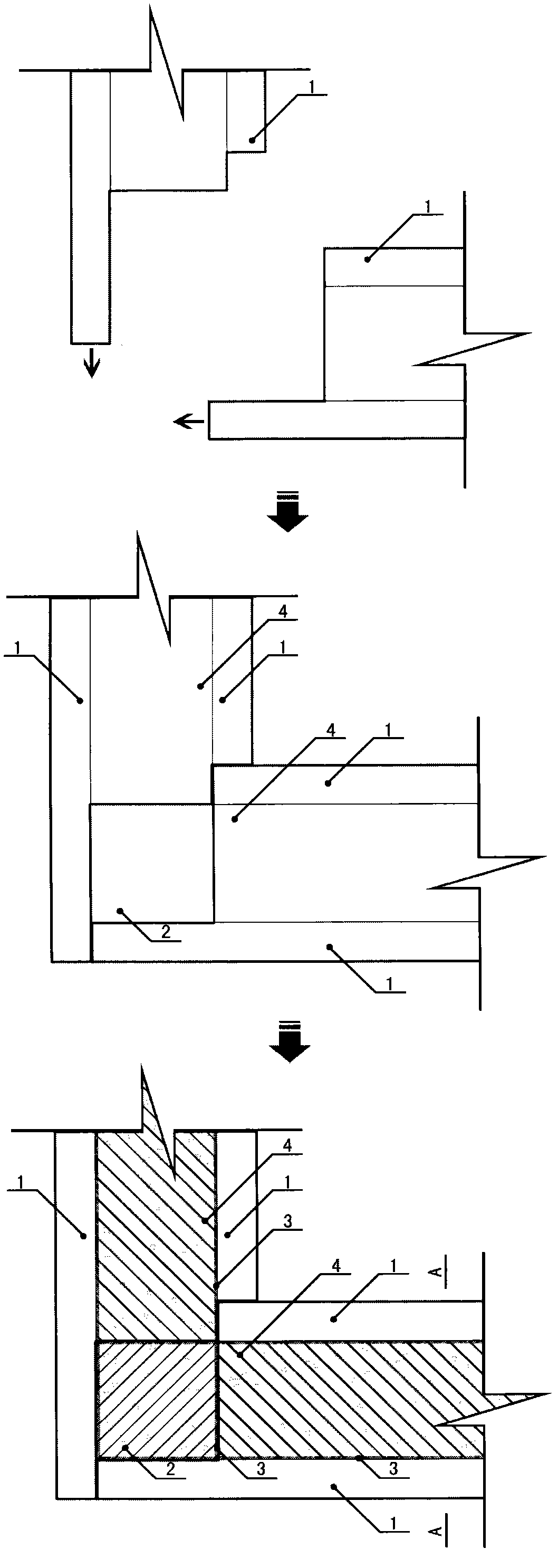

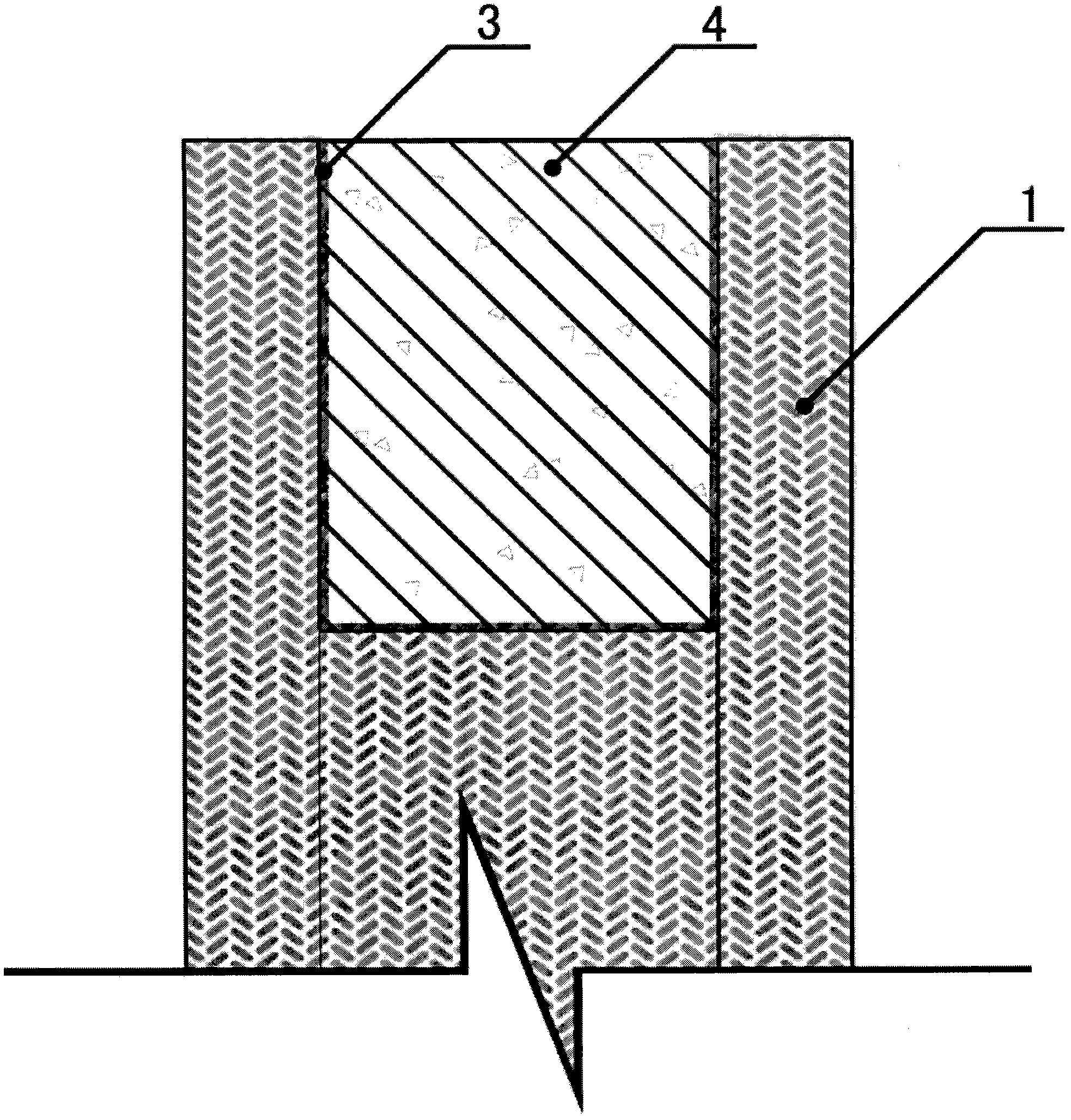

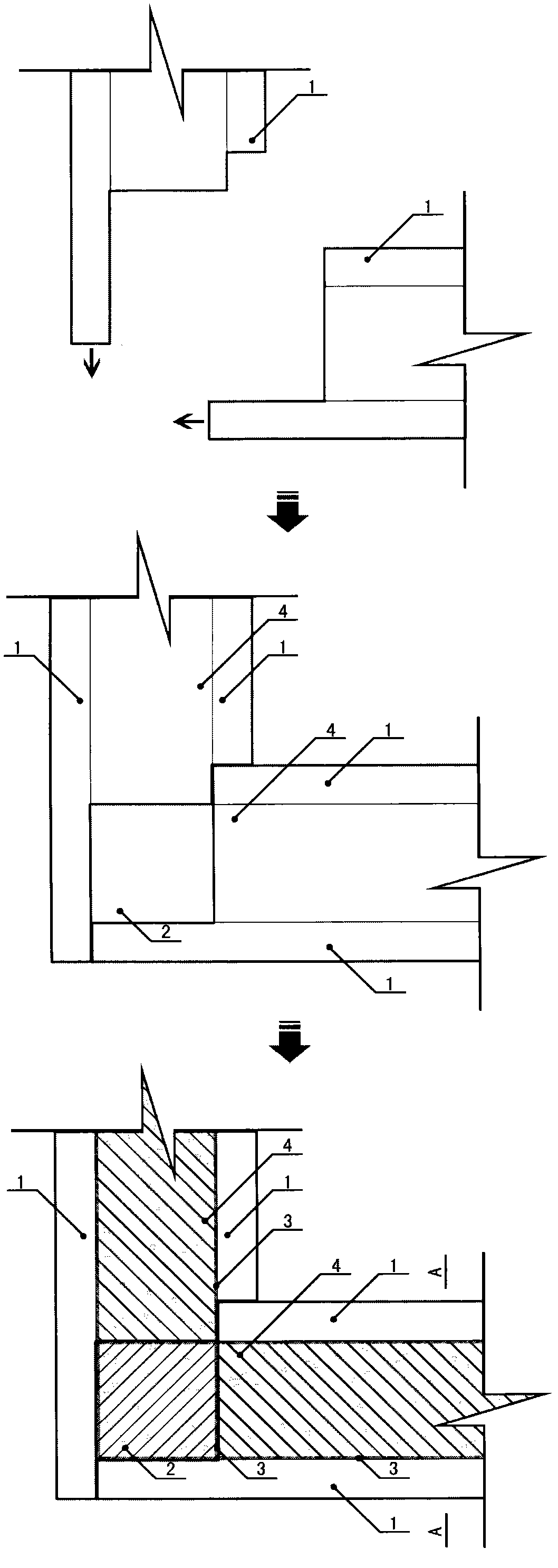

[0039] Referring to the attached drawings, taking the construction of straw houses as an example, the construction steps are as follows:

[0040] 1. Make prefabricated exterior walls. The prefabricated exterior walls are pre-installed with hooked steel bars.

[0041] 2. Construction foundation. The reinforced concrete foundation ring beam is poured according to the design requirements, and the frame column steel head and waterproof structure are reserved on the cast-in-place foundation ring beam according to the design requirements.

[0042] 3. Welding frame column reinforcement. Welding of lapped steel bars is used to connect the reinforced head of the frame column reserved for the foundation with the steel bar of the frame column, and reserve the steel bar head connected to the frame beam and the steel bar head of the frame column on the upper layer.

[0043] 4. Put the wall in place. According to the design requirements, the outer wall is placed on the designated positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com