Cotton picking needle and mechanical cotton picking device provided with same

A cotton-picking needle and cotton-picking technology, which is applied to picking machines, agricultural machinery and implements, harvesters, etc., can solve the problems of not easy to take off cotton, high cost, inconvenient use, etc., and achieves low cost, reduced labor intensity, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

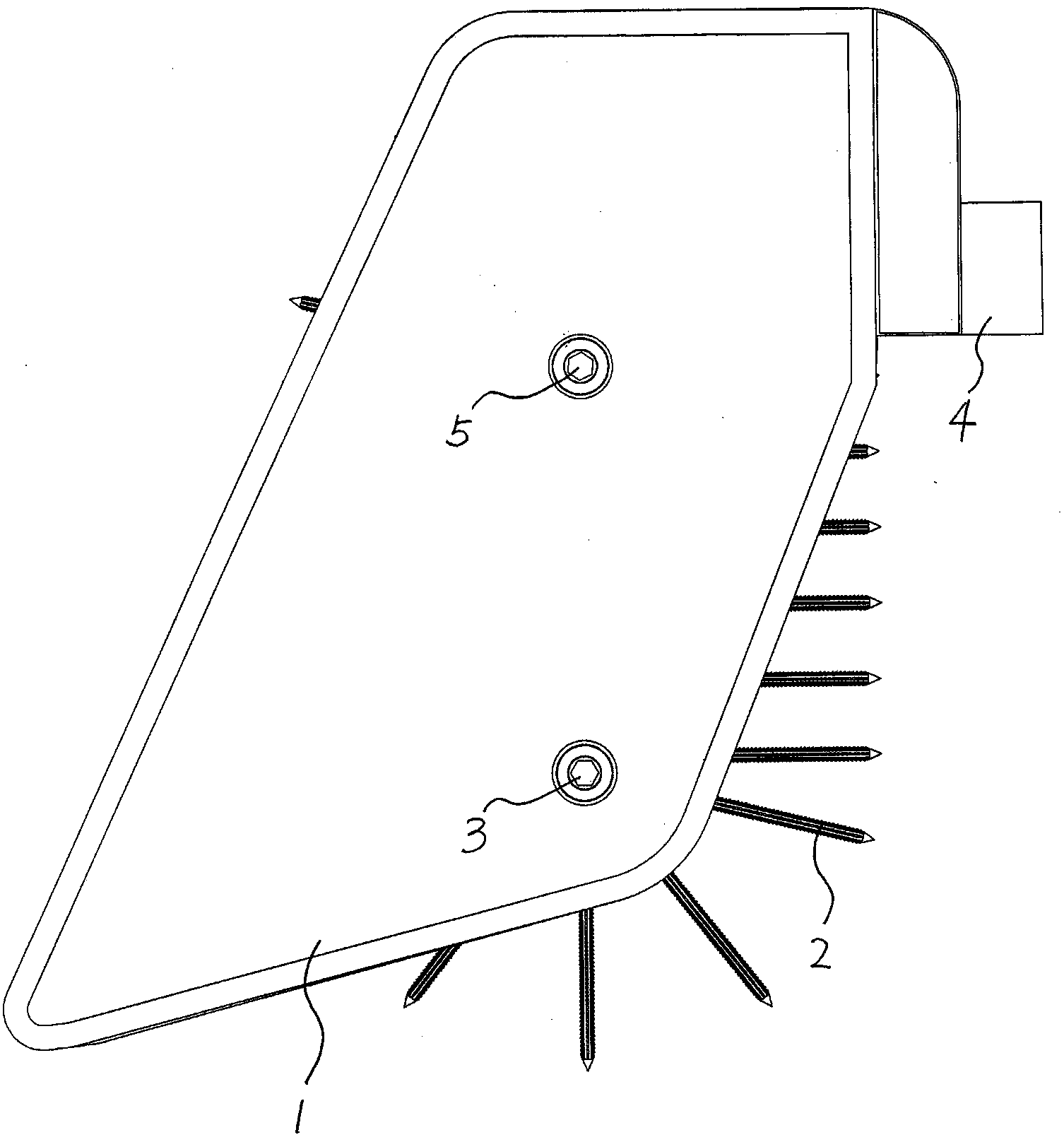

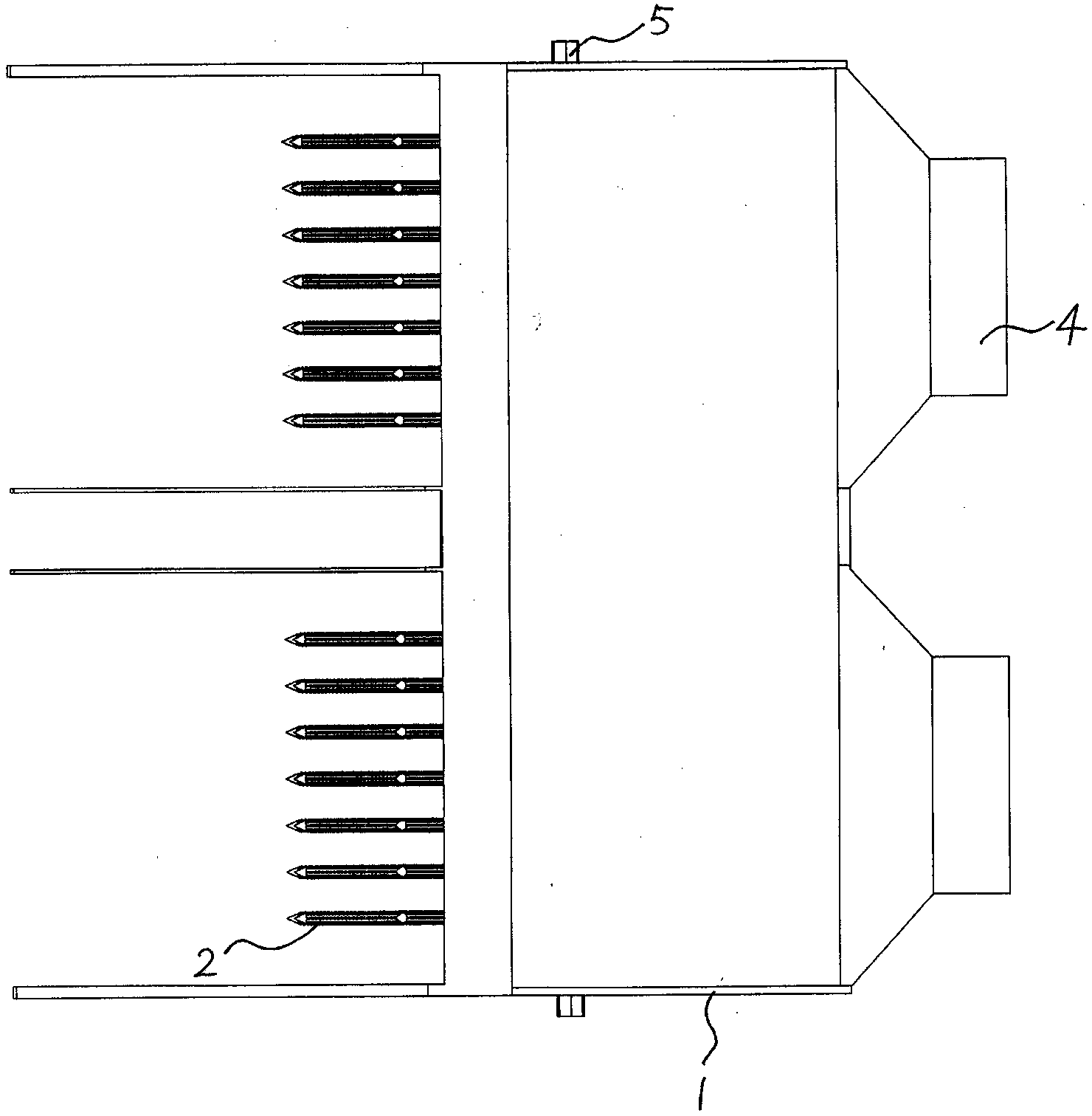

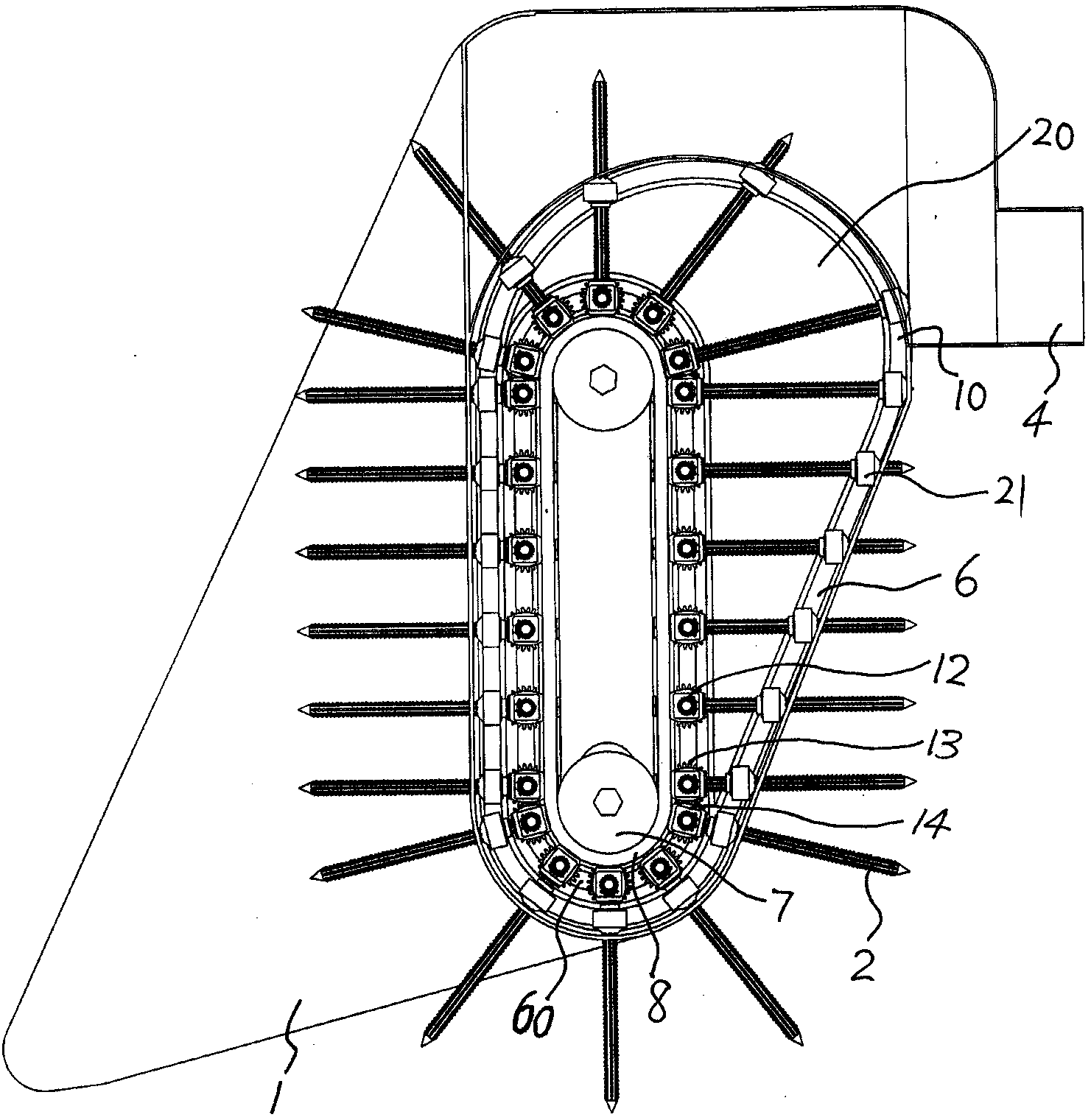

[0027] A cotton picking needle, such as Picture 9 , Picture 10 As shown, the needle body 2 is included. A number of grooves 30 are evenly arranged on the axial outer circumferential surface of the needle body 2, and the axial ribs 31 between two adjacent grooves 30 are evenly arranged and spaced. The cotton picking teeth arranged from the needle to the end of the needle, the outer convex corners of the cotton picking teeth are close to the needle.

[0028] The number of grooves 30 is 8, the cross section of the groove 30 is rectangular, and the cross section of the cotton picking tooth perpendicular to the axis of the needle body 2 is fan-shaped or rectangular.

[0029] The side shape of the cotton picking teeth is a right-angled triangle or an obtuse-angled triangle, and the convex and pointed corners are acute.

[0030] The top surface of the cotton picking tooth is a flat or inverted V-shaped surface.

[0031] The cotton picking teeth are arranged in a spiral line from the needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com