Patents

Literature

61results about How to "Reduce increment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse Dummy Insertion Algorithm

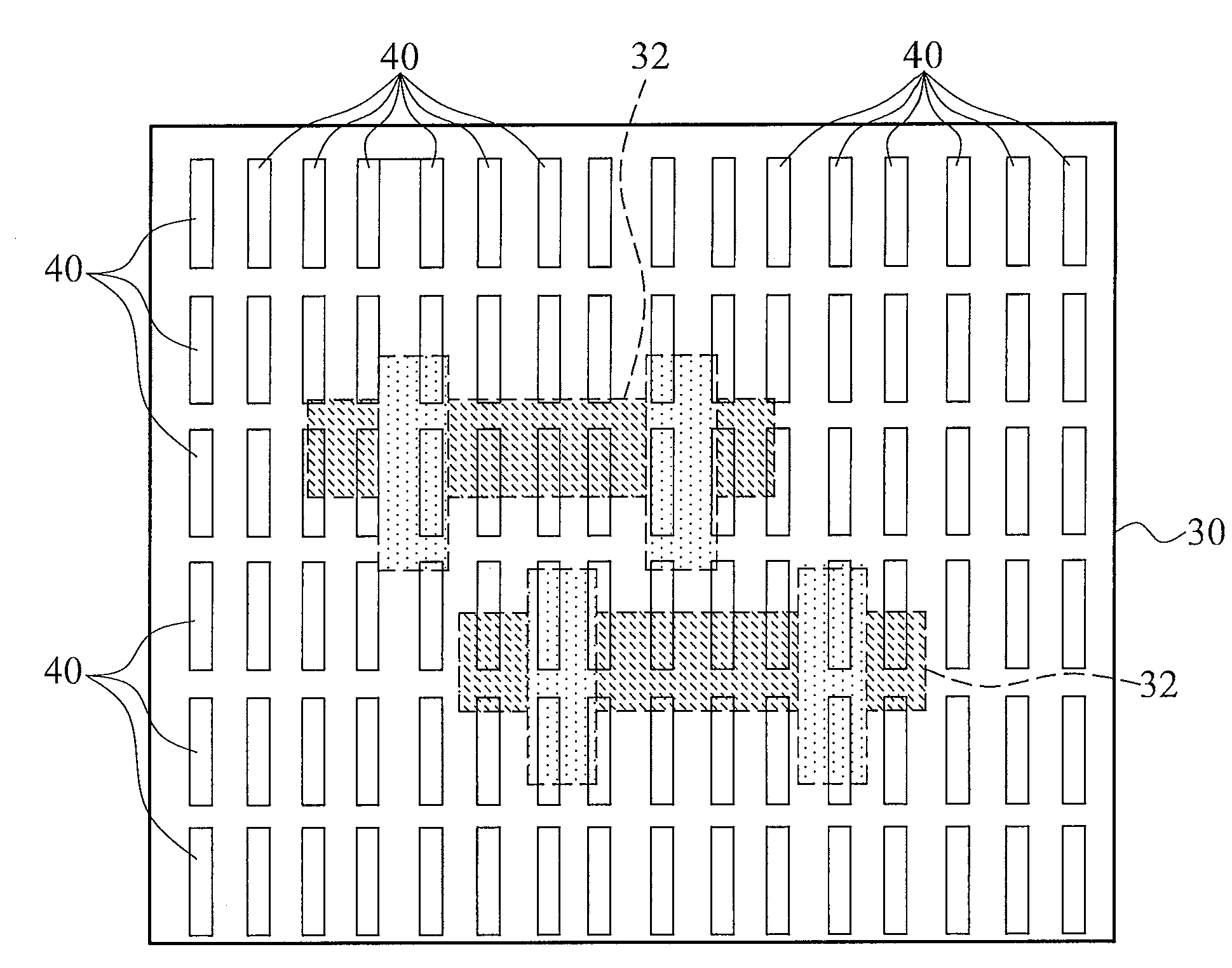

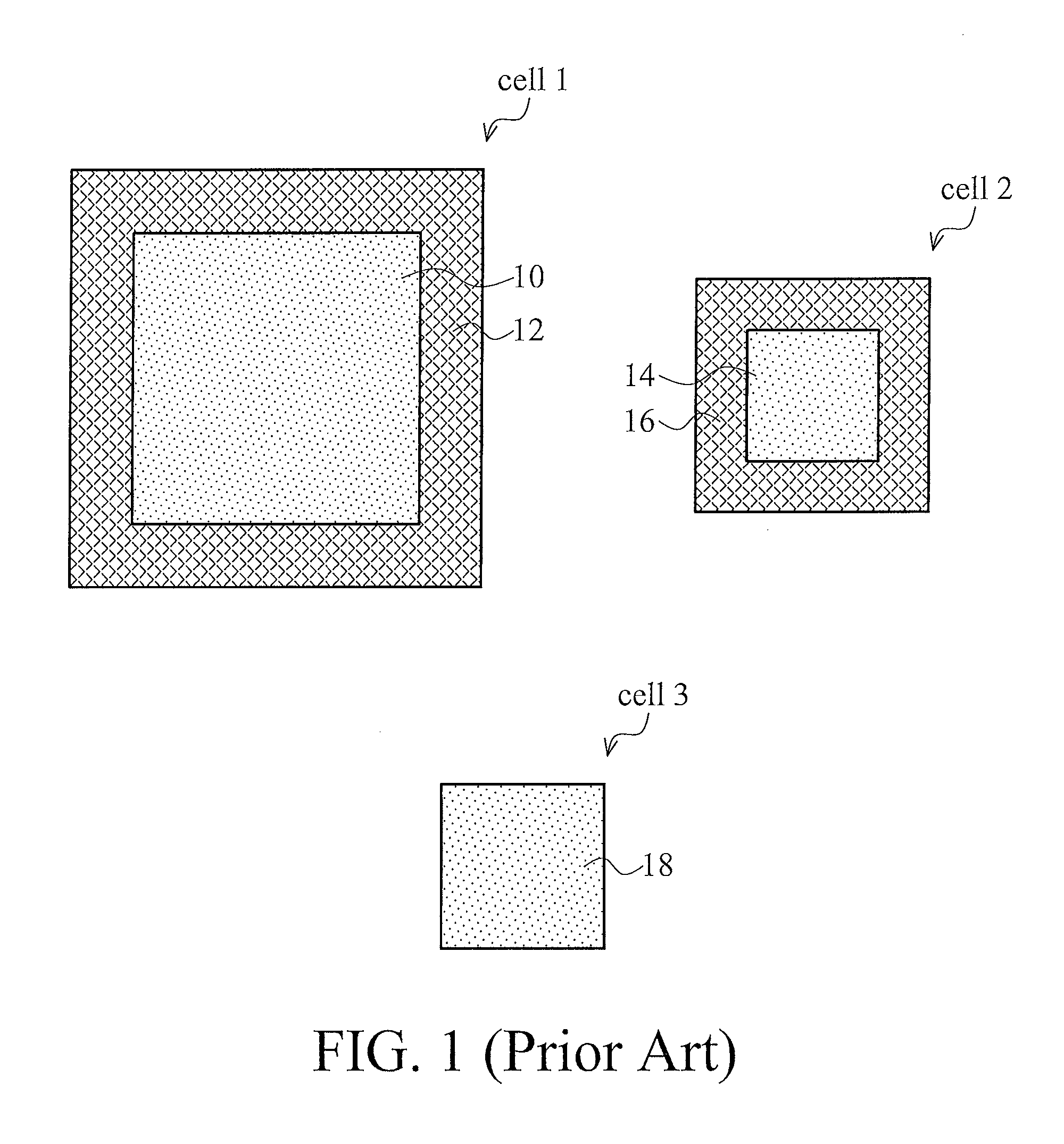

InactiveUS20090181314A1Reduce incrementReduce insertion timeSolid-state devicesOriginals for photomechanical treatmentEngineering

A method of inserting dummy patterns includes providing a window area comprising a main pattern. The main pattern includes first patterns of a first type of features, and second patterns of a second type of features. The first and the second types are different types. The method further includes globally inserting first dummy patterns throughout the window area, wherein the first dummy patterns are dummy patterns of the first type of features; enlarging the main pattern to generate an enlarged main pattern, wherein the enlarged main pattern occupies an enlarged region of the window area; removing the portion of the first dummy patterns in the enlarged region from the first dummy patterns to generate first inversed dummy patterns; and combining the first patterns in the main pattern with the first inversed dummy patterns to generate first mask patterns for the first type of features.

Owner:TAIWAN SEMICON MFG CO LTD

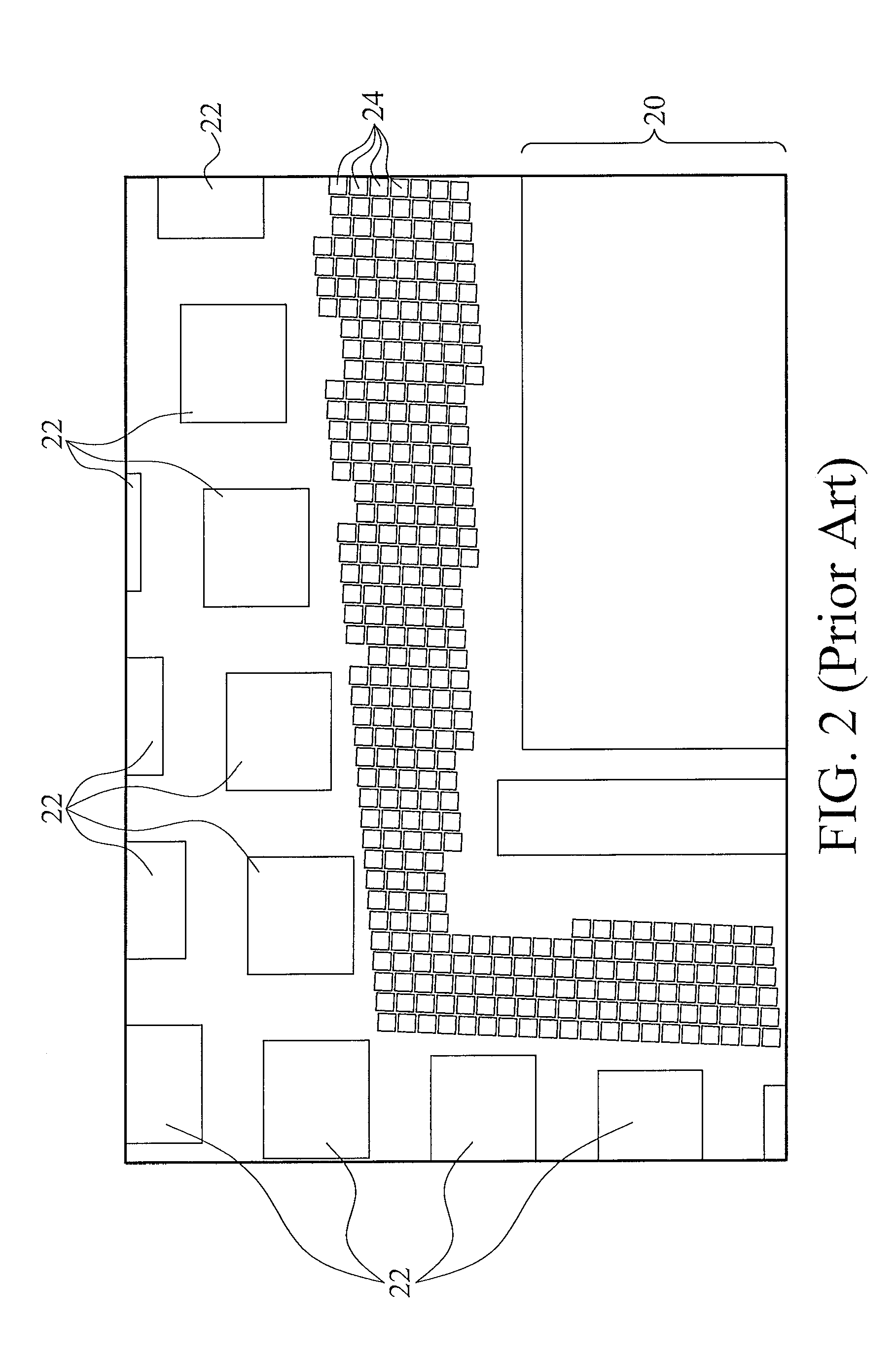

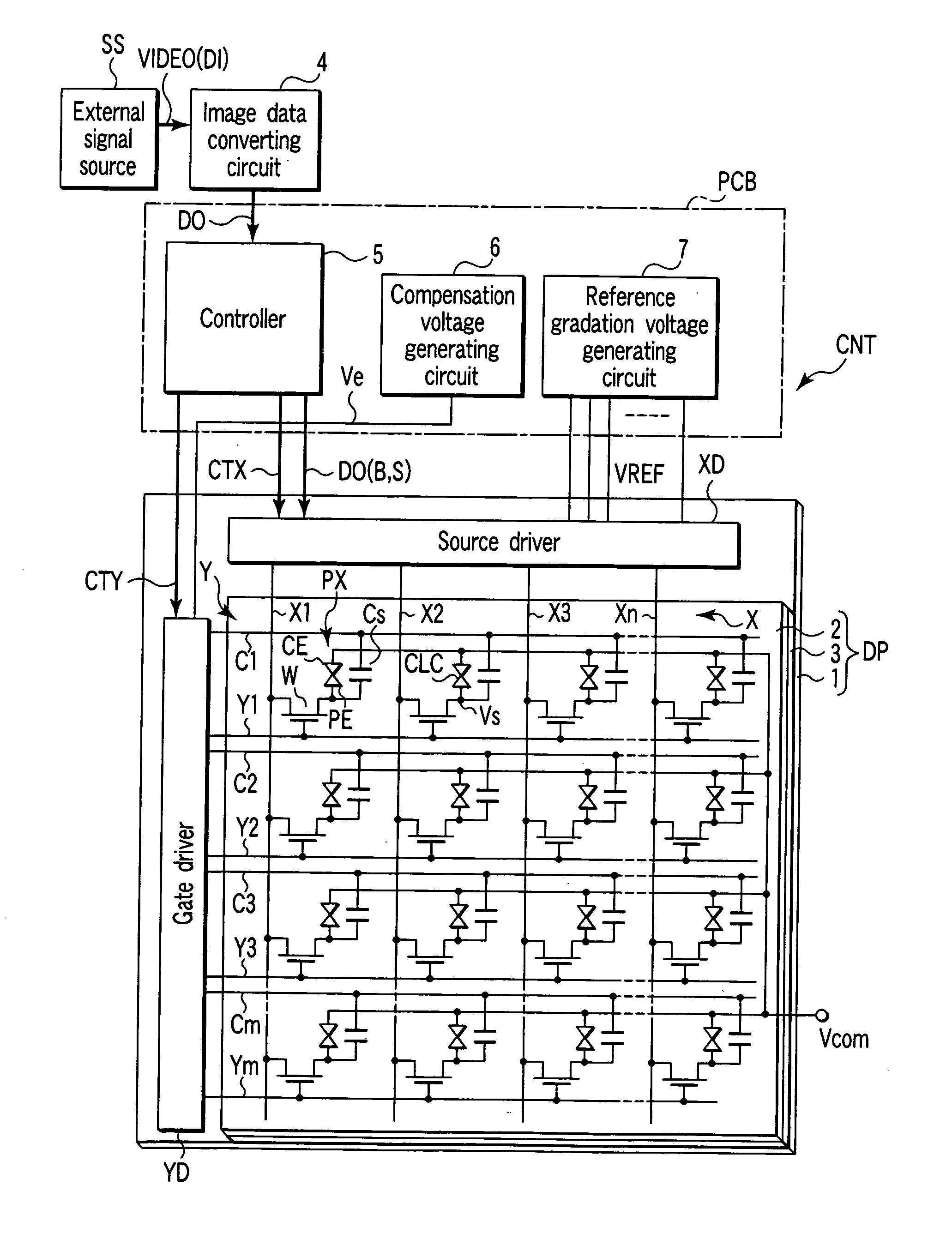

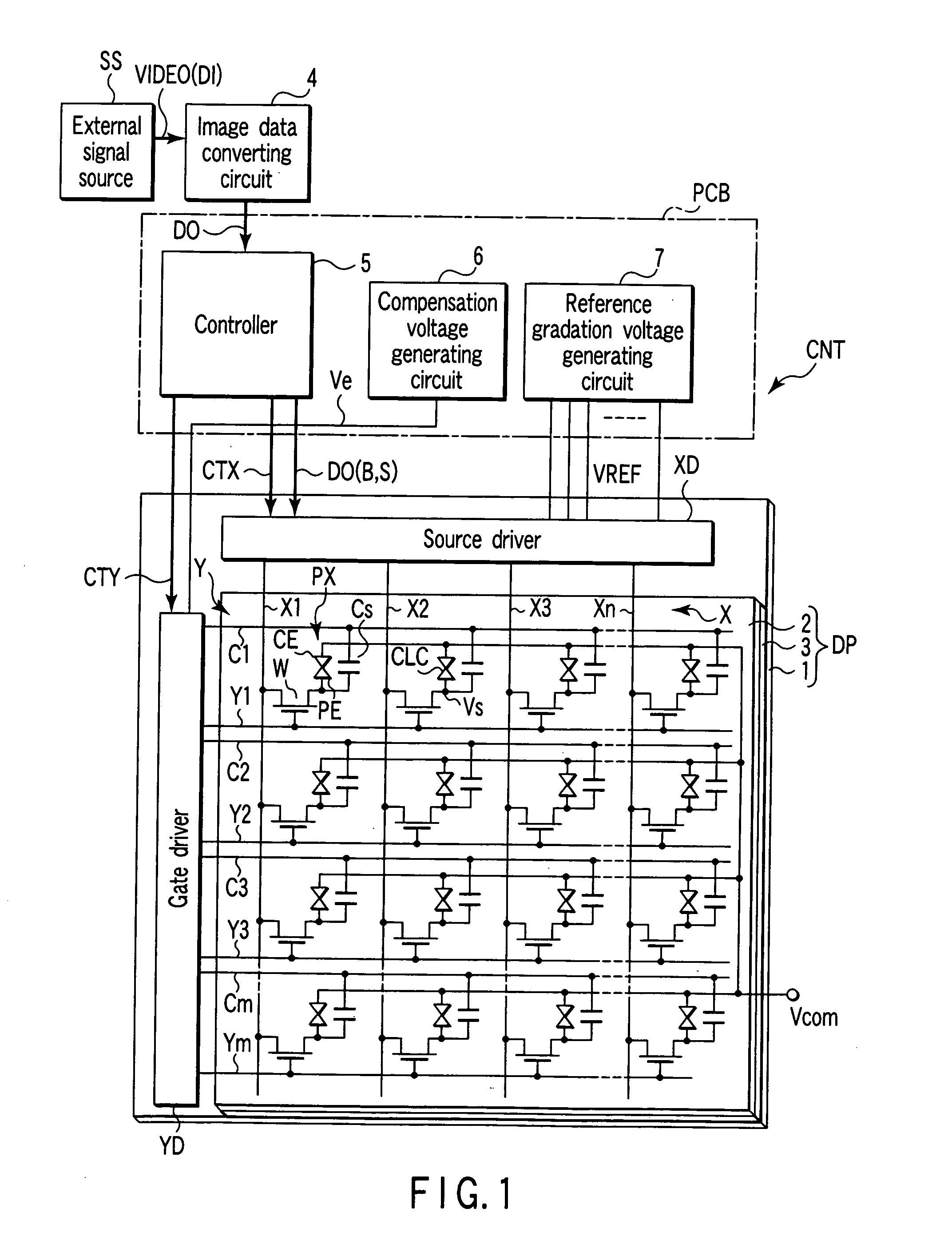

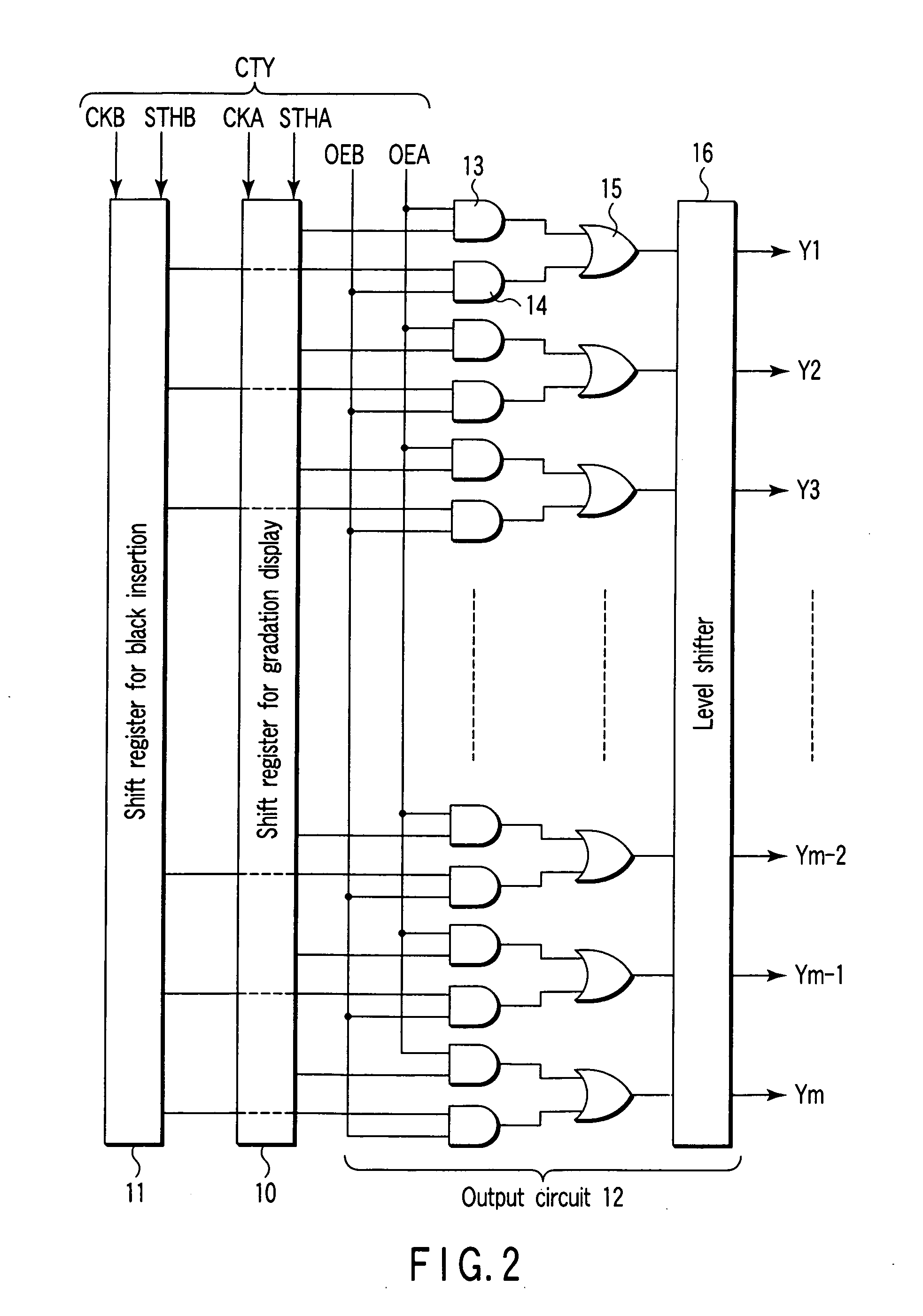

Gate line driving circuit

InactiveUS20060028463A1Easy to fixReduce incrementCathode-ray tube indicatorsDigital storageShift registerDriving circuit

A gate line driving circuit includes a shift register for gradation display, which shifts a first start signal in response to a first clock signal such that the gate lines are selected for gradation display in one vertical scanning period, and a shift register for black insertion, which shifts a second start signal in response to a second clock signal synchronous with the first clock signal such that the gate lines are selected for black insertion in a period substantially equal to the vertical scanning period, and an output circuit that outputs, under control of a first output enable signal, a driving signal to the gate line selected by the shift register for gradation display, and outputs, under control of a second output enable signal, a driving signal to the gate line selected by the shift register for black insertion.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

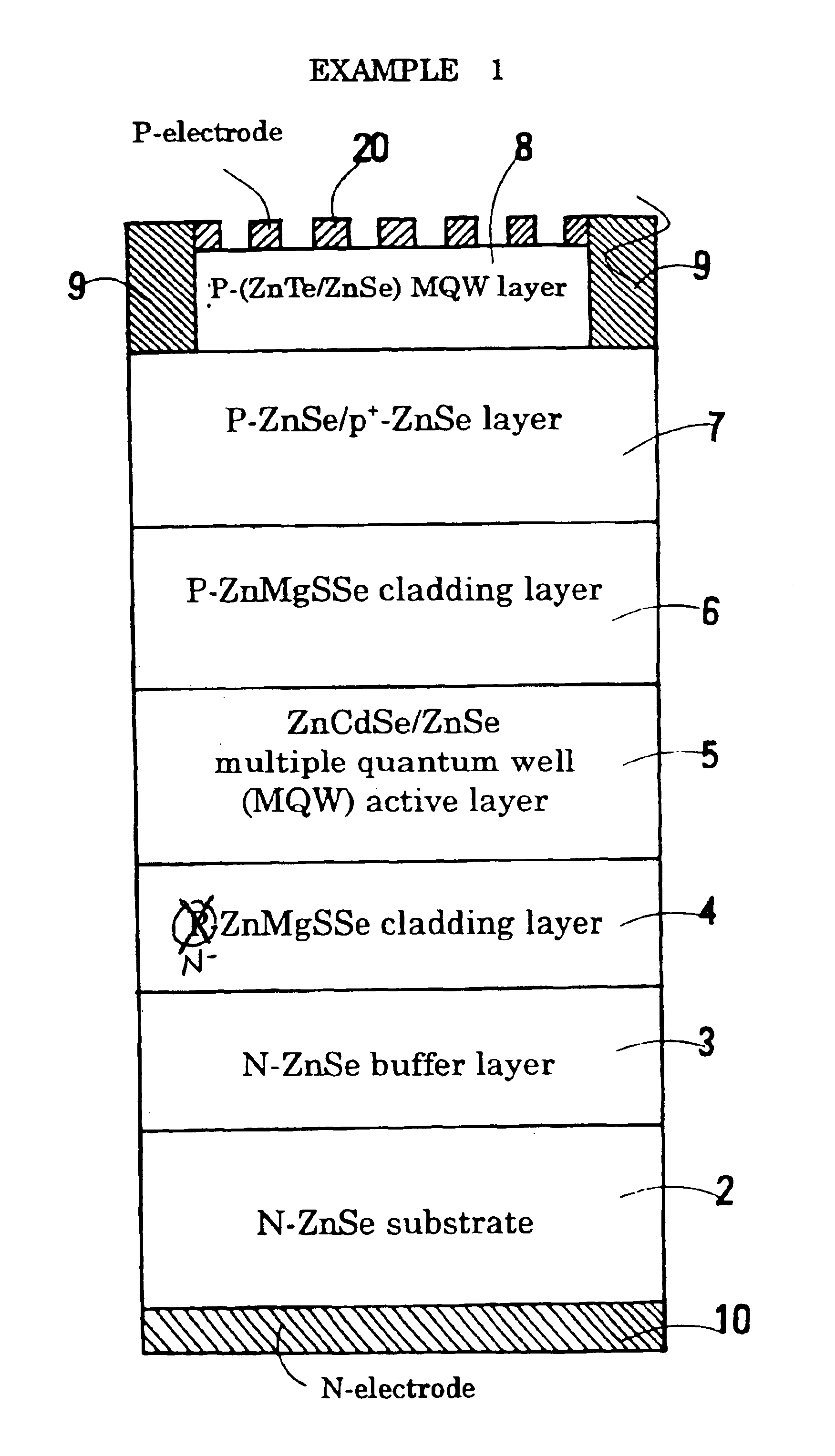

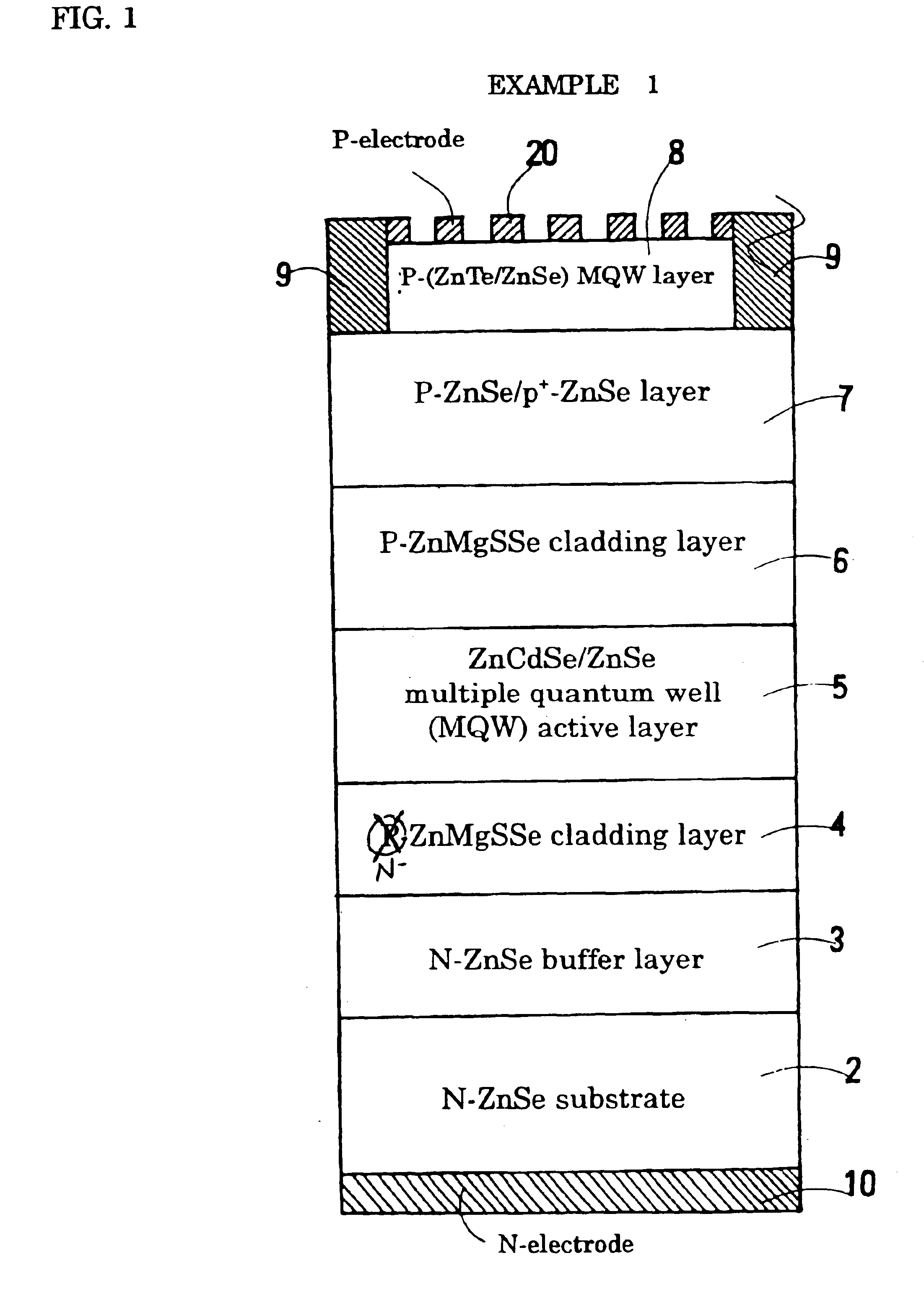

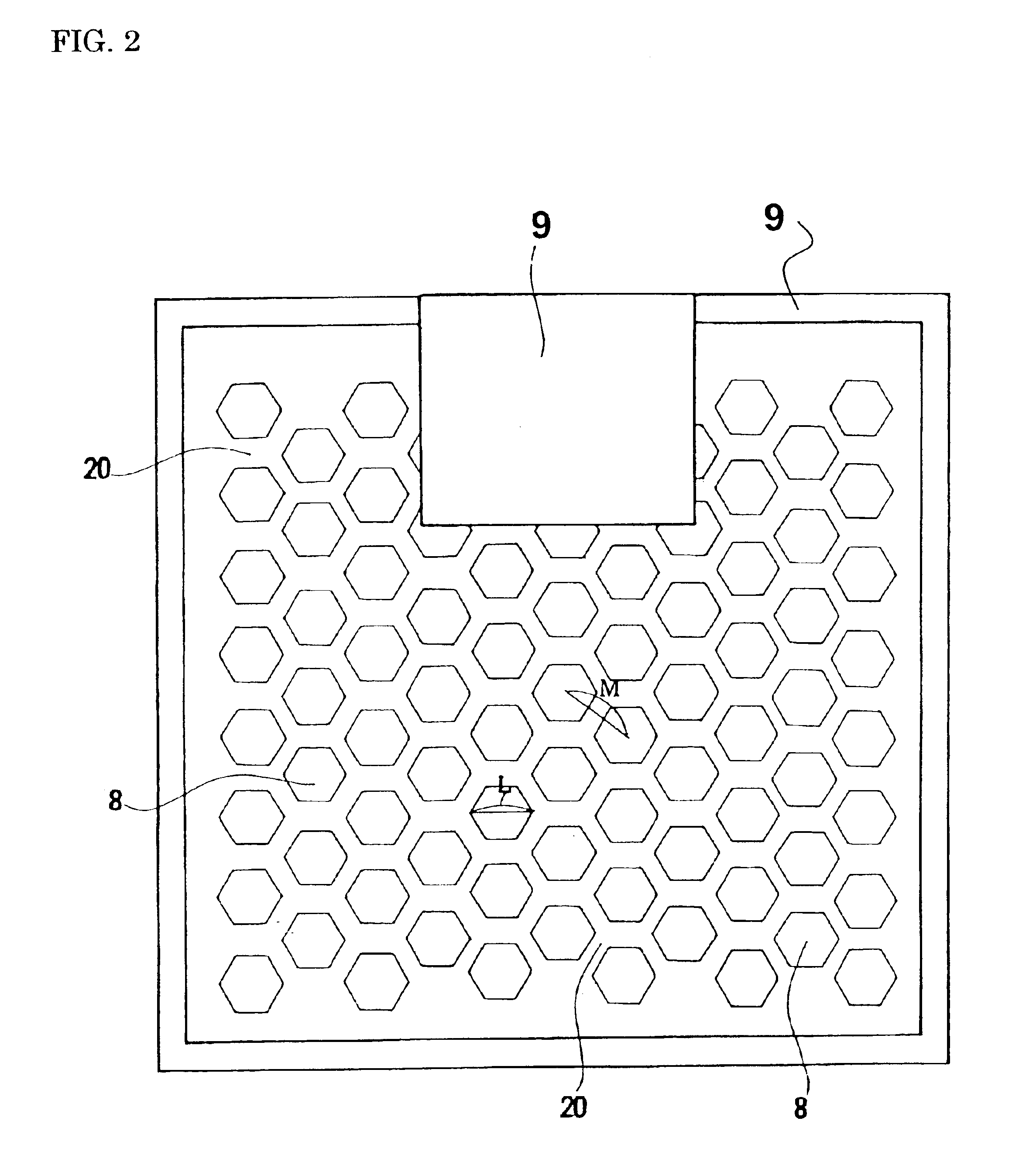

Structure of p-electrode at the light-emerging side of light-emitting diode

InactiveUS6903374B2High light transmittanceImprove light outputSolid-state devicesSemiconductor devicesTransmittanceContact layer

A structure of a p-electrode formed at the light-emerging side of an LED that comprises (a) an n-type semiconductor substrate, (b) an n-type cladding layer, an active layer, a p-type cladding layer, and a p-type contact layer formed on the substrate in this order, and (c) an n-electrode formed on the back face of the substrate. The structure of the p-electrode comprises a mesh-shaped semi-transparent thin-film metal electrode for diffusing electric current formed on the p-type contact layer and a bonding electrode for wire bonding. The metal electrode comprises a covering portion having a transmittance of at least 10% and an opening portion having an opening ratio of at least 20%. The bonding electrode is formed at the periphery of the p-type contact layer and is bonded directly to the mesh-shaped semi-transparent thin-film metal electrode. This structure can increase the intensity of the output light emerging from the p-side.

Owner:SUMITOMO ELECTRIC IND LTD

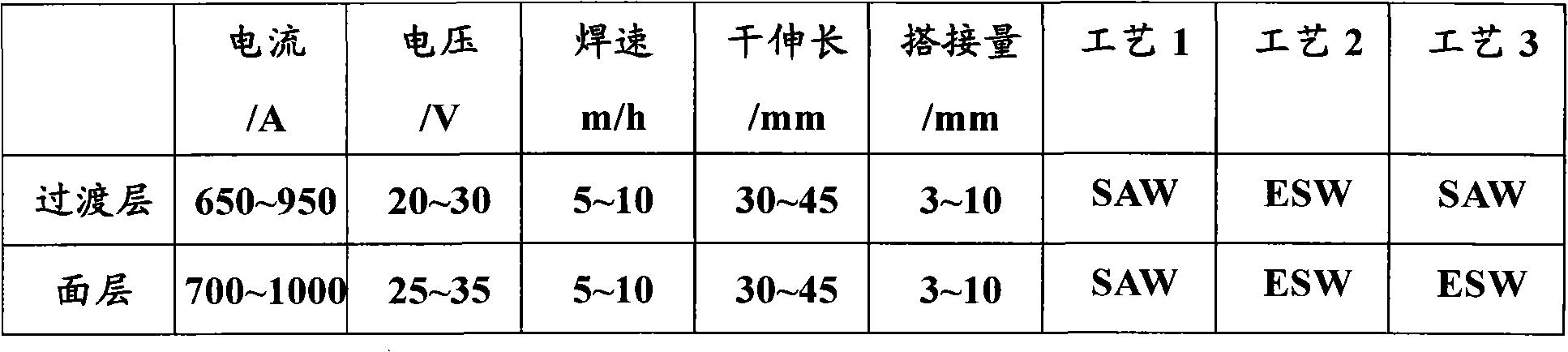

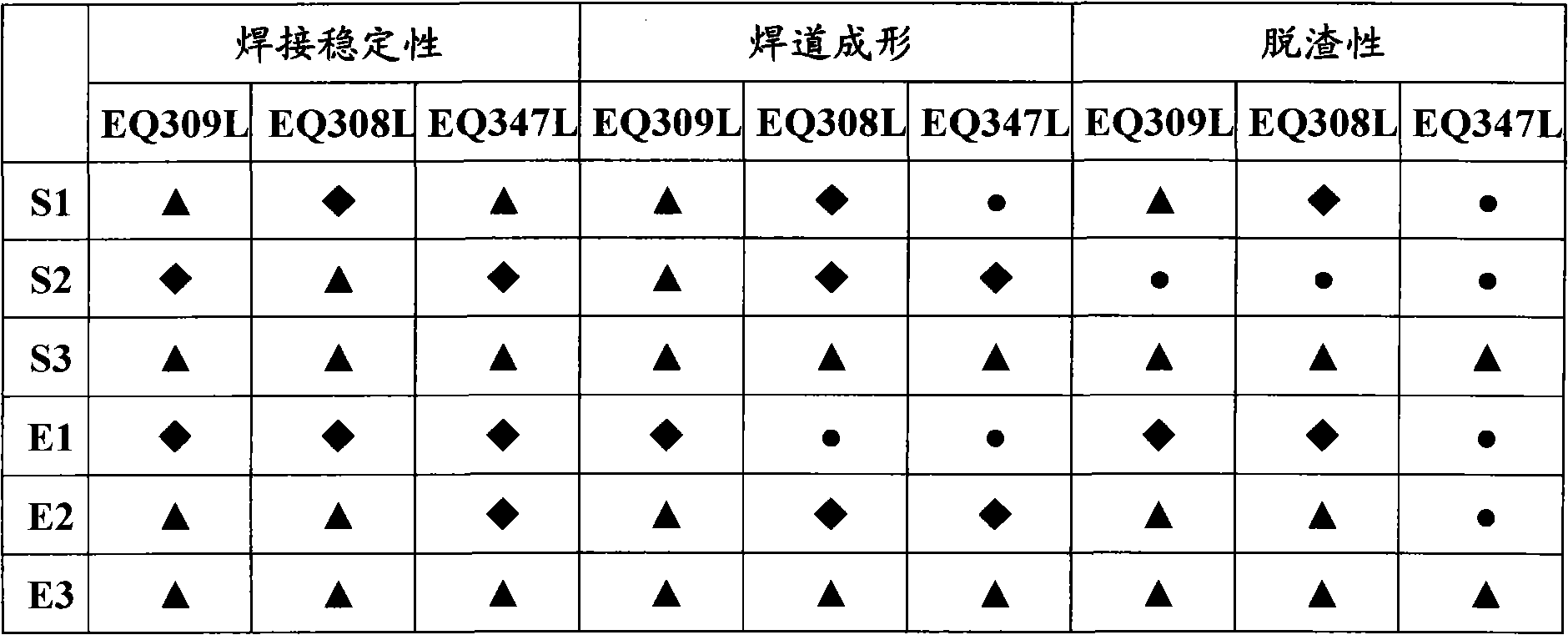

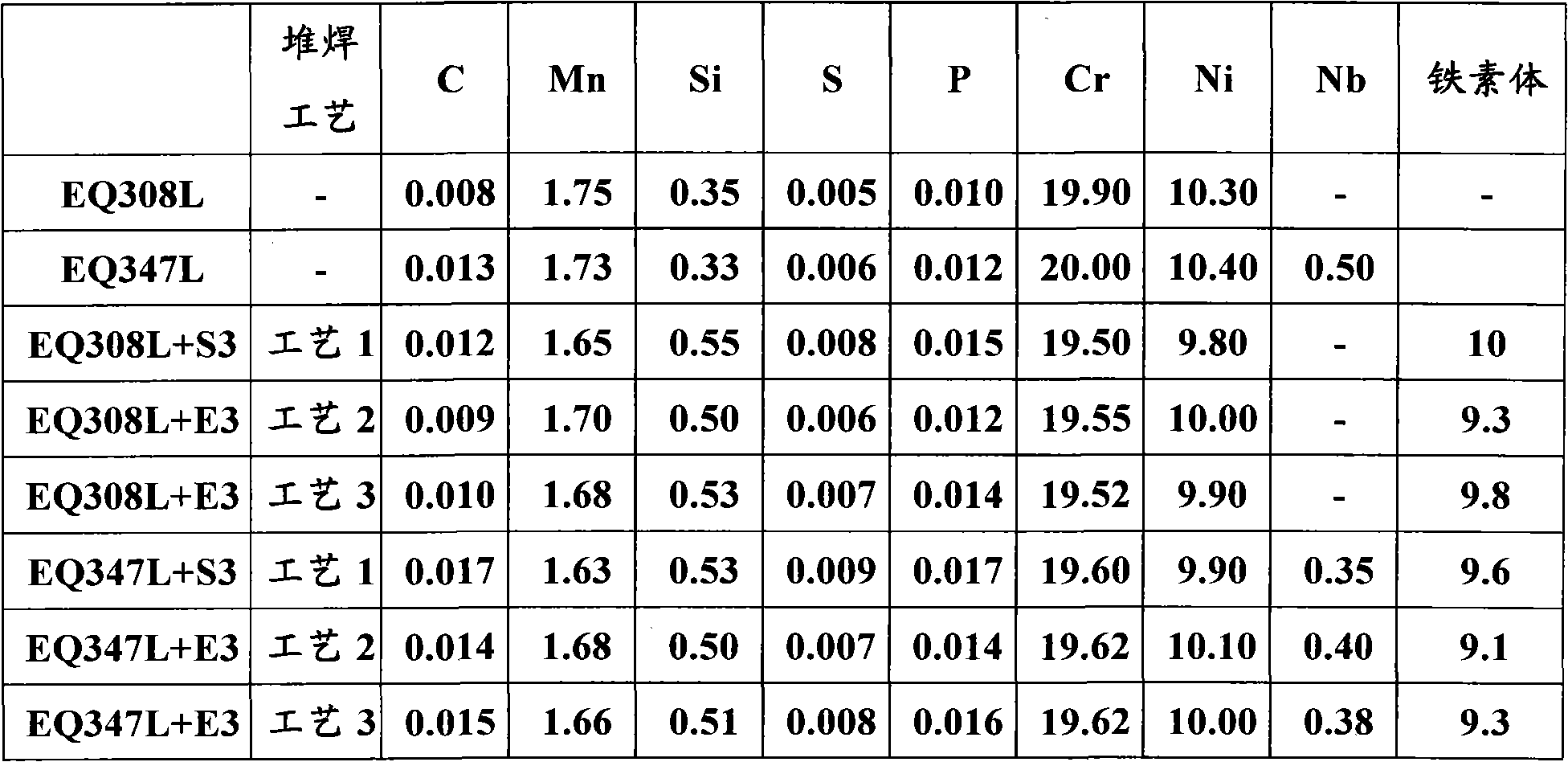

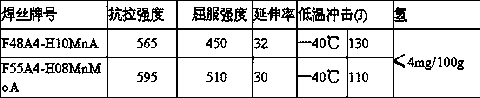

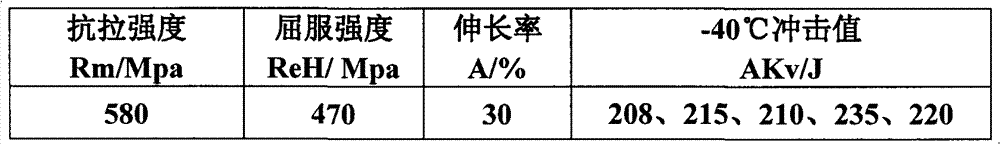

Sintered flux for stainless steel surfacing with band electrode

ActiveCN102581518AAdjustable viscosityWeld firmlyWelding/cutting media/materialsSoldering mediaRaw materialAlloy

The invention relates to a sintered flux for stainless steel surfacing with band electrode. One technical scheme of the sintered flux for stainless steel surfacing with band electrode includes that the sintered flux is formed by sintering the following components and the proportioned raw materials or materials, including 15-30 parts of CaF2, 20-50 parts of MgO, 1-10 parts of Al2O3, 15-30 parts of CaO, 25-50 parts of SiO2, and 1-5 parts of alloy powder. The another technical scheme includes that the sintered flux for stainless steel surfacing with band electrode comprises the following components and the proportioned raw materials or materials including 60-80 parts of CaF2,20-40 parts of Al2O3, 1-5 parts of CaO, 1-5 parts of SiO2, and 1-5 parts of alloy powder. The sintered flux has excellent performance and can meet the service requirements completely.

Owner:BEIJING JINWEI WELDING MATERIAL +1

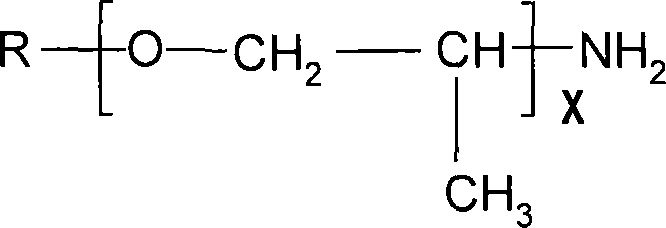

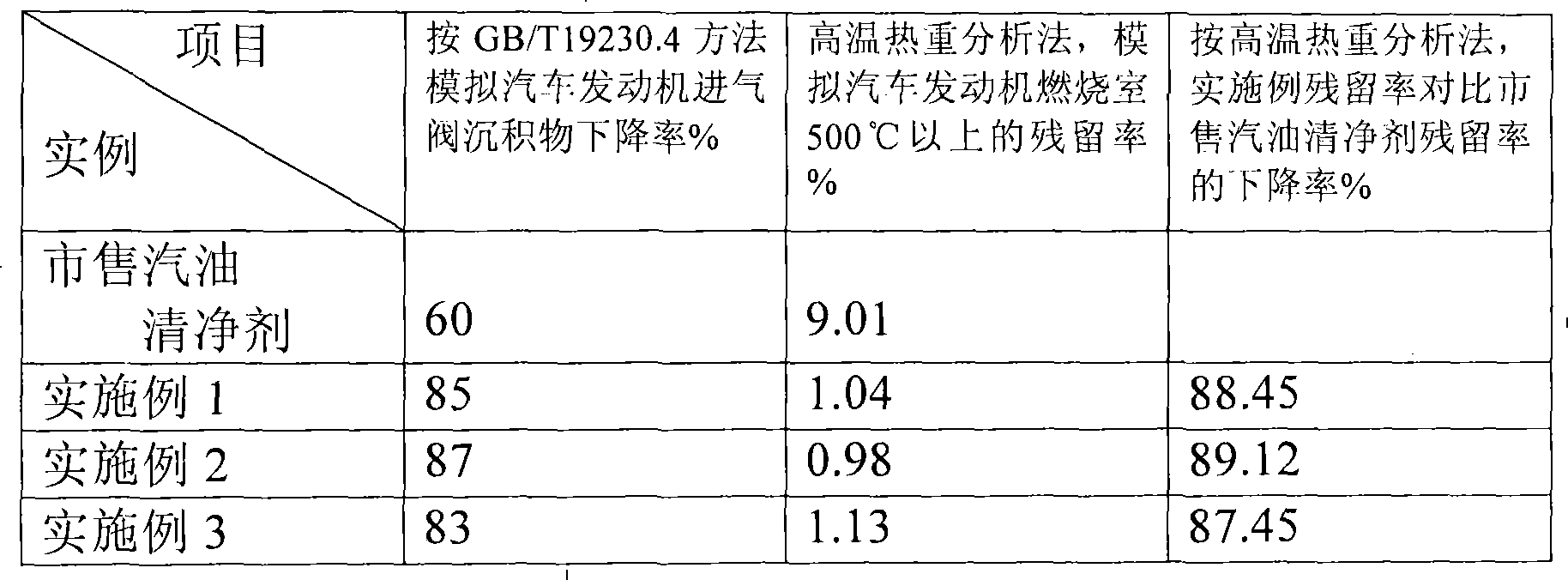

Petrol detergent capable of remarkably reducing deposit of gasoline engine combustion chamber

ActiveCN101230298AReduced drop rateReduce incrementLiquid carbonaceous fuelsFuel additivesSolubilityDemulsifier

The invention relates to a gasoline detergent which can notably reduce deposited matters in the firebox of the gasoline motor. The detergent includes a high-surfactivity polyether amine, a kind of polyether carrier liquid with excellent oil solubility and functional agents of cosolvent, antioxidant, anti-rust agent, preservative and demulsifier thereof. The weigh percentages of the above components are that polyether amine is 40-50 percent; polyether carrier liquid is 40-50 percent; cosolvent and other functional agents are 5-20 percent. When 250-500ppm dosage of the detergent of the invention is added into the commercial car gasoline, not only the oil nozzle and the air inlet valve in the fuel gas inlet system of the motor of the car can be inhibited and cleaned, but also the deposited matters in the firebox of the gasoline motor can be obviously reduced. The increment of deposited matters of the car gasoline using the detergent of the invention in the firebox can be 70 percent above less than the increment of deposited matters of the car gasoline containing the detergent on the market in the firebox.

Owner:天津悦泰石化科技有限公司

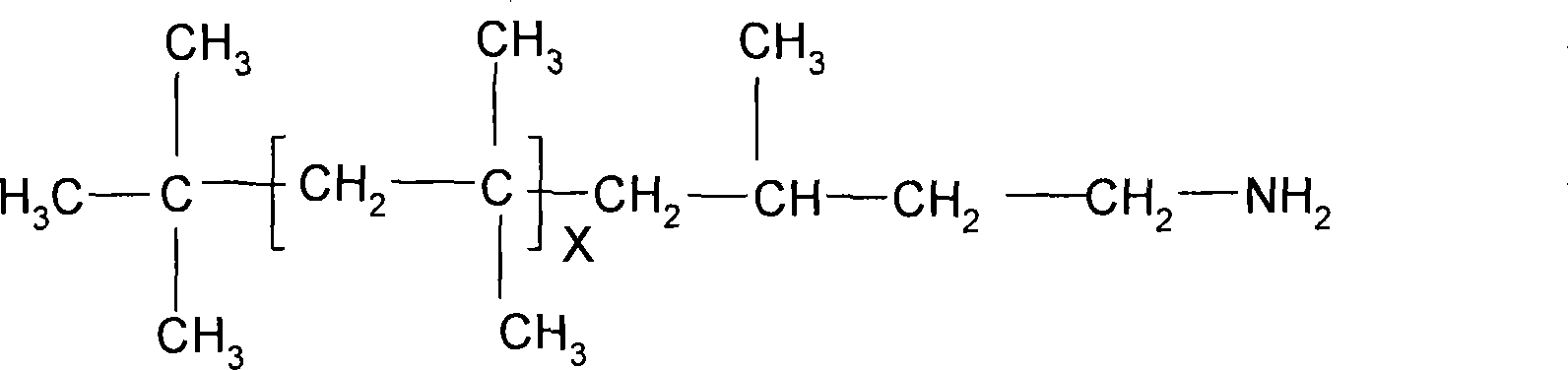

Petrol detergent capable of reducing deposit of gasoline engine combustion chamber

ActiveCN101230297AReduced drop rateReduce incrementLiquid carbonaceous fuelsFuel additivesSolubilityCombustion chamber

The invention relates to a gasoline detergent which can reduce deposited matters in the firebox of the gasoline motor. The detergent includes a high-surfactivity polyisobutene amine, a kind of polyether carrier liquid with excellent oil solubility, and cosolvent, antioxidant, anti-rust agent, preservative, and demulsifier thereof. The weigh percentages of the above components are that polyisobutene amine is 15-30 percent; polyether carrier liquid is 30-45 percent; and cosolvent and other functional agents are 30-50 percent. When 400-600ppm dosage of the detergent of the invention is added into the commercial car gasoline, not only the oil nozzle and the air inlet valve in the fuel gas inlet system of the motor of the car can be inhibited and cleaned, but also the deposited matters in the firebox of the gasoline motor can be obviously reduced. The increment of deposited matters of the car gasoline using the detergent of the invention in the firebox can be 50 percent above less than the increment of deposited matters of the car gasoline containing the detergent on the market in the firebox.

Owner:天津悦泰石化科技有限公司

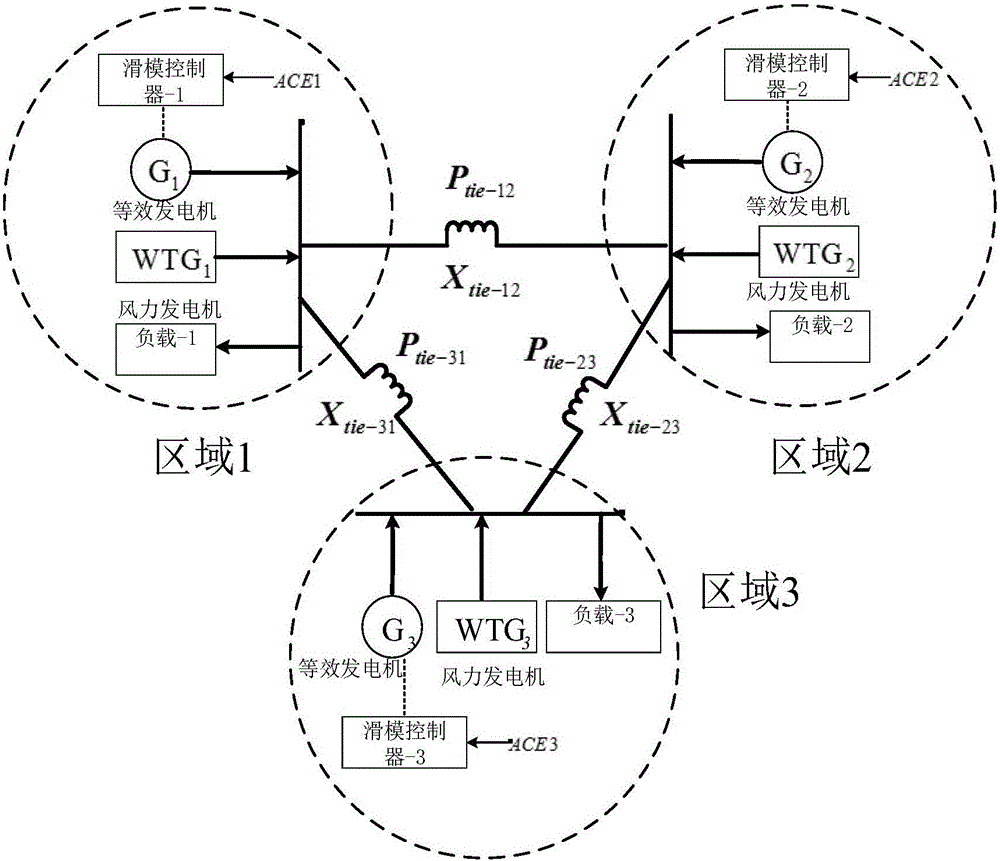

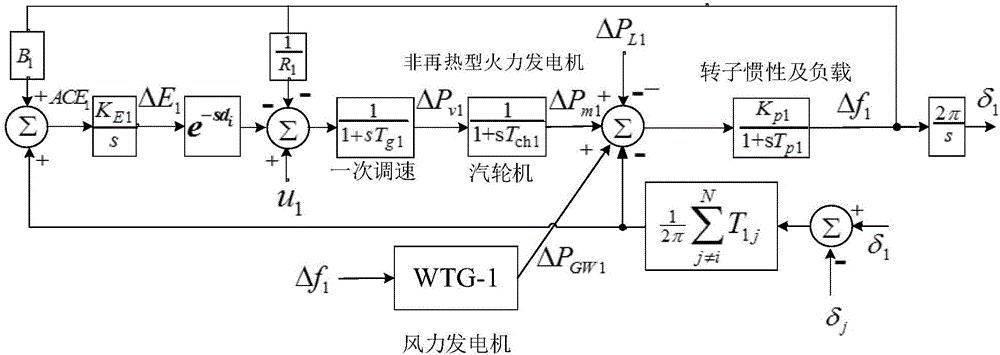

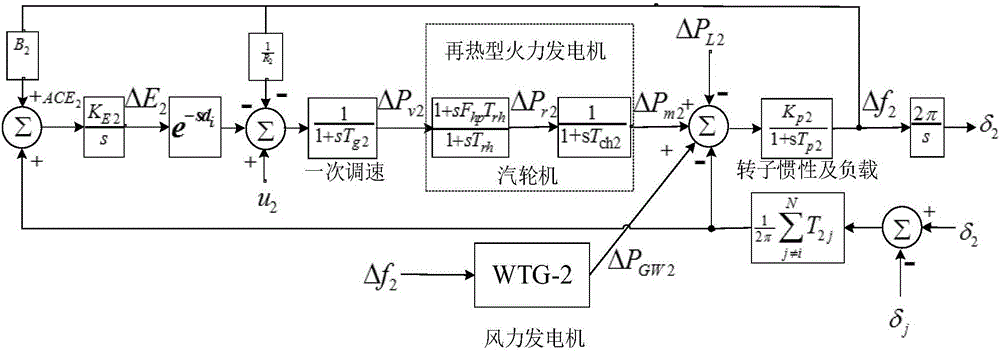

Load-frequency control method of multi-domain time-lag electric power system with high wind energy permeability

ActiveCN105958512AReduce incrementReduce frequency deviationPower oscillations reduction/preventionWind drivenElectric power system

The present invention relates to a load-frequency control method of a multi-domain time-lag electric power system with high wind energy permeability. The method comprises the following steps: S1, establishing a time-lag electric power system with multiple domains, and establishing the mathematics model of each generation system; S2, establishing state models with uncertain items corresponding to each domain according to the mathematics model of a generator; S3, designing an integration type sliding mode surface [Sigma]I (t) according to the state models with uncertain items; S4, designing the sliding mode load frequency controller according to the integration type sliding mode surface [Sigma]I (t); and S5, taking a controller ui(t) obtained in the step S4 as a controlling instruction, and optimizing the load frequency offset of the electric system. Compared with the prior art, a wind driven generator participates the regulation of the system frequency to tightly cooperate the wind power generation with the traditional fire power generation, and the increment of the output power of each generator is evenly reduced to ensure the power supply and demand balance of each area and effectively reduce the frequency offset of each area.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

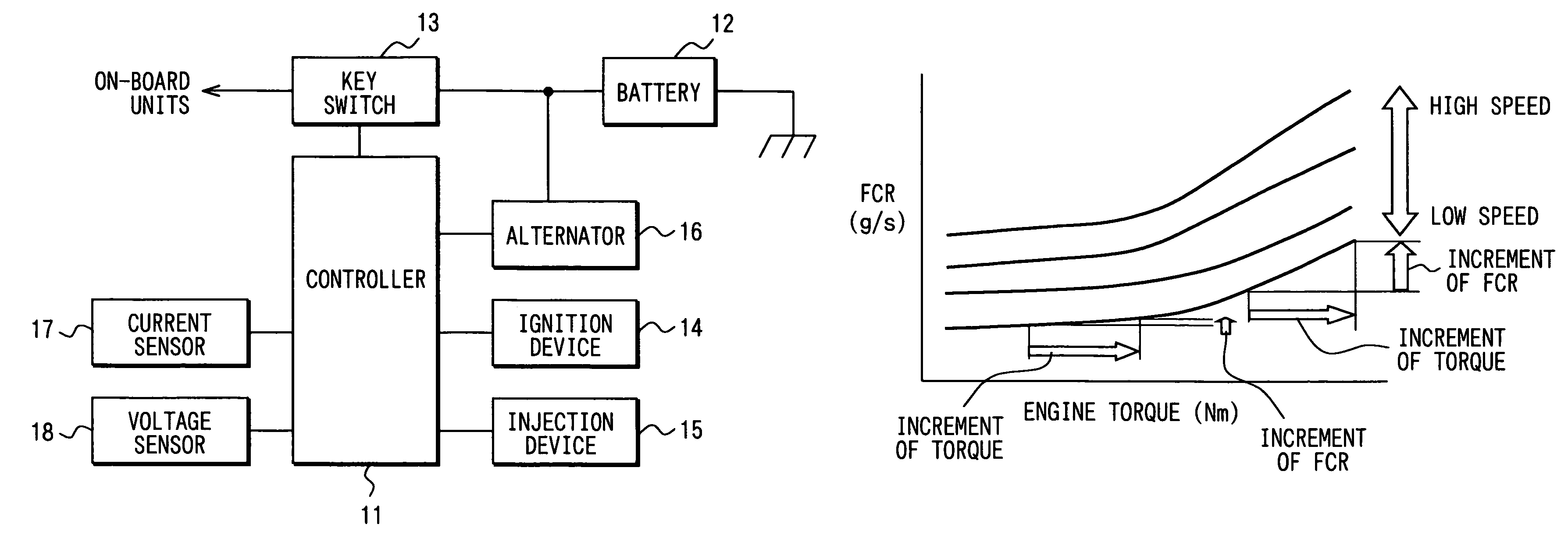

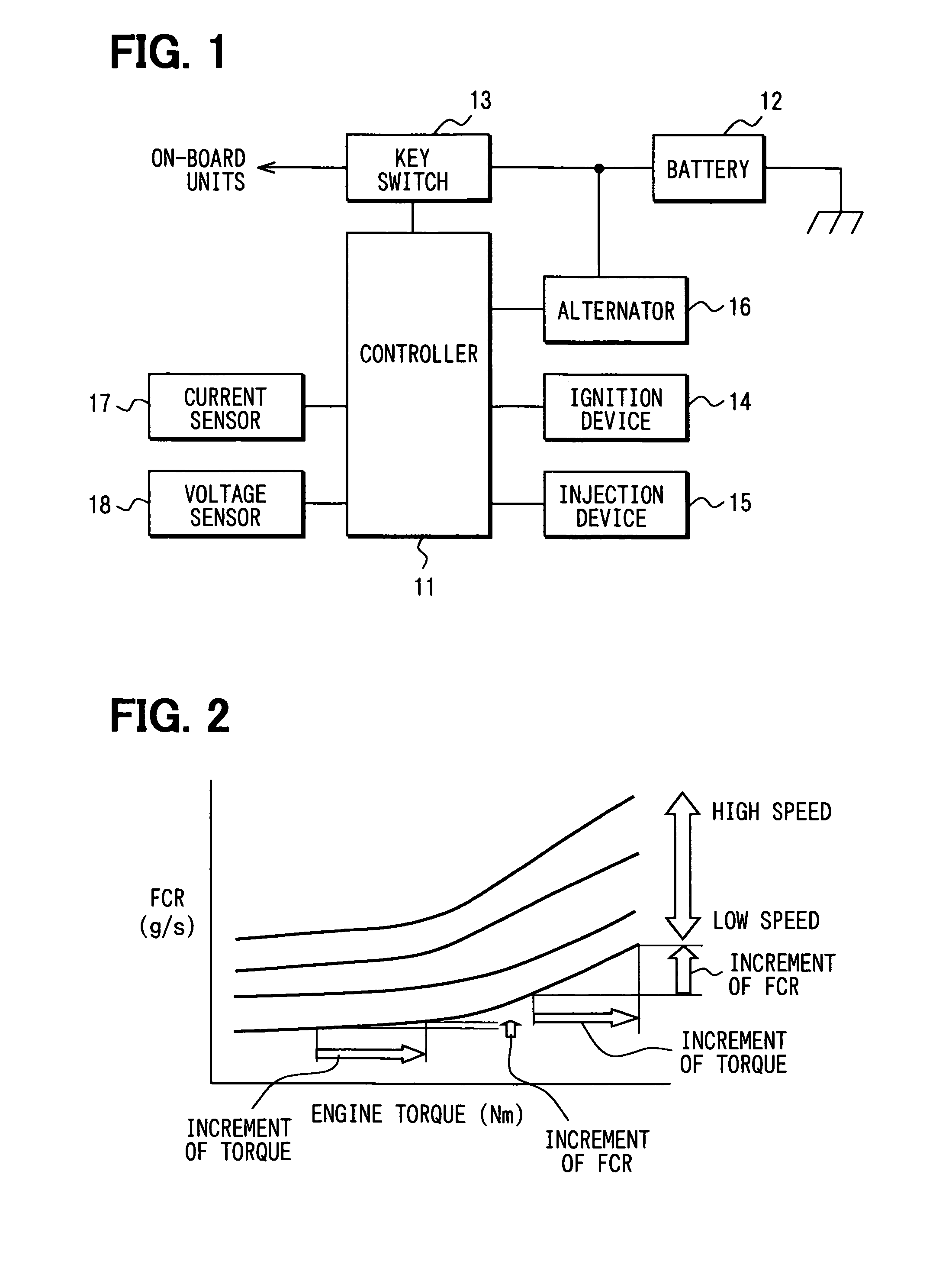

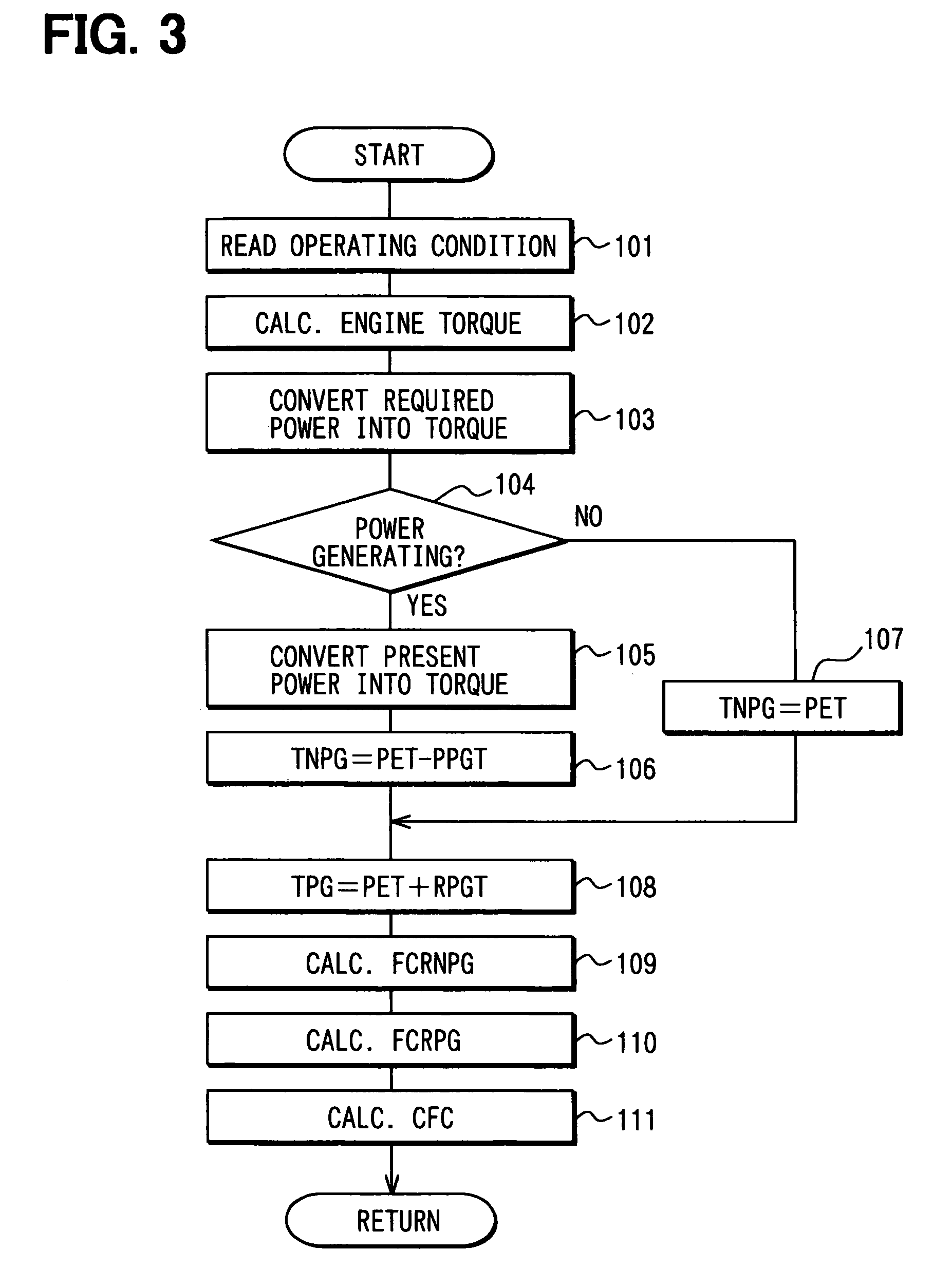

Power generation control apparatus for internal combustion engine

InactiveUS7355292B2Reduce incrementSaving effectBatteries circuit arrangementsLevel controlAlternatorElectric consumption

An increment of a fuel consumption rate caused by power generation is determined from a difference in fuel consumption rate between a case of performing power generation of an alternator and a case of stopping the power generation. The increment of the fuel consumption rate is divided by a power generation amount of the alternator to determine an increment of a fuel consumption per unit power generation amount. A use-frequency of the electric consumption is determined and also a possible power generation amount and average consumption power are calculated. A target electric consumption is set based upon the use-frequency, the possible power generation amount and the average consumption power so that the charge and discharge balance of the battery becomes zero. The present electric consumption is compared with the target electric consumption to determine whether or not to perform the power generation of the alternator.

Owner:DENSO CORP

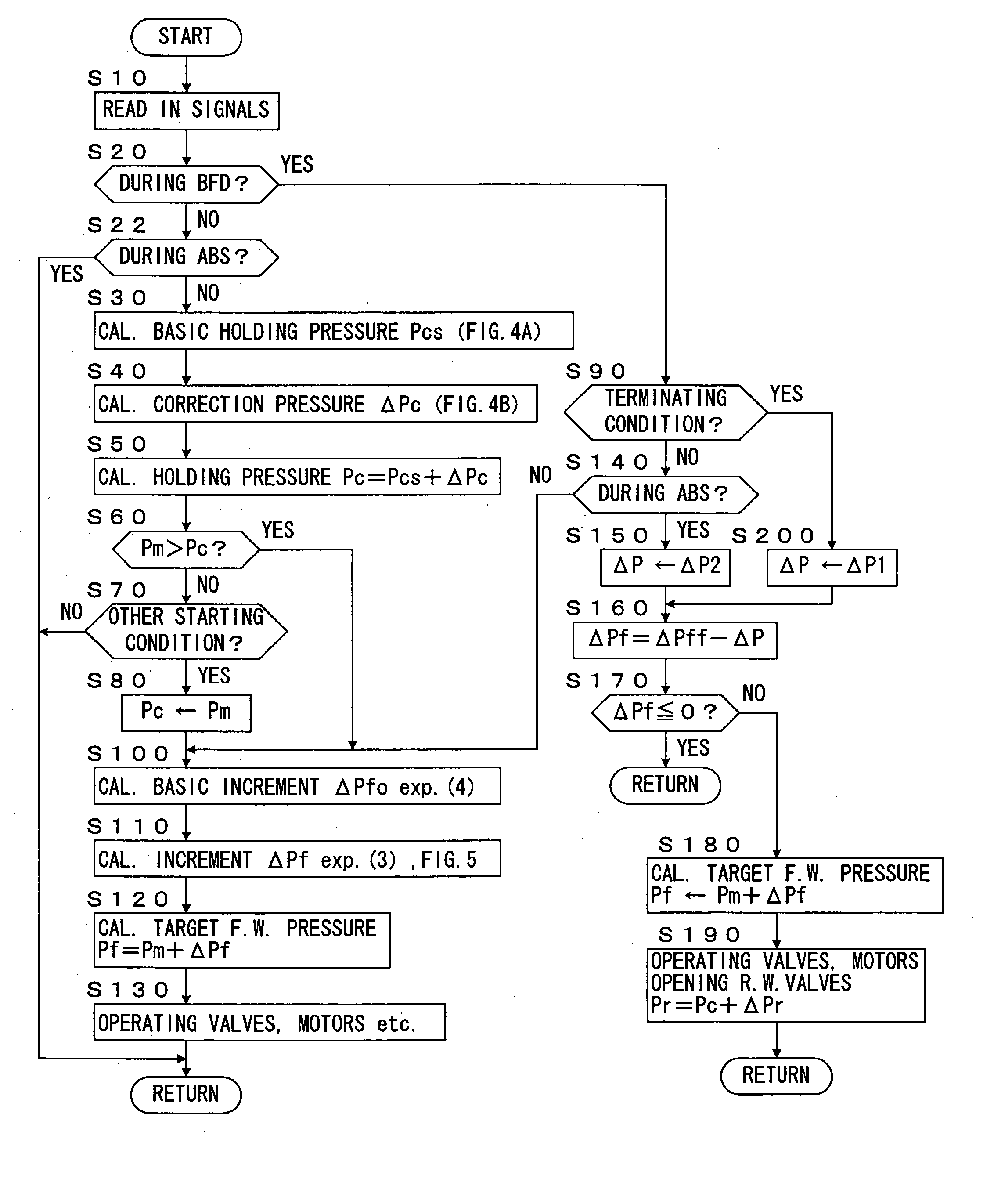

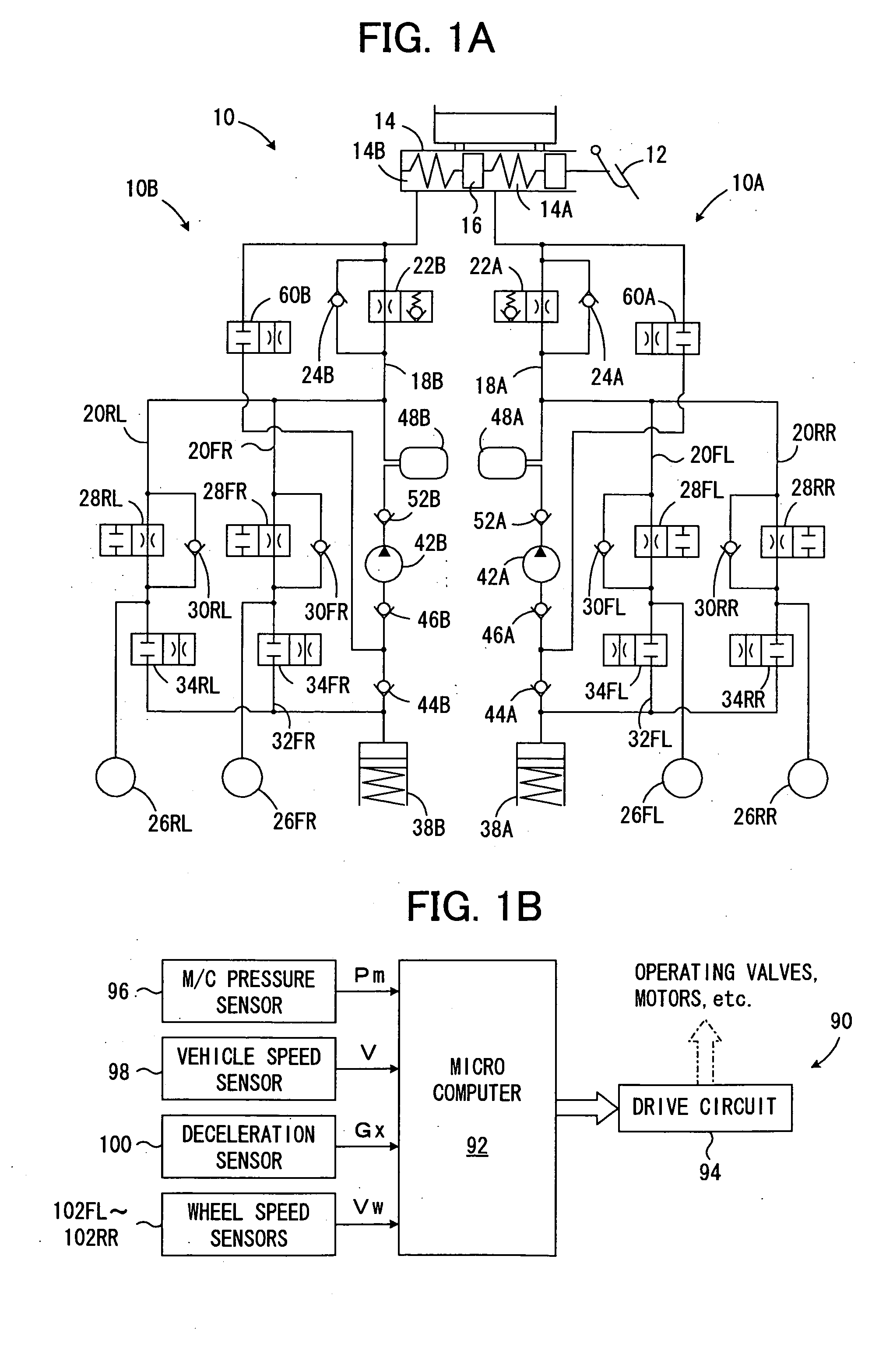

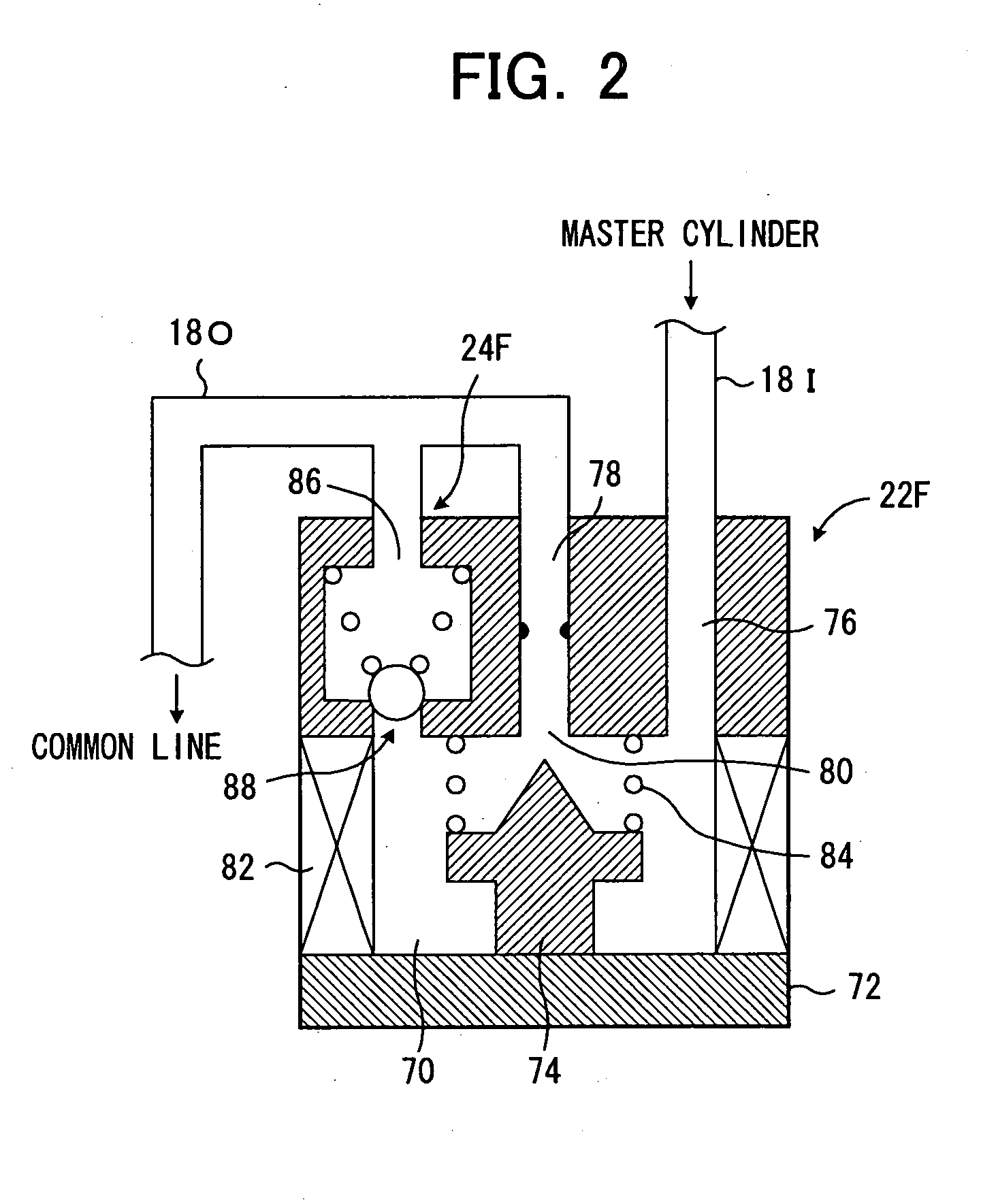

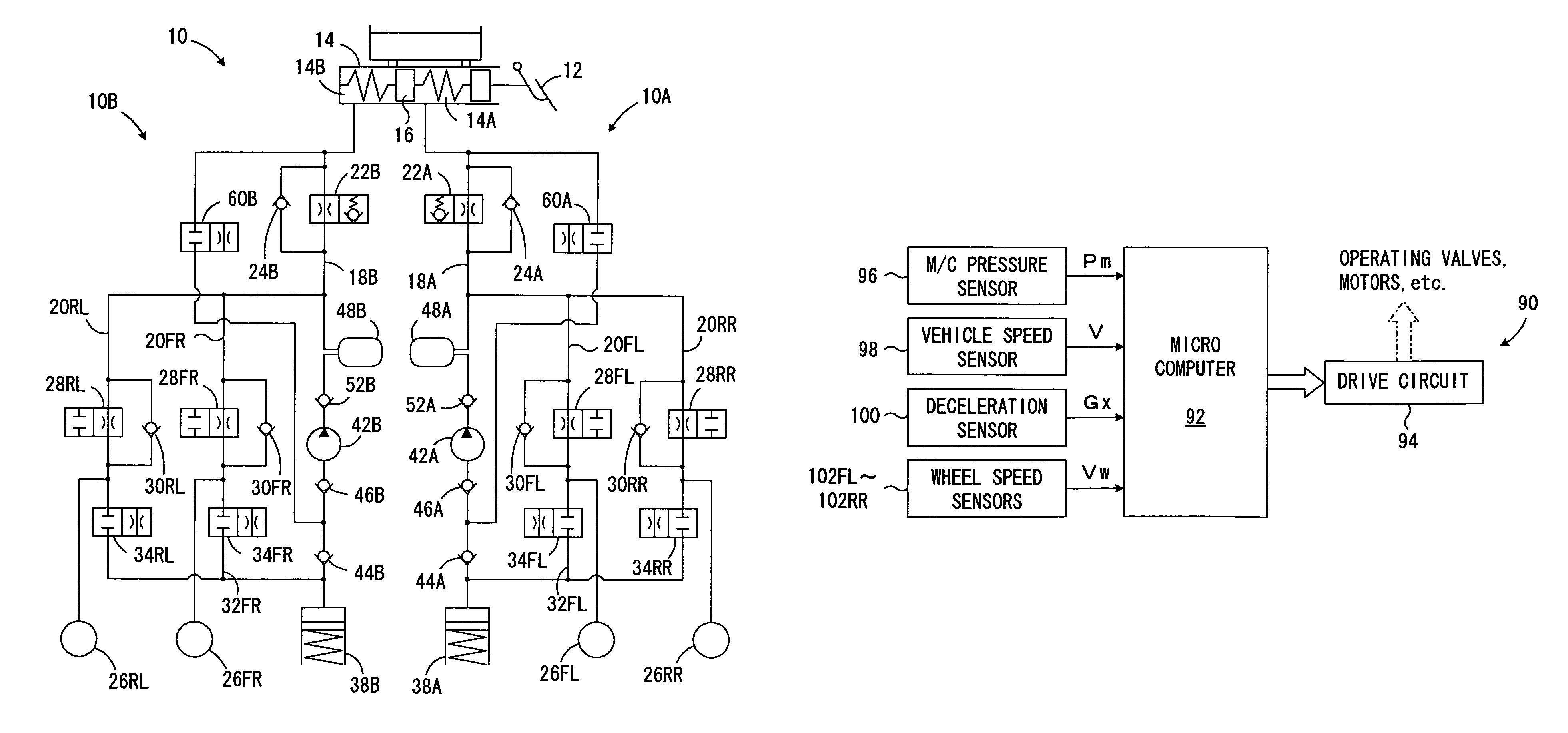

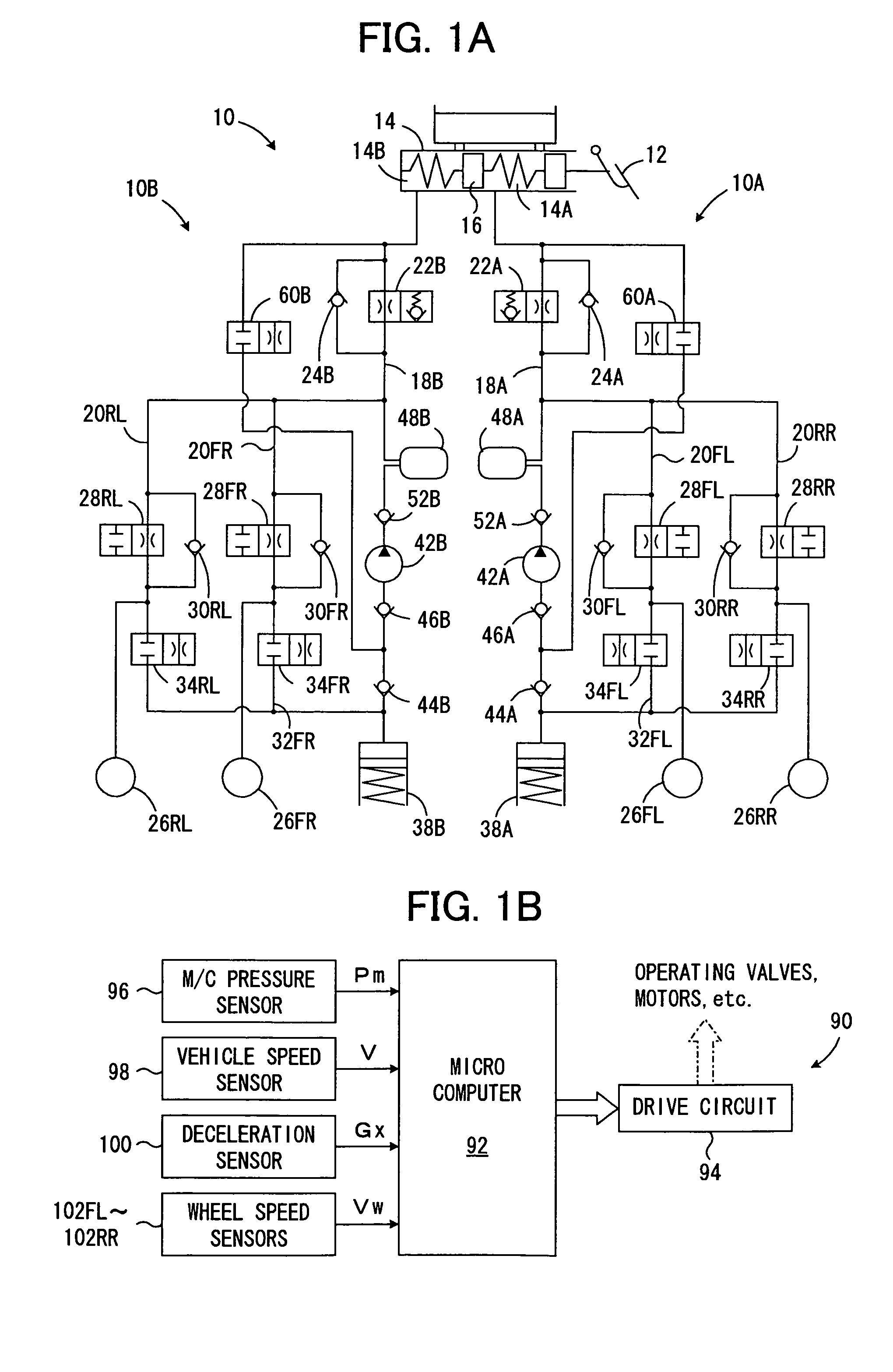

Vehicle braking control device for braking force distribution

InactiveUS20040260446A1Improve braking effectReduce forceAnalogue computers for trafficWheel adhesionEngineeringVehicle brake

Owner:ADVICS CO LTD

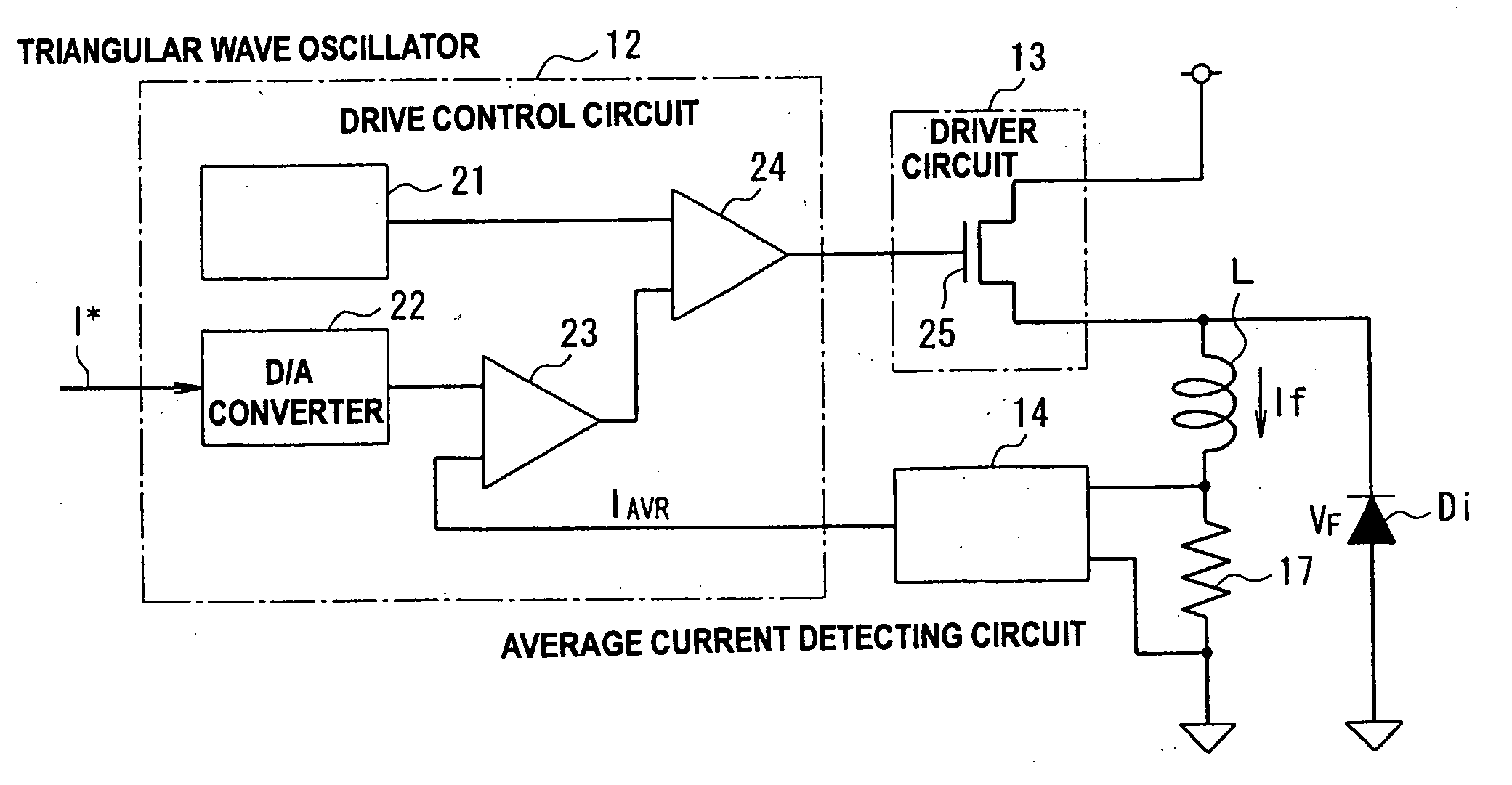

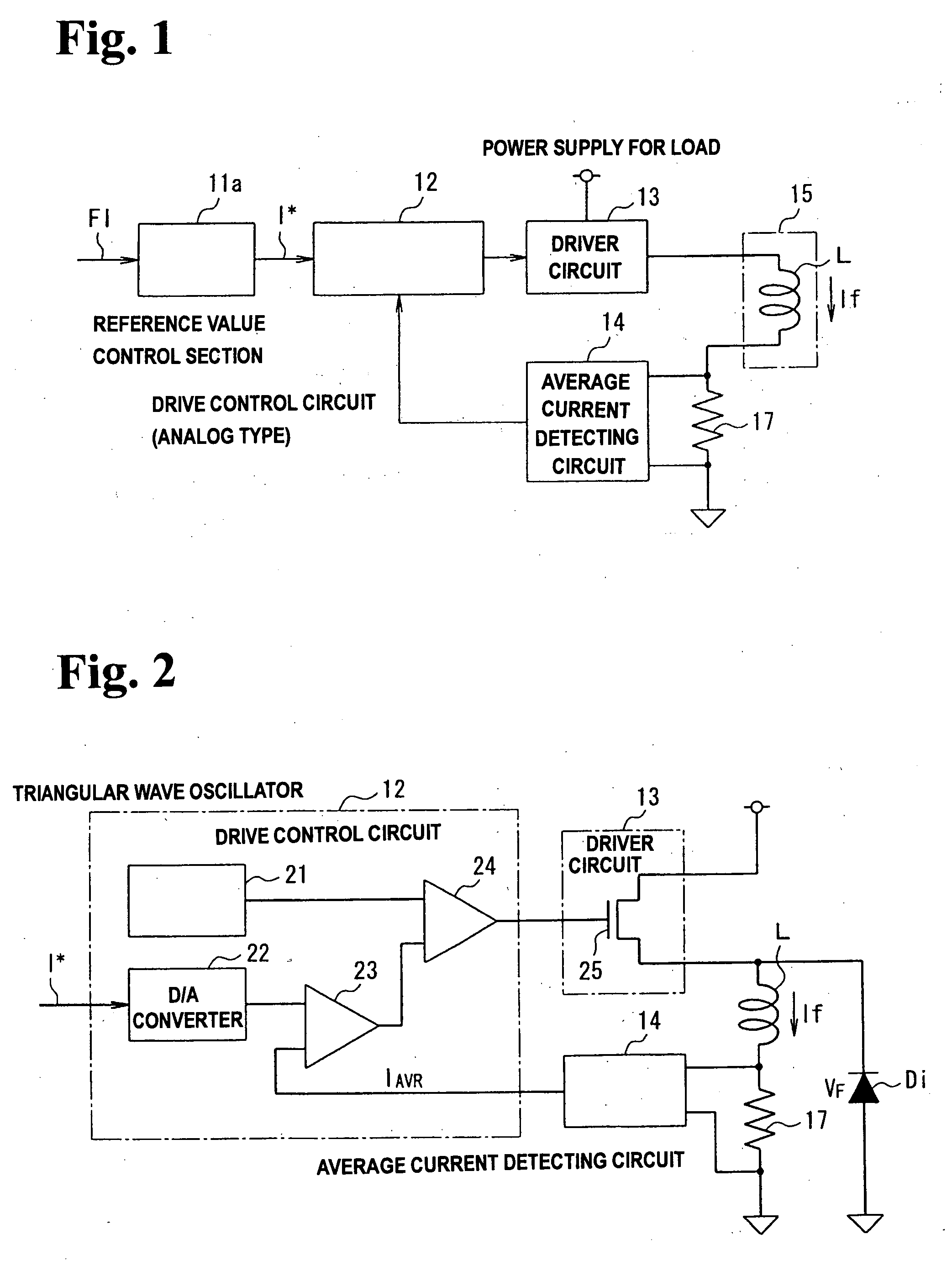

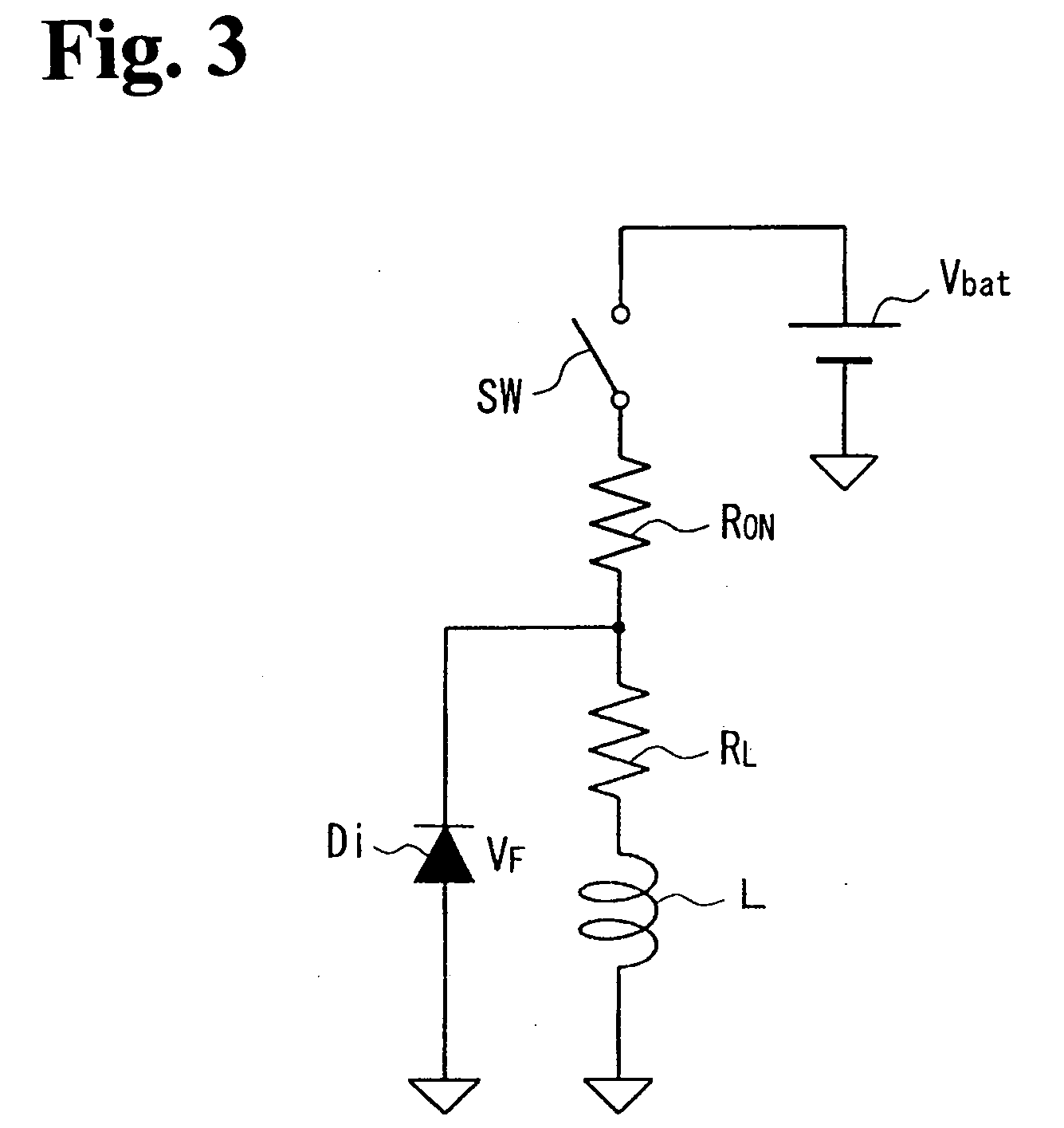

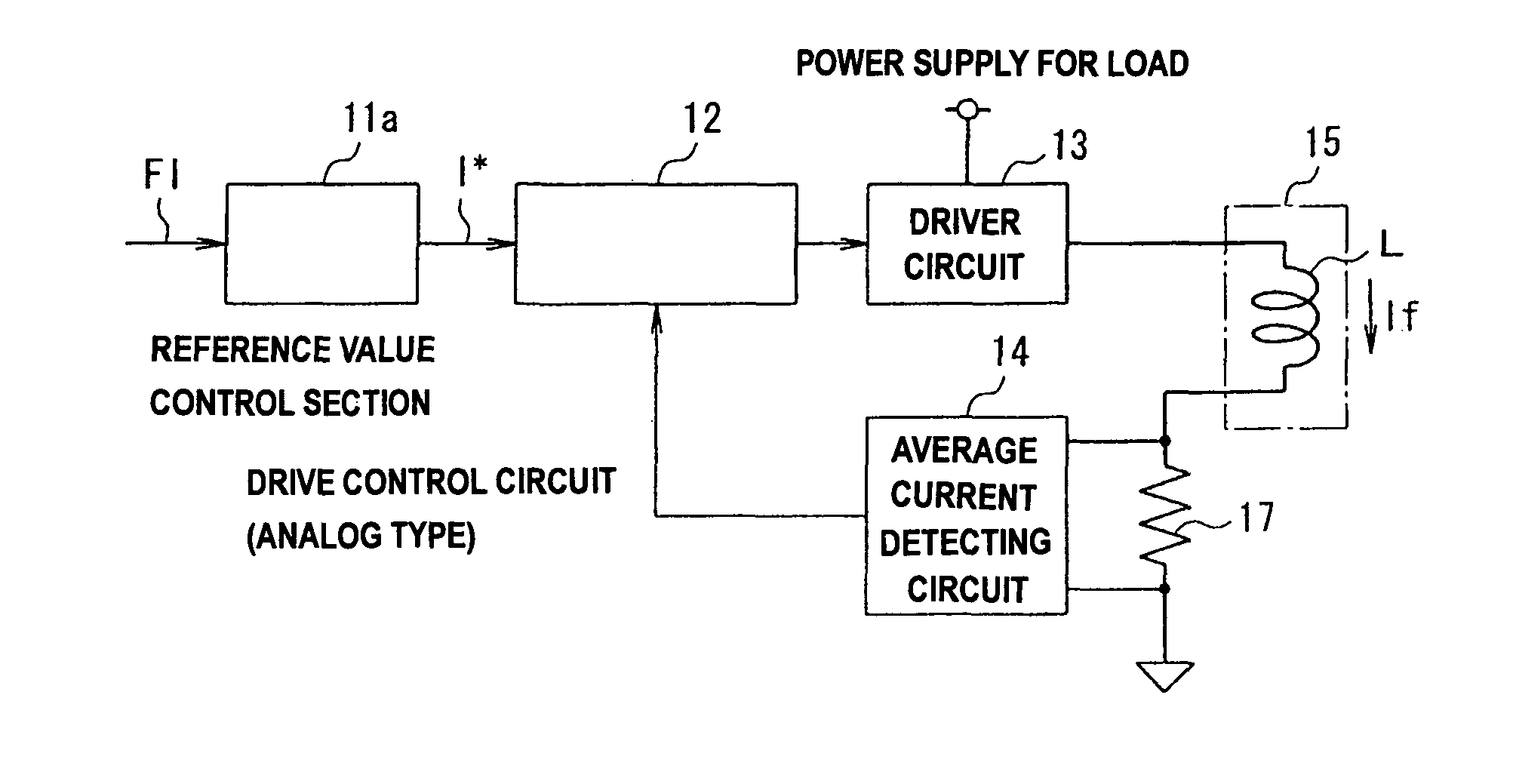

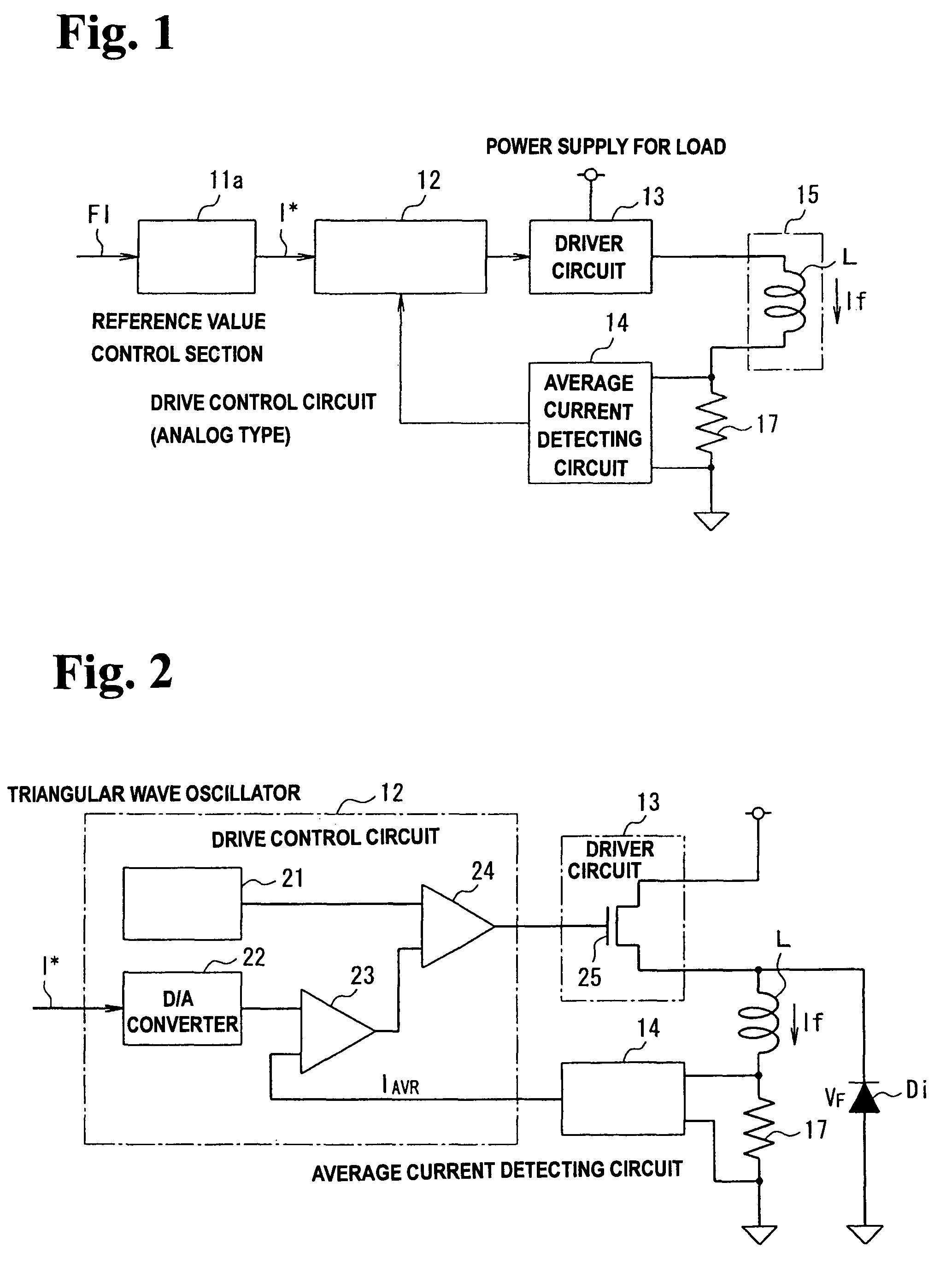

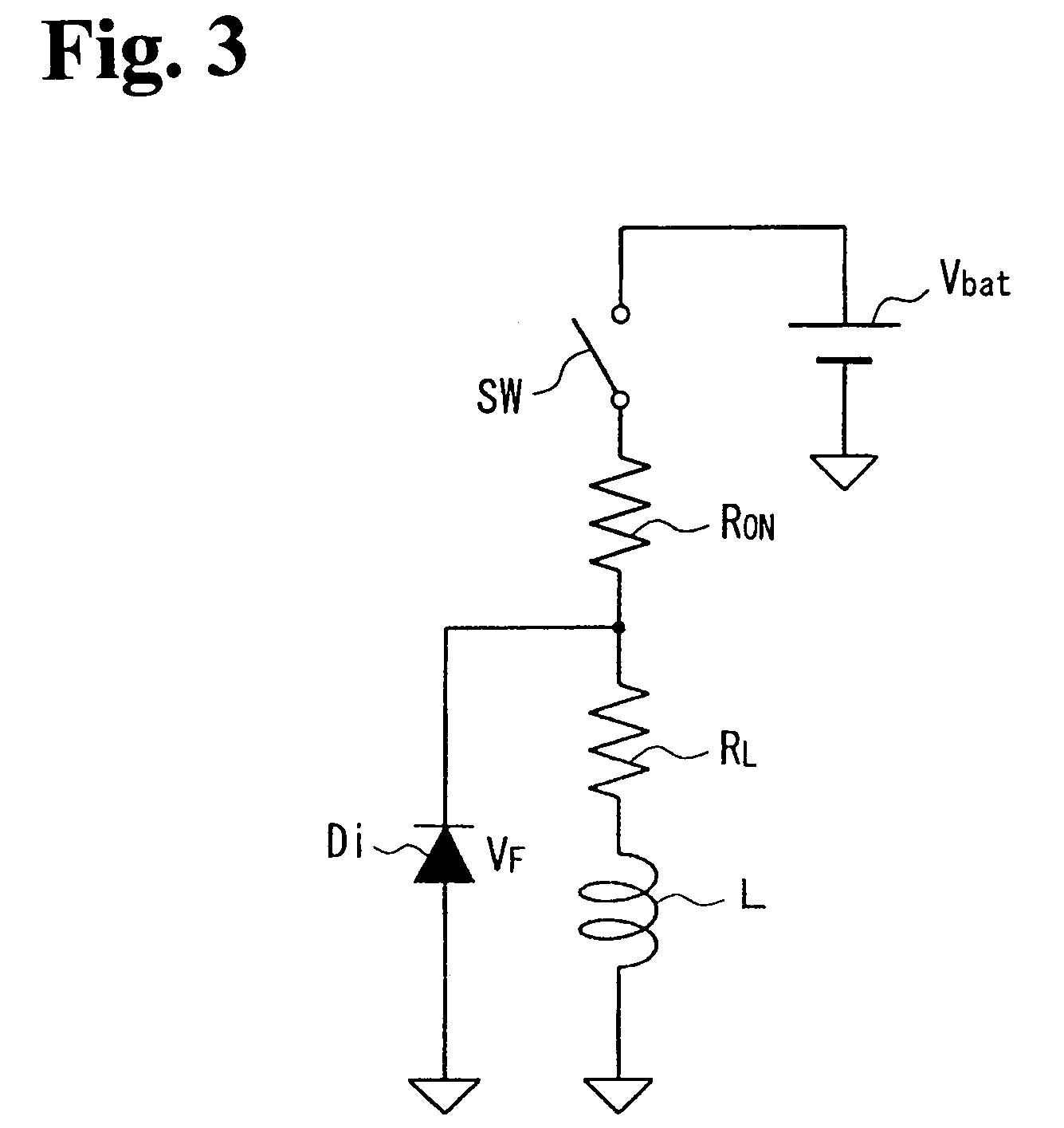

Drive control apparatus for controlling drive of inductive load and drive control method for controlling the same

ActiveUS20090189580A1Reduce currentShorten periodAc-dc conversionDc-dc conversionInductive loadControl equipment

A drive control apparatus controls a drive of an inductive load having a current flowing therethrough. The drive control apparatus includes a drive control device for controlling a variation of the current flowing through the inductive load within a certain period by Pulse Width Modulation control so as to come close to a reference current value, and a reference value control device for controlling a fluctuation period of the reference current value and making the fluctuation period of the reference current value longer than that of the current flowing through the inductive load by the Pulse Width Modulation control.

Owner:FUJI ELECTRIC CO LTD

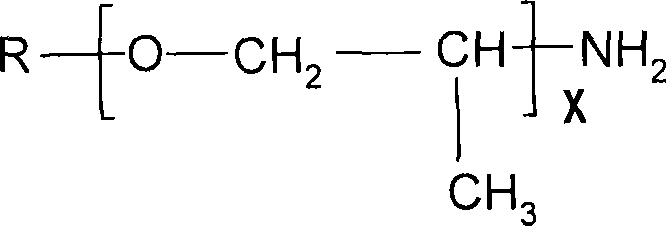

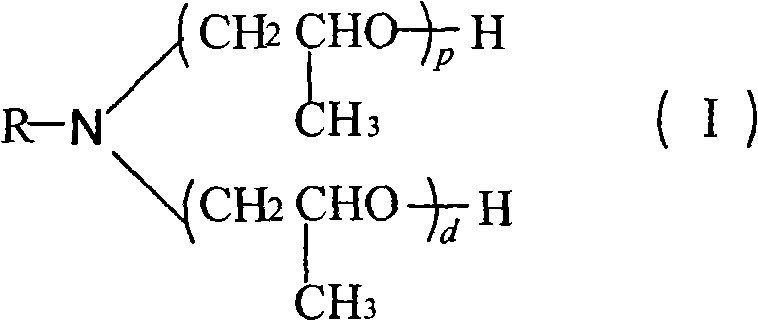

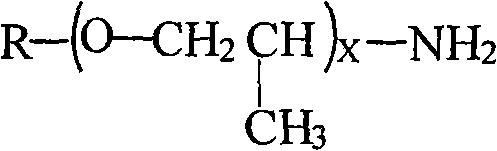

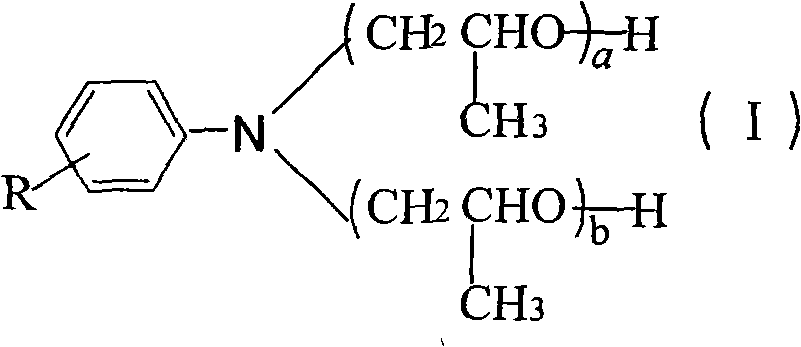

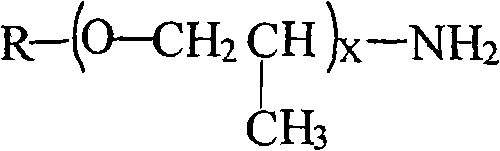

Gasoline detergent prepared by using fatty amine polyoxypropylene ether

InactiveCN101962585AReduce incrementIncreased drop rateLiquid carbonaceous fuelsFuel additivesGasolineFatty amine

The invention relates to a gasoline detergent prepared by using fatty amine polyoxypropylene ether expressed as a structural formula (I), wherein R is alkyl of C10 to C20; and p+d is a natural number of 12 to 31. The gasoline detergent prepared by using the fatty amine polyoxypropylene ether as a main component is used in gasoline and can obviously reduce the generation of sediments of a fuel air inlet system of a gasoline engine.

Owner:冯明星

Cosmetic composite with breast maintenance effect

InactiveCN105816389APromote generationPromote incrementCosmetic preparationsOrganic active ingredientsVitamin CGINSENG EXTRACT

The invention discloses a cosmetic composite with a breast maintenance effect. The cosmetic composite with the breast maintenance effect contains ginseng extract, lupinus albus seed extract, and vitamin C or a vitamin C derivative. The cosmetic composite can nourish and moisten the breast skin, promote blood circulation, relieve collagen damage and enhance collagen synthesis to enable the total collagen protein to be maintained at a high level, and compaction and uprightness of the breasts are achieved.

Owner:FOSHAN QIANRU COSMETICS CO LTD

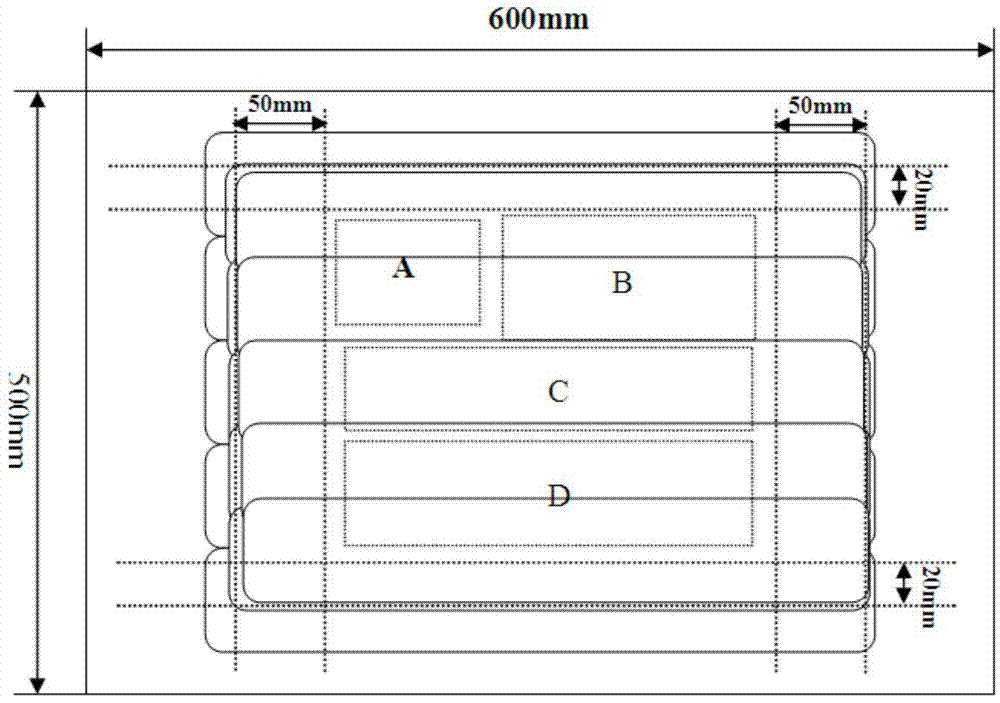

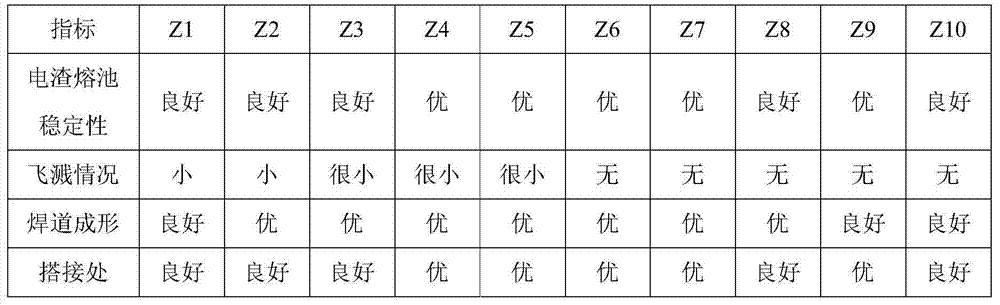

Sintered flux for nickel base strip electrode electro-slag welding

ActiveCN104708231AReduce burning lossImprove the transition coefficientWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Submerged arc sintered flux for stainless steel at low temperature

ActiveCN109175788AAdjustable viscositySmooth transitionWelding/cutting media/materialsSoldering mediaAlloyWollastonite

The invention relates to a submerged arc sintered flux for stainless steel at the low temperature. The submerged arc sintered flux is prepared from dry powder with various components and binder sodiumsilicate and is characterized in that the dry powder is prepared from, by weight, 15-30 parts of fluorite, 15-30 parts of white corundum, 20-35 parts of magnesia, 10-25 parts of wollastonite and 1-5parts of alloy powder. The flux is prepared by a method comprising the following steps that dry powder materials are evenly mixed according to the matching ratios, sodium silicate is added, wet mixingis carried out, then granulation is carried out, the granules are dried at the low temperature of 200-330 DEG C for 30-50 min, screened, sintered at the high temperature of 700-800 DEG C for 45-60 min, cooled and screened, and therefore the submerged arc sintered flux is obtained. The submerged arc sintered flux has the excellent effects shown in the description.

Owner:BEIJING JINWEI WELDING MATERIAL +1

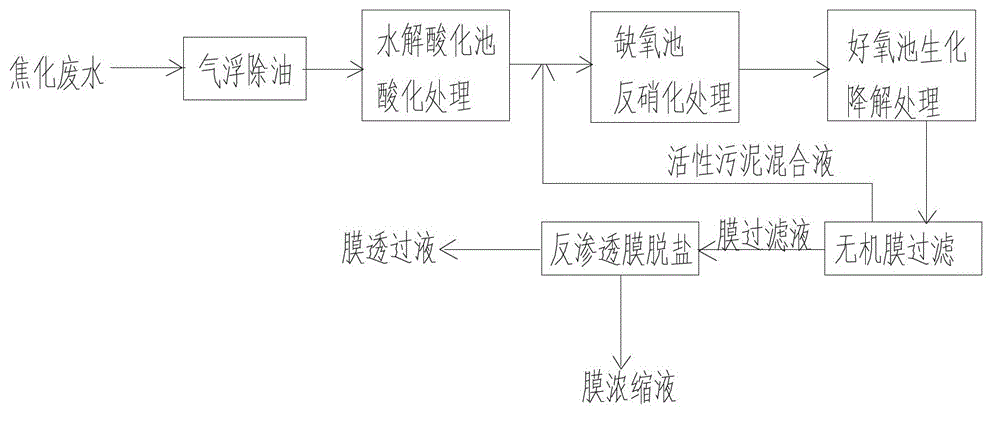

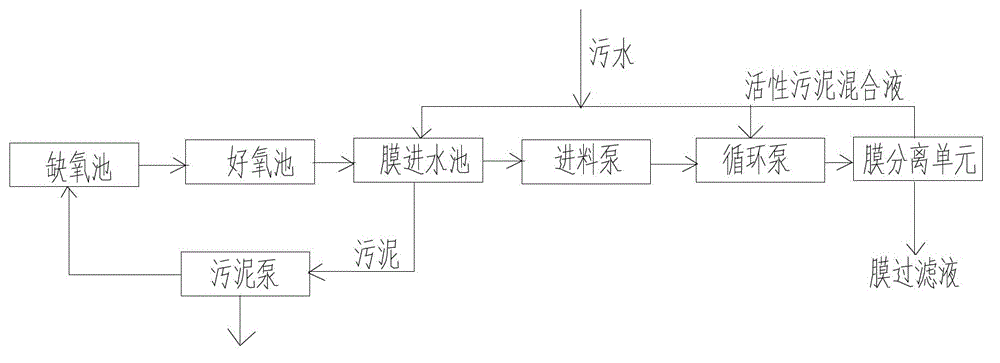

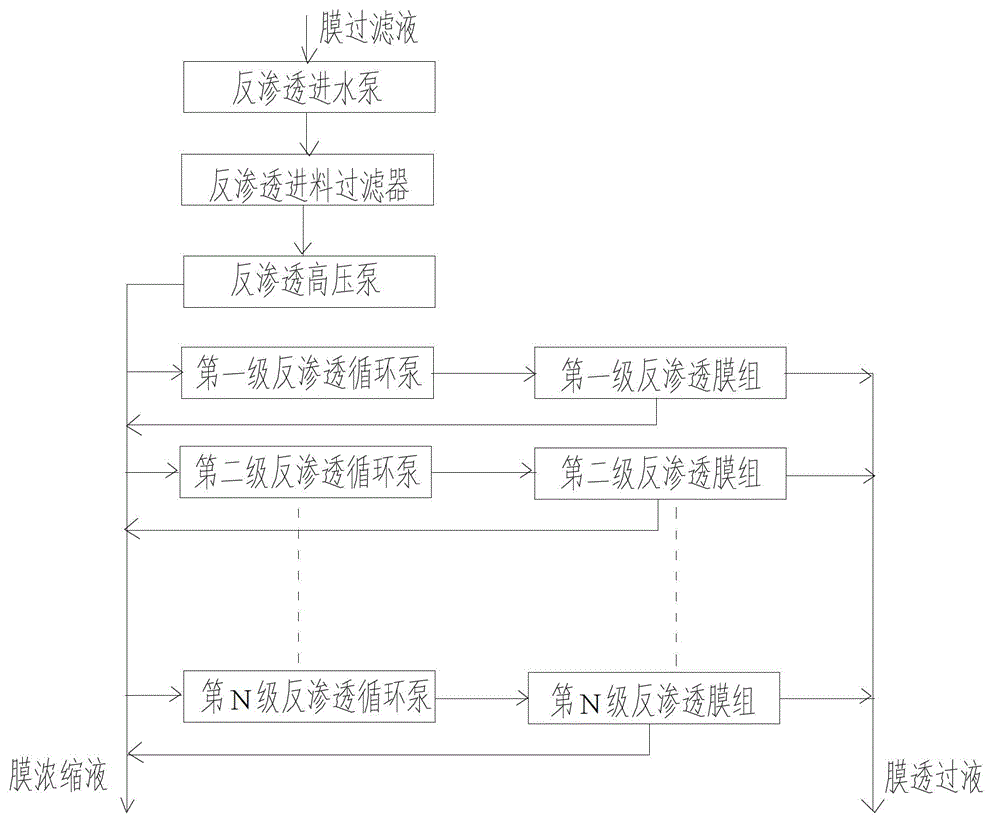

Advanced treatment recovery technology of coking wastewater

ActiveCN104030517ASolve the problem of intolerance to pollution and easy pollutionExtended cleaning cycleGeneral water supply conservationMultistage water/sewage treatmentReverse osmosisCoking wastewater

An advanced treatment recovery technology of coking wastewater comprises the steps of sequentially implemented air floatation oil removal pretreatment, acidifying treatment, denitrification treatment and biodegradation treatment, and also comprises the following steps: 1, processing biodegraded wastewater by using an inorganic membrane filtering device, reusing parts of the obtained membrane filtrate as mineral separation process water, and allowing the residual membrane filtrate to enter a pollution resistant reverse osmosis membrane device to carry out desalination treatment; and 2, pumping the membrane filtrate obtained in step 1 into the pollution resistant reverse osmosis membrane device to carry out desalination treatment in order to remove COD, NH3-N and inorganic salts in water, and directly reusing the obtained membrane permeation liquid as circulating cooling water. The technology adopting an inorganic membrane to carry out the reverse osmosis pretreatment can solve the problems of no pollution resistance and unlikely dirt obstruction of an ultrafilter membrane, and no flocculating agent or a small amount of the flocculating agent is added by adopting inorganic membrane feeding, so the reverse osmosis pollution degree is reduced, thereby the cleaning period of the RO (reverse osmosis) membrane is prolonged, the cleaning effect is good, and the irreversible dirt obstruction of the RO membrane is avoided.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

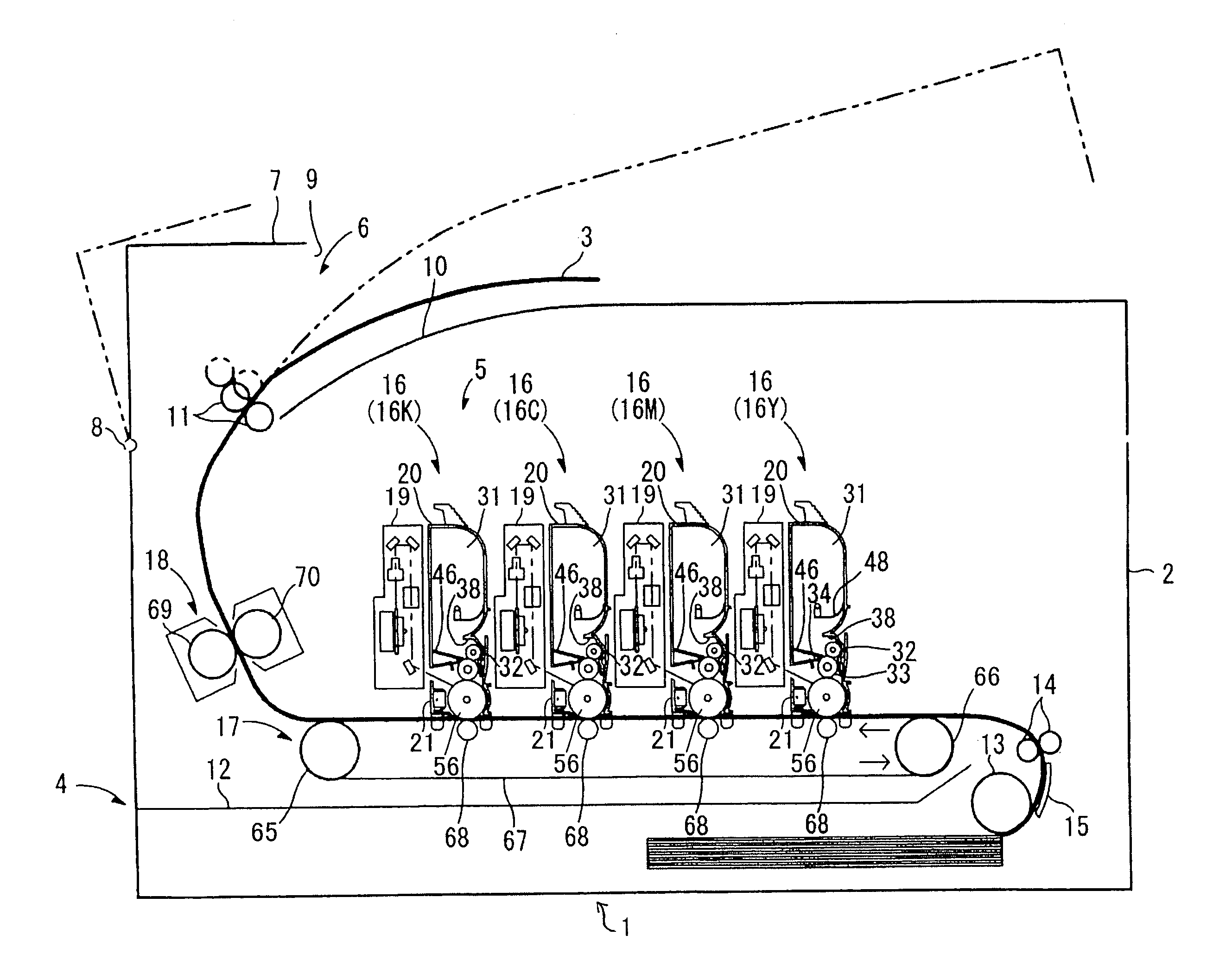

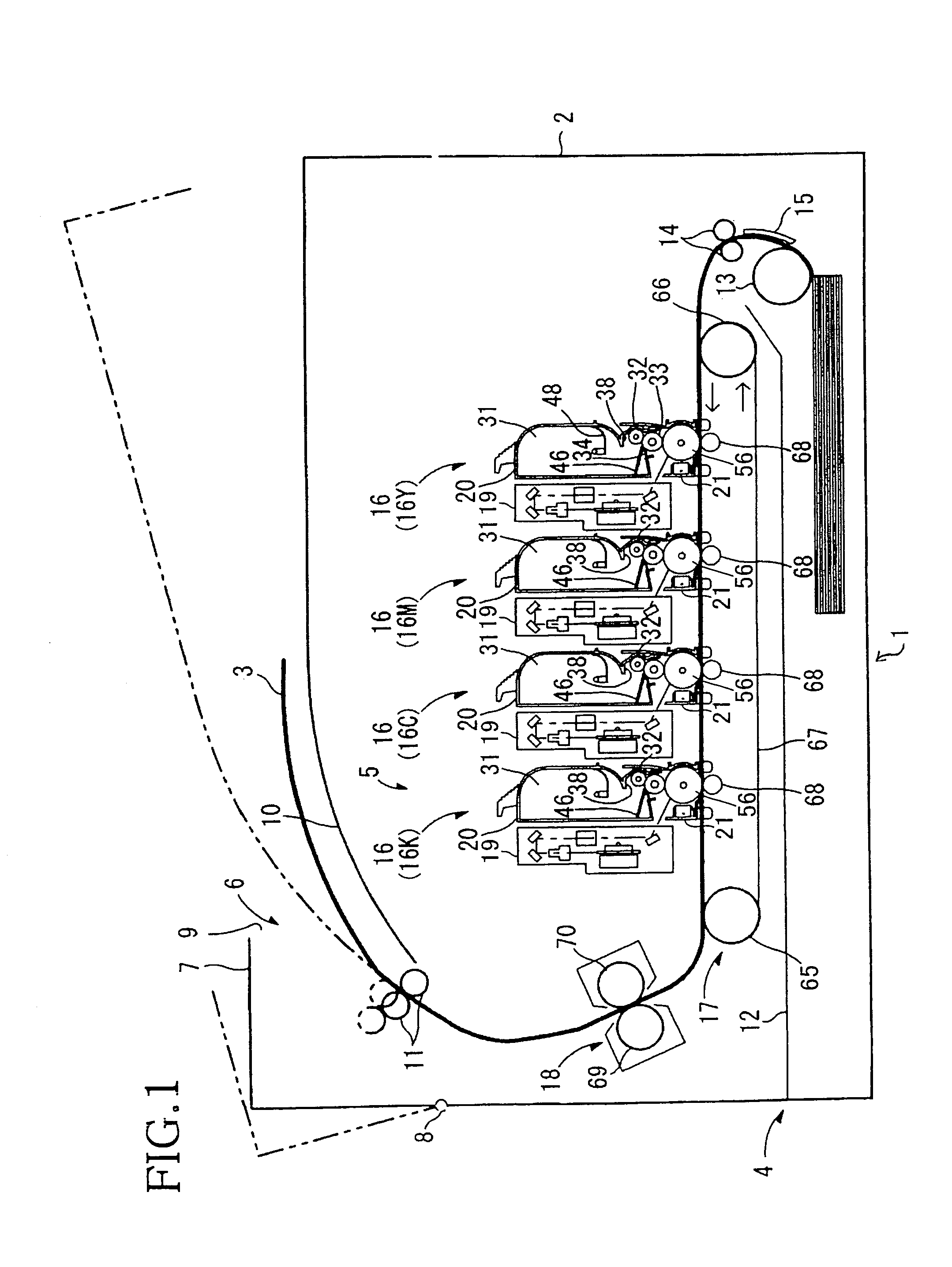

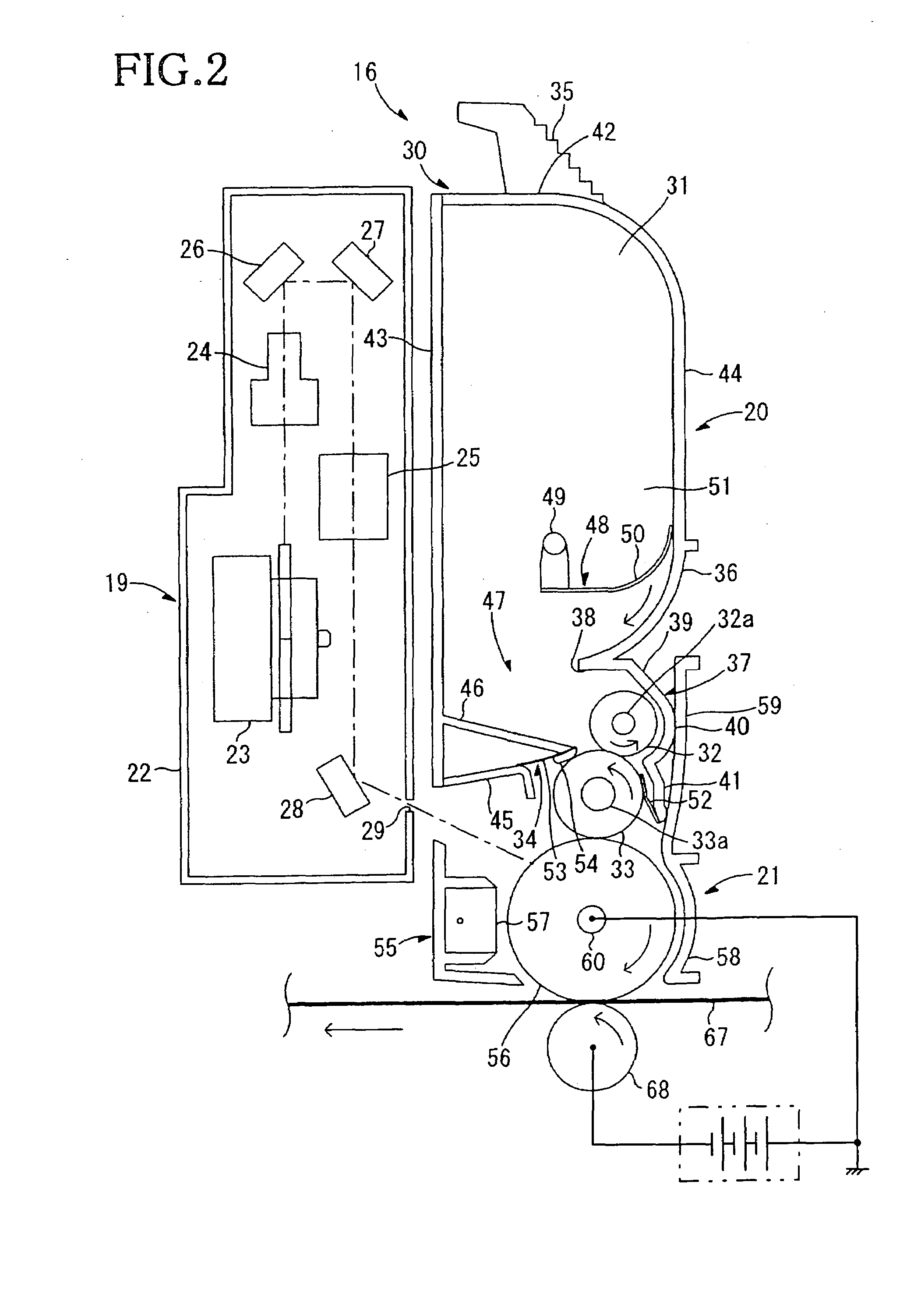

Image forming apparatus for a color laser printer for transferring a higher transfer efficiency on a recording sheet on the upstream side of the imaging forming process

ActiveUS7236731B2Reduce incrementDevelopersElectrographic process apparatusLatent imageImage formation

An image forming apparatus includes developing devices, each of which contains a developing agent of a single color therein; a photosensitive member; a latent image forming device that forms a latent image on the photosensitive member, the latent image being developed into a visible image on the photosensitive member, the visible image being made of developing agent images of each color using the developing agent of the single color supplied by each of the developing devices; and an image receiver member that contacts the photosensitive member and receives the developing agent images of each color formed on the photosensitive member sequentially and electrically. A transfer bias for transfer developing agent images from the photosensitive member to the image receiver member is set lower for the first developing agent image that is transferred than a transfer bias for transferring a second developing agent image.

Owner:BROTHER KOGYO KK

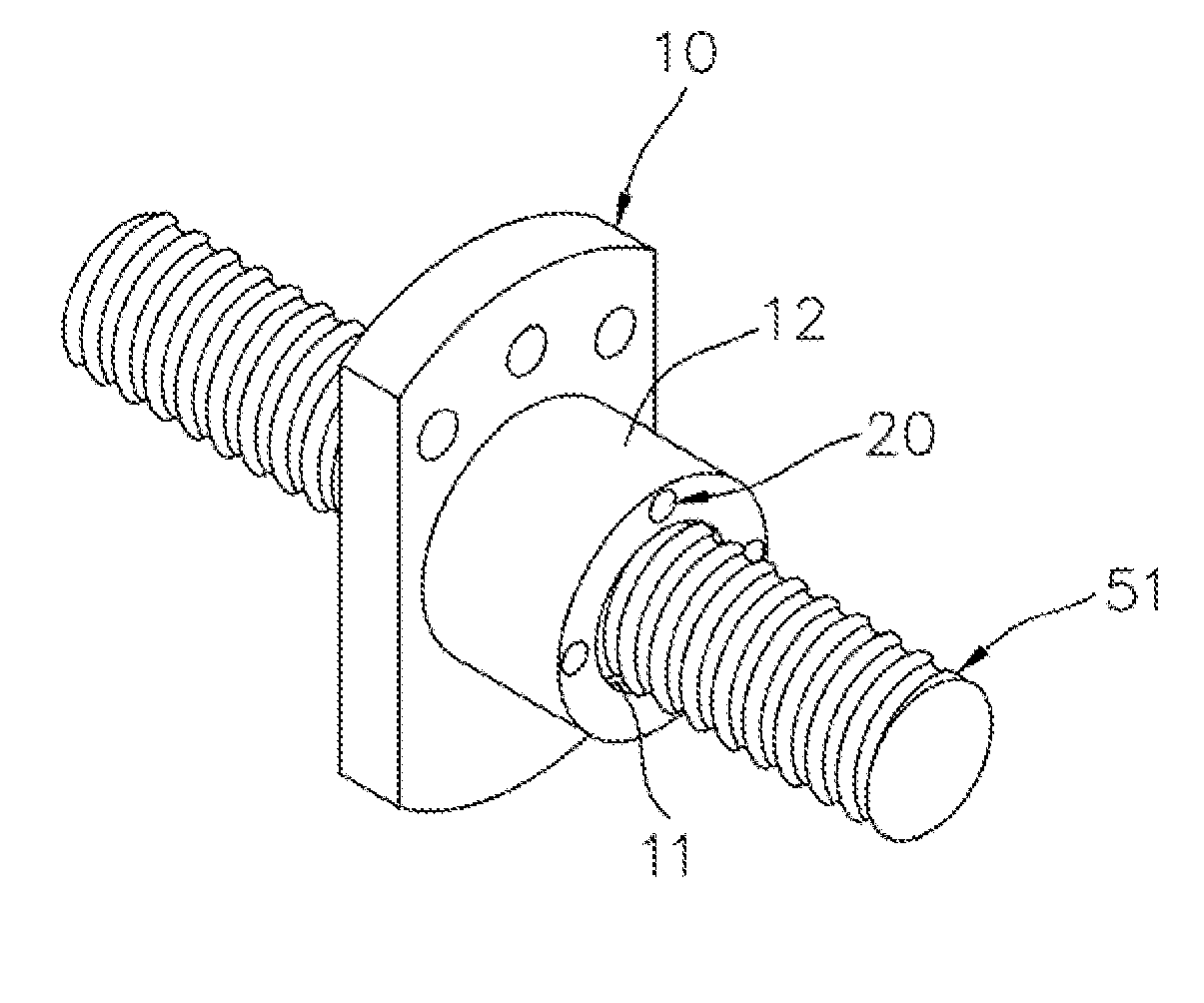

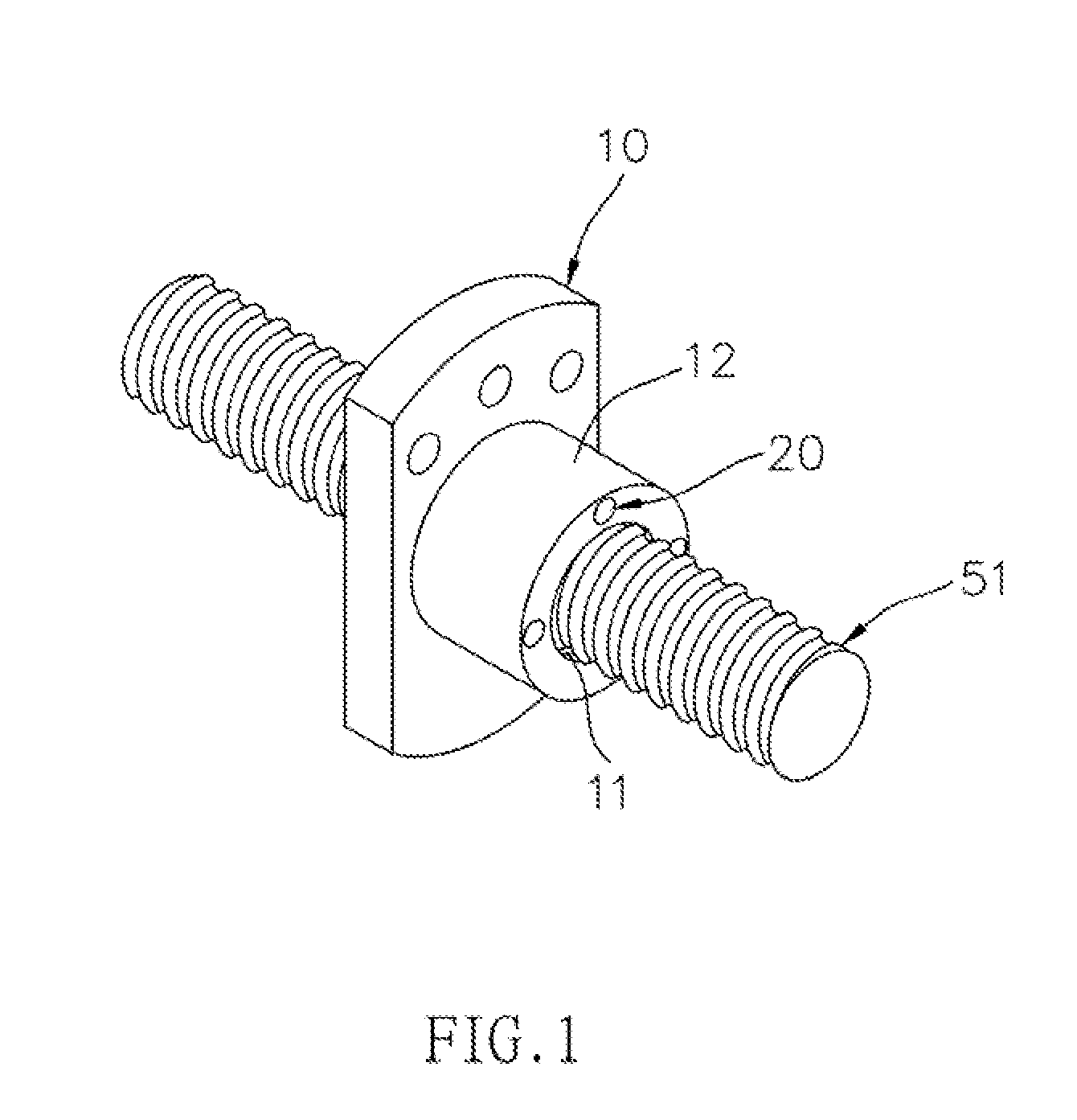

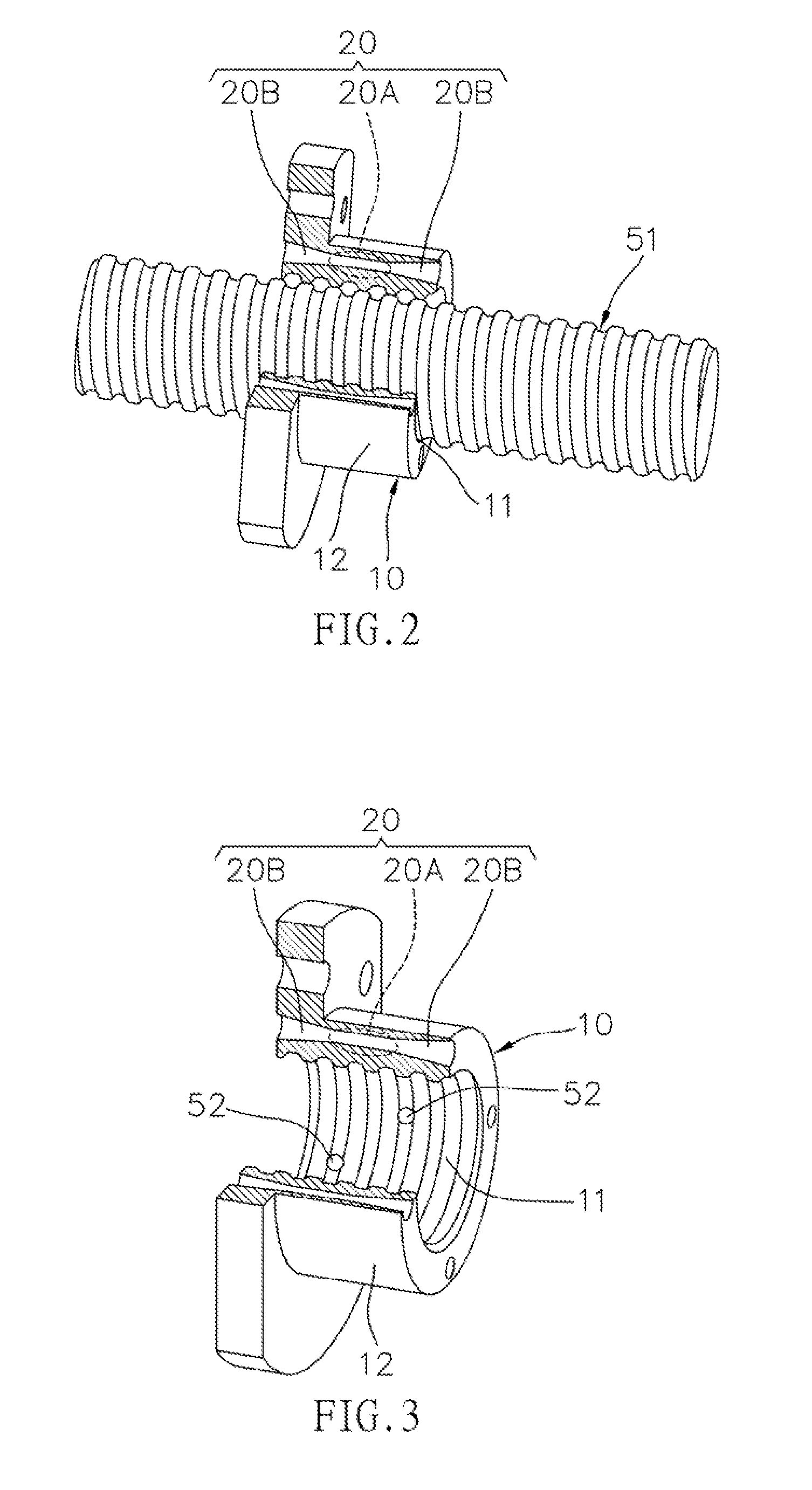

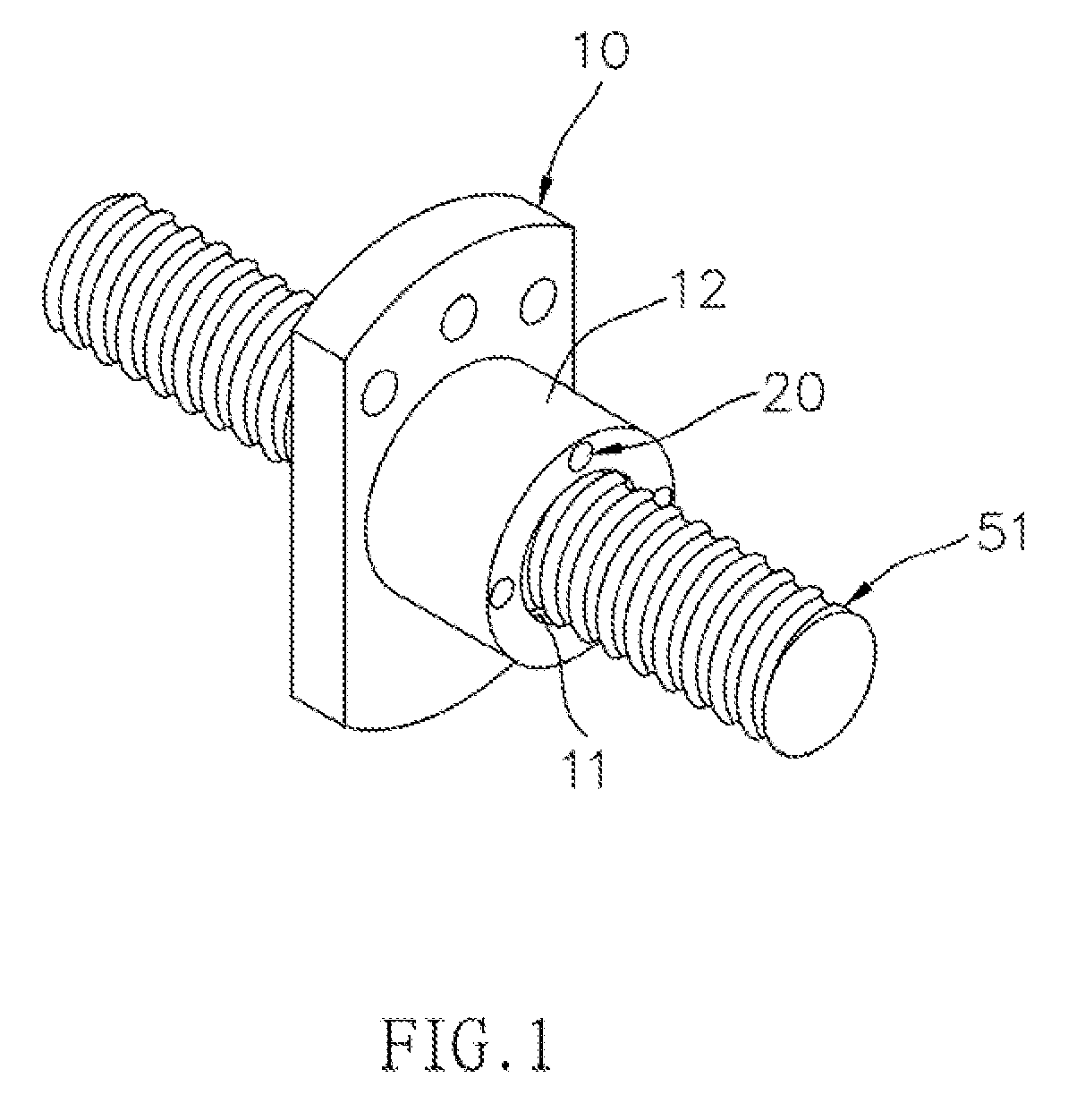

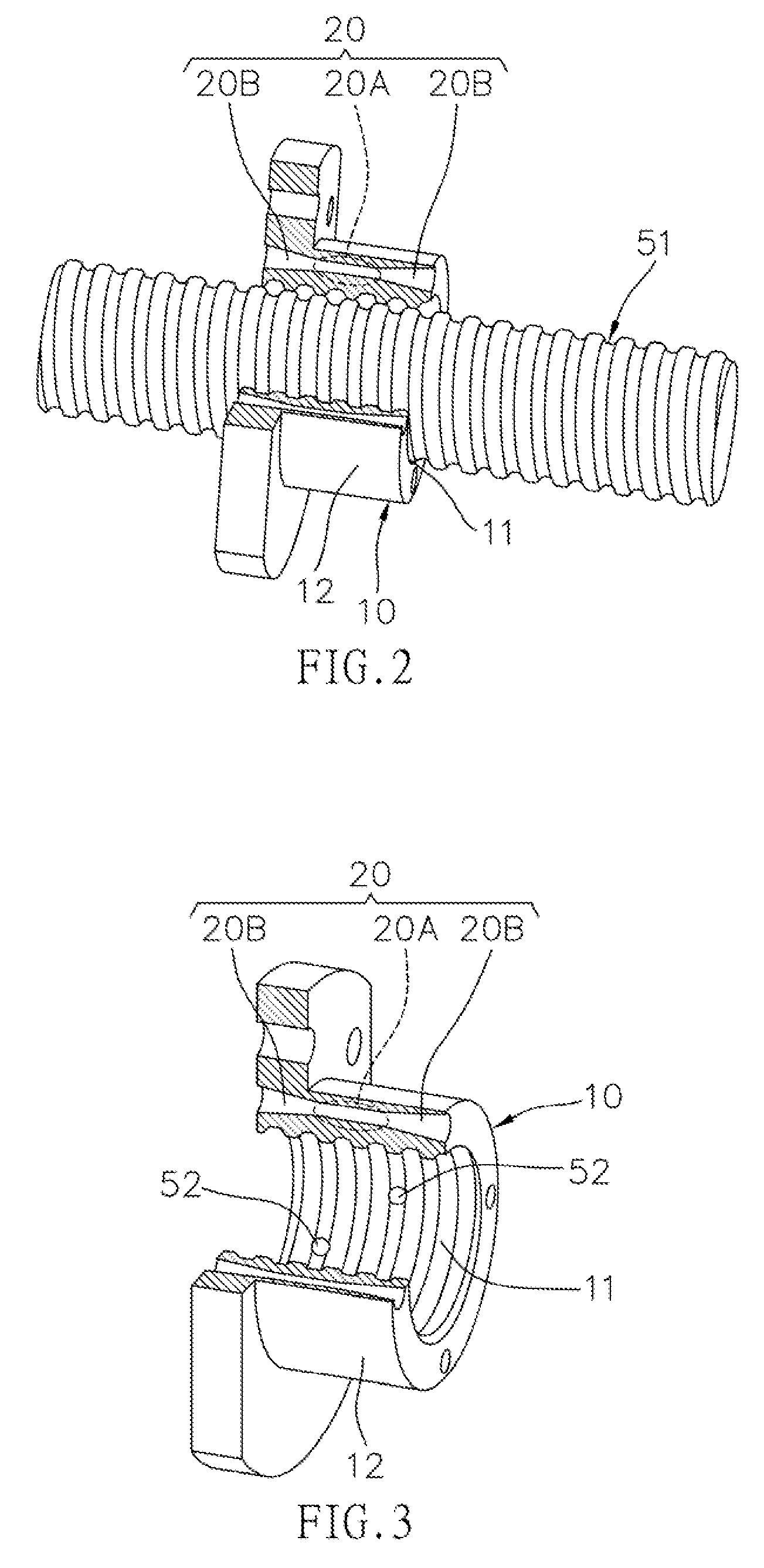

Nut for ball screw

InactiveUS20130145877A1Reduce incrementPrecise positioningToothed gearingsPortable liftingBall screwEngineering

A nut for a ball screw mainly includes a nut, multiple dual-narrowed paths, multiple micro fans, a control portion, and multiple temperature sensing portions. The nut has a threaded path and the dual-narrowed paths are defined through the central axis of the nut and substantially parallel to the threaded path. Each of the dual-narrowed paths has a high-speed area and the diameter of each of the dual-narrowed paths is gradually reduced from two ends toward the high-speed area. The nut has micro fans which drive the air flows and reduce the temperature to increase the life of use and the precision of positioning.

Owner:NAT FORMOSA UNIV

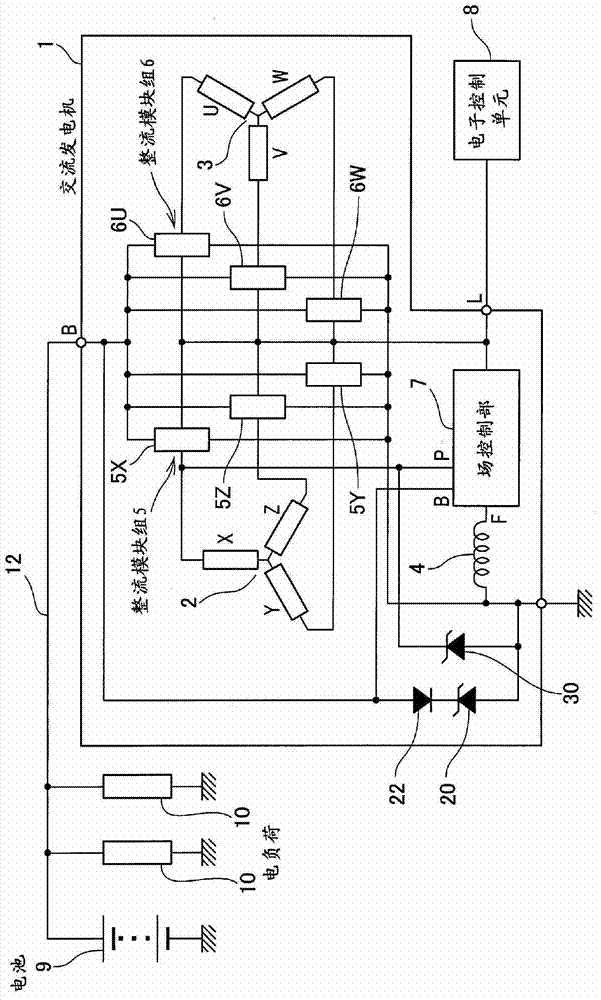

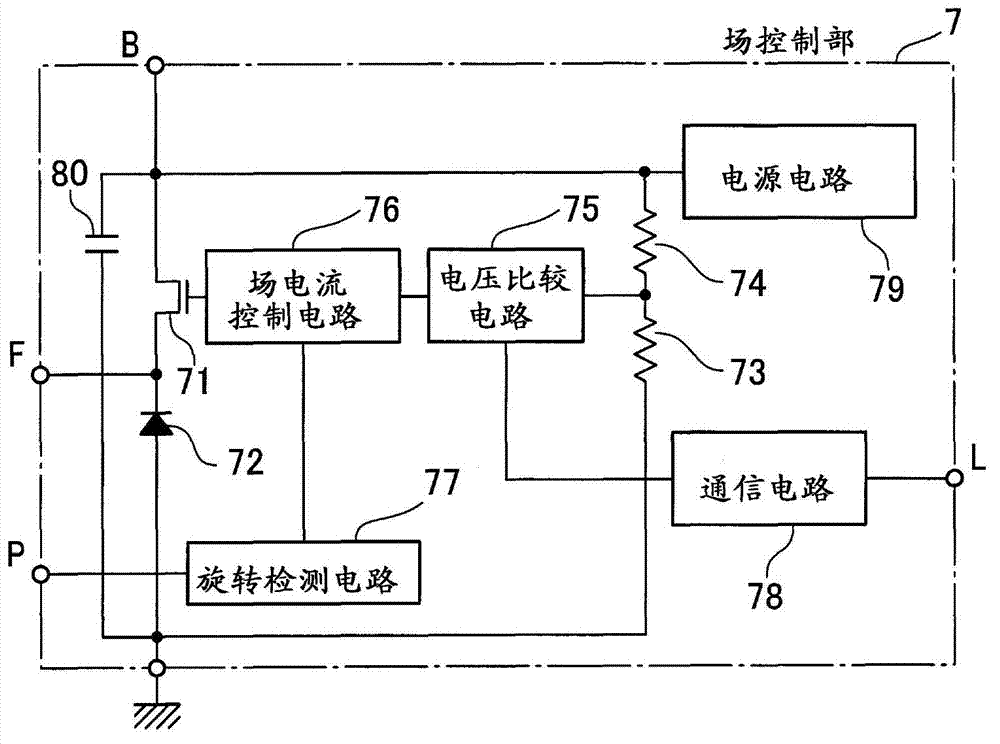

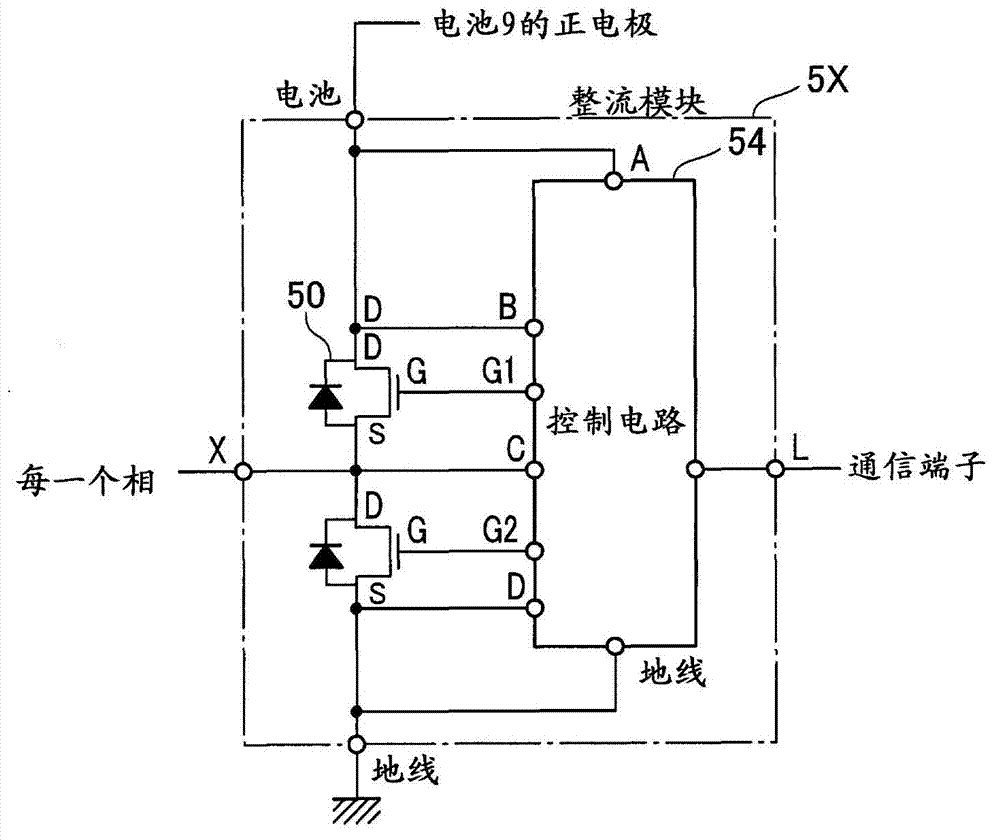

Electric rotary machine for motor vehicle

ActiveCN103580589AReduce incrementAvoid elevationBatteries circuit arrangementsElectric motor controlMobile vehicleAlternator

An alternator has rectifying module groups. The rectifying module groups form a bridge circuit. The rectifying module groups have a load dump protection judgment section for monitoring an output voltage of rectifying module groups. When the monitored output voltage exceeds a first threshold voltage, the load dump protection judgment section provides to a control section an instruction to turn on MOS transistors in a lower arm of the bridge circuit at a time when a predetermined delay time has elapsed. When a second threshold voltage is lower than the first threshold voltage and the monitored output voltage becomes less than the second threshold voltage after the monitored output voltage exceeds the first threshold voltage, the load dump protection judgment section provides to the control circuit an instruction to turn on the MOS transistors in the lower arm after the MOS transistors are turned off during a predetermined time length.

Owner:DENSO CORP

Smelting recovery method for lath-like residual titanium

InactiveCN106119576AShorten the smelting recycling manufacturing process flowIncrease profitProcess efficiency improvementRecovery methodTitanium

The invention relates to a smelting recovery method for lath-like residual titanium. The smelting recovery method includes the steps of residual titanium sizing, surface treatment, distribution and electrode binding, VAR smelting and finished titanium ingot treatment. The procedures of residual titanium crushing, mixing and electrode pressing are omitted, the manufacturing process flow is short, and operation is simple. The utilization rate of the residual titanium is high, specifically, 100% adding and recovery of the residual titanium can be achieved due to the fact that electrode pressing is not needed, the residual titanium adding proportion is increased to 100% from 30%, and the utilization rate of the residual titanium is greatly increased. The production cost is low, and specifically, the production cost is effectively lowered by shortening the manufacturing process flow and increasing the utilization rate of the residual titanium. The smelting recovery quality is good, specifically, due to the fact that the residual titanium crushing procedure is omitted, increment of impurity elements such as Fe, O and N in the crushing process can be effectively reduced, and the quality of titanium ingots obtained through smelting recovery is improved.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Nut for ball screw

InactiveUS8997593B2Reduce incrementIncrease precise positioning and life of useToothed gearingsGear lubrication/coolingBall screwEngineering

A nut for a ball screw mainly includes a nut, multiple dual-narrowed paths, multiple micro fans, a control portion, and multiple temperature sensing portions. The nut has a threaded path and the dual-narrowed paths are defined through the central axis of the nut and substantially parallel to the threaded path. Each of the dual-narrowed paths has a high-speed area and the diameter of each of the dual-narrowed paths is gradually reduced from two ends toward the high-speed area. The nut has micro fans which drive the air flows and reduce the temperature to increase the life of use and the precision of positioning.

Owner:NAT FORMOSA UNIV

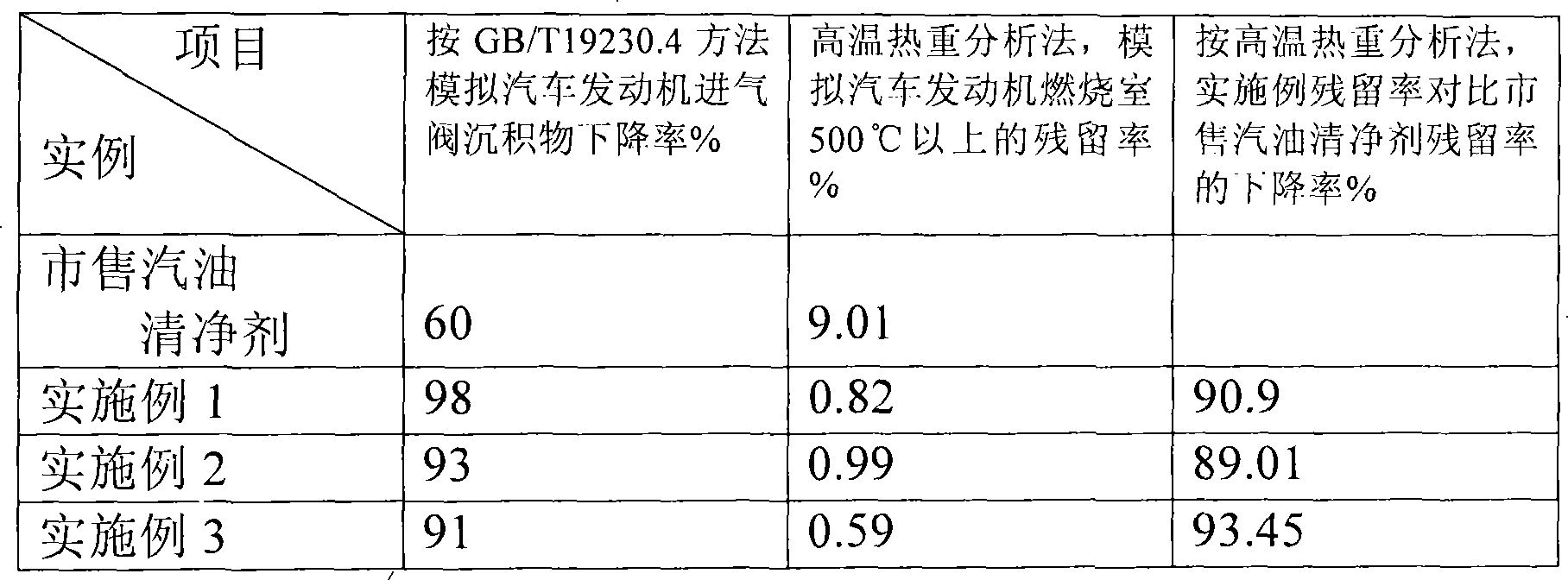

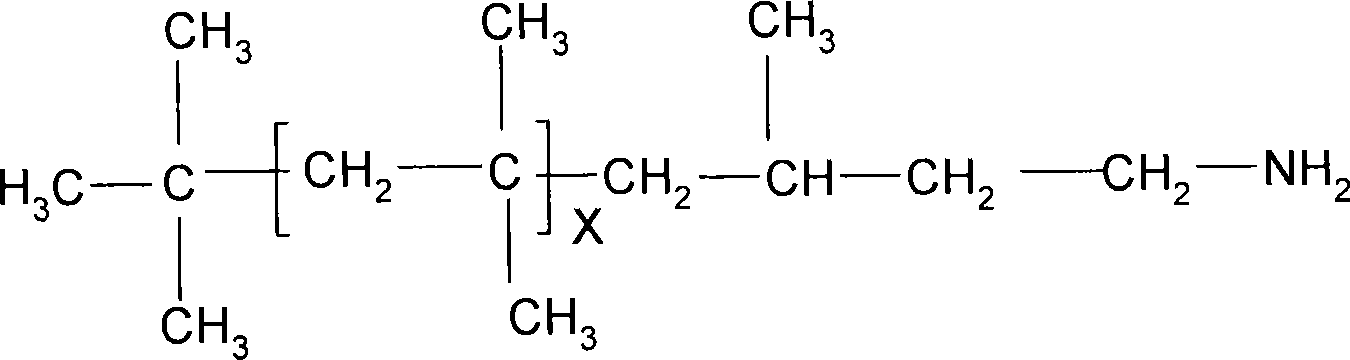

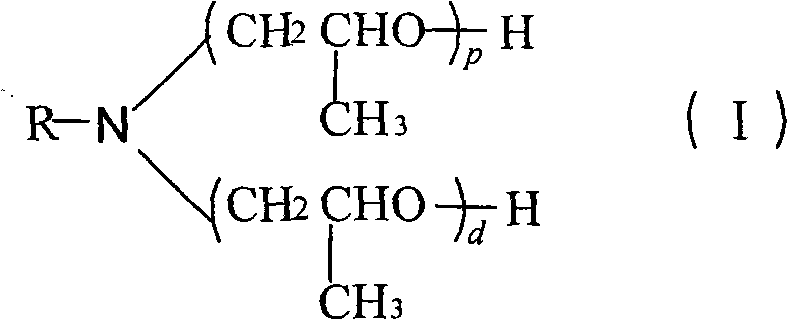

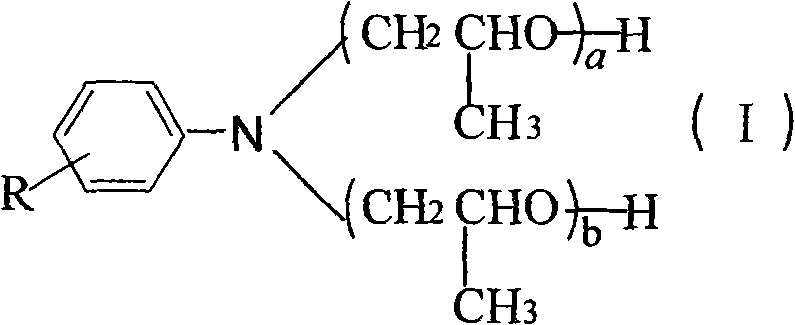

Gasoline detergent prepared from aromatic amine polyoxypropylene ether

InactiveCN101962586AReduce incrementIncreased drop rateLiquid carbonaceous fuelsFuel additivesHydrogenOrtho position

The invention relates to a gasoline detergent prepared from aromatic amine polyoxypropylene ether. The aromatic amine polyoxypropylene ether is represented by a structural formula (I), wherein R is hydrogen or an alkyl group of C1 to C10, and can be positioned at an ortho-position, a meta-position or a para-position on a benzene ring relative to nitrogen atoms; and the summation of a and b is a natural number in the range of 9 to 33. When used in gasoline, the gasoline detergent prepared from the aromatic amine polyoxypropylene ether serving as a main component can remarkably reduce the generation of sediments in fuel-intake system of a gasoline engine.

Owner:冯明星

Drive control apparatus for controlling drive of inductive load and drive control method for controlling the same

ActiveUS7795930B2Reduce incrementReduced sliding resistanceAc-dc conversionDc-dc conversionReference currentControl theory

A drive control apparatus controls a drive of an inductive load having a current flowing therethrough. The drive control apparatus includes a drive control device for controlling a variation of the current flowing through the inductive load within a certain period by Pulse Width Modulation control so as to come close to a reference current value, and a reference value control device for controlling a fluctuation period of the reference current value and making the fluctuation period of the reference current value longer than that of the current flowing through the inductive load by the Pulse Width Modulation control.

Owner:FUJI ELECTRIC CO LTD

Multi-purpose submerged arc sintered flux for alloy steel and preparation method thereof

InactiveCN109128579AReasonable formulaInhibit transitionArc welding apparatusWelding/cutting media/materialsSlagSodium silicate

The invention belongs to the technical field of welding materials, and particularly relates to multi-purpose submerged arc sintered flux for alloy steel and a preparation method thereof. The multi-purpose submerged arc sintered flux is prepared from various compositions of dry powder and binder sodium silicate, and the dry powder is prepared from the following raw materials in percentage: 15-18% of SiO2, 5-8% of MnO, 22-30% of CaF2, 20-25% of Al2O3, 25-30% of MgO, and 1-3% of alloy powder. According to the prepared sintered flux, the viscosity, surface tension and fluidity of slag are well adjusted, when the flux is used for welding, the welding process is stable, the amount of smoke and dust is small, splash is small and the deslagging performance is excellent.

Owner:郑州凤凰新材料科技有限公司

Environment-friendly sludge dehydration conditioner and application method thereof

The invention relates to an environment-friendly sludge dehydration conditioner and application thereof. The sludge dehydration conditioner is composed of a conditioner A and a conditioner B. The conditioner A is prepared from the materials: 30-40 parts of pulverized fuel ash, 10-20 parts of an abandoned wood scrap, 5-10 parts of kieselguhr, 5-10 parts of magnesium oxide and 10-20 parts of bauxite, the conditioner A is obtained by mixing uniformly and stirring for 10-15 minutes, and the additive amount of the conditioner A is 0.05-0.1g / gDS; and the conditioner B is any one of a positive ion PAM solution, a positive ion PAM emulsion, a polysaccharide organic polymer solution and the like, and the effective content additive amount is 1-3mg / gDS. Sludge processed by the conditioner is subjected to mechanical dehydration, finally the sludge moisture content is reduced below 60%, the problem of increment of the sludge after dehydration can be effectively solved, meanwhile, lime is not used,and the subsequent recycling using efficiency of the sludge is greatly improved.

Owner:北京中持净水材料技术有限公司

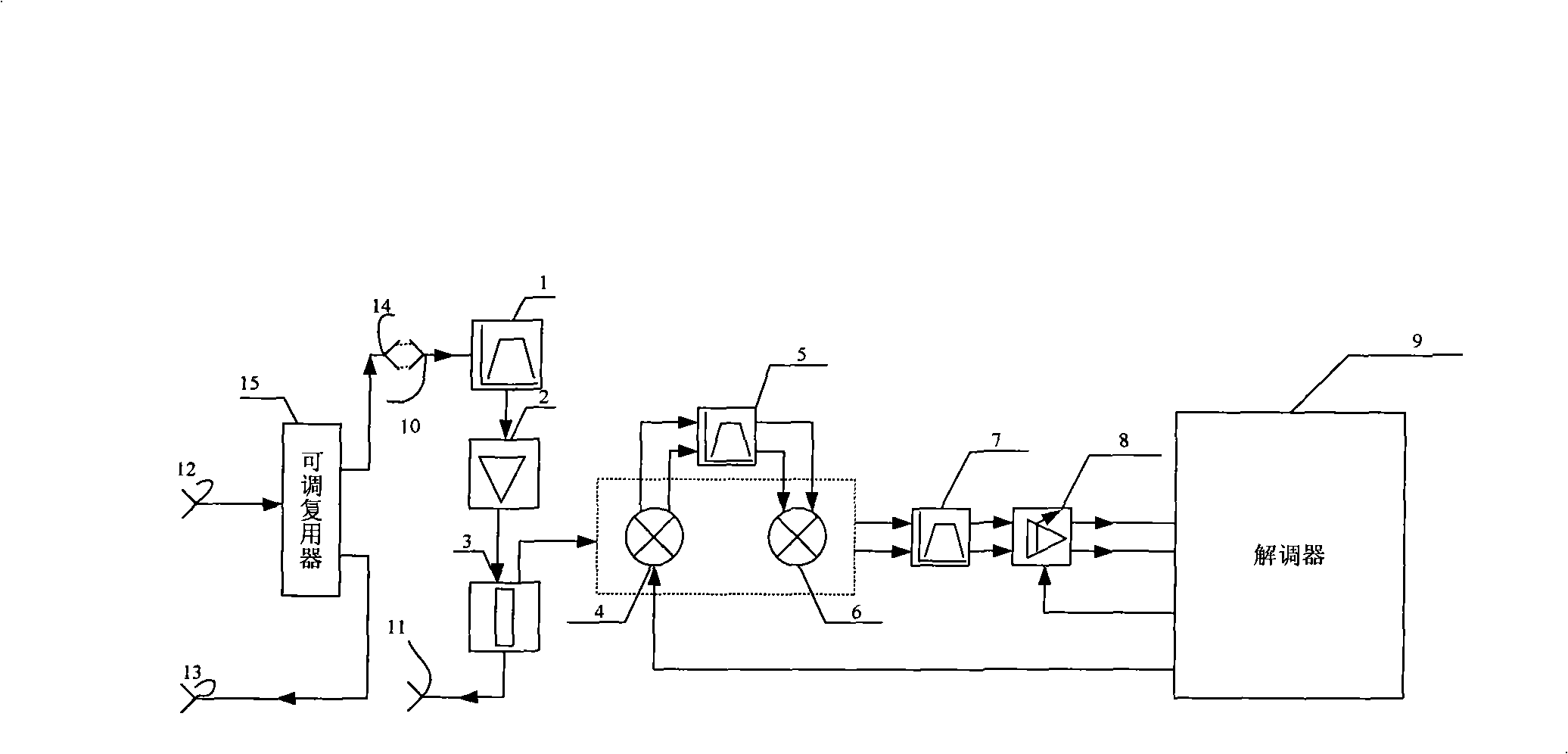

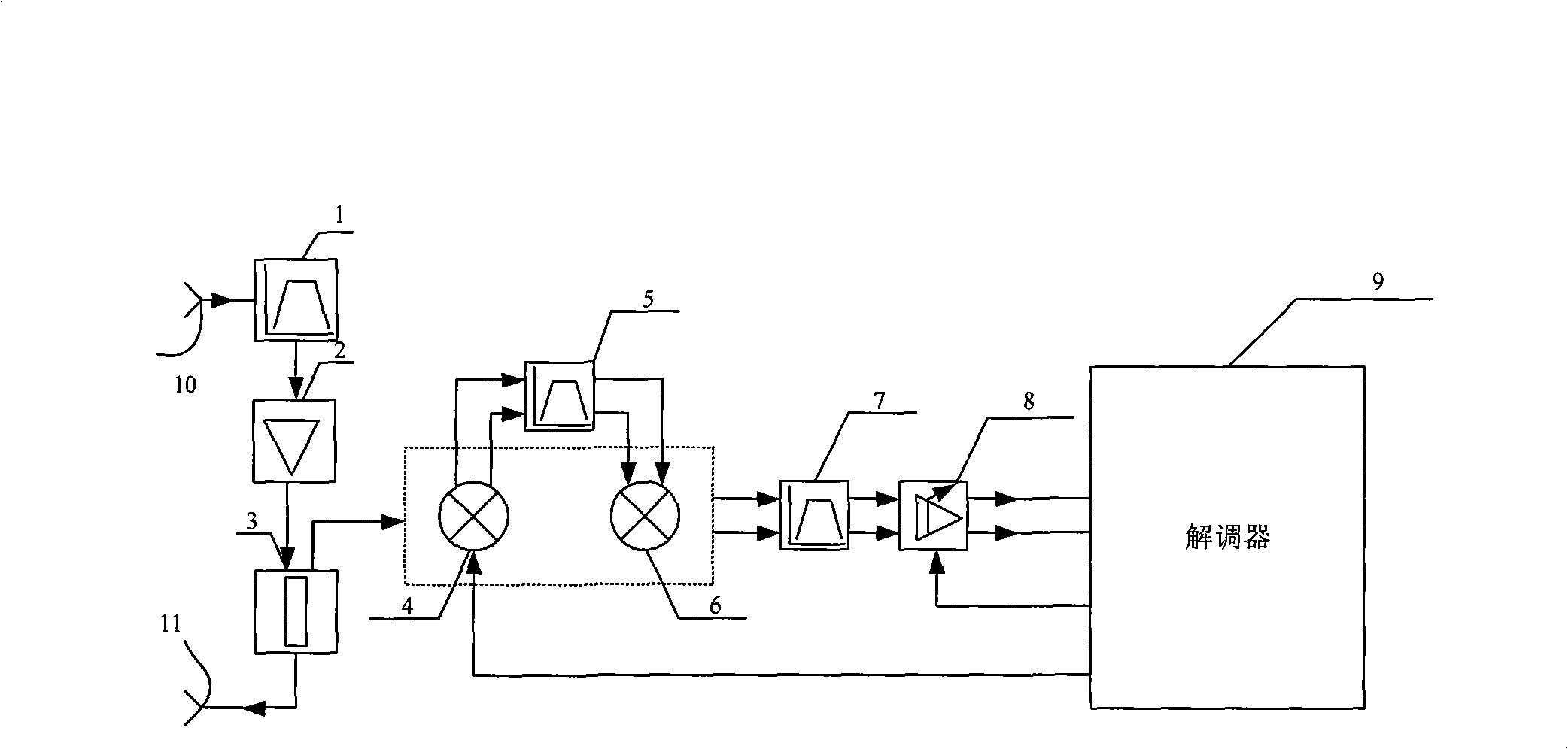

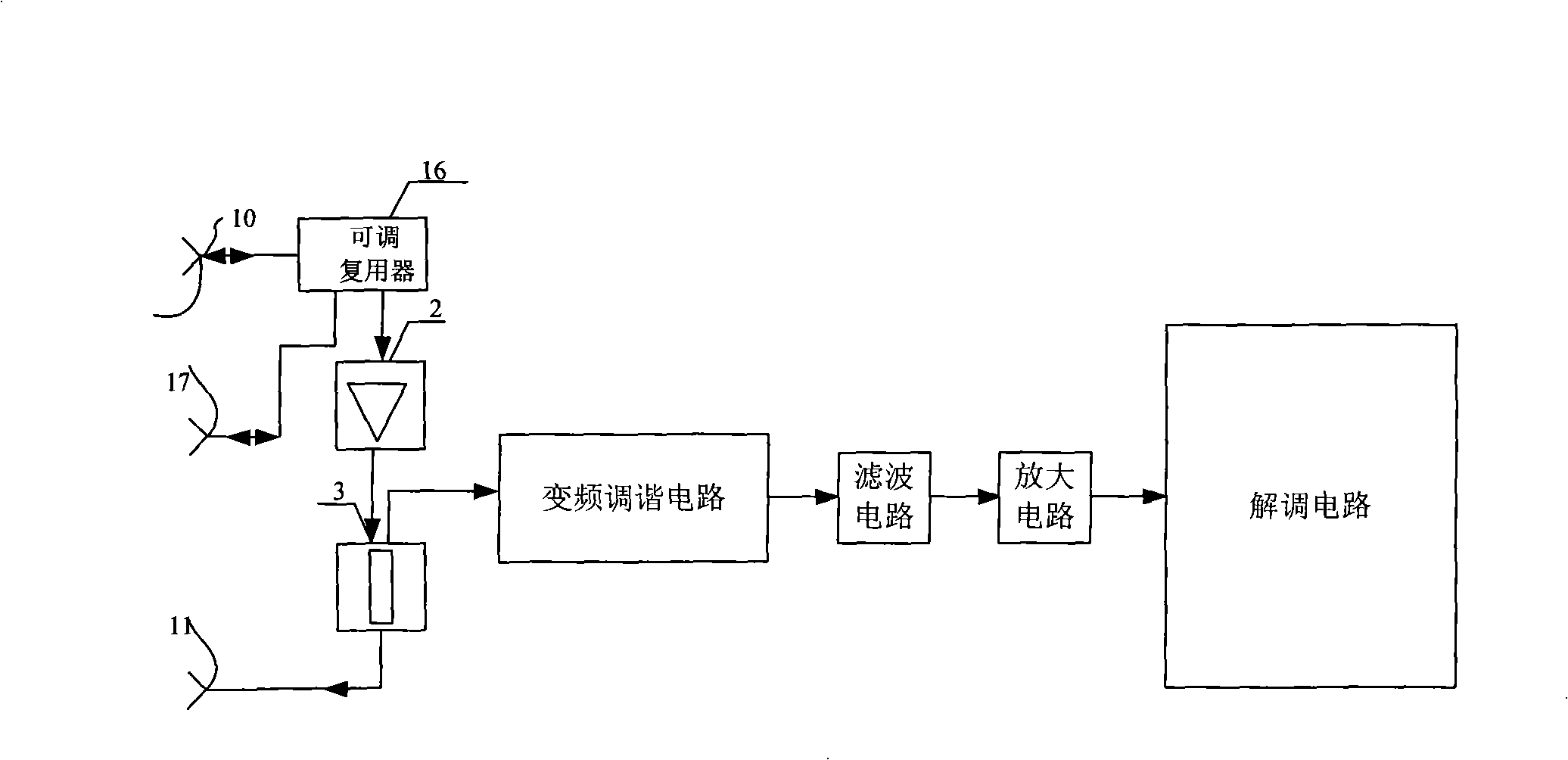

Novel integrated bidirectional tuner

InactiveCN101287077AReduce incrementImprove fade resistanceTelevision system detailsColor television detailsMultiplexerBand-pass filter

The invention provides a novel integrated bidirectional tuner which comprises a tuner input port, a variable frequency tuning circuit, a filter circuit, an amplification circuit and a demodulation circuit which are connected in the way that the output end of the variable frequency tuning circuit is connected with the input end of the filter circuit, the output end of which is connected with the input end of the amplification circuit; and the output end of the amplification circuit is connected with the input end of the demodulation circuit. The novel integrated bidirectional tuner is characterized in that an adjustable multiplexer also is connected between the variable frequency tuning circuit and the tuner input port. The adjustable multiplexer is embedded into a tuner which can not only separate data signals and cable television signals, but also function as a band-pass filter; therefore, compared with the original method that the adjustable multiplexer is arranged outside the tuner, elements, such as cable components or an adapter and a band-pass filter, etc., are reduced, thus not only saving cost, but also reducing extra insertion loss caused by the adding of the cable components or introduced by the adapter.

Owner:雷科通技术(杭州)有限公司

Vehicle braking control device for braking force distribution

InactiveUS8600637B2Improve braking effectReduce forceAnalogue computers for trafficWheel adhesionVehicle brakeVehicle braking

Owner:ADVICS CO LTD

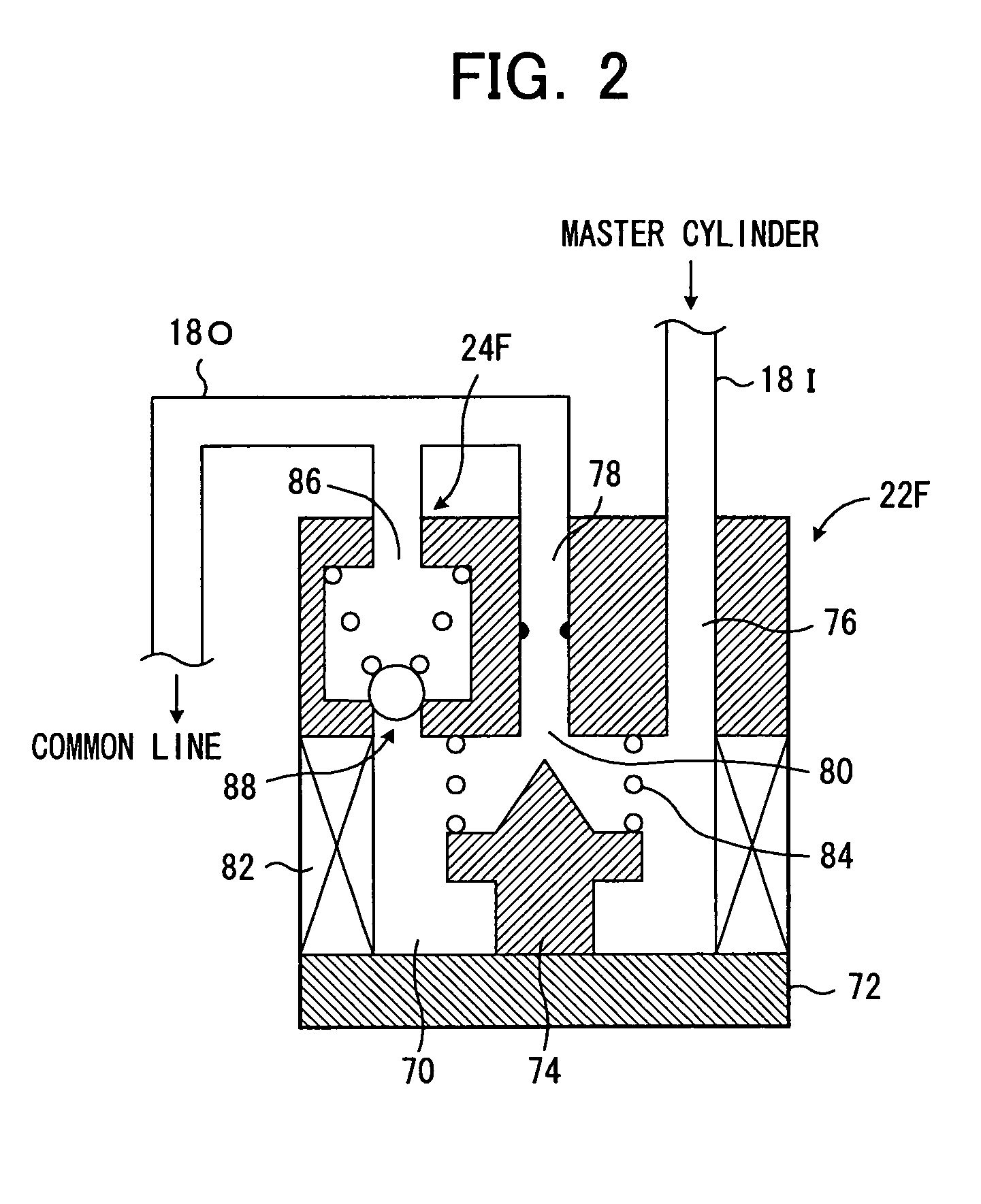

Ultralow-hydrogen type high-alkalinity high-toughness sintered flux

PendingCN112059473AGood technical effectFormulated scientifically and convenientlyWelding/cutting media/materialsSoldering mediaFerro-manganese alloyIron alloys

The invention relates to an ultralow-hydrogen high-alkalinity high-toughness sintered flux. The sintered flux is specifically prepared from dry powder of multiple components and binder water glass, and the dry powder comprises the following components in parts by weight: 12-23 parts of MgO, 15-25 parts of CaF2, 16-26 parts of Al2O3, 10-20 parts of CaCO3, 1-8 parts of SiO2, 1-5 parts of BaCO3, 1-5parts of Li2CO3, 2-5 parts of K2O+Na2O, and 1-5 parts of silicon-manganese-iron alloy. The ultralow-hydrogen type high-alkalinity high-toughness sintered flux is prepared through the method includingthe following steps that the dry powder materials are evenly mixed according to the proportions, the water glass is added, wet mixing is conducted, then granulation is conducted, drying is conducted at the temperature of 280-380 DEG C to remove the moisture, screening is conducted, high-temperature sintering is conducted at the temperature of 750-850 DEG C, cooling and screening are conducted, andthe ultralow-hydrogen type high-alkalinity high-toughness sintered flux is obtained. The ultralow-hydrogen type high-alkalinity high-toughness sintered flux has the excellent technical effects as shown in the specification.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Treatment method for acidic waste etching solution

InactiveCN111020633AAdvantages of the treatment methodReduce incrementPhotography auxillary processesProcess efficiency improvementDistilled waterProcess engineering

The invention discloses a treatment method for an acidic waste etching solution. The treatment method comprises the following steps of electrolyzing the acidic waste etching solution, so that copper ions in the acidic waste etching solution are deposited to obtain electrolyzed clear solutions; performing vacuum concentration for the electrolyzed clear solutions to obtain distilled water containinghydrochloric acid, and concentrated solutions; and cooling and crystallizing the concentrated solutions, and separating solids and liquid to obtain chloride solids and acidic solutions. Compared withthe prior art, the treatment method for the acidic waste etching solution has the advantages that copper can be recycled and the electrolyzed clear solutions are obtained after the acidic waste etching solution is electrolyzed; the hydrochloric acid can be recycled; concentrated solutions are cooled and crystallized to obtain the chloride solids and the acidic solutions, and the chloride solids can be used for preparing the acidic solutions; the acidic solutions can be used for replacing industrial hydrochloric acid, and reused in H2O / HCl series and NaClO3 / HCl series acidic etching solutions;the technological process is shorter, and the increasing amount of the waste etching solution can be reduced greatly; and the treatment method benefits environmental protection.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

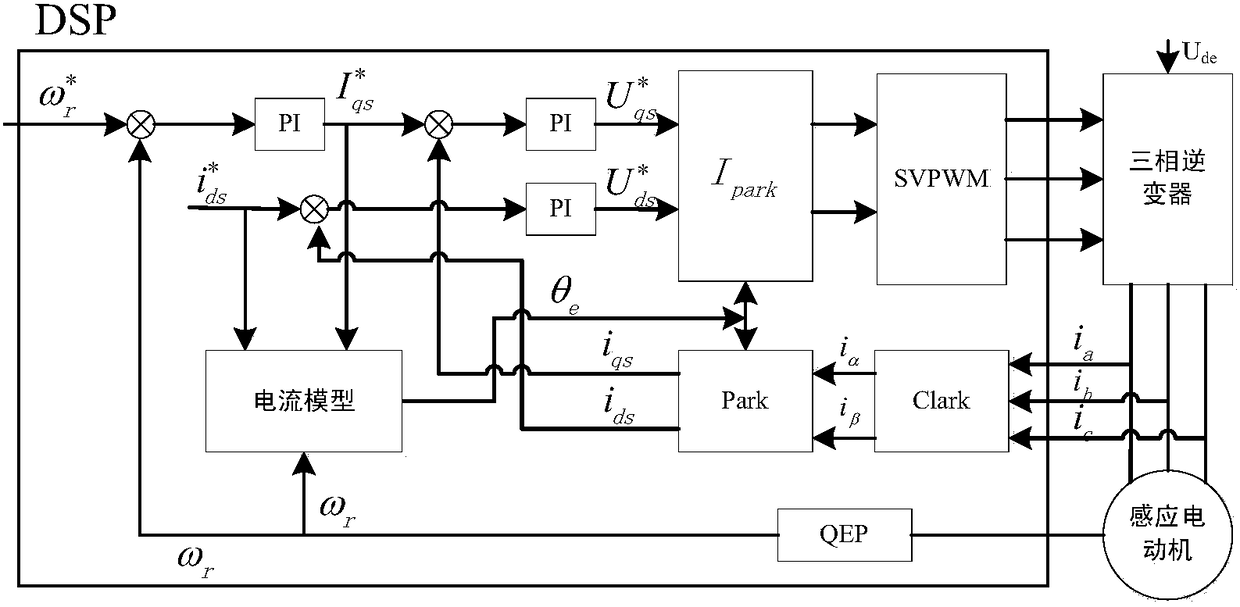

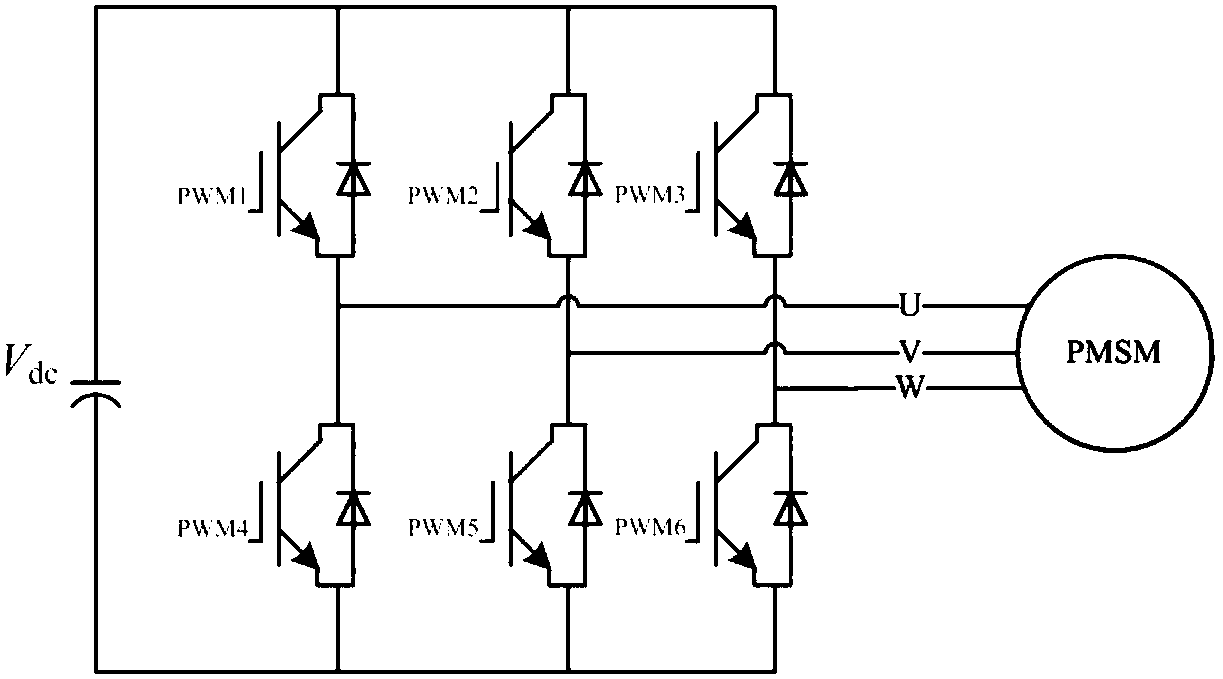

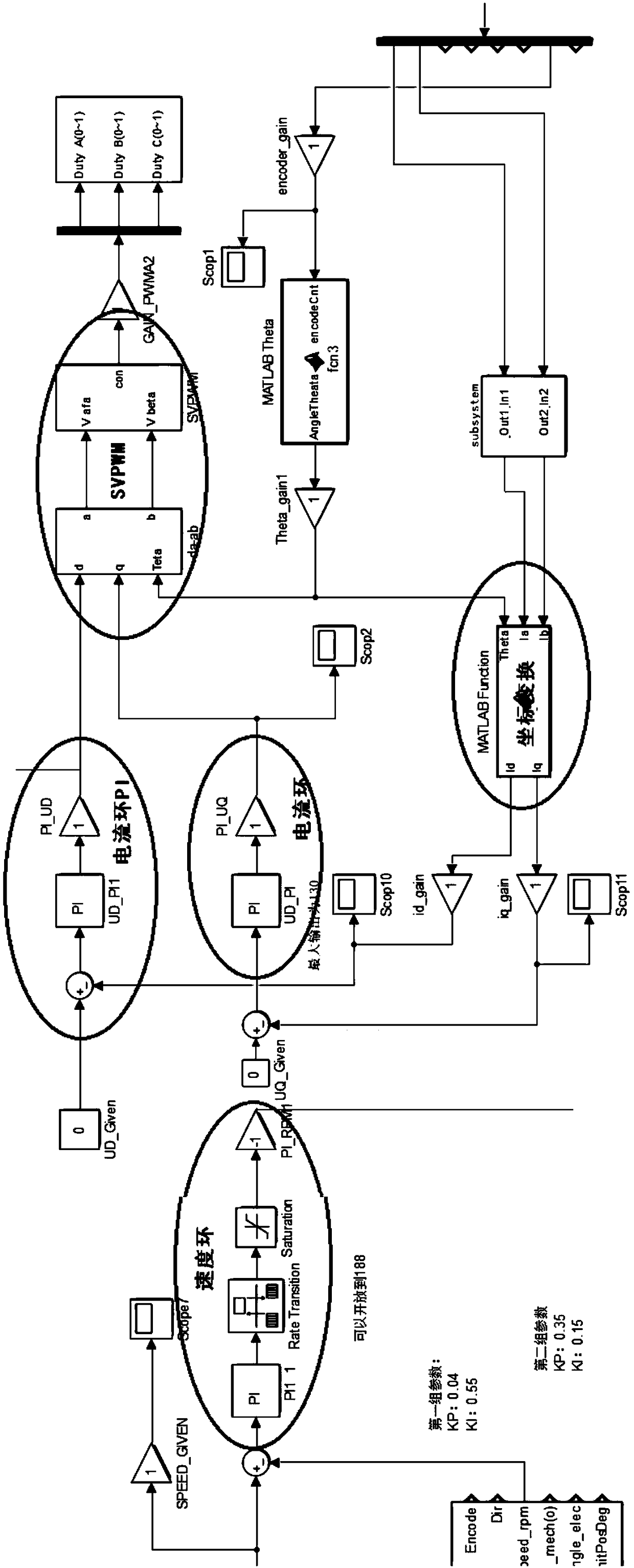

Servo control MBD exploitation platform

InactiveCN108469778AServo control is fastQuick controlProgramme control in sequence/logic controllersBridge typeElectric machine

The invention relates to the software exploitation technology field and provides a servo control MBD exploitation platform. The servo control MBD exploitation platform adopts a host-target machine structure and comprises a real-time simulator, a servo motor and a research and development type driver. The real-time simulator outputs a PWM signal with a dead zone setting function through a motor control card. And then, a three-phase bridge-type inverter circuit on the research and development type driver is used to drive the servo motor to rotate. Simultaneously, incremental code disc signals are collected and a closed-loop control circuit is formed. Through applying a reverse moment load to a dragged load simulation motor, the on-load work characteristic of an alternating current servo motor is verified.

Owner:北京灵思创奇科技有限公司

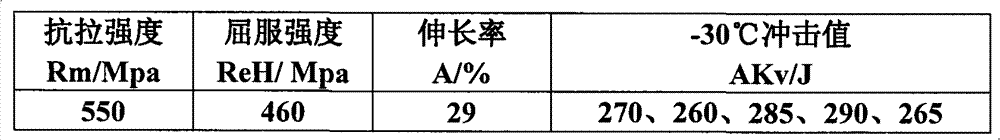

Low-alkalinity and high-toughness sintered flux

ActiveCN102363252BStable arc burningAdjustable viscosityWelding/cutting media/materialsSoldering mediaAlkalinityMetal

The invention provides a low-alkalinity and high-toughness sintered flux, which comprises the components in part by weight: 35-55 parts of CaF2, 35-50 parts of Al2O3, 1-5 parts of MgO, 1-5 parts of CaO, 2-6 parts of SiO2, 1-5 parts of Si-Fe, 1-5 parts of Mn-Fe and 2-5 parts of K2O+Na2O. After the sintered flux is adopted, on the premise of guaranteeing higher low-temperature impact toughness of weld metal, the alkalinity of the flux is reduced, and the welding technological performance of the flux is improved.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com