Smelting recovery method for lath-like residual titanium

A recovery method and technology of titanium residues, which are applied in the field of titanium material processing, can solve the problems of difficult control of impurity elements, low utilization rate of titanium residues, high recycling costs, etc., shorten the manufacturing process flow, improve the utilization rate of titanium residues, Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the recovery of TA1 grade lath-shaped titanium residue

[0030] 1) Use a hydraulic shearing machine to cut the TA1 lath-shaped titanium residue to length. After cutting, the width specification is 20~250mm and the length specification is 200~1500mm.

[0031] 2) Use the alkaline pickling process to remove impurities such as oxide skin and oil stains on the surface of the TA1 strip-shaped titanium residue, and dry it to obtain a clean and dry titanium residue.

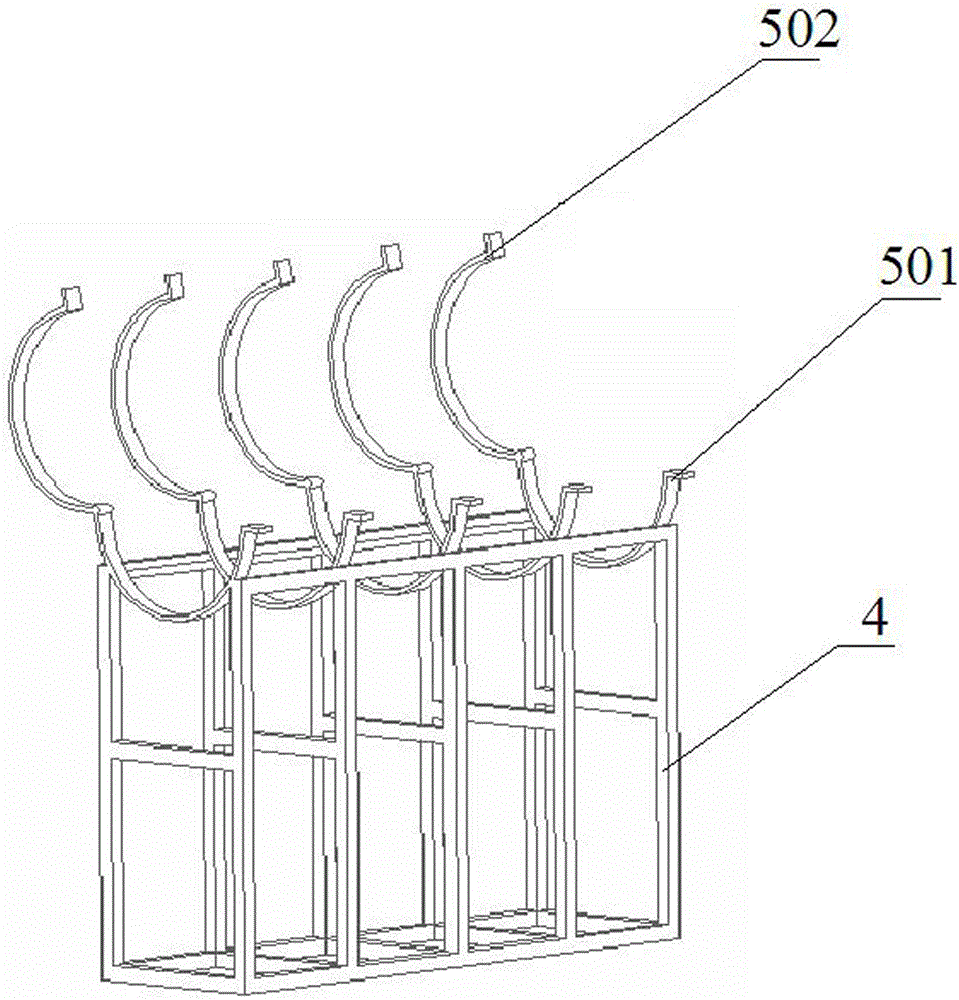

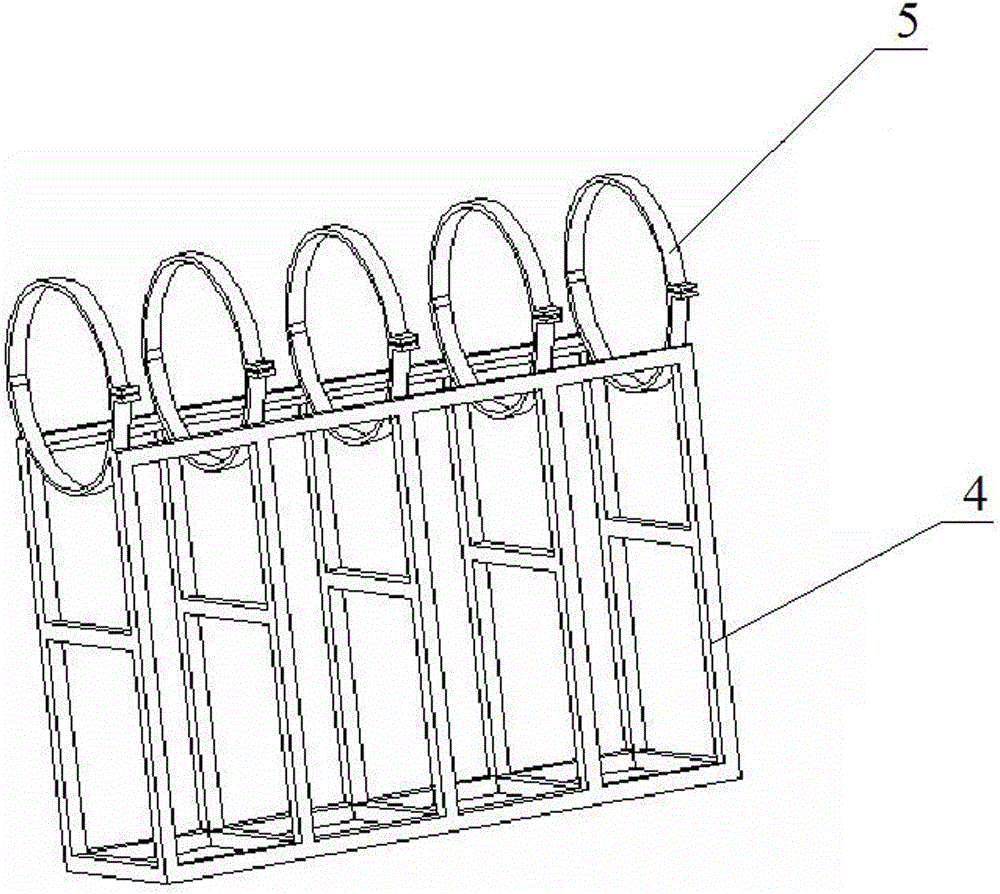

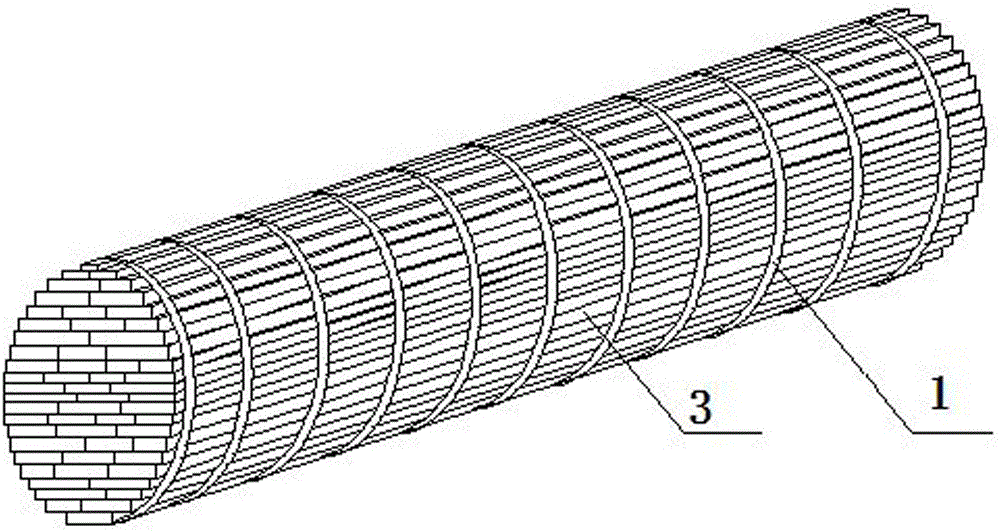

[0032] 3) Use the concentric circular fixture to assist the tooling to distribute, spot weld and bind the electrodes on the TA1 strip-shaped titanium residue. The inner diameter of the circular fixture is 380mm. The shorter slats shall be supplemented to 1500mm, and the fabric shall be uniform and dense. After the cloth is finished, use a 0.8mm thick and 15mm wide pure titanium narrow strip to fasten and bind the cylindrical electrode in the circumferential direction. The lap length of the head and ...

Embodiment 2

[0038] Embodiment 2: the recovery of TC4 brand lath titanium residue

[0039] 1) Use a hydraulic shearing machine to cut the TC4 lath-shaped titanium residue to length. After cutting, the width specification is 50~200mm and the length specification is 500~1500mm.

[0040] 2) Use the shot blasting pickling process to remove impurities such as oxide skin and oil stains on the surface of the TC4 strip-shaped titanium residue, and dry it to obtain a clean and dry titanium residue.

[0041] 3) Use concentric ring-shaped clamps to assist tooling to distribute, spot-weld and bind electrodes for TC4 strip-shaped titanium residues. The inner diameter of the ring-shaped clamps is 380mm. During the fabric distribution process, use the method of argon arc welding spot welding to reduce the size of the shorter slats to 1500mm, and the fabric should be even and dense. After the cloth is finished, use a 1.0mm thick and 20mm wide pure titanium narrow strip to fasten and bind the cylindrical el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com