Ultralow-hydrogen type high-alkalinity high-toughness sintered flux

A sintered flux, high basicity technology, used in ultra-low hydrogen type high basicity and high toughness sintered flux, welding of thick-walled pressure vessels, automatic submerged arc welding of low-alloy steel, can solve serious silicon infiltration, low temperature impact The problems of poor toughness and high content of impurity elements can achieve the effect of excellent technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

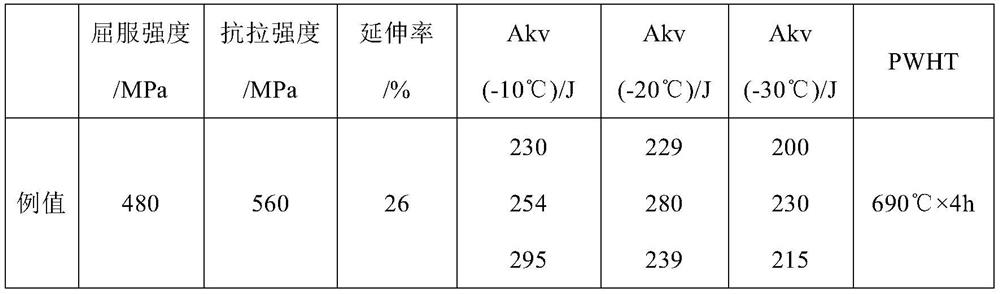

Embodiment 1

[0053] a, flux component (dry powder material): the MgO of 18 weight parts, the CaF of 21 weight parts2, the Al2O3 of 25 weight parts, the CaCO3 of 18 weight parts, the SiO2 of 5 weight parts, the BaCO of 4 weight parts3, the BaCO of 2 weight parts Li2CO3, 3 parts by weight of K2O+Na2O (1:1), 3 parts by weight of ferrosilicon manganese alloy.

[0054] b. Flux alkalinity: 2.44.

[0055] c. Preparation method: sieve the raw materials, weigh according to the formula, put each dry powder material into a dry mixer for dry mixing, put it into a wet mixer after dry mixing evenly, add water glass (binder water The weight ratio of glass to dry powder is 20:100) for wet mixing. After the wet mixing is even, put the wet powder on the granulation tray for granulation. After the granulation is completed, send it to the drying furnace and dry it at 280°C to 380°C. to remove moisture, and then sieve the flux, and send the sieved flux within the standard particle size range (16-80 mesh) into...

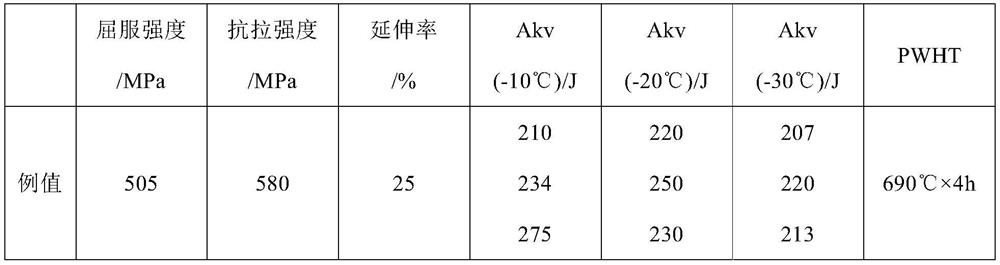

Embodiment 2

[0061] a, flux component (dry powder material): the MgO of 20 parts by weight, the CaF of 18 parts by weight2, the Al2O3 of 23 parts by weight, the CaCO3 of 20 parts by weight, the SiO2 of 4 parts by weight, the BaCO3 of 5 parts by weight3, the BaCO3 of 3 parts by weight Li2CO3, 4 parts by weight of K2O+Na2O (1:1), 2 parts by weight of ferrosilicon manganese alloy.

[0062] b. Flux alkalinity: 2.61.

[0063] c. Preparation method: sieve the raw materials, weigh according to the formula, put each dry powder material into a dry mixer for dry mixing, put it into a wet mixer after dry mixing evenly, add water glass (binder water The weight ratio of glass to dry powder is 20:100) for wet mixing. After the wet mixing is even, put the wet powder on the granulation tray for granulation. After the granulation is completed, send it to the drying furnace and dry it at 280°C to 380°C. to remove moisture, and then sieve the flux, and send the sieved flux within the standard particle size ...

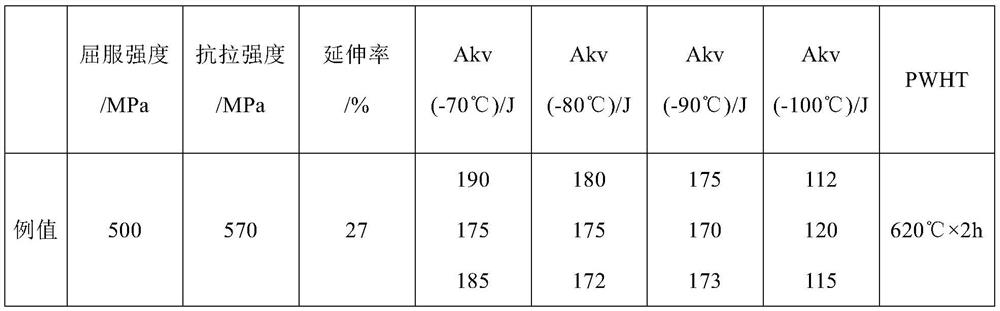

Embodiment 3

[0069] a, flux component (dry powder material): the MgO of 23 parts by weight, the CaF of 15 parts by weight2, the Al2O3 of 20 parts by weight, the CaCO3 of 17 parts by weight, the SiO2 of 7 parts by weight, the BaCO3 of 3 parts by weight3, the BaCO of 2 parts by weight Li2CO3, 3 parts by weight of K2O+Na2O (1:1), 4 parts by weight of ferrosilicon manganese alloy.

[0070] b. Flux alkalinity: 2.36.

[0071] c. Preparation method: sieve the raw materials, weigh according to the formula, put each dry powder material into a dry mixer for dry mixing, put it into a wet mixer after dry mixing evenly, add water glass (binder water The weight ratio of glass to dry powder is 20:100) for wet mixing. After the wet mixing is even, put the wet powder on the granulation tray for granulation. After the granulation is completed, send it to the drying furnace and dry it at 280°C to 380°C. to remove moisture, and then sieve the flux, and send the sieved flux within the standard particle size r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com