Patents

Literature

77 results about "Ferro-manganese alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder metallurgy friction pair for braking of heavy-load vehicle and preparation technology thereof

ActiveCN103785824AGuaranteed uniformityGuaranteed friction and wear performanceAdditive ingredientHeat conducting

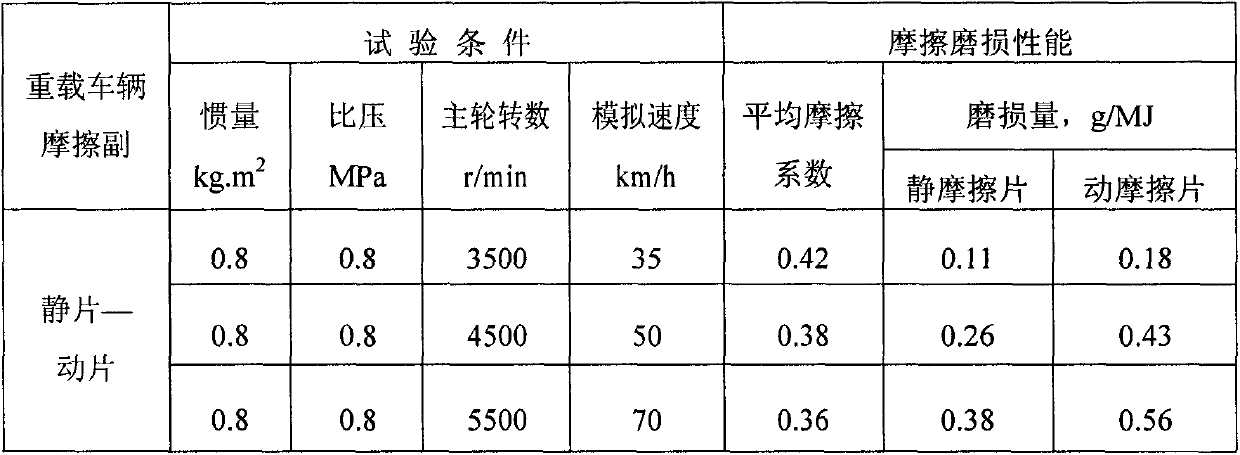

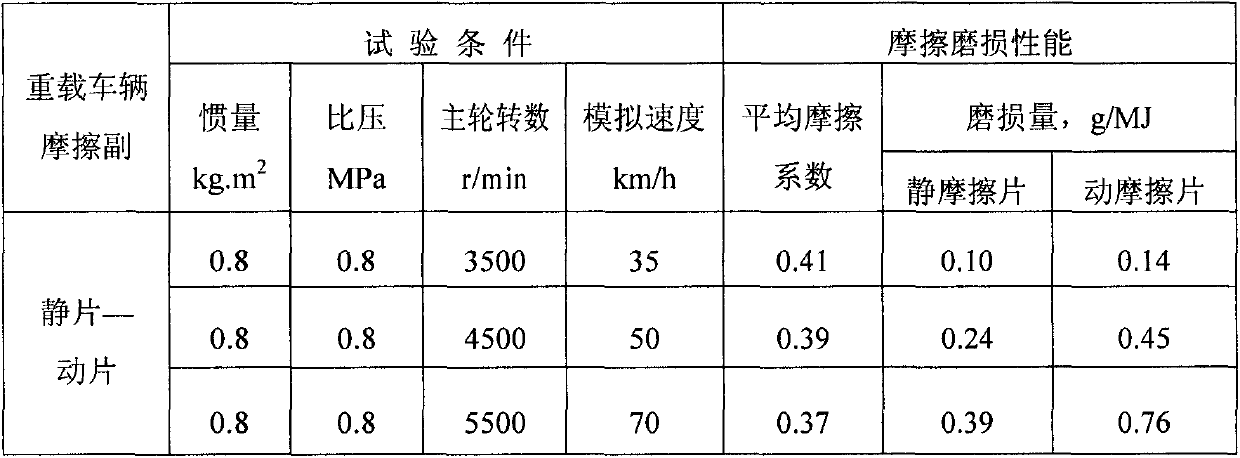

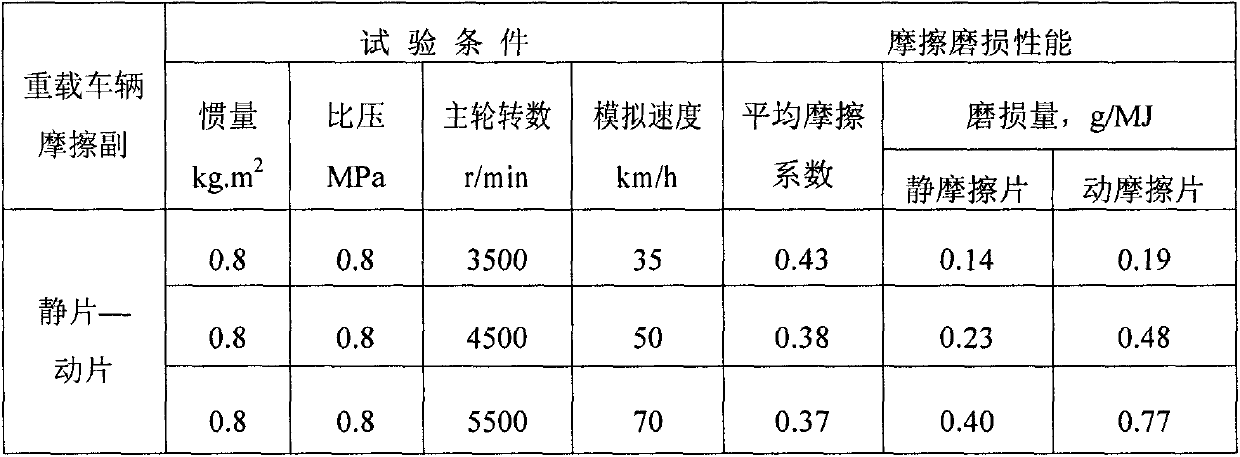

The invention relates to a powder metallurgy friction pair for braking of a heavy-load vehicle and a preparation technology thereof. A static friction piece comprises, by weight, 60-70 parts of reduced iron powder, 12-18 parts of electrolytic copper powder, 2-4 parts of molybdenum disulfide powder, 1-3 parts of ferro-manganese alloy powder, 1-3 parts of electrolytic nickel powder, 3-5 parts of silicon dioxide powder and 6-10 parts of crystalline flake graphite powder. A kinetic friction piece comprises, by weight, 14-18 parts of the reduced iron powder, 40-60 parts of the electrolytic copper powder, 2-4 parts of the molybdenum disulfide powder, 4-6 parts of tin powder, 1-3 parts of ferro-chrome alloy powder, 2-4 parts of the ferro-manganese alloy powder, 1-3 parts of the electrolytic nickel powder, 1-3 parts of chromium powder, 1-3 parts of aluminum oxide powder, 4-7 parts of the silicon dioxide powder and 10-14 parts of the crystalline flake graphite powder. The preparation technology of the powder metallurgy friction pair for braking of the heavy-load vehicle includes the steps of production, sand blasting, reshaping and electroplating of a steel backing and the steps of compounding, mixing, chemical analysis on ingredient uniformity, prepressing shaping, pressure sintering, mechanical processing, product finishing and checking of the power materials. Known from an MM1000 test that the prepared powder metallurgy friction pair for the heavy-load vehicle has the advantages of excellent frictional wear resistance, stable braking performance, low energy consumption and wear rate, good material uniformity and heat-conducting performance and long service life, and the problems of a large breaking wear rate, short service life and the like resulted from severe decline of a high-temperature friction coefficient of an existing friction pair for the heavy-load vehicle are solved.

Owner:北京优材百慕航空器材有限公司

Method for preparing electronic-grade manganese sulfate by utilizing ferro-manganese alloy furnace slag

InactiveCN103274471ASimplify the impurity removal processReduce manufacturing costManganese sulfatesAluminum IonSodium sulphide

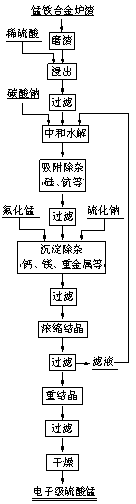

A method for preparing electronic-grade manganese sulfate by utilizing ferro-manganese alloy furnace slag comprises steps as follows: the ferro-manganese alloy furnace slag is ground to particles with particle sizes smaller than 250 mu m, sulfuric acid with the concentration of 30%-60% is added, and a solution is controlled to react for 1-3 hours at the temperature of 60 DEG C-90 DEG C and then filtered; the temperature of filtrate is controlled to be 60 DEG C-90 DEG C, sodium carbonate is added, and the pH value of the solution is adjusted to 4-6.5, so that iron ions and aluminum ions in the solution are hydrolyzed and generate corresponding hydroxide colloids; the solution is cooled to 30 DEG C-50 DEG C and stirred for 0.5-3 hours, so that the hydroxide colloids fully absorb silicon and scandium impurities in the solution, and still standing and filtration are performed; manganese fluoride is added to the filtrate to remove calcium and magnesium impurity ions, sodium sulphide is added to remove heavy metal impurity ions, and still standing and filtration are performed; the filtrate is concentrated, crystallized, washed, recrystallized, filtered and dried, so that an electronic-grade manganese sulfate product is obtained. According to the method, the ferro-manganese alloy furnace slag is taken as a raw material and used for preparing the electronic-grade manganese sulfate, so that the ferro-manganese alloy furnace slag can be recycled, pollution to the environment is reduced, and economic benefits can be obtained.

Owner:CENT SOUTH UNIV

Method for deoxidization and alloying by using ferro-silico-manganese alloy

The invention relates to a method for deoxidization and alloying by using a ferro-silico-manganese alloy. The method comprises the following steps of: firstly detecting the content of dissolved oxygen in a converter, taking 600-1300ppm as the end point of the converter when the content of dissolved oxygen in the converter is blown to 600-1300ppm, secondly adding the ferro-silico-manganese alloy to a steel ladle, stopping adding the ferro-silico-manganese alloy when the content of dissolved oxygen in the steel ladle reaches 100-300ppm, and thirdly inputting aluminium wires to the steel ladle by utilizing a wire feeding machine and stopping inputting the aluminium wires when the content of dissolved oxygen in the steel ladle reaches 15-35ppm, thus obtaining the smelted steel. The method has the following beneficial effects: silicon contained in the ferro-silico-manganese alloy in the molten steel is removed by utilizing the high content of the dissolved oxygen; and as the ferro-silico-manganese alloy is cheaper than the medium ferro-manganese alloys, the cost of smelting low-silicon and low-carbon steel can be lowered by adopting the method.

Owner:BENGANG STEEL PLATES +1

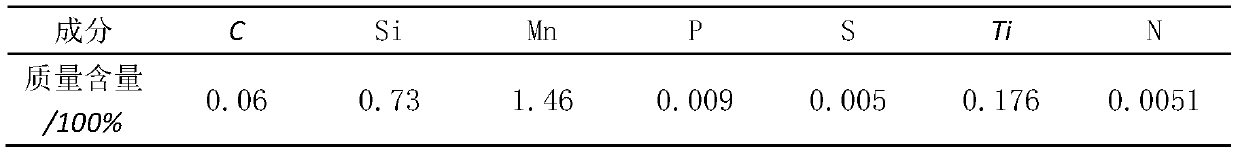

Method for smelting large energy input welded pipeline steel

InactiveCN101705412AAvoid inclusionsHigh strengthManufacturing convertersProcess efficiency improvementHeat-affected zoneSlag

The invention relates to a method for smelting large energy input welded pipeline steel. The technical scheme thereof comprises the following steps: in the process of tapping from a converter, using more than two of silicon barium alloy, manganese silicon alloy, ferro-manganese alloy and ferro-silicon alloy to carry out the procedures of weak deoxidation, LF white slag generation in the converter, RH vacuum carbon deoxidation, LF refining deep desulphurization, ferrotitanium and ferroboron alloying, steel liquid calcium processing and low degree of superheat casting. When the procedure of the weak deoxidation, the content of acid-dissolved-aluminum is less than 0.0020 percent in the steel liquid; the content of dissolved oxygen is 0.0015-0.030 percent in the steel liquid during the procedure of the RH vacuum carbon deoxidation; before casting, the mass ratio of titanium to aluminum is greater than and equal to 10. The invention uses a deoxidation alloying process of the vacuum carbon deoxidation and an added ferrotitanium final deoxidation, strictly controls the content of the aluminum, the titanium and the oxygen in the steel liquid, so that Ti2O3 impurities with 0.2-2 microns can be fully separated out in the steel liquid during the process of solidifying, the oxides doped in the pipeline steel welding heat-affected zone can induce acicular ferrite so as to achieve the purposes of refining the components of the welding heat-affected zone and improving the strength and the toughness of the welding heat-affected zone.

Owner:WUHAN UNIV OF SCI & TECH

Dedicated submerged-arc welding flux for petroleum pipeline

ActiveCN102922175ASimple structureImprove performanceWelding/cutting media/materialsSoldering mediaSesquioxideBarium titanate

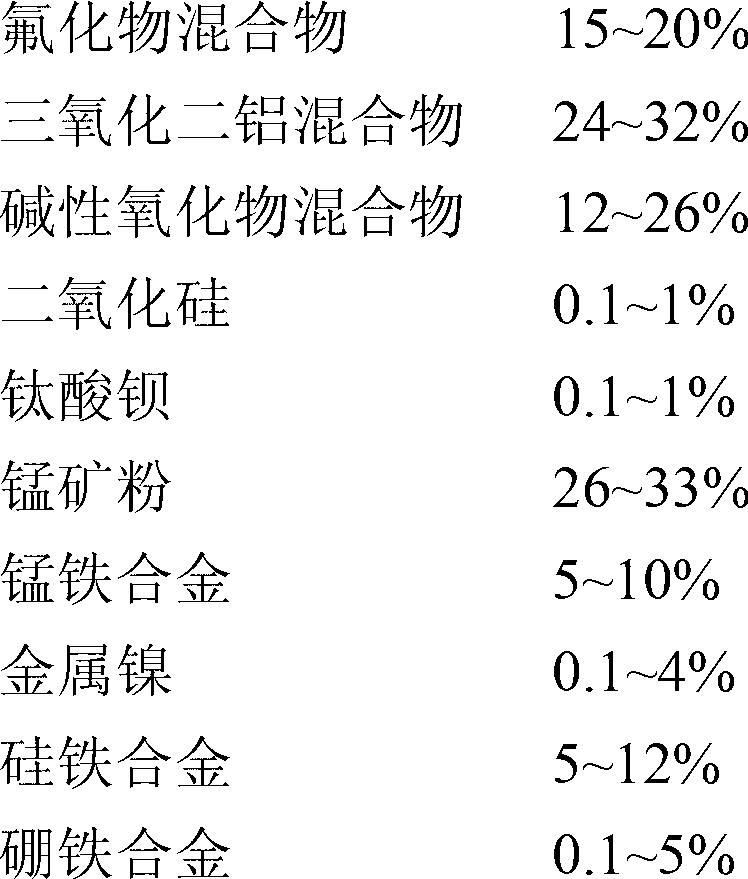

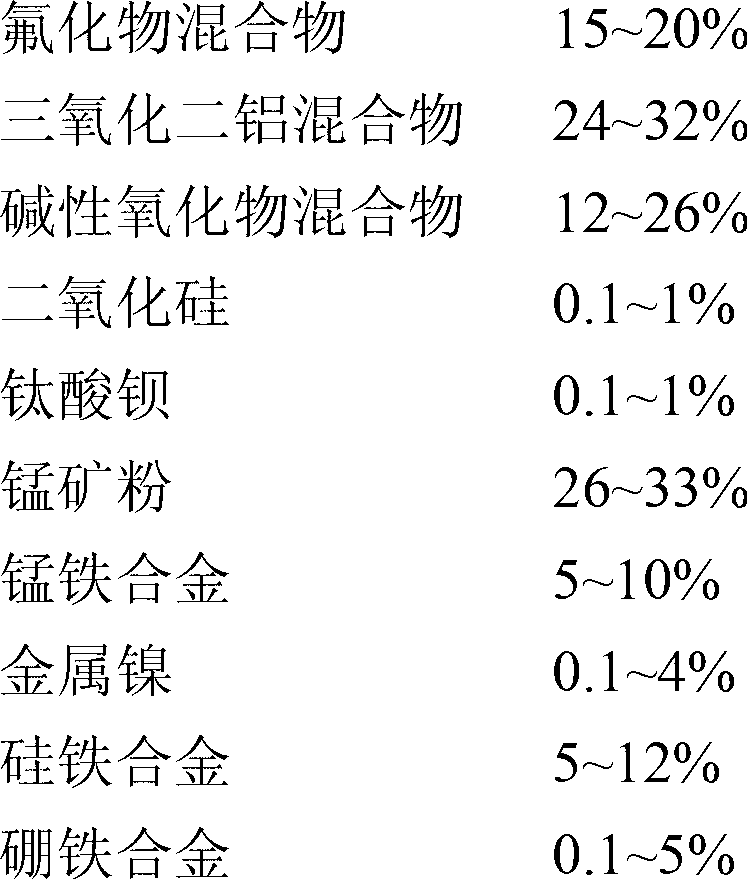

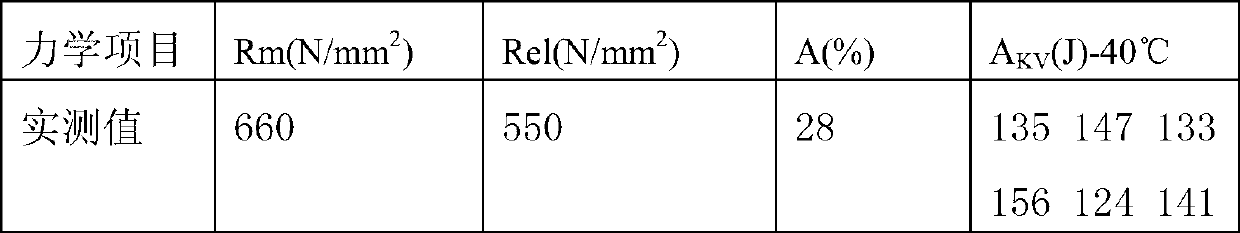

The invention discloses dedicated submerged-arc welding flux for a petroleum pipeline, which comprises welding flux and adhesive, wherein the welding flux comprises the following materials by weight percent: 15 to 20 percent of fluoride compound, 24 to 32 percent of aluminum sesquioxide compound, 12 to 26 percent of basic oxide compound, 0.1 to 1 percent of silicon dioxide, 0.1 to 1 percent of barium titanate, 26 to 33 percent of manganese mineral powder, 5 to 10 percent of ferromanganese, 0.1 to 4 percent of metallic nickel, 5 to 12 percent of ferrosilicon and 0.1 to 5 percent of ferroboron. Through addition of various trace alloying elements, the low-temperature impact ductility of the dedicated submerged-arc welding flux can be improved remarkably; as various fluorides capable of reducing the contents of hazardous elements such as sulfur, phosphorus and hydrogen are added, the comprehensive performance of a weld joint is improved; and as the contents of manganese and silicone are higher, the requirements on welding with larger parameters can be met, manganese and silicone which are lost through burning during a welding process can be effectively supplemented, and the mechanical property of the weld joint is guaranteed.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

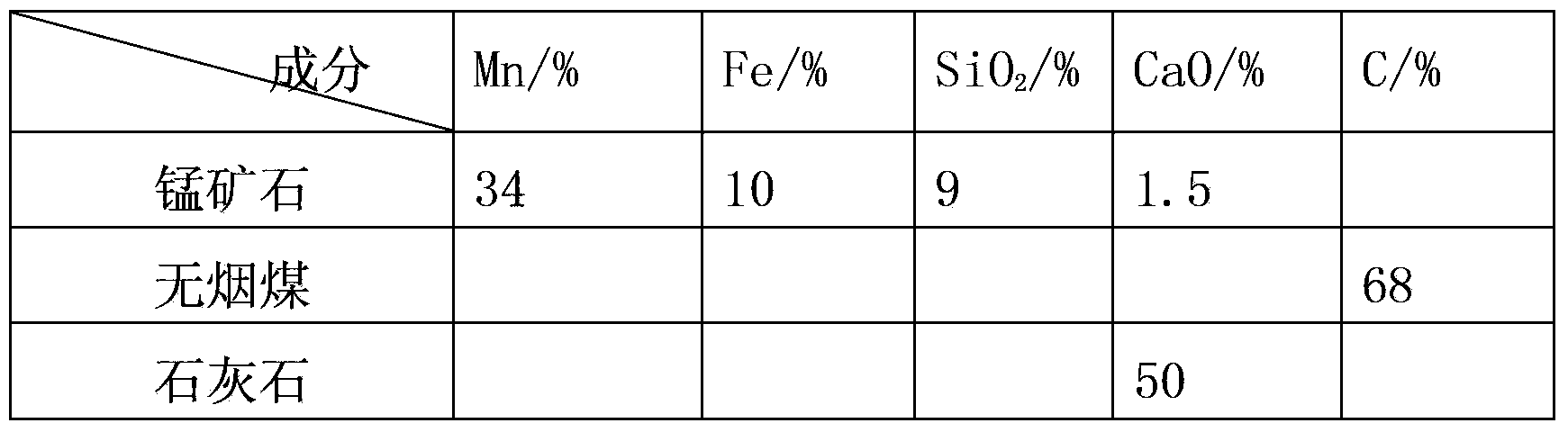

Direct reduction method for producing medium-and-low-carbon manganese-iron alloy

InactiveCN103451348ANo pollution in the processMeet environmental protection requirementsSlagManganese

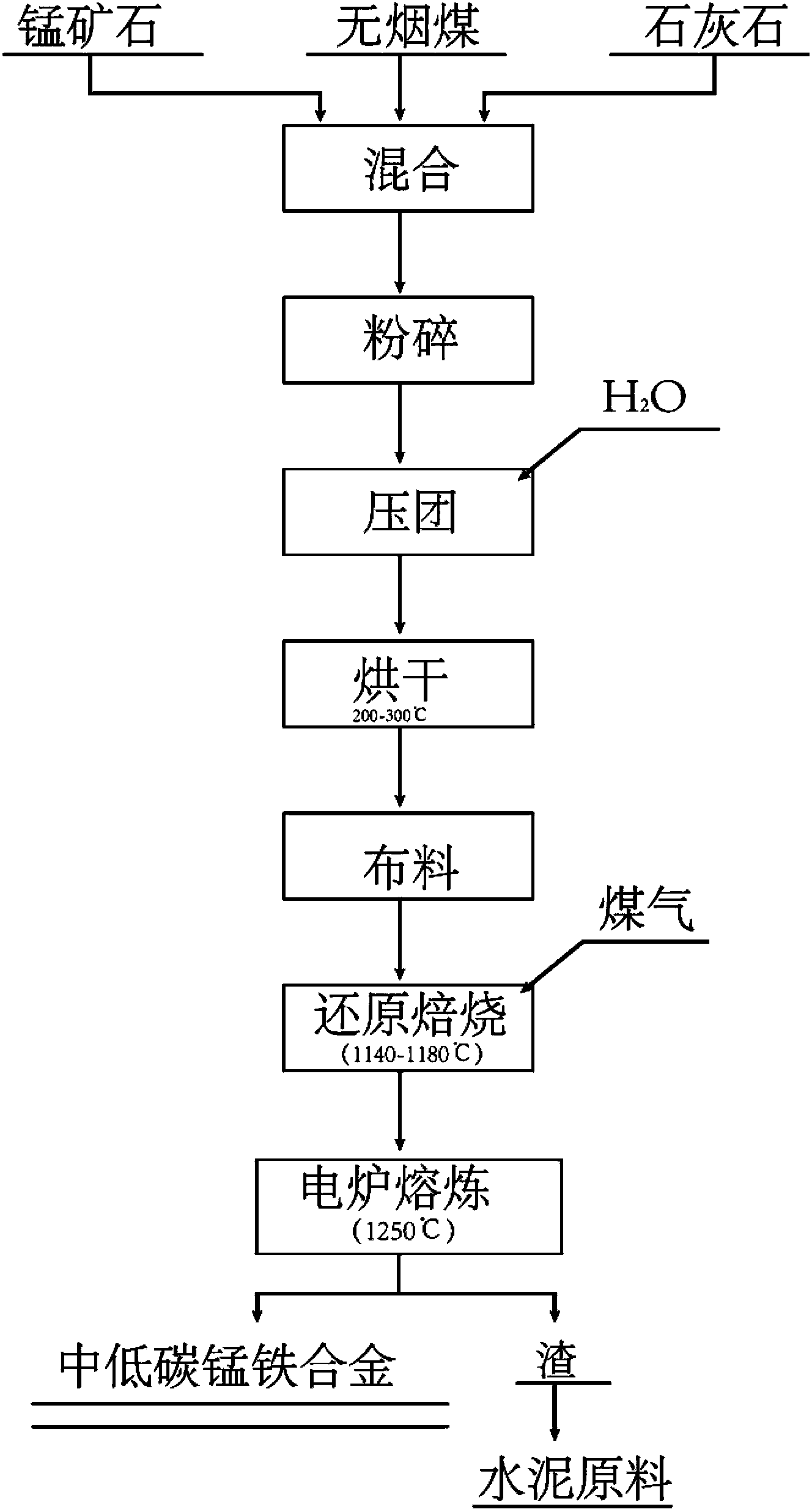

The invention discloses a direct reduction method for producing a medium-and-low-carbon manganese-iron alloy. The invention aims to provide a direct reduction method for producing a medium-and-low-carbon manganese-iron alloy. The method is characterized by comprising the following steps: A, mixing manganese ores, blind coal and limestone, putting into a pulverizer, and pulverizing to 100-120 meshes; B, briquetting the pulverized mixture obtained in the step A, and drying at 200-300 DEG C; C, putting the briquettes obtained in the step B on a distribution vehicle, feeding into a tunnel type reducing furnace, and performing high-temperature reduction roasting with coal gas at 1140-1180 DEG C for 150-180 minutes; and D, throwing the reduction roasting briquettes obtained in the step C into an electric furnace, and smelting to obtain the product medium-and-low-carbon manganese-iron alloy and furnace slag, wherein the furnace slag is transferred to serve as a raw material of cement. The method is mainly used for production of a medium-and-low-carbon manganese-iron alloy.

Owner:黄兴国

Method for casting high-quality castings through blast furnace molten iron with short process

ActiveCN107119168AGood conditionIncreased graphitized coreProcess efficiency improvementIntermediate frequencyFerrosilicon

The invention discloses a method for casting high-quality castings through blast furnace molten iron with a short process. The method comprises the following steps that (1) foundry returns and steel scraps are placed into an intermediate frequency furnace at first, and the blast furnace molten iron is poured into the intermediate frequency furnace; (2) an intermediate frequency furnace power source is switched on before solidification, and ferrosilicon and manganeisen are added at 1350+ / -10 DEG C; (3) heat preservation is conducted for 13-15 min at 1540-1550 DEG C; and (4) a nucleating agent is put in, iron of the molten iron is removed, drossing pouring is conducted, grey castings are obtained, a nodulizing agent is placed in a ladle, part of molten iron is subjected to iron removal and nodulizing treatment, remaining molten iron is added after drossing, the nucleating agent is injected, drossing pouring is conducted, and nodular cast iron is obtained. Through cooling treatment during smelting, alloy adding time adjustment and molten iron superheat control, graphite structures are refined, and the casting quality is improved while the technological process is shortened.

Owner:磐石华兴汽车零部件制造有限公司

Method for casting corrosion-resisting butterfly valve body

The invention discloses a method for casting a corrosion-resisting butterfly valve body. Firstly, raw materials including pig iron 25-32%, steel scrap 25-32%, foundry returns 15-25%, rare earth iron alloy 5-8%, silicon iron 1.7-2.0%, carburant 0.2-0.24% and ferromanganese 5-10% are weighed by weigh ratio, wherein the sum of ingredients is 100%; chemical components including C2.83-3.2%, Si 1.0-1.3%, Mn 0.6-1.0%, P 0.8-1.0%, S 0.03-0.09%, Si 8-15.5%, Cr 0.27-0.33%, Sn 0.01-0.02% and Cu 0.8-1.2% are controlled; the temperature is heated to be 1400-1600 DEG C to melt the ingredients into molten metal, the content of the chemical components is detected, and then corresponding lacking metal elements are added into the molten metal to be mixed evenly to form pouring liquid; and pouring and cooling solidification are performed, and steam treatment is performed to a taken-out coagulum to obtain the corrosion-resisting butterfly valve body. The raw materials are reasonable in formula, the process is simple, produced corrosion-resisting butterfly valve body is good in performance, long in service life and high in qualified rate, the product quality is improved greatly, and the method is suitable for being popularized widely.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Aluminum-silicon-manganese-iron compound deoxidizer for steel making

The invention relates to an aluminum-silicon-manganese-iron compound deoxidizer for steel making. The compound deoxidizer for steel making comprises the following chemical components (wt%): 28-45% of Al, 15-25% of Si, 15-25% of Mn, 19-31% of Fe and inevitable impurities. The preparation method of the compound deoxidizer for steel making comprises the following steps: proportioning aluminum ingots, ferrosilicon, silicomanganese and scrap steel according to a certain ratio and procedure; then melting in a medium-frequency electric furnace; performing mold casting; demolding, cooling, and then packaging after the product is qualified through an analytical test. The compound deoxidizer is high in aluminum-silicon-manganese-iron alloy strength, has a low breaking loss rate in the use processes of transportation, loading and unloading, has a low chalking possibility and is used for the steel making process; because of the big specific gravity and low melting point, the deoxidizing effect is good in a smelting test, so that the operation in the steel making process is simplified; and under the condition of keeping the stable quality of the made steel, the steel making cost is lowered, and the amount of aluminum is saved.

Owner:上海中捷有色金属有限公司

Production of low carbon manganesium iron in medium frequency induction furnace by remelting process

A method for manufacturing low-carbon manganese iron alloy by medium-frequency furnace remelting includes: throwing manganese into medium-frequency furnace, electrofusing liquid, adding manganese solution into steel scrap and smelting with adding amount 5-30wt% of manganese, removing slag, cooling alloy solution in steel ladle, breaking alloy block, and forming require bulk. Its advantages include low cost, simple process and high output.

Owner:宁结算

Method for controlling surface cracks of welding wire steel continuous casting blank

The invention relates to the technical field of ferrous metallurgy, particular to a method for controlling surface cracks of a welding wire steel continuous casting blank. The method specifically comprises the following key process steps that (1) molten iron pretreatment is carried out; (2) converter treatment has two operation manners; (3) special silicon iron of 10 kg / ton of steel is used by analloy, and a low-phosphorous manganese iron alloy of 8 kg / ton of steel is used in cooperation with metal manganese; (4) the refining treatment process is carried out, the temperature of entering an LFfurnace is required to be 1560 DEG C or above, the LF furnace adjusts the adding quantity of lime and the adding quantity of ferrotitanium according to the contents of S and Ti entering the furnace,the temperature is increased to 1580-1600 DEG C at a time, and the top slag ferrotitanium is controlled to range from 1.8 to 2.4; (5) it is guaranteed that the treatment period is larger than or equalto 30 min, and the stirring period is at least 2-3 min; (6) after refining treatment is finished, feed casting is carried out after weak blowing is carried out for 3-5 min; and (7) the secondary cooling water quantity is optimized. According to the method, TiN inclusions are effectively controlled, molten steel flocculant flow is avoided, and surface micocracks of the casting blank are controlled.

Owner:ANGANG STEEL CO LTD

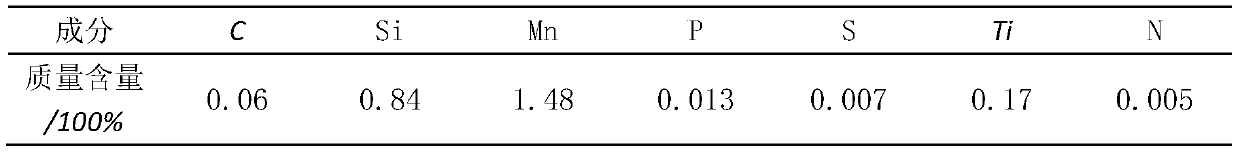

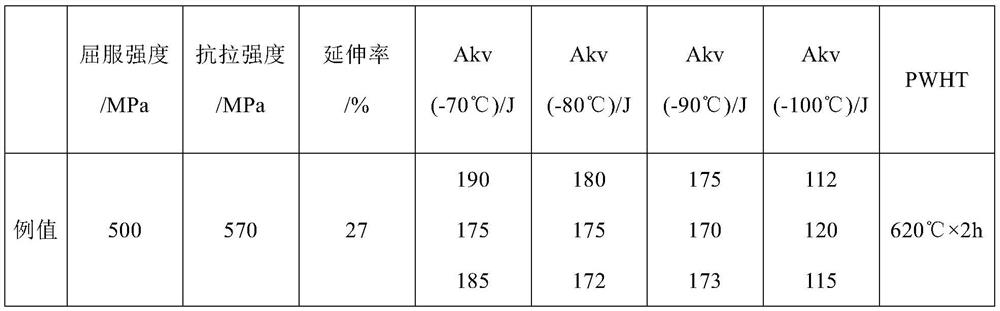

Oversized-linear-energy-resistant sintered flux for submerged-arc welding and manufacturing method thereof

ActiveCN103252596AImprove the ability to withstand high currentModerate fluidityWelding/cutting media/materialsSoldering mediaFerrosiliconMolten slag

The invention discloses an oversized-linear-energy-resistant sintered flux for submerged-arc welding and a manufacturing method of the oversized-linear-energy-resistant sintered flux and belongs to the field of welding materials for submerged-arc automatic welding. The oversized-linear-energy-resistant sintered flux comprises, by mass, 18 percent of alumina, 22 percent of magnesia, 5 percent of natural aedelforsite, 11 percent of fluorite, 6 percent of silica powder, 2 percent of zircon sand, 30 percent of reduced iron powder, 2.5 percent of manganeisen and 3.5 percent of ferrosilicon. The oversized-linear-energy-resistant sintered flux for submerged-arc welding and the manufacturing method of the oversized-linear-energy-resistant sintered flux can effectively avoid the phenomenon that slag formed in welding with a welding current reaching up to 1000A to1400A with a conventional flux can not well cover weld metal, and an even welding bead with a bright and clean surface can be formed.

Owner:郑州固力特新材料有限公司

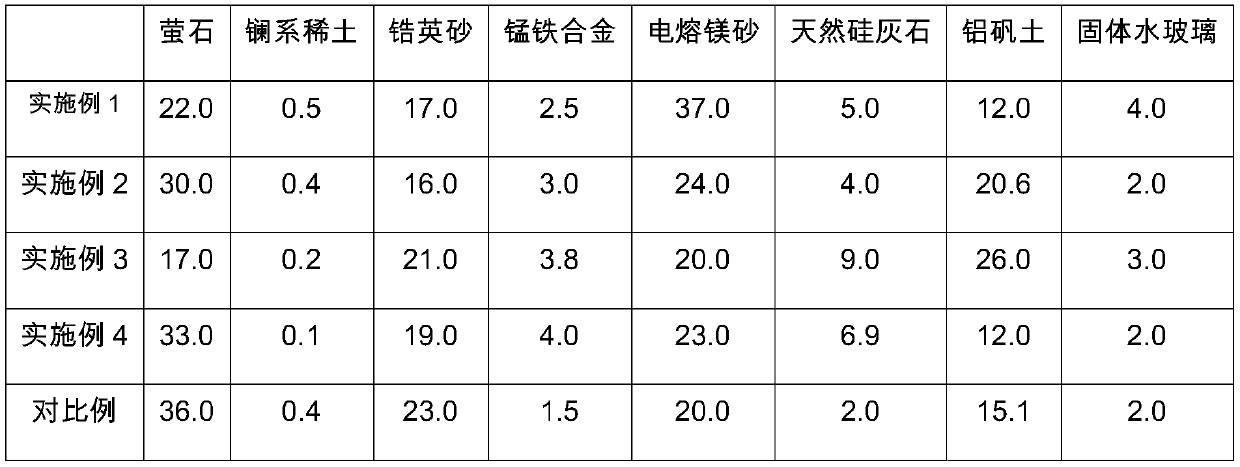

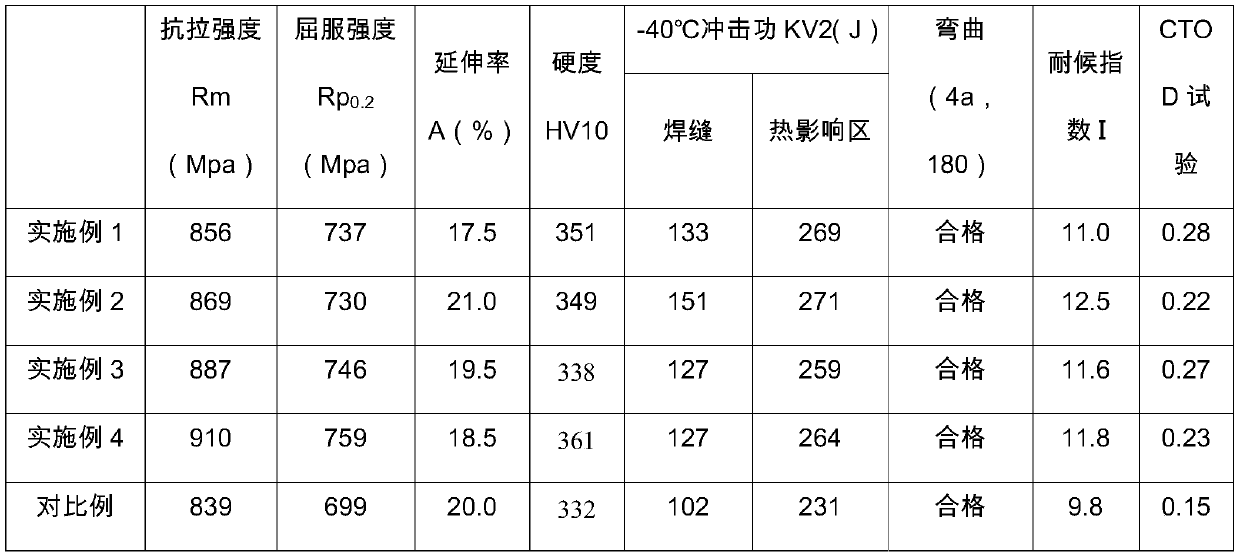

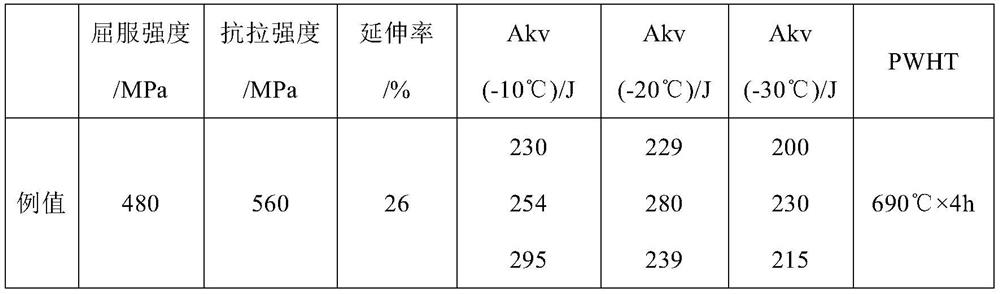

Submerged-arc welding flux matched with 850MPa-grade weather-proof high-strength steel

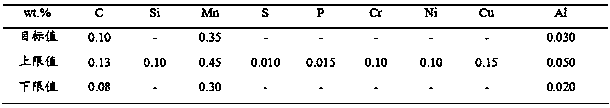

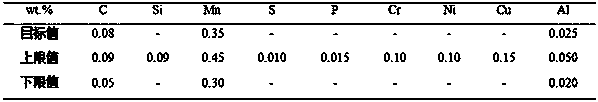

ActiveCN111037155AGood workmanshipGood plasticityWelding/cutting media/materialsSoldering mediaLanthanideZircon

The invention belongs to the technical field of welding materials and discloses a submerged-arc welding flux matched with 850MPa-grade weather-proof high-strength steel and a production and use methodthereof. The welding flux is formed by mixing various ore raw materials and a small amount of alloy powder. The welding flux comprises the following main components: 17-33% of fluorite; 0.1-0.5% of lanthanide series rare earth; 16-21% of zircon sand; 2.5-4% of manganese-iron alloy; 20-37% of fused magnesia; 2-9% of natural wollastonite; 12 to 26% of bauxite; and 2-4% of solid water glass. The welding flux comprises a binder. The main components are uniformly mixed according to the proportions; 20-21.5% of the binder is added into the uniformly mixed main components; an obtained mixture is granulated; an obtained substance is subjected to low-temperature baking at 200-230 DEG C, high-temperature sintering at 680-730 DEG C, and screening sequentially, so that a flux product of which the alkalinity ranges from 2.8 to 3.0 and of which the mesh number ranges from 20 to 50 is obtained. When the welding flux and a special welding wire are matched with each other to weld the 850MPa-grade weather-proof high-strength steel, a deposited metal is obtained. The chemical component C of the deposited metal is smaller than or equal to 0.10%; the chemical component Mn of the deposited metal rangesfrom 1.0 to 2.2%; the chemical component Si of the deposited metal is smaller than or equal to 0.60%; the chemical component P of the deposited metal is smaller than or equal to 0.020%; the chemicalcomponent Cr of the deposited metal is smaller than or equal to 0.60%; the chemical component Mo of the deposited metal ranges from 0.20 to 0.60%; the chemical component Ni of the deposited metal ranges from 2.00 to 3.30%; the chemical component Cu of the deposited metal is smaller than or equal to 0.25%; and the balance of the deposited metal is Fe.

Owner:SICHUAN XIYE NEW MATERIAL

Ferro-silico-manganese alloy for smelting low-silicon low-carbon steel

The invention relates to a ferro-silico-manganese alloy for smelting low-silicon low-carbon steel, which comprises the following chemical components in percentage by mass: 15-20% of silicon, 55-65% of manganese and the balance of iron. The price of the ferro-silico-manganese alloy is very low, so the deoxidation alloying method can lower the cost for smelting low-silicon low-carbon steel. Besides, since the ferro-silico-manganese does not contain aluminum, aluminum oxide can not be generated when adding the ferro-silico-manganese alloy into molten steel, and inclusions in the molten steel can easily float upward, and thus, can not influence the refining procedure.

Owner:BENGANG STEEL PLATES +1

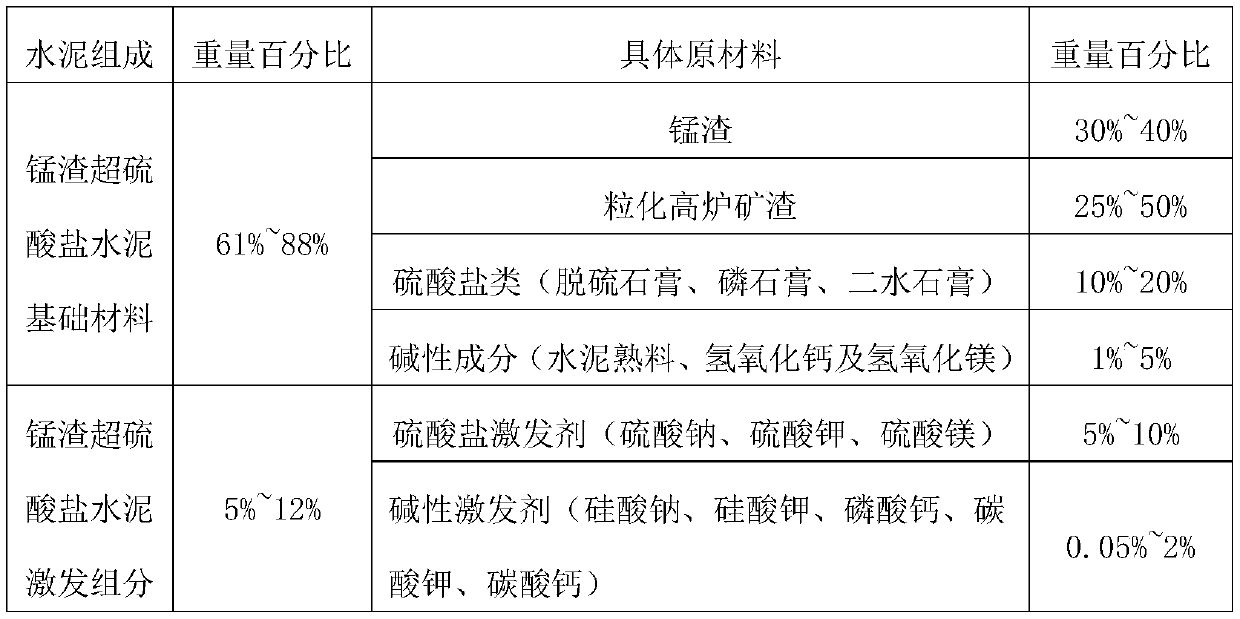

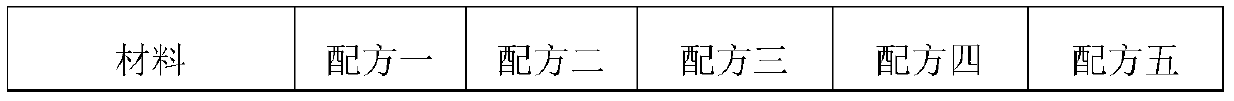

Manganese slag supersulfate cement and preparation method thereof

The invention belongs to the technical field of special cement, and particularly relates to a manganese slag supersulfate cement and a preparation method thereof. The manganese slag supersulfate cement is prepared from the components in percentage by weight: 30-40% of manganese slag, 25%-50% of granulated blast furnace slag powder, 10-20% of sulfates, 5%-10% of a sulfate activator, 1-5% of an alkaline component and 0.05-2% of an alkaline activator. The manganese slag which is a high-temperature slag waste discharged during the blast furnace smelting process of manganese iron or silicomaganeseis used as a main raw material, a material science principle is combined, the mineral characteristics of manganese slag and slag are taken as a basis, the potential hydration activity of the manganeseslag is activated by using sulfates and alkaline environment to form the initial strength, and novel manganese slag supersulfate cement with excellent properties is further designed.

Owner:中建西部建设新疆有限公司 +1

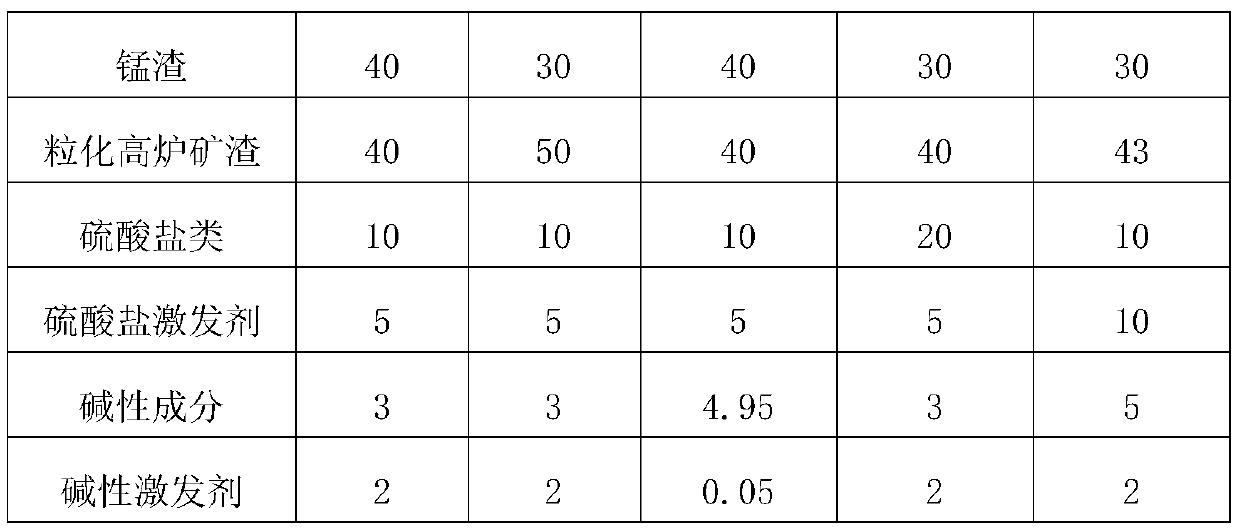

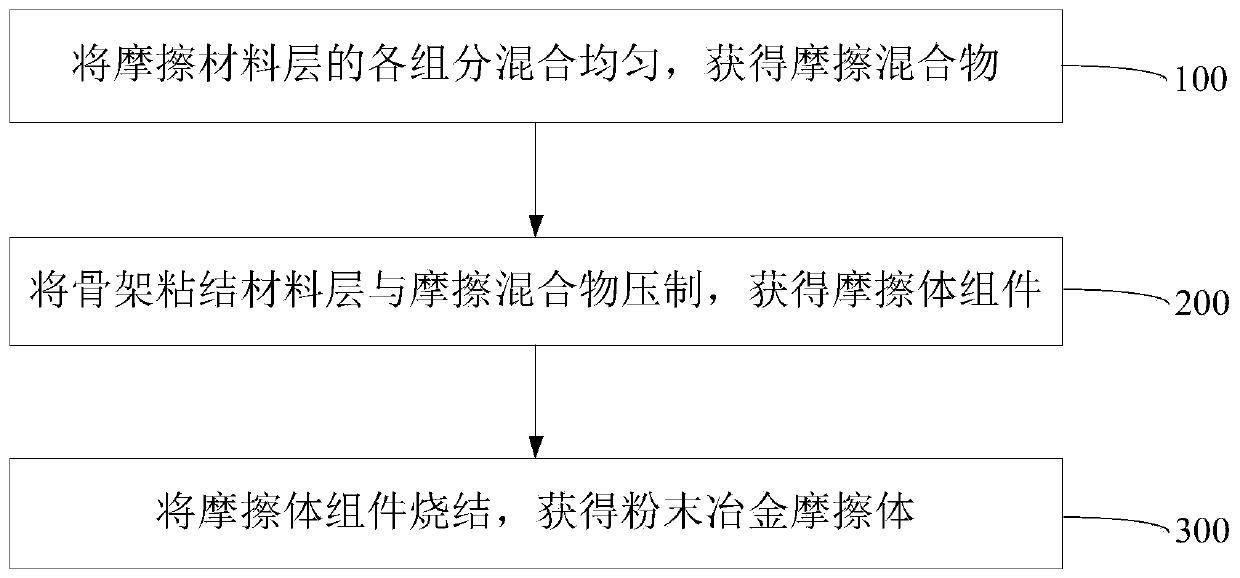

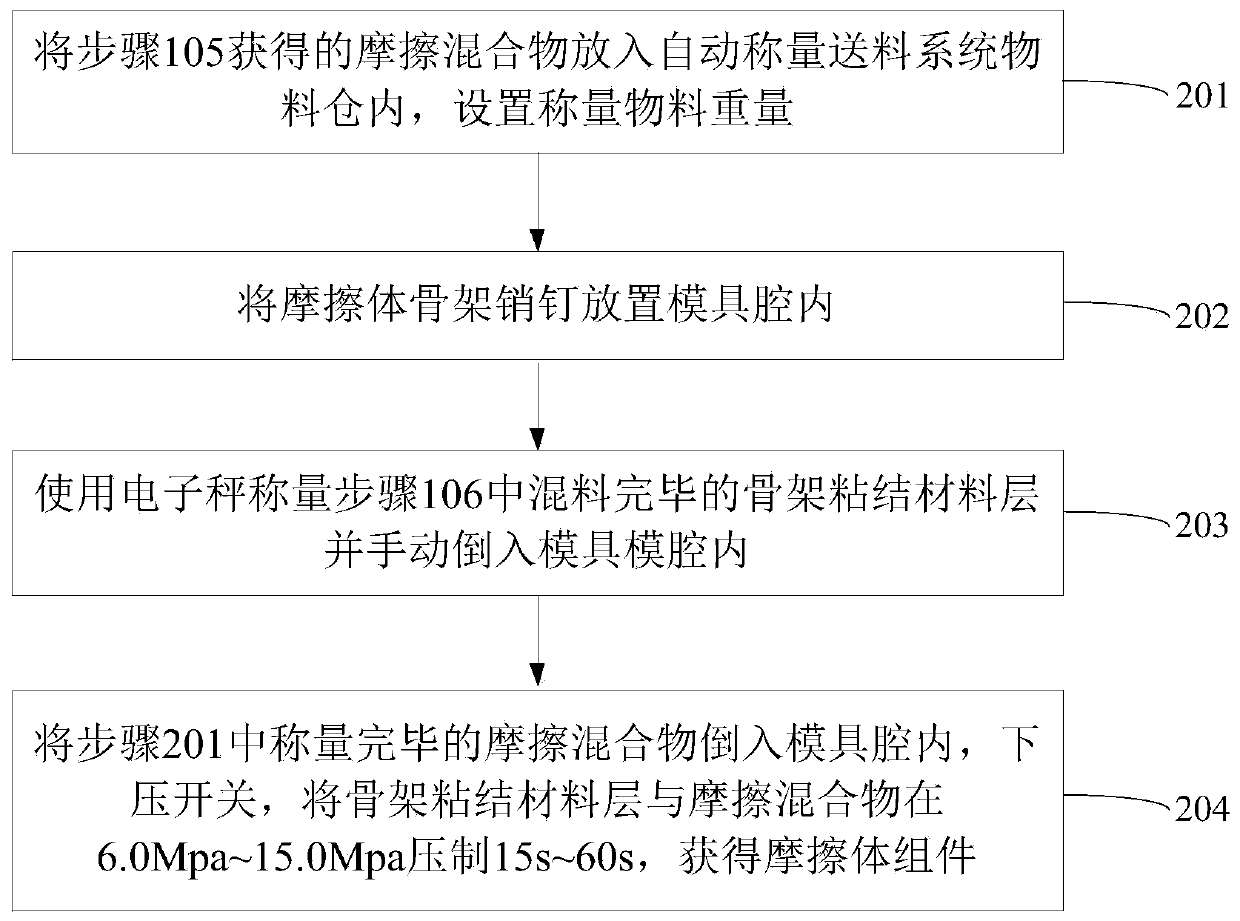

Powder metallurgy friction body and manufacturing method thereof, powder metallurgy brake pad

ActiveCN111570801AImprove matrix strengthExtend your lifeFriction liningActuatorsMolybdenum trioxideFlake graphite

The invention discloses a powder metallurgy friction body and a manufacturing method thereof, and a powder metallurgy brake pad. The powder metallurgy brake pad has relatively strong wear-resisting performance, can solve the phenomena of dreg falling, chip falling and entire friction material fall-off of an existing friction body in the process of vehicle braking, and thereby improves the servicelife of the friction body. The powder metallurgy friction body comprises a friction material layer which is composed of a substrate element, a lubricating element and a friction element, and a skeleton bonding material layer which is used for bonding the friction material layer and a friction body skeleton; the substrate element comprises bronze powder, reduced iron powder, manganese-iron alloy powder and nano molybdenum trioxide; the lubricating element comprises zinc sulfide and crystalline flake graphite; the friction element comprises titanium dioxide, zirconium oxide, feldspar and zirconsand; and the skeleton bonding material layer comprises bronze powder, reduced iron powder, manganese powder, molybdenum powder and tin powder. The powder metallurgy friction body can manufacture thepowder metallurgy brake pad and the powder metallurgy brake pad is applied to the aspect of urban railway transportation.

Owner:北京浦然轨道交通科技股份有限公司 +1

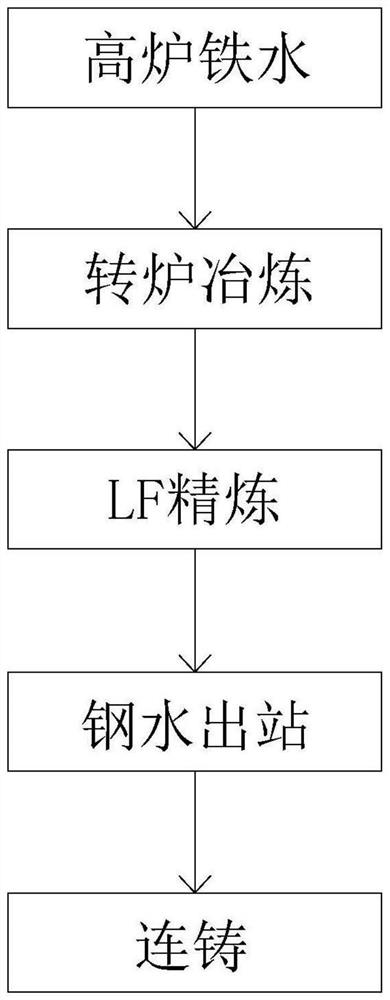

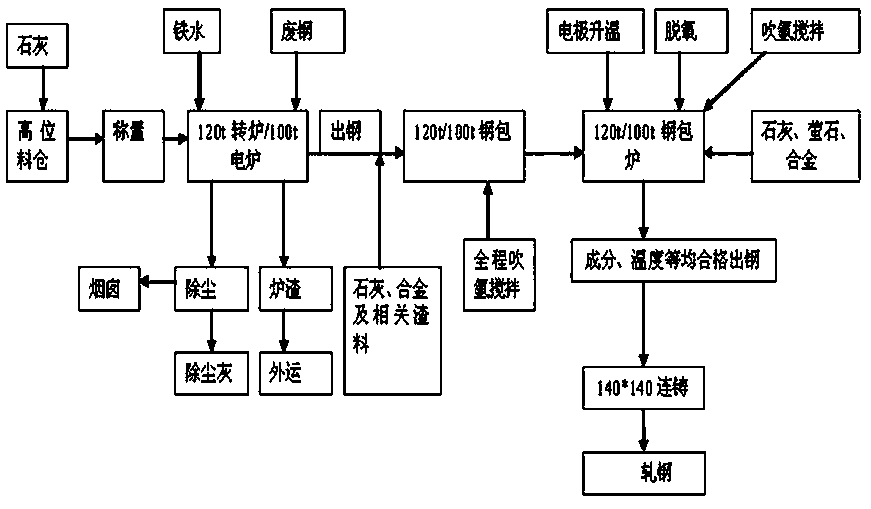

Smelting method of welding rod steel H08Mn

InactiveCN112280923APrevent thinningReduce exposed areaManufacturing convertersProcess efficiency improvementRefining (metallurgy)Oxide

The invention provides a smelting method of welding rod steel H08Mn, and particularly relates to the field of ferrous metallurgy. The smelting method includes the steps of converter smelting: blast furnace molten iron is smelted in a converter to control the endpoint carbon content at 0.03-0.04%, slag-stopping tapping is carried out, pre-deoxidation is carried out by using an aluminum-manganese-iron alloy in the tapping process, and a medium-carbon manganese-iron alloy and active lime are added after tapping; and LF refining: oxygen determination and temperature measurement are performed before each time of temperature rise, an aluminum wire is fed according to a fixed oxygen value, a refining slag modifier is added, the refining temperature rise time is predicted according to a temperature measurement value, the adding amount of the refining slag modifier is increased along with the prolonging of the temperature rise time, and the slag modifier is decomposed to form CO2, the CO2 continuously escapes to form foam slag, so that air is effectively isolated, and molten steel oxygen uptake is weakened; and the oxygen content of molten steel can be controlled to be 0.0030%-0.0060%, theAls content can be controlled to be 0.0035%-0.0065%, then the molten steel is fed into a silicon-calcium line to be subjected to calcium treatment, soft blowing is conducted for 8 min-10 min, and thenthe molten steel is poured on a table. The smelting method of the welding rod steel H08Mn has the characteristics of weakening the oxygen uptake degree of the molten steel, overcoming the bubble defect of a casting blank, reducing the aluminum oxide inclusion formation amount of the molten steel, improving the castability of the molten steel, and ensuring the stable oxygen content of the molten steel.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Chromium-based alloy and manufacturing method thereof

InactiveCN104419855AImprove corrosion resistanceImprove high temperature performanceFuel cellsManganese

A chromium-based alloy and a manufacturing method thereof. The chromium-based alloy comprises following components, by mass, 4-6% of Fe, 0.8-1.2% of Y2O3, 0.1-15% of Mn, not more than 2% of unavoidable impurities and the balanced chromium. The manufacturing method comprises following steps: designing the composition of the components, mixing the components, pressing the components, dewaxing the components and sintering the components to obtain the alloy, cooling the alloy, and analyzing and detecting the alloy. The chromium-based alloy is manufactured with manganese so that an organization structure of a part can be effectively improved since the manganese and manganese-iron alloy are low in melting point and can form liquid-phase sintering when the temperature is higher than 1246 DEG C, thereby finally improving the performances of the part and enabling a corrosion-resistant performance and a high-temperature performance of the chromium-based alloy to be better with influence on thermal-expansion coefficient of the material being less. The chromium-based alloy is excellent in the corrosion-resistant performance and the high-temperature-resistant performance, can be used as a joint plate in a fuel cell, is higher in operation temperature, is longer in service life and is free from greatly influencing assembly and usage since the thermal-expansion coefficient of the alloy matches with other assemblies in the fuel cell.

Owner:NBTM NEW MATERIALS GRP

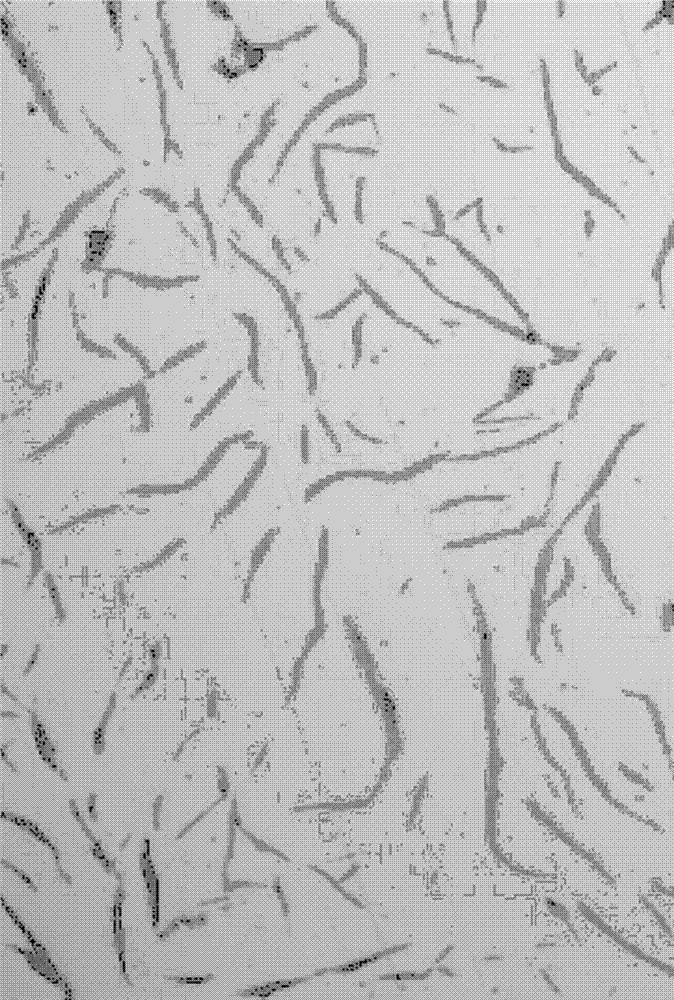

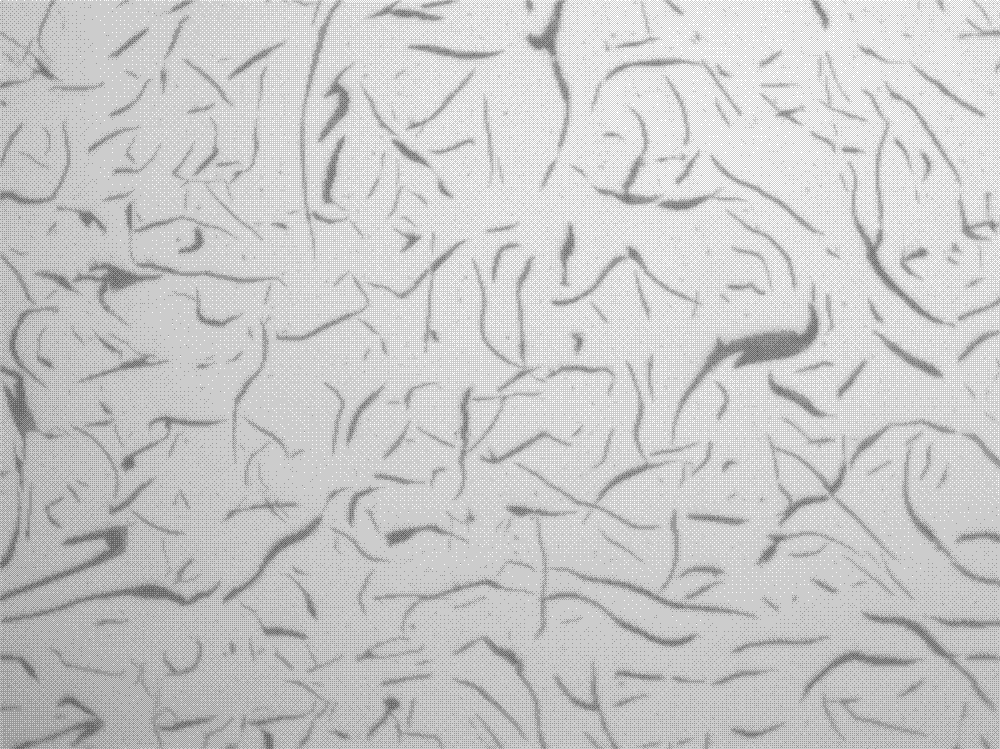

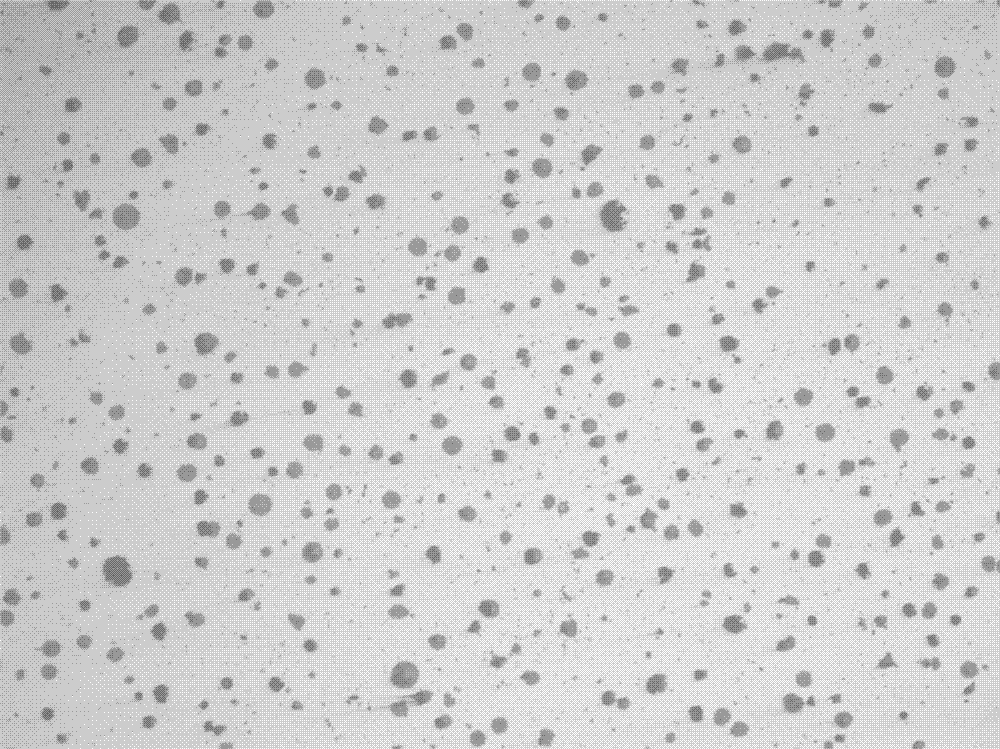

Production method for non-magnetic ferro-manganese alloy powder

InactiveCN107116223AImprove milling efficiencyThe chemical composition of the particles is uniformChemical compositionManufactured material

The invention relates to a production method of non-magnet manganese alloy powder, which includes smelting, atomization, dehydration, drying and screening, uses scrap iron and steel as the main raw material, can reduce costs on the basis of ensuring iron content, and is environmentally friendly , the use of water atomization to produce non-magnetic manganese alloy powder can improve the powder making efficiency and ensure that the powder is easy to be pressed, and the chemical composition of the particles obtained by the non-magnetic manganese alloy powder produced by the water atomization method is uniform, the macro segregation is eliminated, and the composition The material distribution is relatively uniform, and it has a fine-grained structure, and the prepared material has good toughness.

Owner:梅州梅新粉末冶金有限公司

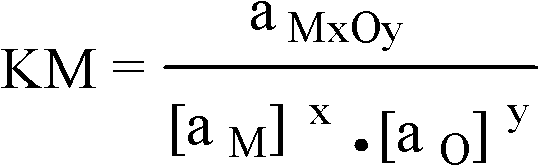

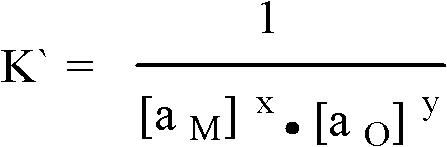

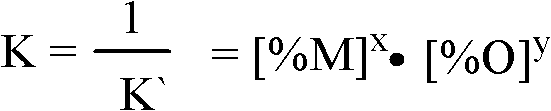

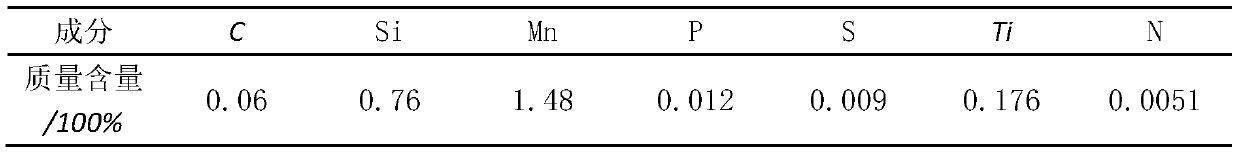

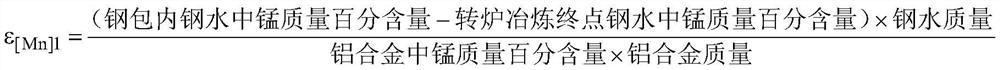

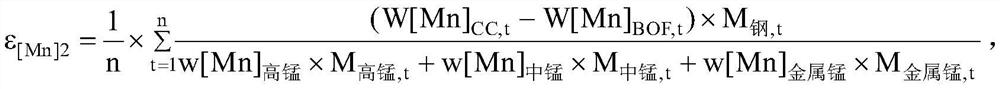

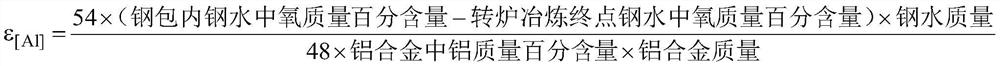

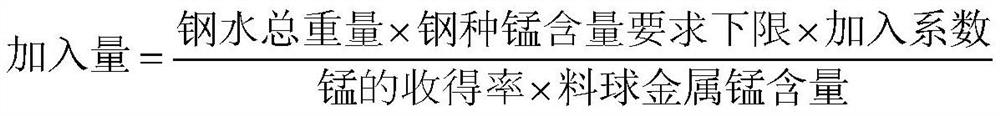

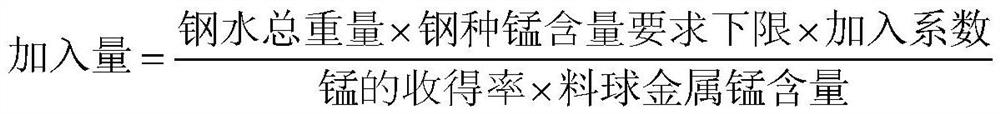

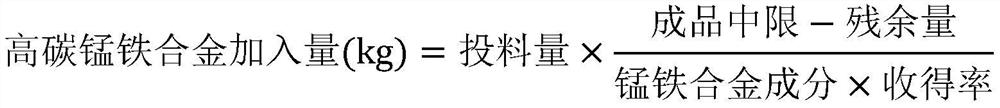

Method for controlling alloy adding amount in converter tapping process

ActiveCN114196795ASolve the problem of excessive carbon or phosphorusCost efficientManufacturing convertersProcess efficiency improvementMolten steelFerro-manganese alloy

The invention discloses a method for controlling the alloy adding amount in the converter tapping process. The method mainly solves the technical problems that the existing ferromanganese alloy adding amount is unreasonably controlled, and the carbon content and the phosphorus content in continuous casting molten steel exceed the standard. According to the technical scheme, the method for controlling the alloy adding amount in the converter tapping process comprises the following steps that current heat data are obtained; calculating the molten steel mass; calculating a control target of a manganese element and a non-manganese alloy element in the continuous casting molten steel; calculating the components of molten steel at the smelting end point of the converter and the redundancy of carbon and phosphorus in continuous casting molten steel; calculating the recarburization amount of the molten steel treated by the LF refining furnace; the aluminum alloy yield is calculated; calculating the adding mass of the aluminum alloy in the converter tapping process; calculating the total adding mass of the manganese alloy and the non-manganese alloy in the molten steel; the adding mass of the manganese alloy and the non-manganese alloy in the converter tapping process is calculated; and alloy adding in the converter tapping process is controlled. According to the method, the alloy cost is greatly reduced under the condition that the requirements of molten steel components are met.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

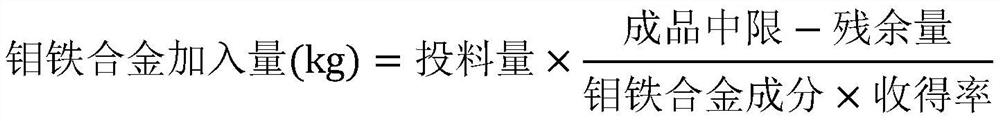

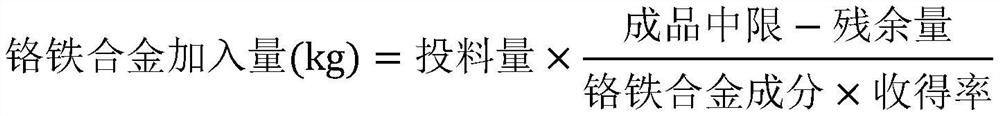

Low-alloy cast steel and application thereof in heavy lorry axle housing, raw materials and machining process

ActiveCN102212755BImprove mechanical propertiesExtended service lifeMachining processThermal treatment

The invention discloses a low-alloy cast steel suitable for a heavy lorry axle housing. The low-alloy cast steel comprises the following elements in percentage by mass: 0.23 to 0.33 percent of C, 0.50 to 1.00 percent of Si, 0.90 to 1.40 percent of Mn, 0.10 to 0.25 percent of Cr, 0.10 to 0.25 percent of Mo, 0.20 to 0.25 percent of V, less than or equal to 0.04 percent of P, less than or equal to 0.04 percent of S, less than or equal to 0.20 percent of residual elements, and the balance of Fe. Waste steel, pig iron, ferromanganese alloy, silicon ferromanganese alloy, ferrochromium alloy, ferromolybdenum alloy and ferrovanadium alloy are used as raw materials of the low-alloy cast steel; and the machining process of the low-alloy cast steel comprises casting and thermal treatment. The low-alloy cast steel has the advantages of high mechanical property, good low-temperature impact toughness and good casting and machining process properties, and is particularly suitable for producing the lorry axle housing.

Owner:山东新达重工机械有限公司

Non-drainage casting method for low-carbon low-silicon aluminum-containing steel

The invention discloses a non-drainage casting method for low-carbon low-silicon aluminum-containing steel, and belongs to the technical field of metallurgical production processes. The method comprises the following specific steps: adopting converter / electric furnace tapping liquid for casting, sequentially adding aluminum ingots, cold heading steel synthetic slag, low-carbon ferromanganese alloy, carbon powder, lime and fluorite into a steel ladle during converter / electric furnace tapping, performing bottom blowing of Ar gas to the steel ladle during tapping, and adding all alloys before tapping is finished; refining the cold heading steel, feeding a pure calcium line to carry out calcium treatment, and then blowing Ar gas to carry out soft stirring; before continuous casting, baking a tundish, blowing Ar gas into a tundish baking hole and an impact area, and adding SiCa powder or a calcium line into a tundish flow plug rod and a sizing nozzle before casting. The method disclosed bythe invention has the advantages of avoiding poor fluidity of molten steel during pouring due to impurities generated by oxidation of the molten steel, avoiding enrichment and blockage of a water gapin the pouring process, and saving energy and production cost.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +1

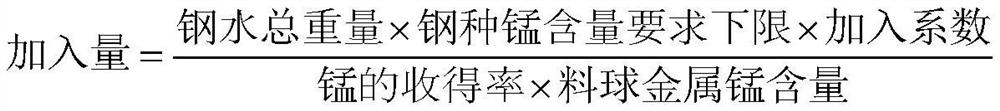

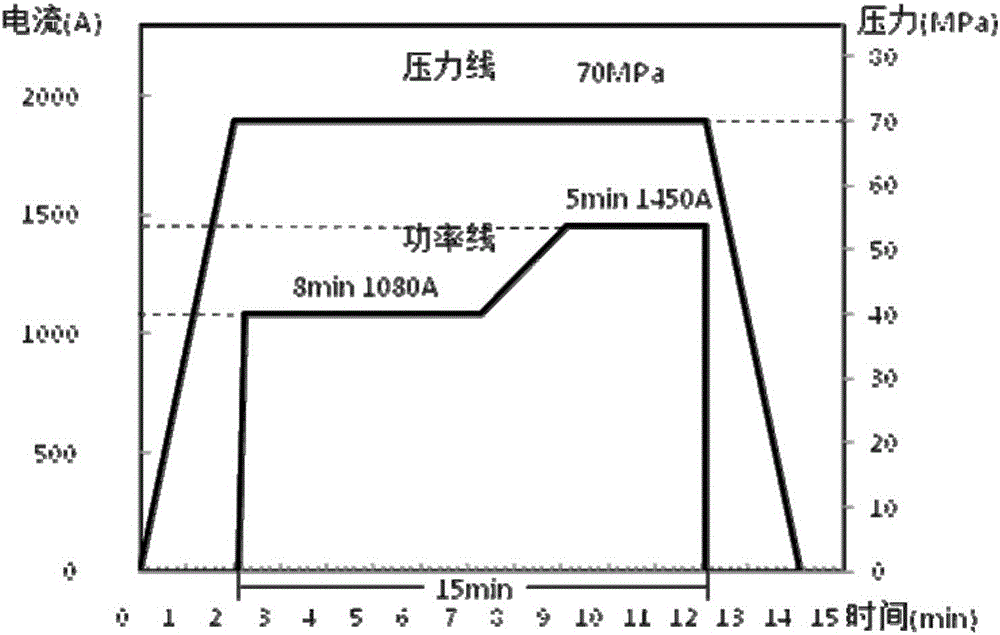

Manganese alloying method for high manganese steel smelting through converter

ActiveCN112853026ASolve the problem of manganese alloyingSolve problemsManufacturing convertersProcess efficiency improvementMetallic aluminumMixed materials

The invention relates to a manganese alloying method for high manganese steel smelting through a converter. The manganese alloying method comprises the following steps that before converter tapping, a mixed material ball prepared from metal manganese and / or manganese-iron alloy, oxidized iron scale and / or waste steel slag and metal aluminum is added into a steel ladle, and after tapping to the steel ladle is carried out, the solid metal manganese and / or manganese-iron alloy are heated and melted by utilizing heat released by oxidation of the metal aluminum, and manganese alloying of molten steel is achieved. The method solves the problem and defect of manganese alloying in high manganese steel smelting through the converter at present, and further can play a role in improving the metal yield.

Owner:ANGANG STEEL CO LTD

Alloy column and manufacturing method thereof

The invention belongs to the field of powder metallurgy and discloses an alloy column. The alloy column comprises three different sections which are an upper section, a middle section and a lower section. The upper section is made of diamond, tungsten carbide and WBn (Me). The middle section is made of tungsten carbide and WBn(Me). The lower section is made of ferro-manganese alloy powder and WBn(Me). The invention further discloses a manufacturing method of the alloy column. According to the method, the raw materials of the three sections of the alloy column are pressed and manufactured into column shapes in a grinding tool through a four-column pressing machine, after dewaxing is carried out, the raw materials are stored into composite pyrophyllite, a six-surface diamond presser is used for carrying out temperature rising, boosting and sintering, and after pressure relief, the materials are taken out. The alloy column is low in manufacturing expense and has wear resistance and toughness.

Owner:张倩楠

Smelting technology of alloyed high-manganese steel

PendingCN113061798AGuaranteed yieldChemically stableProcess efficiency improvementElectric furnaceMolten steelFerrochrome

The invention discloses a smelting technology of alloyed high-manganese steel. The smelting technology comprises the following steps that a ferro-molybdenum alloy is fed into a furnace along with a steel material; the furnace charge is melted, dephosphorizing and decarbonizing are performed after the furnace charge is completely melted down, the furnace charge is kept boiling for at least 5 min after dephosphorizing and decarbonizing, then oxidizing slag is removed, and the furnace is supplemented with slag charge; then a silicon-manganese alloy and / or a medium-carbon ferromanganese alloy are / is added into the furnace for pre-deoxidation, and a ferrochromium alloy is added into the furnace and stirred after slag is formed; the ferrochrome alloy is heated in the furnace for at least 10 min, and the high-carbon ferromanganese alloy is added; finally, a reducing agent is added into the furnace, and a deoxidation and desulfurization process is performed; after smelting is finished, under the conditions of thin slag and good reducing atmosphere, a ferrovanadium alloy is added into the furnace and fully stirred for at least 5 min; and when the content of each element in the molten steel meets the requirement, tapping is performed to finish smelting of the alloyed high-manganese steel. According to the smelting technology, the mechanical performance of the high-manganese steel is improved, the metallographic structure of the high-manganese steel is improved, and the service life of a high-manganese steel frog is prolonged.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

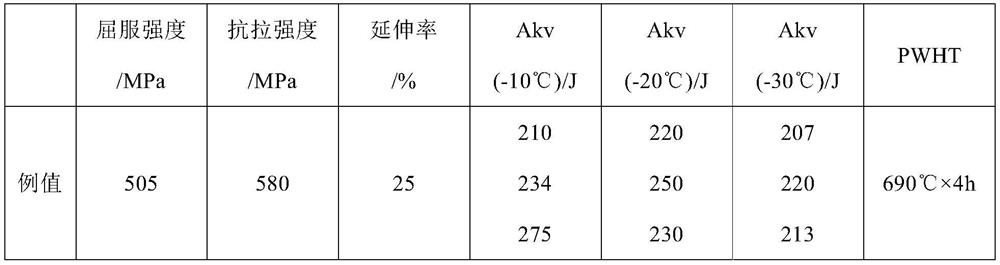

Ultralow-hydrogen type high-alkalinity high-toughness sintered flux

PendingCN112059473AGood technical effectFormulated scientifically and convenientlyWelding/cutting media/materialsSoldering mediaFerro-manganese alloyIron alloys

The invention relates to an ultralow-hydrogen high-alkalinity high-toughness sintered flux. The sintered flux is specifically prepared from dry powder of multiple components and binder water glass, and the dry powder comprises the following components in parts by weight: 12-23 parts of MgO, 15-25 parts of CaF2, 16-26 parts of Al2O3, 10-20 parts of CaCO3, 1-8 parts of SiO2, 1-5 parts of BaCO3, 1-5parts of Li2CO3, 2-5 parts of K2O+Na2O, and 1-5 parts of silicon-manganese-iron alloy. The ultralow-hydrogen type high-alkalinity high-toughness sintered flux is prepared through the method includingthe following steps that the dry powder materials are evenly mixed according to the proportions, the water glass is added, wet mixing is conducted, then granulation is conducted, drying is conducted at the temperature of 280-380 DEG C to remove the moisture, screening is conducted, high-temperature sintering is conducted at the temperature of 750-850 DEG C, cooling and screening are conducted, andthe ultralow-hydrogen type high-alkalinity high-toughness sintered flux is obtained. The ultralow-hydrogen type high-alkalinity high-toughness sintered flux has the excellent technical effects as shown in the specification.

Owner:BEIJING JINWEI WELDING MATERIAL +1

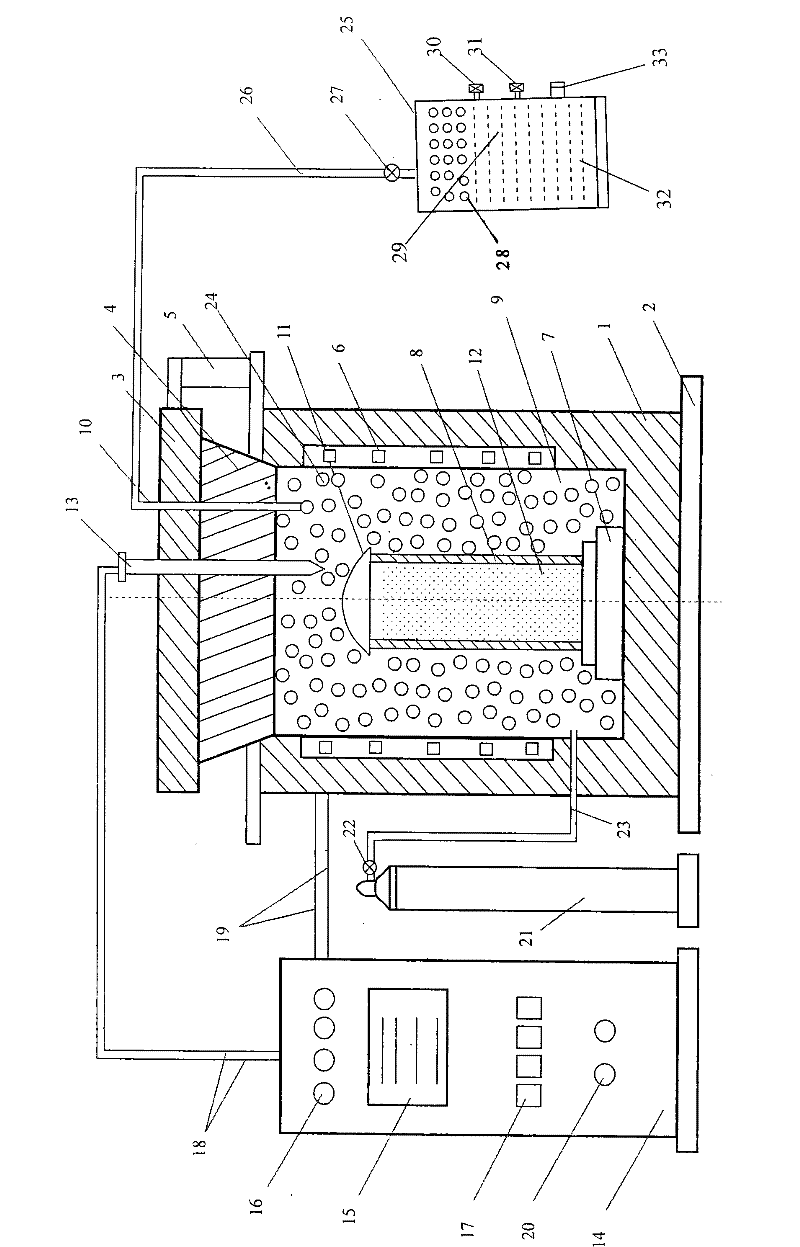

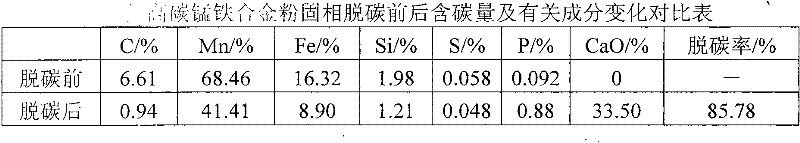

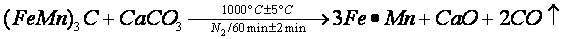

Solid-phase decarburization method of high-carbon Fe-Mn alloy

The invention relates to a solid-phase decarburization method of high-carbon Fe-Mn alloy, and the method aims at the actual situation that the carbon content of Fe-Mn alloy powder is high and adopts the solid-phase decarburization technology. The method comprises the following steps: by using calcium carbonate powder as decarbonizer and nitrogen as protective gas for decarburization, decarburization is performed in a microwave decarbonization furnace, wherein the temperature of microwave heating is 1000 DEG C, the heating time is 60min, the specific power of microwave heating is 10KW / kg and the rate of decarburization is up to 85.78%; and the obtained low and medium carbon Fe-Mn alloy is briquetted by a briquetting machine to prepare a block material for use, wherein the calcium oxide in the material is a good desulfurization and dephosphorization agent, and the generated carbon monoxide gas can be recycled. The method does not discharge metallurgical residue and cause the pollutions caused by waste gas, wastewater and residue, is a clean decarburization technology and is an ideal solid-phase decarburization method of high-carbon Fe-Mn alloy.

Owner:TAIYUAN UNIV OF TECH

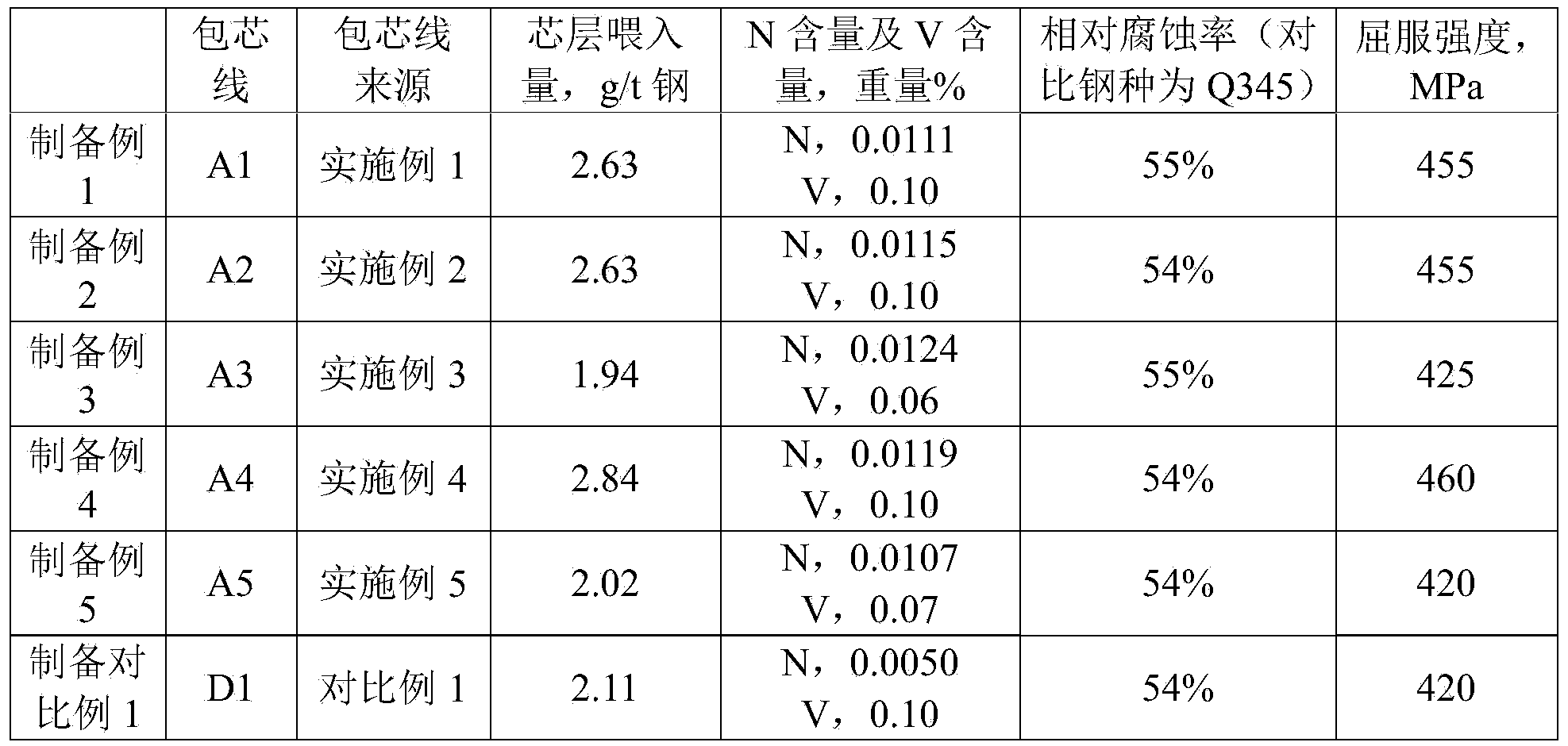

Microalloyed weathering steel, cored wire containing iron alloys and silicon-calcium alloy, application of cored wire, molten steel and preparation method of molten steel

The invention provides a cored wire containing iron alloys and a silicon-calcium alloy and an application thereof. The cored wire comprises a core and an outer layer wrapping the core, wherein the core is a mixture containing a vanadium-iron alloy, manganese silicon nitride, the iron alloys and the silicon-calcium alloy; the iron alloys are a titanium-iron alloy and / or a niobium-iron alloy. The invention provides molten steel and a preparation method thereof. The method comprises the step of feeding the cored wire into the molten steel to be subjected to vanadium-nitrogen alloying to carry out vanadium-nitrogen alloying. The invention provides microalloyed weathering steel. The cored wire is used for achieving vanadium-nitrogen alloying of the molten steel, can effectively increase the nitrogen content according to the requirements, without affecting the vanadium content, and can produce vanadium-containing steel with higher nitrogen content according to the requirement of the molten steel. The steel obtained after casting the vanadium-nitrogen alloyed molten steel obtained by carrying out vanadium-nitrogen alloying on the molten steel by adopting the cored wire has high yield strength, and the relative corrosion rate of steel can not be affected.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

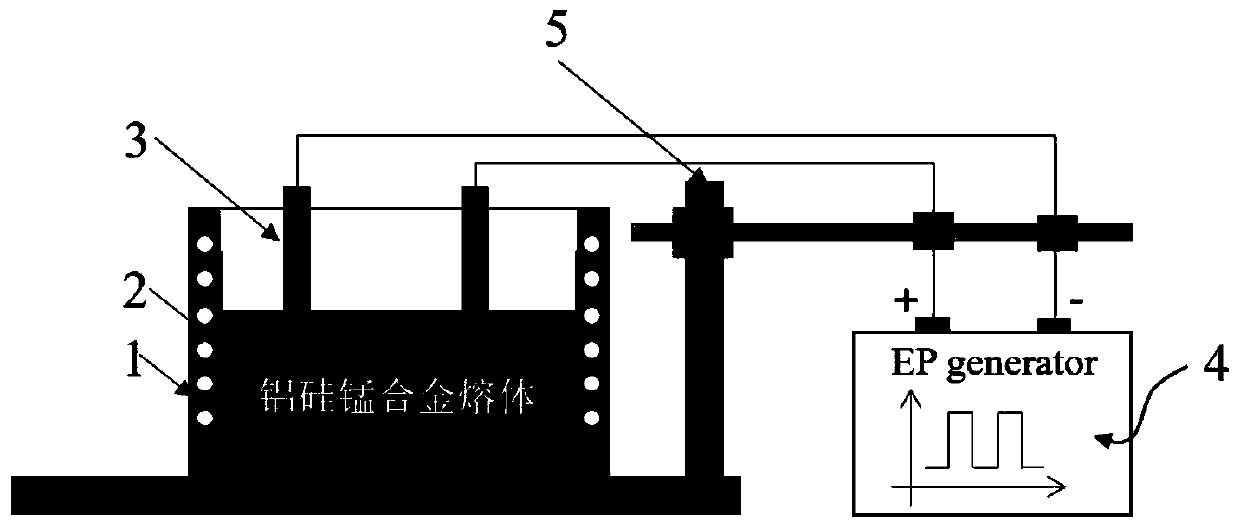

Electrical pulse treatment method for improving chalking resistance of aluminum ferro silicon manganese alloy

The invention discloses an electrical pulse treatment method for improving chalking resistance of an aluminum ferro silicon manganese alloy. The mass percentage of each chemical component in the aluminum ferro silicon manganese alloy is that 49-51% of Mn, 19-21% of Al, 17-20% of Si, 5-14% of Fe and the balance of impurity elements such as carbon. The alloy preparation process comprises the following steps of (1) weighing each raw material according to designed components; (2) adding each raw material to be smelted according to a designed sequence; (3) when all raw materials are melted, switching off an induction furnace power supply; and meanwhile, inserting two pure ferro electrodes connected with an electrical pulse power supply into a high temperature molten pool; and applying high-energy density pulse current to the interior of the molten pool; and (4) after 5-10 minutes of electrical pulse treatment, cooling the molten pool to obtain the aluminum ferro silicon manganese alloy. Theproduct obtained by the electrical pulse treatment method for improving the chalking resistance of the aluminum ferro silicon manganese alloy has the advantages of smaller grain size, compact alloy structure, stable structure, excellent chalking resistance and long alloy storage period. Requirements of a deoxidizing agent for steel making are met.

Owner:CENT SOUTH UNIV

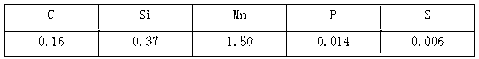

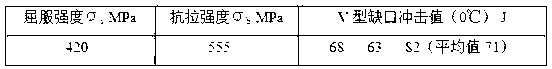

Threaded steel and preparation method thereof

The invention relates to the field of iron and steel smelting, and provides threaded steel and a preparation method thereof. The preparation method is used for improving the intensity of the threadedsteel. The preparation method of the threaded steel provided by the invention sequentially comprises the working procedures of electric furnace smelting, external refining, continuous casting, hot rolling, cooling, cutting and end flattening, wherein in the electric furnace smelting working procedure, cast iron, copper ingots and vanadium ingots are subjected to eutectic melting stirring; in the process from electric furnace smelting to external refining, silicon iron and ferromanganese iron alloy are added; ferro phosphorus is added into the working procedure of external refining; the cast iron accounts for 900 to 1000 mass parts; the copper ingots account for 2 to 4 mass parts; the vanadium ingots account for 0.4 to 0.8 mass parts; the silicon iron accounts for 2.5 to 5 mass parts; the ferromanganese iron alloy accounts for 35 to 45 mass parts; the ferro phosphorus accounts for 10 to 25 mass parts. C, Mn, V, Cu and Fe are compounded to be prepared into alloy; the intensity of the threaded streel can be effectively improved; meanwhile, the toughness of the threaded steel cannot be influenced.

Owner:广州广钢新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com