Smelting method of welding rod steel H08Mn

A smelting method and welding rod steel technology, applied in the field of iron and steel metallurgy, can solve the problems of poor pourability of molten steel, oxygenation of molten steel, etc., achieve the effects of reducing the amount of formation, stabilizing oxygen content, and controlling bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

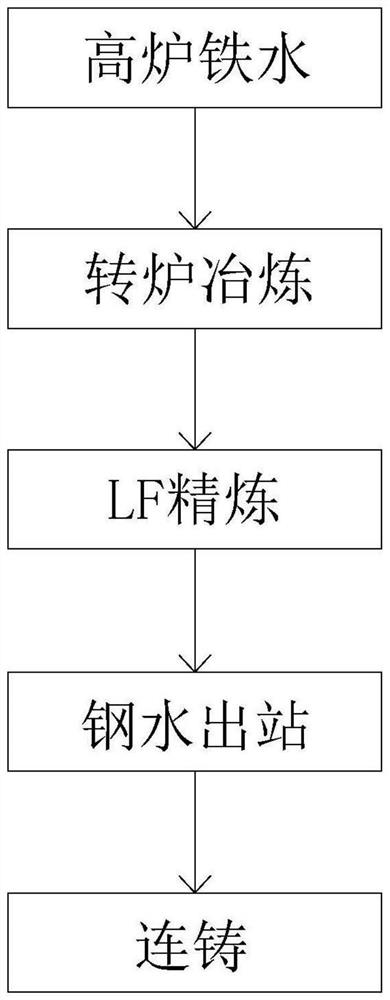

[0040] Such as figure 1 As shown, the welding rod steel H08Mn is smelted through converter smelting, LF refining, and continuous casting. The specific operation is as follows: the blast furnace molten iron is smelted through the converter to control the carbon content at the end point to 0.03%, and the tapping process uses Al-Mn-Fe alloy for pre-deoxidation, Al-Mn-Fe alloy The addition amount is 4kg / t, 11kg / t of medium-carbon ferromanganese, 3kg / t of active lime, 0.0057% of the refining furnace entering the station to fix oxygen; 0.6kg / t of refining slagging agent is added to the refining furnace according to the condition of oxygen fixing, and aluminum Line 0.16kg / t, heat up for 16 minutes once, oxygen 0.0043%; add refining slagging agent 0.4kg / t before the second temperature rise, feed aluminum wire 0.05kg / t, heat up 8 minutes for the second time, fix oxygen 0.0062%, Add 1.4kg / t of medium-carbon ferromanganese alloy during the heating process; add 0.2kg / t refining slagging a...

Embodiment 2

[0043] Welding rod steel H08Mn is smelted through converter smelting, LF refining, and continuous casting. The specific operation is: the blast furnace molten iron is smelted through the converter to control the carbon content at the end point to 0.03%. The tapping process uses Al-Mn-Fe alloy for pre-deoxidation. 4.5kg / t, add medium carbon ferromanganese 11kg / t, active lime 3kg / t, refining furnace fixed oxygen 0.0038%; add refining slagging agent 0.4kg / t before heating up once, feed aluminum wire 0.05kg / t Heat up for 10 minutes, set oxygen at 0.0073%; add refining slagging agent 0.6kg / t before the second temperature rise, feed aluminum wire 0.14kg / t, heat up for the second time for 8 minutes, set oxygen at 0.0031%, add medium-carbon manganese during the second temperature rise Iron 1.2kg / t; heating up for three times for 4 minutes, fixed oxygen 0.0045%, molten steel Als content 0.0059%, feeding silicon-calcium wire 0.69kg / t, soft blowing for 11 minutes and leaving the station; ...

Embodiment 3

[0046] Welding rod steel H08Mn is smelted through converter smelting, LF refining, and continuous casting. The specific operation is: the blast furnace molten iron is smelted through the converter to control the carbon content at the end point to 0.04%. 4.1kg / t, add medium carbon ferromanganese 11kg / t, active lime 3kg / t, refining furnace fixed oxygen 0.0053%; add refining slagging agent 0.4kg / t before heating up once, feed aluminum wire 0.08kg / t, once Heat up for 10 minutes, set oxygen at 0.0042%; add refining slagging agent 0.4kg / t before the second temperature rise, feed aluminum wire 0.03kg / t, heat up for the second time for 7 minutes, set oxygen at 0.0048%, add medium-carbon manganese during the second temperature rise Iron 2kg / t; three times of heating for 3 minutes, fixed oxygen 0.0048%, molten steel Als content 0.0047%, feeding silicon-calcium wire 0.52kg / t, soft blowing for 10 minutes and then leaving the station; the continuous casting process uses a 150mm×150mm sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com