Method for preparing silicon inverse epitaxial wafer and special equipment thereof

A manufacturing method and technology for silicon epitaxial wafers, applied in chemical instruments and methods, from chemical reactive gases, single crystal growth, etc., can solve the problems of low concentration, no large, thick epitaxial layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is described in detail below:

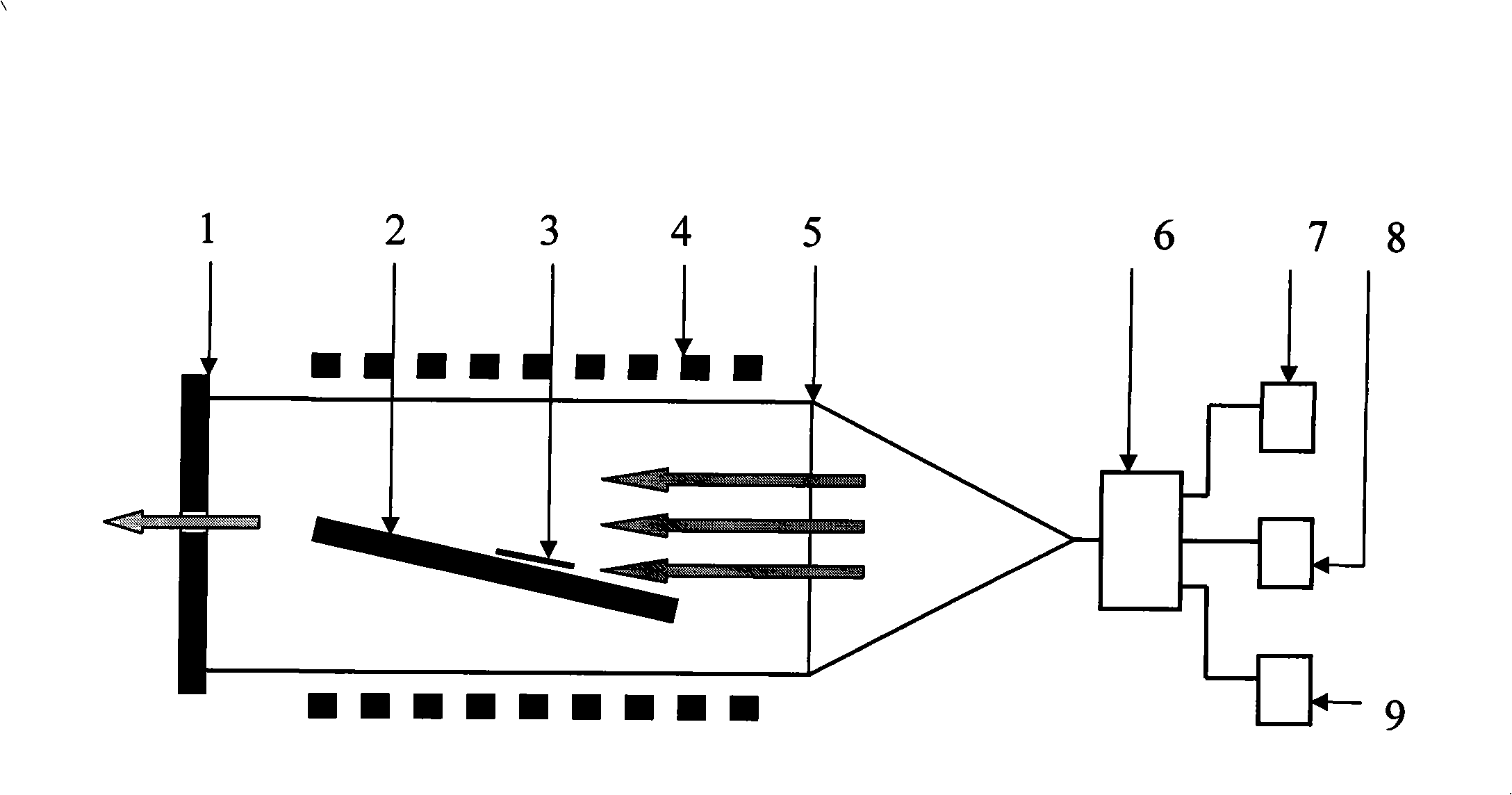

[0017] The used special equipment of the present invention is referring to figure 1 , H 2 Supply source 7, SiHCL 3 and PCl 3 The source 8 and the HCL source 9 are connected to the reactor 5 through the gas control system 6, the reactor 5 is sealed by the reactor sealing cover, the high frequency heating coil 4 is arranged around the reactor 5, and the base 2 is installed in the reactor 5. The reactor 5 is made of a rectangular quartz tube, and the base 2 is made of high-purity graphite after cracking treatment. The size is 80mm×200mm×10mm. The included angle is conducive to high-frequency induction heating, and the temperature of the graphite base can reach 1200 °C. Palladium Tube Furnace for Hydrogen Purifier.

[0018] Reactor and substrate cleaning: The quartz reaction tube and the quartz support must be carefully cleaned before epitaxy to remove impurities and residues adsorbed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com