Polyethylene foaming material preparation method and polyethylene foaming material prepared by preparation method

A technology for polyethylene foaming and low-density polyethylene, which is applied in the petrochemical field, can solve the problems such as the inability to effectively control the foaming stability of polyethylene resin, the inability to prepare uniform cells, the cumbersome preparation method, and the like, and the preparation method is simple and easy. Effects of handling, cell uniformity, thickness dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] As described in the background technology section, the existing preparation methods of polyethylene foam materials are cumbersome and difficult to operate, cannot effectively control the foam stability of polyethylene resin, and cannot prepare foams with uniform cells, high expansion ratio, and thicker thickness. And the problem of polyethylene foam material with excellent dimensional stability. In order to solve the above problems, the present invention provides a method for preparing a polyethylene foam material, the preparation method comprising the following steps: (a) mixing the matrix resin with a processing aid to form a mixture; (b) extruding the mixture Forming the parison; (c) preheating the parison at a temperature of 110°C to 150°C for 10 to 30 minutes, and heating the preheated parison at a temperature of 190°C to 230°C and a pressure of 0.05MPa to 0.2MPa Carry out crosslinking and foaming, and cool and shape the parison after crosslinking and foaming at a ...

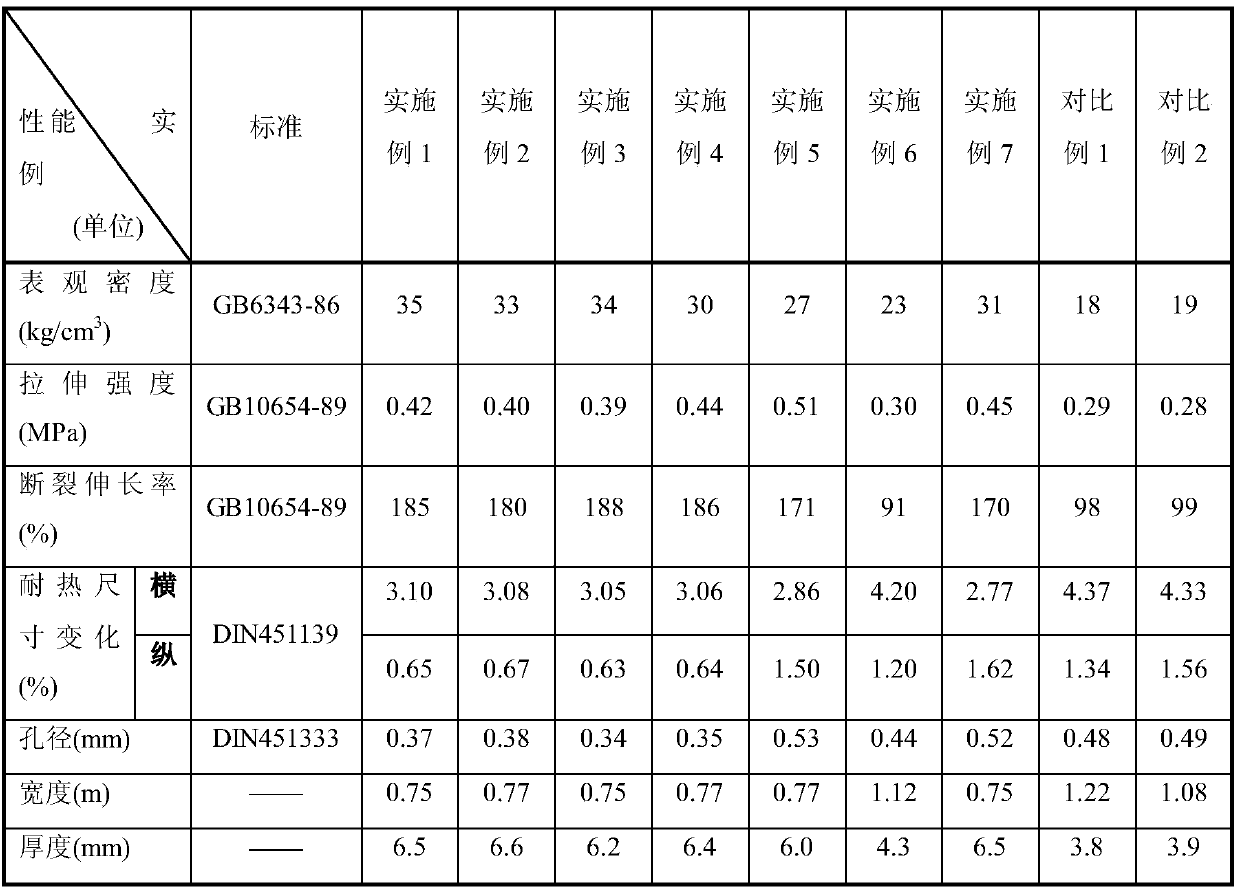

Embodiment 1

[0040] Mix low-density polyethylene (LDPE) and processing aids uniformly through a high-speed mixer, then melt and extrude granules through a twin-screw extruder, control the extrusion temperature at 135°C, and then pass the granulated pellets through the extruder A secondary extrusion into a sheet was performed at an extrusion temperature of 135°C. Place the sheet in a foaming device (industrial tubular foaming furnace provided by Shanghai Shengzhong Furnace Industry Co., Ltd.) for preheating at a temperature of 150°C, and then enter the crosslinking and foaming section at a temperature of 220°C , the pressure is 0.2MPa, and the foaming time is 7min. Finally, the foamed sheet is obtained by cooling and shaping at 60°C and normal pressure. See Table 1 for the formula based on 100 parts by weight of the matrix resin, and see Table 2 for the sample performance test results and test standards.

Embodiment 2

[0042] Mix low-density polyethylene (LDPE) and processing aids uniformly through a high-speed mixer, then melt and extrude granules through a twin-screw extruder, control the extrusion temperature at 135°C, and then pass the granulated pellets through the extruder A secondary extrusion into a sheet was performed at an extrusion temperature of 135°C. Place the sheet in a foaming device (industrial tubular foaming furnace provided by Shanghai Shengzhong Furnace Industry Co., Ltd.) for preheating at a temperature of 110°C, and then enter the crosslinking and foaming section at a temperature of 230°C , the pressure is 0.05MPa, and the foaming time is 7min. Finally, the foamed sheet is obtained by cooling and shaping at 70°C and normal pressure. See Table 1 for the formula based on 100 parts by weight of the matrix resin, and see Table 2 for the sample performance test results and test standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com