Dedicated submerged-arc welding flux for petroleum pipeline

A submerged arc flux, oil pipeline technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high price, lack of mature products, etc., to improve the intergranular structure, improve comprehensive performance, The effect of improving low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

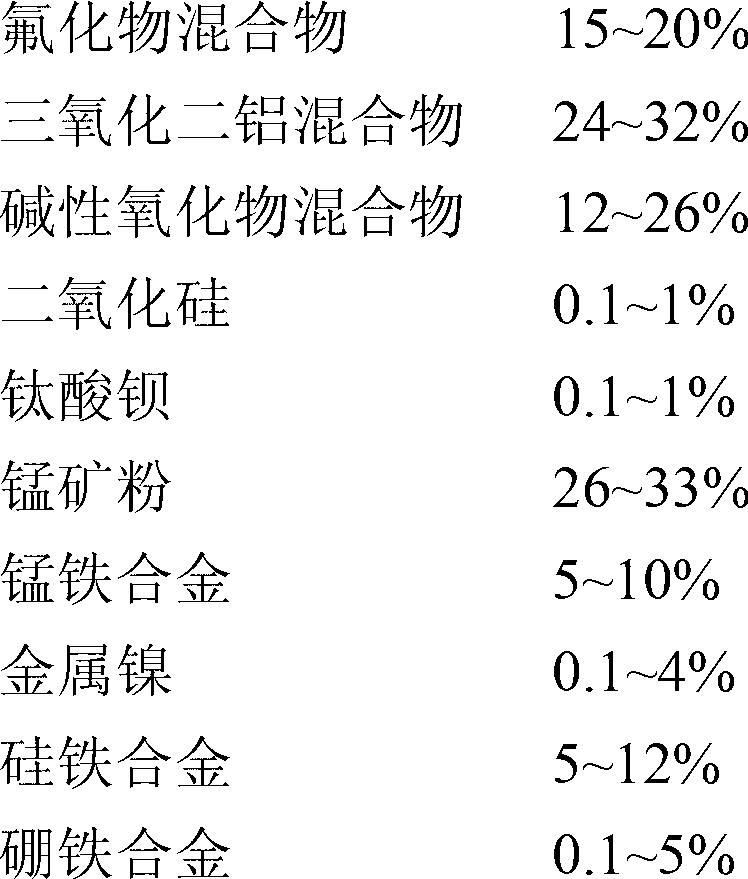

[0026] (1) The weight percentages of various raw materials in the flux powder are as follows: (%)

[0027] calcium fluoride barium fluoride Bauxite Calcined α-alumina White corundum magnesium oxide Calcium Oxide 8 8 7 10 9 8 5 silica Barium titanate Manganese ore powder ferromanganese alloy Metal nickel ferrosilicon alloy Ferro-boron alloy 0.8 0.2 28 6 2 7 1

[0028] Among them, the content of MnO in manganese ore powder is ≥62%, the content of Si in ferrosilicon alloy is ≥72%, and the content of B in ferroboron alloy is ≥15%.

[0029] (2) The binder is high modulus potassium sodium water glass, the modulus is 3.0-3.1, and the ratio of potassium to sodium is 2:1.

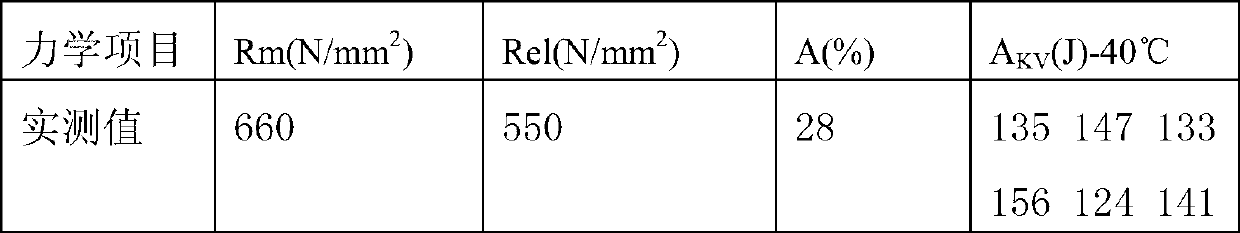

[0030] (3) The submerged arc welding flux was prepared according to the above components for inspection. According to the national standard GB / T 12470-2003, with the submerged arc welding wire H08MnMoTiB for oil pipelines, the chemical composition analysi...

Embodiment 2

[0036] (1) The weight percentages of various raw materials in the flux powder are as follows: (%)

[0037] calcium fluoride barium fluoride Bauxite Calcined α-alumina White corundum magnesium oxide Calcium Oxide 7 9 7 9 10 8 5 silica Barium titanate Manganese ore powder ferromanganese alloy Metal nickel ferrosilicon alloy Ferro-boron alloy 0.8 0.2 28 6 2 7 1

[0038] Among them, the content of MnO in manganese ore powder is ≥62%, the content of Si in ferrosilicon alloy is ≥72%, and the content of B in ferroboron alloy is ≥15%.

[0039] (2) The binder is high modulus potassium sodium water glass, the modulus is 3.0-3.1, and the ratio of potassium to sodium is 2:1.

[0040] (3) The submerged arc welding flux was prepared according to the above components for testing. According to the national standard GB / T 12470-2003, with the submerged arc welding wire H08MnMoTiB for oil pipelines, the chemical composition analysis o...

Embodiment 3

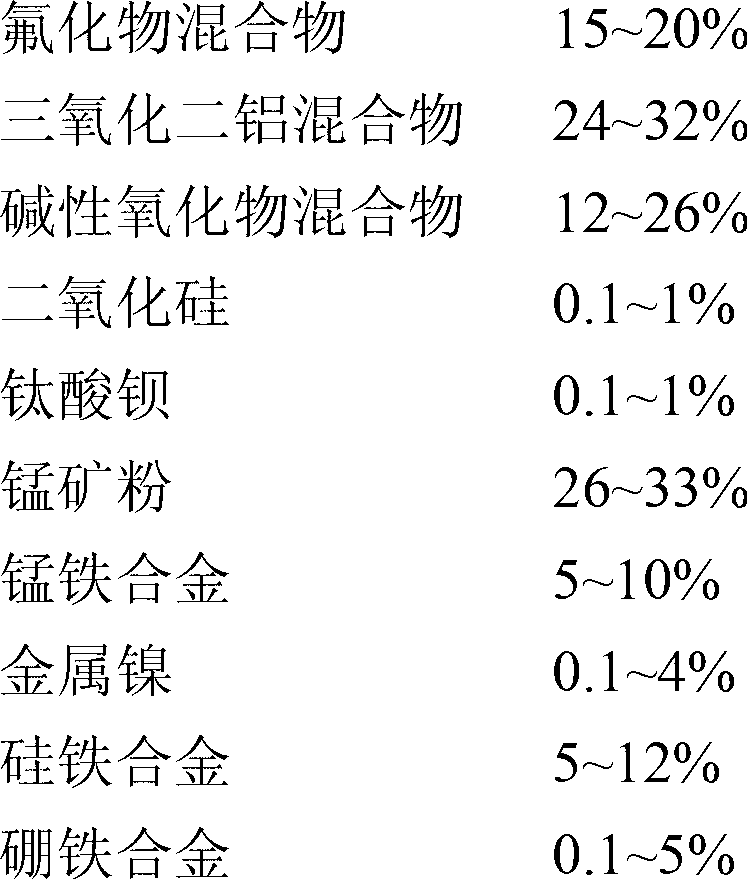

[0046] (1) The weight percentages of various raw materials in the flux powder are as follows: (%)

[0047] calcium fluoride barium fluoride Bauxite Calcined α-alumina White corundum magnesium oxide Calcium Oxide 8 8 7 10 9 6 7 silica Barium titanate Manganese ore powder ferromanganese alloy Metal nickel ferrosilicon alloy Ferro-boron alloy 1 0.2 28 6 2 7 0.8

[0048] Among them, the content of MnO in manganese ore powder is ≥62%, the content of Si in ferrosilicon alloy is ≥72%, and the content of B in ferroboron alloy is ≥15%.

[0049] (2) The binder is high modulus potassium sodium water glass, the modulus is 3.0-3.1, and the ratio of potassium to sodium is 2:1.

[0050] (3) The submerged arc welding flux was prepared according to the above components for inspection. According to the national standard GB / T 12470-2003, with the submerged arc welding wire H08MnMoTiB for oil pipelines, the chemical composition analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com