Patents

Literature

287 results about "Basic oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basic oxides are oxides that show basic properties in opposition to acidic oxides and that either...

Low carbon alkane dehydrogenation catalyst and its preparation method and application

ActiveCN103769079AHigh activityHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The invention discloses a low carbon alkane dehydrogenation catalyst and its preparation method and application. The low carbon alkane dehydrogenation catalyst uses La-containing alumina as a carrier, and chromium as an active component, taking the weight content of oxides as a reference, the lanthanum oxide content in the final catalyst is 0.1 to 5.0%, the chromium oxide content is 5.0% to 20.0%, and La in the La-containing alumina carrier is introduced in during gelatinizing in the alumina preparation process. The preparation method of the low carbon alkane dehydrogenation catalyst comprises the following steps: preparation of the La-containing Al2O3 carrier and a process of loading active component chromium by an impregnation method. The low carbon alkane dehydrogenation catalyst can be used in production of propylene by dehydrogenation of propane. The low carbon alkane dehydrogenation catalyst prepared by the method does not contain alkaline oxides to avoid strong interaction between the alkaline oxides and the active component, and the activity, stability and propylene selectivity of the low carbon alkane dehydrogenation catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the production of a hydrogen rich gas

InactiveUS20010055560A1Less corrosiveImprove energy efficiencyHydrogenMolecular sieve catalystsHydrogenProduct gas

Process for the production of a hydrogen rich gas without formation of hydrocarbons comprising water gas shift conversion of a gas containing carbon monoxide and steam at a temperature of between 400° C. and 850° C. in the presence of a catalyst, which catalyst comprises one or more of the elements Mg, Mn, Al, Zr, La, Ce, Pr, and Nd, being able to form basic oxides, and mixtures thereof.

Owner:HALDOR TOPSOE AS

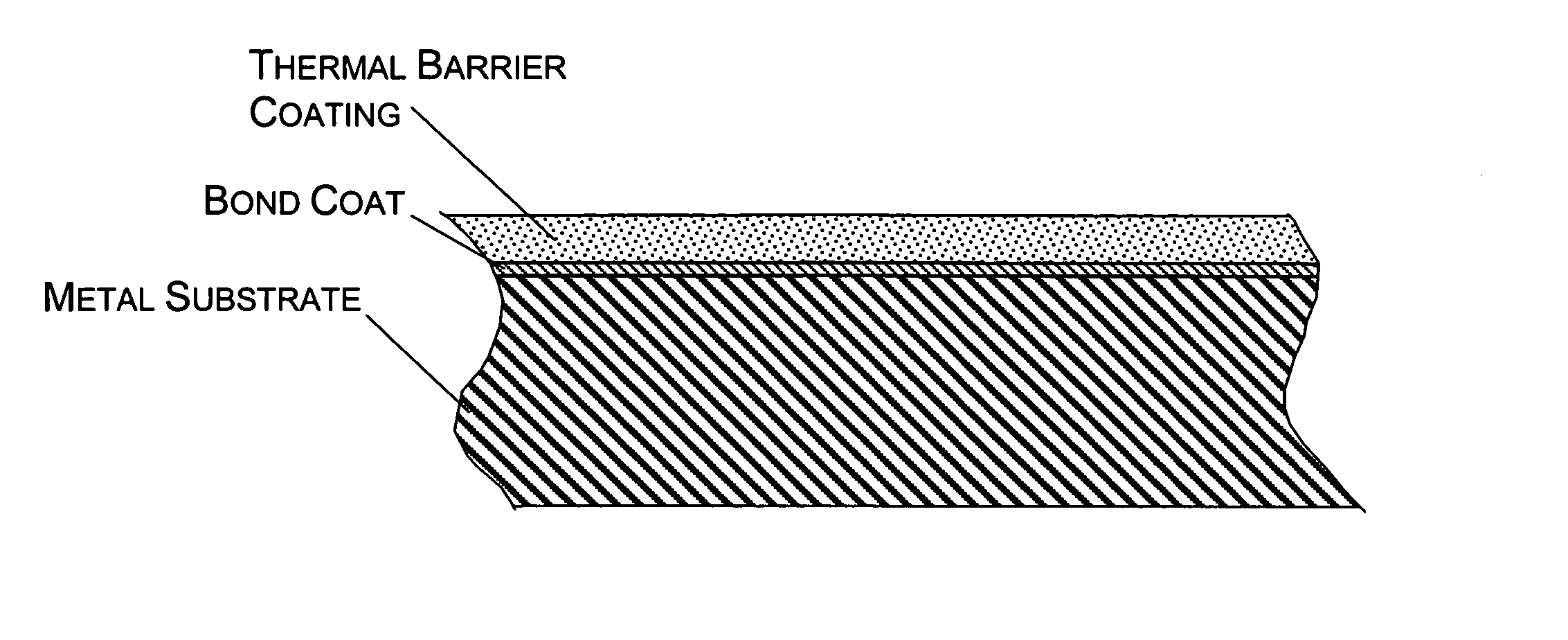

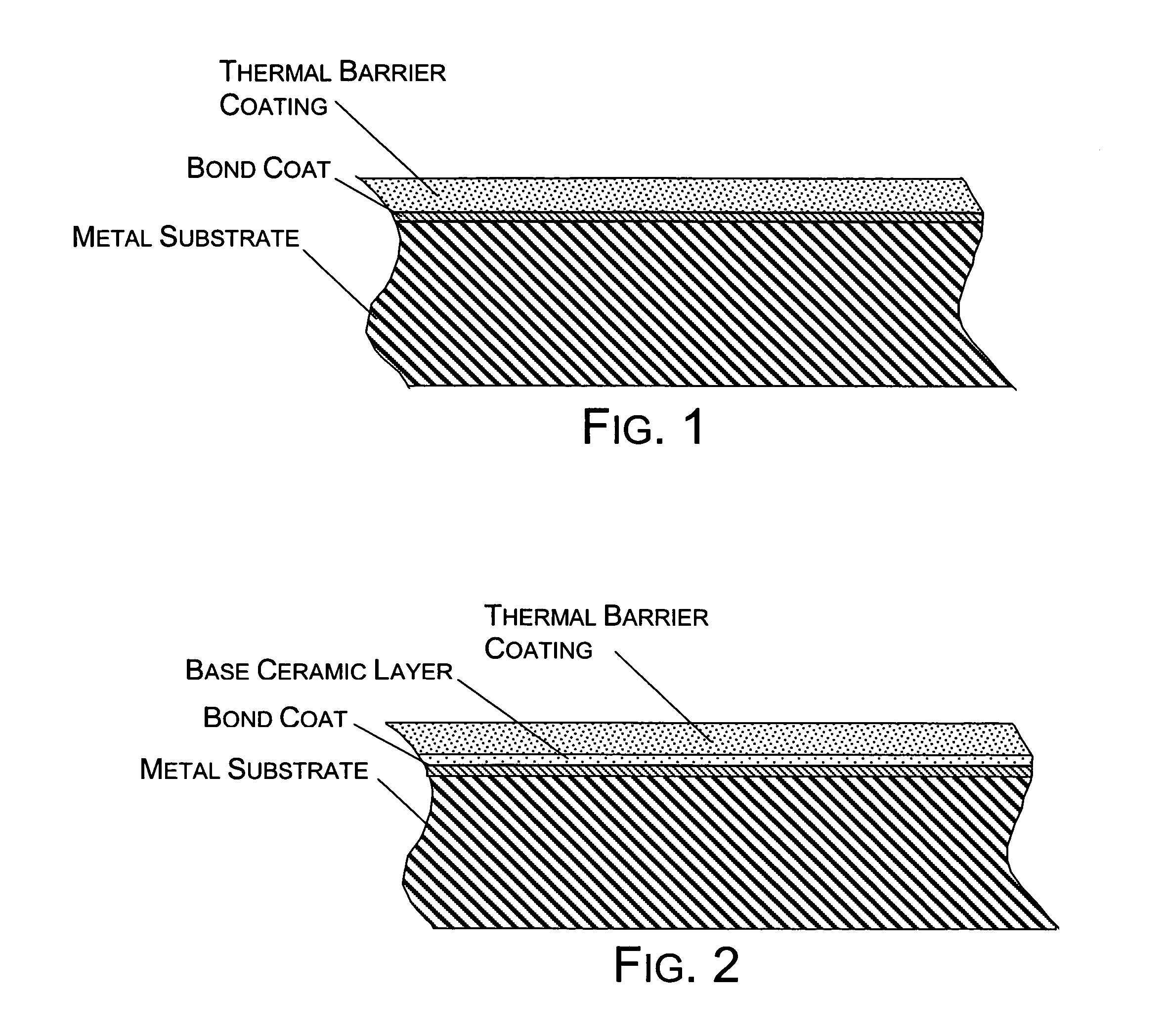

Low conductivity and sintering-resistant thermal barrier coatings

A thermal barrier coating composition is provided. The composition has a base oxide, a primary stabilizer, and at least two additional cationic oxide dopants. Preferably, a pair of group A and group B defect cluster-promoting oxides is used in conjunction with the base and primary stabilizer oxides. The new thermal barrier coating is found to have significantly lower thermal conductivity and better sintering resistance. In preferred embodiments, the base oxide is selected from zirconia and hafnia. The group A and group B cluster-promoting oxide dopants preferably are selected such that the group A dopant has a smaller cationic radius than the primary stabilizer oxide, and so that the primary stabilizer oxide has a small cationic radius than that of the group B dopant.

Owner:OHIO AEROSPACE INST

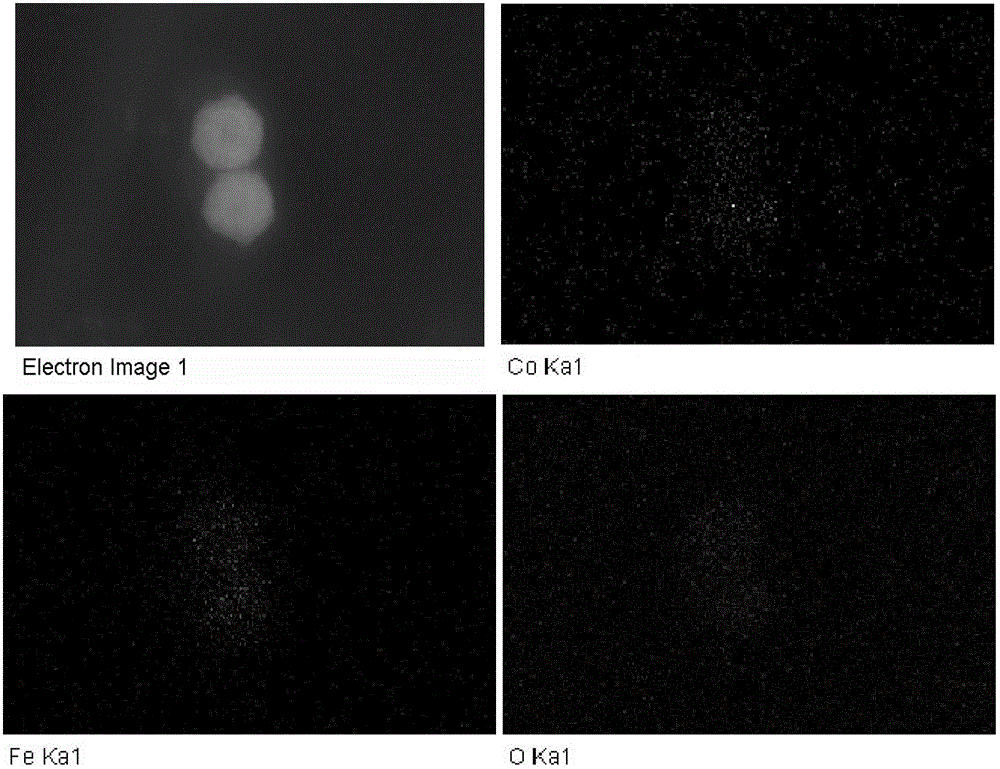

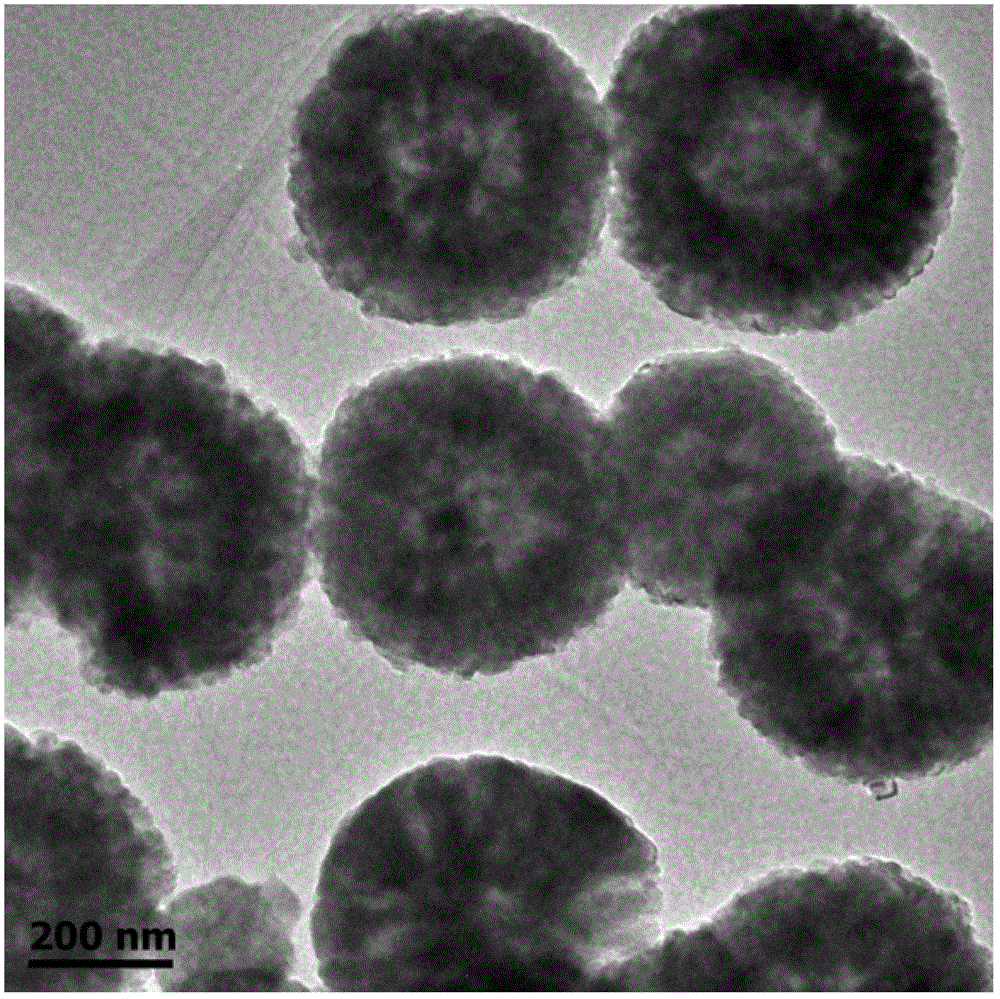

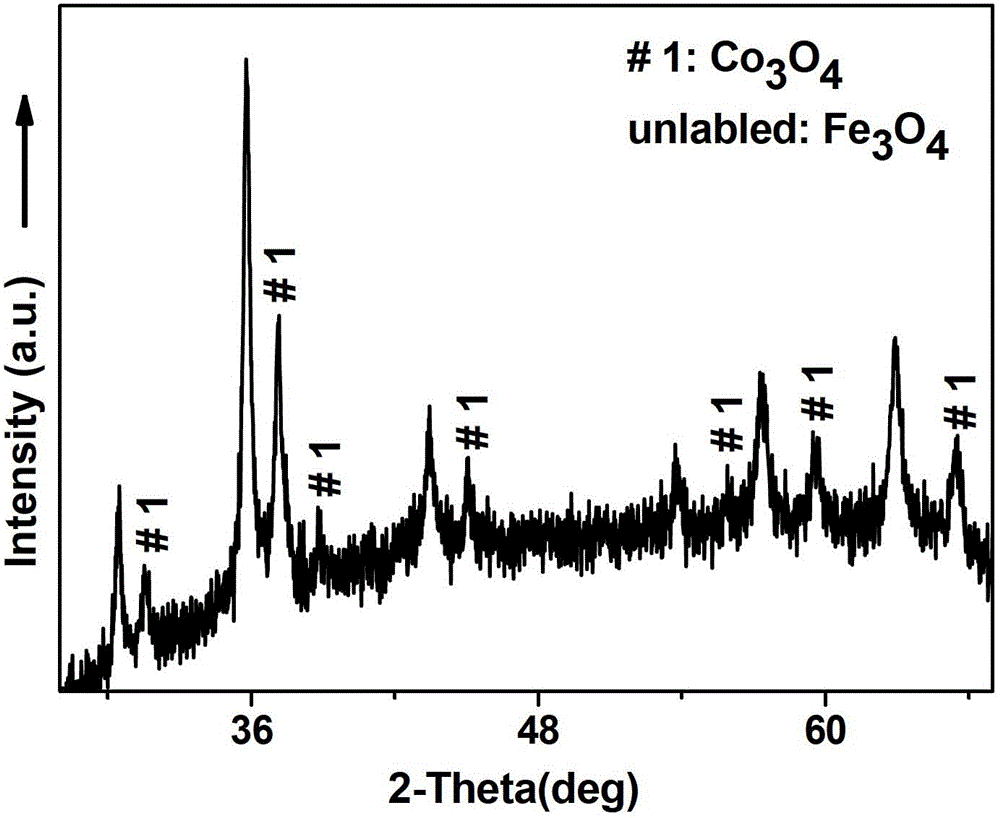

Hollow magnetic nano-grade composite catalytic material and preparation method thereof

ActiveCN102744067ARich varietyRapid responseMetal/metal-oxides/metal-hydroxide catalystsAlcoholPolyol

The invention discloses a hollow magnetic nano-grade composite catalytic material MOx(OH) / ferrite magnetic nano-cluster and a preparation method thereof. According to the invention, metal salt and ferrite magnetic nano-cluster with certain amounts are added into appropriate micro-molecular monohydric alcohol or polyhydric alcohol; the mixture is subjected to heat treatment for a certain period of time under a certain temperature; an obtained product is subjected to magnetic separation-washing, and drying treatment, such that the inorganic nano-grade composite material hollow MOx(OH) / ferrite magnetic nano-cluster is obtained, wherein MOx(OH) is one or a mixture of more than two selected from metal oxide, composite oxide, basic oxide, and metal. The invention provides a simple and pervasive preparation method. With the invention, several types of novel hollow magnetic nano-grade composite catalytic materials are obtained. A novel idea is provided for the preparations of magnetic nano-grade composite catalytic materials. A catalytic performance of the material is evaluated in a benzyl alcohol oxidation system, and a research basis is provided for industrialized application of the material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

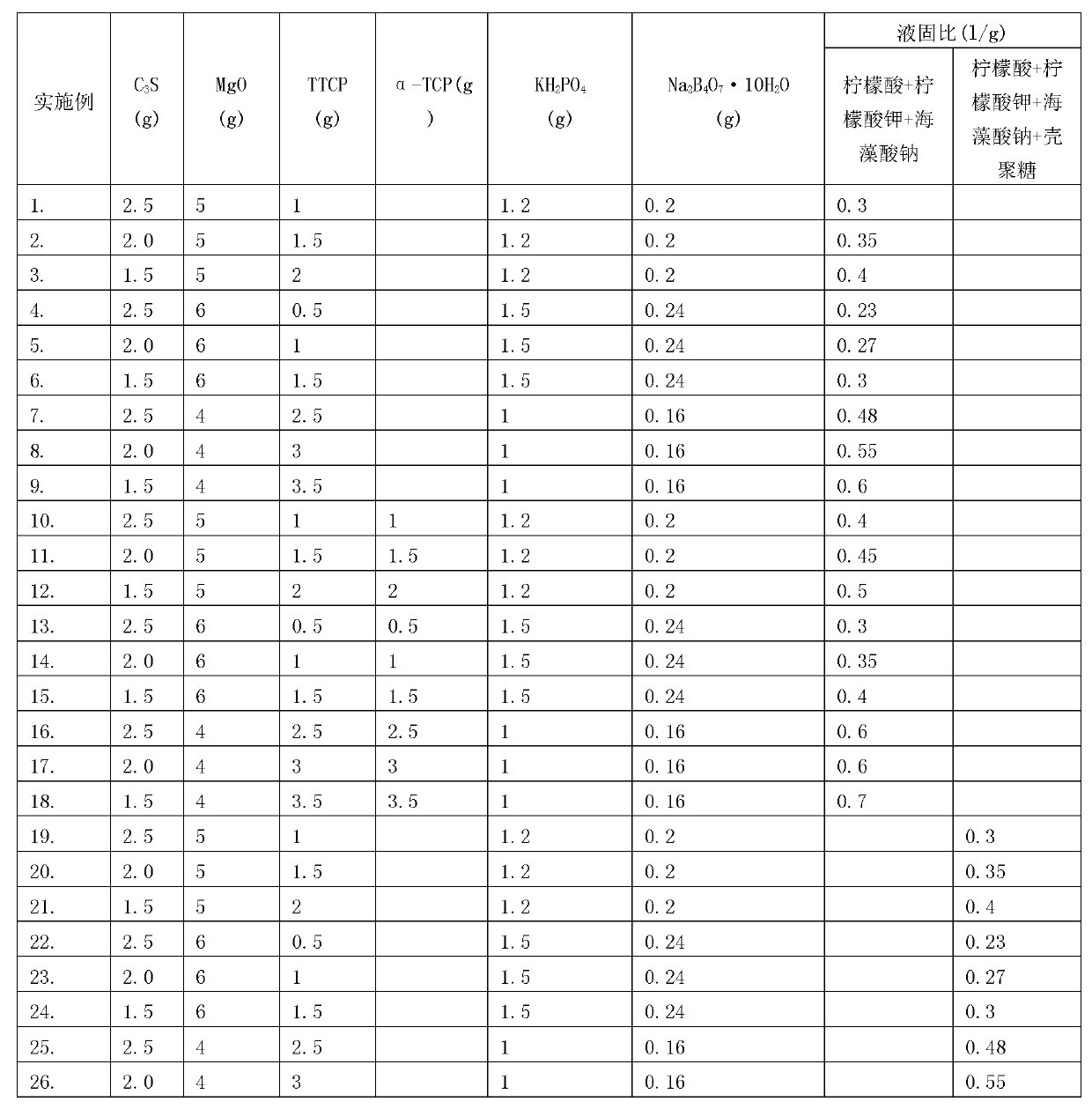

Self-setting composite bone repair material for human body hard tissue repair and application

The invention discloses a self-setting composite bone repair material for human body hard tissue repair and application. The self-setting composite bone repair material comprises solid-phase powder and a liquid phase, wherein the solid-phase powder contains 5-20% of tricalcium silicate, 30-70% of electric smelting magnesium oxide, 5-30% of calcium phosphate bone cement, 5-30% of potassium dihydrogen phosphate or ammonium dihydrogen phosphate, and retarder accounting for 2-10% of the weight of basic oxide, i.e. magnesium oxide; the liquid phase is selected from one or a mixture of more than one of deionized water, soluble phosphate, sodium alginate, citric acid, potassium citrate and chitosan; and the ratio of the liquid phase to the solid phase is 0.3-0.8ml / g, and the solid-phase powder and the liquid phase are uniformly blended. The bone cement material has good combination property; and as the initial setting time of the bone cement material is 3-20 minutes, the final settling time is 7-50 minutes, and the compressive strength is 10-50Mpa in 24 hours and 20-90Mpa in 72 hours, the bone cement material can meet the requirement of clinical application and is suitable for treating bone defect repair and osteoporosis and fixing and treating bone fractures in orthopedic departments, spine surgery, plastic surgery and stomatological departments.

Owner:HENAN POLYTECHNIC UNIV

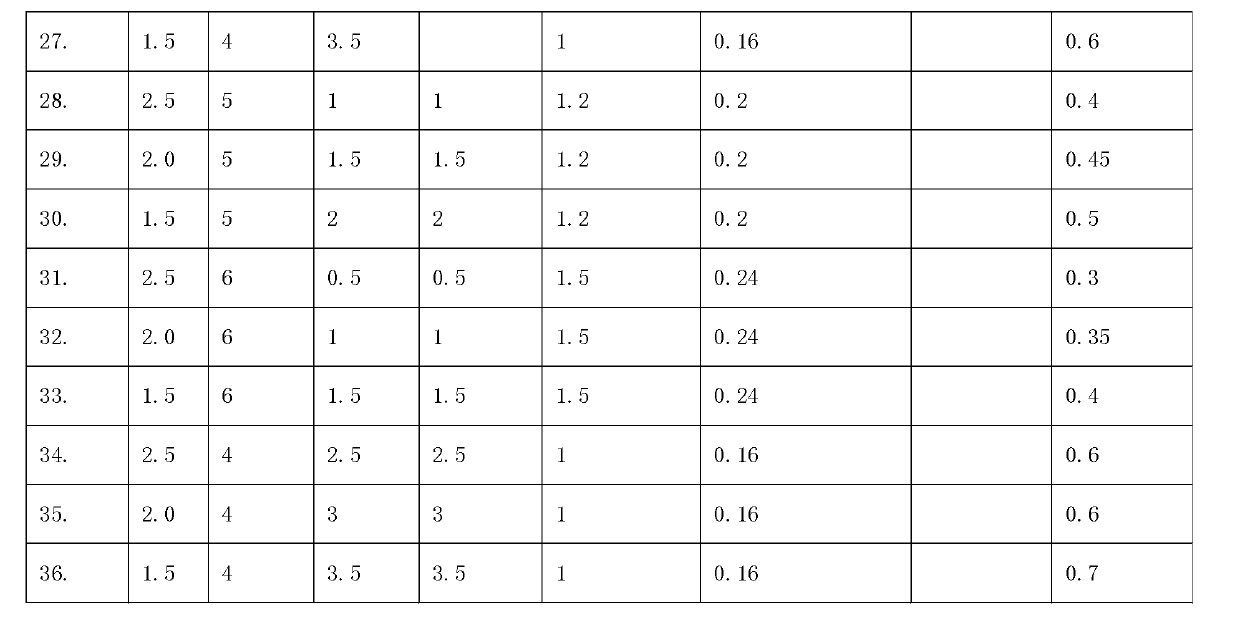

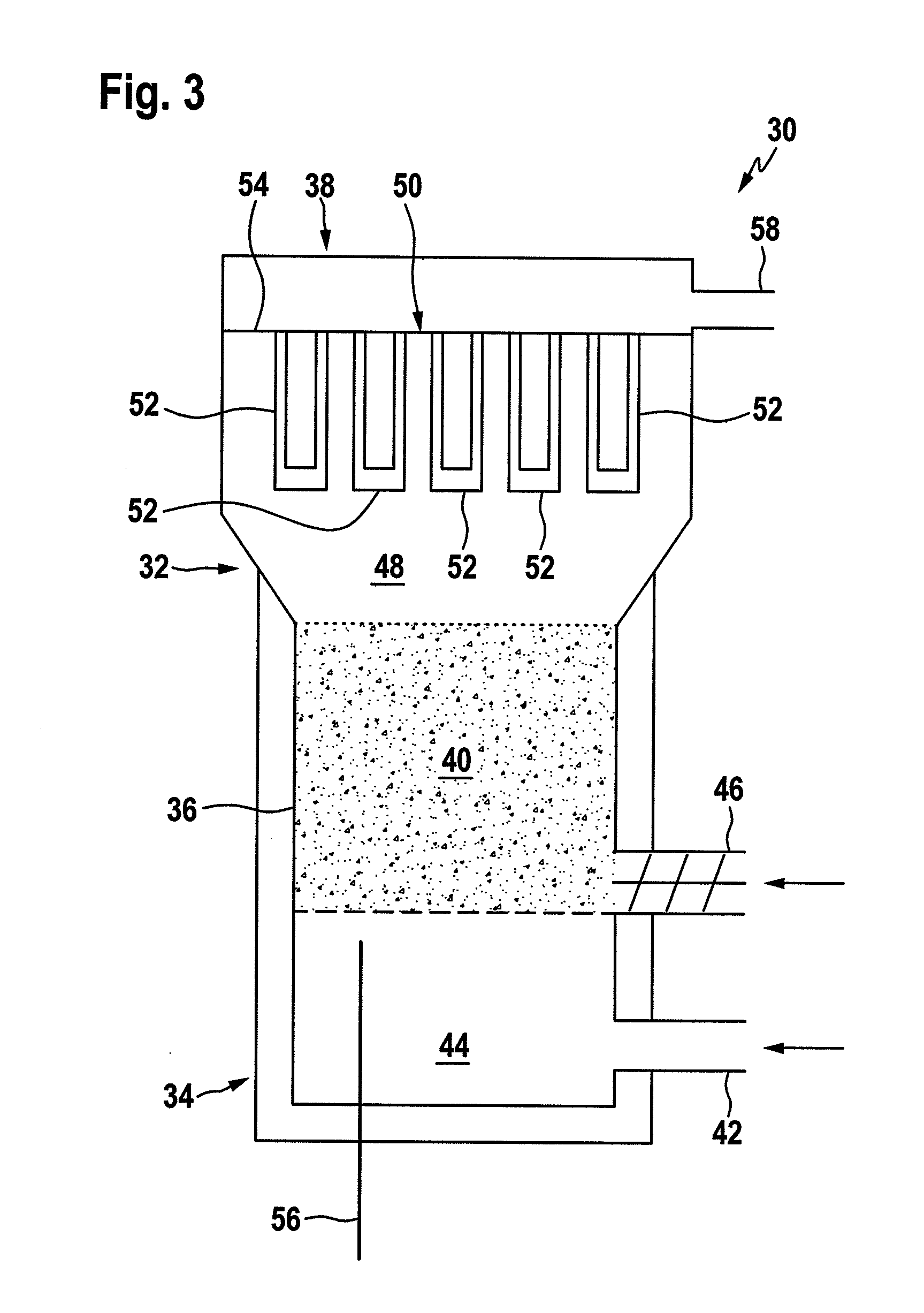

Method and device for treating steel slag

ActiveCN103757152ARealize comprehensive utilizationDigest free calcium oxideCement productionRecycling and recovery technologiesSlagQuenching

The invention provides a method for treating steel slag. The method comprises the steps of feeding silicon-aluminum acidic oxide and steel slag, wherein the total mole ratio of the silicon-aluminum acidic oxide to basic oxide in the mixture is 1:(2.5-2.9); heating and mixing the mixture in a rotary kiln in the presence of a reducing agent, wherein the temperature of the rotary kiln is 1350-1450 DEG C; granulating the product into particles, performing water quenching and cooling, then falling the particles into water, and performing dehydration; and performing magnetic separation on the dehydrated particles to ensure that steel particles are separated from series silicate particles. The invention also provides a device for treating the steel slag, and the device comprises a rotary kiln (5), a coal spraying device (6) which is arranged at the upper end of the tail of the rotary kiln (5), and a granulation wheel (8) which is arranged below a discharge chute (7) in the lower end of the tail of the rotary kiln (5). The series silicates obtained after the treatment of the steel slag by adopting the method disclosed by the invention can replace a silicate cement clinker to produce cement. The method disclosed by the invention realizes comprehensive utilization of industrial wastes.

Owner:BERIS ENG & RES CORP

Steel slag treating method

ActiveCN102559960AEliminate hazardsSafe useRecycling and recovery technologiesThermal energyCalcium silicate

The invention provides a steel slag treating method comprising the following steps of: directly mixing thermal-state revolving furnace steel slag with blast furnace slag in an arc furnace in proportion, adjusting the molten slag in the furnace into a proper temperature by virtue of the arcing of the arc furnace, and stirring the molten slag by virtue of arc disturbance, so that acidic oxide and basic oxide in the molten slag are sufficiently reacted with each other; reacting free calcium oxide and free magnesium oxide in the raw steel slag with silicon dioxide component and low-calcium calcium silicate in the blast furnace slag to generate safe calcium silicate and magnesium silicate, quenching the molten slag to form glass-state solid slag which is higher in hydration reactivity and free of short-term or long-term inflation harm, and further finely grinding the solid slag into slag powder which can be safely used for related building material as the blast furnace slag. According to the method, the damage caused by the free calcium oxide and free magnesium oxide in the steel slag can be removed, and a basis is provided for the whole use of the steel slag. The heat energy of the thermal-state molten slag can be sufficiently used, so that the energy source can be saved, the energy consumption can be reduced, the cost can be reduced, and the discharge of CO2 can be reduced, and the method is extremely high in social meaning and economic meaning.

Owner:北京联合荣大工程材料股份有限公司

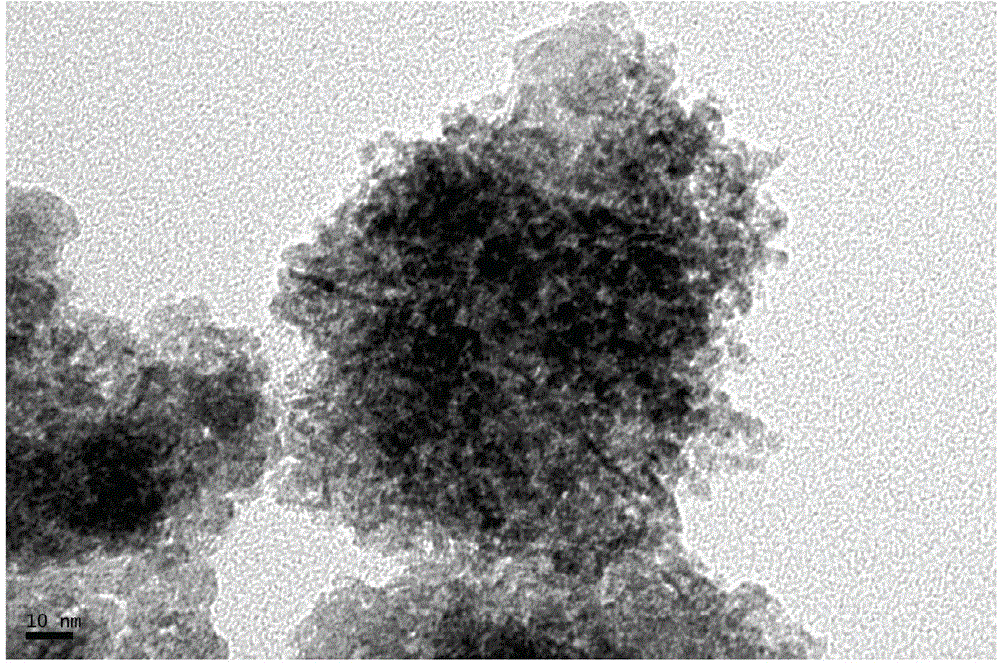

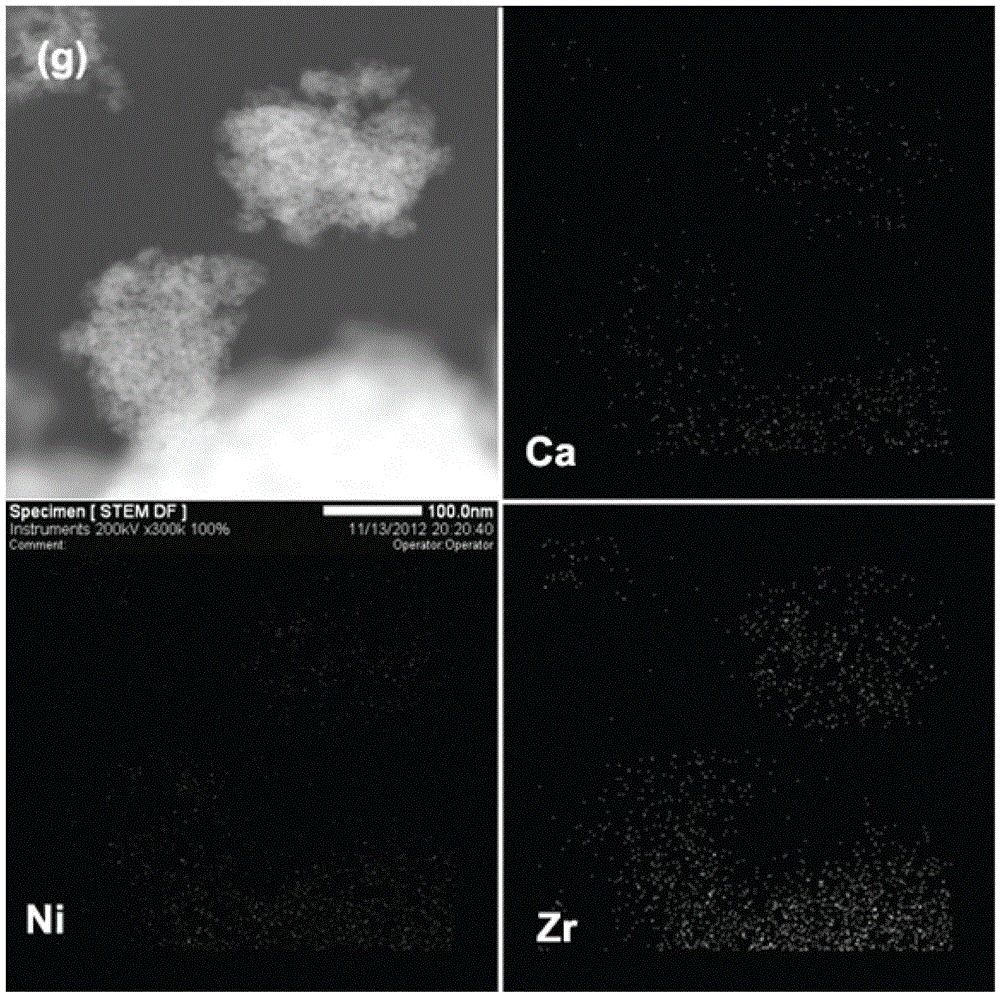

High-dispersion nano-composite catalyst, and preparation method and applications thereof

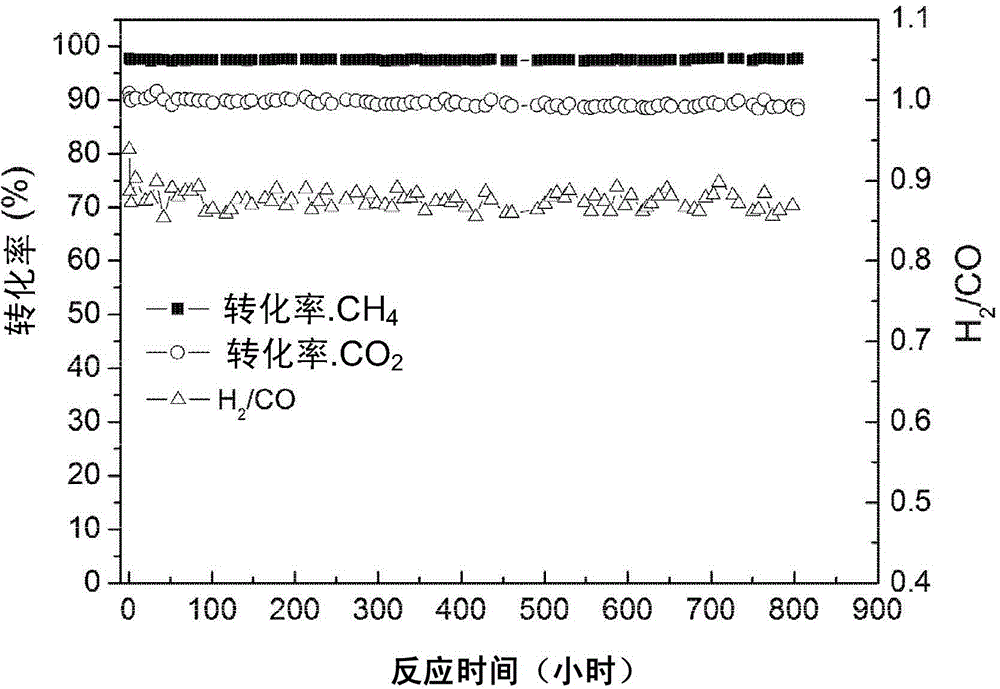

InactiveCN103143364AImprove stabilityHigh activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsAdditive ingredientNanometre

The invention discloses a high-dispersion nano-composite catalyst, and a preparation method and applications thereof. The high-dispersion nano-composite catalyst comprises nano-composite with the dimension of 1-10nm, according to the total weight of the composite as standard, the composite comprises ingredients in percentage by weight: 1-20% of reactive metal oxide, 0-20% of basic oxide promoter, 0-20% of oxidized reducing auxiliary, and 40-99% of zirconium dioxide carriers, the weight percentage sum of the ingredients is 100%. The catalyst has the advantages of being high in dry reforming catalytic activity of methane, good in stability, strong in sintering resistance capability, difficult for carbon accumulation and simple in process, and the like, when being used for reaction of the dry reforming of methane through carbon dioxide.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Method for producing multiplex siliceous fertilizer from molybdenum mine tailings

InactiveCN101050140ASolve the problem of polluted groundwaterAchieve reuseCement productionFertilizer mixturesDolomiteQuenching

This invention discloses a method for producing multi-element silicon fertilizer from molybdenum tailing and dolomite or high-magnesium limestone. The method comprises: calculating the equivalents of acidic oxides and alkaline oxides in molybdenum tailing, dolomite or high-magnesium limestone, and anthracite or white coal, calculating the coal amount for greater than or equal to 1200 deg.C kiln temperature, calculating the amounts of molybdenum tailing and dolomite or high-magnesium limestone at an acidic oxides / alkaline oxides weight ratio of 1:2, mixing with coal, adding calcination additive containing 0.2-1% alkali metal ions, grinding to higher than 80 mesh fine powder, adding into a shaft kiln, calcining at 1200-1350 deg.C to obtain silicon fertilizer clinker, or adding into a pelletizer, adding water, palletizing, calcining at 1200 deg.C or higher to obtain silicon fertilizer clinker, quenching and pulverizing to obtain multi-element silicon fertilizer.

Owner:锦州沈宏集团股份有限公司

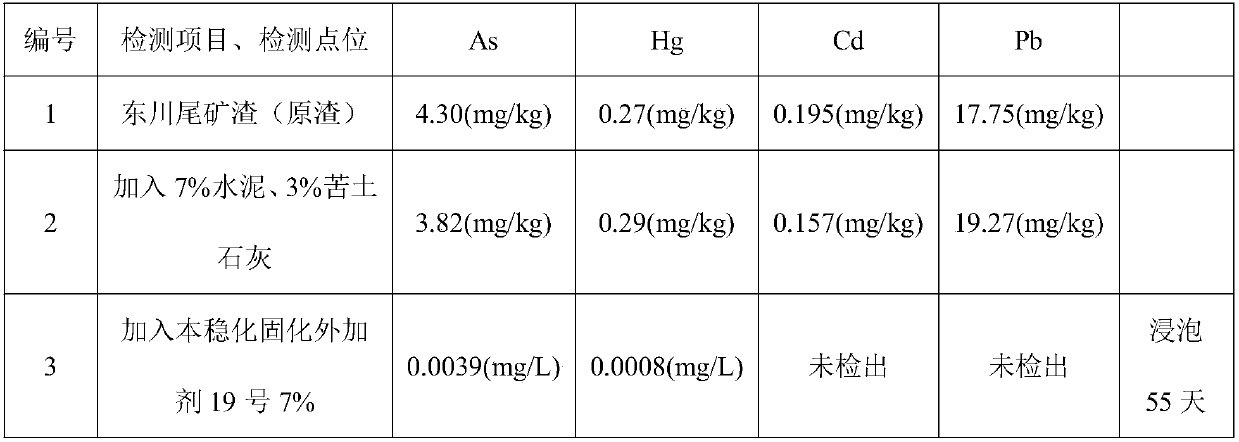

Detoxifying method of dioxin and heavy metal in waste incineration fly ash

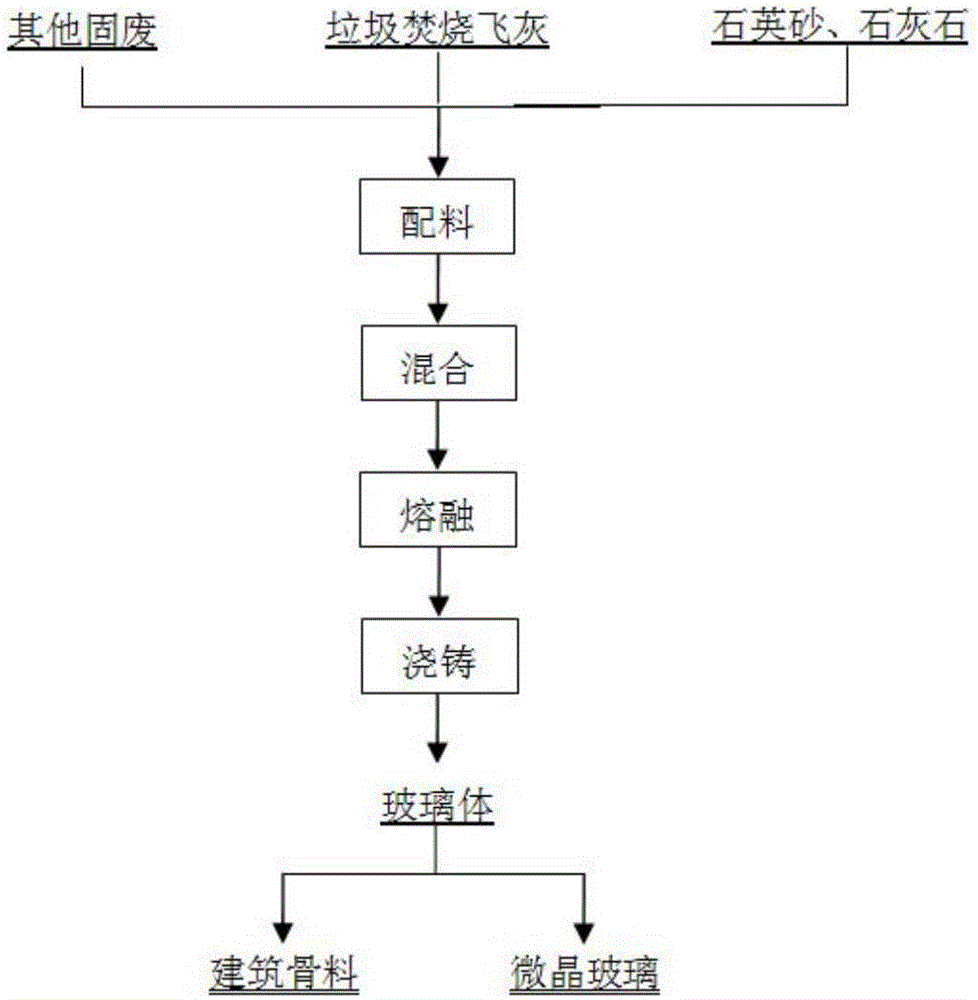

InactiveCN106824983AAvoid resynthesisLow leaching rateSolid waste disposalTransportation and packagingFly ashIncineration

The invention mainly belongs to the field of solid waste disposing and recycling and particularly relates to a detoxifying method of dioxin and heavy metal in waste incineration fly ash. According to the method, the waste incineration fly ash serves as a raw material, auxiliary materials containing alkaline oxides are added, and mixing materials are obtained after mixing. The mixing materials are fused, and a glass body is prepared and obtained. The added auxiliary materials containing the alkaline oxides can restrain secondary synthesis of the dioxin decomposed in the fusing process. Harmless disposal and value-increment of the waste incineration fly ash are achieved, and the detoxifying method of the dioxin and the heavy metal in the waste incineration fly ash has the advantages of wide in raw material source, short in process and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

Low temperature lead-free glass dust and preparation method thereof

The invention relates to low temperature lead-free glass dust and a preparation method thereof. The glass dust comprise the following components as raw materials by weight percent: 30-80% of Bi2O3, 10-60% of B2O3, 0-20% of ZnO, 0-20% of Sb2O3, 0-10% of Al2O3 and 0-7% of alkali metal oxide, wherein the alkali metal oxide is Li2O. The preparation method comprises the following steps: (1) weighing the raw materials in ratio, carrying out ball-milling for 30-60 minutes by taking ethyl alcohol as a medium by using a planet ball grinding mill, then blending uniformly, drying to obtain a uniformly-mixed oxide; (2) after the mixture is melted, pouring the melted mixture into deionized water to obtain glass slag, then drying, and putting the glass slag into a ball-milling pot in the planet ball grinding mill and carrying out ball-milling to obtain a product; and (3) after the ball-milling, sieving the product with a 300-mesh mesh screen to obtain the low temperature lead-free glass dust. The lead-free glass dust prepared by the preparation method disclosed by the invention is low in softening in temperature, high in bonding strength and good in refiring stability.

Owner:SHANGHAI INTELLIGENT SENSOR ELECTRONICS TECHCO

LCD sheet glass

The invention discloses a base plate glass with rare-earth element to dope liquid crystal display device (TFT-LCD), which is characterized by the following: comprising glass basic oxide, lanthanum oxide, cerium oxide, neodymium oxide and or yttrium oxide; setting the mass ratio at (60. 5-195):(0. 003-28) of the glass basic oxide and all rare-earth oxide; adding at least three rare-earth oxide; improving the fusion of the glass; accelerating clarification and equalization in the course of formation; preventing glass crystallizer; decreasing the liquid phase temperature; delaying devitrification speed of the glass; fitting for productive technology of float glass; improving chemical stability of the glass; decreasing the expansion coefficient; fitting for large scale float glass procession.

Owner:CHINA BUILDING MATERIALS ACAD

Low-melting-point neutral nuisanceless glass for electronic paste and preparation method thereof

InactiveCN101624263ALow softening temperatureLower sintering temperatureChemical stabilityAtmosphere

The invention discloses low-melting-point neutral nuisanceless glass for electronic paste and a preparation method thereof. The glass comprises 10-30 mol% of SiO2, 30-76 mol% of Bi2O3, 1-5 mol% of Al2O3, 1-6 mol% of ZnO, 2-6 mol% of MgO, 1-3 mol% of Na2O, 2-12 mol% of B2O3 and 1-3 mol% of V2O5. The low-melting-point neutral nuisanceless glass powder for electronic paste is characterized in that the softening temperature is 380-450 DEG C; the neutral low-melting-point nuisanceless glass is obtained by melting according to the calculation of the ingredients of the acidic oxide and the basic oxide in the glass; and the glass has good chemical stability when sintered under the acidic or basic atmosphere, does not contain toxic and harmful elements, such as Pb, Cd, Tl, Te, As, Cr, Sb, Hg, Co and the like which are forbidden by the environment requirements,, and is widely used for the bonding phase in the electronic paste.

Owner:SINO PLATINUM METALS CO LTD

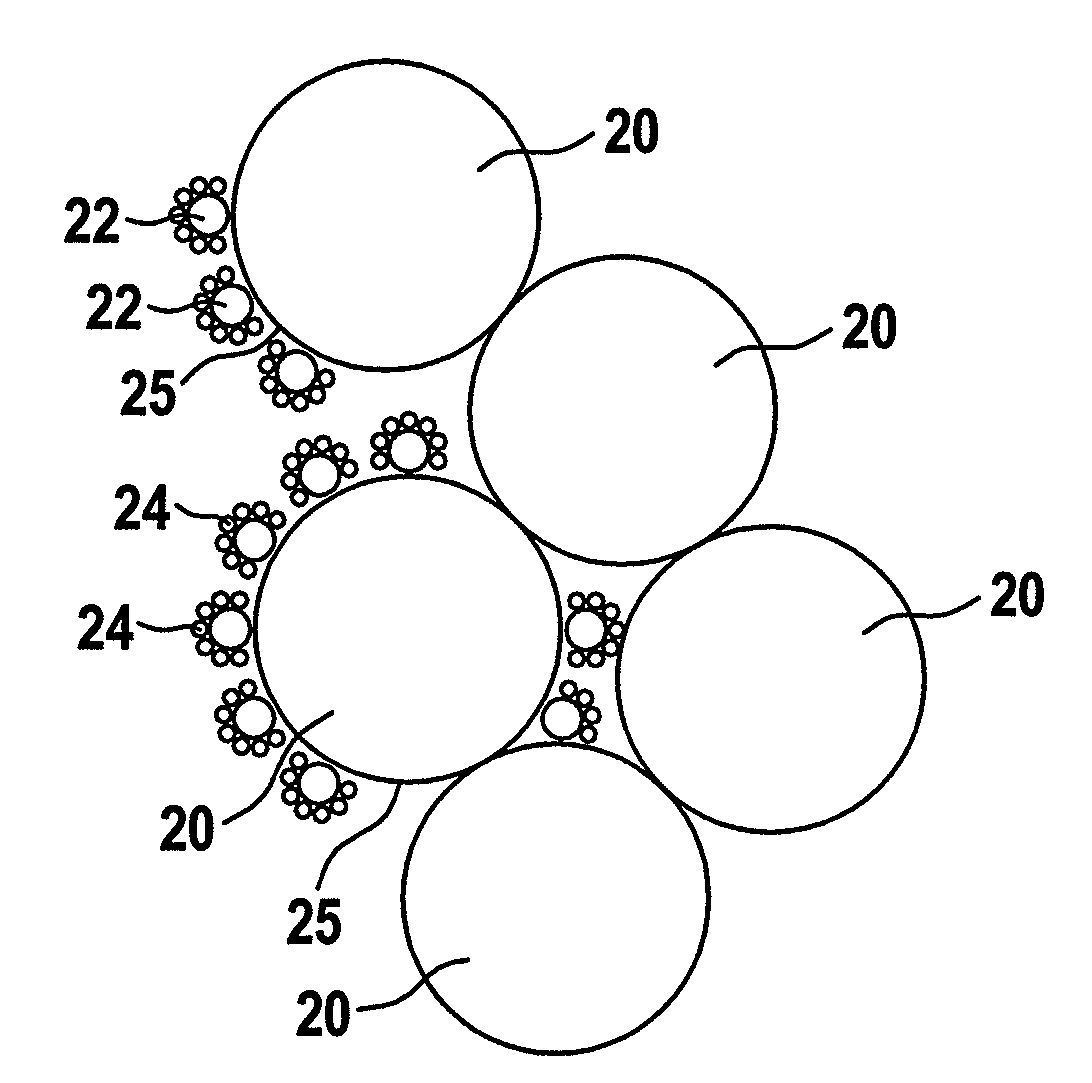

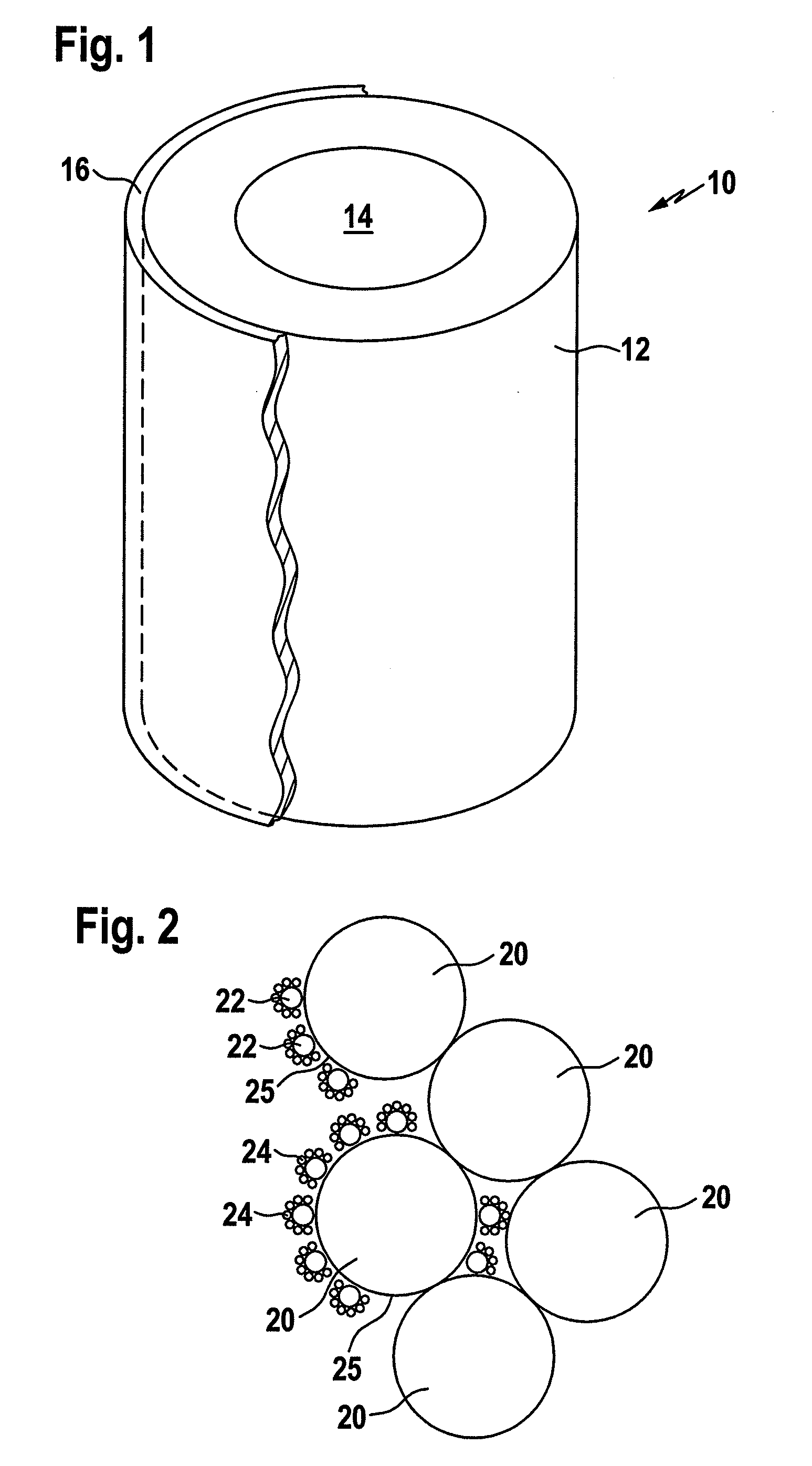

Catalytic element

InactiveUS20090019770A1Improve mechanical stabilityLow flow resistanceCombination devicesCatalytic naphtha reformingGas phaseCompound (substance)

A catalytic element useful for promoting catalytic gas phase reactions is provided, comprising a porous ceramic body comprising a multiplicity of open pores having a coating comprising a basic oxide material and a catalyst material selected from transition metal and noble metal compounds

Owner:PALL CORP

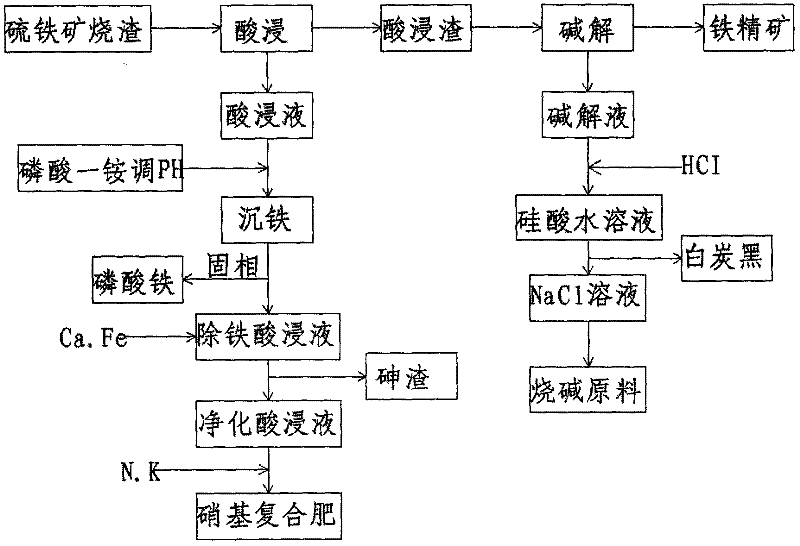

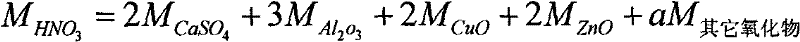

Method for treating pyrite cinder by combining acidic leaching with alkaline dissolving

ActiveCN102534187AEfficient enrichmentRealize cleaner productionProcess efficiency improvementNitro compoundResource utilization

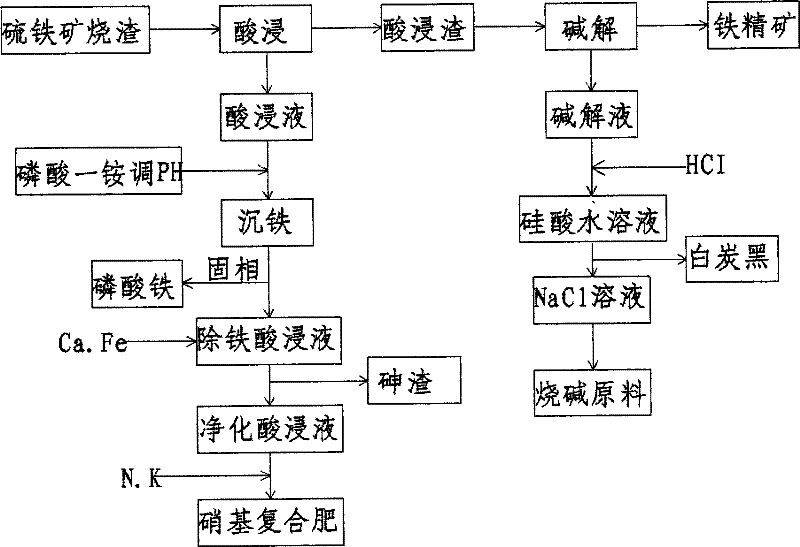

The invention relates to a method for treating pyrite cinder by combining acidic leaching with alkaline dissolving. The method mainly comprises the following steps that: nitric acid is adopted to leach the pyrite cinder, so that alkaline oxide impurities containing sulfur and arsenic are desorbed, most of iron can still exist in a solid phase in the form of ferric oxide, and the iron is effectively enriched, wherein the iron enrichment ratio is more than 90%, the sulfur removal ratio is more than 98%, the arsenic removal ratio is more than 99%, the solid phase is acid-leached residue, and the liquid phase is acid-leached liquor; when the content of silicon dioxide is more than 15% and the total iron content can reach about 50% in the pyrite cinder, an alkaline dissolving treatment is needed, the alkaline-dissolved residue is iron ore concentrate, white carbon black is obtained after acidifying alkaline-dissolved liquor, and the liquid phase is a sodium chloride solution which can be used as a raw material of sodium hydroxide; the acid-leached liquor is added into ammonium dihydrogen phosphate to produce ferric phosphate which can be used as raw materials and ceramic raw materials of a lithium iron phosphate electromagnetic material; and purified acid-leached liquor is obtained after carrying out arsenic removal and can be applied to the production of nitro compound fertilizer. With the adoption of the method for treating the pyrite cinder by combining the acidic leaching with the alkaline dissolving, the pyrite cinder can be fully and comprehensively utilized, and thus, the resource utilization ratio is increased; and the energy-saving and emission-reduction effect is good, the method is beneficial to environment-friendliness, and the clean production in the acid making industry by using the pyrite cinder can be achieved.

Owner:师兆忠

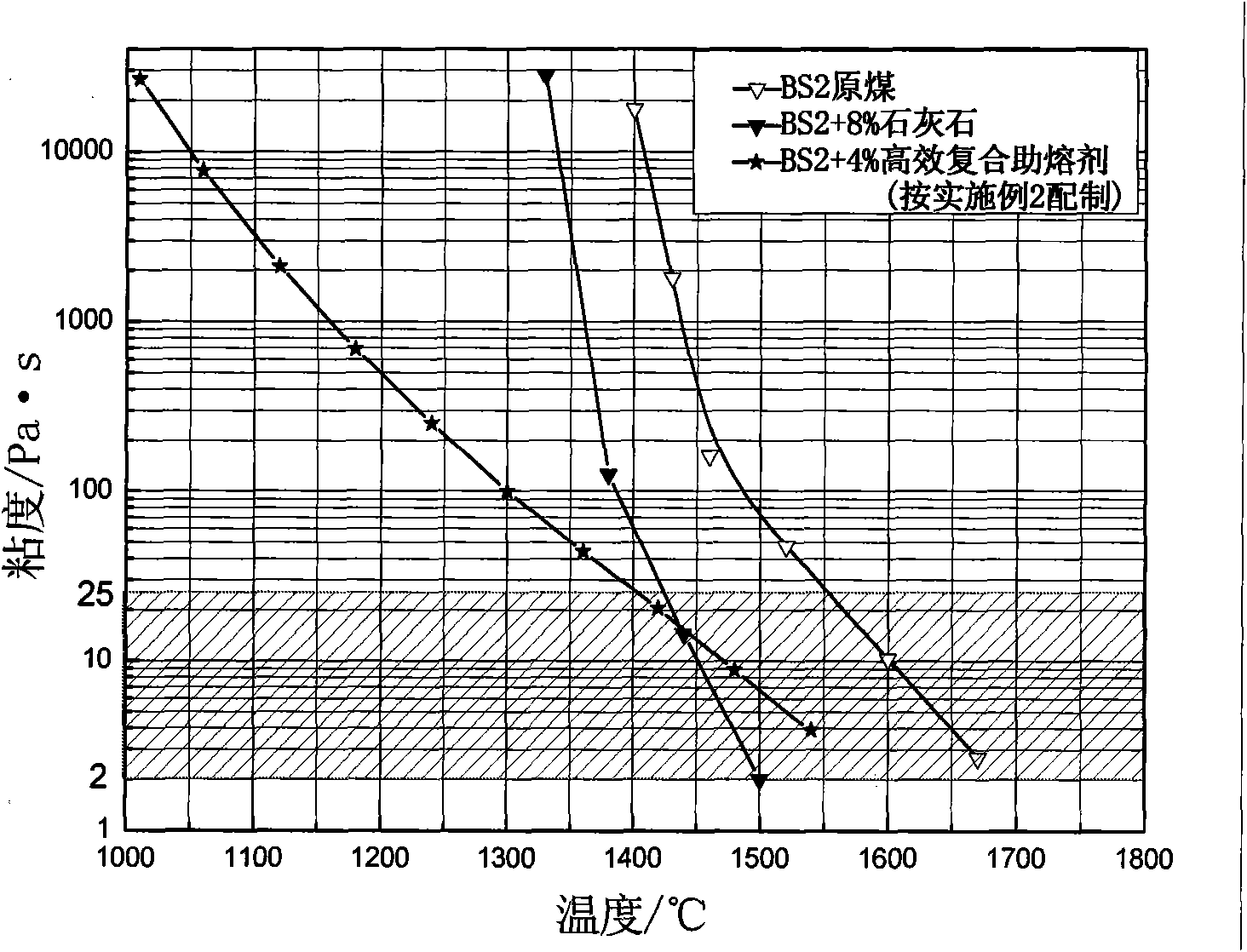

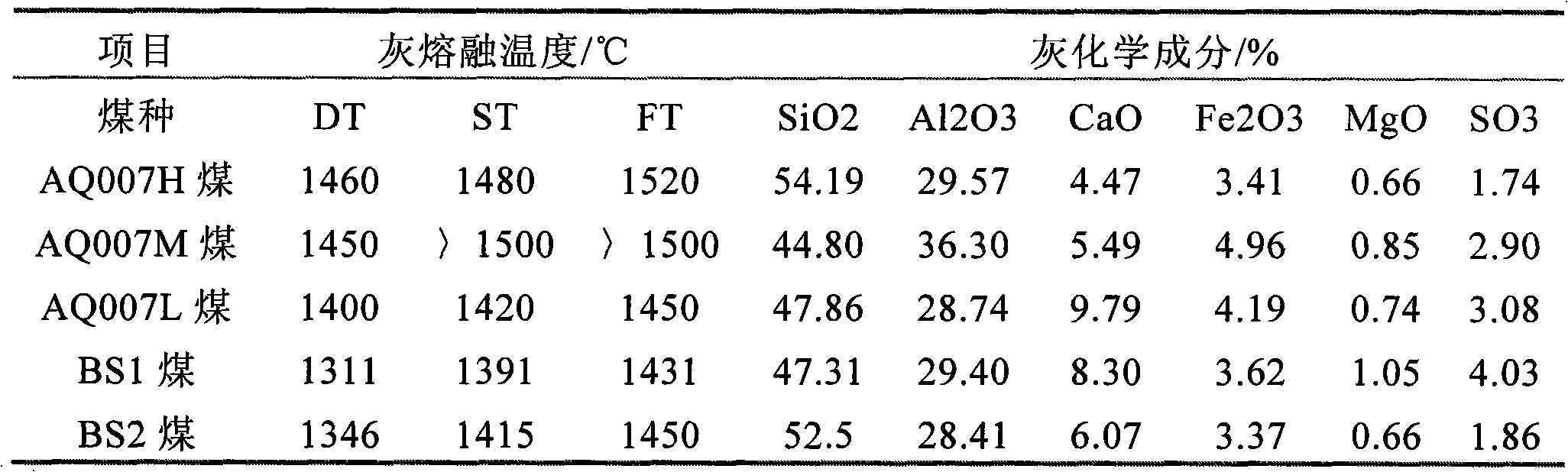

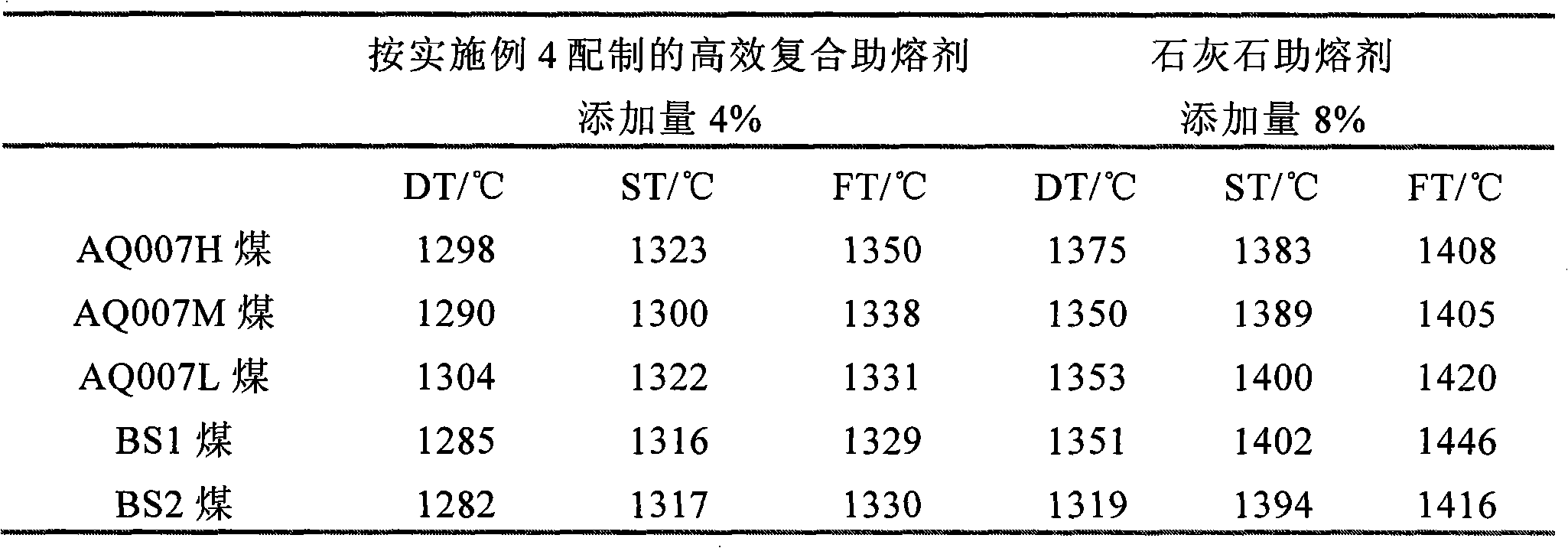

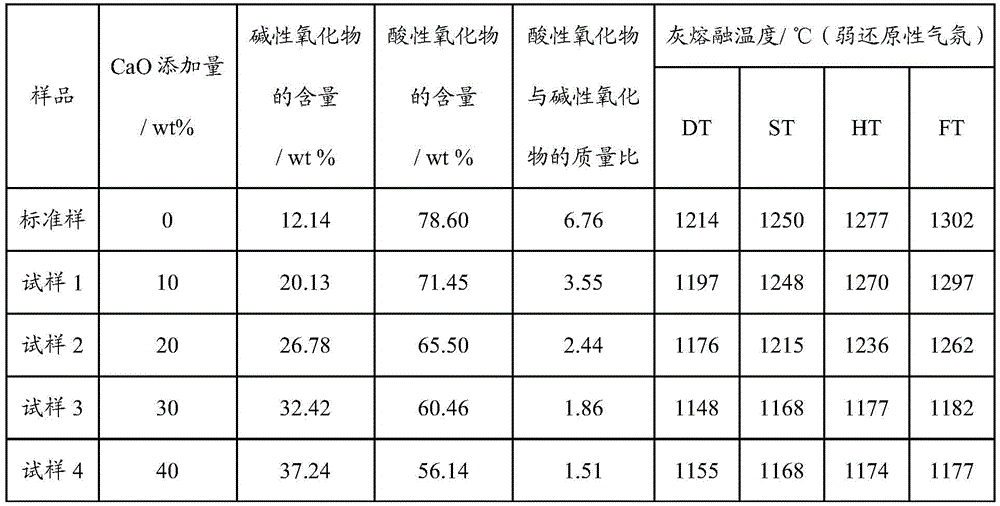

Efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag

The invention provides an efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag. The efficient composite fluxing agent is compounded by two or more ore powders containing basic oxides. The efficient composite fluxing agent comprises the components by weight percentage of 12-30% of MgO and 3-30% of CaO. As for the coals at the mine field in the northern Anhui province, when the addition amount is 2-6%, the melting temperature of the pulverized coal can be reduced from 1500 DEG C to below 1400 DEG C, the viscosity of the pulverized coal can be ranged from 2 to 25 Pa*s, thus effectively improving the melting characteristic of the coals in the mine field in the northern Anhui province. The fluxing agent can be used for replacing lime stone fluxing agent and the addition amount is only half of that of the lime stone.

Owner:CHINA PETROLEUM & CHEM CORP +1

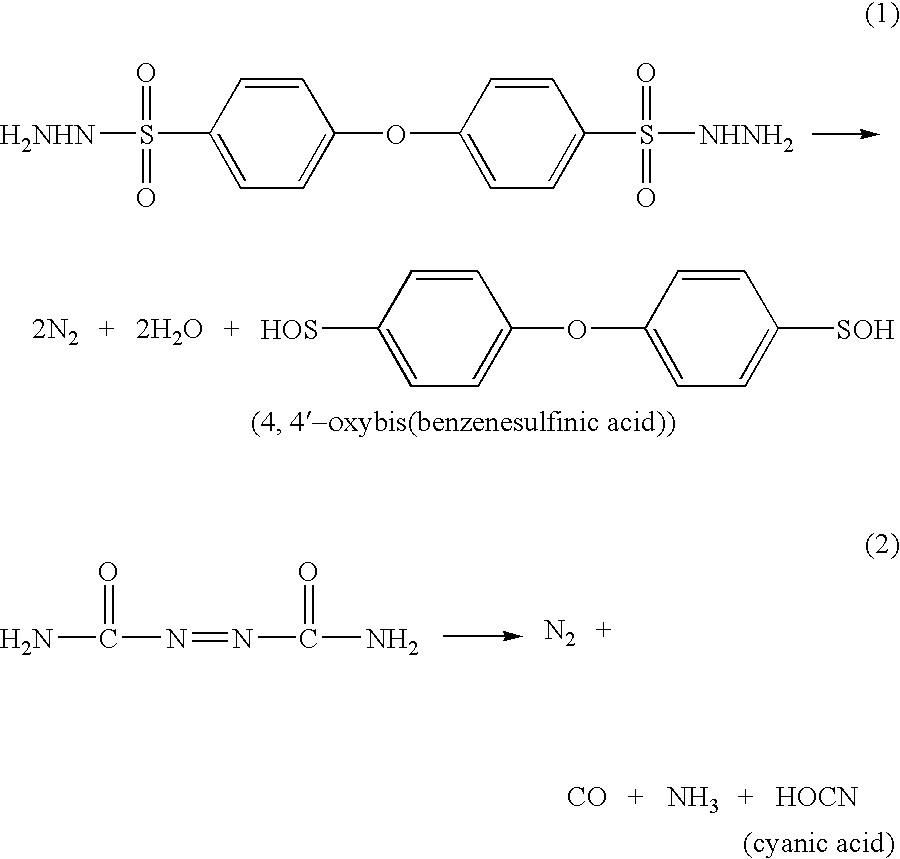

Recycling agent for hydrogen peroxide solution

InactiveCN101554996AGood conditionReduce consumptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesActive componentNuclear chemistry

The invention discloses a recycling agent for a hydrogen peroxide solution with ideal recycling effect and low cost. The recycling agent adopts calcium oxide as an active component, and has a mixture radio: 1-99 percent of calcium oxide and the balance of alkaline oxide, wherein the optimal mixture ratio is: 50-70 percent of calcium oxide, and the balance of the alkaline oxide. The recycling agent produced by the prescription can achieve higher recycling activity, and makes up the limitation of activated alumina recycling agent from multiple aspects, thereby ensuring that the hydrogen peroxide production achieves a new level.

Owner:何国炎

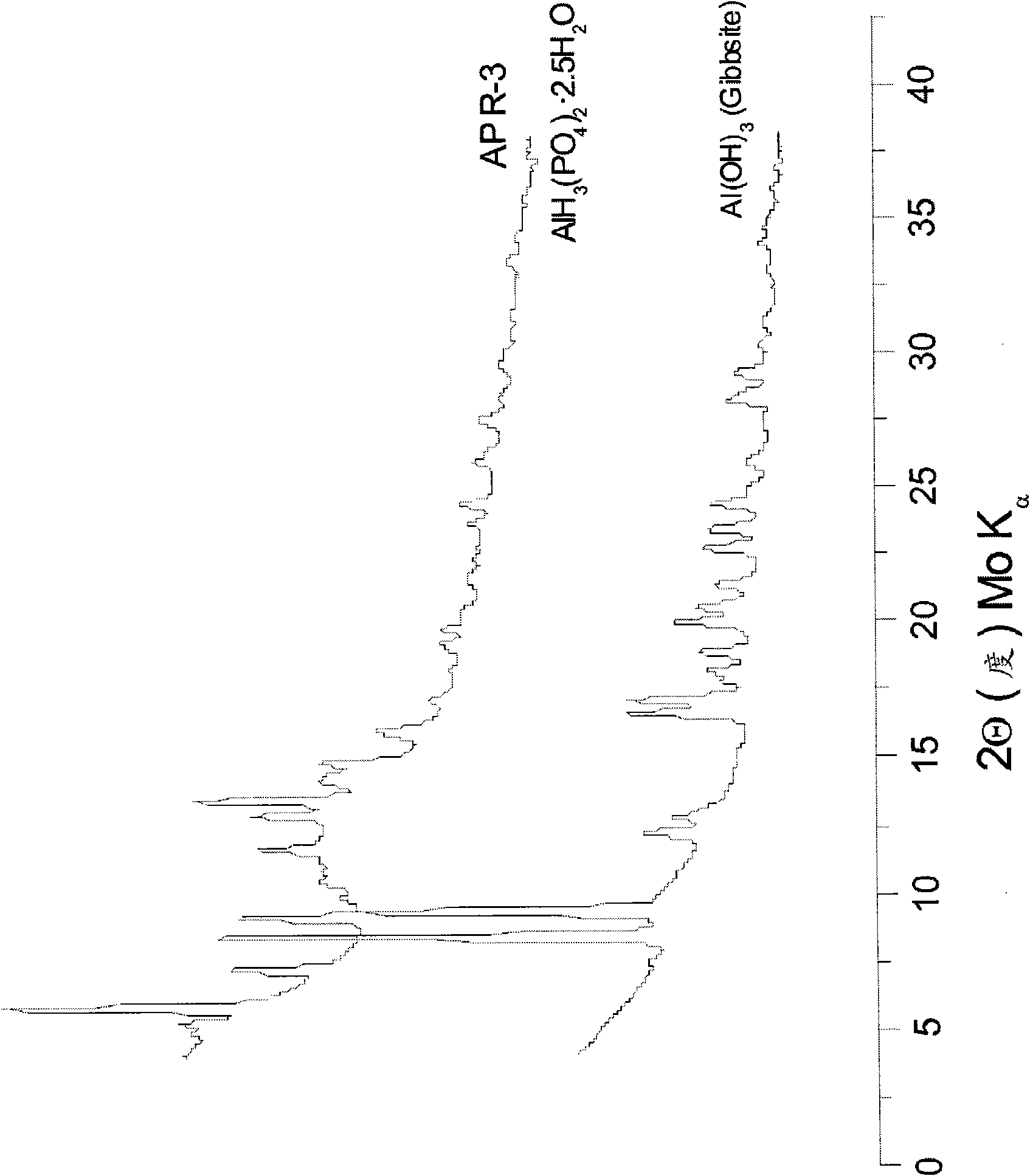

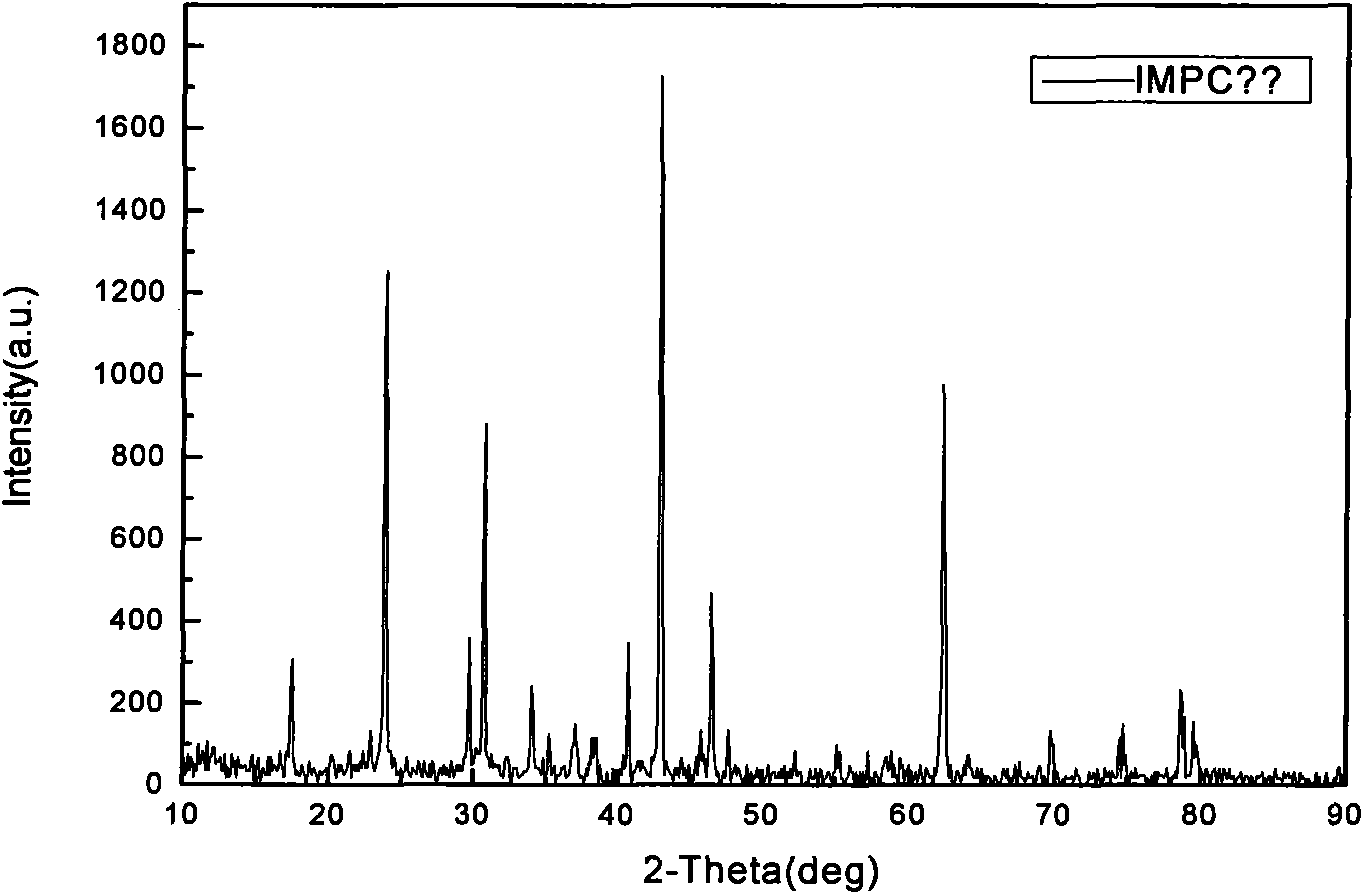

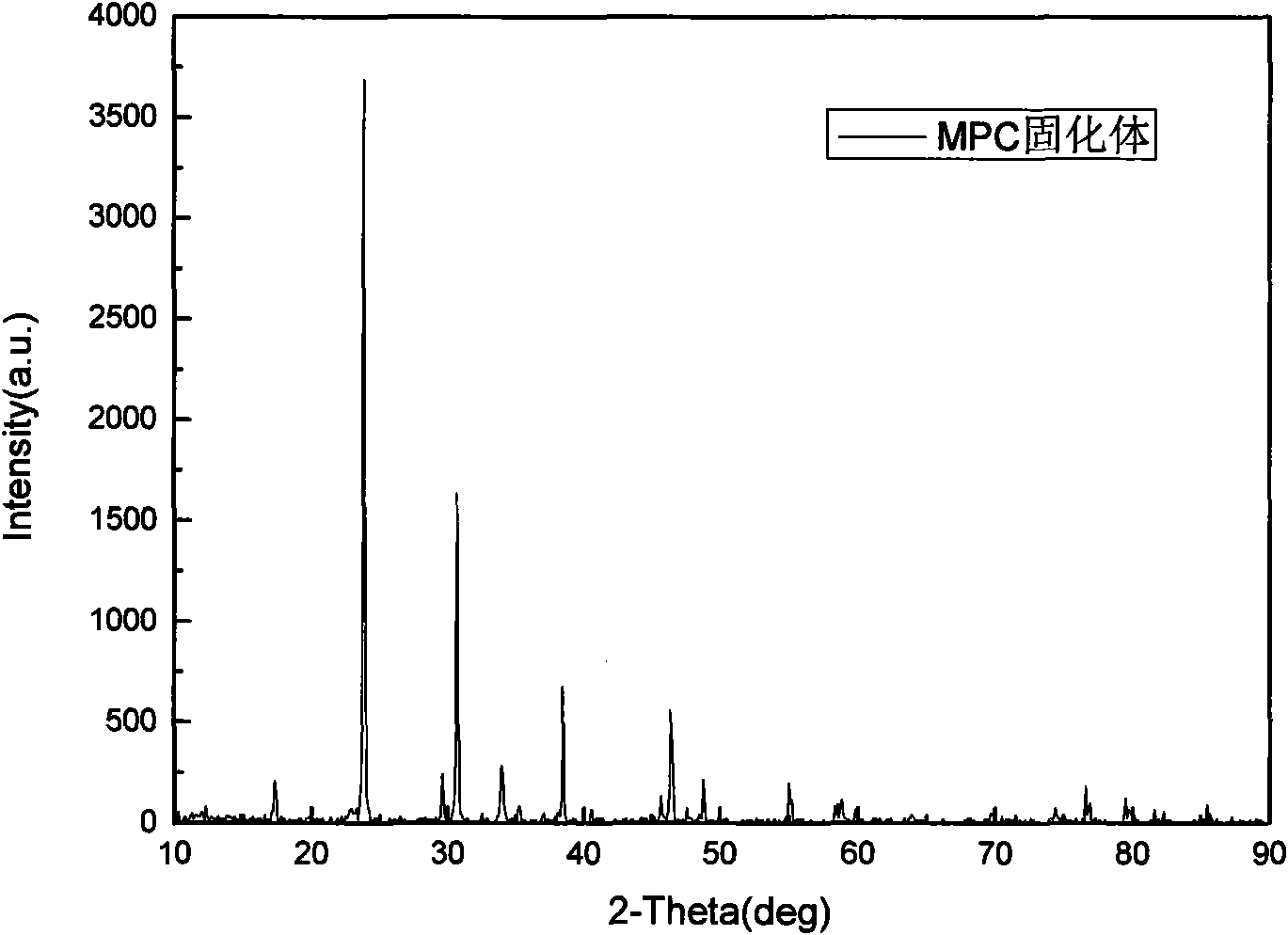

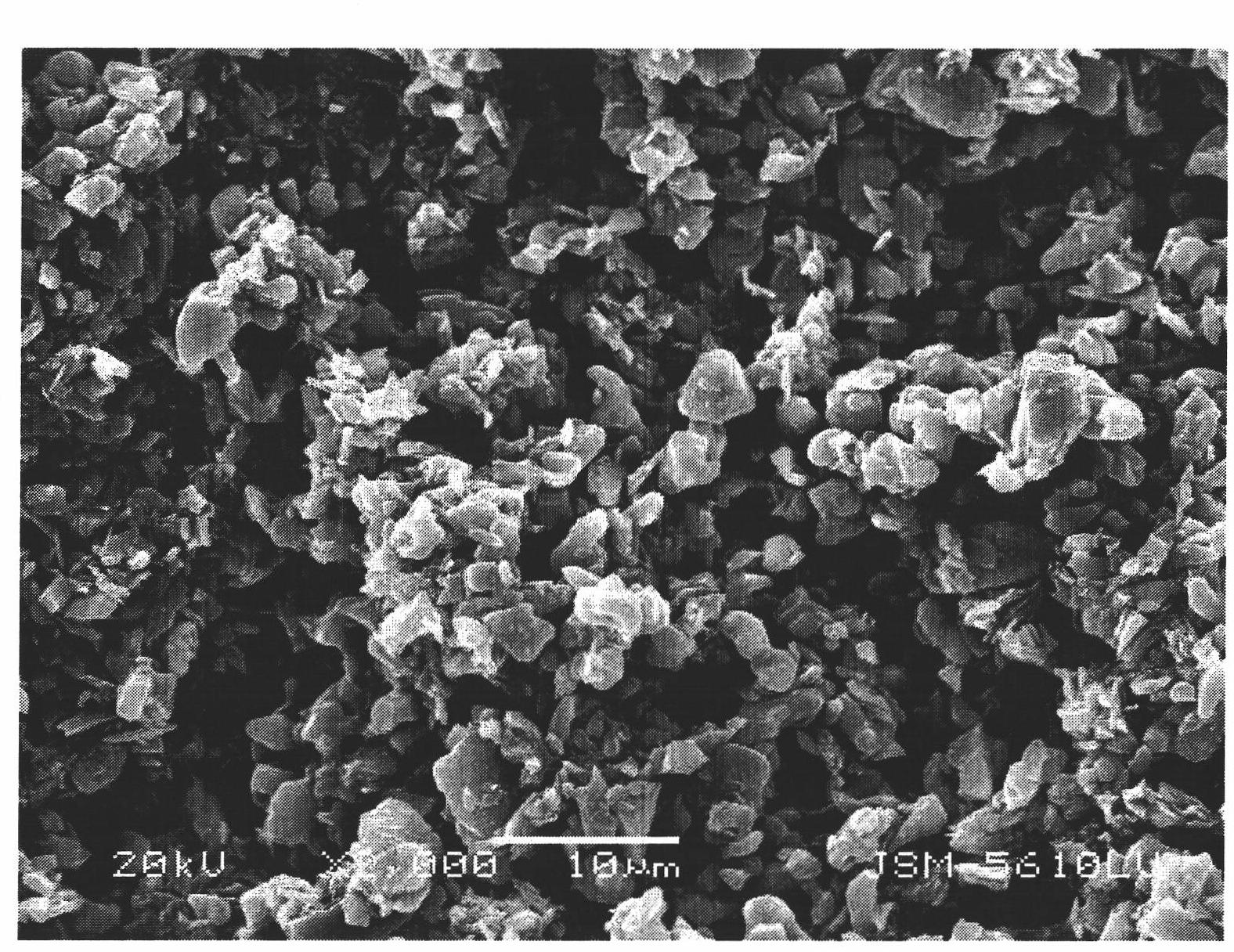

Inorganic phosphate compositions and methods

ActiveCN102781871AMetallic material coating processesLiquid spraying apparatusInorganic phosphateSpray coating

Disclosed and described are multi-component inorganic phosphate formulations of acidic phosphate components and basic oxide / hydroxide components. Also disclosed are high solids, atomizable compositions of same, suitable for spray coating.

Owner:LATITUDE 18

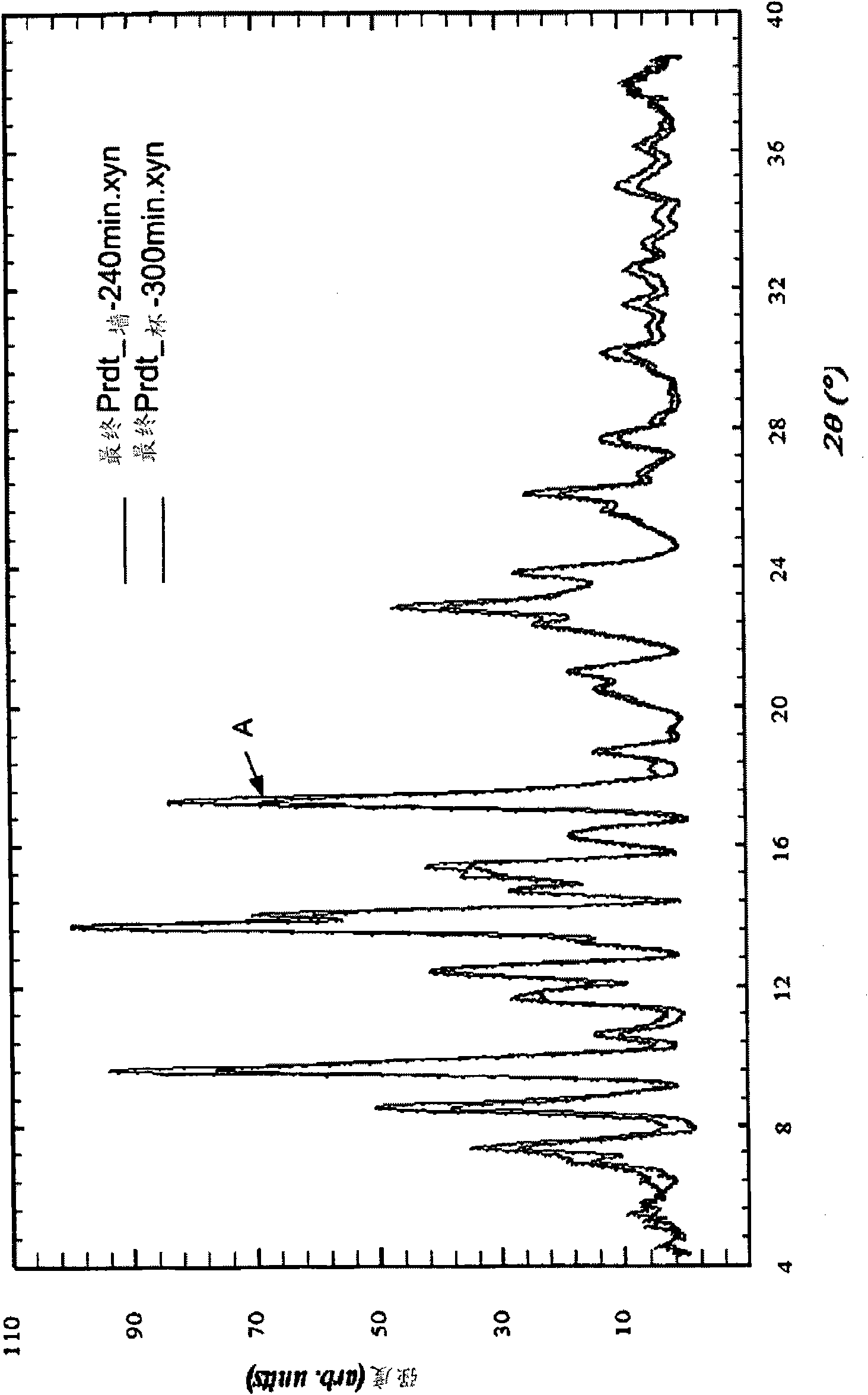

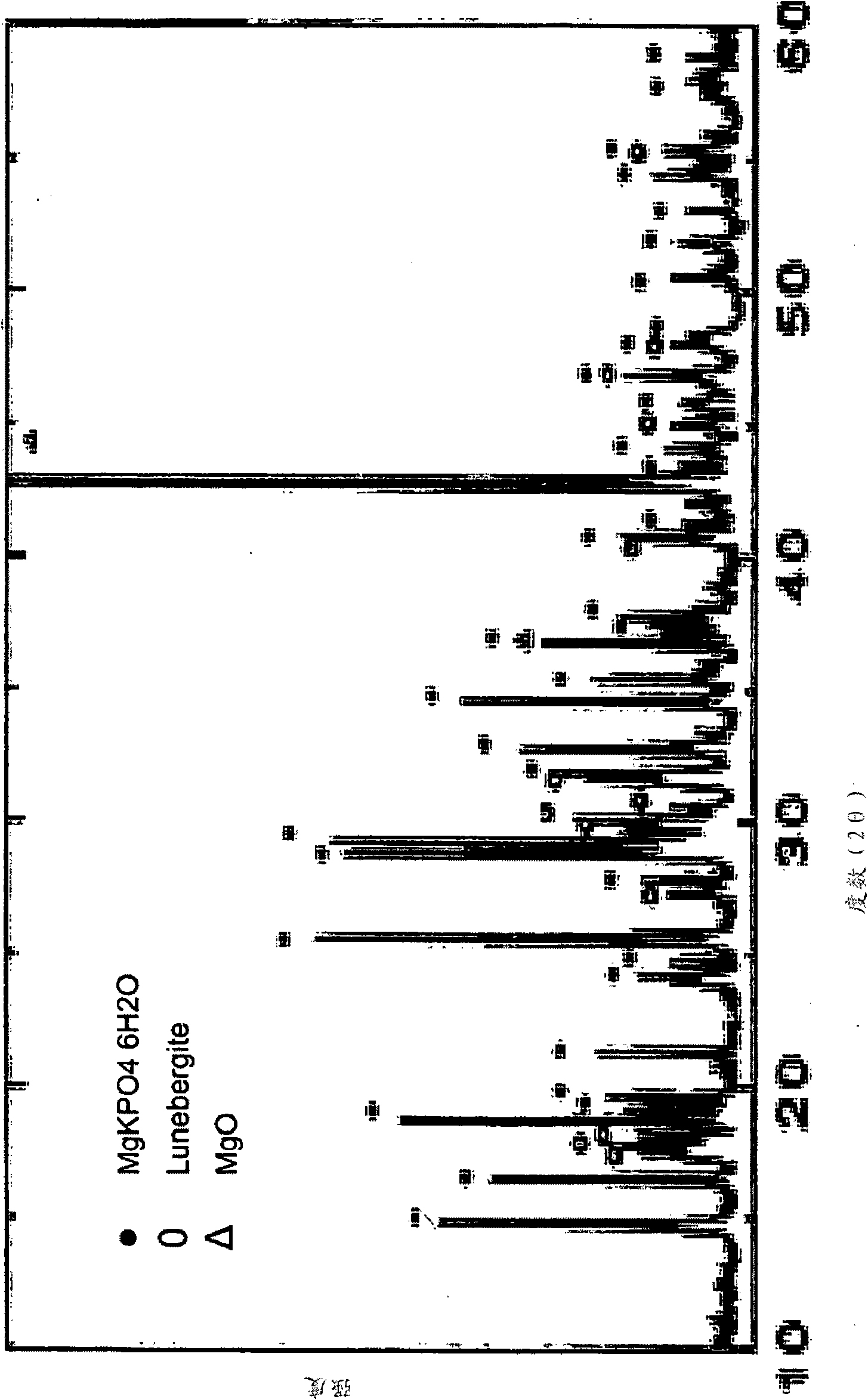

Magnesium-based bone filling adhesive and preparation method and application thereof

InactiveCN102274543AHigh strengthImprove adhesionSurgical adhesivesO-Phosphoric AcidMagnesium phosphate

The invention discloses a magnesium-based bone filling adhesive and its preparation method and application. The adhesive material is composed of a solid phase component and a liquid phase component, wherein the solid phase component is composed of basic oxide, Calcium phosphate, hydrogen phosphate, magnesium phosphate, and starch are mixed evenly; the liquid phase component is prepared by dissolving sugar and hydrogen phosphate in aqueous phosphoric acid. Mix the above-mentioned solid phase components and liquid phase components evenly to form a pasty cement slurry, which is used for filling and repairing bone tissue trauma and treating osteoporosis, especially for the adhesion of bones, tendons, ligaments and prostheses. Bonding and fixing, avoiding the disadvantages of the existing calcium phosphate cement, such as low early strength, non-viscosity, easy collapse, poor biodegradability and magnesium phosphate cement containing ammonium salt, and achieved good results. And it has the characteristics of low raw material cost, simple preparation method, high strength, strong cohesiveness, good collapse resistance, good biodegradability, no ammonia gas, etc., and can be directly injected into the lesion with a syringe or filled into the body after curing and molding. It is very convenient to use, and it can also be used for bonding and fixing building materials such as metal, ceramics, and plastics.

Owner:天津美基生物医药科技有限公司

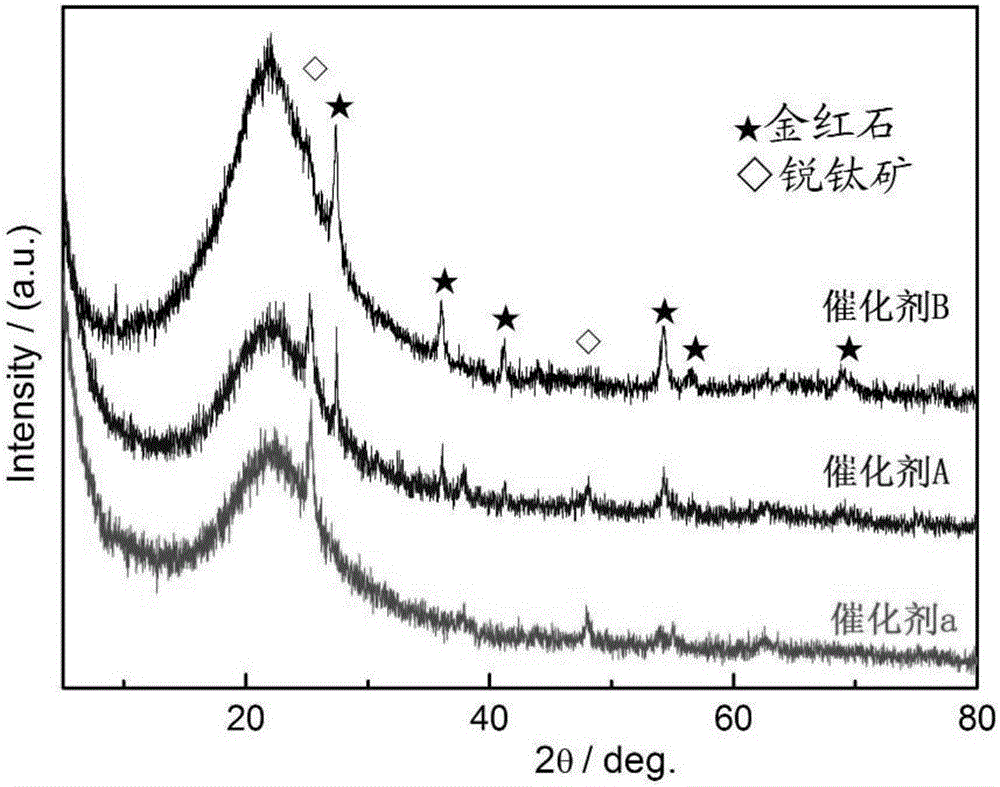

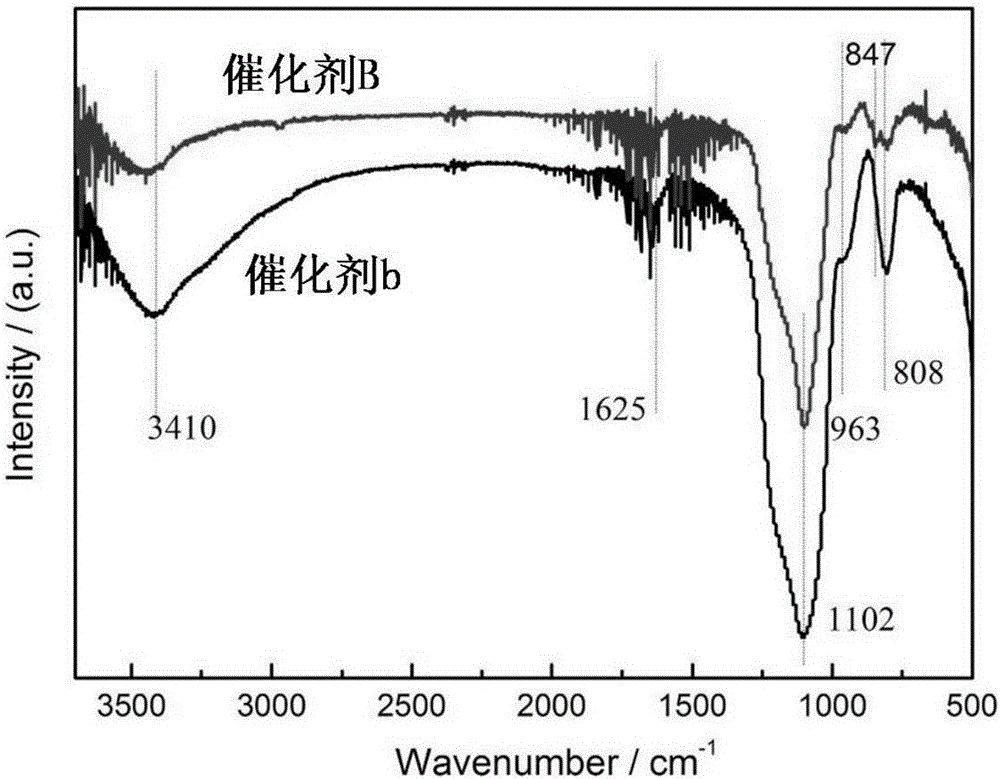

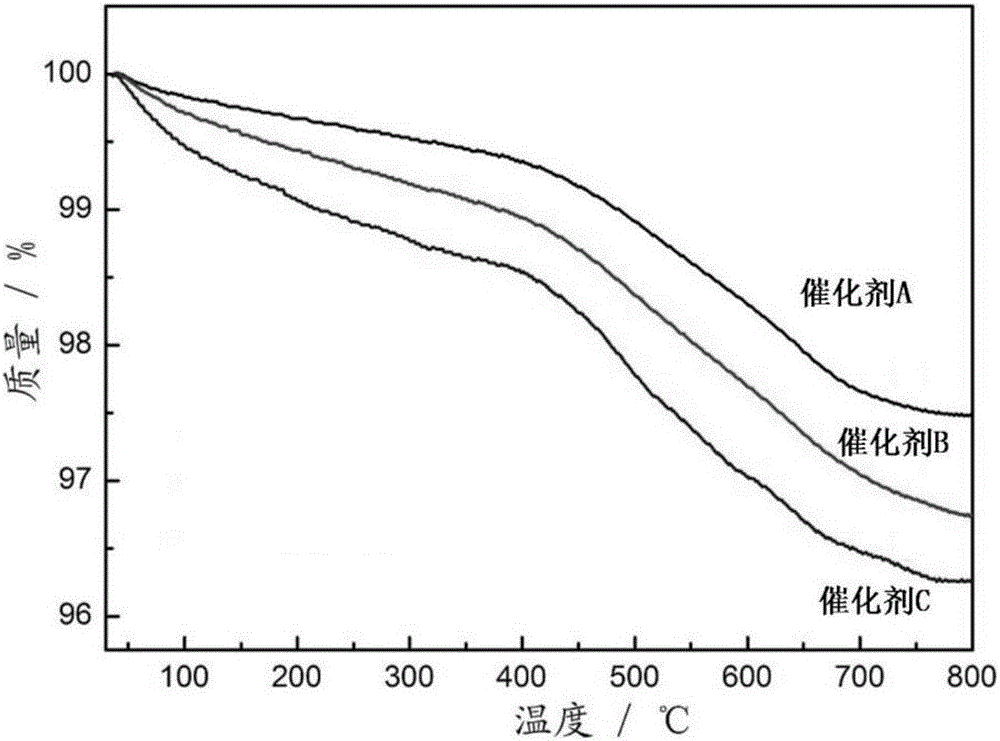

Preparation method and application of titanium-silicon composite oxide catalyst

ActiveCN106334583AAvoid titanium precipitationReduce energy consumptionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTitaniumLow temperature plasma

The invention relates to a preparation method of a titanium-silicon composite oxide catalyst. The method comprises the following steps: 1, simultaneously impregnating a silica carrier with a titanium source and a soluble alkaline metal salt; 2, carrying out low temperature plasma treatment; and 3, modifying by using an organosilane reagent. Alkaline oxide is introduced to modify the catalyst when the impregnation process titanium source loading is carried out, and the low temperature plasma treatment is carried out, so the production of a titanium compound outside a framework and the surface acidity of the catalyst are effectively reduced, thereby the catalyst substantially improves the selectivity and the yield of epoxides in the olefin epoxidation reaction.

Owner:WANHUA CHEM GRP CO LTD

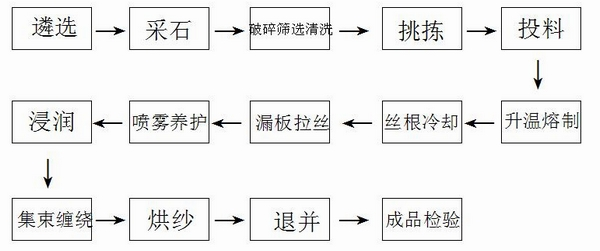

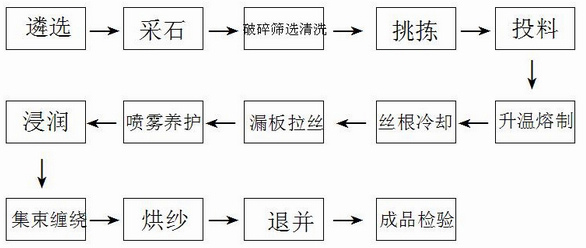

High-strength high-purity basalt continuous fiber production technique

The invention discloses a high-strength high-purity basalt continuous fiber production technique which comprises the main procedures of selection, quarrying, crushing, screening, cleaning, picking, charging, founding by heating up, filament cooling, bushing, drawing, conserving by atomizing, infiltration, clustering, winding, yarn driving, detwisting and finished product inspection. During selection, natural basalt is used as a single component raw material, and natural basalt with uniform crystalline structure and high purity is selected. The basic oxide acidity modulus: MK= (SiO2+Al2O3) / (CaO+MgO), the basic oxide acidity modulus is maintained within the range of 4.3-5.8, and meanwhile, Fe2O3+FeO is controlled between 8-15%. The average fracture strength of the produced continuous fiber base yarn can be stabilized within 0.6-0.7 N / tex and is 50-75% higher than 0.4 N / tex specified by national standards, and the filamentation rate is increased by 10%. The technique has easiness and convenience for operation, stable production and low cost, the technical process is friendly to environment and free of pollution, and the product quality is obvious improved.

Owner:河北通辉科技有限责任公司 +1

Method for preparing activated carbon-silicon dioxide mixed adsorbing material by using silicon tetrachloride

InactiveCN101785990ASpecial adsorption effectImprove processing efficiencyOther chemical processesSilicon dioxideMuffle furnace

The invention relates to a method for preparing an activated carbon-silicon dioxide mixed adsorbing material by using silicon tetrachloride, in particular to the method for preparing the adsorbing material by using a byproduct of polycrystalline silicon, namely SiCl4, which comprises the following steps: firstly, adding solid powders, such as alkaline oxide and calcium salt and the like into water with stirring until the solid powders are fully dissolved, and adding a small amount of carbon-containing substance; secondly, adding the byproduct of the polycrystalline silicon, namely the SiCl4, and the balance of carbon-containing substance for fully stirring, and standing the mixture for a night; and finally, activating the mixture for 3 to 5h at the holding temperature of 600 to 800 DEG C in a muffle furnace, taking the mixture out after cooling, washing the mixture with distilled water until the mixture contains no Cl-, and pumping, drying, weighing to obtain the product. In the method, hydrochloric acid prepared by hydrolyzing the byproduct of the polycrystalline silicon, namely the SiCl4, is directly mixed with a proper amount of chemical reagent and raw materials, and the mixture is activated to obtain the activated carbon-silicon dioxide mixed adsorbing material; and the method has the advantages of simple process, abundant raw materials and low cost, and effectively solves the problem of comprehensive application of the silicon tetrachloride, biomass and carbon-containing waste.

Owner:LESHAN NORMAL UNIV

Method for lowering fusing temperature of coal ash

ActiveCN105542901ALower melting temperatureImprove applicabilitySolid fuelsFuel additivesCoal waterMass ratio

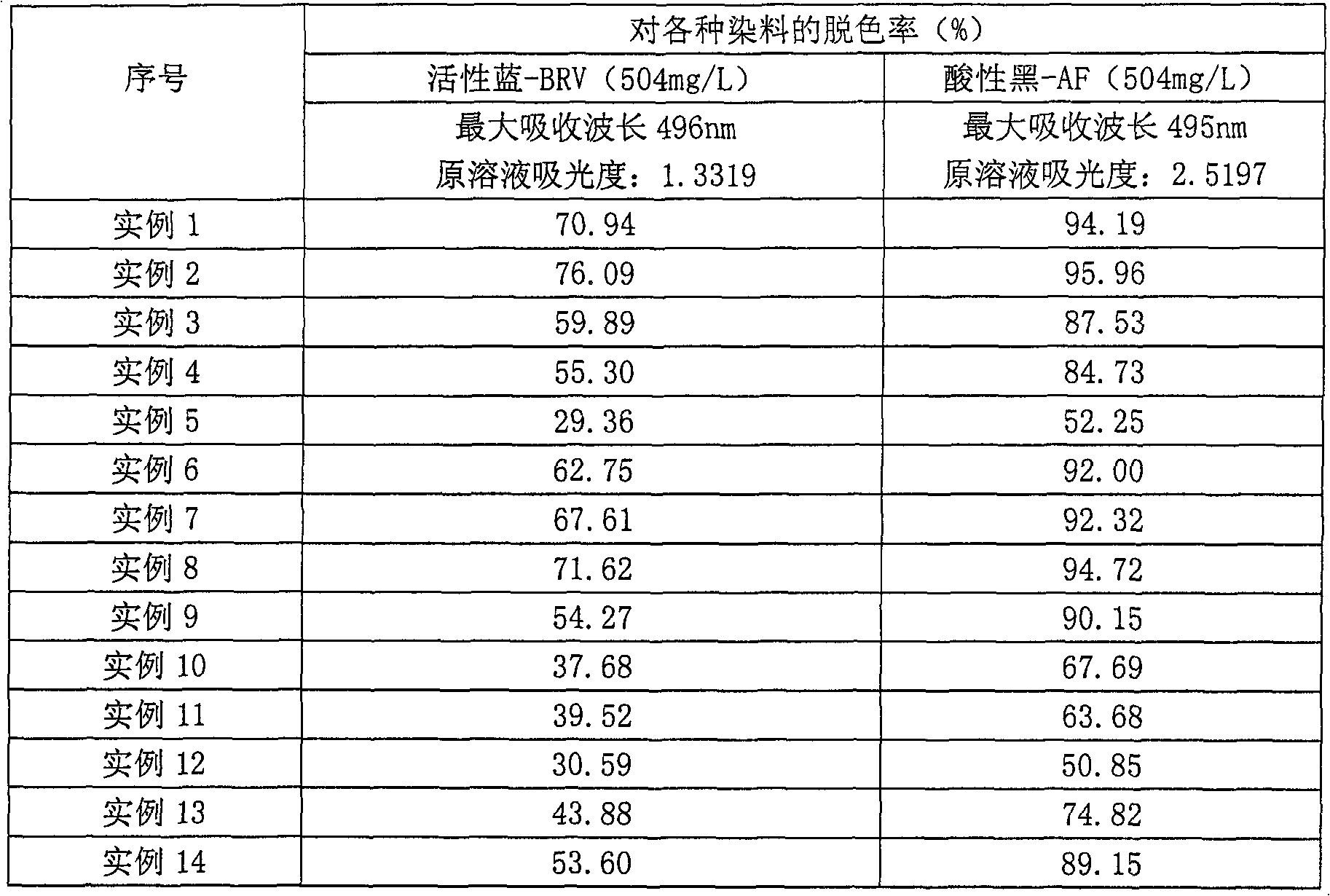

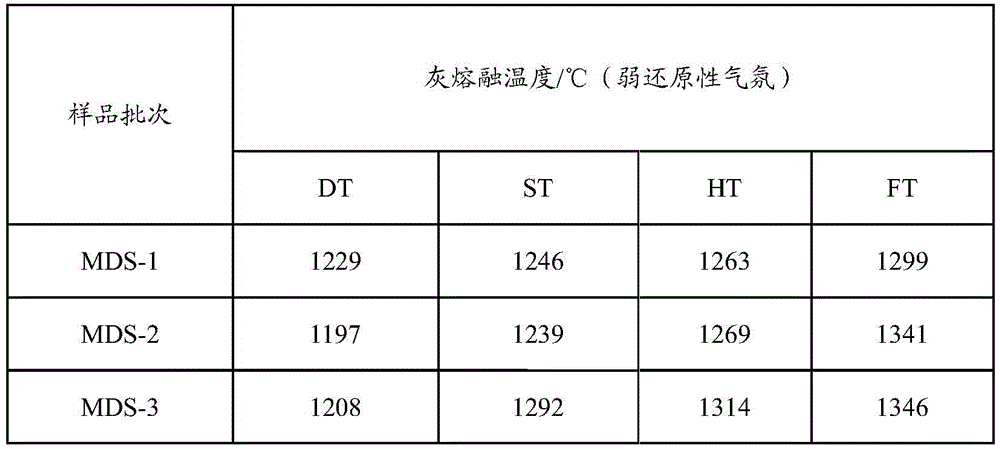

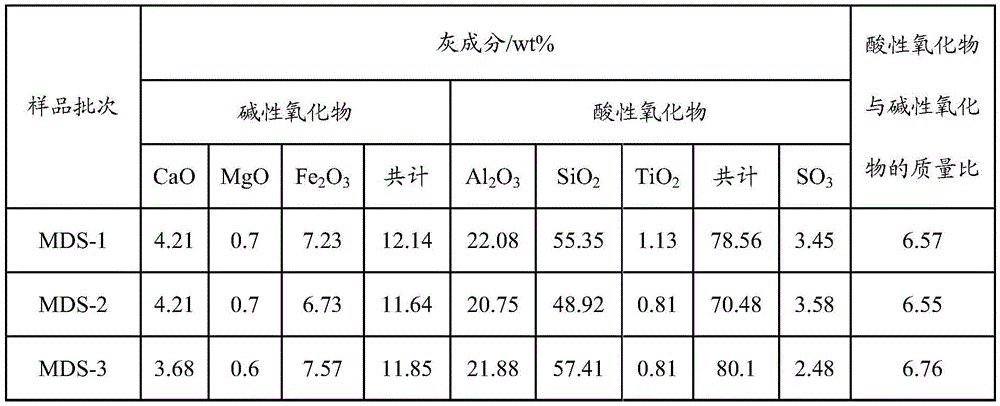

The invention provides a method for lowering a fusing temperature of coal ash. The method comprises the step of adding a fusing assistant into feed coal, wherein the mass ratio of acidic oxides to alkaline oxides in the coal ash resulting from the ashing of the feed coal is greater than 6.5; and the addition level of the fusing assistant is such that the mass ratio of the acidic oxides to the alkaline oxides in the coal ash resulting from the ashing of a mixture of the feed coal and the fusing assistant is 1.5 to 4.5. The method provided by the invention has outstanding applicability, has practical guiding significance in specific industrial coal and is particularly applicable to coal types, of which the mass ratio of the acidic oxides to the alkaline oxides is large; proceeding with adjustment on the ash ingredient ratio of the coal ash, the addition level of the fusing assistant can be adjusted according to different ash ingredients of different feed coals, so that the flexibility is high, and the applicability is high; the fusing assistant is wide in source and low in cost, so that the production cost cannot be increased markedly; and the method is easy and feasible, and the fusing assistant and the feed coal can be subjected to industrial grinding simultaneously and be mixed uniformly, so that the method is applicable to a gas-flow bed technology for coal-water slurry and dry powder coal gasification.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Preparation method of lignin phenolic foams

The invention relates to a preparation method of lignin phenolic foams. Lignin is used for partially replacing phenol through chemical degradation and is subjected to an addition polycondensation reaction with paraformaldehyde in the presence of a basic catalyst which is compounded from a basic oxide and a phosphorated sodium salt. The prepared resin is relatively high in activity, and conventional foaming agents, curing agents and surfactants are adopted to meet requirements for the curing speed of a phenolic foam production line, so that the industrial production can be performed. The preparation method disclosed by the invention not only can reduce the cost of the phenolic foams but also can alleviate the environmental pollution.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

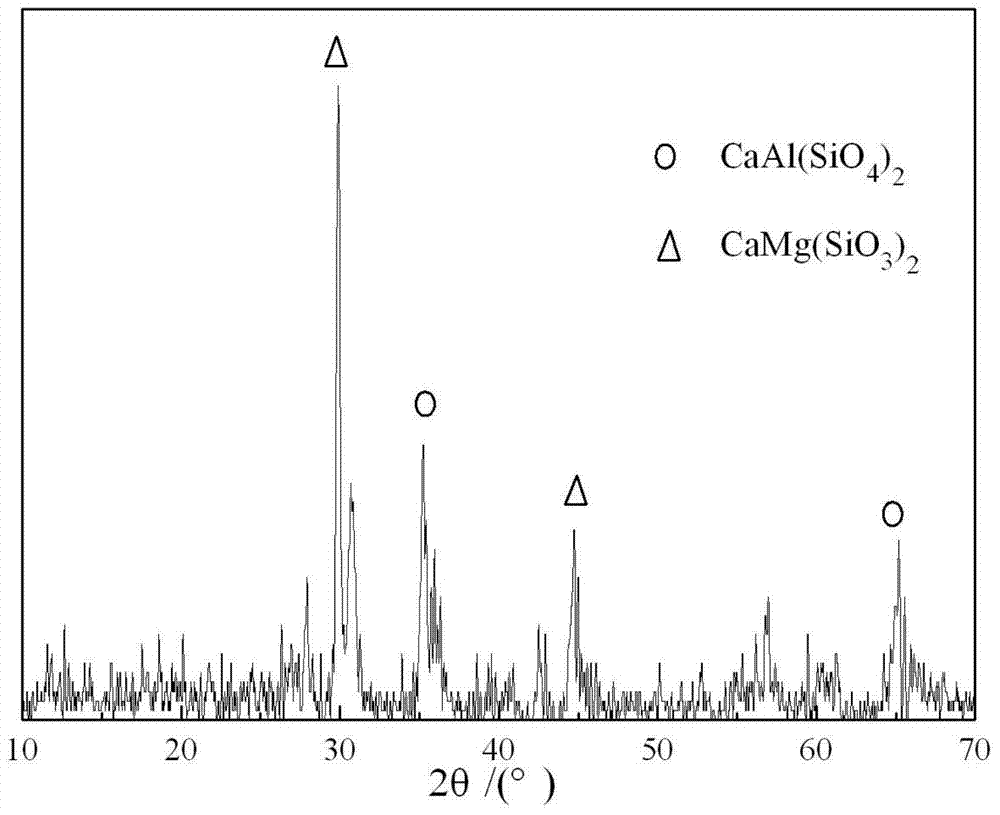

Glass ceramic and float producing process thereof

The invention discloses glass ceramic and a float producing process thereof. The raw material of the glass ceramic contains calcium, and the total content of basic oxide is relatively high, the glass flattening and surface polishing can be carried out by means of gravity and surface tension of liquid glass in the production process, the glass is nucleated and crystallized stepwise in the heating process, and the glass ceramic with flat and smooth surface and excellent performance is finally obtained by controlling the nucleating temperature, the crystallizing temperature, the nucleating time, the crystallizing time and the amount of nucleating agent, and the problems of low yield, low production efficiency and high production cost in the glass ceramic production can be solved.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

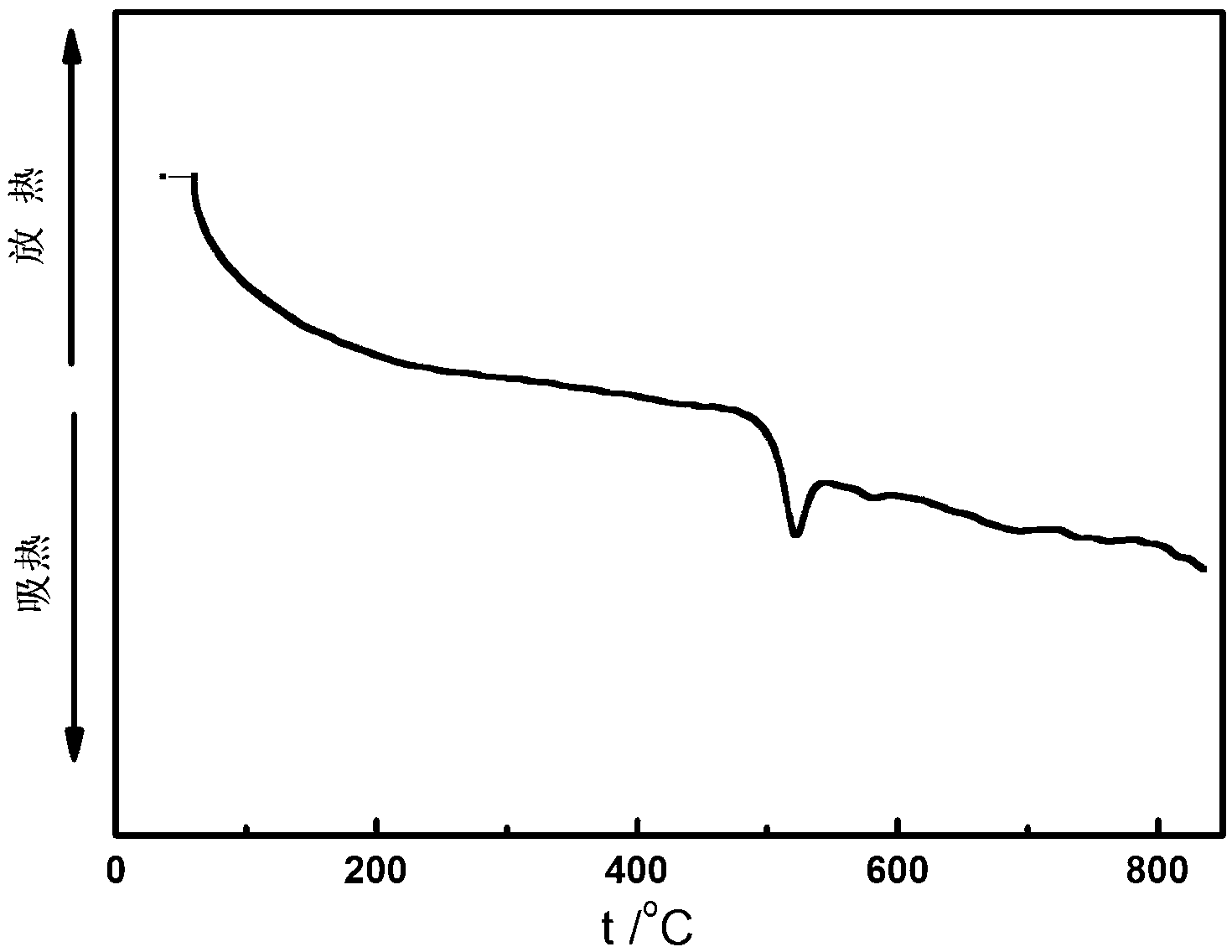

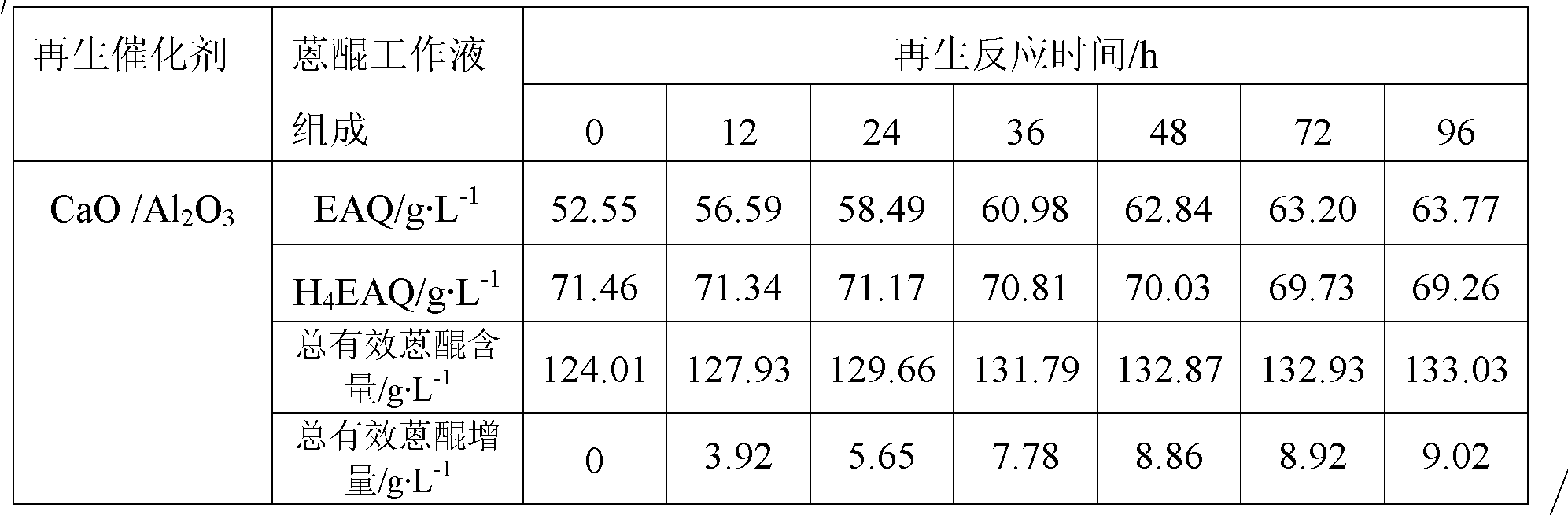

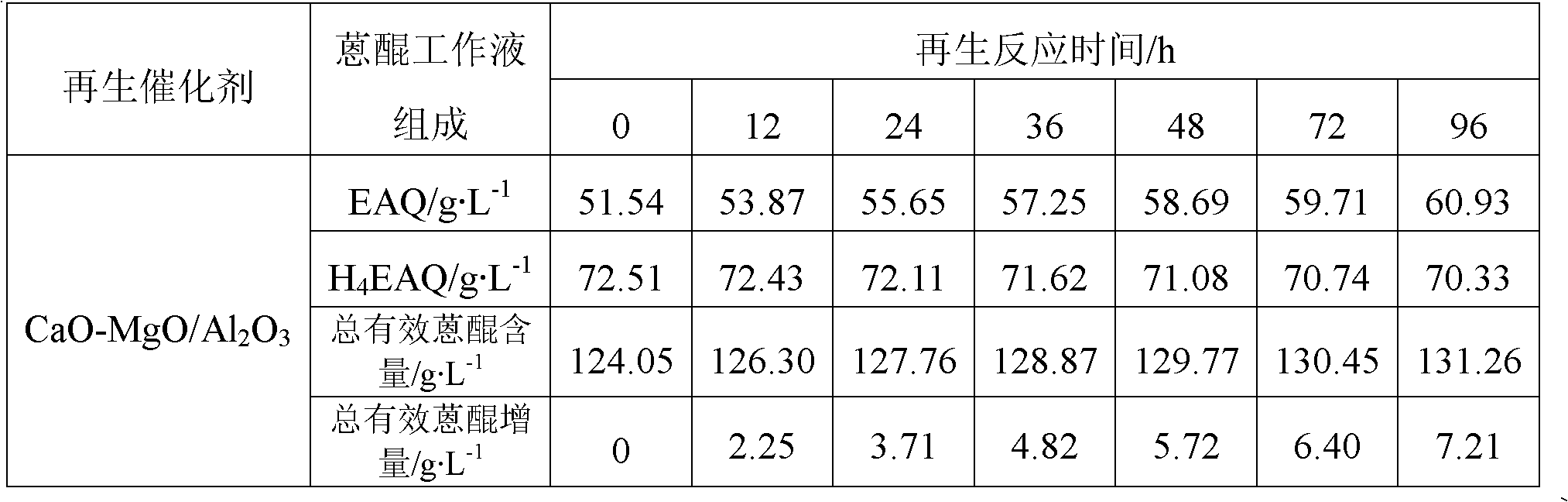

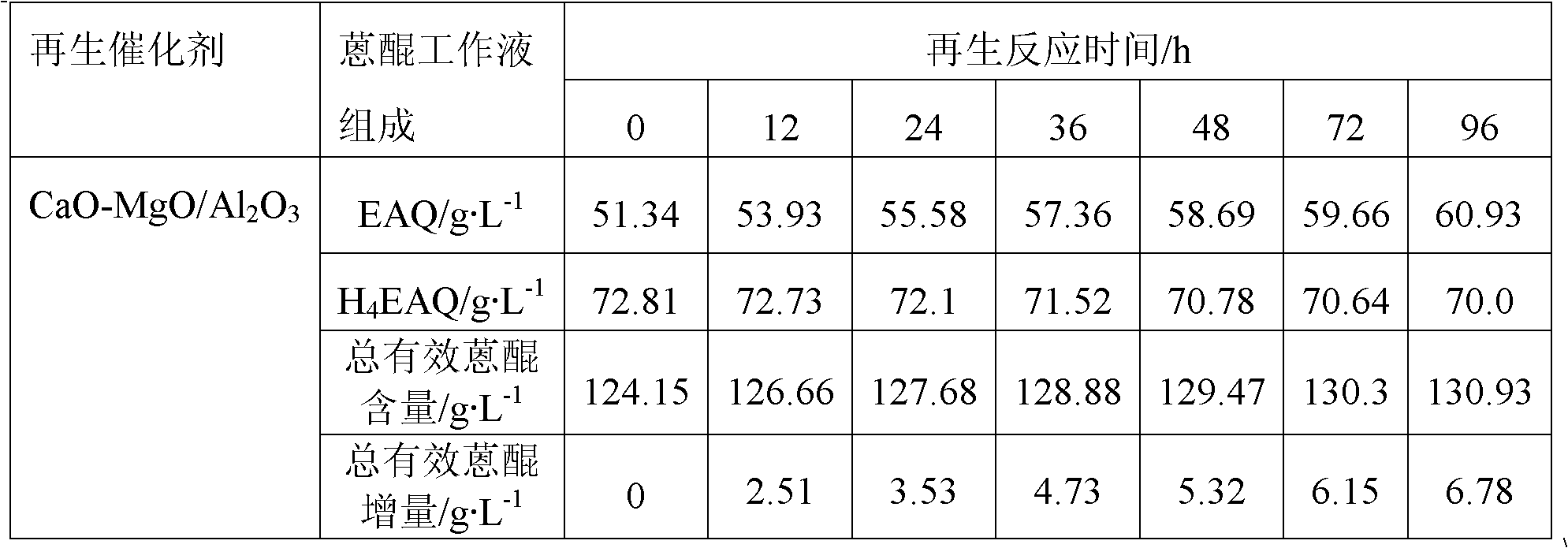

Anthraquinone degradation product regeneration catalyst and preparation method thereof

InactiveCN102728338AReduce manufacturing costSolution to short lifeOrganic compound preparationQuinone preparationHydrotalciteCompressive strength

The invention provides an anthraquinone degradation product regeneration catalyst and a preparation method thereof. MeO / Al2O3 represents the anthraquinone degradation product regeneration catalyst, wherein MeO represents an alkaline oxide; a crystal form of Al2O3 is a gamma form; Al2O3 crystals are in shapes of balls, strips and whitetip clover; a mass percent of MeO is in a range of 1 to 60wt%; a specific surface area of MeO / Al2O3 is in a range of 100 to 300m<2>.g<-1>; a pore volume is in a range of 0.3 to 1.5cm<3>.g<-1>; and compressive strength is in a range of 50 to 150N / particle. The preparation method comprises the following steps of synthesizing a hydrotalcite MeAlCO3-LDH / Al2O3 precursor on surfaces of Al2O3 carriers and in channels of the Al2O3 carriers and carrying out calcination at a temperature of 500 to 600 DEG C to obtain the anthraquinone degradation product regeneration catalyst. The anthraquinone degradation product regeneration catalyst which is an alkaline composite oxide can be used for regeneration of an anthraquinone working solution used in an anthraquinone process-based hydrogen peroxide preparation industry and has a stable regeneration period of 6 to 20 months. Compared with the existing regeneration catalyst used industrially, the anthraquinone degradation product regeneration catalyst has a service life prolonged by 2-3times and higher regeneration efficiency.

Owner:BEIJING UNIV OF CHEM TECH

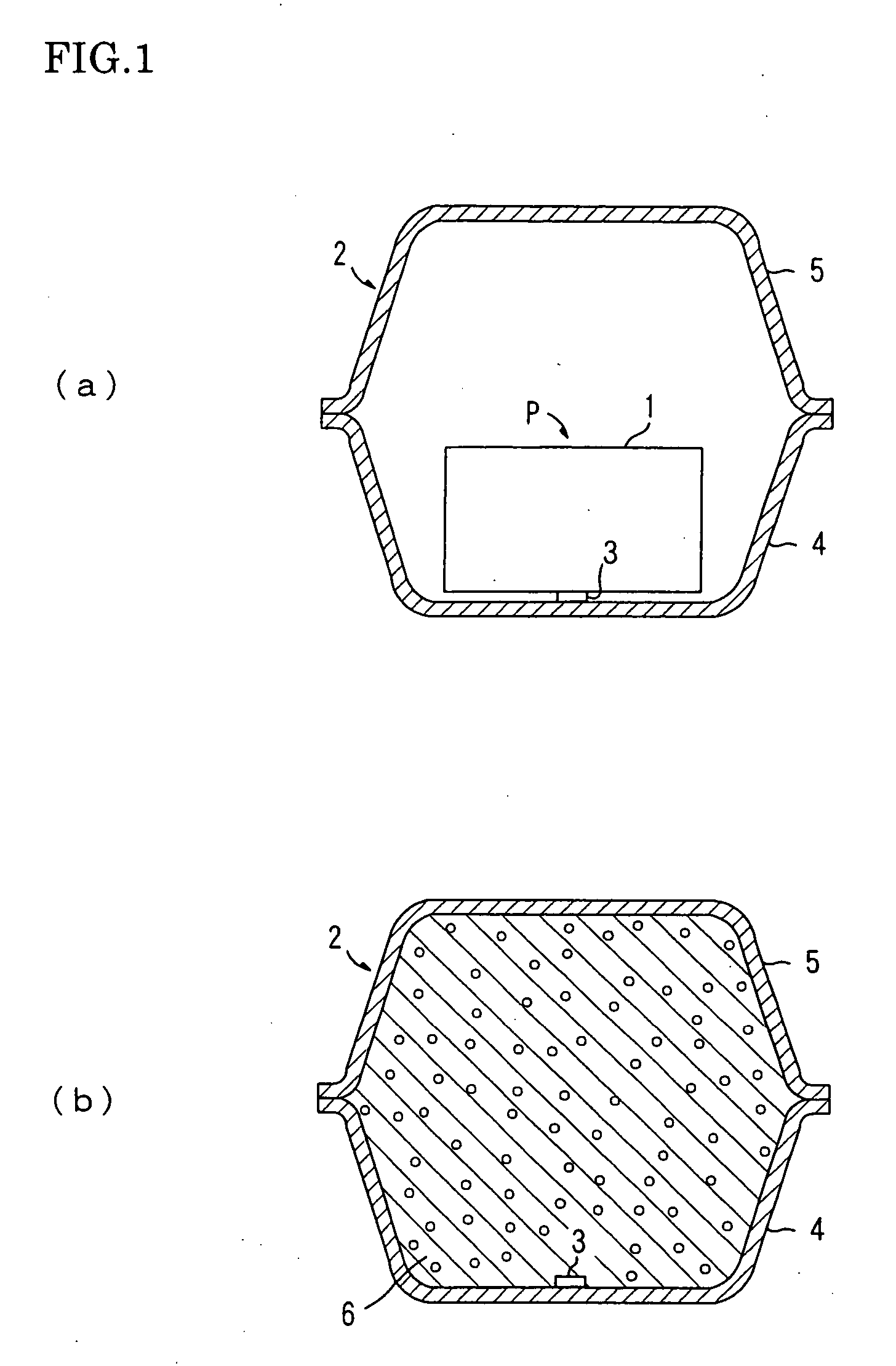

Expandable composition for filling use, expandable member for filling use and expanded article for filling use

InactiveUS20060252860A1Low costImprove rust resistanceEngine sealsOther chemical processesFoaming agentMixing ratio

Filling foam composition capable of providing excellent rustproof and also suppressing reduction of a foam ratio of the filling foam composition even when reusing unwanted parts thereof and inferior goods thereof; a foam filling member using the same filling foam composition; and a filling foam produced by foaming the filling foam composition. The filling foam composition is prepared by mixing foamable polymer, a foaming agent, and a basic oxide in such a mixing ratio that a ratio of the basic oxide can be in the range of 0.05-70 parts by weight per 100 parts by weight of foaming agent. The mounting member for the filling foam composition to be mounted in an internal space of a hollow member is produced by mounting a mounting member on the filling foam composition obtained. The filling foam is formed by fitting the foam filling member in the internal space of the hollow member and, then, foaming the filling foam composition by the application of heat.

Owner:NITTO DENKO CORP

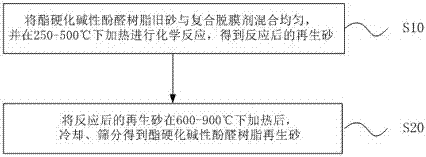

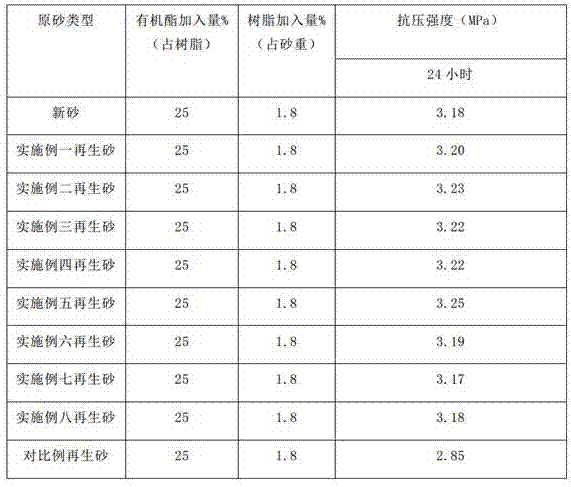

Reclaiming method for ester-hardened alkaline phenolic resin used sand

ActiveCN107321912AGuaranteed performanceImprove performanceMould handling/dressing devicesOrganic acidInorganic salts

The invention provides a reclaiming method for ester-hardened alkaline phenolic resin used sand. The reclaiming method for the ester-hardened alkaline phenolic resin used sand comprises the steps that the ester-hardened alkaline phenolic resin used sand and a compound film-releasing agent are evenly mixed, and then conduct chemical reaction after being heated at 250-500 DEG C, wherein the compound film-releasing agent comprises inorganic acid, organic acid, inorganic salt and water; and reclaimed sand after reaction is heated at 600-900 DEG C and then subjected to cooling and screening, and ester-hardened alkaline phenolic resin reclaimed sand is obtained. According to the reclaiming method for the ester-hardened alkaline phenolic resin used sand, resin films alkaline oxide adhering to the surface of the ester-hardened alkaline phenolic resin used sand can be removed, a sand grain bonding problem and a potassium and sodium remaining problem are avoided, and it is ensured that the obtained ester-hardened alkaline phenolic resin reclaimed sand has the excellent performance which is the same as or similar to the excellent performance of new sand.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

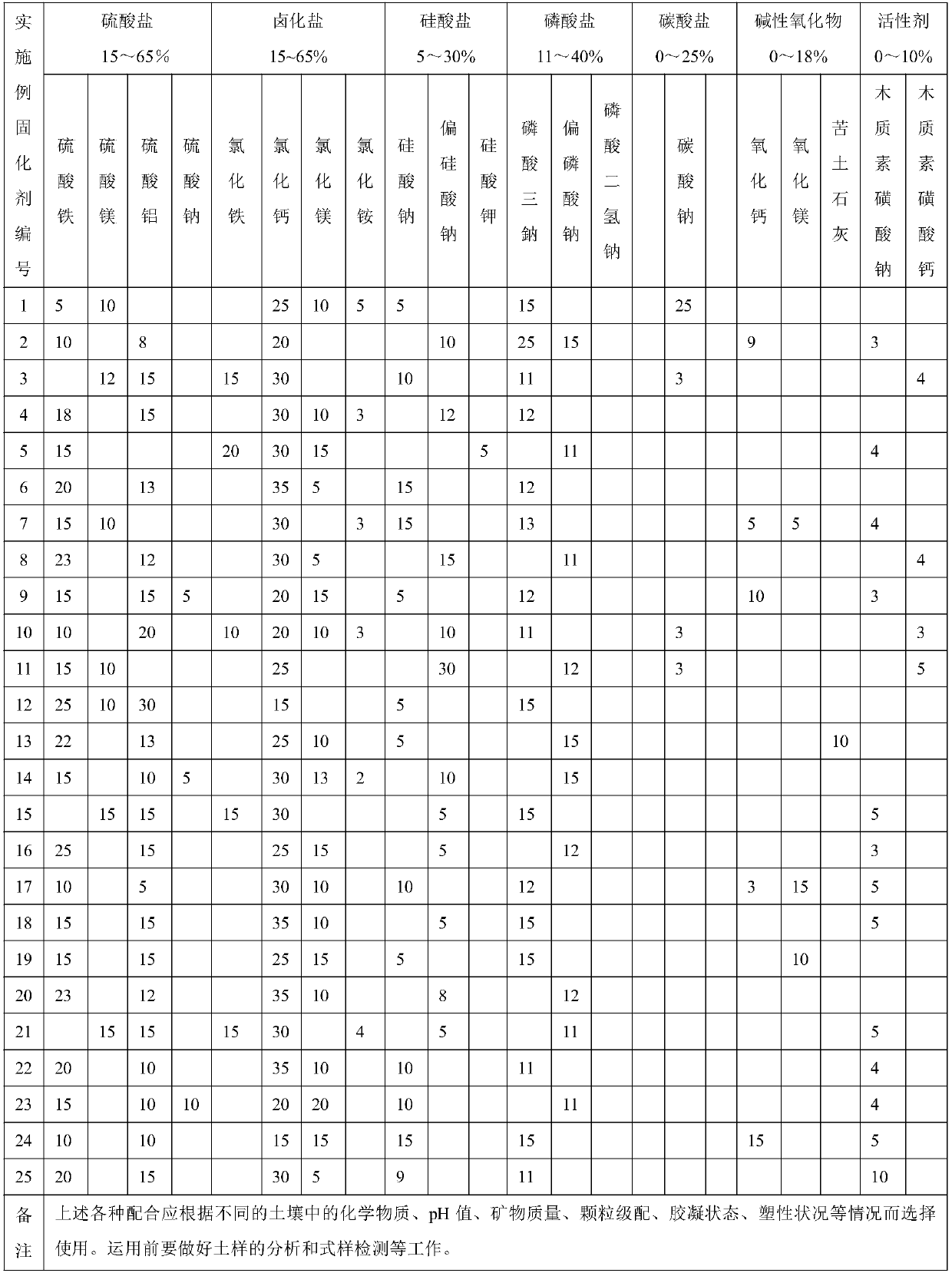

Environment-friendly inorganic soil solidification additive

InactiveCN105950157AImprove compatibilityFull effectOther chemical processesBuilding constructionsSoil propertiesHazardous substance

The invention provides an environment-friendly inorganic soil solidification additive which comprises, by mass, 15-65% of sulfate, 15-65% of halide salt, 11-40% of phosphate, 5-30% of silicate, 0-25% of carbonate, 0-18% of basic oxide and 0-10% of lignosulfonate. The environment-friendly inorganic soil solidification additive is characterized in that all components in soil directly or indirectly undergo soil particle surface chemical modification and modification of substances among soil particles, and generation of colloidal gel materials and generation of various materials of crystal structures are promoted. As time goes, hardened skeletons such as ettringite needle-shaped crystals and apatite crystals appear gradually in solidified soil, soil solidification compressive strength, hydrophobicity, water permeability, stability of heavy metal and other harmful materials and other physical and chemical solidification effects are good, and the environment-friendly inorganic soil solidification additive can adapt to various climates, geographies and soil properties and is high in compatibility and obvious in stabilization and solidification effect on heavy metal and other harmful materials.

Owner:松田勤

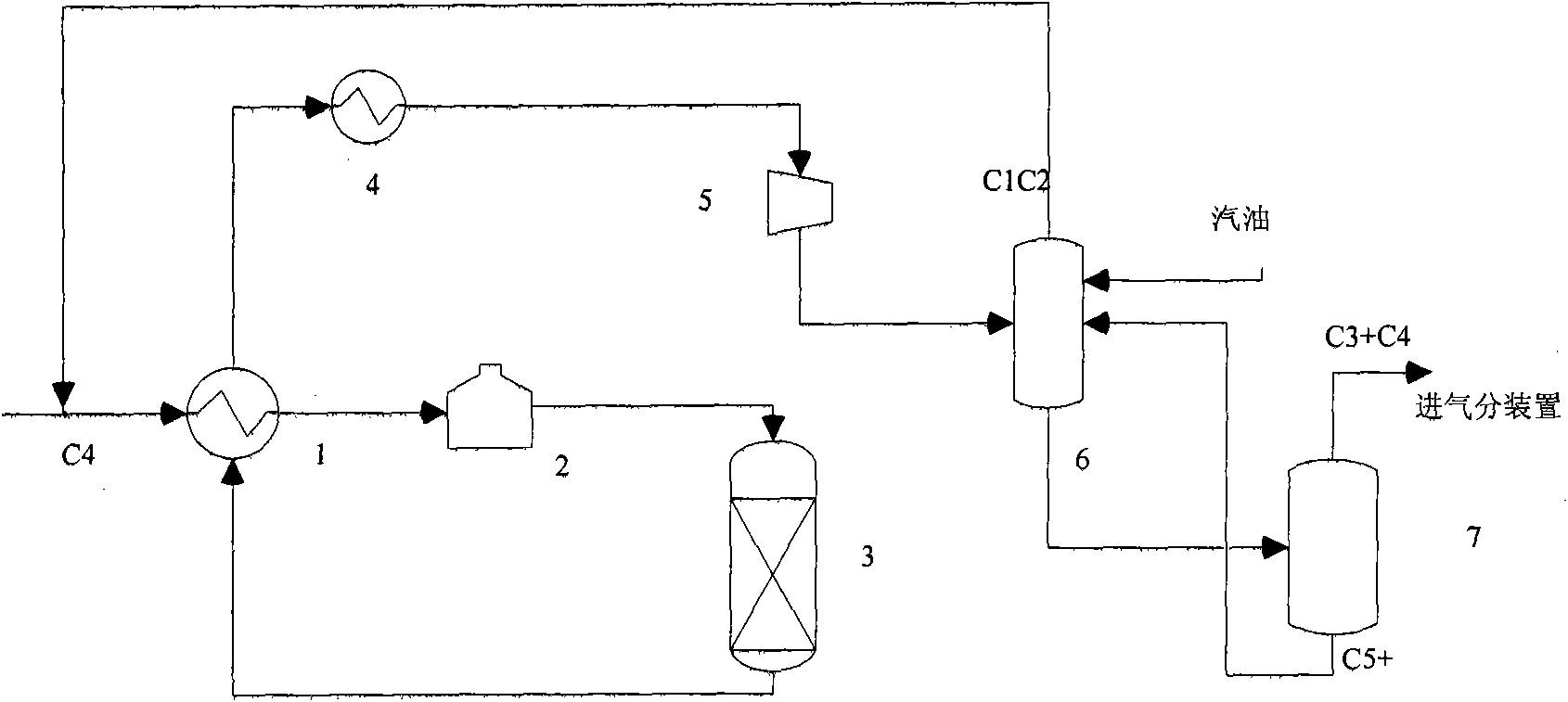

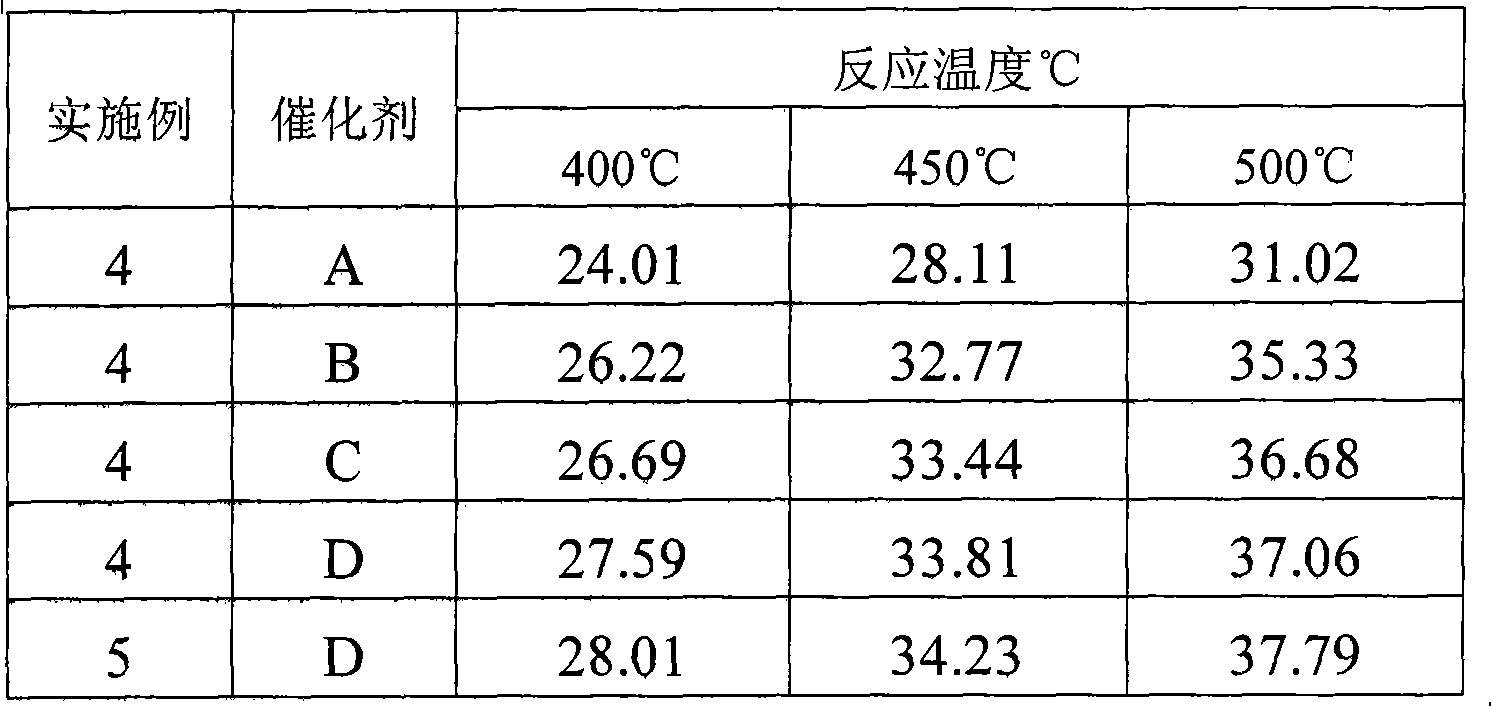

Catalyst for preparing propylene from C4 olefins, and application and regeneration method thereof

ActiveCN101927180ASimple processEasy to operateMolecular sieve catalystsCatalyst regeneration/reactivationLithium oxideFixed bed

The invention discloses a method for increasing yield of propylene by using C4 fraction in ethylene plants and oil plants. In order to solve the problems of catalyst stability and regeneration in the prior art for preparing propylene from C4 olefins, high-silica zeolite and silicon oxide are selected as the main components of the catalyst, and basic oxides and acidic oxides are used for modification to prepare the olefin conversion catalyst, wherein the basic oxides are preferably calcium oxide and lithium oxide, and the acidic oxides are preferably boron oxide and phosphorus oxide. After being tested, the catalyst has favorable stability, and various properties can be restored after the catalyst is regenerated. The application method of the catalyst comprises the following steps: using the mixture of raffinate I or etherified C4 as the raw material, exchanging heat, preheating, contacting with high silicon / aluminum ratio zeolite catalyst in a fixed bed adiabatic reactor to generate the reactant mixture containing ethylene and propylene, exchanging heat, cooling and separating to obtain propylene, ethylene and the like for cycle use. The invention provides an industrially available method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com