High-dispersion nano-composite catalyst, and preparation method and applications thereof

A nanocomposite, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as easy deactivation and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

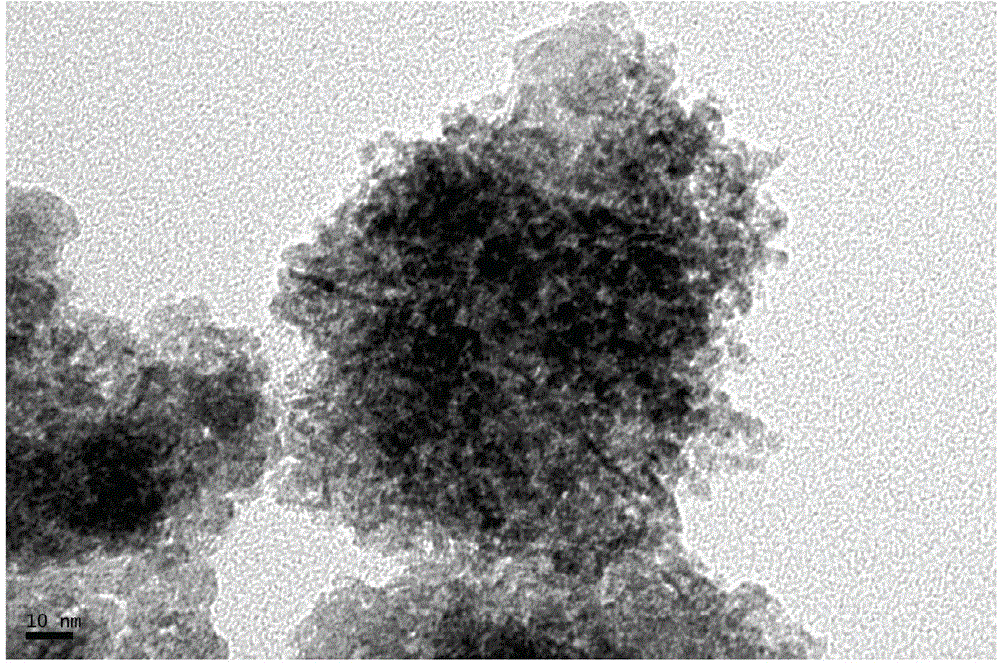

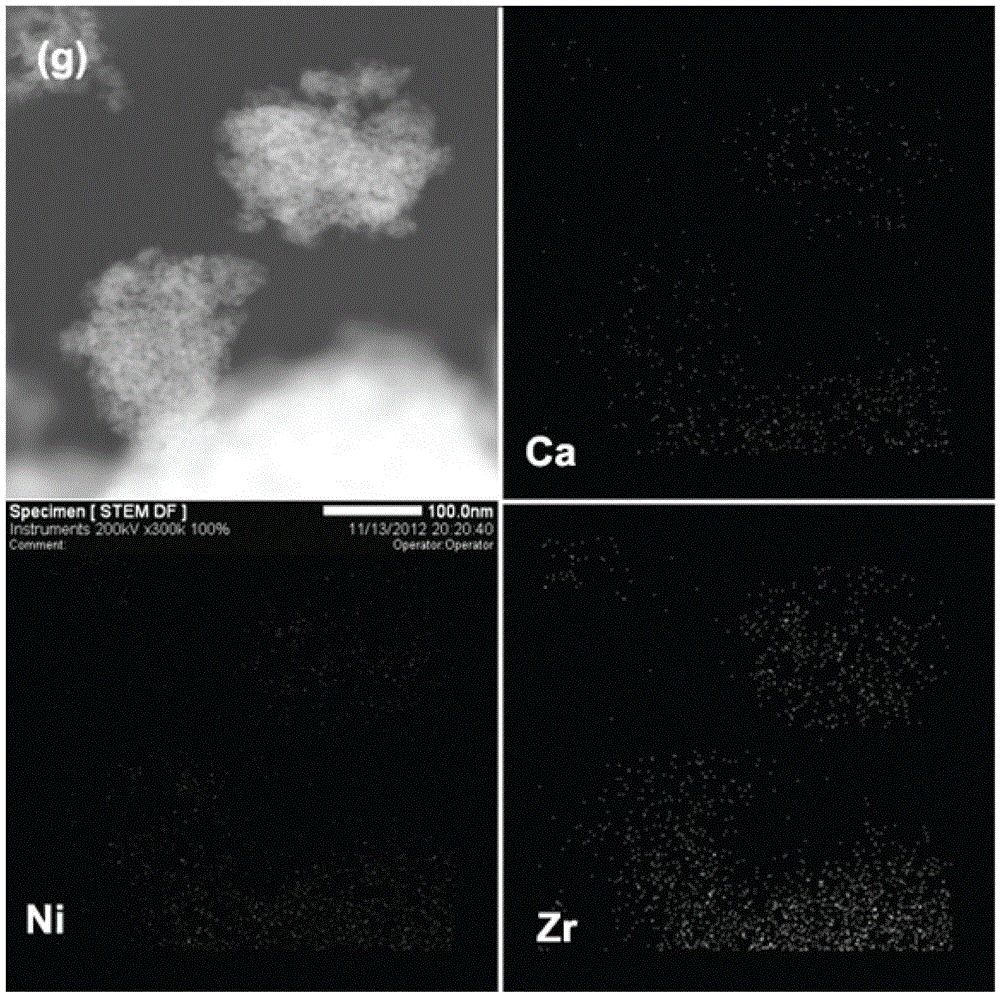

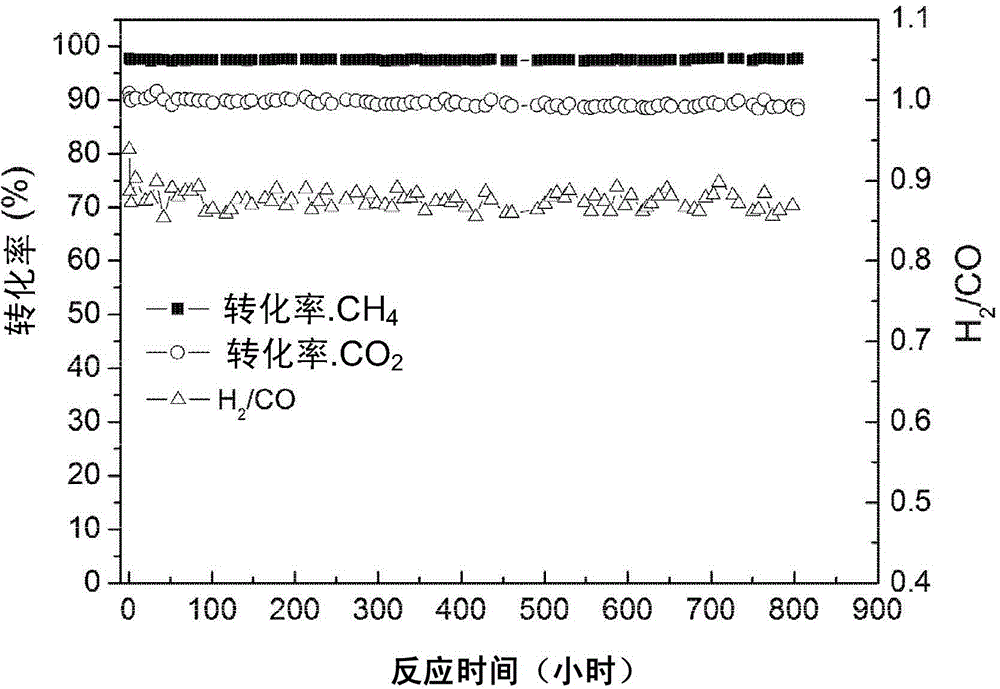

Image

Examples

preparation example Construction

[0034] The present invention also relates to a preparation method of a highly dispersed nanocomposite catalyst, the method comprising the following steps:

[0035] (1) Prepare mixed salt solution and alkaline precipitant solution respectively;

[0036] (2) co-precipitating the mixed salt solution and the alkaline precipitant solution to obtain a composite precipitate;

[0037] (3) reflux aging the composite precipitate to obtain aged composite precipitate; and

[0038] (4) Drying and roasting the aged composite precipitate.

[0039] In the preparation process of the above step (1), the preparation of the mixed salt solution is to mix a certain amount of precursors of active metal oxides, precursors of basic oxide promoters, precursors of redox additives, The precursor of the zirconia support is dissolved in a certain amount of water. The "certain amount" of the precursor of the active metal oxide, the precursor of the basic oxide promoter, the precursor of the redox auxilia...

Embodiment 1

[0060] First, a highly dispersed nanocomposite catalyst is prepared, which includes the following steps (1)-(4).

[0061] (1) Preparation of mixed salt solution and alkaline precipitant: Active metal oxide NiO, alkaline oxide promoter CaO, carrier ZrO in 10g nanocomposite catalyst 2 The mass fraction is 13%, 5%, and 82% to calculate the mass of nickel nitrate, calcium nitrate and zirconium nitrate, and calculate the amount of deionized water required with the concentration of zirconium nitrate as 0.1mol / L. The required nickel nitrate, calcium nitrate and zirconium nitrate are dissolved in deionized water to form a mixed salt solution. Using NaOH solution as a precipitating agent, prepare an aqueous solution with a NaOH concentration of 1 mol / L.

[0062] (2) Co-precipitation of mixed salt solution: under strong stirring, co-current co-precipitation of mixed salt solution and alkaline precipitant to obtain composite precipitate. During the co-precipitation process, the tempera...

Embodiment 2

[0072] First, a highly dispersed nanocomposite catalyst is prepared, which includes the following steps (1)-(4).

[0073] (1) Preparation of mixed salt solution and alkaline precipitant: Active metal oxide NiO, alkaline oxide promoter CaO, and redox additive CeO in 10 g of nanocomposite catalysts 2 , Carrier ZrO 2 The mass ratio is 15%, 5%, 5%, 75% to calculate the mass of nickel nitrate, cerium nitrate, calcium nitrate and zirconium nitrate, and calculate the required amount of deionized water with the concentration of zirconium nitrate as 0.2mol / L . The required nickel nitrate, cerium nitrate, calcium nitrate and zirconium nitrate are dissolved in deionized water to form a mixed salt solution. Using NaOH solution as a precipitating agent, prepare an aqueous solution with a NaOH concentration of 2 mol / L.

[0074] (2) Co-precipitation of mixed salt solution: under strong stirring, co-current co-precipitation of mixed salt solution and alkaline precipitant to obtain composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com