Method for preparing activated carbon-silicon dioxide mixed adsorbing material by using silicon tetrachloride

An adsorption material, silicon tetrachloride technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of difficult separation, small silica market, high cost, and achieve simple process, abundant raw materials and low cost. Effect

Inactive Publication Date: 2010-07-28

LESHAN NORMAL UNIV

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the methods for processing silicon tetrachloride mainly include: 1. Preparation of silicon dioxide powder and hydrolysis precipitation method to produce silicon dioxide, but the application value and market are not large, and silicon tetrachloride is used to produce high value-added gas phase whitening Carbon black silica, but the silica market is relatively small

2. The patent (US4416862(A)) involves the technology of using silicon tetrachloride to produce silicon dioxide and aluminum trichloride, but there are problems of separation difficulties and low added value of products

3. Trichlorosilane, the main raw material for reducing silicon tetrachloride to polysilicon by using hydrogen under high temperature and high pressure, has received the most attention at present, and its primary conversion rate is the key. There are also related patents (CN101445245), but the hydrogenation technology is not mature enough

The biggest problem in China at present is the product trichlorosilane (SiHCl 3 ) yield is not high enough, and the cost of recycling trichlorosilane may be higher than the cost of direct production of trichlorosilane, resulting in that this technology has not yet played an important role in the comprehensive utilization of silicon tetrachloride

4. For the production of ethyl orthosilicate, it is mainly used as a crosslinking agent, the process is simple, but the market is not large

5. There are still many technical difficulties in producing more new organosilicon compounds

6. If sodium and zinc are used to reduce silicon tetrachloride to produce polysilicon, the technology is feasible, but the cost is higher

7. Silicon tetrachloride can be used to produce optical fiber materials, but as a communication material, the total tonnage of optical fiber materials is small, and the amount of polysilicon by-product silicon tetrachloride consumed by optical fiber grade silicon tetrachloride is also extremely limited

In a word, up to now, silicon tetrachloride is sneaked out in the polysilicon industry from time to time, and its hydrolysis produces a large amount of hydrochloric acid, which greatly pollutes rivers and the environment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

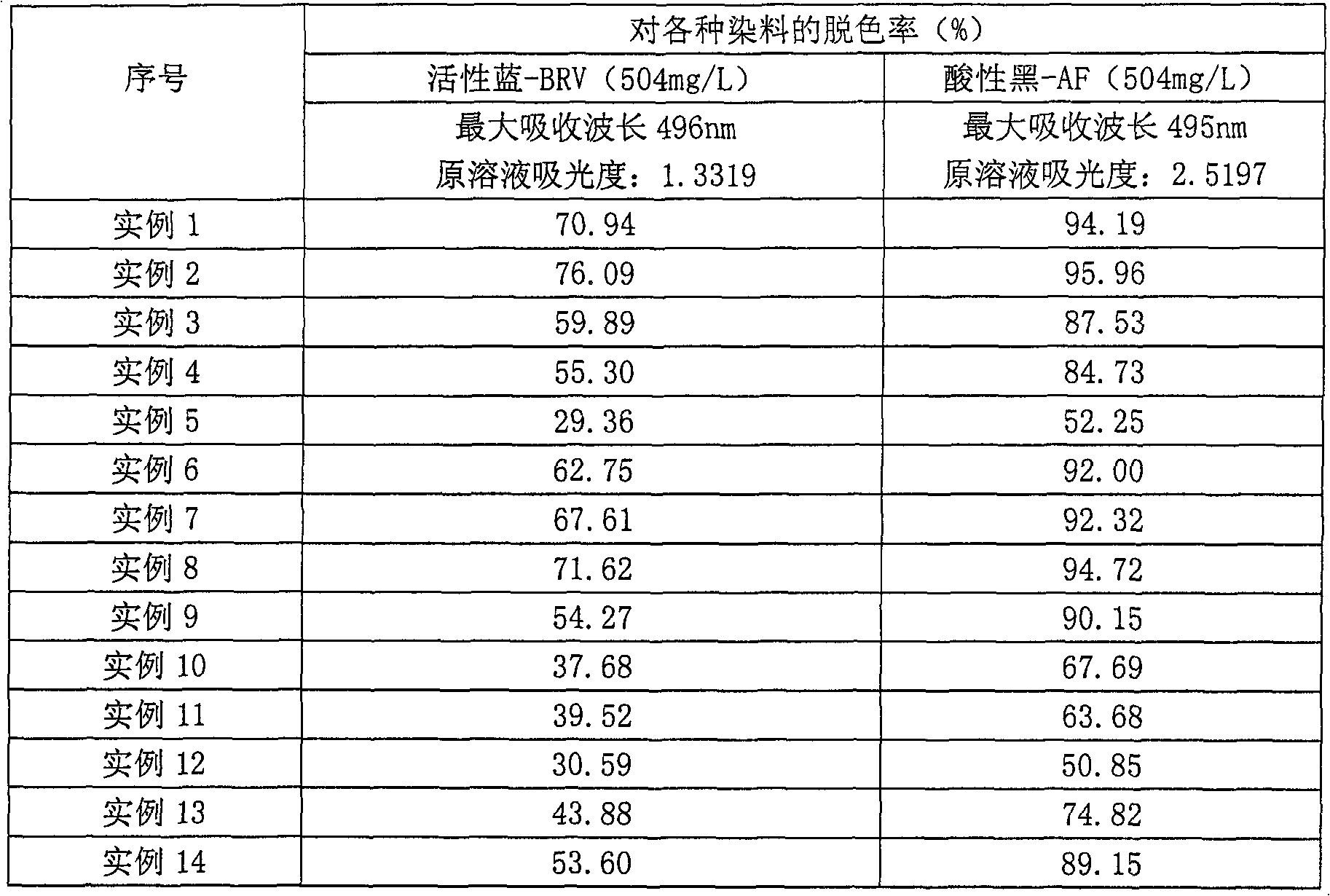

example 1

[0044] Instance 1: 1.6369 Instance 2: 0.5828 Instance 3: 1.6834

example 4

[0045] Instance 4: 0.6902 Instance 5: 1.7129 Instance 6: 1.2297

example 7

[0046] Instance 7: 1.4861 Instance 8: 1.5079 Instance 9: 0.4216

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a method for preparing an activated carbon-silicon dioxide mixed adsorbing material by using silicon tetrachloride, in particular to the method for preparing the adsorbing material by using a byproduct of polycrystalline silicon, namely SiCl4, which comprises the following steps: firstly, adding solid powders, such as alkaline oxide and calcium salt and the like into water with stirring until the solid powders are fully dissolved, and adding a small amount of carbon-containing substance; secondly, adding the byproduct of the polycrystalline silicon, namely the SiCl4, and the balance of carbon-containing substance for fully stirring, and standing the mixture for a night; and finally, activating the mixture for 3 to 5h at the holding temperature of 600 to 800 DEG C in a muffle furnace, taking the mixture out after cooling, washing the mixture with distilled water until the mixture contains no Cl-, and pumping, drying, weighing to obtain the product. In the method, hydrochloric acid prepared by hydrolyzing the byproduct of the polycrystalline silicon, namely the SiCl4, is directly mixed with a proper amount of chemical reagent and raw materials, and the mixture is activated to obtain the activated carbon-silicon dioxide mixed adsorbing material; and the method has the advantages of simple process, abundant raw materials and low cost, and effectively solves the problem of comprehensive application of the silicon tetrachloride, biomass and carbon-containing waste.

Description

technical field [0001] The invention relates to the preparation of novel environmental materials and the comprehensive utilization of waste resources. By reacting silicon tetrachloride (mainly polysilicon by-product) with water to produce silicic acid and hydrochloric acid, the hydrochloric acid produced can be used with a certain amount of chemical reagents to produce activators, and combined with carbon-containing waste (mainly renewable) Biomass) is activated at high temperature to produce porous activated carbon-silica mixed adsorption materials, which are mainly used for environmental wastewater treatment, and can also be used as catalysts and catalyst carrier materials. Others can also be developed through production process adjustment and further modification. Special functional materials. Background technique [0002] Activated carbon is a material mainly made of carbonaceous materials with a black appearance, developed internal pore structure, large specific surfac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J20/20B01J20/32

Inventor 王应红程四清张元勤李晓燕邓迟向清祥熊俊如刘凡刘志昌胡育夏烈文彭琼张文杜佳艳

Owner LESHAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com