Catalyst for preparing propylene from C4 olefins, and application and regeneration method thereof

A carbon tetraolefin and catalyst technology, applied in the field of catalyst and its application and regeneration, can solve the problems of catalyst stability and regeneration that are not seen, and achieve the effects of simple preparation method and regeneration method, low reaction temperature and long service cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

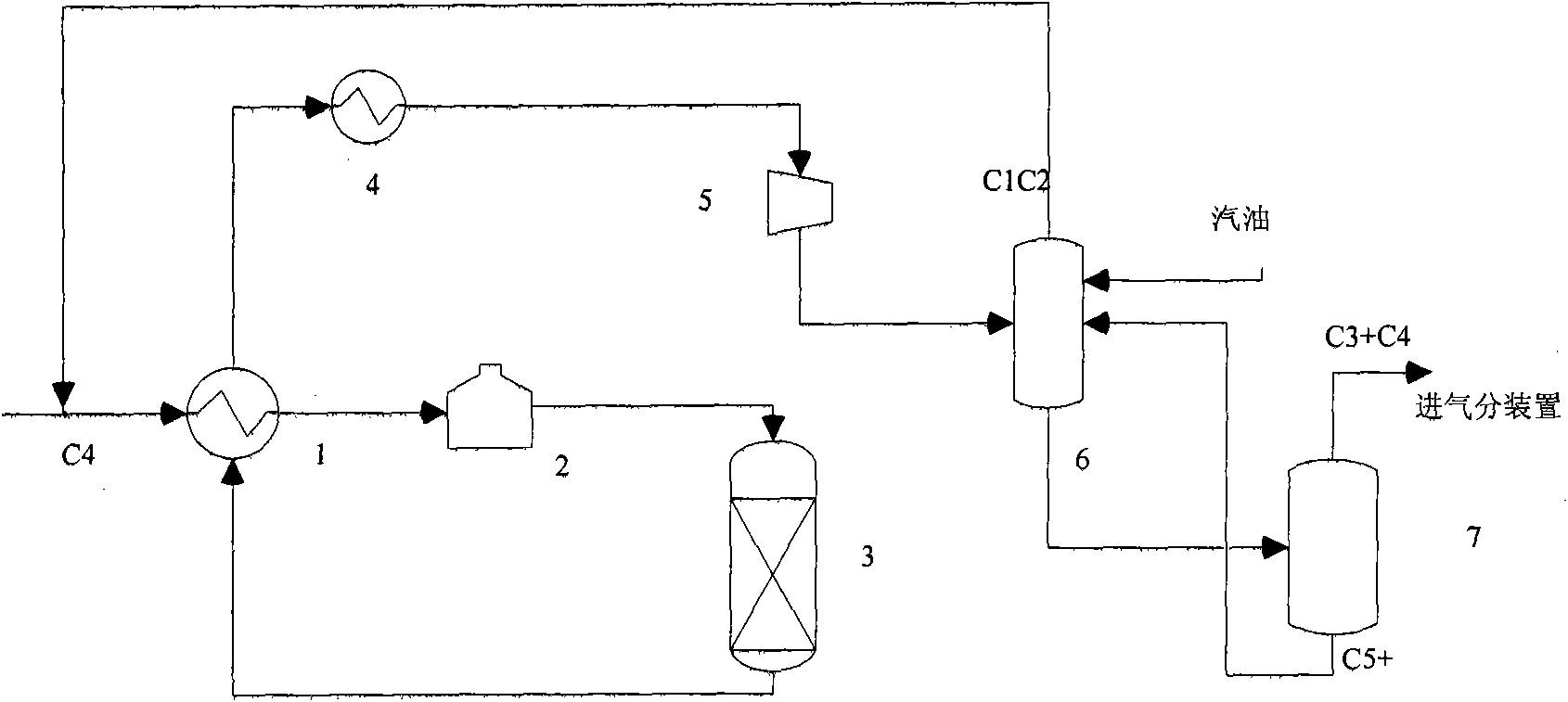

Method used

Image

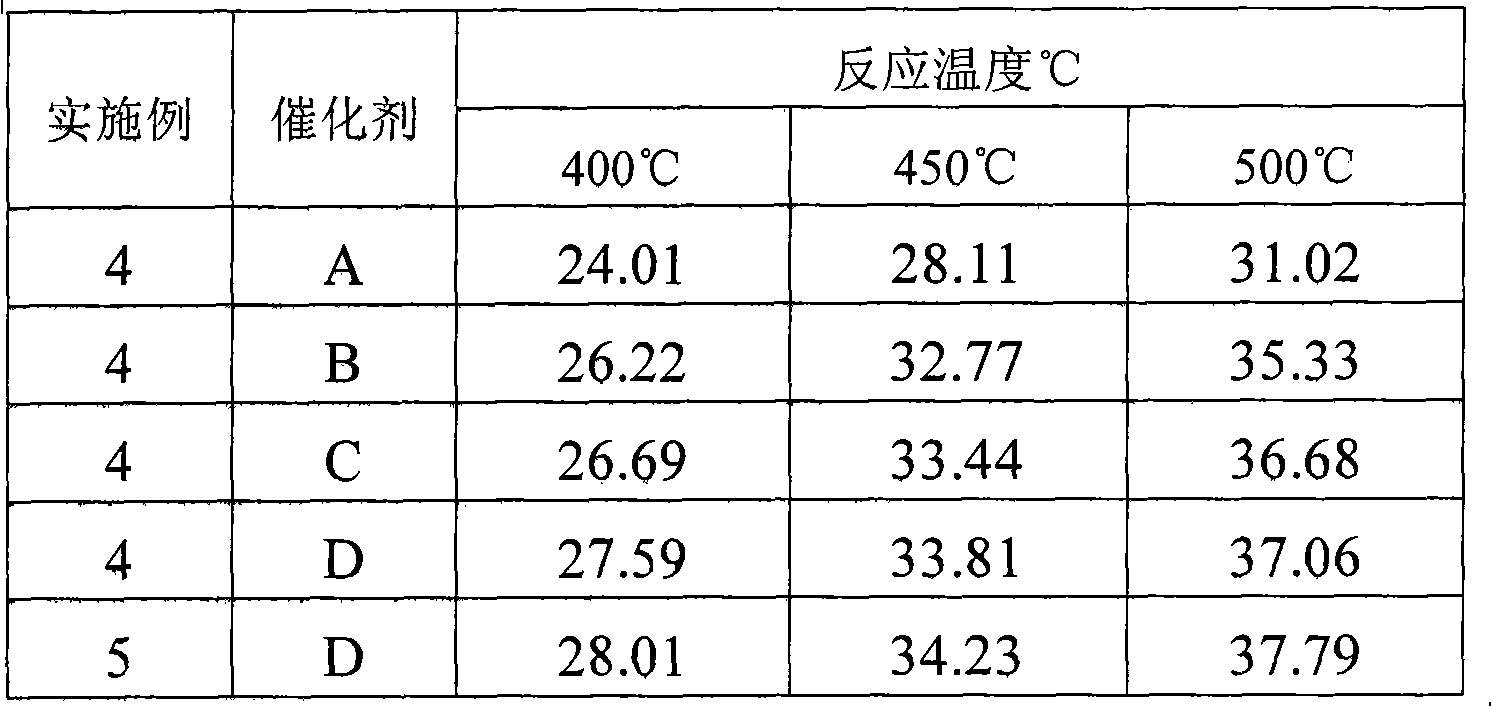

Examples

Embodiment 1

[0036] Embodiment 1 prepares catalyst A

[0037] 85g ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 >200), 15g silicon oxide and 2g squash powder; mix well, add 80ml 5% phosphoric acid, mix well, extrude into 2mm cylindrical shape, and cut into 2~3mm; dry at 80℃ and 120℃ respectively 10 hours, and then calcined at 580°C for 6 hours, took it out and cooled it to room temperature, and put it in a desiccator for later use. The catalyst prepared in this way is designated Catalyst A.

Embodiment 2

[0038] Embodiment 2 prepares catalyst B

[0039] 75g ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 >200), 10g of silicon oxide, 10g of calcium oxide, 2g of boron oxide and 2g of turnip powder were mixed, and after mixing, 80ml of 5% nitric acid was added. Other operating methods are the same as in Example 1. The catalyst prepared in this way was designated Catalyst B.

Embodiment 3

[0040] Embodiment 3 prepares catalyst C

[0041] 75g ZRP molecular sieve (SiO 2 / Al 2 o 3 >200), 10g of silicon oxide, 10g of calcium oxide, 2g of lithium oxide and 2g of turnip powder were mixed, and after mixing, 80ml of 5% phosphoric acid was added. Other operating methods are the same as in Example 1. The catalyst prepared in this way is designated Catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com