Manganese alloying method for high manganese steel smelting through converter

A manganese alloying and converter smelting technology, applied in the direction of manufacturing converters, etc., to achieve sustainable development, improve manganese alloying processing capacity, and reduce overall costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In this embodiment, 100 tons of high manganese steel with a carbon content of 0.10% and a manganese content of 10% to 13% are produced.

[0068] The specific method of manganese alloying of converter smelting high manganese steel is as follows:

[0069] (1) Metal manganese is crushed into particles with a particle size less than 10mm, the iron oxide scale on the surface of the slab is crushed into 80-mesh powder, and the metal aluminum is processed into silk floc;

[0070] (2) Mix the metal manganese particles, iron oxide scale powder, and silk flocculent metal aluminum in the step (1) according to the proportion of 5 parts, 2.5 parts, and 1 part by weight, and use the ball pressing machine to press the mixed materials into a mixture ball with a diameter of 50mm;

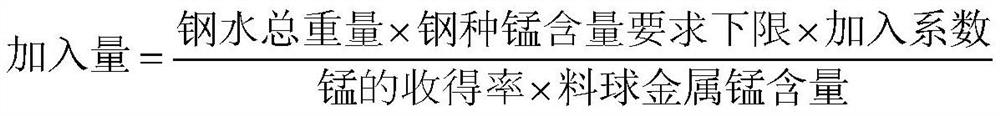

[0071] (3) Add the mixture balls in step (2) to the steel ladle whose inner wall temperature is 1100°C after preheating, and the addition amount is calculated according to the following formula:

[0072] ...

Embodiment 2

[0079] In this embodiment, 100 tons of high manganese steel with a carbon content of 0.20% and a manganese content of 20% to 24% are produced.

[0080] The specific method of manganese alloying of converter smelting high manganese steel is as follows:

[0081] (1) Metal manganese is crushed into particles with a particle size less than 10mm, the iron oxide scale on the surface of the slab is crushed into 80-mesh powder, and the metal aluminum is processed into silk floc;

[0082] (2) Mix the metal manganese particles, iron oxide scale powder, and silk flocculent metal aluminum in the step (1) according to the proportion of 6.5 parts, 3.5 parts, and 2 parts by weight, and use a ball press to press the mixed materials into a mixture ball with a diameter of 50mm;

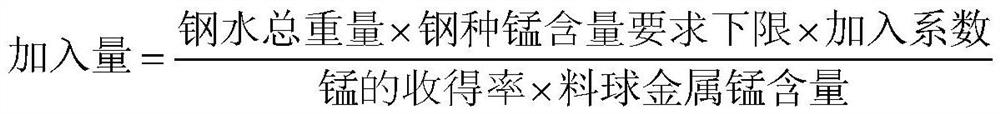

[0083] (3) Add the mixture balls in step (2) to the steel ladle whose inner wall temperature is 1150°C after preheating, and the addition amount is calculated according to the following formula:

[0084]

[0085] ...

Embodiment 3

[0091] In this embodiment, 100 tons of high manganese steel with a carbon content of 0.30% and a manganese content of 15% to 20% are produced.

[0092] The specific method of manganese alloying of converter smelting high manganese steel is as follows:

[0093] (1) Metal manganese is crushed into particles with a particle size less than 10mm, the iron oxide scale on the surface of the slab is crushed into 80-mesh powder, and the metal aluminum is processed into silk floc;

[0094] (2) Mix the metal manganese particles, iron oxide scale powder, and silk flocculent metal aluminum in the step (1) according to the proportion of 6 parts, 3 parts, and 2.5 parts by weight, and use a ball press to press the mixed materials into a mixture ball with a diameter of 50mm;

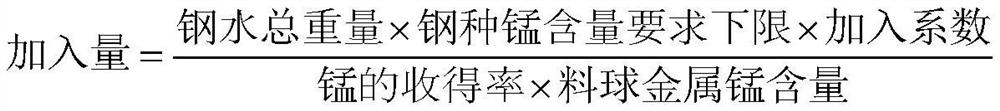

[0095] (3) Add the mixture balls in step (2) to the steel ladle whose inner wall temperature is 1200°C after preheating, and the addition amount is calculated according to the following formula:

[0096]

[0097] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com