Non-drainage casting method for low-carbon low-silicon aluminum-containing steel

A low-carbon, low-silicon, aluminum-steel technology, applied in the field of metallurgical production technology, can solve problems such as reduced benefits, high production costs, and affecting the normal progress of production organizations, so as to save energy, save production costs, and avoid fluidity deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

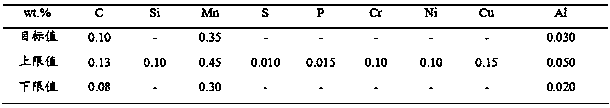

[0018] The low-carbon, low-silicon and aluminum-containing steel described in this example is ML08Al, and its C, Si, Mn, S, P, Cr, Ni, Cu and Al element content requirements are as follows:

[0019]

[0020] In this embodiment, a 120 t converter is used, the ladle is a 120 t ladle, and the ladle furnace is a 120 t ladle furnace (LF refining furnace).

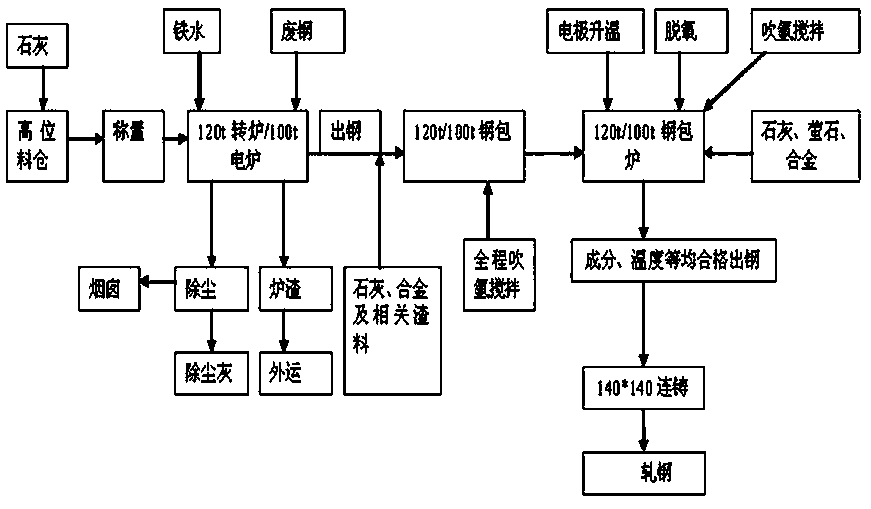

[0021] see figure 1 , Low-carbon, low-silicon and aluminum-containing steel The process before tapping the converter is: add molten iron and scrap steel to the converter, lime is sent to the converter to blow and slag after weighing through the high-level silo, and the slag is transported outside the furnace after the molten steel is tapped. The gas dust is sent into the chimney, and the particle dust is collected as dedusting ash. The molten steel adopts the method of pouring without drainage of the present invention. The specific steps of the method are as follows:

[0022] Step 1. The converter is tapped and fed. The slag...

Embodiment 2

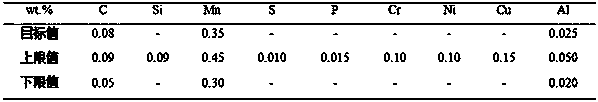

[0026] The low-carbon, low-silicon and aluminum-containing steel described in this example is SWRCH10A, and its C, Si, Mn, S, P, Cr, Ni, Cu and Al element content requirements are as follows:

[0027]

[0028] In this embodiment, a 100 t electric furnace is used, the ladle is a 100 t ladle, and the ladle furnace is a 100 t ladle furnace (LF refining furnace).

[0029] see figure 1 , Low-carbon, low-silicon and aluminum-containing steel converter before tapping process: add molten iron and steel scrap to the electric furnace, lime is sent to the electric furnace to blow and slag after weighing through the high-level silo, after the molten steel is tapped, the slag is transported outside the furnace, The gas dust is sent into the chimney, and the particle dust is collected as dedusting ash. The molten steel adopts the method of pouring without drainage of the present invention. The specific steps of the method are as follows:

[0030]Step 1. Electric furnace tapping and feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com