Electric rotary machine for motor vehicle

一种旋转机器、电压的技术,应用在集电器、电动汽车、车辆部件等方向,能够解决损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, various embodiments of the present invention will be described with reference to the accompanying drawings. In the following description of various embodiments, like reference numerals refer to like parts throughout the several views.

[0021] Exemplary implementation

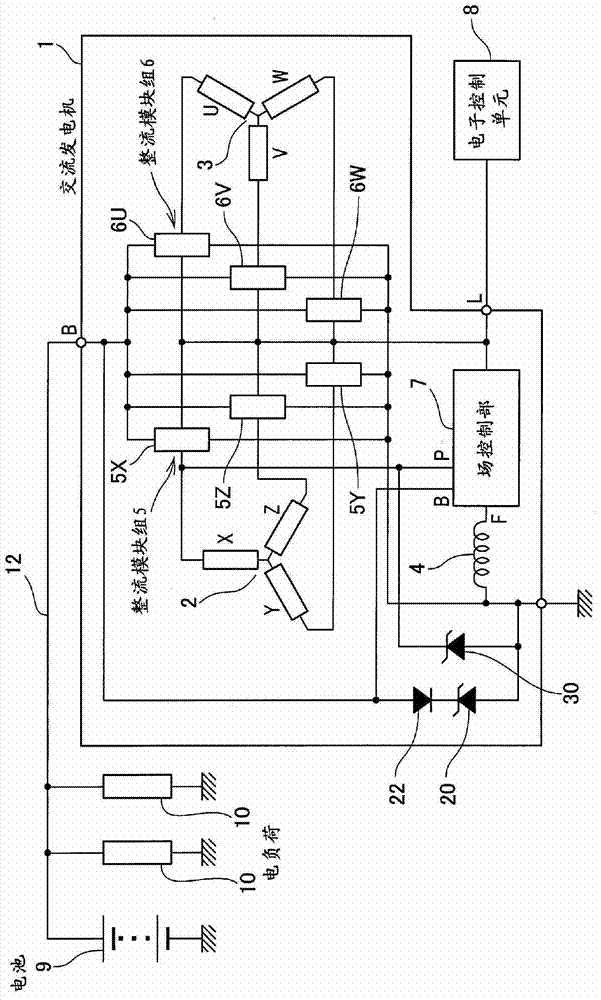

[0022] According to reference Figure 1 to Figure 10 As an exemplary embodiment of the present invention, an alternator 1 as an electric rotating machine used in a motor vehicle will be described.

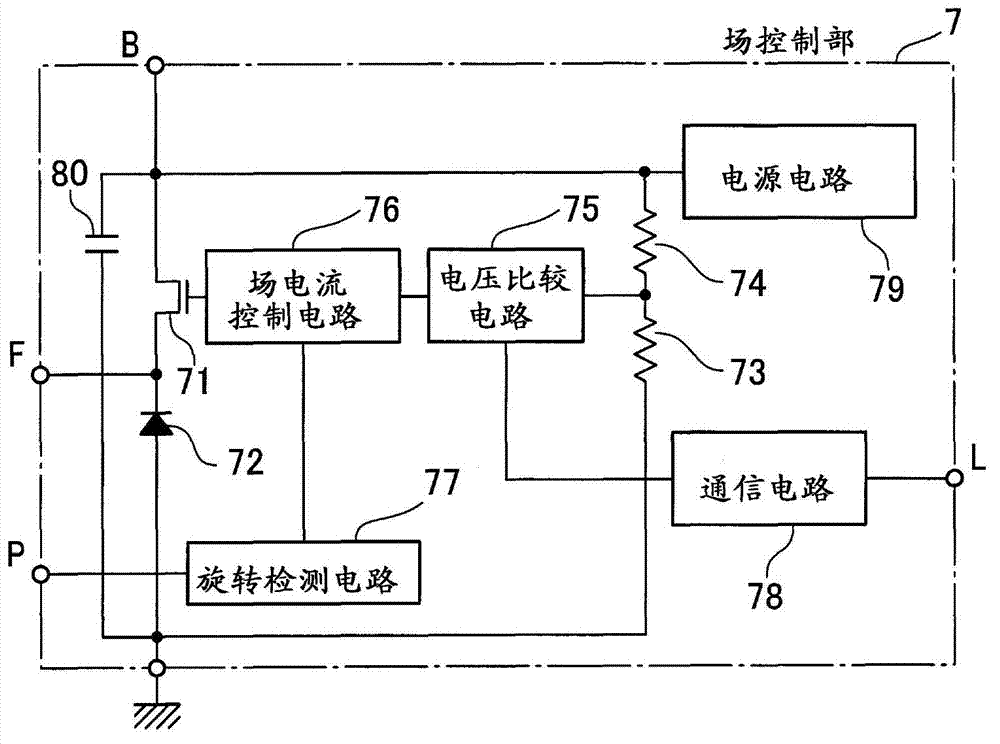

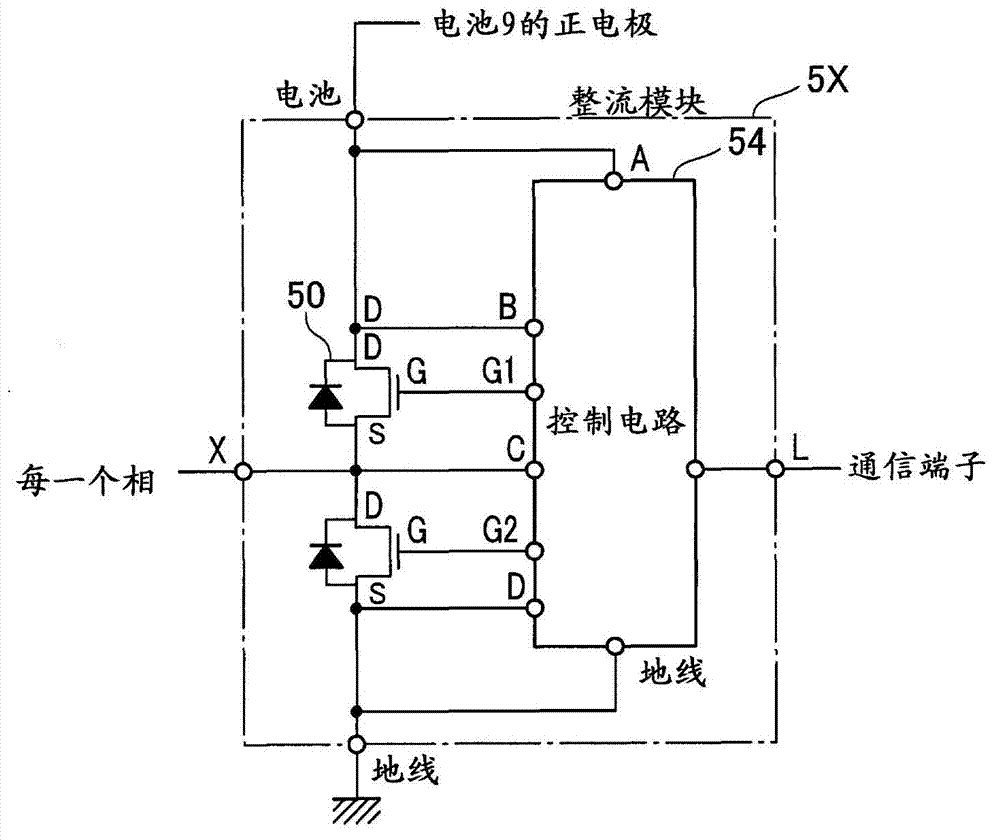

[0023] figure 1 is a view showing the structure of the alternator 1 for a motor vehicle according to the exemplary embodiment. like figure 1 As shown in , an alternator 1 includes two stator windings (or armature windings) 2 and 3 and a field winding 4, two rectification module groups 5 and 6, a field control section 7, Zener diodes 20 and 30, and diode 22 (as a current limiting element). The Zener diode 20 corresponds to a first Zener diode used in the claims. The diode 22 corresponds to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com