Low-alkalinity and high-toughness sintered flux

A technology of sintering flux and alkalinity, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that flux welding process performance and low temperature impact toughness can not be well balanced, and achieve excellent welding process performance, welding The effect of smooth edge transition and low increment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

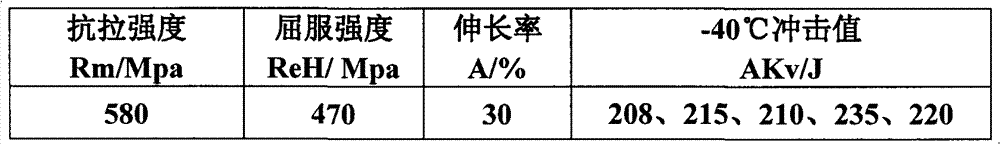

Embodiment 1

[0021] a) Flux composition (wt%): CaF 243, Al 2 o 3 42, MgO 2 , CaO 3 , SiO 2 3,K 2 O+Na 2 O3, Si-Fe2, Mn-Fe2.

[0022] Wherein, Si in the Si-Fe is 65%, and Mn in the Mn-Fe is 92%.

[0023] b) Flux alkalinity: 1.4

[0024] c) Preparation method: sieve the required raw materials and weigh according to the formula. After rechecking the total weight, put the dry powder into a dry mixer for dry mixing. After dry mixing evenly, put it into a wet mixer, and add a) About 20% of the total weight of the ingredients in the water glass is wet-mixed. After the wet-mixing is uniform, the wet powder is sent to the granulation tray through the conveyor belt for granulation. After the granulation is completed, it is sent to the drying furnace through the conveyor belt. Carry out drying, remove the moisture and sieve the flux, send the sieved flux within the standard particle size range into the sintering furnace, sinter at 700°C to 750°C for 1 hour, and sieve again after cooling out ...

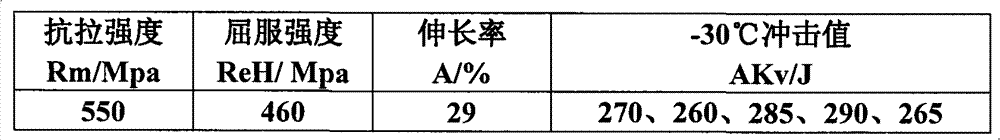

Embodiment 2

[0032] a) Flux composition (wt%): CaF 2 44, Al 2 o 3 42, MgO2, CaO2, SiO2 2 3.5,K 2 O+Na 2 O3, Si-Fe1.5, Mn-Fe2. Wherein, Si in the Si-Fe is 55%, and Mn in the Mn-Fe is 85%.

[0033] b) Flux alkalinity: 1.5

[0034] c) preparation method: same as Example 1

[0035] d) Chemical composition of deposited metal (with H10Mn2HIC welding wire), %

[0036]

C

Si

mn

P

S

Wire Composition

0.091

0.05

1.59

0.005

0.001

Deposited metal composition

0.096

0.37

1.49

0.007

0.004

[0037] e) Mechanical properties of deposited metal (with H10Mn2HIC welding wire)

[0038]

[0039] In addition, referring to the flux prepared by the method described in Example 1 of CN1326838A, it was tested according to e) above, and the impact value at -30°C was 140-175, showing significantly worse performance than the flux of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com