Patents

Literature

33results about How to "Uniform network structure" patented technology

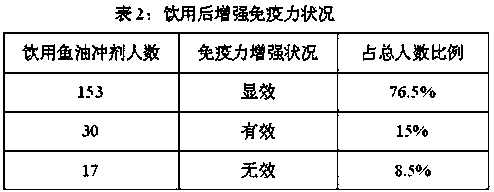

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic silica aerogel heat-insulation composite material

The invention relates to a hydrophobic silica aerogel heat-insulation composite material. The composite material consists of silica aerogel and an inorganic fiber product, wherein the silica aerogel is doped with a flame retardant and an infrared blocking agent; the inorganic fiber product comprises one or more of glass fibers, quartz glass fibers, aluminium silicate fibers, ceramic fibers, alumina fibers, zirconia fibers, rock wool fibers and basalt fibers, and the porosity of the inorganic fiber product is higher than 50%. The composite material has the overall waterproof performance, the extremely low heat conductivity coefficient and the excellent high-temperature heat-insulation performance, can pass an incombustibility test under the condition that the material is ensured to be hydrophobic as a whole, and reaches level A1 according to the incombustibility test; the preparation process is simple, the production cycle is short, the cost is lower, the equipment requirement is low, and reaction conditions are controllable.

Owner:纳诺科技有限公司

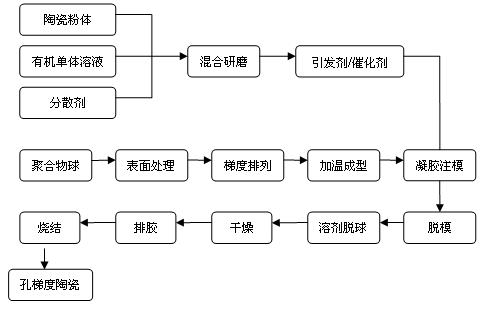

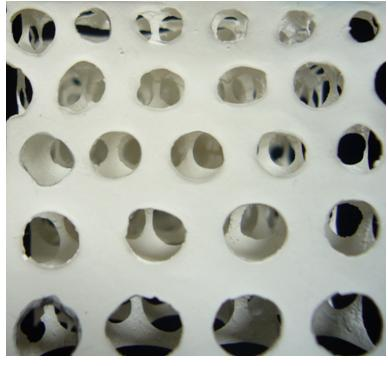

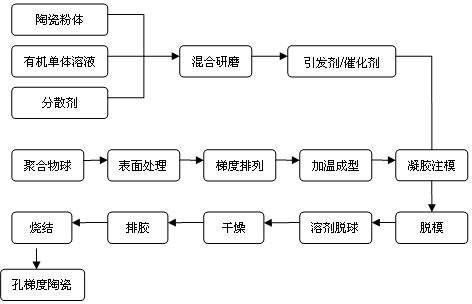

Method for preparing ceramic foams with pore gradient

The invention relates to a method for preparing ceramic foams with pore gradient. The method comprises the following steps: arranging polymers or organic matter spheres to form a template in gradient distribution according to the design requirement, carrying out heating and pressurizing to ensure the spheres to adhere to each other to form a whole, filling the whole into a moulding mould and then injecting slurry for gel casting and removing the mould after drying the spheres to obtain a moulded green body integrating the spheres and solidifying slurry, immersing the green body after removing the mould into a solvent or warming the green body, removing the spheres to obtain a network-shaped body only with the solidifying slurry and obtaining the ceramic foams with pore gradient after binder removal and high-temperature sintering. The ceramic foams prepared according to the technical scheme adopted by the invention have the following advantages: the pore diameters are in gradient distribution; the pore gradient can be designed and controlled; the moulded green body has high strength and can be processed and cut into needed shapes; the sizes and shapes of the products are controllable; the problem that the shapes and sizes of the products as well as the sizes of the pores are usually limited by organic carriers in the process of preparing the ceramic foams is solved; and the shortcomings of less slurry absorbed for moulding, more blind pores and low product strength in the impregnation method are overcome.

Owner:SUZHOU UNIV

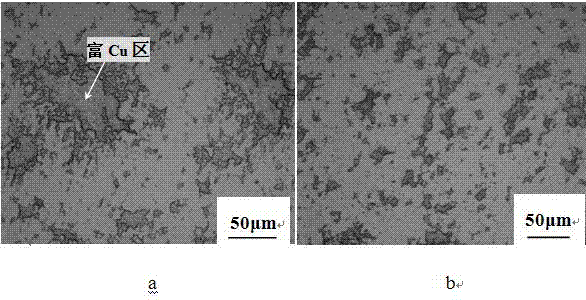

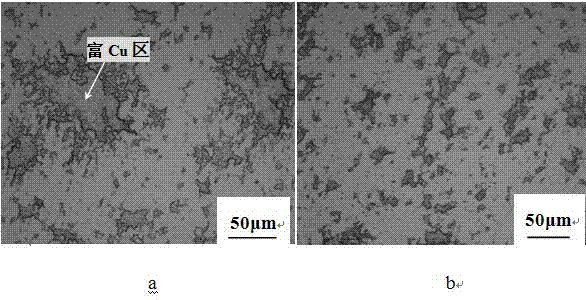

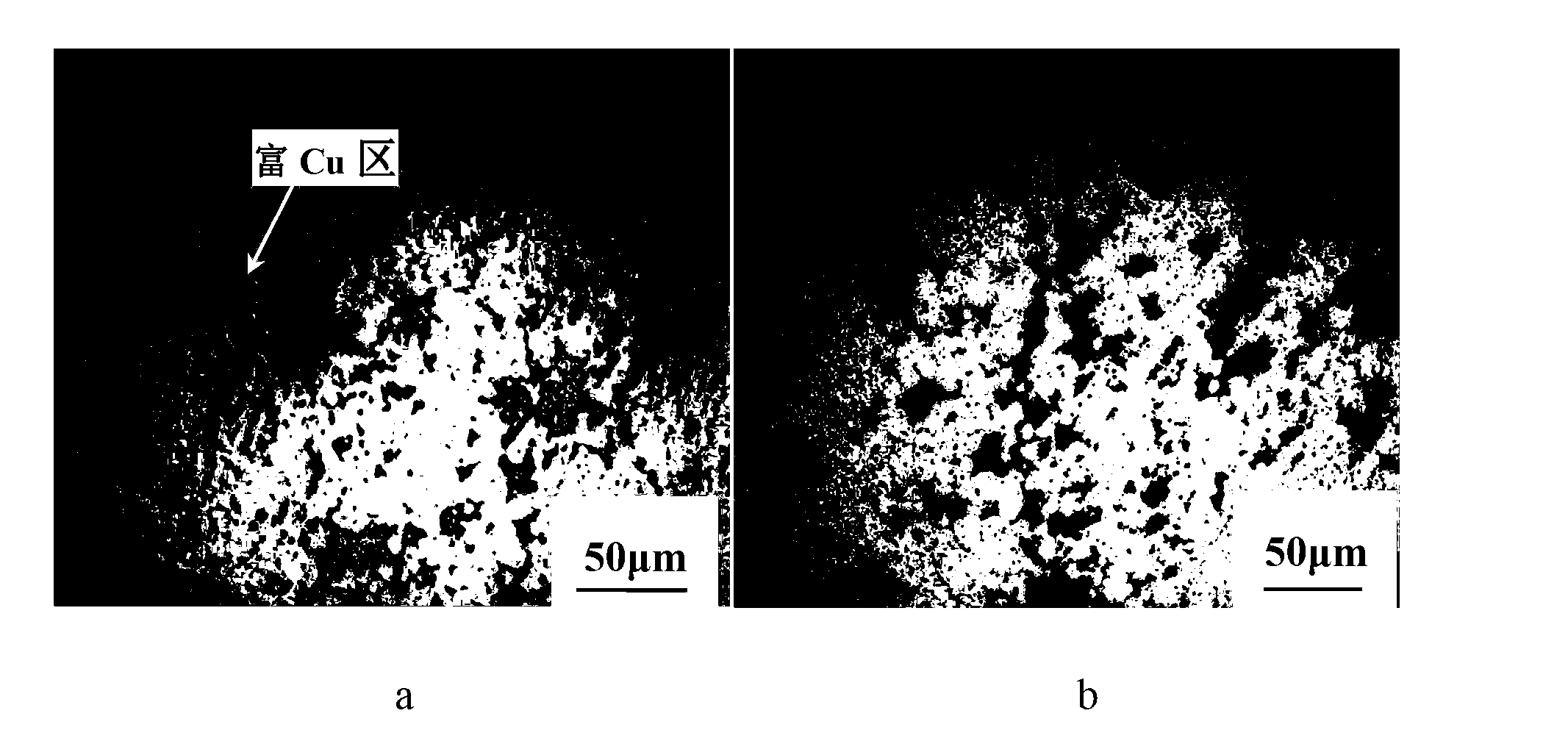

Preparation method of CuW70 contact material

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

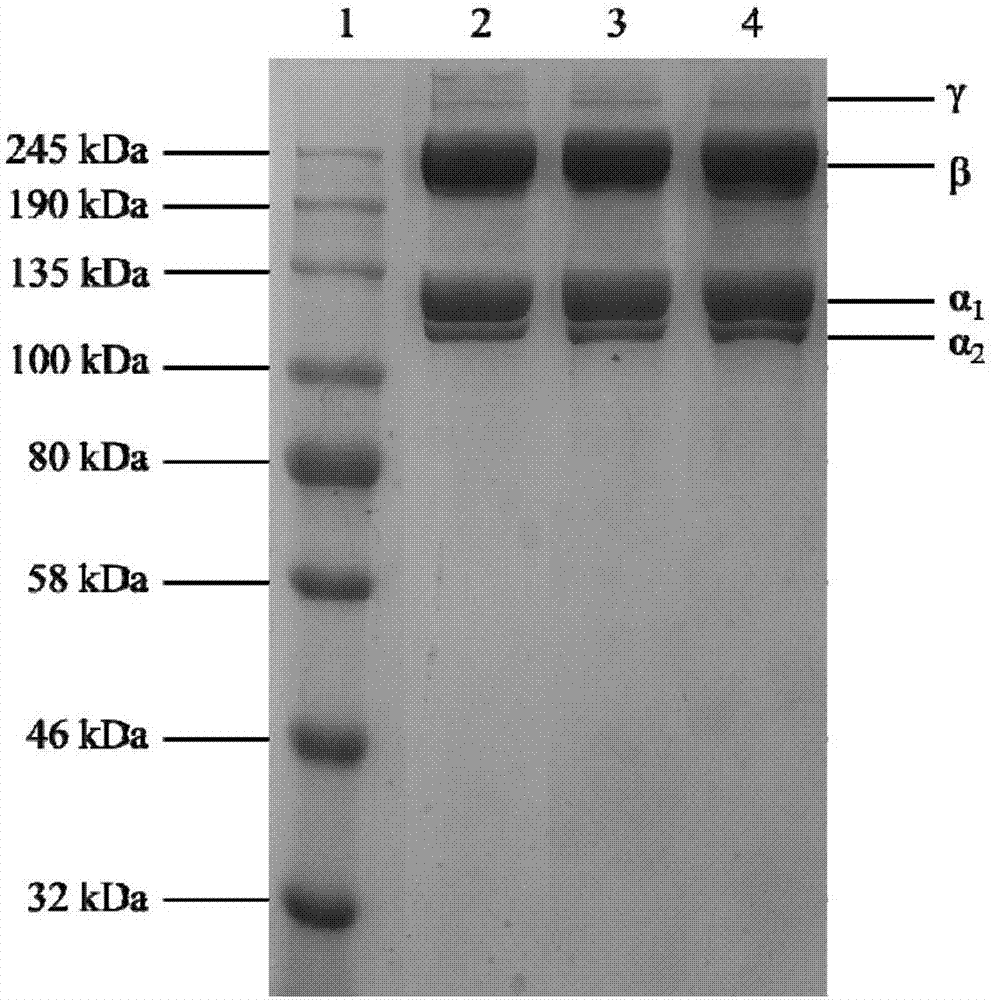

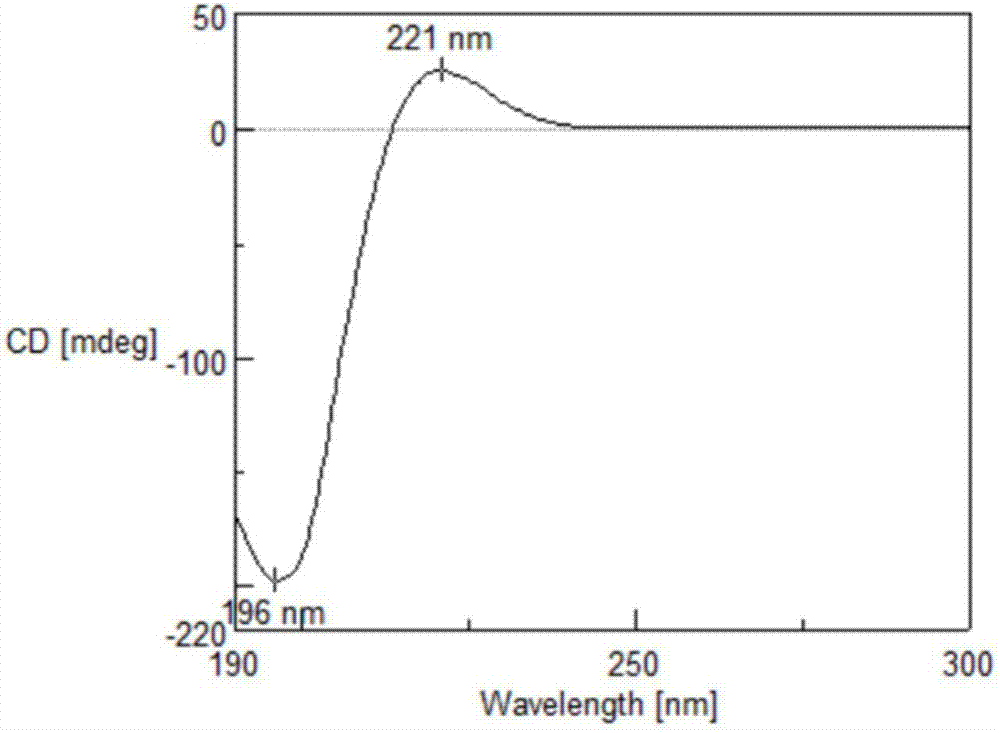

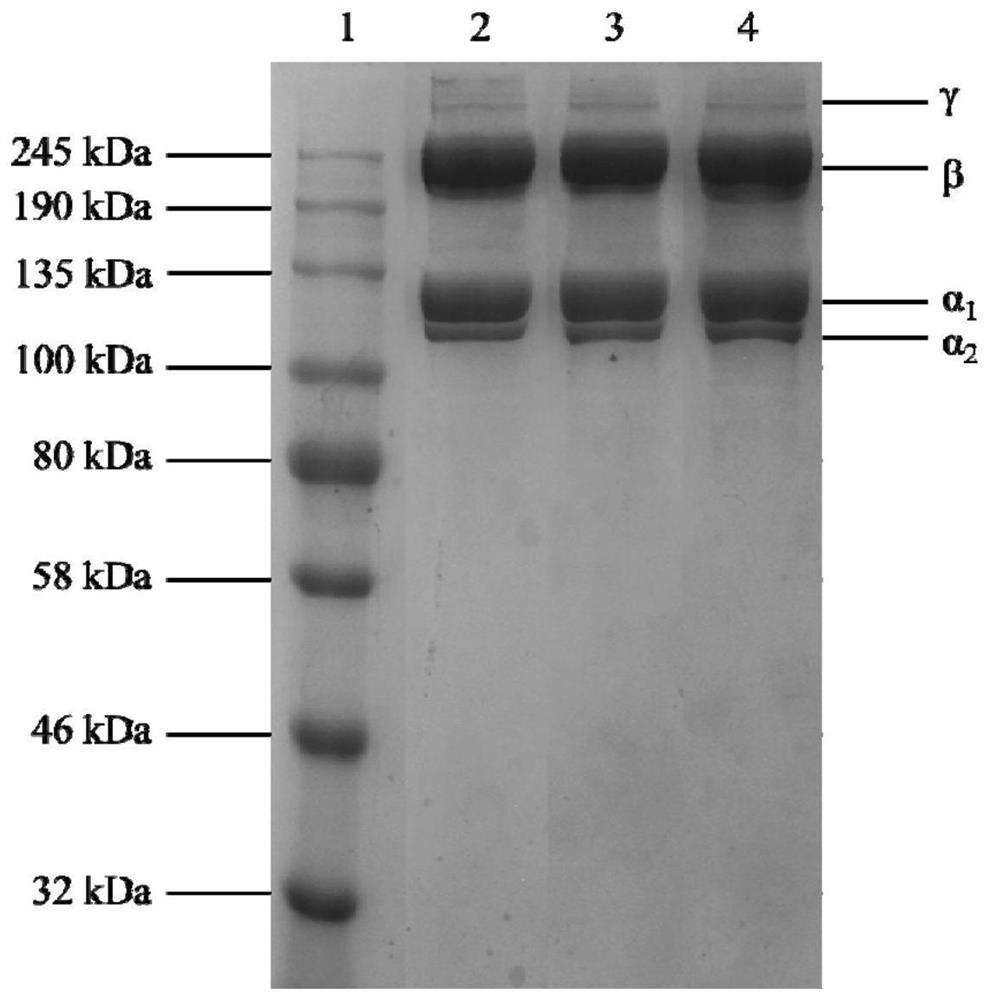

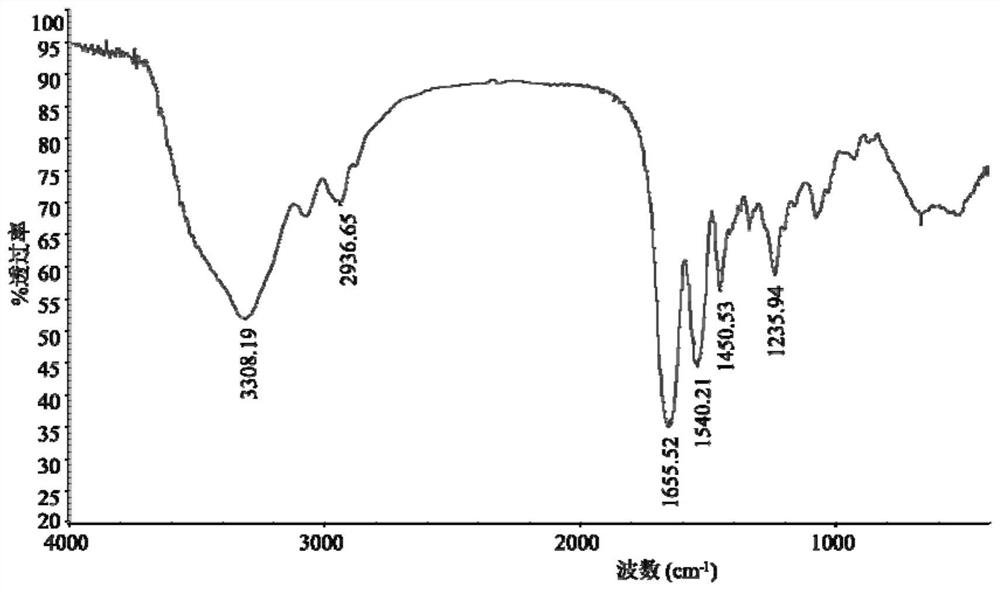

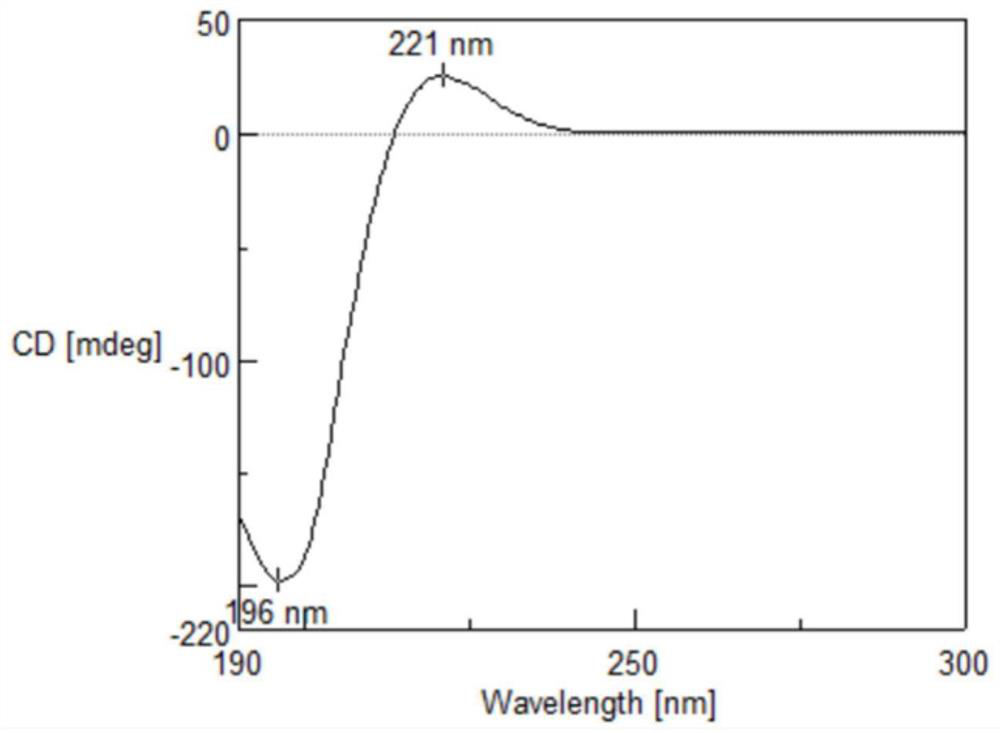

Compound multilayer medical dressing of aquatic biological source crosslinking collagen

ActiveCN107233613AWide variety of sourcesIncrease profitConnective tissue peptidesSurgical adhesivesFreeze-dryingCollagen sponge

The invention discloses an aquatic biological source medical collagen with high purity and activity, and is capable of solving the problems of a natural collagen dressing that the mechanical strength is bad, the degradation resistance ability is weak and the wound is easily infected by microorganisms. An acid extraction method and a method of removing telopeptide by pepsase are used for extracting the collagen, the extraction ratio is improved by the ultrahigh pressure treatment and a tissue mashing method, and through a series of purification operations, such as decellularization, protein elimination, degreasing, repeated salting out, dialysis, degerming, decoloration and heat source removal, the medical collagen with the high purity and activity is prepared. A netlike collagen sponge with uniform pores is prepared by a vacuum freeze-drying technology, and the collagen sponge is modified by a physical crosslinking and chemical crosslinking mode so as to prepare the inner layer, and is compounded with a chitosan outer layer film and a medical non-woven fabric base cloth layer, finally a compound multilayer medical dressing finished product is obtained by Co-60 sterilization.

Owner:OCEAN UNIV OF CHINA

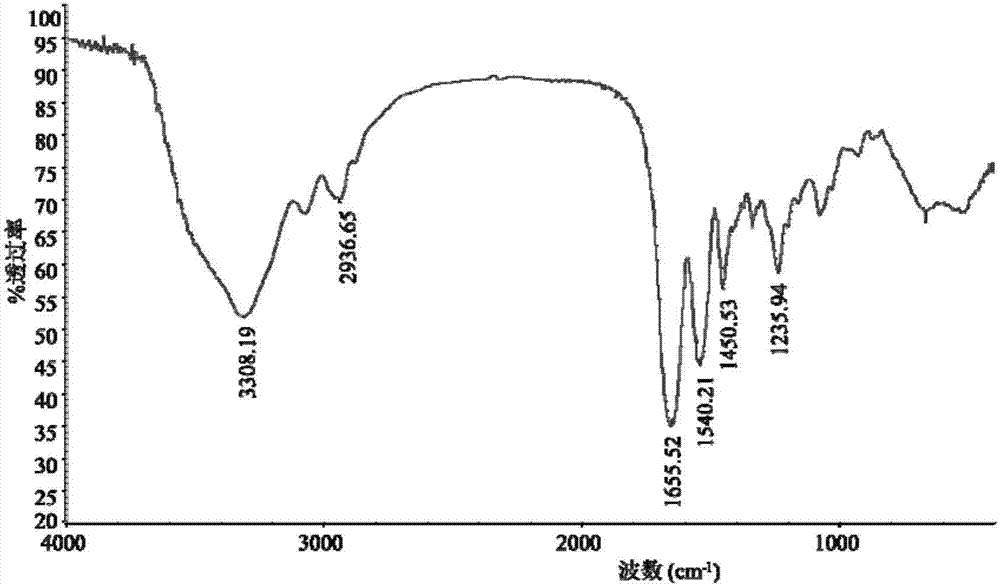

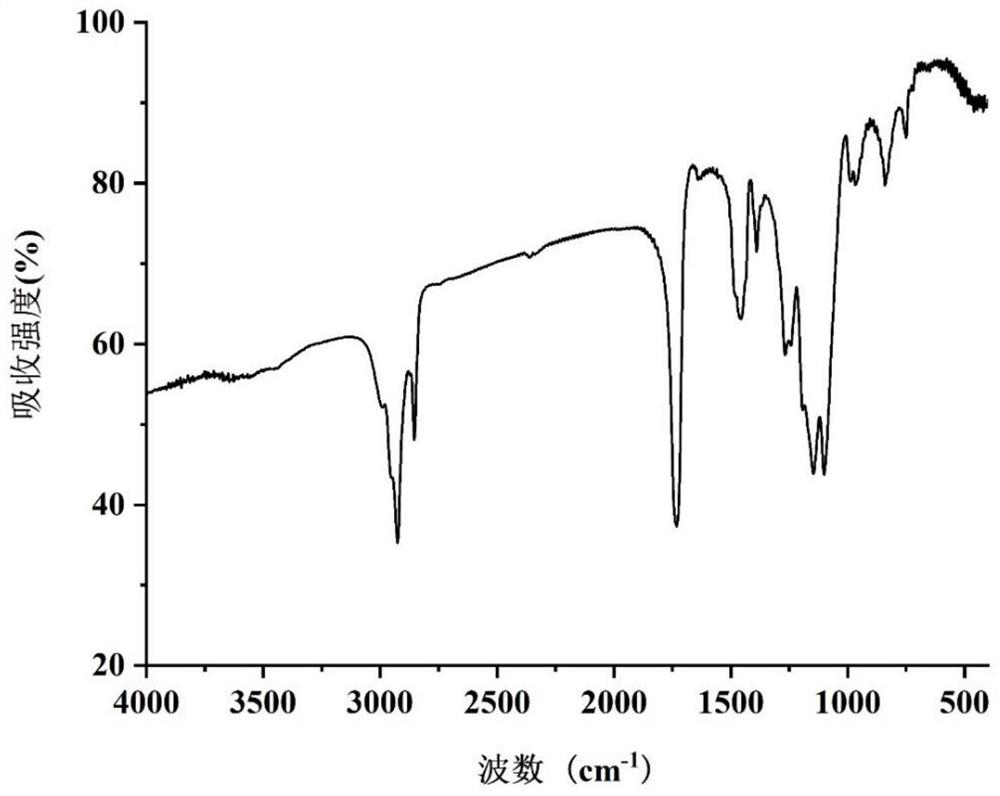

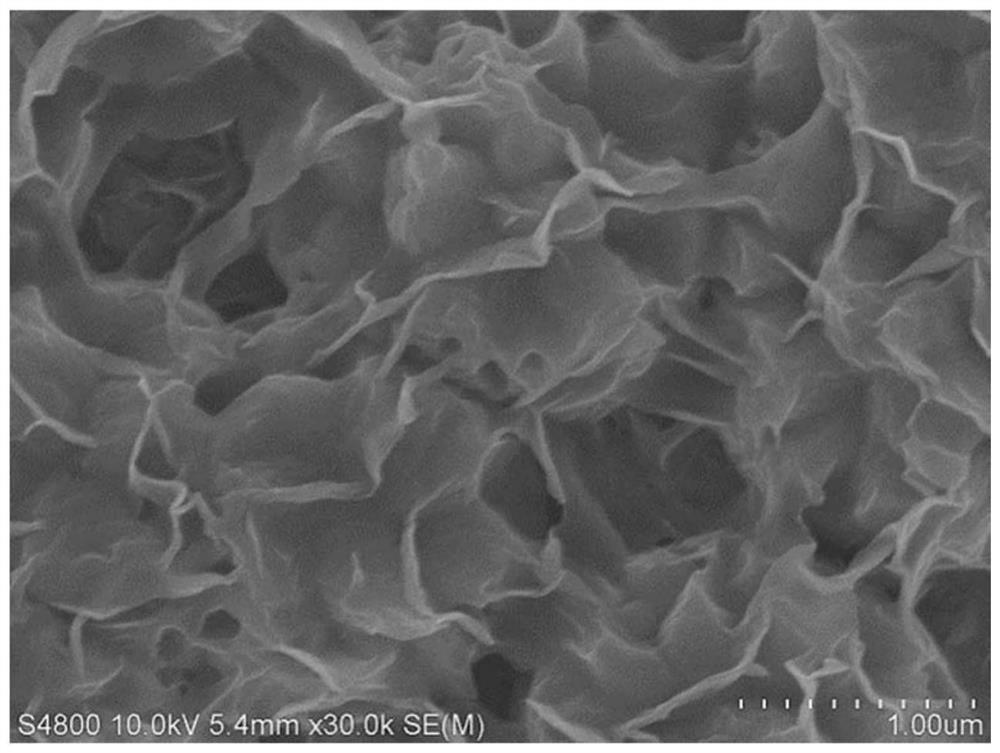

Preparation method of cellulose based conductive hydrogel

InactiveCN106519287AUniform network structureStable network structureBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a preparation method of a cellulose based conductive hydrogel. The preparation method comprises the following steps: (1) dissolving microcrystalline cellulose (MCC) with 1-Butyl-3-methylimidazolium chloride, reacting in a N2 protective atmosphere, and adding N,N-methylenebisacrylamide and benzoyl peroxide to prepare a pure microcrystalline cellulose hydrogel; and (2) soaking the pure microcrystalline cellulose hydrogel obtained in the step (1) in a mixed solution of FeCl3 and sodium p-benzenesulfonate, and immersing in a pyrrole water solution to prepare the cellulose based conductive hydrogel. The cellulose based conductive hydrogel prepared by the method has the advantages of uniform stable network structure, excellent conductivity, swelling property and heat stability, favorable electric conductivity and favorable swelling property; and the equilibrium swelling rate can be up to about 500%.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

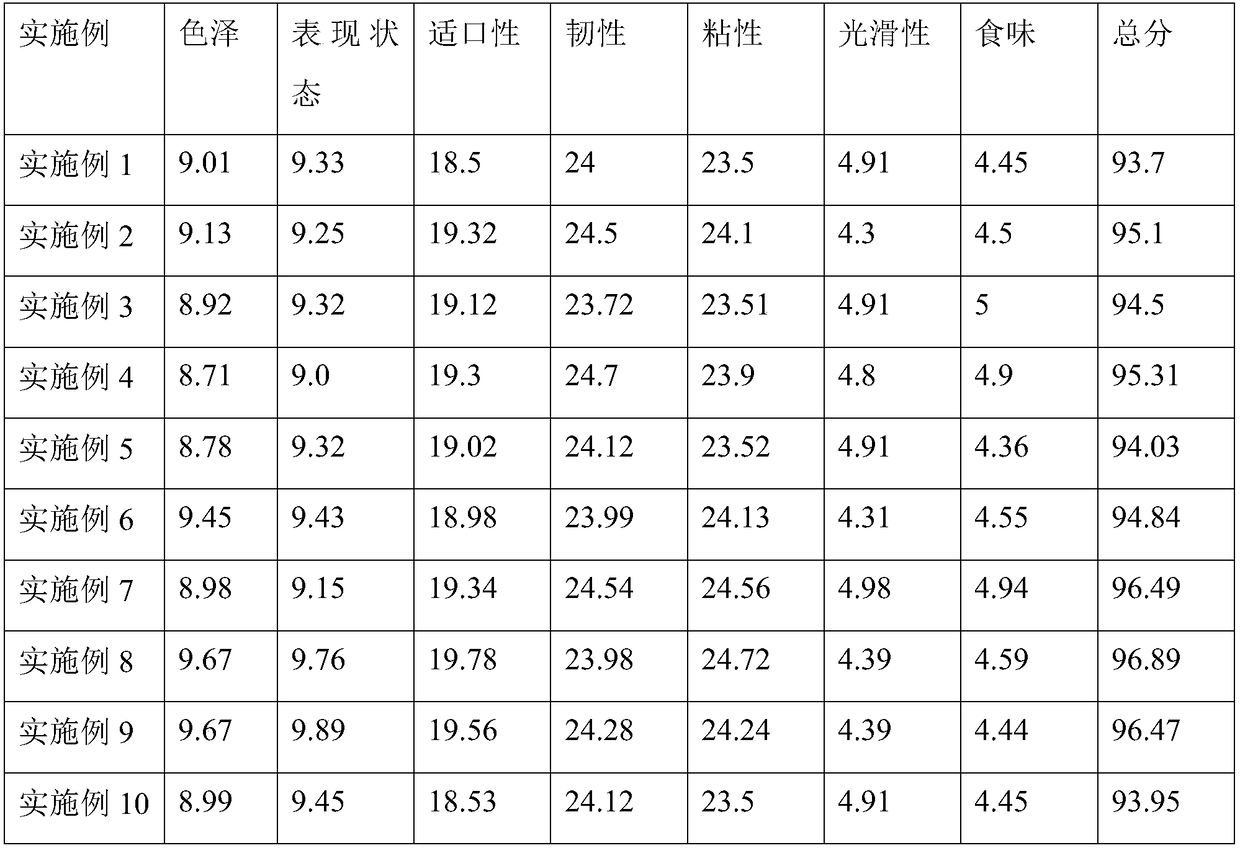

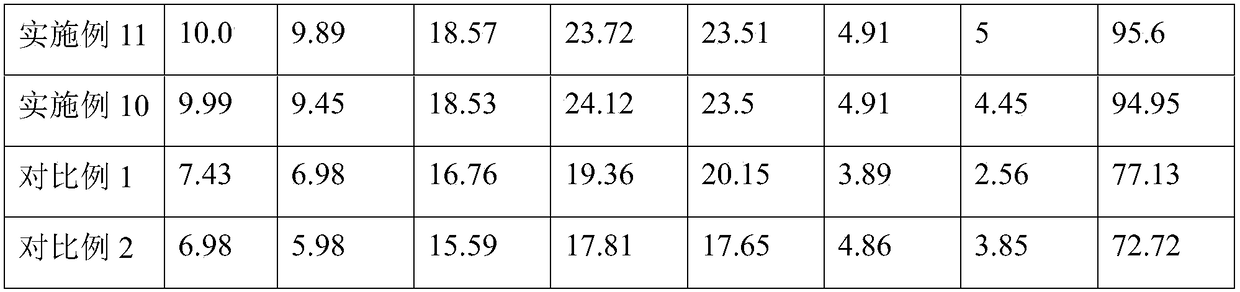

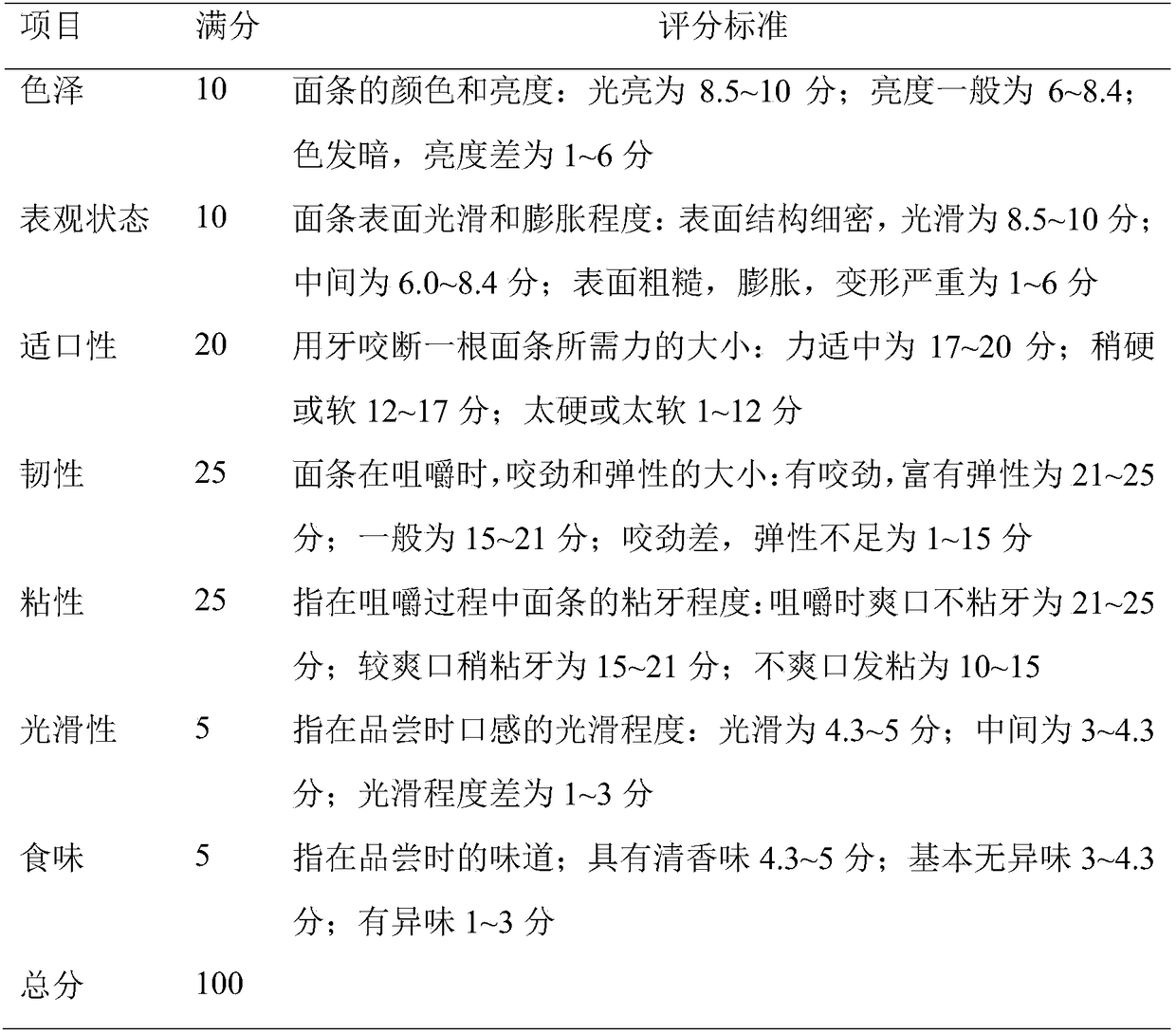

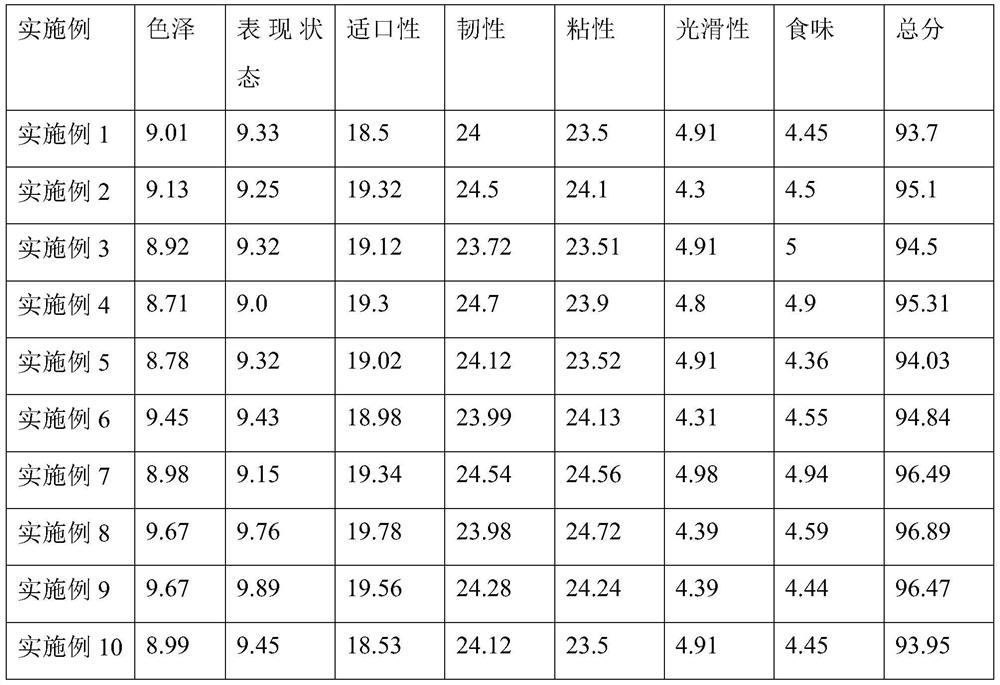

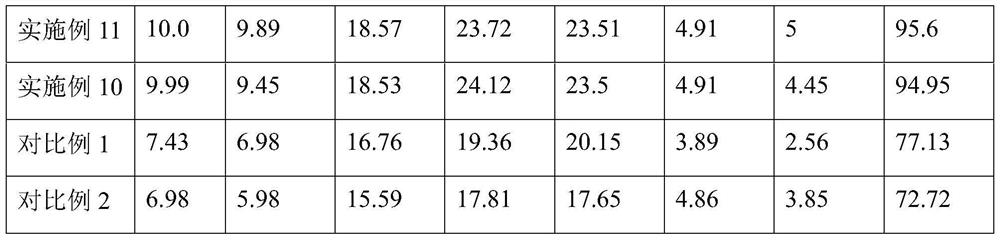

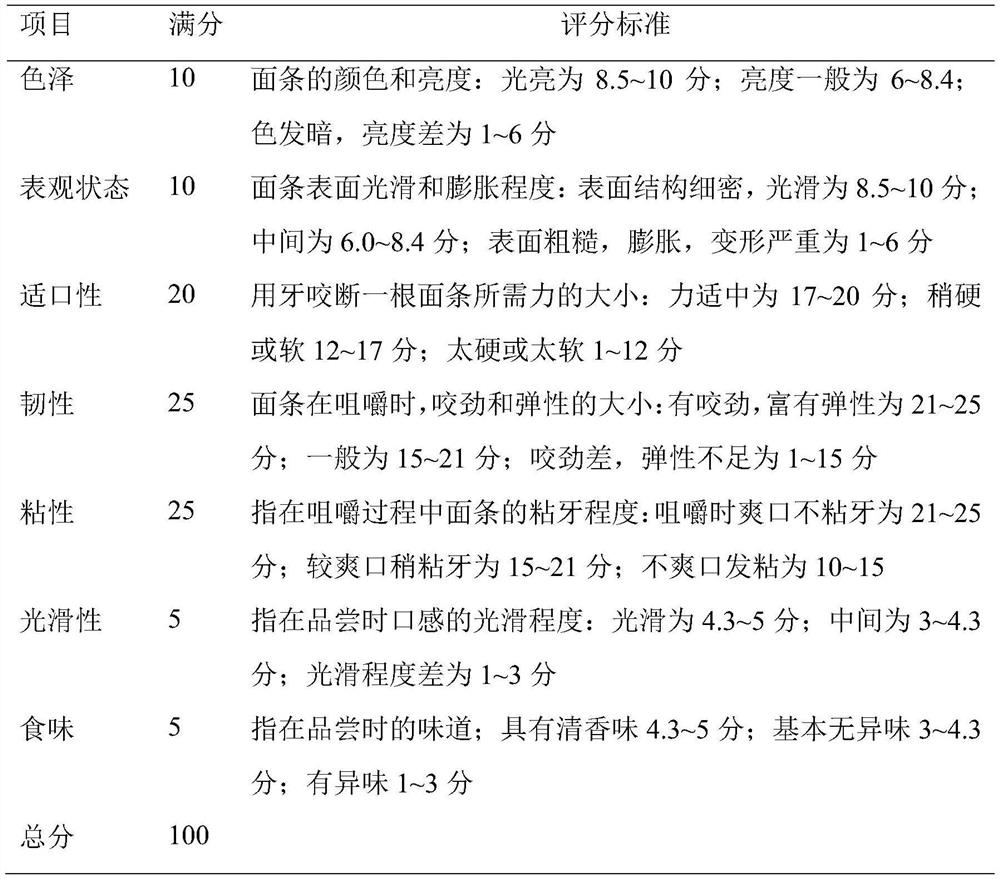

Making technology of potato noodles

The invention discloses a making technology of potato noodles. The making technology comprises the following steps of taking potato whole powder and wheat flour in a proportion of the potato whole powder to the wheat flour being (0.5-2) to 1, and performing uniform stirring to obtain mixed powder; adding vital wheat gluten of which the percentage by weight is 1-3%, alginic acid of which the percentage by weight is 0.2-0.4% and table salt of which the percentage by weight is 3-5% to the mixed powder, performing uniform stirring, adding water, and performing dough mixing; leavening the mixed dough for 15-60min; and putting the leavened dough in a machine, and performing extrusion and shaping. The vital wheat gluten is added during dough mixing, so that the moldability of dough sheets can beimproved, the chewiness is improved, the loss rate of the noodles is reduced, and the expansivity of the noodles is increased; the table salt is added during dough mixing, so that the flavor, the color and the texture characteristics of the noodles can be improved; through addition of an appropriate amount of the table salt, the plump mouth feel of the noodles can be improved, the peculiar smell is concealed, the balanced flavor is increased, and the flexibility of the noodles can be improved. According to the leavening time, the condition that starch and protein can sufficiently absorb moisture is facilitated, so that a uniform network structure is formed, and the quality of the made noodles is good.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

Production method for fish oil microcapsule product with ultrafine edible fungus powder as main wall material

ActiveCN103340398ASuppress fishy smellFragrant smellFood shapingFood preparationBiotechnologyTremella

The invention provides a production method for a fish oil microcapsule product with ultrafine edible fungus powder as a main wall material. Main materials for microcapsule encapsulation are ultrafine mushroom and tremella powder and perilla oil used as a deodorization substance for fish oil. The production method comprises the following steps: preparation of the ultrafine mushroom and tremella powder; preparation of composite fish oil; and preparation of a fish oil microcapsule. The prepared fish oil microcapsule product has a pure white color and good appearance and can effectively encapsulate a core material. The product has strong antibacterial activity, effectively inhibits fishy smell of the fish oil, supplements and reinforces the function of unsaturated fatty acid of the fish oil and has the excellent characteristics of water solubility, thickening performance, gelatinization, film formation, etc. The wall material of the fish oil microcapsule becomes a nutrition component for the product and enriches nutritional functions of the fish oil product.

Owner:浙江天顺控股集团有限公司

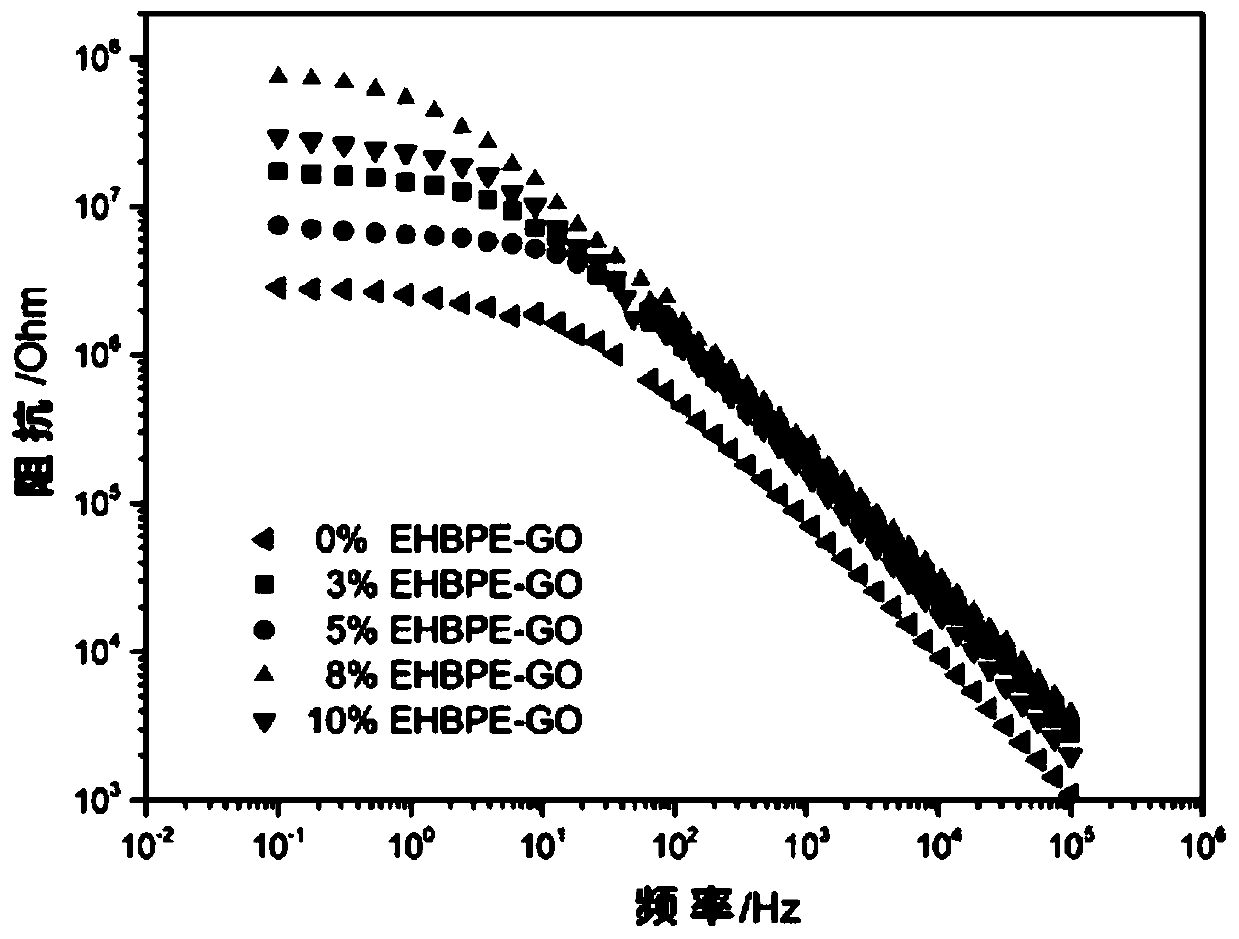

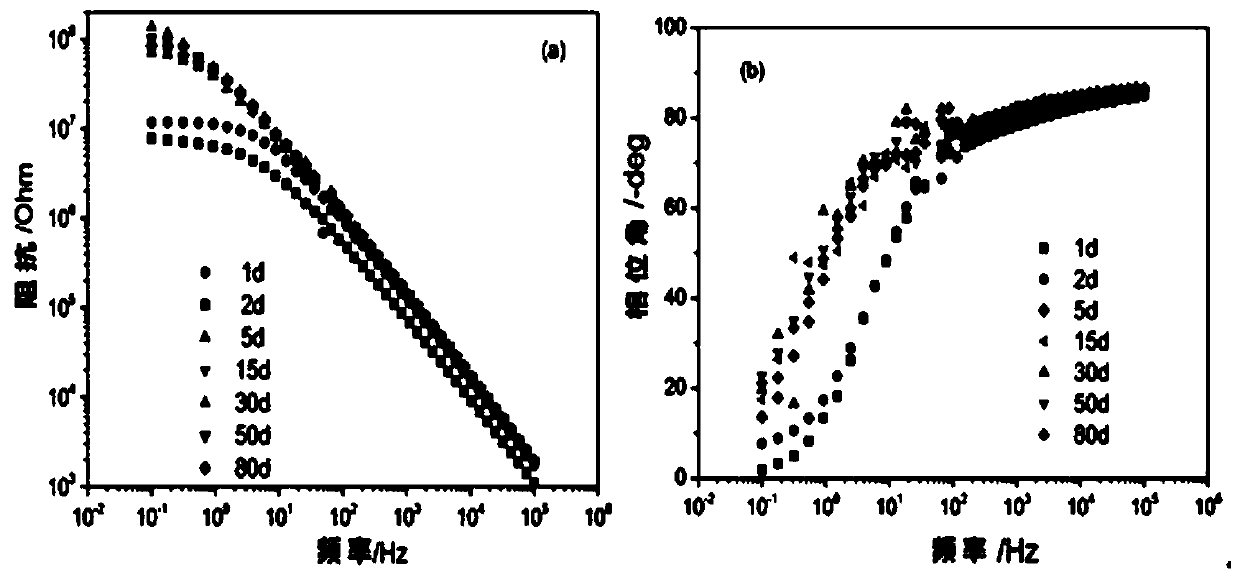

Hyperbranched polyether functionalized graphene/epoxy resin nano composite coating as well as preparation method and application thereof

InactiveCN110791178AGood compatibilityUniform network structureAnti-corrosive paintsEpoxy resin coatingsNanocomposite coatingChemistry

The invention relates to a hyperbranched polyether functionalized graphene / epoxy resin nano composite coating as well as a preparation method and application thereof. The nano composite coating is composed of a component A and a component B, wherein the component A comprises a mixed resin, an antirust pigment, an inorganic pigment, mineral substance powder and an organic solvent; the component B is an epoxy resin curing agent; the mixed resin is composed of an epoxy resin and hyperbranched polyether functionalized graphene; and the hyperbranched polyether functionalized graphene is 2-10% of the mass of the epoxy resin. A coating prepared from the hyperbranched polyether functionalized graphene / epoxy resin nano composite coating can effectively shield corrosive substances, and shows excellent corrosion resistance, and especially the acid resistance of the nano composite coating is obviously improved and is improved by 50% compared with that of a pure epoxy resin coating.

Owner:CHANGZHOU INST OF TECH

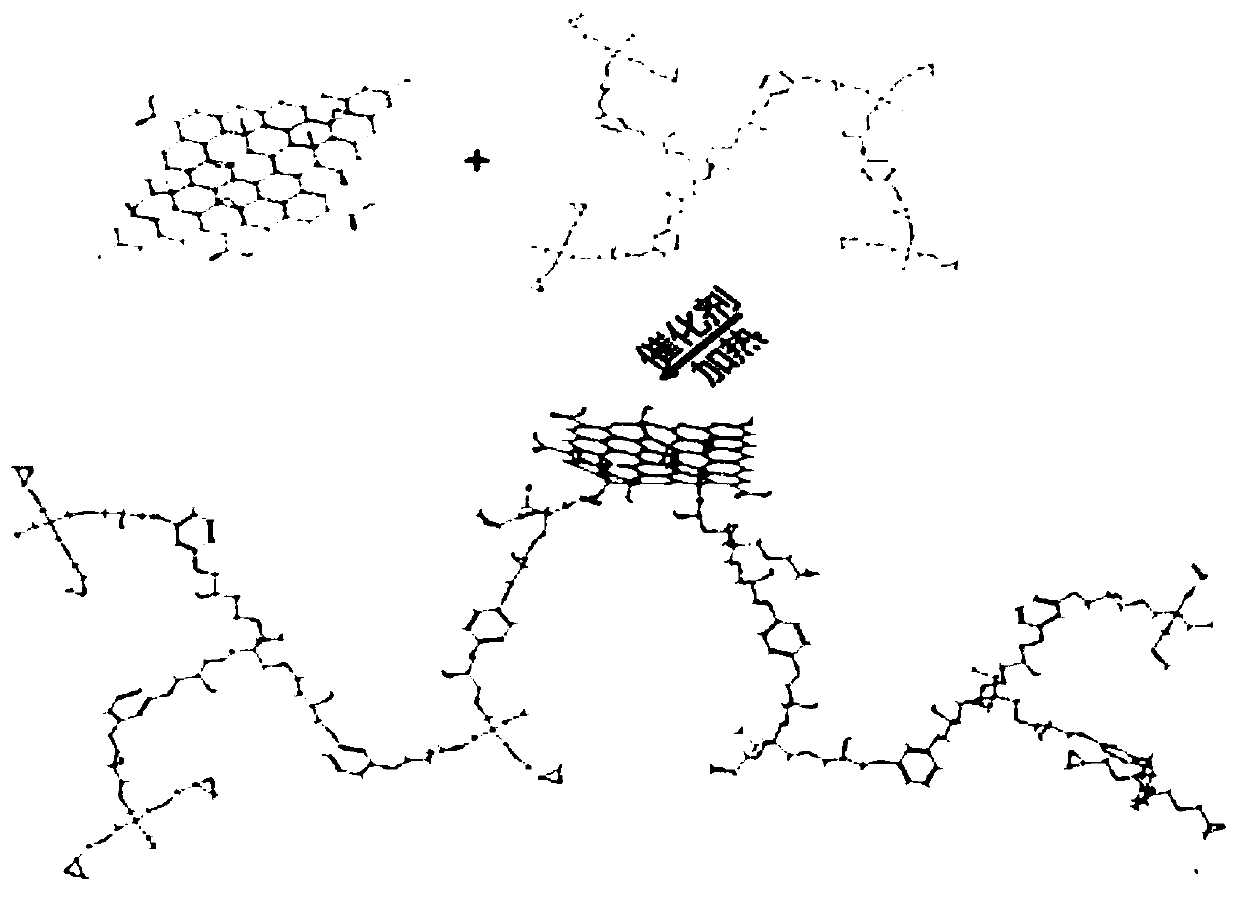

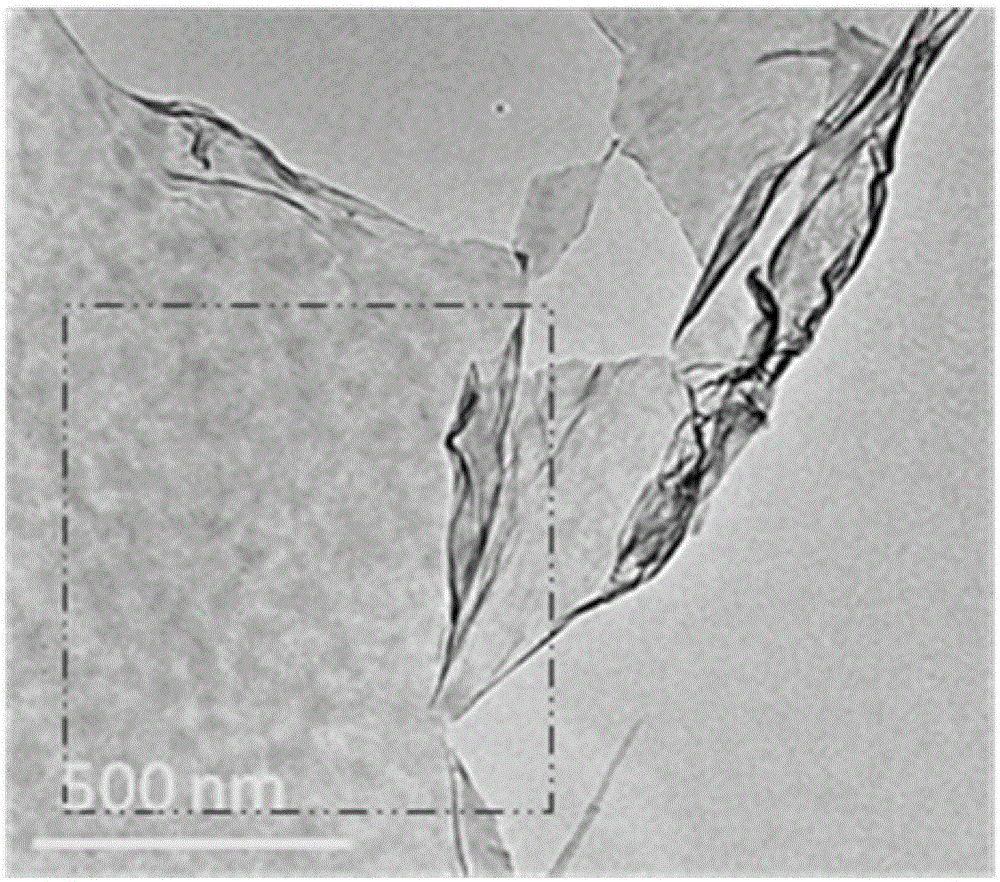

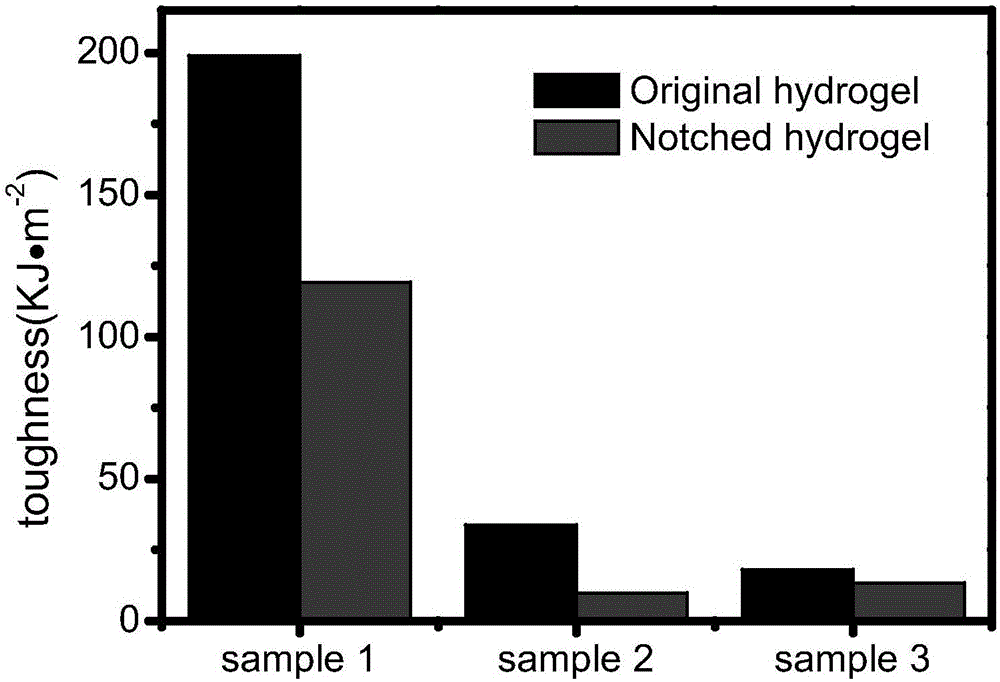

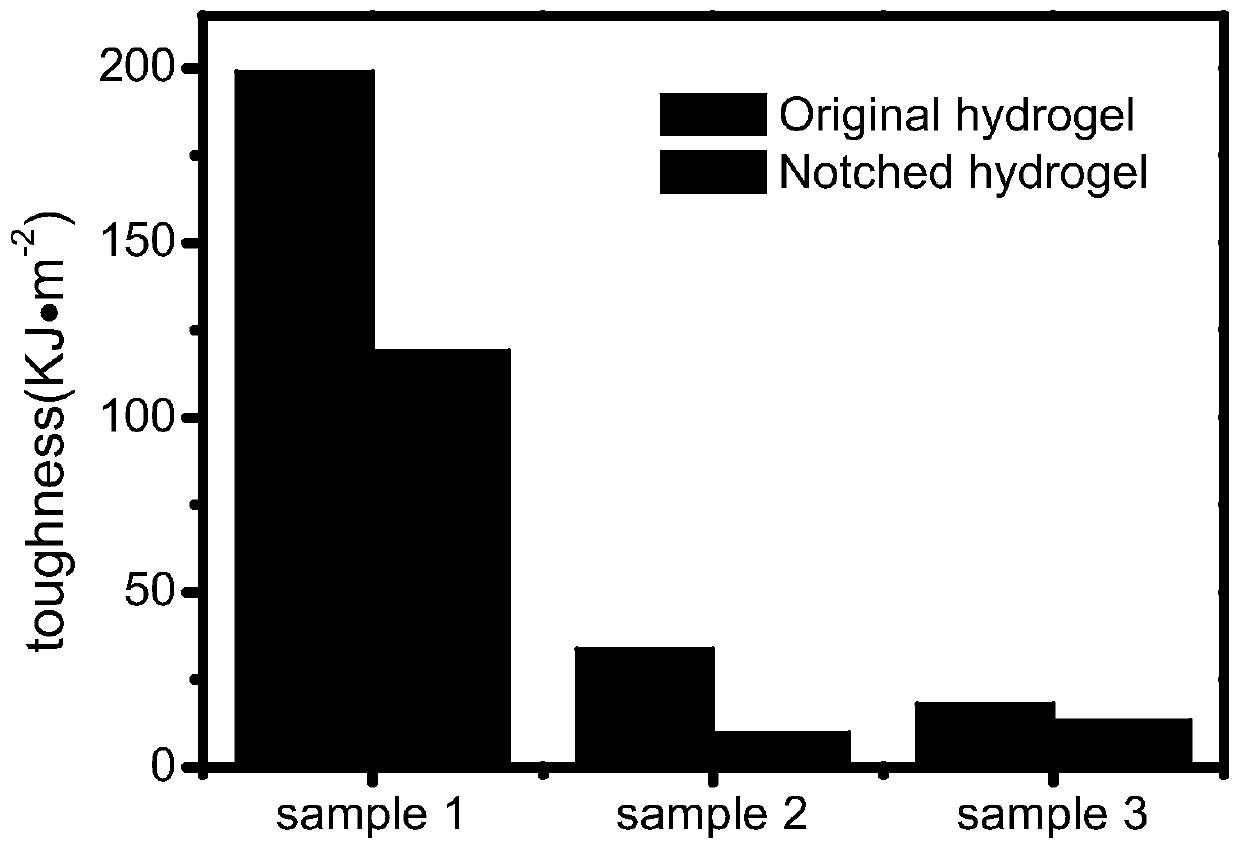

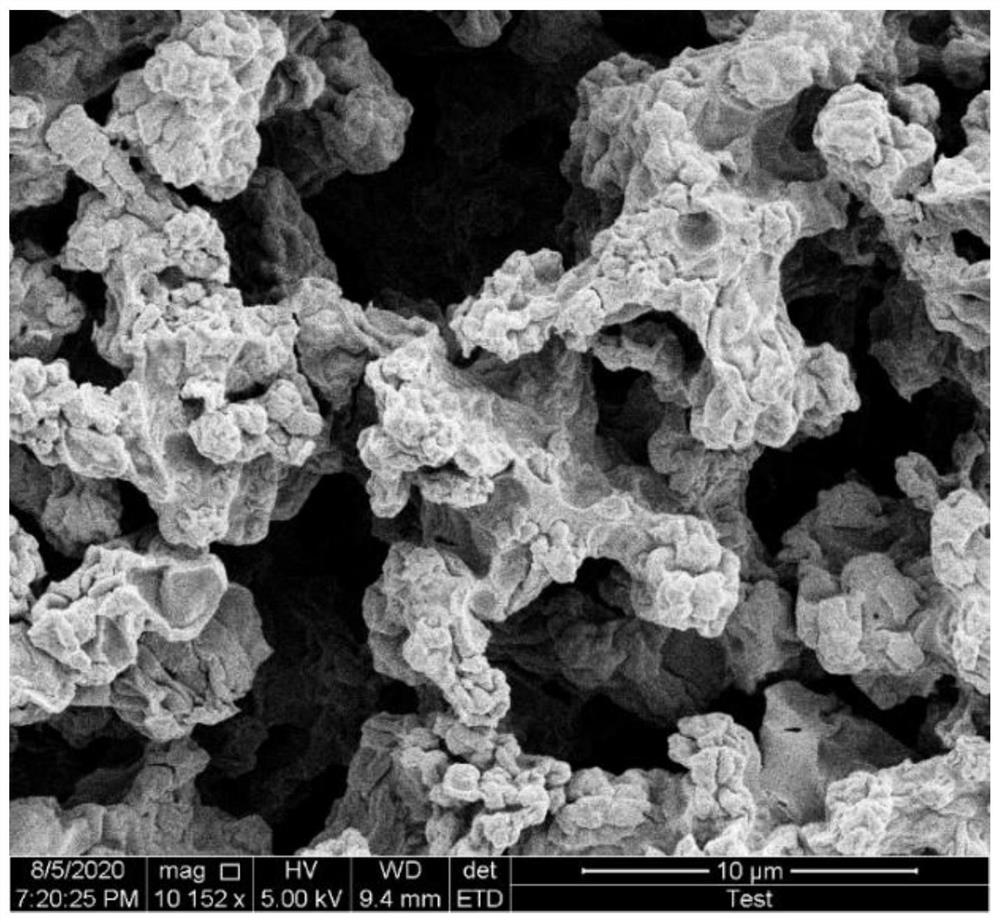

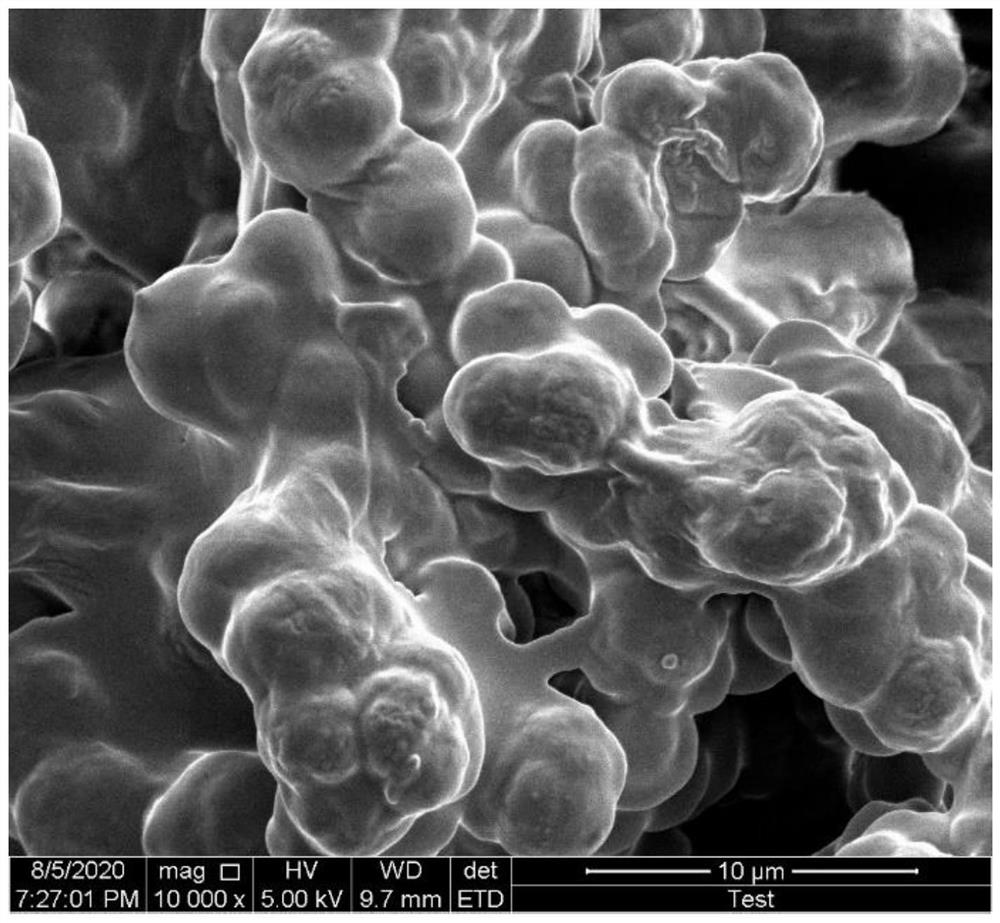

Preparation method of anti-notch-sensitivity graphene-type nano composite aquagel

ActiveCN106674434AUniform network structureAvoid concentrationUltimate tensile strengthNanocomposite hydrogels

The invention discloses a preparation method of an anti-notch-sensitivity graphene-type nano composite aquagel. By using the graphene-oxide-carried supported microgel as a crosslinking agent, the nano composite aquagel has the two crosslinking modes (physical crosslinking and chemical crosslinking), and thus, has favorable ductility and mechanical strength. The inside of the nano composite aquagel has high crosslinking density and complex crosslinking mode, and thus, the material can have favorable energy dissipation mechanism in case of cracking, and can still keep favorable ductility and mechanical strength when a notch appears in the aquagel.

Owner:HEFEI UNIV OF TECH

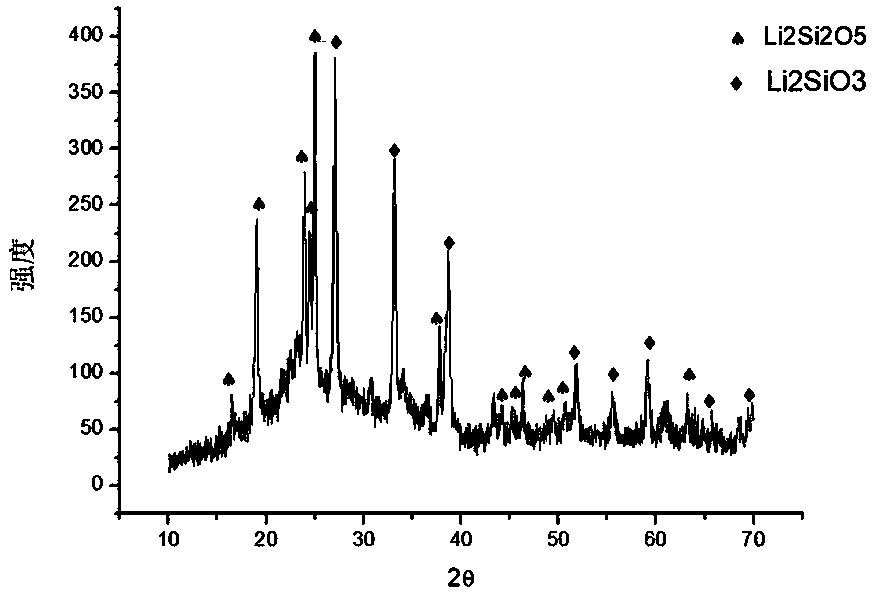

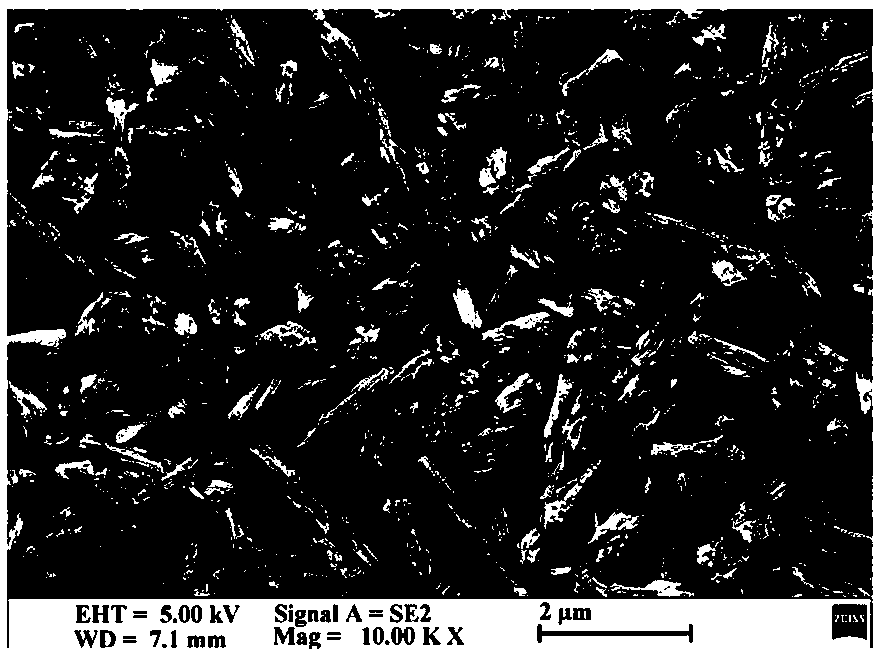

Ce,V and Er co-doped dental microcrystalline glass, and preparation method and application thereof

The invention discloses a Ce,V and Er co-doped dental microcrystalline glass, and a preparation method and application thereof. The raw materials of the microcrystalline glass consist of SiO2, Li2O, K2O, P2O5, Al2O3, ZrO2, Na2O, CeO2, V2O52 and Er2O3. A glass block is obtained through a melt casting method, and microcrystalline glass easy for machining is obtained after crystallization treatment,and then secondary crystallization is carried out to obtain the finished product of the microcrystalline glass which takes Li2Si2O5 as a main crystalline phase. The microcrystalline glass has excellent bending strength, good semi-permeability, fluorescent property, uniform and full coloring and excellent stability. The color and the aesthetic effect of the microcrystalline glass reach the color and the aesthetic effect of A2 in a VITA-Classical colourimetric card and are consistent with the fluorescent characteristic and the semi-permeability of natural teeth, and the microcrystalline glass can be applied to dental whole-porcelain repair materials.

Owner:FUZHOU UNIVERSITY

A preparation method of hydrophobic silica airgel thermal insulation composite material

ActiveCN104556969BReduce replacement timeReduce the number of replacementsSilicon compoundsFiberPolymer science

The invention relates to a method for preparing a hydrophobic silica airgel thermal insulation composite material, comprising the following steps: (1) Preparation of silica sol: using siloxane as a precursor, adding an organic solvent, water and an acid catalyst , to obtain silica sol; (2) Preparation of composite gel: add flame retardant and infrared blocking agent to silica sol, stir evenly; add alkali catalyst, immerse inorganic fiber products in silica sol, Stand still; (3) solvent replacement: replace the composite gel with an organic solvent; (4) dry: dry the composite gel. The invention has the advantages of simple process, short production cycle, low cost, low equipment requirements, controllable reaction conditions, and excellent product performance, and the prepared silica airgel composite material has overall waterproof performance, extremely low thermal conductivity, and excellent high temperature Thermal insulation performance, under the condition of ensuring the overall hydrophobicity of the material, it can pass the non-combustibility test, and its non-combustibility test can reach A1 level.

Owner:纳诺科技有限公司

A kind of aquatic biological source cross-linked collagen composite multi-layer medical dressing

ActiveCN107233613BWide variety of sourcesIncrease profitConnective tissue peptidesSurgical adhesivesDepyrogenationFreeze-drying

Owner:OCEAN UNIV OF CHINA

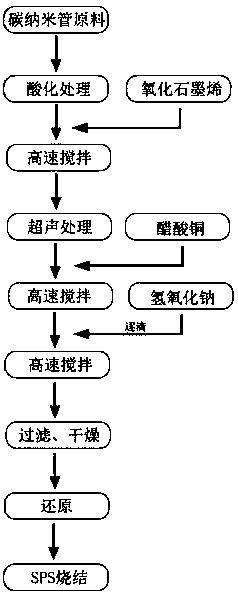

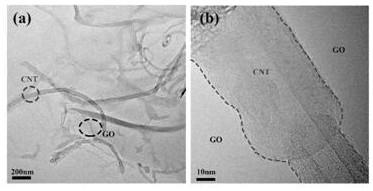

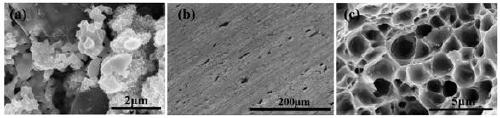

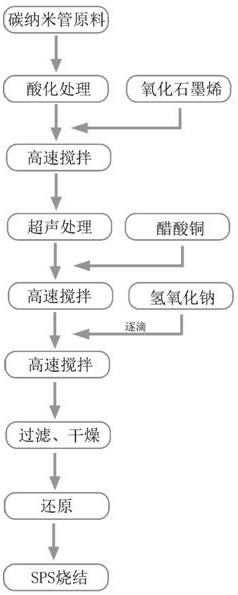

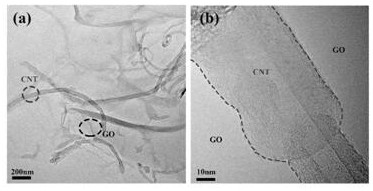

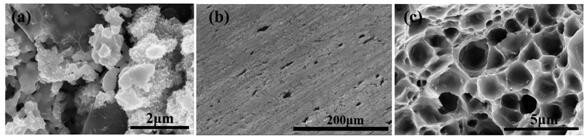

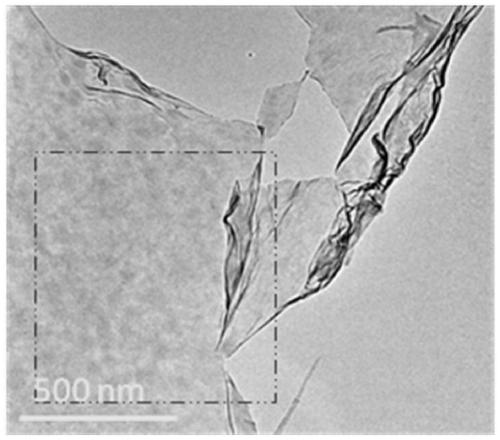

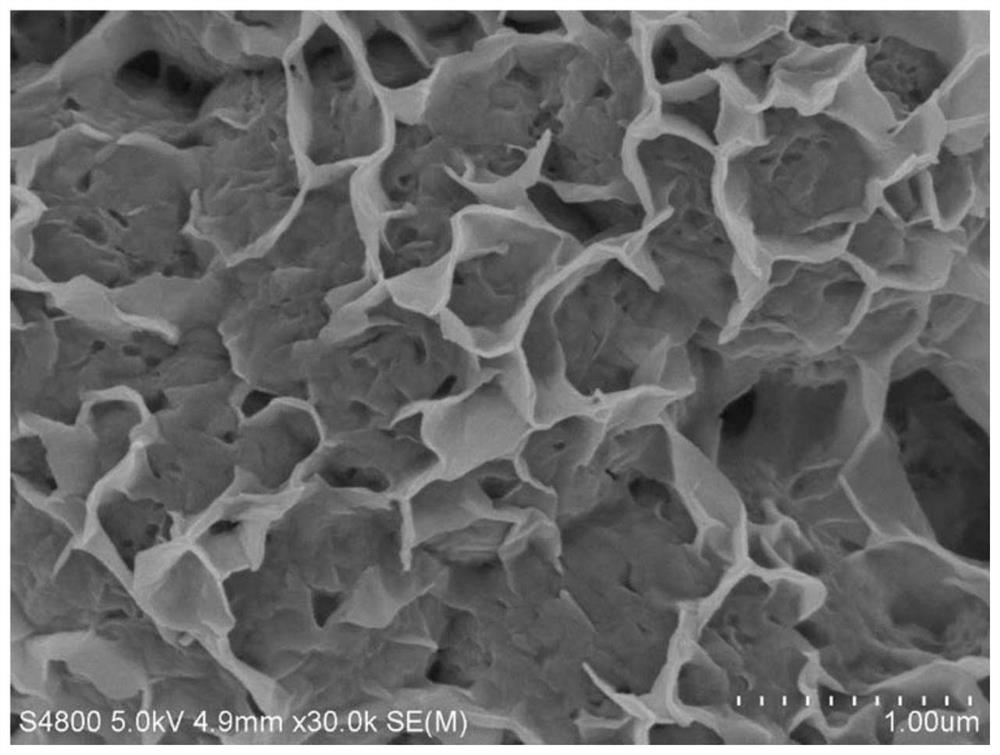

Preparation method of CNT-GO/Cu composite material with hierarchical structure

The invention discloses a preparation method of a CNT-GO / Cu composite material with a hierarchical structure and belongs to the field of metal-based composite material preparation. According to the preparation method, CNTs, GO, sodium hydroxide and copper acetate serve as raw materials, and the CNT-GO / Cu composite material with the hierarchical structure is prepared by adopting a molecule level blending method. The method has the beneficial effects that the process is simple, time is short, and energy consumption is low. Besides, due to the large specific surface area of GO and a high length-diameter ratio of CNTs, after the two are mixed, a mixed reinforced body with a net-shaped structure can be obtained, and the dispersion uniformity of a single reinforced body is improved. In addition,by continuously adjusting a pH value of a solution, the CNT-GO / Cu composite material with the hierarchical structure can be made. The composite material is composed of an enriched area (carbon-rich area) and a depleted area (carbon-poor area) of a carbon nanometer reinforced body, the carbon-rich area can effectively improve the strength of the composite material, and the carbon-poor area can effectively improve the toughness of the composite material, so that the composite material obtains good comprehensive performance.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of CuW70 contact material

InactiveCN102312146BUniform network structureImprove conductivityElectric switchesCopperHigh pressure

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

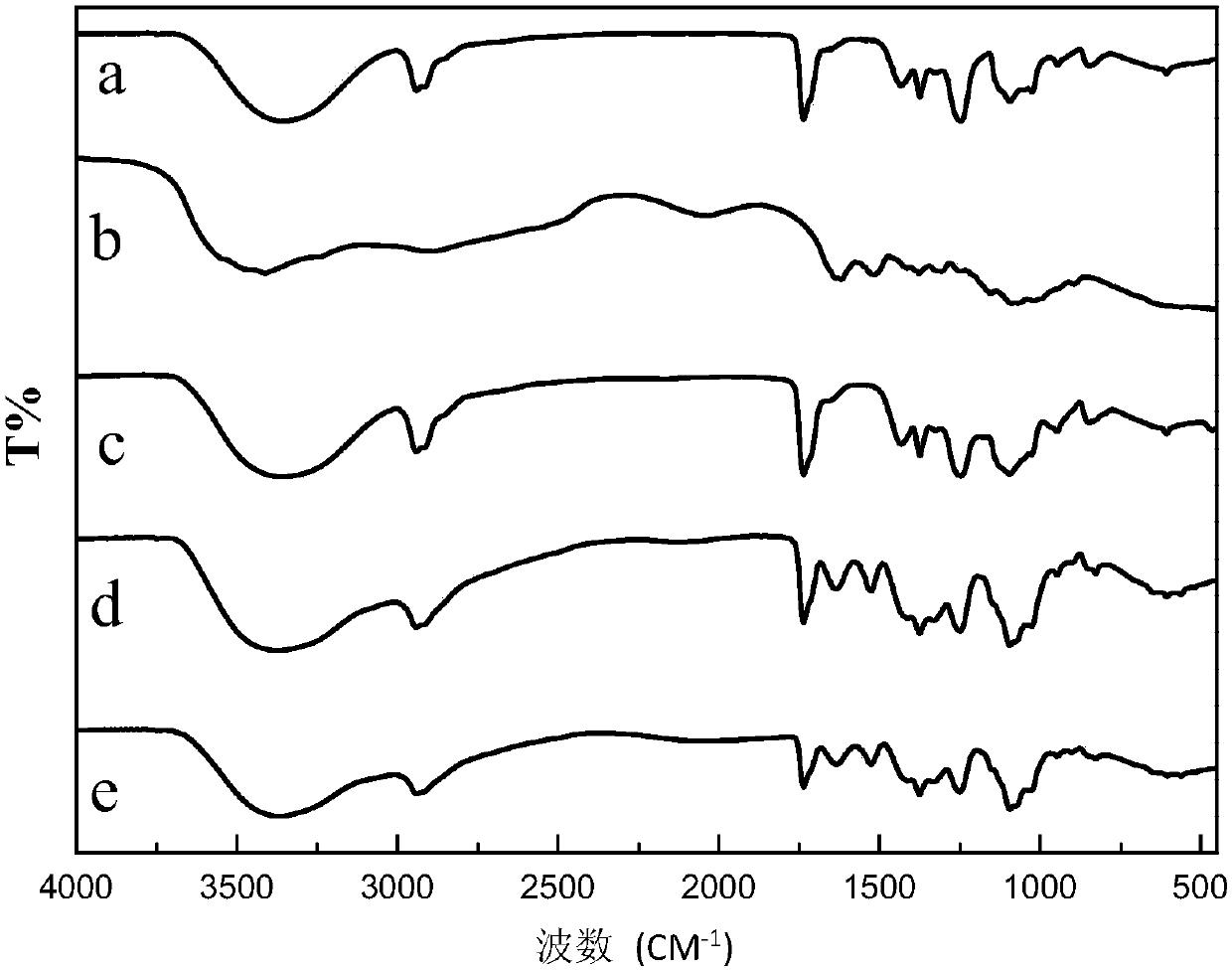

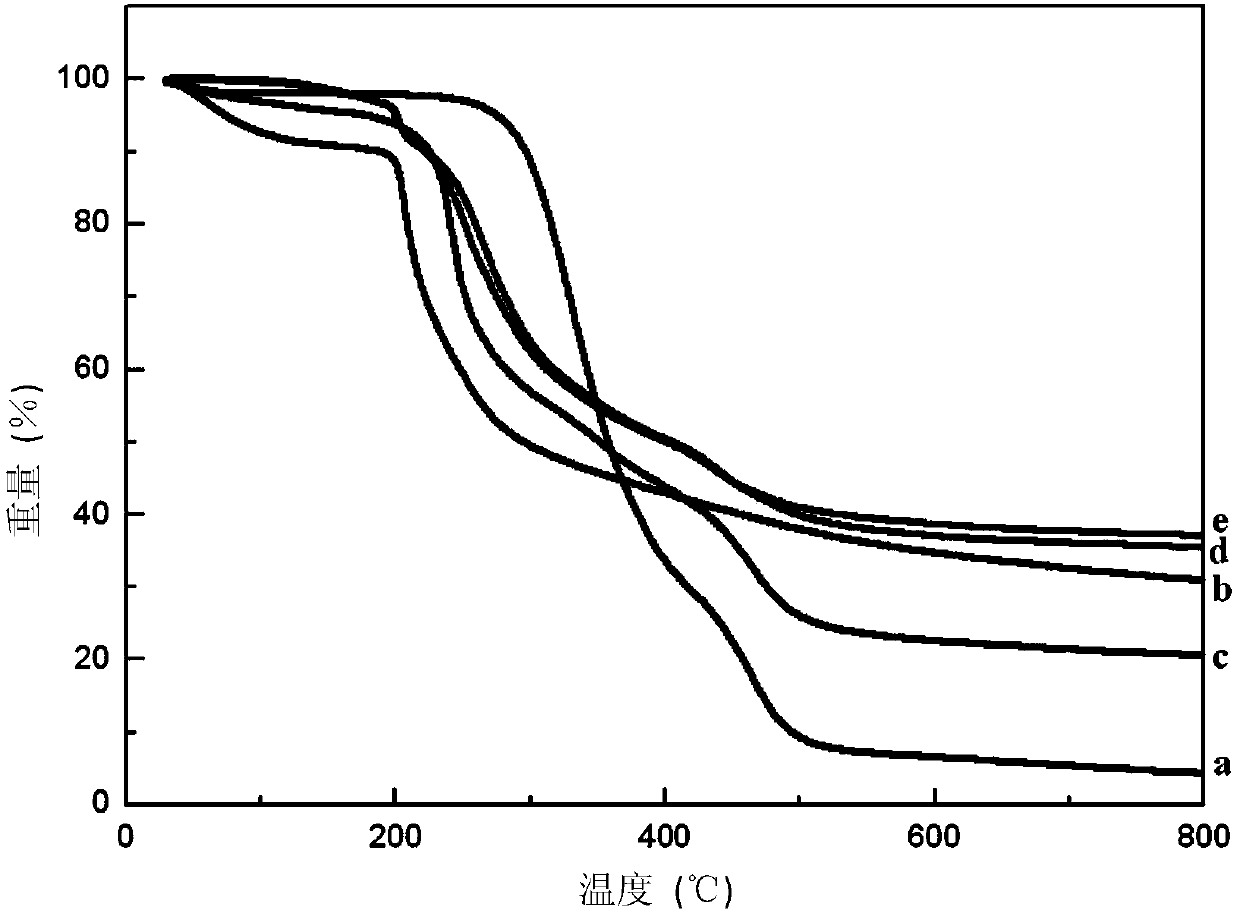

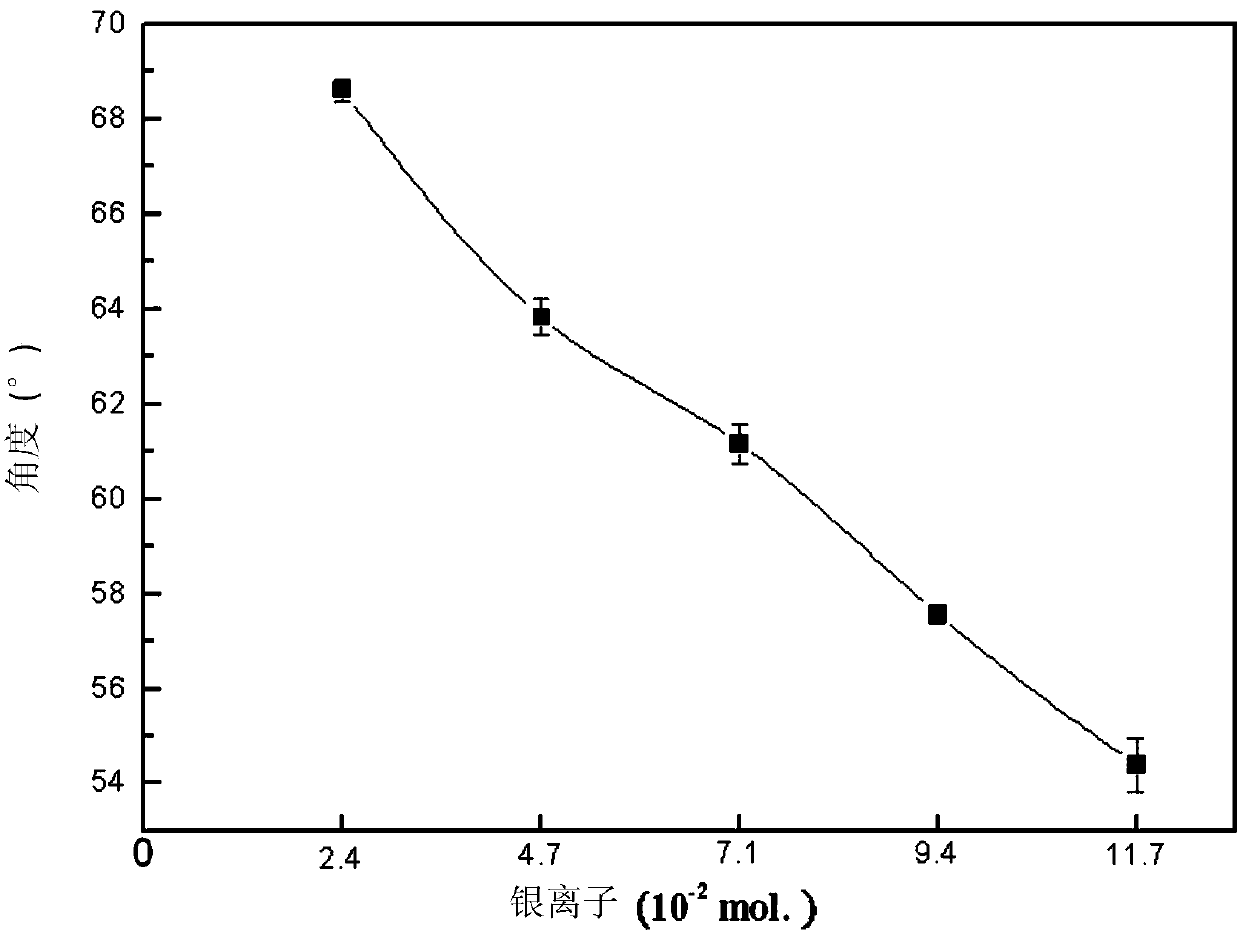

High-permeability and high-selectivity PVA/GA/CS-M<+> pervaporation film for dewatering organic solution

InactiveCN109745873AUniform network structureImprove compatibilityDistillationPolyvinyl alcoholPervaporation

The invention relates to a high-permeability and high-selectivity PVA / GA / CS-M<+> pervaporation film for dewatering an organic solution and a preparation method of the high-permeability and high-selectivity PVA / GA / CS-M<+> pervaporation film. The preparation method includes: heavy metal ions (M<+>) such as Ag<+>, Cu<2+> and Fe<3+> are used to chelate with CS (chitosan) to serve as the precursor, mixing the precursor with PVA (polyvinyl alcohol), and adding GA (glutaraldehyde) to serve as the crosslinking agent to obtain the high-permeability and high-selectivity PVA / GA / CS-M<+> pervaporation filmwhich is high in mechanical strength and heat stability and excellent in permeability and selectivity to the organic solution.

Owner:蔡燕铃 +1

A preparation method of cnt-go/cu composite material with hierarchical structure

The invention discloses a preparation method of a CNT-GO / Cu composite material with a hierarchical structure and belongs to the field of metal-based composite material preparation. According to the preparation method, CNTs, GO, sodium hydroxide and copper acetate serve as raw materials, and the CNT-GO / Cu composite material with the hierarchical structure is prepared by adopting a molecule level blending method. The method has the beneficial effects that the process is simple, time is short, and energy consumption is low. Besides, due to the large specific surface area of GO and a high length-diameter ratio of CNTs, after the two are mixed, a mixed reinforced body with a net-shaped structure can be obtained, and the dispersion uniformity of a single reinforced body is improved. In addition,by continuously adjusting a pH value of a solution, the CNT-GO / Cu composite material with the hierarchical structure can be made. The composite material is composed of an enriched area (carbon-rich area) and a depleted area (carbon-poor area) of a carbon nanometer reinforced body, the carbon-rich area can effectively improve the strength of the composite material, and the carbon-poor area can effectively improve the toughness of the composite material, so that the composite material obtains good comprehensive performance.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of a graphene-type nanocomposite hydrogel with anti-notch sensitivity

ActiveCN106674434BUniform network structureAvoid concentrationUltimate tensile strengthNanocomposite hydrogels

The invention discloses a preparation method of an anti-notch-sensitivity graphene-type nano composite aquagel. By using the graphene-oxide-carried supported microgel as a crosslinking agent, the nano composite aquagel has the two crosslinking modes (physical crosslinking and chemical crosslinking), and thus, has favorable ductility and mechanical strength. The inside of the nano composite aquagel has high crosslinking density and complex crosslinking mode, and thus, the material can have favorable energy dissipation mechanism in case of cracking, and can still keep favorable ductility and mechanical strength when a notch appears in the aquagel.

Owner:HEFEI UNIV OF TECH

Lipid raft@organic-inorganic hybrid monolithic column as well as preparation method and application thereof

PendingCN113385156AUniform network structureImprove adsorption capacityComponent separationOther chemical processesStationary phasePharmaceutical drug

The invention belongs to the field of active pharmaceutical ingredient screening, and particularly relates to a lipid raft@organic-inorganic hybrid monolithic column as well as a preparation method and application thereof. According to the invention, an organic-inorganic hybrid monolithic column is used as a matrix, and the permeability and the specific surface area of the organic-inorganic hybrid monolithic column are superior to the permeability and the specific surface area of a traditional silica gel packed column; a lipid raft well modifies the surface of the organic-inorganic hybrid monolithic column; the prepared lipid raft@organic-inorganic hybrid monolithic column has a uniform net structure; and different screening requirements can be met by adjustment of the aperture and permeability of the organic-inorganic hybrid monolithic column and modification with lipid rafts from different sources. The lipid raft@organic-inorganic hybrid monolithic column can be applied as an affinity screening model to lipid raft chromatography stationary phase research and online drug screening research.

Owner:JIANGSU UNIV

Antibacterial dressing for chemotherapy of skin cancer and preparation method thereof

ActiveCN109731131AOptimize network structureIdeal uniform network structureBandagesSelf-healingInjury mouth

The invention discloses an antibacterial dressing for chemotherapy of skin cancer and a preparation method thereof. The preparation method comprises the steps of (1) dissolving an amino-modified Pluronic F127 drug-carried micelle in water to prepare a solution with the concentration of 2-6 wt%, and uniformly stirring the solution; (2) adding water to dissolve quaternized polyglutamic acid and adding tyramine hydrochloride to prepare a polyglutamic acid solution with the concentration of 15-20 wt%; (3) uniformly mixing the solutions obtained in steps (1) and (2), and then adding 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and N-hydroxysuccinimide, stirring the mixture, pouring the mixture into a mold, and conducting demolding 2-5 minutes later to obtain the antibacterial dressing for the chemotherapy of skin cancer. The prepared antibacterial dressing for the chemotherapy of skin cancer has an ideal uniform network structure, high self-healing efficiency, great broad-spectrum antibacterial property and good wound infection prevention performance and can be used for repairing wounds after a physical resection operation of skin cancer, inhibiting infiltrating tumor tissues which cannot be resected and preventing relapse.

Owner:四川维思达医疗器械有限公司

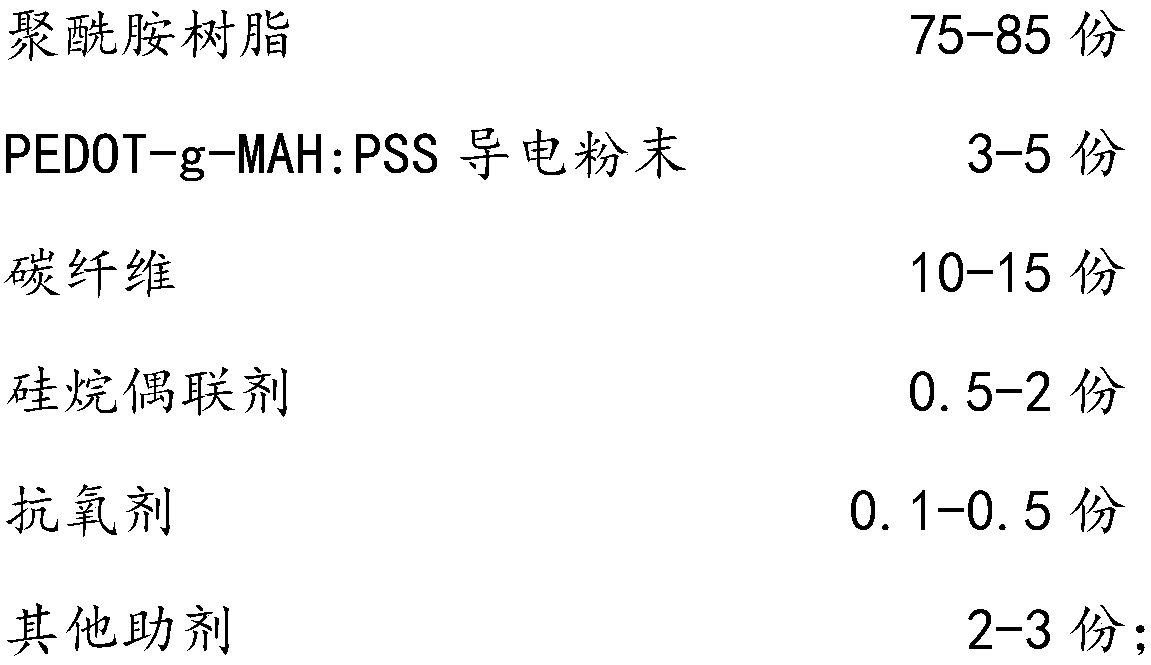

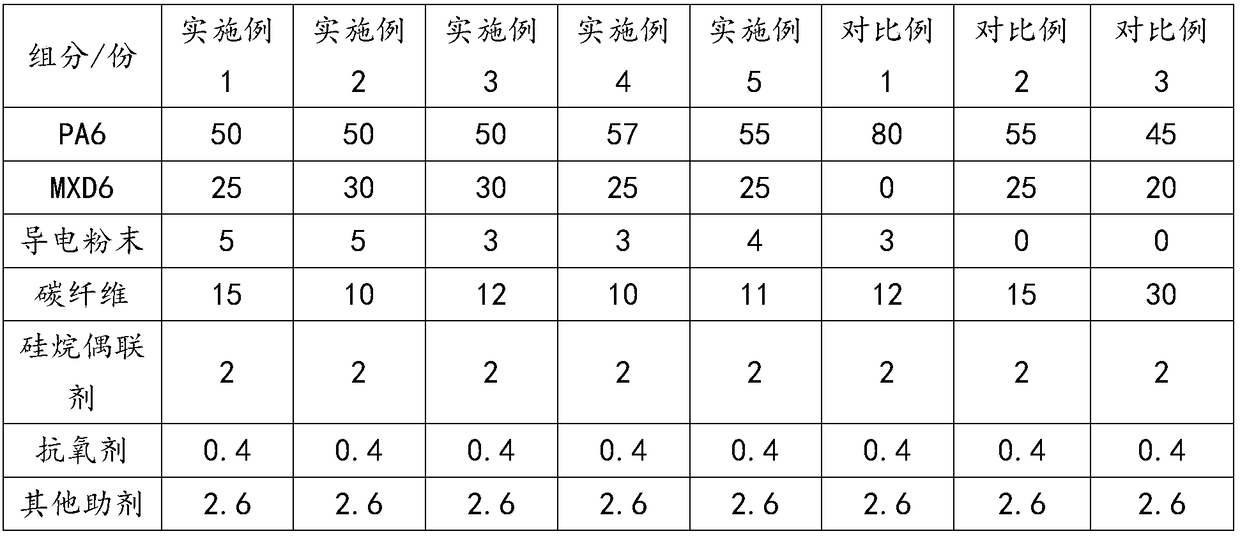

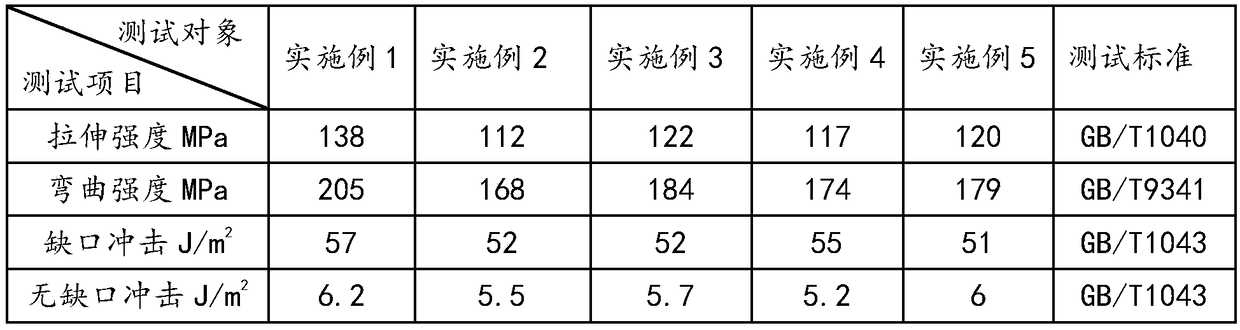

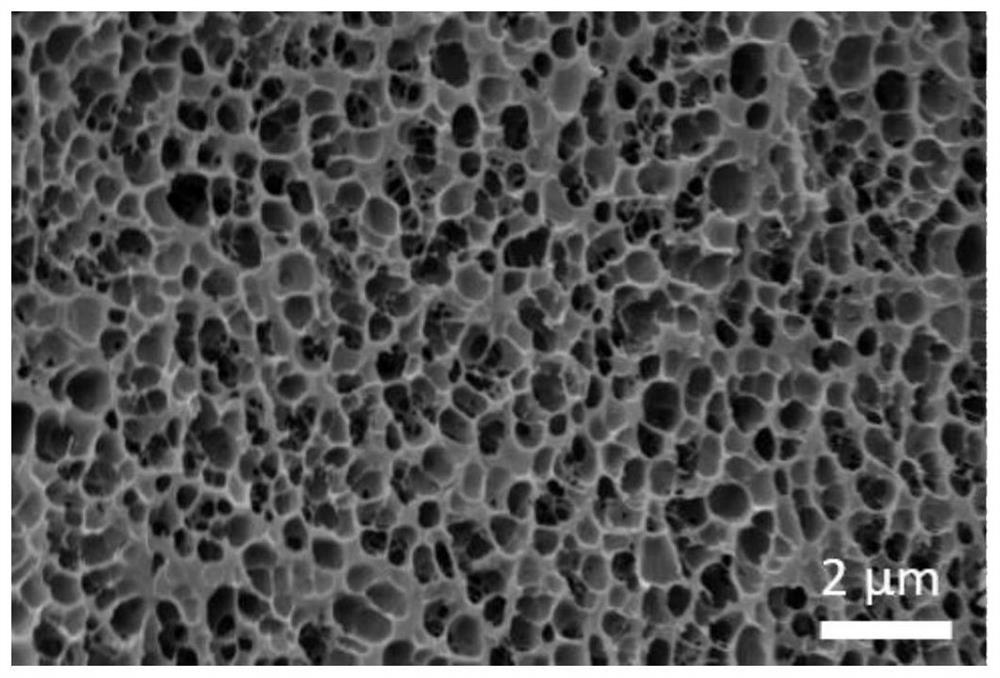

Electromagnetic shielding polyamide material and preparation method thereof

The invention relates to the technical field of polyamide material modification, in particular to an electromagnetic shielding polyamide material and a preparation method thereof. The electromagneticshielding polyamide material is prepared from the following raw materials in parts by weight: 75-85 parts of polyamide resin, 3-5 parts of PEDOT-g-MAH:PSS conductive powder, 10-15 parts of carbon fiber, 0.5-2 parts of a silane coupling agent, 0.1-0.5 part of an antioxidant and 2-3 parts of other auxiliary agents; the PEDOT-g-MAH:PSS conductive powder is prepared from 3,4-dioxyethylene thiophene, 3-thiophene acetic acid and sodium polystyrene sulfonate. The electromagnetic shielding polyamide material provided by the invention has excellent electromagnetic shielding performance and can effectively reduce the percolation threshold of carbon fiber in a composite material, and meanwhile, the material has excellent mechanical properties; a preparation process of the material is simple and easyto operate, and has an important practical application value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Carbon fiber reinforced plastic-thermoplastic laser thermal fusion welding technology

The invention provides a carbon fiber reinforced plastic-thermoplastic laser thermal fusion welding technology. Laser surface pretreatment is conducted on carbon fiber reinforced plastic firstly, and a uniform net-shaped structure is obtained; then the laser welding work procedure is conducted, the carbon fiber reinforced plastic and thermoplastic are overlaid and positioned through pressure; and positioning laser welding is conducted on the thermoplastic and pretreated thermoplastic. According to the carbon fiber reinforced plastic-thermoplastic laser thermal fusion welding technology, the technical defect that an existing carbon fiber reinforced plastic-thermoplastic connecting technology is poor in manufacturability is overcome, the technical effects that after the carbon fiber reinforced plastic is pretreated, an extra adhesive does not need to be used, and subsequent clearing is not needed are achieved, the mechanical performance of obtained weld joints is excellent, the welding efficiency is high, and manufacturing cost is reduced.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation method and application of composite aerogel filter disc

InactiveCN113713790AUniform network structureRich pore structureOther chemical processesMembrane filtersPolymer scienceUltra Low Temperature Freezer

Owner:ZHEJIANG FORESTRY UNIVERSITY

Hydrogel constructed synergistically by macromolecular self-assembly and metal coordination

PendingCN114773624AUniform network structureImprove mechanical propertiesCasein micellesUltraviolet lights

The invention discloses hydrogel synergistically constructed by macromolecular self-assembly and metal coordination, and relates to the field of biomedical high polymer materials, and the hydrogel is prepared by the following steps: firstly, preparing nano-scale spherical casein micelles with negative charges on the surface by utilizing the characteristic that casein can be self-assembled into micelles in an aqueous solution; secondly, metal ions are added and reassembled with the casein micelles to form a spherical aggregate with the metal ions on the surface; and then adding an organic small molecule compound containing disulfide bonds to generate dynamic coordination bonds with metal ions, thereby preparing the nanoscale micelle cross-linking agent. And finally, introducing the nano-micelle cross-linking agent into a monomer solution, and constructing the high-strength multifunctional hydrogel with a uniform internal structure under the induction of ultraviolet light. The hydrogel obtained in the invention has excellent biocompatibility and relatively high adaptability, and is a multifunctional hydrogel with great medical potential.

Owner:ANHUI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

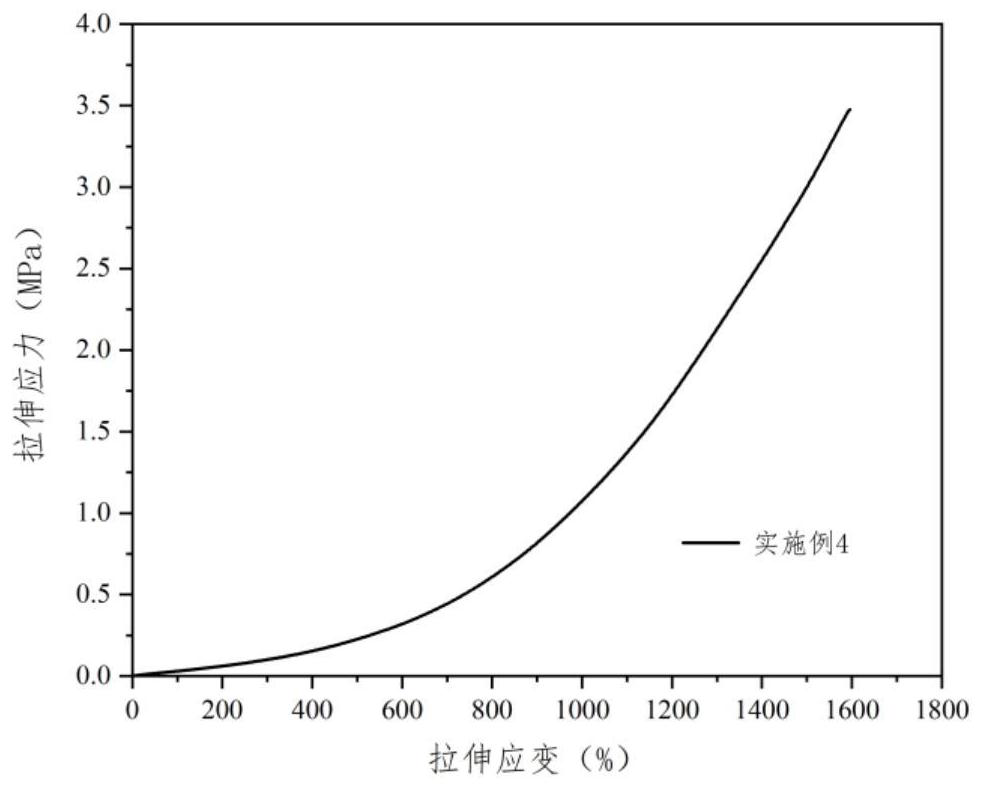

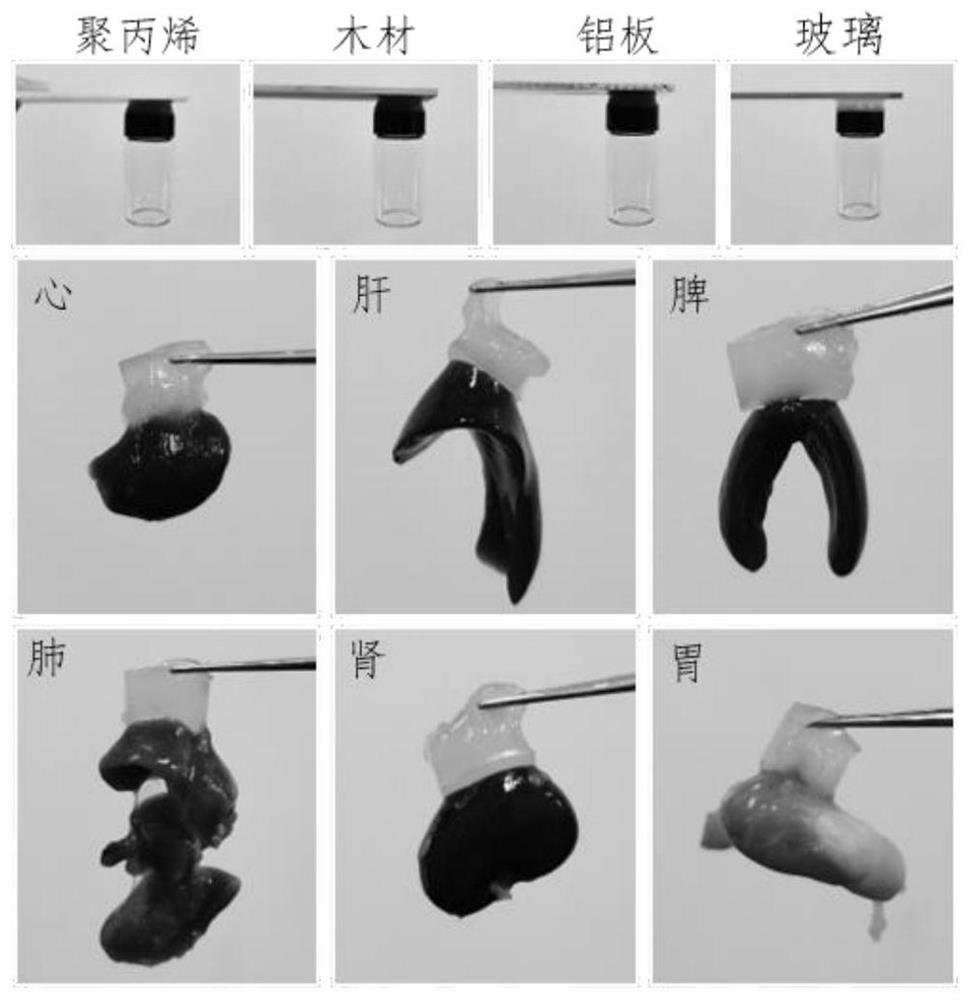

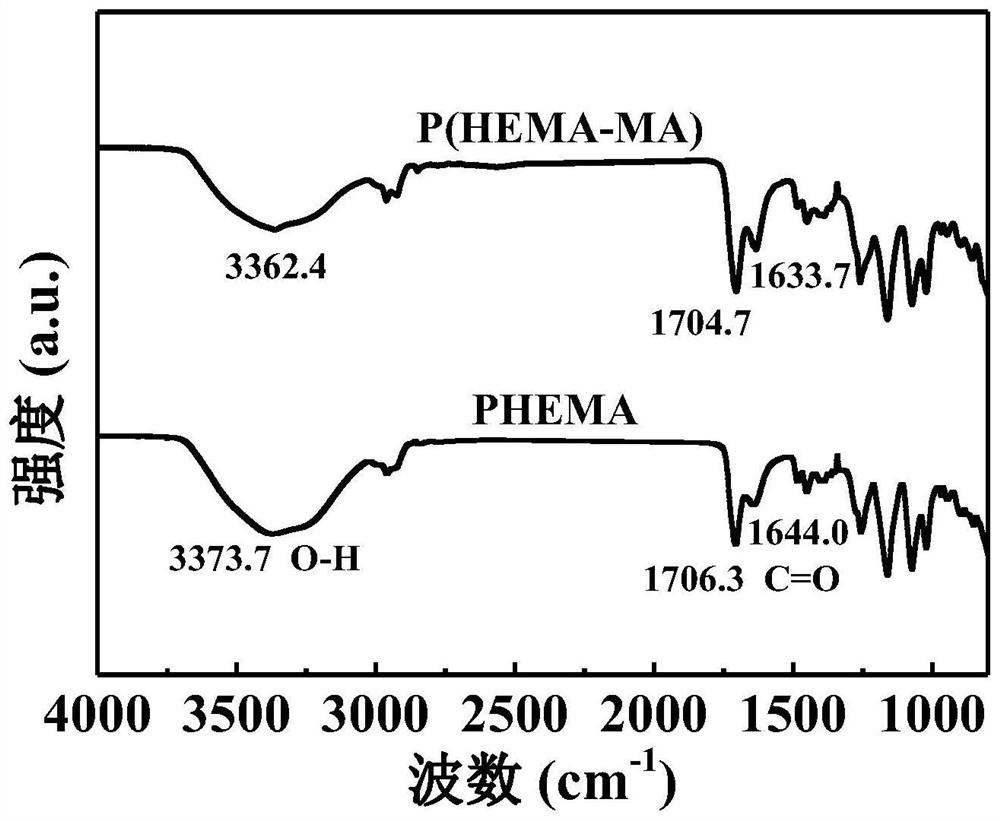

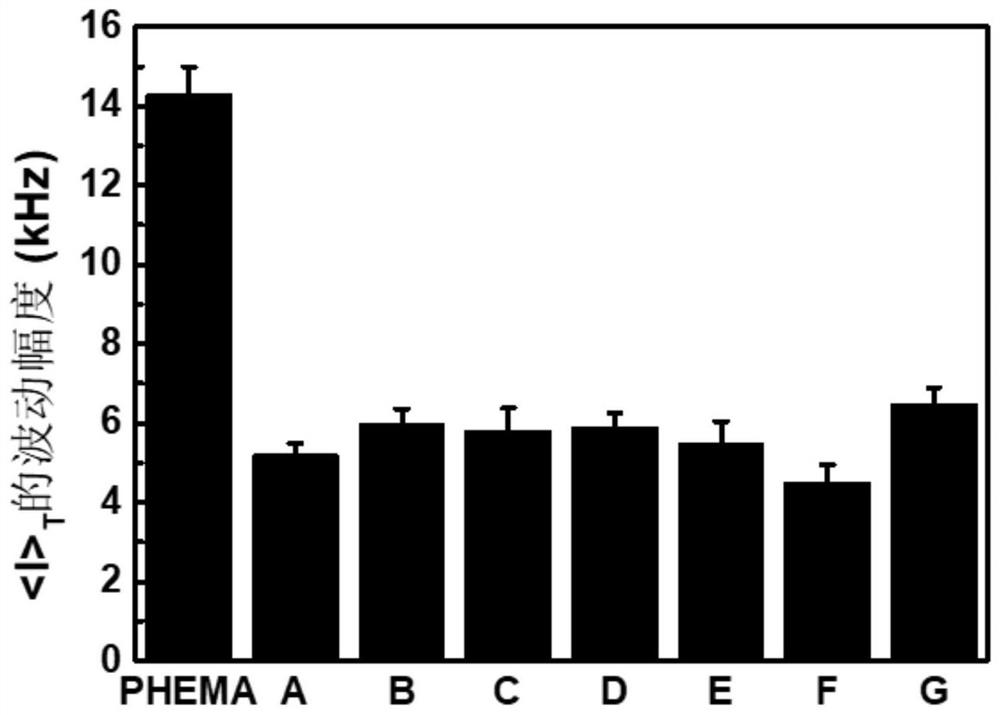

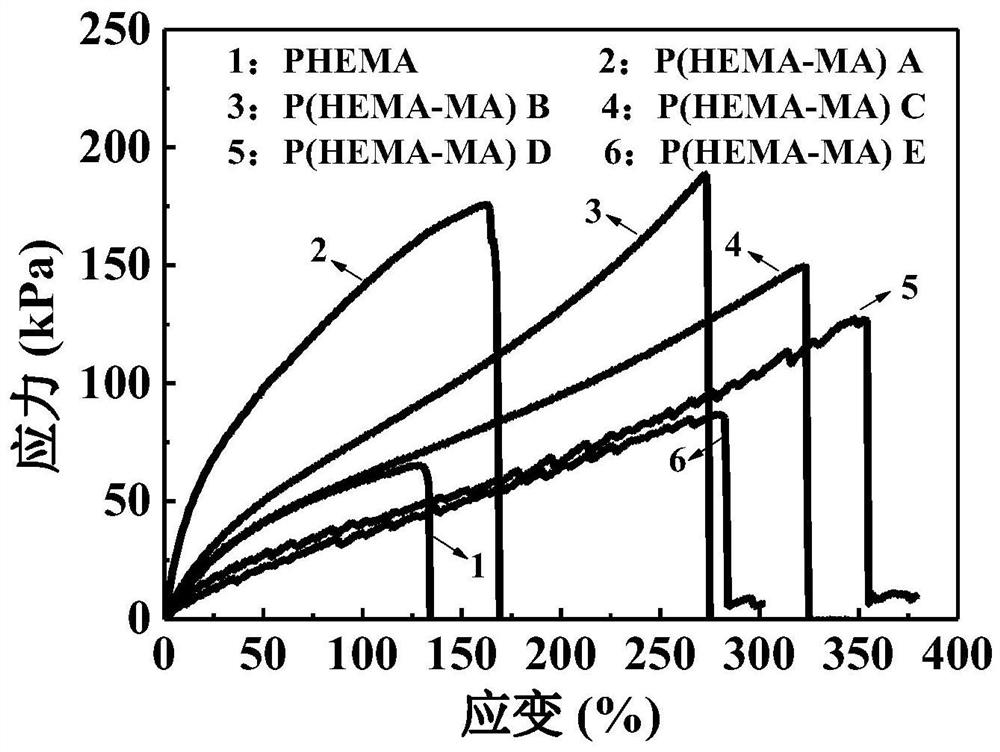

High-toughness hydrogel based on PHEMA as well as preparation method and application of the high-toughness hydrogel

PendingCN112940173AAvoid sudden increases in stressLow initial Young's modulusTissue regenerationProsthesisMaleic anhydrideComposite material

The invention provides high-toughness hydrogel based on PHEMA as well as a preparation method and application of the high-toughness hydrogel, and belongs to the technical field of high polymer materials. The structure of the hydrogel is shown as a formula I, and x is 100-200; y is from 50 to 100; and z is in a range of 200 to 300. The hydrogel with a uniform cross-linked network structure and hydrogen-bond interaction is obtained by copolymerization of hydroxyethyl methylacrylate and maleic anhydride. The hydrogel has relatively high fracture toughness and can meet the requirements of being used as a substitute material for breasts and the like; meanwhile, thehydrogel has low elastic modulus, and stem cell adipogenic differentiation can be induced easily; in addition, the hydrogel is good in biocompatibility and has the effect of promoting growth of breast related cells. The hydrogel has excellent mechanical properties and biocompatibility, and can promote growth of breast related cells, so that the hydrogel can overcome the defects of existing breast substitute materials and the like, a breast substitute material with more excellent performance is prepared, and the hydrogel has a good application prospect.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV +2

A kind of antibacterial dressing for skin cancer chemotherapy and preparation method thereof

ActiveCN109731131BOptimize network structureIdeal uniform network structureBandagesEthyl groupOncology

Owner:四川维思达医疗器械有限公司

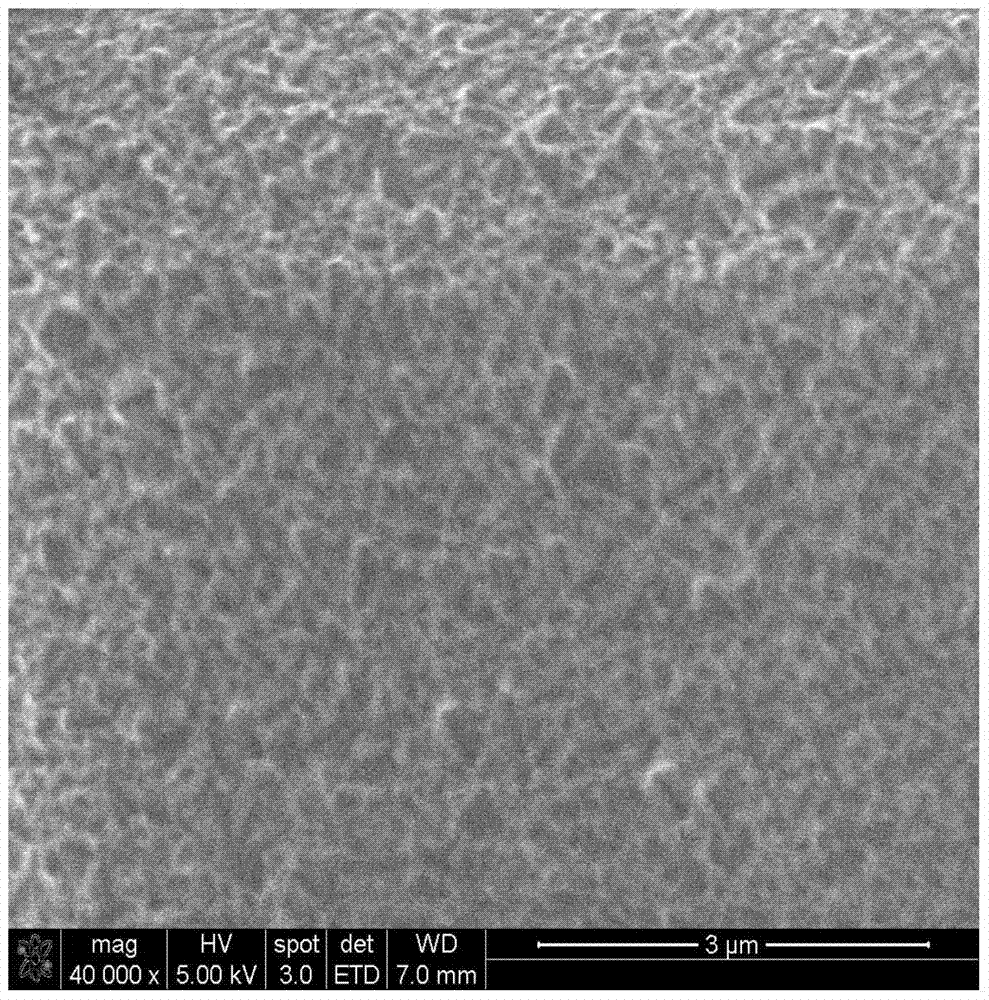

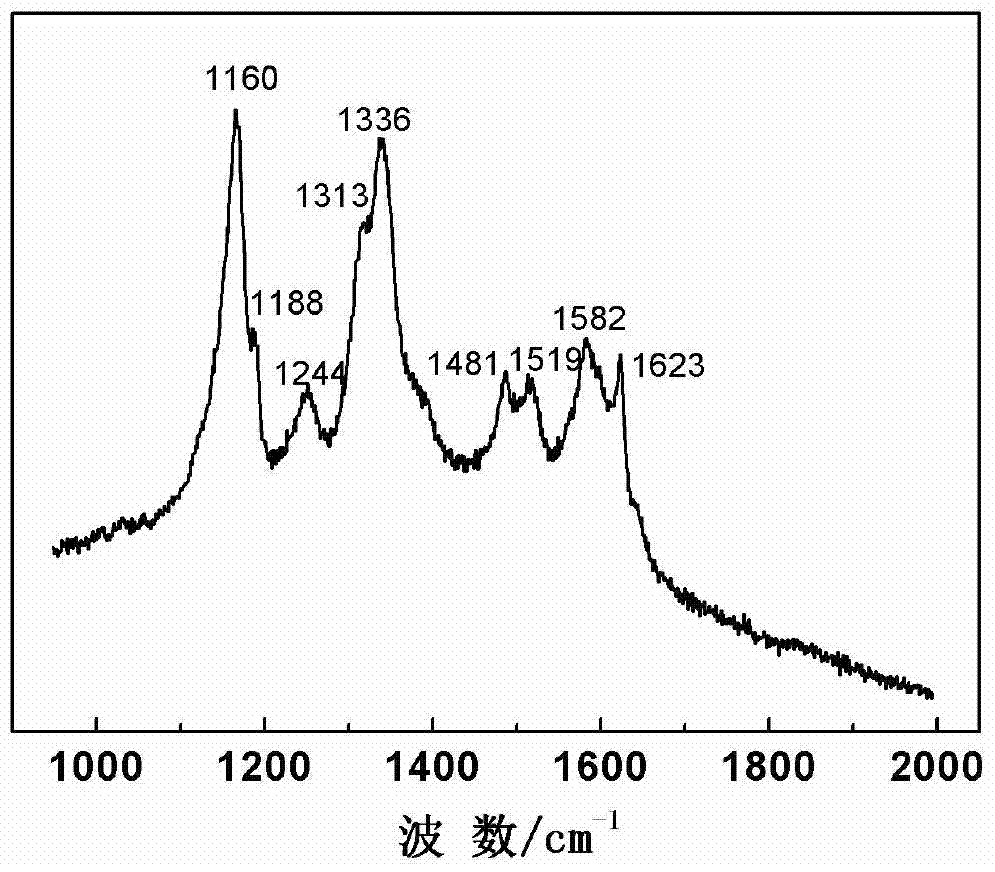

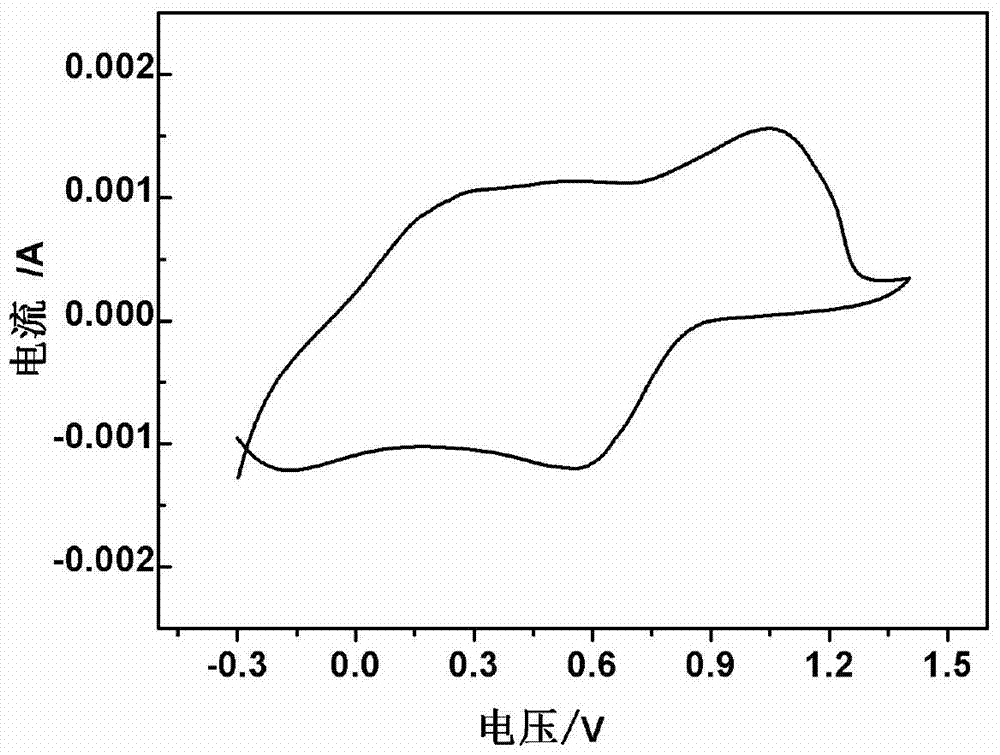

A kind of method for preparing polyaniline electrochromic film by hydrothermal self-assembly

The invention provides a hydrothermal preparation method of conductive polyaniline film. The raw materials such as aniline monomer and oxidant are pre-reacted at low temperature, and the FTO glass that has been hydroxylated beforehand is put into the hydrothermal reaction kettle with the conductive side facing down. , and then transfer the pre-reacted mixed solution into a hydrothermal reactor to react at a certain temperature for 3-4 hours; the polymer prepared by the method of the present invention can self-assemble and grow on FTO conductive glass, and the results of characterization and testing prove that polyaniline The thin film has good electrical conductivity and electrochromic performance, and can be used in electrochromic materials and the like.

Owner:XIAN UNIV OF SCI & TECH

Crosslinkable organoysiloxane compositions

The invention relates to organosiloxane compositions which can be crosslinked by hydrosilylation reaction and contain: (A) cyclosiloxanes of formula (I): [RaR1 bR2 cSiO2 / 2]m wherein the radicals and indices have the meaning given in claim 1, with the proviso that a + b + c is equal to 2, at least 3 radicals R1 are present per siloxane molecule (A) and at least m-3 radicals R2 are present per siloxane molecule (A), (B) organosilicon compounds having two Si-bonded hydrogen atoms and at least one aromatic radical and (C) catalysts that promote the addition of Si-bonded hydrogen to aliphatic multiple bonds. The invention also relates to a method for the production thereof and to the use thereof and vulcanizates obtainable therefrom.

Owner:WACKER CHEM GMBH

Preparation Technology of Potato Noodles

ActiveCN108419991BNetwork structure reinforcementGood molding effectFood scienceOff-flavourProcess engineering

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

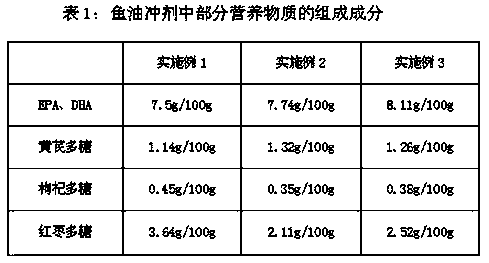

Fish oil granule for enhancing immunity and preparation method thereof

ActiveCN106937744BWide variety of sourcesHigh nutritional valueGranular deliveryFood shapingNutritive valuesIsomaltooligosaccharide

The invention discloses edible soluble fish oil granules with the effect of improving immunity and a preparation method thereof. The edible soluble fish oil granules are prepared from fish oil as a base material, mixed fine powder as a wall material, xanthan gum and isomaltooligosaccharides according to a weight ratio of the mixed fine powder, xanthan gum, isomaltooligosaccharides to fish oil of 2.5-3: 0.5-1: 0.3-0.6: 1.1-1.6. The mixed fine powder comprises radix astragali powder, wolfberry powder, pitted red date powder and walnut kernel powder according to a ratio of 1-3: 1-2: 2-3: 1-3. The xanthan gum and isomaltooligosaccharides are edible additives approved by the FDA and have wide sources. Radix astragali, wolfberry, red dates and walnuts are common Chinese medicinal materials, are rich in polysaccharides, have a high nutritional value and can improve immunity. The preparation method can be operated simply and has stable processes. The edible soluble fish oil granules have smooth surfaces and uniform sizes, are easy to convey and store and have a good development and application prospect in the field of foods and medicines.

Owner:HENAN UNIV OF SCI & TECH

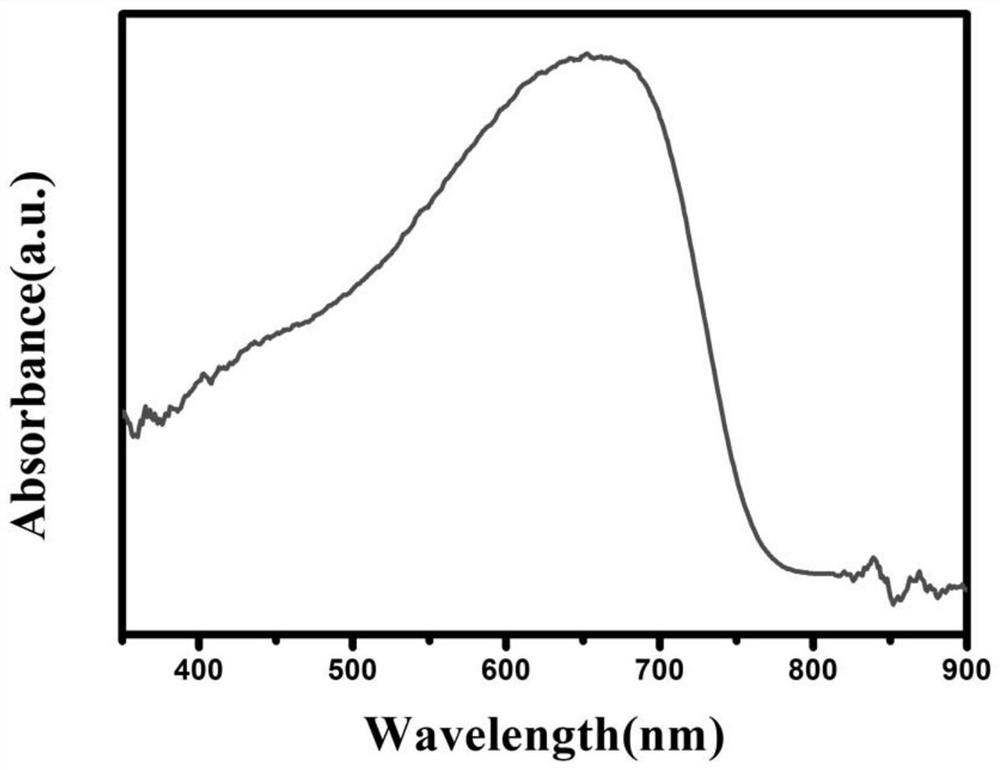

A kind of antimony sulfide-based heterojunction photocathode and its preparation method and application

The invention discloses an antimony sulfide-based heterojunction photocathode and its preparation method and application. The structure consists of conductive glass, antimony sulfide light-absorbing layer, ultra-thin titanium dioxide layer and promoter layer from bottom to top. The antimony sulfide light-absorbing layer has a network structure; the thickness of the ultra-thin titanium dioxide layer is 5-10nm. The preparation method is as follows: sequentially depositing an antimony sulfide light-absorbing layer, an evenly covered ultra-thin titanium dioxide layer, and a co-catalyst layer on the conductive glass. In the present invention, the antimony sulfide material with nano-morphology is used as the light-absorbing material of the photocathode for the first time, and a photoelectrode with strong light absorption in the visible spectrum and high photoresponse characteristics is obtained through structural design. The equipment used in the invention is simple, easy to operate, and the preparation process is green and non-toxic. The photoelectrode film grows uniformly and has good crystal quality, which is conducive to large-scale production and application, and has broad development prospects.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com