A preparation method of cnt-go/cu composite material with hierarchical structure

A technology of CNT-GO and composite materials, applied in the field of preparation of CNT-GO/Cu composite materials, can solve the problems of affecting the performance of composite material reinforcements, harmful mechanical properties of reinforcements, deliberately manufacturing reinforcements, etc., and achieve good electrical conductivity. , Short operating time, the effect of improving tensile strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

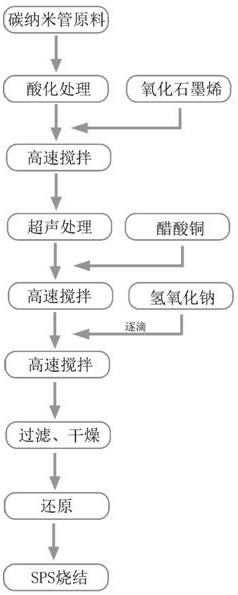

[0034] (1) Acidification treatment of CNTs: Add CNTs to a mixed solution of concentrated sulfuric acid / concentrated nitric acid (volume ratio 3:1) and heat in a water bath at 70 °C for 4 hours, then filter and dry to obtain acidified CNTs powder.

[0035] (2) Preparation of composite precursor: Add 0.032g of CNT-GO (volume ratio of 6:1, 0.027g of CNTs, 0.005g of GO) into 900ml of deionized water, and use a high-shear emulsifier (6000rpm / min) Stir for 20min, then sonicate for 1.5h; then add 17.37g of copper acetate to the CNT-GO solution (in the CNT-GO / Cu composite, the volume fraction of the CNT-GO hybrid reinforcement is 2.5%) , and stirred with a high-shear emulsifier for 10 min; then, at the same speed, sodium hydroxide solution was added dropwise until the pH reached 14; CNT-GO / CuO powder was obtained after filtration and drying.

[0036] (3) Preparation of composite powder: After argon hydrogen (H 2 The composite precursor prepared in step (2) was reduced in a tube furn...

Embodiment 2

[0041] (1) Acidification treatment of CNTs: Add CNTs to a mixed solution of concentrated sulfuric acid / concentrated nitric acid (volume ratio 3:1) and heat in a water bath at 70 °C for 4 hours, then filter and dry to obtain acidified CNTs powder.

[0042] (2) Preparation of composite precursor: Add 0.019g of CNT-GO (volume ratio of 6:1, 0.016g of CNTs, 0.003g of GO) into 900ml of deionized water, and use a high-shear emulsifier (6000rpm / min) Stir for 20min, then sonicate for 1.5h; then add 17.37g of copper acetate to the CNT-GO solution (in the CNT-GO / Cu composite, the volume fraction of the CNT-GO hybrid reinforcement is 1.5%) , and stirred with a high-shear emulsifier for 10 min; then, at the same speed, sodium hydroxide solution was added dropwise until the pH reached 14; CNT-GO / CuO powder was obtained after filtration and drying.

[0043] (3) Preparation of composite powder: After argon hydrogen (H 2 The composite precursor prepared in step (2) was reduced in a tube furn...

Embodiment 3

[0047] (1) Acidification treatment of CNTs: Add CNTs to a mixed solution of concentrated sulfuric acid / concentrated nitric acid (volume ratio 3:1) and heat in a water bath at 70 °C for 4 hours, then filter and dry to obtain acidified CNTs powder.

[0048] (2) Preparation of composite precursor: Add 0.006g of CNT-GO (volume ratio of 6:1, 0.005g of CNTs, 0.001g of GO) into 900ml of deionized water, and use a high-shear emulsifier (6000rpm / min) Stir for 20min, then sonicate for 1.5h; then add 17.37g of copper acetate to the CNT-GO solution (in the CNT-GO / Cu composite, the volume fraction of the CNT-GO hybrid reinforcement is 0.5%) , and stirred with a high-shear emulsifier for 10 min; then, at the same speed, sodium hydroxide solution was added dropwise until the pH reached 14; CNT-GO / CuO powder was obtained after filtration and drying.

[0049] (3) Preparation of composite powder: After argon hydrogen (H 2 The composite precursor prepared in step (2) was reduced in a tube furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com