Preparation method of bionic coating carrying bioactive factors

A bioactive factor and coating technology, applied in coatings, dental preparations, pharmaceutical formulations, etc., can solve problems such as low efficiency, poor stability, and small binding force, and achieve the effect of achieving osseointegration and promoting early occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of RGD-crosslinked collagen / hyaluronic acid polyelectrolyte composite layer loaded with bioactive factors

[0040] Dissolve the RGD-containing polypeptide segment GRGDSPC (S-S) CPSDGRG and a certain amount of hyaluronic acid in water, then add EDC / NHS, react for 4 hours, the reaction product is dialyzed for 1 week, and freeze-dried; the reaction product is directly dissolved in water, added Muthulose was reacted for 4 hours, dialyzed for one week, and freeze-dried to obtain RGD-grafted sodium hyaluronate with free sulfhydryl groups.

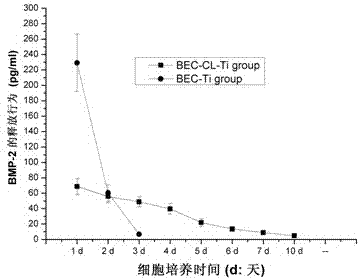

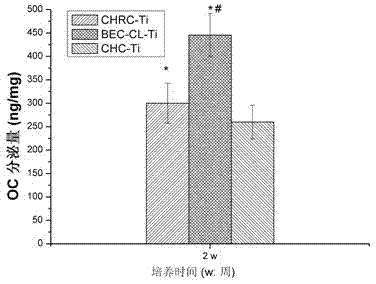

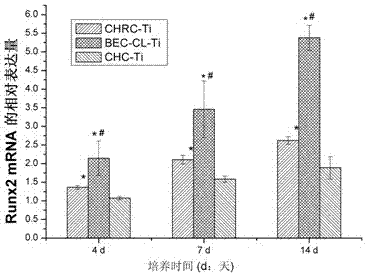

[0041] The RGD-grafted hyaluronic acid and collagen were dissolved in 0.1 mol / L NaCl solution, and the concentration of both was 1 mg / ml. Add BMP-2 to the prepared collagen solution so that the final concentration in the solution is 20 μg / ml (if bFGF is added, the final concentration is 0.1 mg / ml). The pH value of the prepared above solution was adjusted to 4.0. The surface of the implant was sandblasted with large...

Embodiment 2

[0042] Example 2: Preparation of acid-soluble gelatin / hyaluronic acid polyelectrolyte composite layer loaded with bioactive factors cross-linked by RGD

[0043] The method is the same as in Example 1, except that the collagen is replaced with acid-soluble gelatin (the source of which is porcine, bovine or mouse).

Embodiment 3

[0044] Example 3: Preparation of RGD crosslinked chitosan / hyaluronic acid polyelectrolyte composite layer loaded with biologically active factors

[0045] The method is the same as in Example 1, except that the collagen is replaced by chitosan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com