Ce,V and Er co-doped dental microcrystalline glass, and preparation method and application thereof

A glass-ceramic and dental technology, applied in the field of dental glass-ceramic and its preparation and application, can solve the problems of aesthetic effect, semi-permeability and fluorescence characteristics that cannot be matched with natural teeth, so as to increase the fluorescence performance and semi-transparency properties, reduce dissolution, and enhance the effect of network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

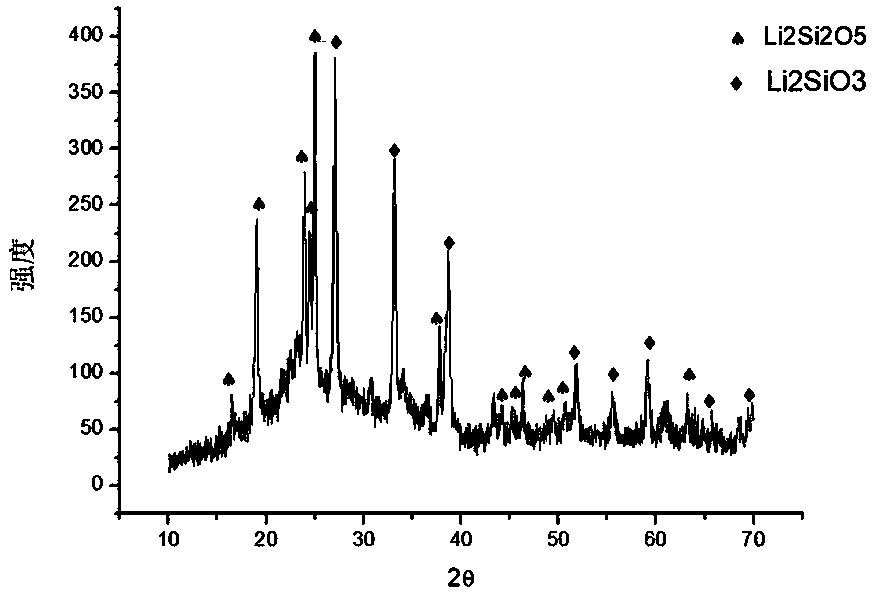

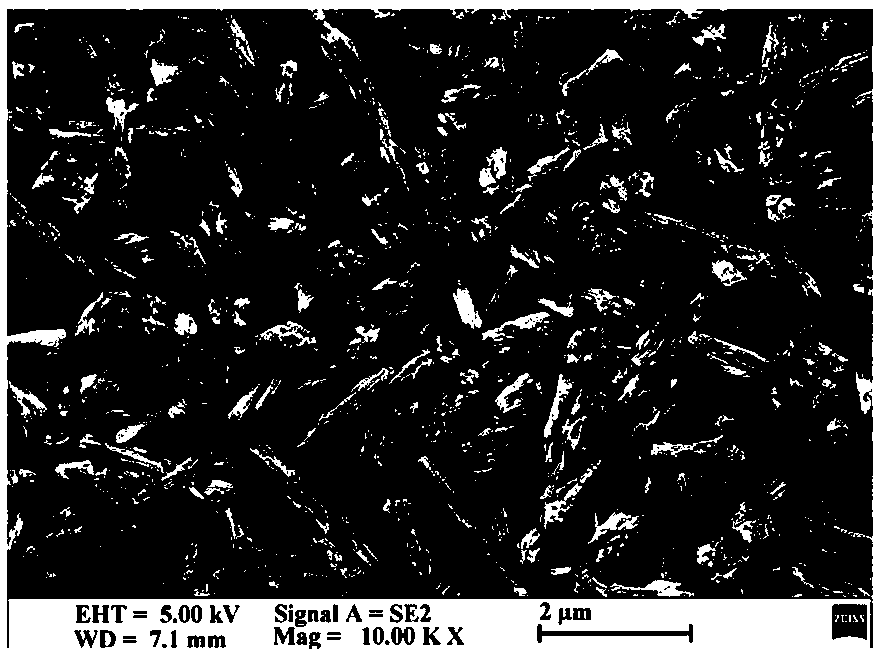

[0047] Embodiment 1: preparation of material and performance test result

[0048] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、K 2 CO 3 , NH 4 h 2 PO 4 、Al 2 o 3 、Na 2 CO 3 and ZrO 2 ), use a ball mill to mix evenly for 7 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 3°C / min to 330°C and 840°C for 30 minutes each to remove nitrogen and carbon , continue to heat up to 1500 ° C, and keep it warm for 40 minutes; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again through a 325-mesh sieve, and mix the colorant CeO 2 、Er 2 o 3 and V 2 o 5 Add it to the basic glass powder obtained by ball milling and mix evenly, then directly heat up to 1500°C / 40 minutes for remelting; cast the remelted glass liquid into a preheated mold at...

Embodiment 2

[0049] Embodiment 2: preparation of material and performance test result

[0050] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、K 2 CO 3 , NH 4 h 2 PO 4 、Al 2 o 3 、Na 2 CO 3 and ZrO 2 ), use a ball mill to mix evenly for 7 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 3°C / min to 330°C and 840°C for 30 minutes each to remove nitrogen and carbon , continue to heat up to 1500 ° C, and keep it warm for 40 minutes; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again through a 325-mesh sieve, and mix the colorant CeO 2 , V 2 o 5 and Er 2 o 3Add it to the basic glass powder obtained by ball milling and mix evenly, then directly heat up to 1500°C / 40 minutes for remelting; cast the remelted glass liquid into a preheated mold at...

Embodiment 3

[0051] Embodiment 3: preparation of material and performance test result

[0052] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、K 2 CO 3 , NH 4 h 2 PO 4 、Al 2 o 3 、Na 2 CO 3 and ZrO 2 ), use a ball mill for 7 hours to mix evenly; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, heat it at 3°C / min to 330°C and 840°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500 ° C, and keep it warm for 40 minutes; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, pass through a 325-mesh sieve, and mix the colorant CeO 2 , V 2 o 5 and Er 2 o 3 Add it to the basic glass powder obtained by ball milling and mix evenly, then directly heat up to 1500°C / 40 minutes for remelting; cast the remelted glass liquid into a preheated mold at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com