High-permeability and high-selectivity PVA/GA/CS-M<+> pervaporation film for dewatering organic solution

A pervaporation and organic solution technology, applied in the field of high permeation and high selectivity pervaporation thin films and their preparation, can solve the problems of consuming hydrophilic groups of polymer chains, consuming hydroxyl groups, etc., to promote permeation efficiency, improved compatibility, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0046] The invention provides a pervaporation film with high permeability and high selectivity for dehydration of organic solutions and a preparation method thereof, the method comprising:

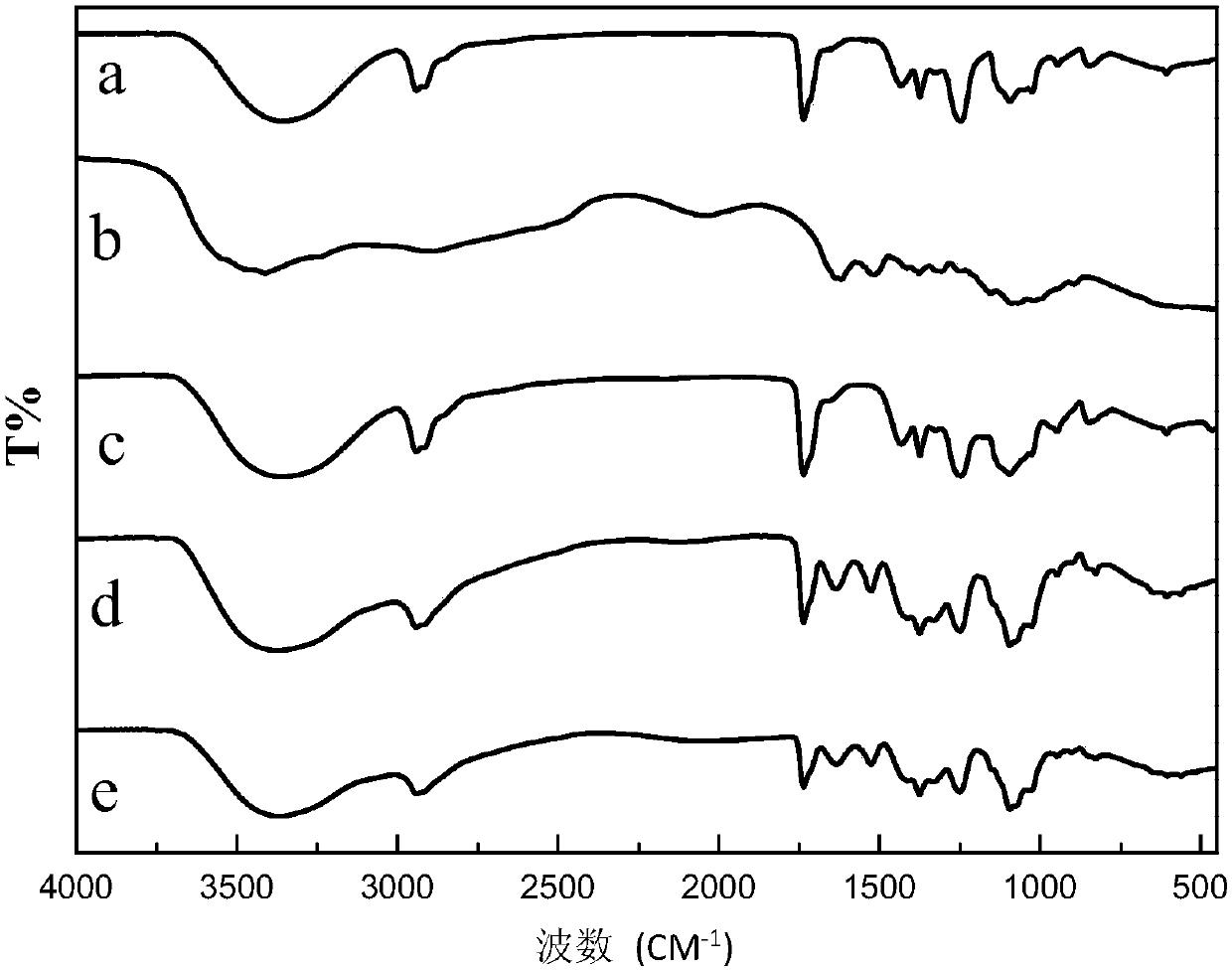

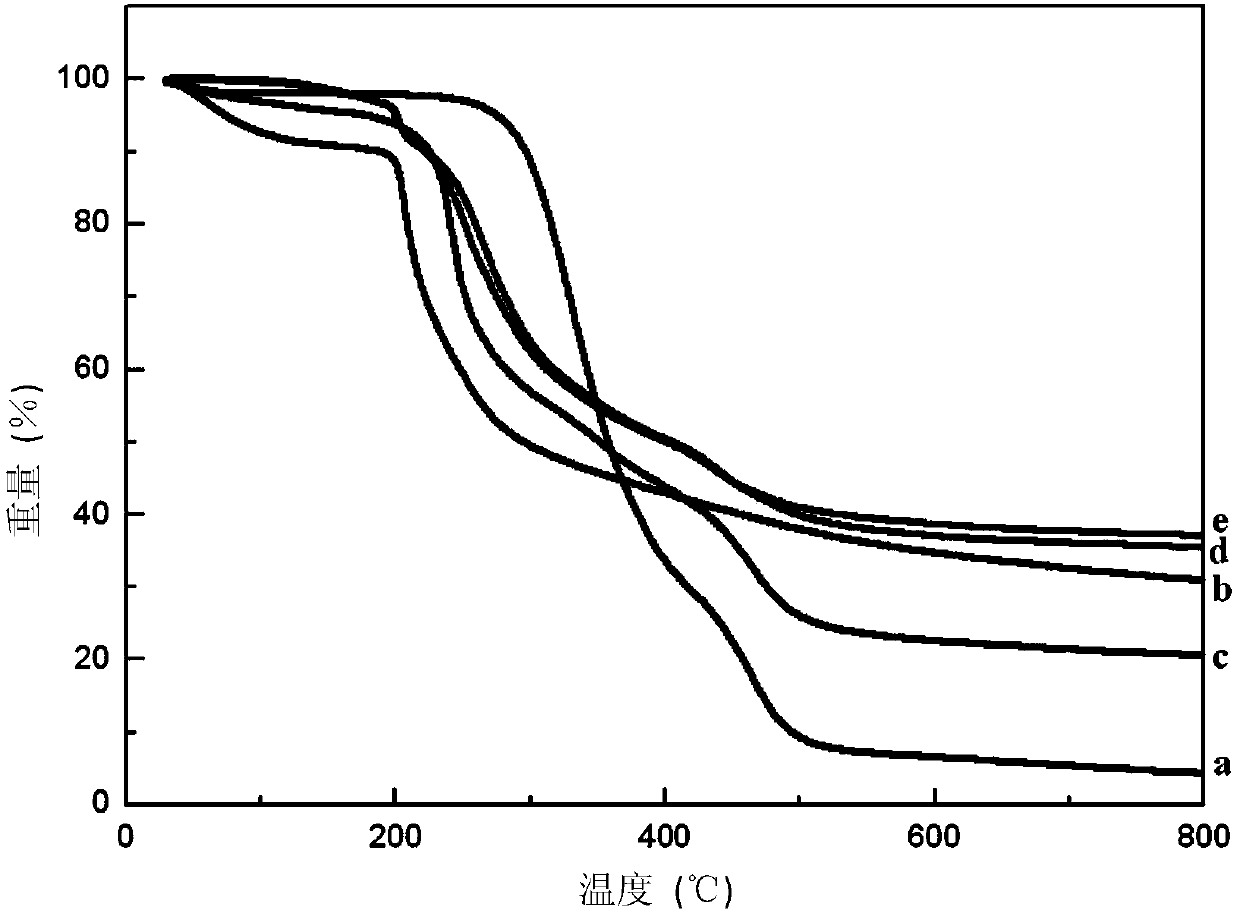

[0047] Preparation materials: polyvinyl alcohol (PVA) (Mw~125,000), chitosan (CS) (Mw~30,000), 25wt% glutaraldehyde (GA), and 99wt% isopropanol (IPA), ethanol ( EtOH) and acetone (Acetone). All chemical reagents were of reagent grade and no further purification was required.

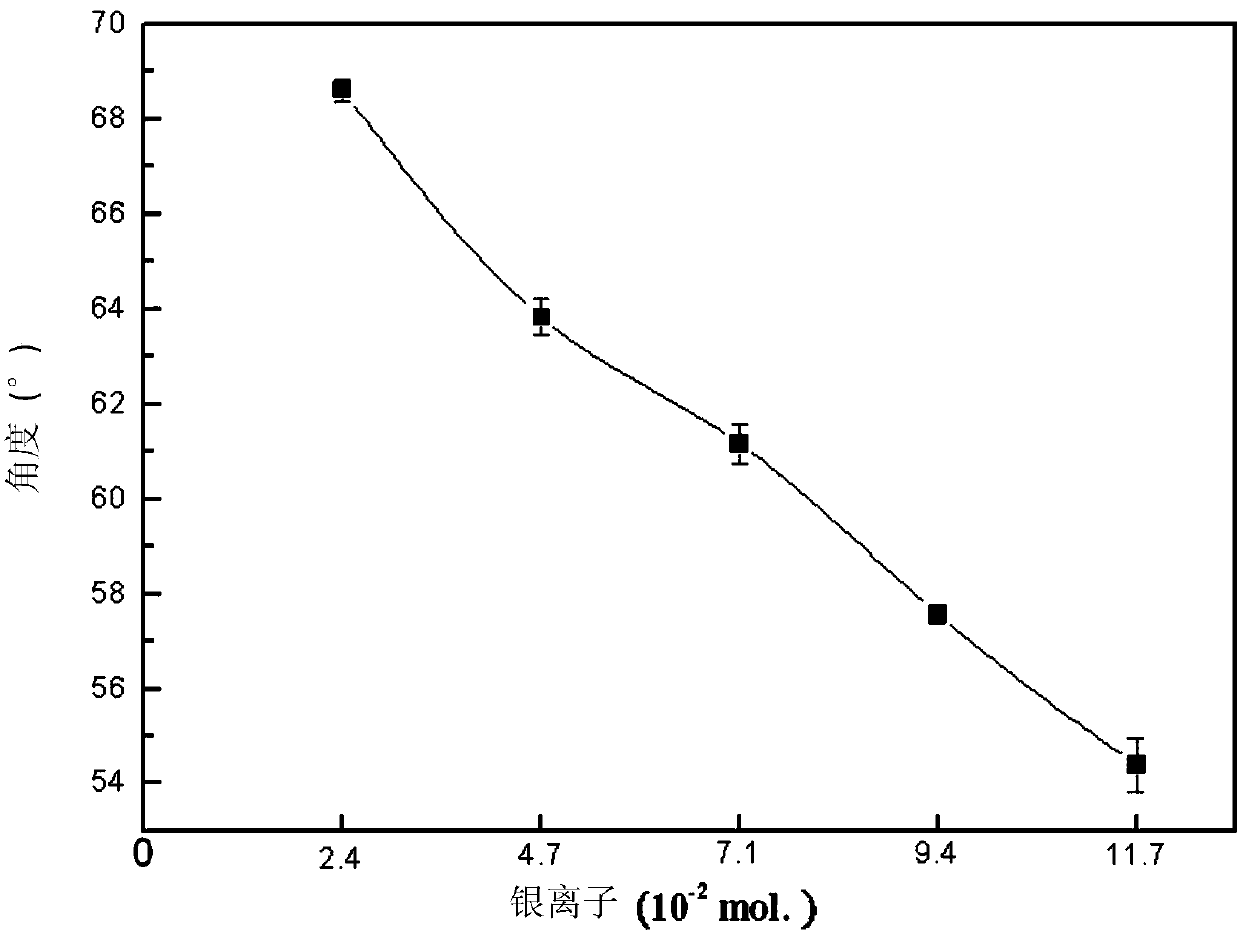

[0048] Preparation process: Dissolve 5g of CS in 45g of deionized water, stir at room temperature for 7 to 10 hours, especially 8 hours, and then add different weights of silver, copper, and iron ions, that is, nitrates, to the front In a solution, li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com